Ceramic Cnc Machining Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for ceramic cnc machining

In the increasingly competitive landscape of manufacturing, sourcing reliable ceramic CNC machining solutions poses a significant challenge for B2B buyers across various regions, including Africa, South America, the Middle East, and Europe. The demand for high-performance ceramic components is on the rise, driven by industries such as aerospace, electronics, and medical equipment. However, the intricacies involved in machining ceramics—characterized by their hardness and brittleness—require specialized knowledge and expertise. This guide aims to demystify ceramic CNC machining, providing a comprehensive overview of the processes, types of ceramics, applications, and critical supplier vetting strategies.

Throughout this guide, international B2B buyers will gain insights into the essential parameters that influence machining performance, including cutting speeds, feed rates, and tool selection. We will explore the diverse applications of ceramic materials and the specific challenges associated with their machining, ensuring that you are well-equipped to make informed decisions. Additionally, the guide will address cost considerations, helping you navigate pricing structures effectively.

By empowering you with knowledge and actionable insights, this resource is designed to enhance your sourcing strategies and improve your purchasing decisions in the global ceramic CNC machining market. Whether you are looking to optimize production efficiency or ensure the highest quality standards, this guide serves as a valuable tool for your business needs.

Understanding ceramic cnc machining Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CNC Milling | Uses rotating tools for material removal; ideal for complex geometries. | Aerospace, medical devices, electronics | Pros: High precision, versatile shapes. Cons: Longer setup times, potential for tool wear. |

| Surface Grinding | Employs abrasive wheels for fine surface finish; ideal for achieving smooth surfaces. | Defense, automotive, high-stress applications | Pros: Excellent surface quality, tight tolerances. Cons: Slower processing time, limited to surface refinement. |

| Laser Cutting | Utilizes focused laser beams for cutting; minimizes mechanical stress on ceramics. | Electronics, art, intricate designs | Pros: Clean cuts, no tool wear. Cons: Limited to thinner materials, higher initial costs. |

| Core Drilling | Involves hollow drill bits for creating holes; maintains integrity of material. | Aerospace, automotive, industrial applications | Pros: Precision hole creation, minimal cracking. Cons: Requires specialized tools, can be slower than other methods. |

| Fine Grinding | Focuses on achieving high tolerances and surface finishes; often follows milling. | Precision instruments, medical components | Pros: Exceptional finish quality, tight dimensional control. Cons: Increased processing time, requires skilled operators. |

What Are the Key Characteristics of CNC Milling in Ceramic Machining?

CNC milling is a prevalent method in ceramic machining, characterized by its ability to create complex shapes and intricate geometries. This process involves rotating cutting tools, typically diamond-coated, which effectively handle the hardness of ceramics. Suitable for industries like aerospace and medical devices, CNC milling allows for high precision and versatility in design. Buyers should consider the setup time and potential tool wear, which may affect production schedules and costs.

How Does Surface Grinding Enhance Ceramic Component Quality?

Surface grinding is essential for achieving fine surface finishes on ceramic materials. It employs abrasive wheels to smooth the surface, making it ideal for applications in high-stress environments such as defense and automotive sectors. This technique ensures tight tolerances and exceptional surface quality. However, buyers should be aware that while it produces superior results, the process may be slower and is primarily focused on surface refinement.

What Are the Advantages of Using Laser Cutting for Ceramics?

Laser cutting is distinguished by its use of focused laser beams to cut through ceramic materials, offering a non-contact method that minimizes mechanical stress. This technique is particularly advantageous for creating intricate designs and thin sections, commonly utilized in the electronics and art sectors. While it provides clean cuts and eliminates tool wear, buyers should consider that it is limited to thinner materials and may come with higher initial investment costs.

Why Is Core Drilling Important in Ceramic Machining?

Core drilling is a specialized technique used to create precise holes in ceramic parts while maintaining the integrity of the material. It utilizes hollow, diamond-coated drill bits, making it suitable for aerospace and automotive applications where precision is critical. While it ensures minimal cracking and high accuracy, buyers should note that it requires specific tools and can be slower compared to other machining methods.

How Does Fine Grinding Contribute to Precision in Ceramic Parts?

Fine grinding is a crucial step following initial machining processes, aimed at achieving high tolerances and surface finishes. This technique is particularly important for precision instruments and medical components, where dimensional accuracy is paramount. While fine grinding delivers exceptional quality, it can lead to increased processing times and necessitates skilled operators, making it essential for buyers to weigh these factors against their production needs.

Key Industrial Applications of ceramic cnc machining

| Industry/Sector | Specific Application of Ceramic CNC Machining | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Engine components and heat shields | Enhanced durability and thermal resistance | Certification of materials, precision tolerances |

| Medical Devices | Surgical instruments and implants | Biocompatibility and precision in critical applications | Compliance with health regulations, material sourcing |

| Electronics | Insulators and substrates for circuits | Improved performance and reliability in devices | Material specifications, thermal and electrical properties |

| Automotive | Engine components and braking systems | Weight reduction and improved fuel efficiency | Supplier reliability, testing for safety standards |

| Defense and Security | Armor plates and protective gear | Increased strength and lightweight options | Material certifications, compliance with military standards |

How Is Ceramic CNC Machining Used in Aerospace Applications?

In the aerospace sector, ceramic CNC machining is employed to manufacture engine components and heat shields that require high durability and thermal resistance. Ceramics are ideal for these applications due to their ability to withstand extreme temperatures and pressures. For international buyers, especially from regions like Africa and South America, sourcing components that meet stringent aerospace standards is crucial. Buyers should ensure that suppliers can provide certified materials and maintain tight tolerances to guarantee performance and safety.

What Are the Benefits of Ceramic CNC Machining in Medical Devices?

Ceramic CNC machining plays a pivotal role in producing surgical instruments and implants that require high precision and biocompatibility. This technology allows manufacturers to create complex geometries that enhance the functionality of medical devices while ensuring patient safety. For buyers in the Middle East and Europe, it’s essential to collaborate with suppliers who comply with health regulations and can provide detailed documentation regarding material sourcing and processing methods to ensure the quality of the devices.

How Does Ceramic CNC Machining Enhance Electronics Manufacturing?

In the electronics industry, ceramic CNC machining is used to create insulators and substrates for circuits, which are critical for the performance and reliability of electronic devices. The high dielectric strength and thermal stability of ceramics make them suitable for these applications. B2B buyers, particularly from regions like Vietnam and Nigeria, should consider sourcing from suppliers who can guarantee the specific thermal and electrical properties required for their applications, alongside robust quality control measures.

What Advantages Does Ceramic CNC Machining Offer in Automotive Applications?

Ceramic CNC machining is utilized in the automotive industry to produce lightweight engine components and braking systems. The use of ceramics helps reduce overall vehicle weight, thereby improving fuel efficiency and performance. For international buyers, it’s important to evaluate suppliers based on their reliability and ability to test components for safety standards, particularly in regions where automotive regulations are stringent.

Why Is Ceramic CNC Machining Important for Defense and Security?

In the defense sector, ceramic CNC machining is essential for manufacturing armor plates and protective gear that offer increased strength while remaining lightweight. The unique properties of ceramics make them ideal for applications requiring high-impact resistance. Buyers in the defense industry must prioritize sourcing from certified suppliers who meet military standards and can provide the necessary documentation to verify material integrity and performance under extreme conditions.

3 Common User Pain Points for ‘ceramic cnc machining’ & Their Solutions

Scenario 1: Managing High Tool Wear and Costs in Ceramic CNC Machining

The Problem: B2B buyers often face significant challenges with tool wear when machining ceramics. Ceramics are inherently hard and abrasive, leading to rapid degradation of cutting tools, especially in high-volume production settings. This not only increases operational costs due to frequent tool replacements but also can result in production delays and inconsistencies in product quality. Buyers may feel frustrated when they realize that their current tool choices and machining parameters are not optimized for the specific ceramic materials they are using, leading to wasted resources and inefficiencies.

The Solution: To mitigate high tool wear, it is crucial to invest in high-quality, wear-resistant cutting tools specifically designed for ceramic machining. Diamond-coated tools or those made from cubic boron nitride (CBN) are excellent choices, as they withstand the abrasive nature of ceramics while maintaining precision. Additionally, buyers should consider implementing a robust tool management strategy that includes regular monitoring of tool wear rates and performance. Adjusting machining parameters—such as reducing the cutting speed and feed rate—can also minimize stress on the tools. Collaborating with suppliers who offer technical support can help buyers optimize their machining processes, ensuring that they select the right tools for their specific ceramic materials while keeping production costs in check.

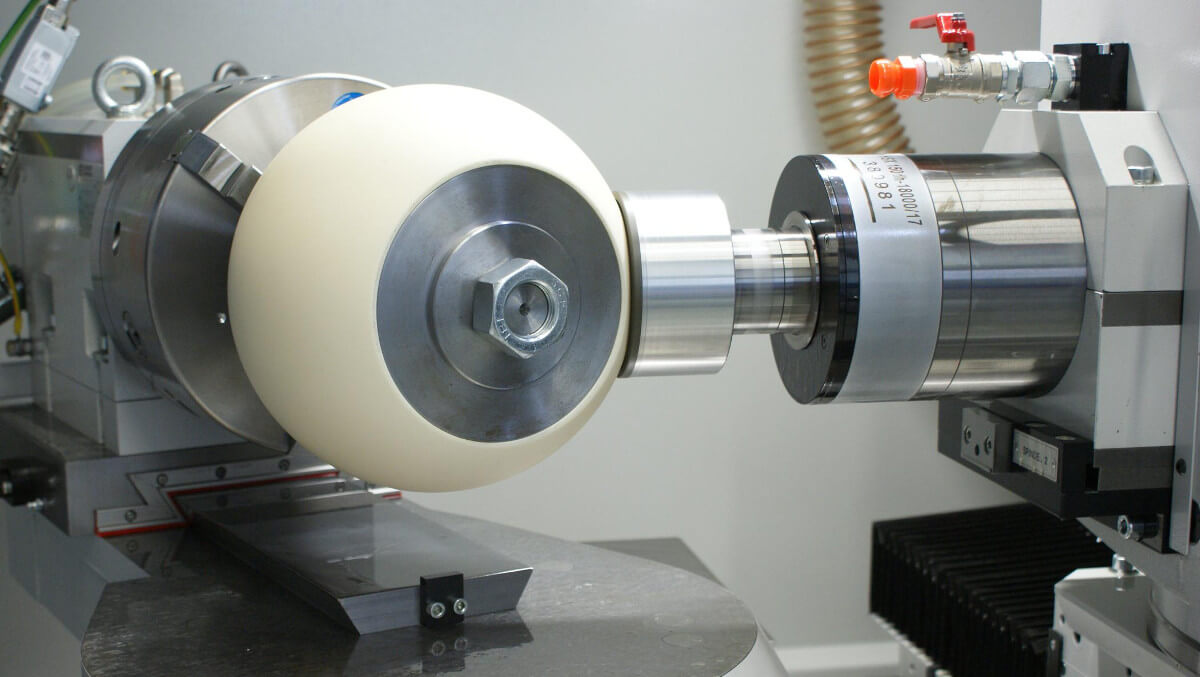

Illustrative image related to ceramic cnc machining

Scenario 2: Achieving Tight Tolerances in Complex Ceramic Parts

The Problem: Many industries, including aerospace and medical, require ceramic components with tight tolerances. B2B buyers often struggle to achieve the necessary precision during CNC machining, leading to parts that fail to meet stringent quality standards. The brittleness of ceramics can complicate the machining process, making it challenging to produce intricate geometries without risking cracks or deformities. This can result in wasted materials and increased costs due to rework or scrapping of non-compliant parts.

The Solution: To successfully achieve tight tolerances, buyers should focus on a multi-faceted approach that includes meticulous planning of the machining process. This involves selecting the right CNC machine with high precision capabilities and employing advanced cutting techniques, such as fine grinding and laser cutting, to refine complex geometries. Implementing a quality control system that includes frequent inspections during the machining process can help catch deviations early. Additionally, investing in simulation software can aid in visualizing and optimizing the machining process before actual production begins, reducing the risk of errors and ensuring that the final products meet the required specifications.

Scenario 3: Overcoming Thermal Management Issues in Ceramic CNC Machining

The Problem: Effective thermal management is a critical pain point for B2B buyers involved in ceramic CNC machining. Ceramics are poor heat conductors, and excessive heat buildup during machining can lead to thermal stress, resulting in cracks and compromised part integrity. Buyers often find it challenging to balance cutting speeds and feed rates to manage heat while still achieving efficient material removal, leading to frustrations with production consistency and quality.

The Solution: To address thermal management issues, buyers should prioritize the use of appropriate cooling techniques during machining. Utilizing coolants and lubricants can significantly reduce heat generation and improve surface finish. It’s essential to select coolants that are compatible with ceramic materials and can effectively dissipate heat without causing chemical reactions. Furthermore, optimizing the spindle speed and feed rate is crucial; lower speeds and slower feed rates generally produce less heat but may require adjustments to maintain efficiency. Buyers should also consider investing in advanced CNC machinery equipped with integrated cooling systems to maintain optimal operating temperatures throughout the machining process. Regular training for operators on the importance of thermal management and its impact on product quality will further enhance machining outcomes.

Illustrative image related to ceramic cnc machining

Strategic Material Selection Guide for ceramic cnc machining

What Are the Key Materials for Ceramic CNC Machining?

Ceramic CNC machining involves various types of ceramic materials, each with distinct properties, advantages, and limitations. Understanding these materials is crucial for international B2B buyers seeking to optimize their manufacturing processes and product performance.

1. Alumina (Aluminum Oxide)

Key Properties: Alumina is known for its excellent hardness, high-temperature resistance (up to 1,600°C), and good electrical insulation properties. It also exhibits high corrosion resistance, making it suitable for various industrial applications.

Pros & Cons: The durability of alumina makes it ideal for high-wear applications, such as in the aerospace and automotive industries. However, its brittleness can lead to challenges during machining, requiring specialized tools and techniques. The cost of alumina is moderate, making it accessible for many businesses, but the complexity of machining can increase overall production costs.

Impact on Application: Alumina is widely used in electrical insulators, cutting tools, and wear-resistant components. Its compatibility with various media, including chemicals and high temperatures, enhances its applicability in harsh environments.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards such as ASTM and ISO. Additionally, understanding the sourcing of alumina, which may vary in quality based on supplier location, is crucial for maintaining product standards.

2. Zirconia (Zirconium Dioxide)

Key Properties: Zirconia exhibits exceptional toughness and high fracture toughness, along with good thermal stability (up to 2,400°C). It also has low thermal conductivity, making it suitable for thermal barrier applications.

Pros & Cons: The primary advantage of zirconia is its ability to withstand high mechanical stress, making it ideal for dental and biomedical applications. However, it is more expensive than alumina, which can be a limiting factor for some manufacturers. The machining process can also be complex, requiring advanced CNC technology.

Impact on Application: Zirconia is commonly used in dental crowns, oxygen sensors, and wear-resistant components. Its compatibility with biological media makes it a preferred choice in medical applications.

Considerations for International Buyers: Buyers should be aware of the varying quality of zirconia based on the manufacturing process. Compliance with medical device regulations is essential for buyers in the healthcare sector, particularly in Europe.

3. Silicon Nitride

Key Properties: Silicon nitride is known for its high strength, excellent thermal shock resistance, and low thermal expansion coefficient. It can operate effectively at temperatures exceeding 1,200°C and has good wear resistance.

Pros & Cons: The robustness of silicon nitride makes it suitable for high-performance applications, including turbine components and cutting tools. However, its higher cost and complex machining requirements can be a barrier for some manufacturers.

Impact on Application: Silicon nitride is often used in the aerospace and automotive industries due to its ability to withstand extreme conditions. Its compatibility with various media, including corrosive environments, enhances its application range.

Considerations for International Buyers: Buyers should consider the availability of silicon nitride in their region and the associated shipping costs. Understanding the specific application requirements and ensuring compliance with industry standards is critical.

Illustrative image related to ceramic cnc machining

4. Boron Nitride

Key Properties: Boron nitride is recognized for its excellent thermal conductivity, high-temperature stability, and chemical inertness. It can withstand temperatures up to 2,000°C and is an effective electrical insulator.

Pros & Cons: The primary advantage of boron nitride is its versatility, making it suitable for a wide range of applications, including electronics and high-temperature environments. However, its cost is relatively high, which may deter some buyers. Additionally, its machining can be challenging due to its unique properties.

Impact on Application: Boron nitride is often used in semiconductor manufacturing and as a lubricant in high-temperature applications. Its compatibility with various media enhances its use in specialized industries.

Considerations for International Buyers: Buyers should ensure that boron nitride products comply with international standards, particularly in electronics. Understanding local regulations and sourcing reliable suppliers is essential for maintaining product quality.

Summary Table of Ceramic Materials for CNC Machining

| Material | Typical Use Case for ceramic cnc machining | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Alumina | Electrical insulators, cutting tools | Excellent hardness and corrosion resistance | Brittle, complex machining | Medium |

| Zirconia | Dental crowns, biomedical applications | High toughness and thermal stability | Expensive, complex machining | High |

| Silicon Nitride | Aerospace components, cutting tools | High strength and thermal shock resistance | Higher cost, complex machining | High |

| Boron Nitride | Semiconductor manufacturing, lubricants | Excellent thermal conductivity | High cost, challenging machining | High |

In-depth Look: Manufacturing Processes and Quality Assurance for ceramic cnc machining

What Are the Main Stages of Manufacturing in Ceramic CNC Machining?

Ceramic CNC machining encompasses several critical stages that ensure high-quality and precise components suitable for various applications. Each stage plays a pivotal role in the overall manufacturing process, contributing to the final product’s integrity and performance.

1. Material Preparation

Before machining, ceramic materials must be prepared adequately. This often involves sourcing high-quality ceramic blocks or blanks that are uniform in density and free from defects. Proper material selection is crucial, as the properties of the ceramic will significantly influence machining performance and final product characteristics. Suppliers should provide certificates of analysis to verify material quality.

2. Rough Milling

Rough milling is the first substantial machining operation where the bulk of material is removed to form the desired shape. This is typically done using CNC milling machines equipped with diamond-coated tools. The use of diamond tools is essential due to the hardness of ceramics, which can quickly wear out conventional cutting tools. The rough milling stage sets the foundation for the finer details to be added later.

3. Fine Grinding

After rough milling, fine grinding refines the dimensions and surface finish of the ceramic part. This stage employs precision grinding tools that ensure adherence to tight tolerances, often ranging from 0.01 to 0.05 mm. Fine grinding is critical for applications requiring high precision, such as in medical or aerospace components.

4. Surface Finishing

The surface finishing process involves polishing and applying any necessary coatings to enhance the part’s aesthetic and functional qualities. This step ensures that the ceramic component not only meets dimensional accuracy but also possesses the required surface finish for its intended application, which may include resistance to wear or chemical exposure.

5. Assembly (if applicable)

For components that require assembly, such as multi-part systems, this stage involves precise fitting and securing of various ceramic pieces. Assembly must be conducted with care to prevent damage to the brittle ceramic materials.

What Key Techniques Are Employed in Ceramic CNC Machining?

Ceramic CNC machining relies on advanced techniques to shape and finish ceramic materials effectively. Understanding these techniques allows B2B buyers to evaluate the capabilities of their suppliers.

CNC Milling

CNC milling is a fundamental technique in ceramic machining, utilizing rotating diamond-coated tools to achieve complex geometries. This process allows manufacturers to produce intricate designs while maintaining high precision.

Surface Grinding

Surface grinding employs abrasive wheels to smooth the surface of the ceramic workpiece. This technique is essential for achieving the fine surface finishes required in high-stress environments.

Laser Cutting

For delicate or intricate designs, laser cutting is employed. This method minimizes mechanical stress on the material, preventing cracks and ensuring clean edges. Laser cutting is particularly useful for thin ceramic sheets or complex patterns.

Core Drilling

Core drilling utilizes diamond-tipped drill bits to create holes in ceramic parts. This technique is vital for applications requiring precise openings without compromising the structural integrity of the ceramic.

How Is Quality Assurance Managed in Ceramic CNC Machining?

Quality assurance (QA) is paramount in ceramic CNC machining, especially given the critical applications of ceramic components in industries such as aerospace, electronics, and medical devices. International and industry-specific standards guide the QA process.

What International Standards Should B2B Buyers Be Aware Of?

Understanding relevant international standards is crucial for ensuring quality and compliance. ISO 9001 is the most widely recognized quality management standard, emphasizing continual improvement and customer satisfaction. Additionally, industry-specific standards such as CE marking for European markets and API specifications for oil and gas applications provide further assurance of product quality.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to catch defects early. Key checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular checks ensure that machining parameters remain within acceptable limits.

-

Final Quality Control (FQC): Upon completion, the finished products undergo comprehensive testing and inspection to verify compliance with customer specifications and standards.

What Testing Methods Are Commonly Used?

Several testing methods are employed to ensure the integrity and performance of ceramic components, including:

-

Dimensional Inspection: Using coordinate measuring machines (CMM) to verify that parts meet specified tolerances.

-

Surface Roughness Measurement: Assessing the surface finish to ensure it meets industry standards.

-

Mechanical Testing: Evaluating the strength and durability of ceramics through various tests, such as flexural strength tests.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, verifying the quality control processes of potential suppliers is crucial for ensuring reliable partnerships. Here are some strategies to consider:

Illustrative image related to ceramic cnc machining

Conducting Supplier Audits

Performing on-site audits allows buyers to assess the supplier’s manufacturing capabilities, quality control measures, and adherence to international standards. During the audit, buyers should review the supplier’s quality management system, testing protocols, and equipment maintenance records.

Requesting Quality Assurance Reports

Buyers should request detailed quality assurance reports, which may include inspection results, testing data, and compliance certifications. These documents provide insights into the supplier’s QC performance and reliability.

Utilizing Third-Party Inspections

Engaging third-party inspection services can add an extra layer of assurance. Independent inspectors can evaluate the supplier’s processes and products, providing unbiased feedback on quality and compliance with specifications.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing ceramic components internationally, particularly from regions like Africa, South America, the Middle East, and Europe, buyers should be aware of specific nuances:

-

Cultural Differences: Understanding local business practices and communication styles can enhance collaboration and negotiation.

-

Regulatory Compliance: Different regions may have varying regulatory requirements. Buyers should ensure that their suppliers comply with both local and international standards.

-

Supply Chain Logistics: Consideration of logistical challenges, including shipping times and customs regulations, is vital to maintaining supply chain efficiency.

By understanding the manufacturing processes and quality assurance measures in ceramic CNC machining, B2B buyers can make informed decisions, ensuring they partner with reliable suppliers capable of delivering high-quality components.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘ceramic cnc machining’

Introduction

Navigating the procurement of ceramic CNC machining services can be challenging, especially for international B2B buyers. This step-by-step checklist is designed to provide you with actionable insights to ensure you select a supplier that meets your technical, quality, and logistical requirements. Following these steps will help you make informed decisions and foster successful partnerships.

1. Define Your Technical Specifications

Clearly outlining your technical requirements is the foundation of effective sourcing. Specify the type of ceramic materials needed, desired tolerances, and any specific geometries or surface finishes required for your application. This will help potential suppliers assess their capability to meet your needs and provide accurate quotes.

2. Research and Shortlist Suppliers

Conduct thorough research to identify potential suppliers specializing in ceramic CNC machining. Look for companies with a strong reputation in the industry and proven expertise in handling ceramics. Utilize platforms like industry directories, trade shows, and online reviews to compile a list of candidates.

3. ✅ Verify Supplier Certifications

Before proceeding, ensure that the shortlisted suppliers hold relevant certifications, such as ISO 9001 for quality management systems. Certifications indicate adherence to industry standards and commitment to quality control. Additionally, check if they have specific certifications for handling ceramic materials, which can further ensure reliability.

4. Evaluate Manufacturing Capabilities

Assess each supplier’s manufacturing capabilities, focusing on their machinery, technology, and processes. Look for suppliers equipped with advanced CNC machines and diamond tools that can handle the hardness and brittleness of ceramics. A visit to the facility, if feasible, can provide insight into their operational efficiency and quality control measures.

5. Request Samples and Prototypes

Before finalizing your decision, request samples or prototypes of previous work. This allows you to evaluate the quality, precision, and surface finish of their ceramic machining. Pay close attention to the tolerances achieved and overall craftsmanship, as these factors are critical for high-performance applications.

6. Discuss Lead Times and Pricing

Engage in discussions about lead times and pricing structures. Understanding the supplier’s production capacity and delivery timelines is essential for aligning with your project schedules. Additionally, compare pricing but consider the total cost of ownership, including quality and service, rather than just the initial quote.

7. Establish Clear Communication Channels

Effective communication is vital for a successful partnership. Ensure that the supplier has a dedicated contact person who can address your queries promptly. Establishing clear communication channels will facilitate smoother project management and help resolve any issues that may arise during production.

By following this checklist, B2B buyers can confidently navigate the procurement process for ceramic CNC machining services, ensuring they select the right supplier to meet their specific needs and standards.

Comprehensive Cost and Pricing Analysis for ceramic cnc machining Sourcing

What Are the Key Cost Components in Ceramic CNC Machining?

When sourcing ceramic CNC machining services, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

Illustrative image related to ceramic cnc machining

-

Materials: The type of ceramic material significantly impacts the overall cost. High-performance ceramics like alumina or zirconia are more expensive than standard options. Additionally, prices fluctuate based on market demand and availability.

-

Labor: Skilled labor is essential in the CNC machining process due to the complexities involved in working with ceramics. Labor costs can vary based on the region, with developed markets often commanding higher wages than emerging markets.

-

Manufacturing Overhead: This encompasses the indirect costs of production, such as utilities, equipment maintenance, and facility costs. These expenses can vary widely based on the supplier’s operational efficiency and location.

-

Tooling: Specialized cutting tools, often diamond-coated, are necessary for machining ceramics effectively. The costs associated with tooling can be substantial, particularly for custom or low-volume projects requiring frequent tool changes.

-

Quality Control (QC): Rigorous quality control measures are essential to ensure that the machined parts meet the required specifications and tolerances. This may include testing, inspections, and certifications, which can add to the overall cost.

-

Logistics: Shipping and handling costs are critical, especially for international transactions. Factors such as distance, shipping methods, and customs regulations can significantly influence logistics expenses.

-

Margin: Suppliers typically add a profit margin on top of the manufacturing costs. Understanding the market standards for margins can help buyers negotiate more effectively.

How Do Volume and Customization Affect Pricing in Ceramic CNC Machining?

Pricing in ceramic CNC machining is heavily influenced by order volume and customization requirements.

-

Volume/MOQ: Higher order volumes often lead to reduced per-unit costs due to economies of scale. Suppliers may offer discounts for bulk purchases, making it economically advantageous for buyers to consolidate orders.

-

Specifications and Customization: Custom designs or specialized tolerances require additional time and resources, leading to higher costs. Buyers should clearly communicate their specifications to obtain accurate quotes and avoid unexpected expenses.

What Role Do Quality and Certifications Play in Pricing?

Quality assurance and certifications can significantly influence the cost of ceramic CNC machining services. Suppliers with ISO certifications or other quality standards may charge higher prices due to the assurance of consistent quality. Buyers should weigh the importance of these certifications against their specific application needs, especially in critical industries like aerospace or medical manufacturing.

What Supplier Factors Should Buyers Consider in the Pricing of Ceramic CNC Machining?

Several supplier-specific factors can impact pricing:

-

Reputation and Experience: Established suppliers with a proven track record may charge premium prices for their expertise and reliability.

-

Location: Suppliers located in regions with higher operational costs will typically have higher pricing structures. Conversely, sourcing from regions with lower costs can result in savings but may also involve trade-offs in terms of quality or lead times.

What Are Effective Negotiation Tips for B2B Buyers Sourcing Ceramic CNC Machining?

To ensure cost-efficiency, B2B buyers should consider the following negotiation strategies:

-

Understand Total Cost of Ownership (TCO): Assess not just the upfront costs but also the long-term implications of sourcing decisions. This includes maintenance, potential downtime, and the quality of the final product.

-

Leverage Quotes from Multiple Suppliers: Gathering quotes from various suppliers can provide insight into market pricing and help in negotiating better terms.

-

Be Transparent About Expectations: Clearly communicate your needs and expectations regarding quality, delivery timelines, and pricing. This can foster better relationships with suppliers and lead to favorable pricing arrangements.

What Pricing Nuances Should International Buyers Be Aware Of?

International buyers, especially from regions like Africa, South America, and the Middle East, should be aware of specific pricing nuances:

-

Incoterms: Understanding Incoterms is crucial for determining who bears the costs and risks during shipping. This can influence the total cost significantly.

-

Currency Fluctuations: Exchange rates can impact the final pricing, so it’s advisable to negotiate terms that account for potential fluctuations.

-

Customs and Tariffs: Be mindful of additional costs associated with importing goods, which can add to the overall expense.

Disclaimer on Indicative Prices

It’s important to note that the prices for ceramic CNC machining services can vary widely based on the aforementioned factors. Buyers should seek tailored quotes from suppliers to get an accurate understanding of the costs involved in their specific projects.

Alternatives Analysis: Comparing ceramic cnc machining With Other Solutions

Understanding Alternatives to Ceramic CNC Machining

As industries increasingly demand high-performance materials for specialized applications, the need for efficient manufacturing processes has grown. Ceramic CNC machining is a prominent option, but alternative methods can also meet specific project requirements. Evaluating these alternatives helps B2B buyers make informed decisions based on performance, cost, and suitability for their unique needs.

Comparison of Ceramic CNC Machining with Alternative Solutions

| Comparison Aspect | Ceramic CNC Machining | 3D Printing | Traditional Machining |

|---|---|---|---|

| Performance | High precision; tight tolerances | Varies with technology; good for complex geometries | Good for metals; precision can vary |

| Cost | Higher initial setup costs; cost-effective for large runs | Lower setup costs; material costs can add up | Generally lower initial costs; labor-intensive |

| Ease of Implementation | Requires skilled operators; setup complexity | User-friendly; quick prototyping | Requires skilled labor; longer setup times |

| Maintenance | High maintenance for tooling; regular checks needed | Minimal maintenance; software updates | Regular maintenance required for machines |

| Best Use Case | Aerospace, medical devices, electronics | Prototyping, low-volume production | High-volume, less complex parts |

Analyzing 3D Printing as an Alternative

3D printing, or additive manufacturing, offers unique advantages in terms of design flexibility and lower initial setup costs. It allows for the creation of complex geometries that may be challenging to achieve through traditional machining methods. However, the performance of 3D printed ceramics can be inconsistent, particularly in terms of mechanical properties and surface finish. For projects requiring rapid prototyping or low-volume production, 3D printing can be an excellent choice, but it may not deliver the same precision and durability as ceramic CNC machining.

Evaluating Traditional Machining

Traditional machining methods, such as turning and milling, are well-established processes that can be cost-effective, especially for high-volume production runs. While they excel in processing metals and plastics, traditional methods may struggle with the unique properties of ceramics, which are harder and more brittle. This can lead to challenges in achieving the necessary tolerances and surface finishes. Traditional machining is best suited for projects that do not require the high precision that ceramic CNC machining offers, making it a viable option for simpler designs and materials.

Making the Right Choice for Your Business Needs

When deciding between ceramic CNC machining and its alternatives, B2B buyers must consider several factors. If precision and durability are paramount, especially in industries like aerospace or medical, ceramic CNC machining is likely the best choice. However, for businesses focused on rapid prototyping or lower production volumes, 3D printing may provide the flexibility needed at a lower cost. Traditional machining remains a viable option for simpler projects, particularly in metalworking. Ultimately, the right solution depends on the specific application, budget constraints, and the desired quality of the final product.

Essential Technical Properties and Trade Terminology for ceramic cnc machining

What Are the Key Technical Properties of Ceramic CNC Machining?

1. Material Grade

Material grade refers to the specific classification of ceramic material used in machining processes. Common grades include alumina, zirconia, and silicon carbide, each possessing unique properties such as hardness, thermal stability, and chemical resistance. Selecting the appropriate material grade is critical for ensuring the performance and longevity of the final product, particularly in demanding applications like aerospace or medical devices.

2. Tolerance

Tolerance defines the permissible limits of variation in a manufactured part’s dimensions. In ceramic CNC machining, tolerances typically range from 0.01 to 0.05 mm. Achieving these tight tolerances is essential for ensuring that components fit correctly and function as intended, especially in applications where precision is crucial, such as in electronic components or automotive parts.

3. Surface Finish

Surface finish measures the texture and smoothness of the machined surface, often quantified in micrometers. A high-quality surface finish is vital in applications requiring low friction or improved aesthetics. For instance, in medical devices, a smooth finish can prevent bacteria accumulation, thereby enhancing safety and functionality.

4. Cutting Speed

Cutting speed refers to the rate at which the cutting tool moves through the ceramic material. It is crucial to maintain an optimal cutting speed to prevent overheating and cracking of the brittle ceramic. Understanding the ideal cutting speed ensures that the machining process is efficient while preserving the integrity of the material.

5. Feed Rate

Feed rate indicates how quickly the cutting tool advances through the material during machining. A well-controlled feed rate minimizes mechanical stress on the ceramic, reducing the risk of fractures. This property is particularly important for maintaining the quality of intricate designs and ensuring consistent production rates.

Which Trade Terminology Should B2B Buyers Understand in Ceramic CNC Machining?

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is essential for buyers as it determines the quality and reliability of the components they procure, especially in high-stakes industries like automotive or aerospace.

2. MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it impacts inventory management and cost efficiency. Knowing the MOQ helps businesses plan their purchasing strategy effectively, ensuring they meet production needs without overcommitting financially.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing for specific products or services. It is a vital part of the procurement process, allowing buyers to compare prices, terms, and conditions. A well-structured RFQ can lead to better pricing negotiations and streamlined supplier selection.

4. Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for B2B buyers as they clarify who is responsible for shipping, insurance, and tariffs, minimizing misunderstandings during cross-border transactions.

5. Tolerance Levels

Tolerance levels refer to the permissible variations in the dimensions of machined parts. Understanding these levels is vital for B2B buyers to ensure that their specifications align with the capabilities of the machining service provider, thus avoiding costly reworks or production delays.

6. Vibration Control

Vibration control is a critical aspect of CNC machining that ensures stability during the machining process. For ceramic materials, controlling vibrations helps prevent defects and ensures the precision of the final product. Buyers should prioritize suppliers that have effective vibration control measures in place to guarantee high-quality outputs.

Understanding these technical properties and trade terminologies can empower B2B buyers to make informed decisions in the intricate landscape of ceramic CNC machining, ultimately enhancing their procurement strategy and operational success.

Navigating Market Dynamics and Sourcing Trends in the ceramic cnc machining Sector

What Are the Current Market Dynamics and Key Trends in Ceramic CNC Machining?

The global ceramic CNC machining market is witnessing significant growth, driven by the increasing demand for precision-engineered components in various industries, including aerospace, medical, and electronics. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe seek advanced manufacturing solutions, the focus is shifting toward high-performance ceramics that offer durability and reliability. Emerging technologies, such as additive manufacturing and advanced CNC machining techniques, are redefining the landscape, enabling manufacturers to produce complex geometries with tight tolerances.

Key trends include the integration of Industry 4.0 practices, which emphasize automation, real-time data analytics, and smart manufacturing. These advancements enhance efficiency and reduce operational costs, making ceramic CNC machining more accessible to businesses in developing markets. Additionally, there is a growing emphasis on customization, as buyers increasingly demand bespoke solutions tailored to specific application requirements. This trend necessitates a collaborative approach between suppliers and manufacturers, fostering innovation and adaptability in the supply chain.

Illustrative image related to ceramic cnc machining

Another notable dynamic is the increasing investment in research and development to improve machining processes and tools. Companies are exploring novel materials and coatings that can withstand the harsh conditions of machining ceramics, thus enhancing tool life and performance. This focus on innovation is essential for maintaining competitive advantage and meeting the diverse needs of global buyers.

How Important Is Sustainability and Ethical Sourcing in Ceramic CNC Machining?

Sustainability and ethical sourcing have become critical considerations for B2B buyers in the ceramic CNC machining sector. The environmental impact of manufacturing processes, particularly concerning energy consumption and waste generation, is under scrutiny. Companies are increasingly adopting sustainable practices, such as using energy-efficient machinery and minimizing waste through optimized machining processes. This shift not only aligns with global sustainability goals but also resonates with consumers who prioritize environmentally responsible sourcing.

Moreover, the importance of ethical supply chains cannot be overstated. Buyers are increasingly seeking suppliers that demonstrate a commitment to ethical labor practices and responsible sourcing of raw materials. This includes ensuring that materials are sourced from suppliers who adhere to environmental regulations and labor rights standards. Certifications such as ISO 14001 for environmental management and Fair Trade certifications can serve as indicators of a supplier’s commitment to sustainability and ethical practices.

The use of “green” materials in ceramic CNC machining is also gaining traction. Eco-friendly ceramics, which are produced with lower environmental impact, are becoming more popular among buyers looking to enhance their sustainability profile. This trend is particularly relevant in industries like electronics and medical devices, where the demand for sustainable materials is growing.

What Is the Brief Evolution of Ceramic CNC Machining in the B2B Context?

Ceramic CNC machining has evolved significantly over the past few decades, transitioning from traditional manual machining methods to advanced CNC technologies. Initially, ceramics were primarily used for household items; however, advancements in material science and machining techniques have expanded their application across various high-tech industries. The introduction of CNC technology revolutionized the production process, allowing for higher precision and efficiency in machining complex ceramic components.

As industries such as aerospace and medical manufacturing began to recognize the benefits of ceramics—such as their exceptional hardness, wear resistance, and thermal stability—the demand for precision ceramic parts surged. This evolution paved the way for specialized machining techniques tailored to the unique properties of ceramic materials, including diamond tooling and laser cutting. Today, ceramic CNC machining stands at the forefront of innovation, driven by technological advancements and the increasing demand for high-performance materials in global markets.

Frequently Asked Questions (FAQs) for B2B Buyers of ceramic cnc machining

-

How do I ensure the quality of ceramic CNC machined parts?

To guarantee quality in ceramic CNC machined parts, it’s essential to collaborate with suppliers who implement rigorous quality assurance (QA) processes. Look for manufacturers with certifications such as ISO 9001 or similar quality management systems. Request detailed documentation, including material certifications and inspection reports, and consider conducting on-site audits if feasible. Establish clear communication about your quality expectations and tolerances upfront. Additionally, utilizing advanced inspection techniques, such as coordinate measuring machines (CMM), can help verify that the finished components meet the required specifications. -

What is the best cutting tool for ceramic CNC machining?

Diamond-coated tools are widely regarded as the best choice for ceramic CNC machining due to their exceptional hardness and wear resistance. These tools can effectively handle the abrasive nature of ceramic materials, ensuring precision and longevity during the machining process. Depending on your specific application, consider using diamond end mills for milling operations and diamond grinding wheels for finishing. When selecting tools, it’s crucial to match the tool type to the specific ceramic material to achieve optimal cutting performance and surface finish. -

What are the typical minimum order quantities (MOQs) for ceramic CNC machining?

Minimum order quantities for ceramic CNC machining can vary significantly based on the supplier and the complexity of the parts. Generally, MOQs can range from as low as 10 units for simple components to several hundred for complex designs. When sourcing, it’s important to communicate your needs clearly and inquire about flexibility in MOQs, especially if you’re a smaller business or testing new products. Some manufacturers may offer lower MOQs for initial prototypes or samples, allowing you to evaluate quality before committing to larger orders. -

How can I assess the reliability of a ceramic CNC machining supplier?

To assess a ceramic CNC machining supplier’s reliability, start by reviewing their industry experience and expertise. Request references from previous clients, particularly those in your industry, and examine case studies or testimonials. Check for certifications that demonstrate adherence to quality standards, such as ISO 9001. Additionally, evaluate their production capabilities, including technology used and lead times. Establishing a clear line of communication and visiting the facility, if possible, can provide further assurance of their operational integrity. -

What payment terms should I expect when sourcing ceramic CNC machining?

Payment terms for ceramic CNC machining can vary widely based on the supplier and the size of your order. Common arrangements include upfront deposits (typically 30-50%) with the balance due upon delivery or prior to shipping. Some suppliers may offer net 30 or net 60 terms for established clients. It’s essential to clarify payment terms during the negotiation phase and ensure they align with your cash flow needs. Additionally, consider discussing options for secure payment methods, such as letters of credit, to mitigate risks associated with international transactions. -

What factors influence the lead time for ceramic CNC machining projects?

Lead times for ceramic CNC machining projects are influenced by several factors, including the complexity of the part design, material availability, and the supplier’s production capacity. Custom designs typically require longer lead times due to additional steps in the process, such as prototyping and tooling. Additionally, unexpected delays in material sourcing or machine availability can impact timelines. To ensure timely delivery, communicate your deadlines clearly and consider working with suppliers who have a track record of meeting delivery commitments. -

How can I customize ceramic CNC machined components for my specific needs?

Customization of ceramic CNC machined components begins with a clear understanding of your specific requirements, including dimensions, tolerances, and surface finishes. Collaborate closely with your supplier during the design phase to discuss material options and machining techniques that can achieve your desired outcomes. Many manufacturers offer design assistance to optimize parts for production. Providing detailed drawings and specifications will facilitate the customization process, ensuring that the final product meets your exact needs. -

What logistics considerations should I keep in mind when sourcing ceramic CNC machined parts internationally?

When sourcing ceramic CNC machined parts internationally, logistics considerations are crucial for ensuring timely and safe delivery. Evaluate shipping options, including air versus sea freight, based on your timeline and budget. Be aware of customs regulations and import duties that may apply to your shipments, as these can affect overall costs. Collaborating with a logistics partner experienced in international shipping can help streamline the process. Additionally, consider the packaging requirements for fragile ceramic components to minimize the risk of damage during transit.

Top 9 Ceramic Cnc Machining Manufacturers & Suppliers List

1. Great Ceramic – Precision Ceramic Machining

Domain: great-ceramic.com

Registered: 2020 (5 years)

Introduction: Great Ceramic specializes in advanced ceramic machining, offering high-quality precision ceramic parts. Key services include: 1. Ceramic CNC Machining: High dimensional accuracy and complex shapes using diamond abrasive tools. 2. Ceramic Substrate Laser Machining: Low-cost, high-efficiency method for cutting and marking ceramic substrates. 3. Ceramic Grinding Machining: Various grinding equipment …

2. Bullen Ultrasonics – Advanced Ceramic Machining

Domain: bullentech.com

Registered: 2006 (19 years)

Introduction: Bullen Ultrasonics offers advanced ceramic machining services, including Diamond Tool Machining and Ultrasonic Machining. Key features include:

– Diamond Tool Machining: Utilizes diamond-coated tools for high precision and wear resistance, allowing for customized tool geometry and extended tool life.

– Ultrasonic Machining: Employs ultrasonic vibrations for controlled abrasions, enhancing cuttin…

3. Precision Ceramics – Technical Ceramic Machining Services

Domain: precision-ceramics.com

Registered: 2013 (12 years)

Introduction: Precision Ceramics offers high-tolerance technical ceramic machining services including CNC Milling, Grinding, Brazing, Joining, Glazing, Lapping, Polishing, and Metalizing. General tolerances are ±.02mm for grinding, ±.03mm for turning and milling, with capabilities to achieve ±.01mm. CNC Milling bed capacity is 1000mm in X and 510mm in Y, with a spindle speed of 12,000 rpm. CNC Turning capabilit…

4. An-Prototype – CNC Machining Ceramics

Domain: an-prototype.com

Registered: 2016 (9 years)

Introduction: CNC machining ceramics is a complex process that requires understanding ceramic material properties, cutting tool technology, and cutting parameter optimization. Advantages of machining ceramics include high strength and hardness, low coefficient of friction, and biocompatibility. CNC machining is preferred for its precision, accuracy, and repeatability. Commonly machined ceramics include zirconia…

5. Valley Design – Ceramic CNC Machining Services

Domain: valleydesign.com

Registered: 1995 (30 years)

Introduction: Valley Design offers Ceramic CNC Machining Services specializing in precision machining of various ceramics including 96% Alumina, 99.6% Alumina, Aluminum Nitride, Fused Silica, Glass, Sapphire, Silicon Carbide, and Silicon Silicon-Carbide. Their capabilities include 3, 4, and 5 axis CNC machining, with a focus on high-quality, rapid on-demand services. They can process parts from as small as 0.12…

6. Ceramic Manufacturing – Precision Ceramic Components

Domain: ceramicmanufacturing.net

Registered: 2015 (10 years)

Introduction: Ceramic machining is the process of designing and creating precision ceramic components using various machining processes. Key products include: Alumina Ceramic, Alumina Crucible, Ceramic Bearing, Ceramic Insulator, Ceramic Nozzle, Ceramic Rod, Ceramic Spacer, Ceramic Tube, Custom Ceramic, Industrial Ceramic, Machined Ceramic, Sapphire Machining, Silicon Carbide, and Zirconia Ceramic. Notable manu…

7. Karnasch – Abrasive Tools and End Mills

Domain: karnasch.tools

Introduction: – Product Categories:

– Abrasive Blocks (2)

– Ball Nose End Mills (1)

– Burrs:

– Ball Nosed Cone, KEL, L, SL (4)

– Ball Nosed Tree, RBF, F, SF (6)

– Ball, KUD, D, SD (6)

– Cone, SKM, M, SM (4)

– Corner Radius End Mills (1)

– Cylinder (Ball Nosed), WRC, C, SC (6)

– Cylinder (End Cut), ZYB, B, SB (6)

– Cylinder (No End Cut), ZYA, A, SA (6) …

8. At Machining – Ceramic CNC Machining

Domain: at-machining.com

Registered: 2014 (11 years)

Introduction: Ceramic CNC Machining involves using computer numerical control technology to shape and produce intricate ceramic parts. Key properties of ceramics include high strength, durability, wear resistance, thermal insulation, biocompatibility, and electrical insulation. Common ceramics used in machining include Alumina (Al2O3), Zirconia (ZrO2), Silicon Nitride (Si3N4), Silicon Carbide (SiC), and Machina…

9. Practical Machinist – CNC Machining Solutions

Domain: practicalmachinist.com

Registered: 2000 (25 years)

Introduction: CNC Machining of ceramics, particularly alumina (Al2O3). Suggested machines include used Haas VF2. Emphasis on upgrading wipers/coolant systems. Typical tooling includes diamond tools and grinding wheels. Recommended spindle speeds between 5,000 to 12,000 SFM. Importance of filtering coolant to a minimum of 5 microns. Discussion of laser-assisted machining techniques. Consideration of pre-fired ma…

Strategic Sourcing Conclusion and Outlook for ceramic cnc machining

As the demand for high-performance materials continues to grow across various industries, the strategic sourcing of ceramic CNC machining services becomes increasingly critical for international B2B buyers. Understanding the intricacies of ceramic machining—such as the importance of tool selection, precise machining parameters, and effective thermal management—can significantly enhance the quality of your components and reduce production costs.

Investing in strategic sourcing not only ensures access to advanced machining technologies but also fosters partnerships with suppliers who prioritize quality, innovation, and sustainability. This is particularly vital for businesses in regions like Africa, South America, the Middle East, and Europe, where the need for durable and precise components is on the rise.

Looking ahead, embracing ceramic CNC machining will not only position your business at the forefront of technological advancements but also unlock new opportunities in diverse sectors, from aerospace to medical equipment. Take the next step by exploring reputable suppliers and investing in the right machining solutions that meet your specific needs. The future of your manufacturing capabilities is bright—seize the opportunity today!

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.