Telehandler For Sale: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for telehandler for sale

In today’s competitive landscape, sourcing telehandlers for sale can present significant challenges for international B2B buyers. With an array of options available across various markets, selecting the right machine that meets specific operational needs while ensuring cost-effectiveness is crucial. This guide aims to equip buyers from Africa, South America, the Middle East, and Europe—regions where telehandlers are becoming increasingly essential in construction, agriculture, and logistics—with the insights necessary to navigate this complex purchasing process.

Throughout this comprehensive resource, we will delve into various types of telehandlers, highlighting their unique applications and advantages. Additionally, we will provide actionable strategies for vetting suppliers, understanding pricing structures, and assessing the total cost of ownership. By addressing key considerations such as maintenance, availability of parts, and after-sales support, this guide empowers businesses to make informed purchasing decisions.

As telehandlers continue to gain traction globally, understanding the nuances of the market can significantly impact operational efficiency and project success. Whether you’re a buyer in Vietnam looking for robust performance or a company in Germany seeking the latest technology, this guide is designed to streamline your purchasing journey and enhance your competitive edge.

Understanding telehandler for sale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Telehandler | Versatile lifting capabilities, 4-wheel drive, various lift heights | Construction, agriculture, landscaping | Pros: High versatility and lifting capacity. Cons: May require more space to maneuver. |

| Heavy-Duty Telehandler | Enhanced lifting capacity (over 12,000 lbs), robust construction | Heavy construction, mining, industrial | Pros: Ideal for heavy loads. Cons: Higher initial investment and maintenance costs. |

| Compact Telehandler | Smaller footprint, lower lifting capacity (5,000-7,000 lbs) | Tight spaces, urban construction | Pros: Highly maneuverable in confined areas. Cons: Limited lifting height and capacity. |

| Agricultural Telehandler | Specialized attachments for farming, higher ground clearance | Farming, agriculture, material handling | Pros: Tailored for agricultural needs. Cons: May not be suitable for non-agricultural tasks. |

| Electric Telehandler | Battery-powered, lower emissions, quiet operation | Indoor use, environmentally conscious projects | Pros: Eco-friendly and low operating costs. Cons: Limited by battery life and charging time. |

What are the Characteristics and Suitability of Standard Telehandlers?

Standard telehandlers are designed for a wide range of applications, making them a popular choice in various sectors such as construction and landscaping. With a typical lifting capacity ranging from 6,000 to 12,000 lbs and versatile attachments, these machines can handle diverse tasks, from lifting materials to providing support in rough terrain. When purchasing, consider factors such as the required lift height and reach, as well as the machine’s ability to navigate the job site.

How Do Heavy-Duty Telehandlers Stand Out in the Market?

Heavy-duty telehandlers are engineered for demanding environments where maximum lifting capacity is essential, often exceeding 12,000 lbs. These machines are commonly used in heavy construction and mining operations, where robustness is critical. Buyers should assess the machine’s durability, maintenance requirements, and the specific tasks it will perform, as the initial investment can be substantial, but the return on investment may be significant in high-demand applications.

Why Choose Compact Telehandlers for Urban Construction?

Compact telehandlers are ideal for projects in tight spaces, such as urban construction sites. With a lower lifting capacity (generally between 5,000 to 7,000 lbs) and a smaller footprint, these machines excel in maneuverability. They are particularly suited for jobs where space constraints limit the use of larger equipment. Buyers should consider their specific site conditions and whether the compact size offsets the limitations in lifting height and capacity.

What Makes Agricultural Telehandlers Unique?

Agricultural telehandlers come equipped with specialized attachments that cater to farming needs, such as bale handlers and pallet forks designed for agricultural tasks. These machines typically feature higher ground clearance and are built to operate effectively in uneven terrain. When considering a purchase, it’s crucial to evaluate the type of agricultural tasks to be performed and the compatibility of attachments to maximize efficiency in farming operations.

How Do Electric Telehandlers Contribute to Sustainable Practices?

Electric telehandlers are gaining traction due to their environmentally friendly design, producing lower emissions and operating quietly. They are particularly suitable for indoor applications and projects focused on sustainability. Buyers should consider the operational range, battery life, and charging infrastructure, as these factors can affect overall productivity. While the initial cost may be higher, the lower operational costs and eco-friendly benefits can lead to long-term savings.

Key Industrial Applications of telehandler for sale

| Industry/Sector | Specific Application of telehandler for sale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Lifting and placing heavy materials on job sites | Increases efficiency and safety in material handling | Capacity, reach, and terrain adaptability are critical. |

| Agriculture | Handling bales, pallets, and equipment on farms | Enhances productivity and reduces manual labor | Look for models with specialized attachments for agricultural tasks. |

| Mining | Transporting materials and equipment in mines | Improves operational efficiency in rugged terrains | Durability and off-road capabilities are essential for mining. |

| Logistics and Warehousing | Moving goods in and out of storage facilities | Streamlines operations and reduces loading times | Consider size, maneuverability, and lifting capacity for tight spaces. |

| Infrastructure Development | Supporting road and bridge construction projects | Facilitates heavy lifting and precise placement | Ensure compliance with local regulations and standards. |

How is a Telehandler Used in Construction, and What Problems Does It Solve?

In the construction industry, telehandlers are invaluable for lifting and placing heavy materials, such as steel beams and concrete blocks, at various heights. They streamline material handling, allowing for safer and more efficient operations on job sites. By minimizing manual labor and reducing the risk of accidents, telehandlers enhance overall productivity. International buyers, especially from regions like Africa and South America, should consider models that are robust enough to handle diverse terrains and are equipped with various attachments to suit different construction tasks.

What Role Does a Telehandler Play in Agriculture?

Telehandlers are essential in agriculture for handling bales, pallets, and farm equipment. They significantly enhance productivity by allowing operators to lift and transport heavy loads with ease, thereby reducing the need for manual labor. This efficiency is particularly beneficial during peak seasons when time is critical. Buyers in agricultural sectors should prioritize models with attachments like forks or grapples that are designed specifically for agricultural use, ensuring versatility in handling different materials.

How Can Mining Operations Benefit from Telehandlers?

In mining operations, telehandlers are used to transport materials and equipment across rugged terrains, improving operational efficiency. They are particularly effective for loading and unloading supplies in areas that are difficult to access with traditional forklifts. The durability and off-road capabilities of telehandlers are crucial for withstanding harsh mining environments. Buyers in the Middle East and Europe should focus on telehandlers with high lifting capacities and robust build quality to meet the demanding requirements of mining applications.

Why are Telehandlers Important in Logistics and Warehousing?

In logistics and warehousing, telehandlers facilitate the movement of goods in and out of storage facilities. They help streamline operations by reducing loading and unloading times, which is critical for maintaining supply chain efficiency. The ability to maneuver in tight spaces while lifting heavy loads makes them ideal for warehouses with limited room. International buyers should assess the size, maneuverability, and lifting capacity of telehandlers to ensure they meet the specific requirements of their logistics operations.

How Do Telehandlers Support Infrastructure Development Projects?

Telehandlers play a crucial role in infrastructure development, particularly in road and bridge construction projects. They assist in lifting heavy materials and placing them with precision, which is essential for the integrity of infrastructure projects. By improving the efficiency of material handling, telehandlers help reduce project timelines and labor costs. Buyers should ensure that the telehandlers they consider comply with local regulations and standards, especially in Europe, where safety and environmental considerations are paramount.

3 Common User Pain Points for ‘telehandler for sale’ & Their Solutions

Scenario 1: Difficulty in Assessing Equipment Reliability

The Problem: One of the primary concerns for B2B buyers in the market for telehandlers is the reliability and condition of used equipment. Buyers often face challenges in determining whether the telehandler has been well-maintained, especially when dealing with sellers from different regions. Inadequate information about the machine’s history, usage hours, and maintenance records can lead to costly decisions, including unexpected repairs or operational downtimes.

The Solution: To mitigate this risk, buyers should prioritize purchasing telehandlers from reputable dealers who provide comprehensive equipment history reports. Utilizing platforms that offer detailed listings, including service records and previous usage, can enhance transparency. Moreover, it’s advisable to request a third-party inspection, which can provide an unbiased assessment of the equipment’s condition. This step not only ensures that the telehandler meets the necessary standards but also builds trust between the buyer and seller, particularly in international transactions where local regulations and standards may differ.

Scenario 2: Navigating Compliance and Certification Requirements

The Problem: When sourcing telehandlers for operations in different countries, B2B buyers often encounter various compliance and certification requirements that can complicate the purchasing process. Each region may have its own regulations regarding safety standards, emissions, and operational capabilities, which can lead to confusion and delays in procurement. For instance, telehandlers intended for use in Europe may need to comply with stringent EU safety standards, while those in South America may face different requirements.

The Solution: To successfully navigate these complexities, buyers should conduct thorough research on the specific regulations applicable in their target market. Engaging with local experts or consultants who specialize in equipment compliance can be invaluable. Additionally, it’s wise to only consider telehandlers that come with appropriate certifications for the intended market. This proactive approach not only streamlines the purchasing process but also reduces the risk of legal issues or operational delays post-purchase.

Scenario 3: Overcoming Budget Constraints While Maximizing Value

The Problem: Budget limitations are a significant pain point for many B2B buyers looking to invest in telehandlers. Buyers must balance their need for high-quality equipment against financial constraints, often leading to compromises on features or specifications that could impact operational efficiency. This dilemma is exacerbated in competitive markets, where the pressure to minimize costs can overshadow the importance of investing in reliable equipment.

The Solution: To address budget constraints without sacrificing quality, buyers should consider a multi-faceted strategy. First, exploring financing options such as leasing or installment payments can make higher-quality telehandlers more accessible. Additionally, participating in auctions or seeking out reputable used equipment marketplaces can yield significant savings. Buyers should also prioritize creating a detailed cost-benefit analysis, comparing the long-term operational costs and potential downtime associated with lower-quality machines against the upfront savings. This approach ensures that the chosen telehandler not only fits the budget but also provides the best value over its operational lifespan.

Strategic Material Selection Guide for telehandler for sale

When selecting materials for telehandlers, it is essential to consider their performance characteristics, costs, and suitability for specific applications. This guide analyzes four common materials used in telehandler construction, providing insights that are particularly relevant for international B2B buyers from regions such as Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Steel in Telehandler Construction?

Steel is the most prevalent material used in the construction of telehandlers, particularly for the frame and structural components. Its key properties include high tensile strength, excellent durability, and resistance to deformation under load. Steel can withstand extreme temperatures and pressures, making it suitable for heavy-duty applications.

Pros and Cons: The primary advantage of steel is its strength and longevity, which translates to a longer lifespan for telehandlers. However, steel is susceptible to corrosion, especially in humid or saline environments, which can lead to increased maintenance costs. Additionally, the manufacturing process can be complex and energy-intensive, impacting overall costs.

Impact on Application: Steel’s compatibility with various media, such as hydraulic fluids, makes it a reliable choice for telehandlers used in diverse environments.

Considerations for International Buyers: Compliance with international standards, such as ASTM or DIN, is crucial. Buyers from regions with high humidity or coastal environments should prioritize galvanized or coated steel options to enhance corrosion resistance.

How Does Aluminum Compare as a Material for Telehandlers?

Aluminum is increasingly used in telehandler construction, particularly for components where weight reduction is critical, such as booms and frames. Its lightweight nature contributes to improved fuel efficiency and maneuverability.

Pros and Cons: The key advantage of aluminum is its excellent strength-to-weight ratio, allowing for increased payloads without compromising performance. However, aluminum can be more expensive than steel and is generally less durable under heavy loads, making it less suitable for extreme applications.

Impact on Application: Aluminum is resistant to corrosion, making it ideal for telehandlers operating in harsh environments. However, its lower tensile strength may limit its use in applications requiring heavy lifting.

Considerations for International Buyers: Buyers should consider the cost implications and potential trade-offs in strength. Compliance with relevant standards is also essential, particularly in regions with stringent safety regulations.

What Role Does Composite Material Play in Telehandlers?

Composite materials, often a combination of fiberglass and resin, are utilized in specific telehandler components, such as panels and covers. Their lightweight nature and resistance to corrosion are significant advantages.

Pros and Cons: Composites offer excellent durability and are resistant to environmental factors, making them suitable for outdoor applications. However, they can be more expensive to manufacture and may not provide the same structural integrity as metals.

Impact on Application: Composites can be particularly effective in reducing overall weight, enhancing fuel efficiency, and improving handling. However, their use is generally limited to non-load-bearing components.

Considerations for International Buyers: Understanding the manufacturing standards for composites is vital, as different regions may have varying regulations regarding their use.

How Does Cast Iron Fit into Telehandler Design?

Cast iron is primarily used in telehandlers for components that require high wear resistance, such as gears and housings. Its properties include excellent compressive strength and good wear resistance.

Pros and Cons: The main advantage of cast iron is its durability and ability to withstand high loads without deforming. However, it is brittle compared to other materials, making it susceptible to cracking under impact.

Impact on Application: Cast iron is ideal for applications involving heavy machinery and high-stress conditions. However, its weight can negatively affect the overall maneuverability of the telehandler.

Considerations for International Buyers: Buyers should be aware of the varying quality standards for cast iron in different regions, ensuring compliance with local regulations.

Summary Table of Material Selection for Telehandlers

| Material | Typical Use Case for telehandler for sale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Frame and structural components | High strength and durability | Susceptible to corrosion | High |

| Aluminum | Booms and lightweight components | Excellent strength-to-weight ratio | More expensive and less durable | Medium |

| Composite | Panels and non-load-bearing components | Lightweight and corrosion-resistant | Higher manufacturing costs | Medium to High |

| Cast Iron | Gears and housing | Durable and wear-resistant | Brittle and heavy | Medium |

This material selection guide provides valuable insights for B2B buyers looking to invest in telehandlers, ensuring they choose the right materials for their specific operational needs and environmental conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for telehandler for sale

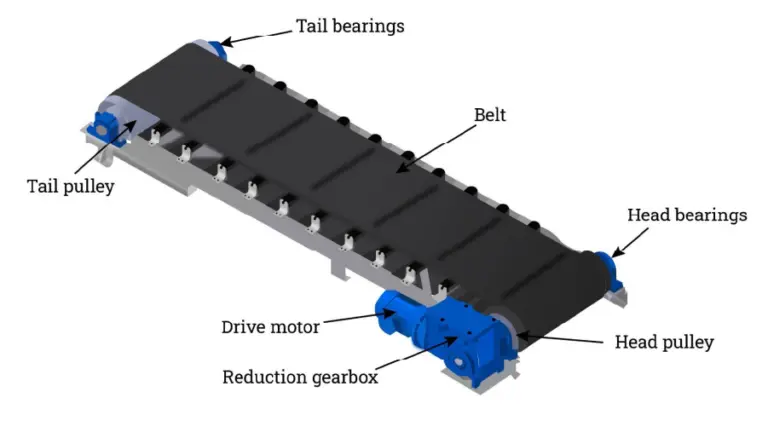

What Are the Key Stages in Telehandler Manufacturing Processes?

The manufacturing process for telehandlers involves several critical stages, each designed to ensure that the final product meets stringent performance and safety standards. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step in manufacturing telehandlers is sourcing high-quality materials, typically steel and aluminum alloys, which are essential for the structural integrity and durability of the machine. Suppliers often undergo a rigorous selection process to ensure they meet material specifications. This stage may also involve pre-treatment processes such as cutting, bending, and welding components that will be used in the assembly.

-

Forming: In this stage, the prepared materials undergo various forming techniques, including machining, forging, and stamping. Advanced technologies such as computer numerical control (CNC) machines are commonly used to achieve precise dimensions and tolerances. The forming process ensures that critical components such as the boom, chassis, and lift arms are manufactured to exact specifications, which is vital for performance and safety.

-

Assembly: After forming, the components are assembled into a cohesive unit. This stage typically involves both manual and automated processes to ensure accuracy and efficiency. Key components such as the hydraulic system, engine, and electrical systems are integrated during this phase. The assembly line may include stations for quality checks to ensure that each component functions correctly before moving to the next stage.

-

Finishing: The final stage of manufacturing involves finishing processes that enhance the telehandler’s durability and aesthetics. This includes surface treatments like painting, powder coating, and galvanization to protect against corrosion. Additionally, final inspections are conducted to ensure that all systems operate as intended and that the telehandler meets all regulatory requirements.

How Is Quality Assurance Implemented in Telehandler Production?

Quality assurance (QA) is a critical component of telehandler manufacturing, ensuring that every unit produced meets international standards and customer expectations. QA processes encompass various international standards and industry-specific certifications, including ISO 9001, CE marking, and API standards.

-

International Standards and Industry Certifications: ISO 9001 is a globally recognized quality management system standard that emphasizes continuous improvement and customer satisfaction. CE marking indicates compliance with EU safety, health, and environmental protection standards, while API standards are crucial for equipment used in the oil and gas industry. Compliance with these standards is often a prerequisite for international buyers.

-

Quality Control Checkpoints: Throughout the manufacturing process, several quality control checkpoints are implemented:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins.

– In-Process Quality Control (IPQC): Quality checks are conducted at various stages of the manufacturing process to identify any defects early. This may include monitoring dimensions, assembly accuracy, and system performance.

– Final Quality Control (FQC): Before a telehandler leaves the factory, a comprehensive final inspection is conducted. This includes functional testing of hydraulic systems, lifting capabilities, and safety features. -

Common Testing Methods: Various testing methods are employed to validate performance and safety, including:

– Load Testing: Assessing the telehandler’s lifting capacity and stability under maximum load conditions.

– Hydraulic System Testing: Ensuring that the hydraulic systems function efficiently without leaks.

– Operational Testing: Simulating real-world operating conditions to verify that all systems work harmoniously.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential to ensure that the telehandlers meet their operational needs. Here are effective ways to conduct this verification:

-

Supplier Audits: Conducting on-site audits of potential suppliers is one of the most effective ways to evaluate their manufacturing processes and quality control practices. Buyers can assess the production environment, staff qualifications, and adherence to safety and quality standards.

-

Requesting Quality Reports: Suppliers should be able to provide documentation of their quality control processes, including inspection reports, test results, and compliance certificates. Buyers should request these documents to verify that the supplier adheres to relevant quality standards.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of a supplier’s manufacturing processes and quality controls. These agencies can perform inspections at various stages of production, ensuring compliance with specified quality standards.

-

Certification Verification: Buyers should verify the authenticity of certifications like ISO 9001 and CE marking. This can often be done through the issuing bodies, ensuring that the supplier’s claims are legitimate.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must navigate specific nuances related to quality control when purchasing telehandlers from global suppliers. Understanding these nuances can help mitigate risks associated with cross-border procurement.

-

Regulatory Compliance: Different regions have varying regulatory requirements for machinery. Buyers should be aware of local laws regarding safety, emissions, and operational standards. Understanding these regulations can help ensure that the telehandler complies with the destination market’s requirements.

-

Cultural Considerations: Quality expectations may differ by region. Buyers should be prepared to discuss and negotiate quality standards clearly with suppliers from different cultural backgrounds to ensure mutual understanding.

-

Logistical Challenges: International shipping can introduce risks to product quality, including damage during transit. Buyers should consider suppliers who offer robust packaging and handling processes to protect telehandlers during transportation.

-

After-Sales Support: Quality assurance doesn’t end with the purchase. Buyers should inquire about the supplier’s after-sales support, including warranty terms, availability of spare parts, and maintenance services. This ongoing support is critical for ensuring the long-term performance of the telehandler.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing telehandlers, ensuring they select reliable suppliers capable of delivering high-quality equipment that meets their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘telehandler for sale’

The procurement of telehandlers is a significant investment for businesses operating in construction, agriculture, and logistics. This guide provides a structured approach to ensure that international B2B buyers make informed decisions when sourcing telehandlers.

Step 1: Define Your Technical Specifications

Before engaging suppliers, it’s essential to outline your specific requirements. Consider factors such as the lifting capacity, reach, height, and any additional features such as four-wheel drive or attachments. This clarity helps streamline the selection process and ensures that the telehandler meets your operational needs.

Step 2: Research Market Trends and Pricing

Understanding current market conditions is crucial for negotiating effectively. Analyze pricing trends for new and used telehandlers across different regions, especially in Africa, South America, the Middle East, and Europe. Pay attention to factors such as currency fluctuations and shipping costs, as these can significantly affect your overall budget.

Step 3: Evaluate Potential Suppliers

It’s vital to assess potential suppliers thoroughly before making a commitment. Request company profiles, customer testimonials, and case studies to understand their credibility and reliability. Additionally, check for certifications or memberships in industry associations, which can signify a commitment to quality and compliance with safety standards.

Step 4: Inspect Equipment Quality

When considering used telehandlers, arrange for an inspection to assess their condition. Look for signs of wear and tear, maintenance history, and any potential issues that could affect performance. An on-site inspection allows you to verify the seller’s claims and helps avoid costly repairs down the line.

Step 5: Understand Warranty and After-Sales Support

A robust warranty and reliable after-sales support are vital components of your purchase decision. Inquire about warranty terms, including coverage duration and what it includes. Additionally, ensure that the supplier offers comprehensive after-sales services, such as maintenance support and access to spare parts, to minimize downtime.

Step 6: Negotiate Payment Terms and Delivery

Discuss payment options and delivery timelines with your chosen supplier. Consider whether they offer flexible financing solutions or leasing options, especially if budget constraints are a concern. Clear communication about delivery schedules is crucial to ensure that the telehandler arrives when needed, avoiding potential project delays.

Step 7: Finalize the Purchase Agreement

Once you have selected a supplier and agreed on terms, finalize the purchase agreement. Ensure that all details, including price, specifications, warranty, and delivery terms, are clearly outlined in the contract. This document serves as a legal safeguard for both parties and helps prevent misunderstandings during the transaction.

By following these steps, B2B buyers can navigate the procurement process for telehandlers effectively, ensuring a purchase that aligns with their operational needs and budget constraints.

Comprehensive Cost and Pricing Analysis for telehandler for sale Sourcing

What Are the Key Cost Components in Telehandler Pricing?

When sourcing telehandlers, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materials: The quality of materials used in manufacturing telehandlers significantly affects the price. High-grade steel, advanced hydraulic systems, and durable components contribute to higher costs but can also enhance performance and longevity.

-

Labor: Skilled labor is necessary for assembly and quality control. Labor costs can vary widely based on the country of production, impacting the overall pricing of telehandlers.

-

Manufacturing Overhead: This includes costs related to the production facility, utilities, and indirect labor. These overheads can vary based on the efficiency of the manufacturing process and the location of the factory.

-

Tooling and Quality Control (QC): Specialized tooling for production and stringent QC processes ensure that telehandlers meet safety and performance standards. These investments are reflected in the pricing.

-

Logistics: Shipping costs can vary depending on the destination and the chosen Incoterms. International shipping may involve customs duties and taxes, which should be factored into the total cost.

-

Margin: Suppliers typically add a margin to cover their operational costs and profit, which can vary based on market demand and competition.

How Do Price Influencers Affect Telehandler Costs?

Several factors can influence the pricing of telehandlers:

-

Volume/MOQ (Minimum Order Quantity): Purchasing in bulk often leads to discounts. Buyers should consider their needs to negotiate better terms.

-

Specifications and Customization: Custom features, such as specific lifting capacities or attachments, can lead to increased costs. Buyers should assess whether these customizations are necessary for their operations.

-

Materials and Quality Certifications: Telehandlers made with premium materials or those that meet specific certifications (e.g., ISO standards) typically command higher prices. Buyers should weigh the benefits of enhanced durability against the costs.

-

Supplier Factors: Established suppliers with a strong reputation may charge more due to perceived reliability and service. However, newer or less-known suppliers might offer competitive pricing to build their client base.

-

Incoterms: The choice of Incoterms (e.g., FOB, CIF) can significantly impact the total cost. Buyers should understand their responsibilities under each term to avoid unexpected expenses.

What Are the Best Practices for Negotiating Telehandler Prices?

Negotiation is a vital aspect of sourcing telehandlers. Here are some actionable tips:

-

Research Market Prices: Understanding the market rates for different telehandler models helps in negotiating effectively. Use platforms like Equipment Trader and IronPlanet to gather comparative pricing data.

-

Leverage Total Cost of Ownership (TCO): Consider the long-term costs associated with owning a telehandler, including maintenance, fuel, and potential downtime. This approach can justify a higher initial investment if it leads to lower overall costs.

-

Build Relationships with Suppliers: Establishing a rapport with suppliers can lead to better pricing and terms. Long-term partnerships often result in more favorable negotiations.

-

Be Flexible with Specifications: If possible, be open to different models or configurations that may be more cost-effective. Flexibility can lead to significant savings.

What Pricing Nuances Should International B2B Buyers Be Aware Of?

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should consider several nuances:

-

Currency Fluctuations: Exchange rates can impact the final cost. Buyers should monitor currency trends and possibly negotiate prices in a stable currency to mitigate risks.

-

Import Duties and Taxes: Be aware of any import duties, taxes, or fees that may apply when bringing telehandlers into your country. These can significantly affect the total cost.

-

Shipping and Delivery Times: International shipping can lead to delays. Ensure that the timeline aligns with project needs to avoid potential disruptions.

-

Cultural Differences: Understanding local business practices and negotiation styles can facilitate smoother transactions and foster stronger relationships with suppliers.

Disclaimer for Indicative Prices

The prices mentioned in this analysis are indicative and can vary based on the current market conditions, the specific model, and the supplier. Always verify with suppliers for the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing telehandler for sale With Other Solutions

Exploring Alternatives to Telehandlers: What Are the Viable Options?

In the realm of heavy machinery, telehandlers are often the go-to solution for various lifting and material handling tasks. However, depending on specific operational needs, there are alternative technologies worth considering. This analysis compares telehandlers for sale with two viable alternatives: forklifts and cranes. Each option has unique strengths and weaknesses that can significantly impact project efficiency and cost.

Comparison Table

| Comparison Aspect | Telehandler For Sale | Forklift | Crane |

|---|---|---|---|

| Performance | High lifting capacity (up to 12,000 lbs) and extended reach (up to 58 ft) | Moderate lifting capacity (up to 15,000 lbs) but limited vertical reach | Very high lifting capacity (up to 500 tons) with extensive vertical reach |

| Cost | Generally ranges from $20,000 to $150,000 for new/used models | Typically ranges from $15,000 to $70,000 depending on type and capacity | High initial investment, starting around $50,000 and can exceed millions |

| Ease of Implementation | Requires minimal setup; versatile for rough terrain | Easy to operate; suitable for indoor/outdoor use but limited in rough terrain | Complex setup; requires skilled operators and may need permits for operation |

| Maintenance | Moderate; routine checks necessary for hydraulic systems | Low; easier maintenance with standard checks | High; requires specialized maintenance and inspections |

| Best Use Case | Ideal for construction sites, agriculture, and uneven terrains | Best for warehouses, manufacturing, and flat surfaces | Suitable for large construction projects and heavy lifting in open spaces |

Detailed Breakdown of Alternatives

How Do Forklifts Compare to Telehandlers?

Forklifts are a common alternative to telehandlers, particularly in controlled environments like warehouses and manufacturing facilities. They offer ease of operation and generally lower costs. However, their limitations in lifting height and rough terrain capabilities make them less versatile than telehandlers. For businesses that primarily operate on flat surfaces and require quick, efficient material movement, forklifts can be an excellent choice. Yet, for tasks requiring significant vertical lifting or maneuvering in uneven areas, telehandlers are superior.

What Are the Advantages of Cranes Over Telehandlers?

Cranes provide an impressive lifting capacity and vertical reach, making them indispensable for large-scale construction projects. They excel in moving heavy loads over significant distances and heights. However, cranes come with high initial costs and require skilled operators for safe operation. Their setup can be complex, often necessitating permits and inspections. While cranes are unmatched for heavy lifting in open areas, they lack the versatility and maneuverability of telehandlers, especially in tighter spaces or rough terrains.

How Should B2B Buyers Choose the Right Solution?

Choosing the right equipment for material handling depends on various factors, including the specific application, budget constraints, and operational environment. For projects demanding high versatility and mobility, telehandlers are the preferred option. In contrast, forklifts are ideal for indoor settings with limited space, while cranes are suited for large-scale outdoor projects requiring heavy lifting. By carefully evaluating the unique demands of their operations, B2B buyers can make informed decisions that align with their project requirements and budget considerations.

Essential Technical Properties and Trade Terminology for telehandler for sale

What Are the Key Technical Properties of Telehandlers for Sale?

When considering a telehandler for sale, understanding its technical specifications is crucial for making informed purchasing decisions. Here are some essential technical properties:

-

Lifting Capacity

This refers to the maximum weight the telehandler can safely lift. It is typically measured in pounds (lbs) or kilograms (kg). For instance, many models range from 6,000 lbs to 12,000 lbs. B2B buyers must assess their specific lifting needs to ensure the telehandler can handle the intended loads without risking safety or efficiency. -

Maximum Lift Height

This specification indicates how high the telehandler can lift materials, often measured in feet or meters. Models commonly reach heights between 30 to 60 feet. Understanding lift height is vital for applications in construction or warehousing, where vertical reach may be required to stack materials or access elevated areas. -

Forward Reach

Forward reach is the horizontal distance from the base of the telehandler to the furthest point it can extend the load. This is crucial for tasks requiring the operator to place materials at a distance without moving the machine. Buyers should consider the reach to ensure it fits their operational requirements, especially in tight spaces. -

Engine Power and Type

The engine’s horsepower (HP) and type (diesel, gas, or electric) determine the telehandler’s performance and efficiency. Most telehandlers have engines ranging from 50 HP to over 100 HP. B2B buyers should evaluate the power needs based on the terrain and application, as a more powerful engine can enhance productivity in demanding environments. -

Mast Type

Telehandlers typically feature either a telescopic or a rigid mast. The mast type affects the machine’s stability, lifting speed, and maximum height. Understanding the differences can help buyers select a model that best suits their worksite conditions and safety requirements. -

Hydraulic System Capacity

This refers to the power and efficiency of the hydraulic system that controls lifting and extending mechanisms. A robust hydraulic system ensures smoother operation and better load handling. Buyers should consider the hydraulic capacity to ensure it meets the demands of their specific applications.

What Are Common Trade Terms Used in Telehandler Transactions?

Navigating the telehandler market involves understanding specific trade terminology that can impact purchasing decisions. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. For telehandlers, OEM parts are essential for maintaining equipment reliability and performance. B2B buyers should prioritize OEM parts for repairs and maintenance to ensure compatibility and quality. -

MOQ (Minimum Order Quantity)

This term indicates the smallest quantity of a product that a supplier is willing to sell. In the telehandler market, knowing the MOQ is crucial for budgeting and inventory management. Buyers often need to meet MOQ requirements to secure bulk purchasing discounts. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specific products. In telehandler transactions, submitting an RFQ helps buyers receive competitive pricing and terms, allowing for better budget management and procurement strategy. -

Incoterms (International Commercial Terms)

These are internationally recognized terms that define the responsibilities of buyers and sellers in global transactions. Understanding Incoterms is vital for B2B buyers to clarify shipping costs, insurance, and risk management in telehandler purchases, particularly when importing equipment from other countries. -

TCO (Total Cost of Ownership)

TCO encompasses all costs associated with owning and operating equipment, including purchase price, maintenance, fuel, and depreciation. B2B buyers should calculate TCO to make informed decisions, ensuring they consider long-term financial implications beyond the initial purchase. -

Warranty and Service Plans

Warranties and service plans provide assurance regarding the equipment’s reliability and maintenance support. Buyers should evaluate these offerings when purchasing telehandlers, as they can significantly affect operational costs and machine longevity.

Understanding these technical properties and trade terminologies can empower B2B buyers to make informed, strategic decisions when purchasing telehandlers, ensuring they select the right equipment for their needs.

Navigating Market Dynamics and Sourcing Trends in the telehandler for sale Sector

What are the Current Market Dynamics and Key Trends Influencing Telehandlers for Sale?

The global telehandler market is currently experiencing significant growth, driven by increasing demand from construction, agriculture, and logistics sectors. The rising trend of urbanization, particularly in developing regions such as Africa and South America, is fueling infrastructure projects that require versatile lifting equipment. In Europe, where efficiency and precision are paramount, telehandlers are being integrated with advanced technology, such as telematics and automation, to enhance operational efficiency. This trend is particularly appealing to international B2B buyers who prioritize maximizing productivity while minimizing downtime.

Emerging technologies are also shaping sourcing strategies. B2B buyers are increasingly leveraging online platforms and digital marketplaces, such as IronPlanet and Equipment Trader, to compare prices and features, streamlining the purchasing process. Additionally, the shift towards used equipment is notable; buyers are seeking cost-effective options without compromising on quality. This trend is particularly prevalent in regions like the Middle East and parts of Europe, where budget constraints often dictate purchasing decisions.

Moreover, as the market evolves, so do the expectations around service and support. Buyers are now looking for suppliers who can provide comprehensive after-sales service, including maintenance packages and training programs. This shift underscores the importance of long-term partnerships in the telehandler market, as businesses seek reliable suppliers who can adapt to their changing needs.

How is Sustainability Influencing Sourcing Trends in the Telehandler Market?

Sustainability is becoming a critical consideration in the sourcing of telehandlers. Environmental concerns are prompting B2B buyers to evaluate the lifecycle impact of their equipment choices. This includes assessing fuel efficiency, emissions, and the overall environmental footprint of the machines they purchase. As a result, manufacturers are increasingly focusing on producing telehandlers that meet stringent environmental standards, appealing to eco-conscious buyers.

Ethical sourcing is also gaining traction, with businesses prioritizing suppliers that uphold responsible practices throughout their supply chains. This includes ensuring that materials are sourced from sustainable sources and that labor practices meet ethical standards. Buyers are increasingly seeking certifications that demonstrate a commitment to sustainability, such as ISO 14001 for environmental management and LEED certification for sustainable building practices.

In addition, the demand for “green” technologies is on the rise. Telehandlers equipped with electric or hybrid engines are becoming more popular as companies look to reduce their carbon footprint. This trend is particularly relevant in regions where regulatory pressures around emissions are tightening, such as Europe, prompting a shift toward cleaner machinery options.

What is the Historical Context of Telehandlers in the B2B Market?

The telehandler’s evolution traces back to the early 1970s when it was first introduced as a versatile lifting solution for the construction industry. Initially designed for agricultural use, the telehandler quickly gained popularity in construction due to its ability to handle various attachments, such as forks, buckets, and winches. This adaptability allowed it to perform multiple functions on job sites, making it an invaluable asset for contractors.

Over the decades, technological advancements have significantly enhanced telehandler capabilities. The introduction of hydraulic systems improved lifting power and precision, while innovations in safety features, such as stability monitoring and operator aids, have made them safer and easier to operate. Today, telehandlers are a staple in various industries, including construction, agriculture, and logistics, with ongoing improvements continuing to expand their utility and market appeal.

In conclusion, understanding these market dynamics, sustainability considerations, and the historical context of telehandlers will empower international B2B buyers to make informed purchasing decisions, aligning their operational needs with current trends and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of telehandler for sale

-

How do I select the right telehandler for my business needs?

Selecting the right telehandler involves assessing your specific operational requirements. Consider the maximum lift capacity, reach, and height needed for your projects. Evaluate the terrain where the telehandler will operate; for rough terrains, a model with four-wheel drive may be necessary. Additionally, factor in your budget and whether you prefer new or used equipment. Consulting with suppliers about your application can also provide insights into the best models for your needs. -

What are the key specifications to look for when purchasing a telehandler?

When purchasing a telehandler, key specifications to consider include lift capacity (typically ranging from 6,000 to 12,000 lbs), maximum lift height (up to 56 feet), and reach distance. Other important factors are the type of attachments available, fuel efficiency, and maintenance requirements. Additionally, check for features such as stability systems and operator safety measures, which can significantly impact performance and safety on the job site. -

What are the common payment terms when buying telehandlers internationally?

Payment terms for international telehandler purchases can vary widely. Common options include letters of credit, advance payments, or payment upon delivery. It’s crucial to clarify these terms with your supplier early in the negotiation process. Additionally, consider the implications of currency fluctuations and transaction fees. Establishing clear payment milestones based on delivery and acceptance can also mitigate risks for both parties. -

How can I ensure the quality of the telehandler I am purchasing?

To ensure quality, request detailed specifications and maintenance records from the seller. If possible, conduct a physical inspection of the equipment or hire a third-party inspector. Look for warranties or guarantees offered by the supplier, which can provide additional assurance. Additionally, consider sourcing from reputable dealers or manufacturers with positive reviews and a solid track record in the industry. -

What are the logistics involved in importing a telehandler?

Importing a telehandler involves several logistical steps, including securing shipping arrangements, customs clearance, and potential duties or tariffs. It’s essential to collaborate with experienced freight forwarders who can navigate these processes efficiently. Ensure that all necessary documentation, such as bills of lading and import permits, is prepared ahead of time to avoid delays. Understanding local regulations regarding heavy machinery importation is also crucial. -

Are there customization options available for telehandlers?

Many manufacturers and suppliers offer customization options for telehandlers to better fit your specific operational needs. Customizations may include different attachments, enhanced safety features, or modifications for unique terrains. When discussing potential purchases, communicate your requirements to the supplier and inquire about available options. Custom-built telehandlers may come at a premium, so factor this into your budget. -

What is the minimum order quantity (MOQ) for telehandlers?

The minimum order quantity for telehandlers can vary based on the supplier and the model selected. Some dealers may allow for single-unit purchases, while others may have MOQs of two or more units, especially for bulk orders. It’s advisable to negotiate with the supplier to determine if exceptions can be made or if discounts are available for larger orders, which can also benefit logistics and transport costs. -

How do I vet suppliers for telehandlers effectively?

Vetting suppliers involves researching their reputation, experience, and customer reviews. Look for certifications and affiliations with industry organizations. Request references from past clients and inquire about their satisfaction with the equipment and service. Additionally, assess their responsiveness to inquiries and willingness to provide information. Conducting a site visit or attending trade shows can also help establish trust and verify the supplier’s credibility.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Telehandler For Sale Manufacturers & Suppliers List

1. Telehandler – 4,073 Listings

Domain: equipmenttrader.com

Registered: 1998 (27 years)

Introduction: Telehandler For Sale – Equipment Trader

Key Product Details:

1. **Total Listings**: 4,073 Equipment Listings For Sale

2. **Top Makes**:

– GENIE: 898

– JLG: 829

– SKYTRAK: 757

– JCB: 602

– GEHL: 233

– MANITOU: 139

– CATERPILLAR: 128

– SKYJACK: 98

– Others: BOBCAT, DIECI, INGERSOLL-RAND, LULL, MERLO, PETTIBONE, SANY, TEREX, XTREME MANUFACTURING

3. **Sample Listings**:

…

2. Telehandlers – Auction Listings

Domain: ironplanet.com

Registered: 1999 (26 years)

Introduction: Telehandlers are available for auction with various makes including Cat, Gehl, Genie, JCB, JLG, Manitou, Merlo, SkyTrak, and Skyjack. There are 631 telehandlers listed, with 524 available through auction, 146 in online auction format, and 75 available for immediate purchase. The telehandlers are located in the United States, Canada, Australia, and Europe, with a range of prices from $5,000 to $499…

3. Telehandlers – Various Models

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Telehandlers available on eBay include various models from manufacturers such as JCB, Genie, JLG, SkyTrak, Gehl, Lull, and CAT. Load capacities range from less than 4,000 lbs to more than 10,000 lbs, with specific listings showing capacities like 5,000 lbs, 5,500 lbs, 6,000 lbs, 7,000 lbs, 9,000 lbs, and 10,000 lbs. The maximum mast/lift heights vary, with options available for heights less than 3…

4. Telehandlers – Used Equipment for Sale

Domain: govplanet.com

Registered: 2007 (18 years)

Introduction: Telehandlers for sale at GovPlanet, featuring hundreds of parts and fully assembled machines. Available brands include Genie, JCB, JLG, and SkyTrak. Types include used telehandlers with various models such as Model 10042, Model 10054, Model 1255, and more. Buying formats include auction, online auction, sealed auction, buy now, and make offer. IronClad Assurance is available for many items. Locati…

5. Telehandlers – Used Equipment Listings

Domain: machinerypete.com

Registered: 2001 (24 years)

Introduction: Used Telehandlers for Sale – 653 Listings | Machinery Pete. Categories include various makes such as Bobcat, Caterpillar, Genie, JCB, and more. Filters available for price, year, and location. Options for financing and shipping quotes. Extended warranty plans offered through Machinery Scope.

6. Telehandlers – Used Listings

Domain: boomandbucket.com

Registered: 2020 (5 years)

Introduction: Used Telehandlers for sale – 404 listings. Popular makes include Bobcat, Case, Caterpillar, Genie, JLG, and more. Listings include various models with details such as year, hours, price, and estimated monthly payments. Examples: 2013 Caterpillar TL1055C, 3,623 Hours, $57,500, $1,193/mo; 2015 Genie GTH1056, 4,837 Hours, $38,850, $806/mo; 2016 JCB 507-42, 2,079 Hours, $39,995, $830/mo; 2014 SkyTrak …

Strategic Sourcing Conclusion and Outlook for telehandler for sale

In the competitive landscape of telehandler procurement, strategic sourcing emerges as a vital approach for international buyers. By focusing on a comprehensive understanding of market dynamics, including pricing trends and equipment specifications, businesses can make informed decisions that optimize their operational efficiency. The variety of telehandlers available, ranging from compact models to heavy-duty options, allows buyers to select equipment that best meets their specific project requirements.

Investing in quality equipment is not merely about immediate cost; it’s about long-term reliability and performance. Buyers should prioritize reputable suppliers, examine equipment history, and consider financing options that align with their budgetary constraints. Furthermore, exploring auctions and online marketplaces can yield significant savings while providing access to a broader range of equipment.

Looking ahead, the demand for telehandlers is expected to grow, driven by infrastructure development and construction projects across Africa, South America, the Middle East, and Europe. International B2B buyers are encouraged to seize this opportunity by engaging with trusted suppliers and leveraging strategic sourcing to enhance their operational capabilities. By doing so, they position themselves for sustained success in an evolving marketplace.