Key Sales And Supply: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for key sales and supply

In today’s dynamic global market, B2B buyers face the pressing challenge of efficiently sourcing key sales and supply solutions that meet their unique operational needs. Whether you’re looking to acquire bakery products, deli meats, or retail supplies, understanding the complexities of supplier relationships and market trends is crucial for success. This comprehensive guide aims to empower international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, by providing actionable insights into types of products, their applications, supplier vetting processes, and cost considerations.

As you navigate this intricate landscape, you will discover essential strategies for evaluating suppliers, ensuring product quality, and negotiating favorable terms. The guide delves into various sectors, highlighting best practices that can enhance your purchasing decisions, streamline your supply chain, and ultimately boost your bottom line. By leveraging the information presented, buyers will be better equipped to make informed choices that align with their business objectives, thus fostering stronger partnerships and driving growth in their respective markets.

This resource not only clarifies the nuances of key sales and supply but also serves as a roadmap for cultivating long-term, successful relationships with suppliers. Prepare to transform your procurement strategy and unlock new opportunities as you explore the wealth of knowledge contained within this guide.

Understanding key sales and supply Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Wholesale Distribution | Bulk purchasing, lower prices, extensive product range | Retail, food service, manufacturing | Pros: Cost-effective, diverse options. Cons: Requires large upfront investment. |

| Specialty Brokerage | Focus on niche markets, personalized service | Bakery, deli, and specialty food products | Pros: Expertise in specific sectors. Cons: Limited to specific product lines. |

| Direct Supply Agreements | Long-term contracts, stable pricing, and consistent supply | Manufacturing, construction, and retail | Pros: Predictable costs, reliable supply. Cons: Less flexibility in product changes. |

| E-commerce Platforms | Online ordering, real-time inventory, and delivery tracking | Retail and consumer goods | Pros: Convenience, accessible product information. Cons: Potential for delayed shipping. |

| Private Label Solutions | Custom branding, tailored products, and exclusive rights | Retail and grocery sectors | Pros: Brand differentiation, higher margins. Cons: Requires investment in marketing and development. |

What Are the Key Characteristics of Wholesale Distribution?

Wholesale distribution is characterized by bulk purchasing and lower prices, making it an attractive option for businesses looking to buy large quantities of products. This model is particularly beneficial for retailers and food service operations that require a wide range of items at competitive prices. When engaging in wholesale distribution, businesses should consider the minimum order quantities, payment terms, and supplier reliability to ensure a smooth purchasing process.

How Does Specialty Brokerage Differ from Other Supply Types?

Specialty brokerage focuses on niche markets, providing personalized service and expert knowledge of specific sectors, such as bakery and deli products. These brokers act as intermediaries between manufacturers and retailers, facilitating tailored solutions that meet unique business needs. B2B buyers should evaluate the broker’s industry expertise and customer service capabilities, as these factors can significantly impact the overall purchasing experience.

Why Choose Direct Supply Agreements for Your Business Needs?

Direct supply agreements involve long-term contracts with suppliers, ensuring stable pricing and a consistent supply of products. This model is particularly advantageous for businesses in manufacturing and retail, where predictability is crucial for operations. Buyers should assess the terms of the agreement, including pricing structures and delivery schedules, to ensure alignment with their operational requirements.

What Are the Advantages of E-commerce Platforms in B2B Sales?

E-commerce platforms offer the convenience of online ordering, real-time inventory management, and delivery tracking, making them an essential tool for modern B2B transactions. This approach is particularly useful for businesses in retail and consumer goods, where speed and efficiency are paramount. When utilizing e-commerce platforms, buyers should consider the platform’s user experience, customer support, and integration capabilities with existing systems.

How Can Private Label Solutions Benefit Your Brand?

Private label solutions allow businesses to create custom-branded products, providing a unique market position and potential for higher profit margins. This option is especially relevant in the retail and grocery sectors, where brand differentiation can drive customer loyalty. B2B buyers considering private label products should factor in the costs associated with product development, marketing strategies, and the need for effective supply chain management to ensure success.

Key Industrial Applications of key sales and supply

| Industry/Sector | Specific Application of key sales and supply | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Distribution of Bakery, Deli, and Retail Meat products | Ensures a consistent supply of high-quality products, enhancing customer satisfaction and loyalty. | Quality certifications, reliable delivery schedules, and compliance with local food safety regulations. |

| Retail | Supply chain management for grocery and specialty retailers | Streamlines inventory management, reduces overhead costs, and improves product availability. | Understanding local market trends, pricing strategies, and customer preferences. |

| Construction | Provision of construction materials and supplies | Facilitates timely project completion and adherence to quality standards, boosting contractor reputation. | Sourcing durable materials, compliance with building codes, and logistical considerations for delivery. |

| Hospitality | Supply of restaurant and hotel kitchen equipment | Enhances operational efficiency and food quality, leading to improved guest experiences. | Supplier reliability, equipment compatibility, and after-sales support for maintenance. |

| Healthcare | Distribution of medical supplies and equipment | Ensures timely access to essential medical products, supporting patient care and operational efficiency. | Regulatory compliance, product traceability, and sourcing from certified manufacturers. |

How Is Key Sales and Supply Utilized in the Food and Beverage Industry?

Key Sales and Supply plays a crucial role in the food and beverage sector by facilitating the distribution of Bakery, Deli, and Retail Meat products. This ensures that retailers consistently receive high-quality food items, which is essential for maintaining customer satisfaction and loyalty. For international buyers, especially from regions like Africa and South America, understanding local food safety regulations and quality certifications is vital for compliance and successful market entry.

What Role Does Key Sales and Supply Play in Retail Supply Chain Management?

In the retail sector, Key Sales and Supply enhances supply chain management for grocery and specialty retailers. By streamlining inventory management and reducing overhead costs, it ensures that products are readily available to meet consumer demand. International B2B buyers must consider local market trends and customer preferences when sourcing products to tailor their offerings effectively.

How Does Key Sales and Supply Impact the Construction Industry?

In construction, Key Sales and Supply is instrumental in providing necessary materials and supplies, which helps contractors complete projects on time while adhering to quality standards. This reliability boosts the contractor’s reputation and client trust. For buyers from the Middle East and Europe, sourcing durable materials that comply with local building codes is essential for successful project execution.

Why Is Key Sales and Supply Important for the Hospitality Sector?

The hospitality industry relies on Key Sales and Supply for the procurement of kitchen equipment and supplies essential for restaurant and hotel operations. This not only enhances operational efficiency but also improves food quality, significantly impacting guest experiences. Buyers in regions like Europe must ensure that suppliers offer reliable delivery and compatibility with existing equipment to maintain service standards.

How Does Key Sales and Supply Support the Healthcare Sector?

In healthcare, Key Sales and Supply is vital for the timely distribution of medical supplies and equipment, which supports patient care and operational efficiency in medical facilities. For international buyers, such as those in Africa and the Middle East, ensuring regulatory compliance and sourcing from certified manufacturers is crucial for maintaining product integrity and safety in healthcare settings.

3 Common User Pain Points for ‘key sales and supply’ & Their Solutions

Scenario 1: Navigating Complex Supply Chain Logistics

The Problem: International B2B buyers often face significant challenges in managing complex supply chain logistics when sourcing products from Key Sales and Supply. These challenges can include delays in shipping, unexpected tariffs, and difficulties in tracking shipments, leading to increased costs and disruptions in the supply chain. For buyers in regions like Africa or South America, where infrastructure may be less developed, these issues can be exacerbated, causing frustration and financial strain.

The Solution: To mitigate these challenges, B2B buyers should prioritize building strong relationships with reliable logistics partners. Engage with Key Sales and Supply to gain insights into their shipping processes and recommended freight forwarders. By establishing a clear communication line with both the supplier and the logistics partner, buyers can set realistic timelines and receive real-time updates on shipment statuses. Moreover, conducting thorough research on potential tariffs and customs regulations in the destination country can help prevent unexpected costs. Utilizing technology, such as supply chain management software, can further enhance visibility and streamline processes, ensuring a smoother logistical experience.

Scenario 2: Ensuring Product Quality and Compliance

The Problem: Another common pain point for B2B buyers is the concern over product quality and compliance with international standards. With Key Sales and Supply representing various manufacturers, buyers may worry about whether the products meet their specific requirements and adhere to local regulations. This concern is particularly relevant for industries like food and retail, where subpar quality can lead to significant repercussions, including financial losses and damage to reputation.

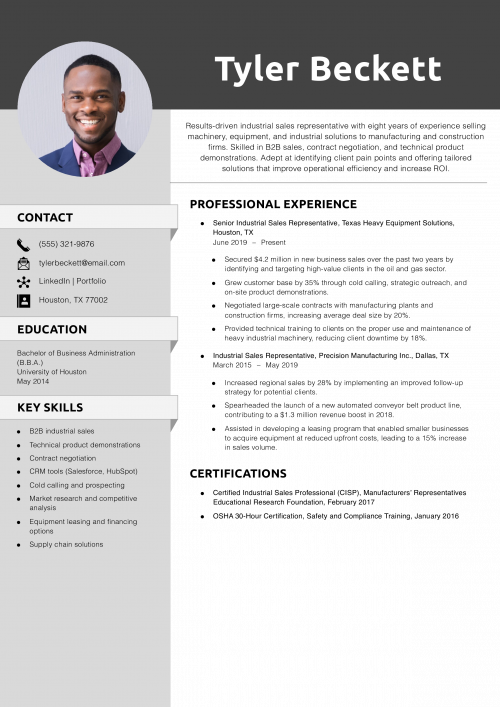

Illustrative image related to key sales and supply

The Solution: To address these concerns, buyers should implement a robust vetting process when selecting suppliers. This includes requesting samples of products and conducting quality inspections prior to finalizing orders. Key Sales and Supply can assist by providing detailed product specifications and compliance documentation. Additionally, buyers should establish clear quality standards and communicate these expectations upfront to avoid misunderstandings. Regular audits and feedback loops with suppliers can help maintain consistent quality and ensure that products continue to meet evolving regulatory requirements.

Scenario 3: Overcoming Communication Barriers

The Problem: Effective communication is crucial in B2B transactions, yet many international buyers face language barriers and cultural differences when dealing with suppliers like Key Sales and Supply. Miscommunication can lead to errors in orders, misunderstandings regarding product specifications, and ultimately, a breakdown in the buyer-supplier relationship. This is particularly challenging for buyers from diverse regions, such as the Middle East or Europe, where communication styles and business practices can vary significantly.

The Solution: To overcome these barriers, buyers should invest in translation services or bilingual staff who can facilitate clear communication with suppliers. Additionally, utilizing visual aids, such as diagrams or product images, can bridge the gap when language differences arise. Establishing a clear and structured communication protocol, including regular check-ins and updates, can also foster better relationships. Key Sales and Supply can support this process by offering dedicated account managers who understand the buyer’s language and culture, ensuring that all parties are on the same page throughout the transaction. By prioritizing effective communication, buyers can enhance collaboration and reduce the risk of costly misunderstandings.

Strategic Material Selection Guide for key sales and supply

When selecting materials for key sales and supply, understanding the properties, advantages, and limitations of various materials is essential for optimizing product performance and meeting client expectations. Below, we analyze four common materials used in the industry, focusing on their suitability for international B2B buyers.

What Are the Key Properties of Stainless Steel in Key Sales and Supply?

Stainless steel is renowned for its excellent corrosion resistance, high tensile strength, and ability to withstand extreme temperatures. These properties make it an ideal choice for applications in food processing and storage, where hygiene and durability are paramount. Stainless steel can handle pressures up to 10,000 psi, depending on the grade, making it versatile for various product designs.

Pros: It is highly durable, easy to clean, and resistant to rust and staining. Its longevity can lead to lower lifecycle costs.

Cons: The initial cost can be high, and some grades may be susceptible to pitting corrosion in chloride environments.

Impact on Application: Stainless steel is compatible with a wide range of media, including acidic and alkaline substances, making it suitable for food and beverage applications.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial. Buyers from Europe and the Middle East often prefer specific grades that meet stringent food safety regulations.

How Does Polypropylene Compare for Applications in Key Sales and Supply?

Polypropylene is a thermoplastic polymer known for its chemical resistance, lightweight nature, and flexibility. It is commonly used in packaging, containers, and automotive parts.

Pros: It is cost-effective, has a low density, and offers excellent resistance to chemicals and fatigue.

Cons: Polypropylene has lower temperature resistance compared to metals and can degrade under UV exposure unless treated.

Impact on Application: It is suitable for applications involving food packaging and storage, as it does not leach harmful substances.

Considerations for International Buyers: Buyers should ensure that polypropylene products comply with local food safety standards, which can vary significantly between regions.

What Are the Benefits of Using Aluminum in Key Sales and Supply?

Aluminum is lightweight yet strong, making it an excellent choice for applications requiring a good strength-to-weight ratio. It is often used in manufacturing components for machinery and packaging.

Pros: Aluminum is highly malleable, corrosion-resistant, and can be easily recycled, making it an environmentally friendly option.

Cons: It can be more expensive than other materials like steel or plastic, and its strength may not be suitable for heavy-duty applications.

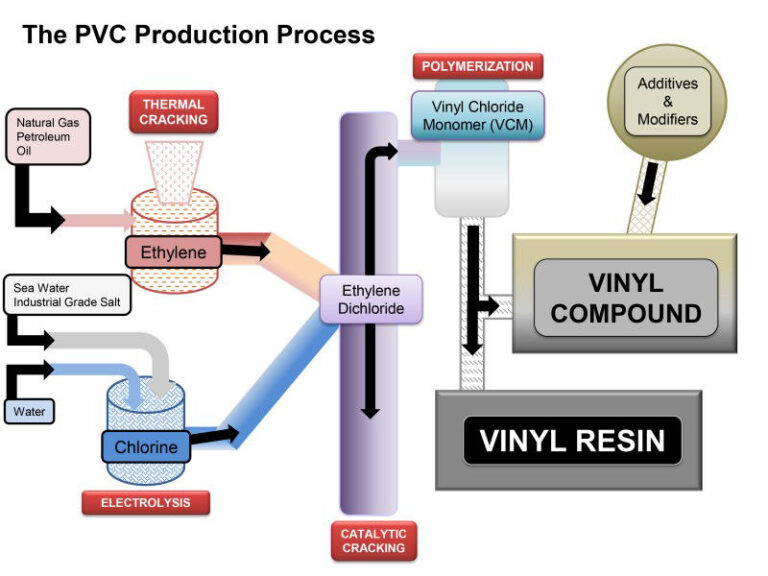

Illustrative image related to key sales and supply

Impact on Application: Aluminum’s lightweight nature is beneficial in applications where weight savings are critical, such as in transportation and aerospace.

Considerations for International Buyers: Compliance with international aluminum standards (e.g., JIS in Japan) is essential. Buyers should also consider the availability of specific alloys that meet their application requirements.

Why Is Wood Still Relevant in Key Sales and Supply?

Wood remains a popular material for various applications, particularly in furniture and construction. Its natural aesthetic and insulation properties make it a preferred choice for many buyers.

Pros: Wood is renewable, offers excellent insulation, and can be cost-effective depending on the type.

Cons: It is susceptible to moisture, pests, and decay, which can limit its lifespan in certain environments.

Impact on Application: Wood is ideal for applications requiring aesthetic appeal and thermal insulation, but it may not be suitable for high-moisture environments.

Considerations for International Buyers: Buyers must consider local regulations regarding sustainable sourcing and treatment standards to prevent pest infestations.

Summary Table of Material Selection for Key Sales and Supply

| Material | Typical Use Case for key sales and supply | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food processing equipment | Excellent corrosion resistance | High initial cost | High |

| Polypropylene | Packaging and containers | Cost-effective and lightweight | Low temperature resistance | Low |

| Aluminum | Machinery components | Lightweight and recyclable | Higher cost than steel | Medium |

| Wood | Furniture and construction | Aesthetic and renewable | Susceptible to moisture and pests | Medium |

This guide provides a comprehensive overview of material selection for international B2B buyers in key sales and supply, emphasizing the importance of understanding material properties, advantages, and compliance considerations to make informed purchasing decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for key sales and supply

What Are the Main Stages of Manufacturing Processes in B2B Supply Chains?

In the context of Key Sales and Supply, understanding the manufacturing processes is crucial for B2B buyers looking for high-quality products. The typical stages of manufacturing include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial phase involves sourcing high-quality raw materials, which are critical for ensuring the durability and functionality of the final product. Suppliers often establish relationships with reliable vendors to ensure consistent material quality. For instance, in the bakery and deli sectors, ingredients such as flour, meats, and seasonings must meet specific industry standards.

-

Forming: The forming process varies significantly depending on the product. For instance, meat products may undergo processes like grinding and molding, while bakery items might involve mixing and kneading. Advanced techniques such as extrusion or molding are employed to achieve the desired shape and texture, directly impacting the end product’s quality.

-

Assembly: In sectors like deli and retail meat, assembly involves combining various components, such as packaging and labeling, to create a ready-to-sell product. This stage requires meticulous attention to detail, as any oversight can lead to compromised quality or regulatory non-compliance.

-

Finishing: The finishing stage enhances the product’s appeal and ensures it meets market standards. This can include processes like baking, smoking, or applying glazes. Quality assurance practices are vital here, as they ensure that every product meets the established specifications before reaching the buyer.

How Do Quality Control Measures Ensure Product Excellence?

Quality control (QC) is an integral part of the manufacturing process, ensuring that products meet international standards and customer expectations. For B2B buyers, understanding the QC measures in place can significantly influence purchasing decisions.

-

International Standards: Many manufacturers adhere to international quality standards such as ISO 9001, which provides a framework for quality management systems. Compliance with such standards signifies a commitment to quality and consistency. Industry-specific certifications like CE (Conformité Européenne) for European markets or API (American Petroleum Institute) for oil and gas products further assure buyers of adherence to safety and quality standards.

-

QC Checkpoints: Quality control is typically structured around several key checkpoints:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified standards. For instance, a bakery supplier may test flour for moisture content and gluten strength.

– In-Process Quality Control (IPQC): During production, continuous monitoring is crucial. Techniques such as statistical process control (SPC) can help identify variances in real-time, allowing for immediate corrective actions.

– Final Quality Control (FQC): Before products are packaged and shipped, a final inspection ensures that they meet all specifications. This may include taste testing in food products or visual inspections for packaging integrity. -

Common Testing Methods: B2B buyers should be aware of various testing methods used in quality control, such as:

– Chemical Analysis: For food products, ensuring that ingredients are free from harmful substances.

– Microbiological Testing: Especially important in the food industry to prevent contamination.

– Physical Testing: Assessing texture, flavor, and appearance to ensure product quality aligns with consumer expectations.

How Can B2B Buyers Verify Supplier Quality Control Practices?

Verification of supplier quality control practices is essential for B2B buyers to mitigate risks associated with poor product quality. Here are actionable insights on how to conduct thorough assessments:

-

Supplier Audits: Conducting audits is one of the most effective ways to evaluate a supplier’s quality control processes. These audits can be either announced or unannounced and should assess compliance with both internal and external standards. A well-structured audit will cover all aspects of the manufacturing process, from raw material sourcing to final product inspection.

-

Quality Control Reports: Requesting regular QC reports from suppliers can provide insights into their quality management processes. These reports should detail results from IQC, IPQC, and FQC activities, along with any corrective actions taken for non-conformance.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of a supplier’s quality control practices. This is particularly important for international buyers who may not have the resources to conduct on-site inspections.

What Are the QC and Certification Nuances for International B2B Buyers?

For B2B buyers, especially those from diverse regions like Africa, South America, the Middle East, and Europe, understanding the nuances of QC and certification is vital:

-

Regional Regulations: Different regions have specific regulations governing product quality and safety. For instance, buyers in Europe must consider compliance with CE marking, while buyers in the Middle East might focus on GSO standards. Understanding these regulations can help buyers navigate the complexities of international trade.

-

Cultural Considerations: Cultural differences can affect perceptions of quality and service. For example, buyers from Germany may prioritize meticulous documentation and adherence to standards, while buyers from Nigeria might value personal relationships and trust in supplier partnerships.

-

Language and Communication: Clear communication is essential in international transactions. Buyers should ensure that suppliers can provide documentation and support in a language that is mutually understood to avoid misunderstandings regarding quality expectations.

In conclusion, a thorough understanding of manufacturing processes and quality assurance practices is essential for B2B buyers seeking reliable suppliers. By focusing on these areas, buyers can make informed decisions that align with their quality standards and business objectives.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘key sales and supply’

To effectively procure key sales and supply services, it’s essential for B2B buyers to follow a structured approach. This guide outlines actionable steps to streamline your sourcing process, ensuring you make informed decisions that cater to your business needs.

Step 1: Define Your Business Needs

Understanding your specific requirements is crucial before reaching out to suppliers. Assess the types of products or services you need, including volumes, quality standards, and any unique specifications. This clarity will guide your conversations with potential suppliers and help you identify those who can meet your expectations.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in your required categories, such as bakery, deli, or retail meat products. Utilize industry directories, trade shows, and online platforms to gather information. Focus on suppliers with a proven track record and positive reviews, particularly those with experience in your region.

Step 3: Evaluate Supplier Credentials

Before entering negotiations, verify the credentials of potential suppliers. This includes checking for relevant certifications, industry affiliations, and compliance with local regulations. Strong credentials not only demonstrate reliability but also indicate that the supplier adheres to quality standards and ethical practices.

Step 4: Request Samples and Product Information

Request samples of the products you intend to procure to assess quality firsthand. Along with samples, ask for detailed product specifications, pricing, and lead times. This step is vital to ensure the supplier’s offerings align with your business standards and that you can make informed purchasing decisions.

Step 5: Negotiate Terms and Conditions

Once you have shortlisted suppliers, engage in negotiations to discuss pricing, delivery schedules, payment terms, and any potential discounts for bulk orders. Clear communication during this phase can prevent misunderstandings and ensure both parties are on the same page regarding expectations.

Step 6: Conduct a Trial Order

Before committing to a long-term partnership, consider placing a trial order. This allows you to evaluate the supplier’s reliability, product quality, and customer service in a real-world scenario. Monitor the entire process from order placement to delivery, taking notes on any issues that arise.

Step 7: Establish a Long-Term Relationship

If the trial order meets your expectations, focus on building a long-term relationship with the supplier. Regular communication, feedback, and collaboration can lead to better pricing, priority service, and innovative solutions tailored to your evolving needs. A strong partnership can enhance your supply chain efficiency and drive mutual growth.

By following these steps, B2B buyers can effectively navigate the sourcing process for key sales and supply, ensuring they partner with suppliers that align with their business goals and operational needs.

Comprehensive Cost and Pricing Analysis for key sales and supply Sourcing

What Are the Key Cost Components in B2B Sales and Supply?

When engaging with key sales and supply sourcing, understanding the cost structure is essential for effective budgeting and negotiation. The primary cost components include:

-

Materials: This is often the largest portion of the cost structure. The choice of raw materials can significantly affect pricing, especially if sourced from different regions. For example, high-quality ingredients for food products or durable components for manufacturing will naturally incur higher costs.

-

Labor: Labor costs include wages for employees involved in manufacturing, logistics, and sales. Efficient labor management can lead to significant savings, making it vital for companies to assess their workforce needs accurately.

-

Manufacturing Overhead: This encompasses all indirect costs related to production, such as utilities, rent, and administrative expenses. Companies must evaluate how these costs are allocated to products, as they can influence pricing strategies.

-

Tooling: Investment in tooling is critical, particularly for customized products. The design and production of specialized tools can require substantial upfront costs, which should be factored into pricing.

-

Quality Control (QC): Ensuring that products meet specific quality standards can involve additional costs. Implementing rigorous QC processes is essential, especially for international buyers who may have stringent import regulations.

-

Logistics: The cost of transporting goods can vary widely based on distance, shipping method, and the complexity of the supply chain. International logistics can introduce additional factors such as tariffs and customs duties.

-

Margin: The profit margin is a crucial element that varies between suppliers. It is essential for buyers to understand the margins applied by suppliers to negotiate effectively.

How Do Price Influencers Affect B2B Sales and Supply?

Several factors can influence the pricing of key sales and supply products:

-

Volume/MOQ: Buyers should be aware that minimum order quantities (MOQ) can significantly impact pricing. Larger orders typically lead to lower per-unit costs, which can enhance profitability.

-

Specifications and Customization: Custom products generally incur higher costs due to the additional resources required for design and production. Buyers must weigh the benefits of customization against potential cost increases.

-

Materials and Quality Certifications: The quality of materials used can drive up costs, particularly if they come with certifications (e.g., organic, fair trade). Buyers should consider whether the added expense aligns with their target market’s expectations.

-

Supplier Factors: The reputation and reliability of the supplier can also affect pricing. Established suppliers may charge more for their products due to perceived quality and service assurance.

-

Incoterms: Understanding Incoterms is crucial for international transactions, as they define responsibilities for shipping, insurance, and tariffs. Misunderstanding these terms can lead to unexpected costs.

What Buyer Tips Can Enhance Cost Efficiency?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, the following tips can help optimize cost efficiency:

Illustrative image related to key sales and supply

-

Negotiation: Engage in open discussions with suppliers about pricing, especially regarding volume discounts and payment terms. Building a strong relationship can lead to better deals.

-

Total Cost of Ownership (TCO): Consider not just the purchase price but the total cost of ownership, which includes maintenance, logistics, and potential downtime. A lower upfront cost may not always translate to overall savings.

-

Pricing Nuances for International Buyers: Be aware of fluctuations in currency exchange rates, which can impact costs. Additionally, familiarize yourself with the import regulations in your country to avoid unexpected fees.

-

Research and Benchmarking: Conduct market research to understand average pricing in your industry. This knowledge will empower you during negotiations and help you identify fair pricing.

Disclaimer

The prices mentioned herein are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct due diligence before finalizing any agreements.

Alternatives Analysis: Comparing key sales and supply With Other Solutions

Understanding Alternatives in Key Sales and Supply Solutions

In the competitive landscape of B2B supply and sales, it’s essential to evaluate various alternatives to ensure that your business is equipped with the best solutions. Whether you are sourcing products or services, understanding different methodologies can provide insight into which option aligns with your operational goals and budget constraints. This analysis will focus on comparing ‘Key Sales and Supply’ with two alternative solutions: Direct Sourcing and Third-Party Logistics (3PL).

Comparison Table

| Comparison Aspect | Key Sales And Supply | Direct Sourcing | Third-Party Logistics (3PL) |

|---|---|---|---|

| Performance | Strong relationships with retailers; focused on bakery and deli sectors | High control over product quality and selection | Efficient logistics and distribution capabilities |

| Cost | Moderate; includes service and broker fees | Potentially lower if buying in bulk | Variable; depends on service level and volume |

| Ease of Implementation | Requires partnership development; relationship-driven | Requires market knowledge and supplier negotiation | Generally straightforward; relies on established systems |

| Maintenance | Ongoing relationship management required | Requires continuous supplier evaluation | Regular performance assessments needed |

| Best Use Case | Retail-focused businesses in the Midwest | Companies looking for specific products at competitive prices | Businesses needing streamlined logistics and distribution |

Detailed Breakdown of Alternatives

Direct Sourcing

Direct sourcing involves procuring products straight from manufacturers without intermediaries. This approach allows businesses to establish direct relationships with suppliers, leading to potentially lower costs due to the elimination of middlemen. However, it requires extensive market knowledge and negotiation skills, which can be a barrier for some companies. Additionally, managing multiple supplier relationships can be resource-intensive and may require a dedicated team to oversee quality and delivery.

Third-Party Logistics (3PL)

Third-party logistics providers offer a comprehensive solution for businesses looking to outsource their supply chain operations. This model excels in logistics and distribution, providing flexibility and scalability to businesses of all sizes. By leveraging the expertise of a 3PL, companies can enhance their operational efficiency and reduce overhead costs associated with warehousing and transportation. However, the costs can vary significantly based on the level of service required, and businesses must conduct regular assessments to ensure that the provider meets their performance standards.

Illustrative image related to key sales and supply

Conclusion: How to Choose the Right Solution for Your Needs

When deciding between ‘Key Sales and Supply’ and its alternatives, B2B buyers must assess their specific needs, operational capabilities, and long-term goals. Companies focused on building strong retailer relationships may find ‘Key Sales and Supply’ most beneficial, particularly in the bakery and deli sectors. Conversely, businesses seeking cost-effective product sourcing might lean towards direct sourcing, while those prioritizing logistics efficiency may benefit from engaging a 3PL provider. Conducting a thorough analysis of each option’s advantages and drawbacks will empower buyers to make informed decisions tailored to their unique business environments.

Essential Technical Properties and Trade Terminology for key sales and supply

What Are the Critical Technical Properties in Key Sales and Supply?

Understanding the essential technical properties is crucial for B2B buyers, especially when sourcing products from manufacturers. Here are some key specifications to consider:

1. Material Grade

Material grade refers to the quality and type of materials used in product manufacturing. For instance, in the bakery and deli industries, the choice of flour grade can significantly affect product quality. Higher grades often yield better performance, impacting shelf life and customer satisfaction. Buyers should prioritize suppliers that adhere to industry standards for material grades to ensure consistency and quality.

2. Tolerance Levels

Tolerance levels indicate the acceptable limits of variation in product dimensions and characteristics. For example, in the meat supply chain, precise weight tolerances are vital for accurate pricing and inventory management. Tighter tolerances can lead to higher production costs but are essential for maintaining quality. Understanding tolerance specifications helps buyers ensure that products meet their operational requirements.

3. Shelf Life

Shelf life denotes the duration a product remains safe and suitable for consumption. In the food industry, particularly for perishable goods like deli meats, knowing the shelf life is crucial for inventory management and minimizing waste. Buyers should inquire about shelf life and storage conditions to make informed purchasing decisions that align with their supply chain capabilities.

Illustrative image related to key sales and supply

4. Compliance Standards

Compliance standards refer to regulations that products must meet to ensure safety and quality. In the bakery and deli sectors, adherence to food safety regulations is non-negotiable. Buyers must verify that suppliers comply with local and international standards, such as HACCP (Hazard Analysis and Critical Control Points), to mitigate risks and maintain consumer trust.

5. Packaging Specifications

Packaging specifications encompass the materials and design used for product containment. Effective packaging not only protects products but also enhances branding and shelf appeal. Buyers should assess packaging for durability, sustainability, and compliance with shipping regulations, as these factors can influence both product quality and marketability.

Which Trade Terms Should B2B Buyers Be Familiar With?

Familiarity with industry jargon can empower B2B buyers to navigate negotiations and contracts effectively. Here are some commonly used trade terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships helps buyers identify who is responsible for product quality and warranty, impacting purchasing decisions.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity a supplier is willing to sell. Knowing MOQs is essential for budget-conscious buyers, as they can affect cash flow and inventory levels. Buyers should negotiate MOQs that align with their purchasing capabilities and market demand.

Illustrative image related to key sales and supply

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. This process allows buyers to compare offers and negotiate favorable terms. A well-structured RFQ can lead to better pricing and service agreements.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international shipping terms that clarify the responsibilities of buyers and sellers. Familiarity with Incoterms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is crucial for understanding shipping costs and liability, ensuring that agreements are clear and enforceable.

5. Lead Time

Lead time refers to the period between placing an order and receiving the goods. Understanding lead times helps buyers plan their inventory and production schedules effectively. Buyers should communicate their expectations regarding lead times to avoid disruptions in their supply chain.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance their purchasing strategies and ensure successful supplier relationships.

Navigating Market Dynamics and Sourcing Trends in the key sales and supply Sector

What Are the Current Market Dynamics and Key Trends in Key Sales and Supply?

The key sales and supply sector is experiencing transformative shifts driven by globalization, technological advancements, and evolving consumer preferences. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe are navigating a landscape that is increasingly interconnected. One of the primary drivers is the rise of e-commerce platforms, which facilitate easier access to suppliers and manufacturers across borders. Additionally, the adoption of data analytics and artificial intelligence is enabling companies to optimize inventory management and enhance demand forecasting, leading to more efficient supply chain operations.

Emerging trends in B2B sourcing include the increased focus on digital transformation, which allows for streamlined procurement processes and improved supplier collaboration. Blockchain technology is also gaining traction, providing transparency and traceability in transactions, crucial for building trust among international partners. Moreover, sustainability is becoming a pivotal consideration, with buyers prioritizing suppliers who adhere to ethical practices and environmental standards. This shift is particularly pronounced in Europe, where regulations around sustainability are stringent, influencing purchasing decisions.

How Is Sustainability and Ethical Sourcing Reshaping B2B in Key Sales and Supply?

Sustainability and ethical sourcing are no longer just buzzwords in the key sales and supply sector; they have become essential components of business strategy. The environmental impact of sourcing practices has come under scrutiny, prompting buyers to seek suppliers who demonstrate a commitment to reducing their carbon footprint. This includes sourcing materials that are sustainably produced and minimizing waste throughout the supply chain.

The importance of ethical supply chains cannot be overstated, especially for international buyers who are increasingly aware of the social implications of their sourcing decisions. Certifications such as Fair Trade, Rainforest Alliance, and ISO 14001 are becoming critical indicators of a supplier’s commitment to responsible practices. By aligning with suppliers who prioritize sustainability, businesses can not only enhance their brand reputation but also mitigate risks associated with regulatory compliance and consumer backlash.

Investing in ‘green’ materials and processes is becoming a competitive advantage, as consumers and businesses alike are more inclined to support companies that reflect their values. This trend is particularly relevant in regions with growing environmental consciousness, such as Germany, where demand for ethically sourced products is on the rise.

Illustrative image related to key sales and supply

How Has the Key Sales and Supply Sector Evolved Over Time?

The evolution of the key sales and supply sector is marked by significant changes in how businesses approach sourcing and sales strategies. Initially, the focus was predominantly on local markets, with suppliers and buyers often constrained by geographical limitations. However, as globalization took hold, the landscape expanded dramatically, allowing for a greater variety of products and suppliers to enter the market.

Technological advancements have played a pivotal role in this evolution. The introduction of digital tools and platforms has streamlined communication and transactions, enabling quicker responses to market demands. Additionally, the rise of data analytics has allowed businesses to make informed decisions based on consumer behavior and market trends.

Today, the sector is characterized by a complex interplay of local and international players, with an emphasis on building sustainable and ethical supply chains. This evolution reflects a broader shift towards transparency and accountability in business practices, catering to an increasingly discerning global customer base. As the market continues to evolve, international B2B buyers must remain agile, adapting to new trends and technologies while prioritizing sustainability and ethical sourcing.

Frequently Asked Questions (FAQs) for B2B Buyers of key sales and supply

-

How can I effectively vet suppliers in the key sales and supply industry?

To effectively vet suppliers, start by conducting thorough background checks. Look for suppliers with a proven track record and positive reviews from previous clients. Request references and case studies that demonstrate their ability to meet quality and delivery standards. Additionally, assess their financial stability and compliance with international trade regulations. Visiting their facilities, if possible, can provide deeper insights into their operational capabilities. Finally, consider their responsiveness and willingness to collaborate on your specific needs, as this can indicate their commitment to customer service. -

What is the minimum order quantity (MOQ) for key sales and supply products?

Minimum order quantities (MOQ) can vary significantly based on the supplier and the specific products you are interested in. Generally, MOQs are established to ensure cost-effectiveness for both parties. It’s essential to communicate your purchasing needs with potential suppliers to understand their MOQ policies. Some suppliers may offer flexibility for first-time buyers or smaller businesses, while others might maintain strict MOQs. Always clarify these details before proceeding to avoid unexpected costs. -

What payment terms should I expect when sourcing internationally?

Payment terms can differ widely in international trade. Common arrangements include advance payment, letters of credit, or payment upon delivery. It’s crucial to discuss these terms upfront and ensure they are documented in your purchase agreement. Consider factors such as currency fluctuations, transaction fees, and your cash flow needs. Establishing a trustworthy relationship with your supplier can also lead to more favorable payment terms over time, such as extended payment deadlines or discounts for early payments. -

How do I ensure quality assurance in my orders?

To ensure quality assurance, establish clear product specifications and standards before placing an order. Request samples to evaluate the quality firsthand. Implement a quality control process that includes inspections at various stages of production and prior to shipment. Consider using third-party quality assurance services, especially for large orders or new suppliers. Clear communication about your quality expectations and regular updates throughout the manufacturing process can also help mitigate risks. -

What are the best practices for logistics and shipping in international trade?

Effective logistics and shipping practices begin with selecting reliable freight forwarders who understand the complexities of international shipping. Ensure that you have a clear understanding of incoterms, which define the responsibilities of buyers and sellers in shipping. Plan for customs clearance and ensure that all documentation, such as invoices and packing lists, is complete. Regularly track shipments to anticipate delays and keep your customers informed. Collaborating with suppliers who have experience in your target markets can also streamline the logistics process. -

What should I know about customs regulations when importing goods?

Understanding customs regulations is crucial for smooth international transactions. Each country has specific import regulations, including tariffs, taxes, and required documentation. Familiarize yourself with the customs codes for your products and ensure compliance with local regulations in your destination country. Engaging a customs broker can help navigate these complexities and minimize delays. Additionally, staying updated on any changes in trade agreements or tariffs can help in planning your sourcing strategies effectively. -

How can I customize products to meet my specific needs?

To customize products, start by discussing your requirements with potential suppliers during the initial inquiry stage. Many suppliers are open to customization, but you should clearly articulate your specifications, including materials, sizes, and packaging. Be prepared for possible minimum order increases for customized products. Request prototypes or samples to evaluate the customized offerings before committing to larger orders. Establishing a strong relationship with your supplier can also facilitate smoother customization processes. -

What are the key factors influencing pricing in the key sales and supply sector?

Pricing in the key sales and supply sector is influenced by several factors, including raw material costs, production capabilities, and market demand. Additional considerations include shipping and logistics costs, currency exchange rates, and the supplier’s pricing strategy. Understanding these factors can help you negotiate better terms and make informed purchasing decisions. It’s also beneficial to compare prices from multiple suppliers to ensure you’re receiving competitive offers while considering the quality of products and services provided.

Top 4 Key Sales And Supply Manufacturers & Suppliers List

1. Locksmith Ledger – Security Solutions

Domain: locksmithledger.com

Registered: 1998 (27 years)

Introduction: Electronics and Access Control, Door Hardware, Locks, Keys and Tools, Safes, Alarms and Video.

2. Key Sales and Supply – KLC Keyed Lock for Power Supply

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “KLC Keyed Lock for Power Supply”, “Brand”: “Key Sales and Supply”, “Condition”: “New”, “Price”: “US $17.06”, “Shipping Cost”: “US $8.79 UPS Ground”, “Returns”: “30 days returns, buyer pays for return shipping”, “Seller”: “DK Hardware Supply”, “Seller Rating”: “96.1% positive”, “Quantity Available”: “More than 10”, “Item Number”: “266846110523”, “Category”: “Business & Industrial …

3. Key Sales & Supply Co. – Locks and Hardware

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Key Sales & Supply Co. manufactures a range of locks including automobile locks, cabinet locks, padlocks, key blanks, and door hardware.

4. Key Sales and Supply – KLC Keyed Lock for Power Supply

Domain: dkhardware.com

Registered: 2006 (19 years)

Introduction: {“product_name”: “KLC KEYED LOCK FOR POWER SUPPLY”, “item_number”: “KLC”, “brand”: “Key Sales and Supply”, “price”: “$17.06”, “bulk_discount”: “SAVE UP TO 1.71”, “stock_status”: “In Stock”, “quantity_available”: “53 units”, “shipping_info”: “Usually ships in 1 business day”, “product_type”: “Cylinders”, “usage”: “KEYED LOCK FOR POWER SUPPLY ENCLOSURES, USE: 900-KL FOR SCH”, “return_policy”: “30 Da…

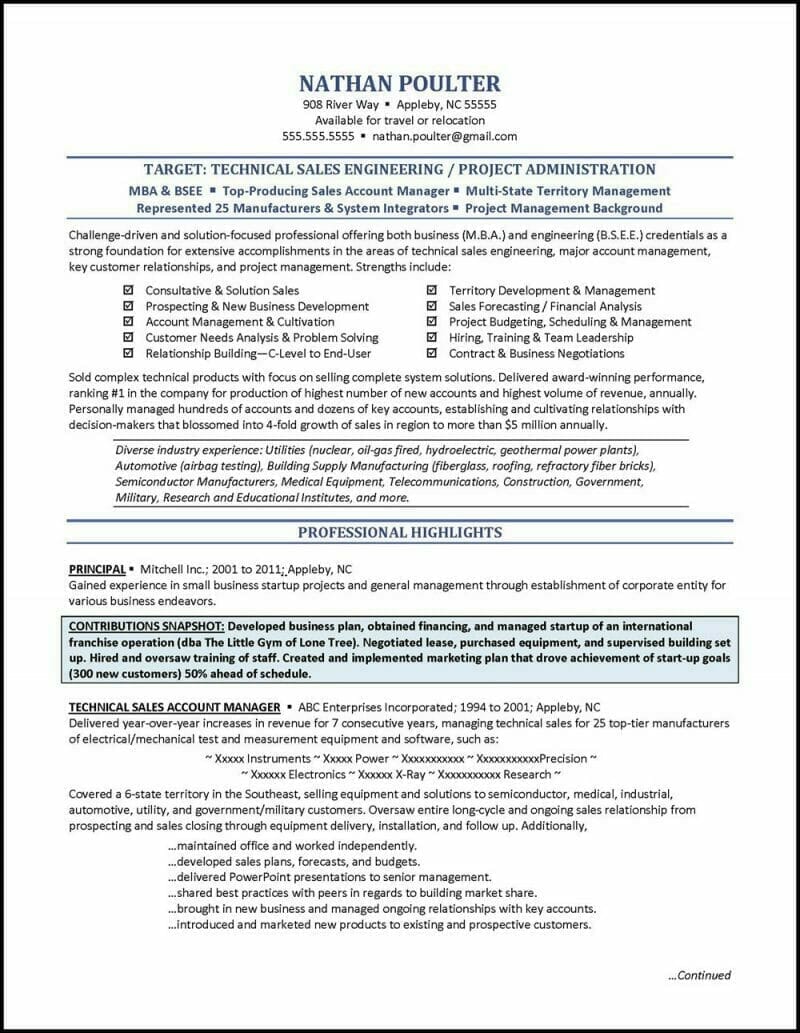

Strategic Sourcing Conclusion and Outlook for key sales and supply

In today’s competitive global marketplace, strategic sourcing is more crucial than ever for international B2B buyers seeking to optimize their supply chains. By prioritizing partnerships with reliable suppliers, businesses can enhance their operational efficiency, reduce costs, and ensure the quality of their products. This proactive approach not only fosters stronger relationships with manufacturers and distributors but also allows companies to adapt swiftly to market changes and consumer demands.

Illustrative image related to key sales and supply

For buyers from Africa, South America, the Middle East, and Europe, leveraging strategic sourcing can open doors to diverse markets and innovative products. By understanding regional dynamics and consumer preferences, businesses can tailor their offerings to meet specific needs, thereby gaining a competitive edge.

As we look ahead, it is essential for B2B buyers to embrace technology and data analytics in their sourcing strategies. These tools can provide valuable insights into market trends and supplier performance, enabling informed decision-making.

In conclusion, the future of key sales and supply lies in collaboration, adaptability, and strategic foresight. Engage with trusted partners, leverage data-driven insights, and position your business for success in an increasingly interconnected world. Start your strategic sourcing journey today to unlock new opportunities and drive sustainable growth.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to key sales and supply

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.