Everything You Need to Know About 48 Diameter Concrete Form Tubes Sourcing in 2025

Introduction: Navigating the Global Market for 48 diameter concrete form tubes

In the complex landscape of international construction, sourcing 48 diameter concrete form tubes presents unique challenges for B2B buyers. The growing demand for durable and efficient construction materials, particularly in regions like Africa, South America, the Middle East, and Europe, necessitates a strategic approach to procurement. This guide is designed to equip businesses with the insights needed to make informed purchasing decisions, covering essential aspects such as types of form tubes, their various applications, supplier vetting processes, and cost considerations.

Concrete form tubes are crucial for constructing round columns in diverse settings, from residential structures to commercial projects. Understanding the specifications and characteristics of these tubes is vital for ensuring they meet project requirements while optimizing cost-efficiency. Additionally, this guide will delve into the importance of selecting reliable suppliers who can provide quality products that adhere to regional standards, thereby minimizing risks associated with procurement.

By navigating this comprehensive resource, international buyers can streamline their sourcing processes, reduce project delays, and enhance overall construction quality. This guide empowers B2B buyers by providing actionable insights and practical knowledge, enabling them to confidently navigate the global market for 48 diameter concrete form tubes and secure the best materials for their projects.

Understanding 48 diameter concrete form tubes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Concrete Form Tubes | Made from recycled cardboard, moisture-resistant. | Column construction for buildings and structures. | Pros: Lightweight, easy to handle. Cons: Single-use, may require disposal costs. |

| Heavy-Duty Concrete Form Tubes | Thicker walls for greater durability and load capacity. | Heavy structural applications, like bridges. | Pros: Enhanced strength and stability. Cons: Higher cost compared to standard tubes. |

| Insulated Concrete Form Tubes | Incorporates insulation material for thermal efficiency. | Energy-efficient building projects. | Pros: Reduces energy costs. Cons: Higher initial investment. |

| Custom-Length Concrete Form Tubes | Tailored lengths to specific project requirements. | Specialized construction projects. | Pros: Reduces waste, tailored to needs. Cons: May require longer lead times for production. |

| Collapsible Concrete Form Tubes | Designed for easy storage and transport. | Temporary structures, events, and exhibitions. | Pros: Space-saving, reusable. Cons: May be less sturdy than traditional forms. |

What Are the Characteristics of Standard Concrete Form Tubes?

Standard concrete form tubes are primarily made from recycled cardboard, making them a lightweight and cost-effective solution for column construction. These tubes are moisture-resistant, allowing for use in various weather conditions without compromising structural integrity. They are ideal for applications such as building columns, light posts, and other residential or commercial structures. B2B buyers should consider their ease of handling, but note that they are single-use, which could lead to additional disposal costs.

How Do Heavy-Duty Concrete Form Tubes Differ from Standard Options?

Heavy-duty concrete form tubes feature thicker walls designed to support greater loads and withstand harsh conditions. They are particularly suitable for heavy structural applications, such as bridges or high-rise buildings, where additional strength is paramount. While these tubes offer enhanced durability and stability, buyers should be aware of their higher price point, which may impact budget-sensitive projects.

Why Choose Insulated Concrete Form Tubes for Energy Efficiency?

Insulated concrete form tubes integrate insulation materials, providing thermal efficiency for energy-conscious building projects. These tubes help maintain consistent internal temperatures, reducing energy costs over time. B2B buyers focused on sustainability and energy efficiency will find these tubes appealing, although the initial investment is typically higher than standard options. It’s essential to weigh long-term savings against upfront costs when considering this type.

What Advantages Do Custom-Length Concrete Form Tubes Offer?

Custom-length concrete form tubes can be tailored to specific project requirements, minimizing waste and ensuring that materials fit the exact needs of the construction. This flexibility makes them suitable for specialized construction projects that require unique dimensions. While they enhance efficiency and reduce waste, buyers must consider potential longer lead times for production, which can affect project timelines.

How Do Collapsible Concrete Form Tubes Benefit Temporary Structures?

Collapsible concrete form tubes are designed for easy storage and transport, making them an excellent choice for temporary structures, events, or exhibitions. Their space-saving design allows for efficient logistics and reusability. However, buyers should be cautious, as these tubes may not offer the same level of sturdiness as traditional forms, which could be a concern for more permanent applications.

Key Industrial Applications of 48 diameter concrete form tubes

| Industry/Sector | Specific Application of 48 diameter concrete form tubes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Used to create structural columns for commercial buildings | Provides quick setup, reducing labor costs and project timelines | Ensure compliance with local building codes and standards |

| Infrastructure | Forming bases for light poles and traffic signals | Enhances durability and stability of urban infrastructure | Availability of moisture-resistant materials for harsh climates |

| Landscaping | Creating decorative garden columns and features | Adds aesthetic value and can enhance property appeal | Sourcing from eco-friendly suppliers to meet sustainability goals |

| Utility Services | Supporting utility poles and posts for telecommunications | Improves reliability and safety in utility installations | Consider local sourcing to reduce shipping costs and delays |

| Industrial Facilities | Forming bases for large machinery and equipment | Ensures stability and safety of heavy equipment | Look for tubes that can withstand heavy loads and harsh conditions |

How Are 48 Diameter Concrete Form Tubes Used in Construction?

In the construction industry, 48 diameter concrete form tubes are primarily utilized to create robust structural columns for commercial buildings. These tubes streamline the building process by eliminating the need for traditional wood forms, significantly reducing labor costs and project timelines. For international buyers, particularly in regions with varying construction standards, it’s essential to source tubes that comply with local building codes to ensure safety and structural integrity.

What Role Do These Tubes Play in Infrastructure Development?

For infrastructure projects, 48 diameter concrete form tubes are essential for forming stable bases for light poles and traffic signals. Their durability ensures that these installations can withstand environmental stresses, which is crucial in urban areas. Buyers in regions prone to extreme weather conditions should prioritize moisture-resistant materials to maintain the longevity of these installations and reduce maintenance costs.

How Are Concrete Form Tubes Used in Landscaping?

In landscaping, these tubes serve as bases for decorative garden columns and other aesthetic features. They not only enhance the visual appeal of outdoor spaces but also provide structural integrity. Buyers focused on sustainability may seek eco-friendly options, such as tubes made from recycled materials, to align with environmentally conscious practices and enhance their brand’s reputation.

What Is the Importance of Form Tubes for Utility Services?

In utility services, 48 diameter concrete form tubes are utilized to support poles and posts for telecommunications, ensuring reliability and safety in installations. The stability these tubes provide is critical for preventing outages and maintaining service quality. Buyers should consider sourcing locally to minimize shipping costs and ensure timely delivery, especially in regions where rapid deployment of services is necessary.

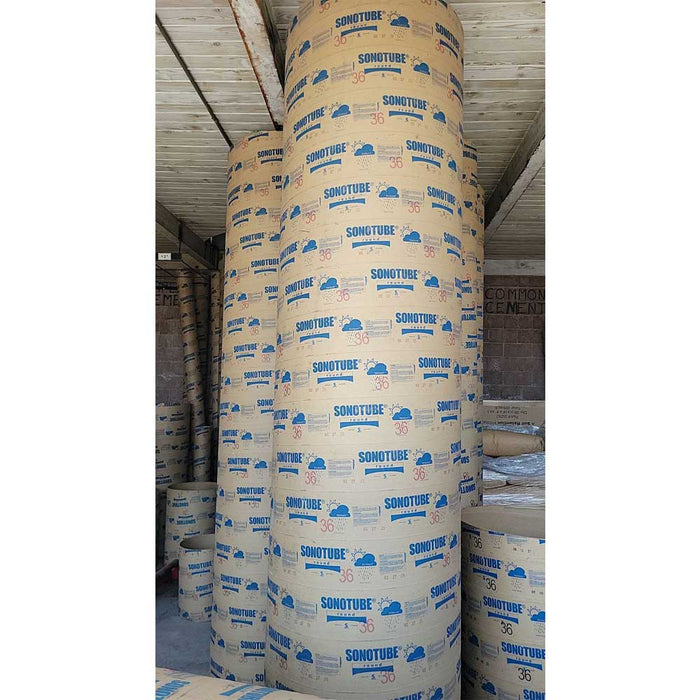

Illustrative image related to 48 diameter concrete form tubes

How Do Industrial Facilities Benefit from Using These Tubes?

Within industrial facilities, 48 diameter concrete form tubes are used to create sturdy bases for large machinery and equipment. This application is vital for ensuring the safety and stability of heavy machinery, which can be subject to significant operational stresses. It is advisable for buyers to look for form tubes that can withstand heavy loads and harsh conditions, as this will contribute to the overall efficiency and safety of industrial operations.

3 Common User Pain Points for ’48 diameter concrete form tubes’ & Their Solutions

Scenario 1: Navigating Supply Chain Disruptions in Concrete Form Tube Procurement

The Problem:

B2B buyers often face significant challenges when procuring 48-inch diameter concrete form tubes, particularly in regions with fluctuating supply chains like Africa and South America. Delays caused by transportation issues, limited local suppliers, or unexpected demand surges can lead to project slowdowns or even cancellations. This unpredictability can jeopardize timelines, increase costs, and strain relationships with clients who expect timely delivery.

The Solution:

To mitigate supply chain disruptions, B2B buyers should establish relationships with multiple suppliers across different regions. This diversification can ensure access to alternative sources when local suppliers face shortages. Additionally, implementing a just-in-time inventory system can help maintain adequate stock levels without overcommitting resources. Buyers should also consider utilizing technology for real-time tracking of shipments and inventory management, enabling proactive adjustments to orders based on current project needs. Regular communication with suppliers about upcoming projects can also allow for better forecasting and prioritization of orders, ensuring smoother operations.

Scenario 2: Ensuring Structural Integrity with Proper Installation Techniques

The Problem:

One of the critical pain points for buyers is ensuring that the concrete form tubes are installed correctly to maintain structural integrity. Incorrect installation can lead to issues such as misalignment, inadequate curing, and ultimately, structural failures. This is particularly crucial in commercial applications where safety regulations and standards are stringent. Buyers may struggle with how to effectively train their teams or subcontractors in best practices for installation.

The Solution:

Investing in training and certification programs for installation teams can significantly enhance the quality of work. Buyers should seek out resources such as workshops or online courses focused on the specific techniques for handling and installing 48-inch diameter concrete form tubes. Providing detailed installation guides, including step-by-step instructions and best practices, can also be beneficial. Additionally, conducting on-site supervision during the initial installations can help identify and correct mistakes in real-time. Employing a quality control checklist that covers all installation aspects—from site preparation to final curing—can further ensure that each project meets the necessary standards for safety and longevity.

Scenario 3: Managing Moisture and Weather Effects on Concrete Form Tubes

The Problem:

Another common issue faced by B2B buyers is the impact of moisture and adverse weather conditions on concrete form tubes during construction. In regions with high humidity or frequent rain, standard cardboard tubes can absorb moisture, compromising their structural integrity and the quality of the poured concrete. This is particularly concerning for long-term projects or in areas where weather conditions can change rapidly, leading to delays and increased costs.

The Solution:

To combat moisture-related issues, buyers should look for moisture-resistant concrete form tubes specifically designed to withstand wet conditions. These tubes often feature specialized coatings that prevent water absorption and can endure prolonged exposure to rain or humidity. Implementing a weather monitoring system on-site can also help teams prepare for adverse conditions and take preemptive measures, such as covering the tubes with tarps or moving operations indoors when necessary. Lastly, establishing a contingency plan that includes alternative materials or methods for protecting the tubes can ensure that projects stay on track despite unexpected weather changes.

Strategic Material Selection Guide for 48 diameter concrete form tubes

What Are the Key Materials for 48-Inch Diameter Concrete Form Tubes?

When selecting materials for 48-inch diameter concrete form tubes, understanding the properties, advantages, and limitations of each option is crucial for B2B buyers. The following analysis covers four common materials used in the production of these form tubes: cardboard, plastic, fiberglass, and metal.

How Does Cardboard Perform in Concrete Form Tubes?

Key Properties: Cardboard form tubes are lightweight and easy to handle, making them suitable for various applications. They are typically moisture-resistant, allowing them to withstand short periods of precipitation without compromising structural integrity.

Pros & Cons: The primary advantage of cardboard is its cost-effectiveness and ease of installation. However, they are single-use and may not withstand extreme weather conditions or heavy loads, limiting their application in harsher environments.

Impact on Application: Cardboard forms are ideal for creating round columns in residential and light commercial structures. However, they may not be suitable for projects requiring extended durability or exposure to moisture.

Considerations for International Buyers: B2B buyers should ensure compliance with local building codes and standards, such as ASTM or DIN, which may dictate the use of more robust materials in certain climates.

What Are the Advantages of Plastic Form Tubes?

Key Properties: Plastic form tubes are known for their durability and resistance to moisture, chemicals, and corrosion. They can handle a wider range of temperatures and pressures compared to cardboard.

Pros & Cons: The primary advantage of plastic tubes is their reusability and longevity, making them suitable for larger projects. However, they tend to be more expensive than cardboard options and may require specialized handling during installation.

Impact on Application: Plastic tubes are ideal for heavy-duty applications, including large commercial structures and infrastructure projects, where structural integrity is paramount.

Considerations for International Buyers: Buyers should look for products that meet international standards for safety and environmental impact, especially in regions where regulations are stringent.

How Do Fiberglass Form Tubes Compare?

Key Properties: Fiberglass form tubes offer excellent strength-to-weight ratios and are resistant to corrosion and chemicals. They can withstand high temperatures and pressures, making them versatile for various applications.

Pros & Cons: The main advantage of fiberglass is its durability and long service life. However, the manufacturing process can be complex and costly, leading to higher prices.

Impact on Application: These tubes are suitable for demanding environments, such as coastal areas or regions with extreme weather conditions, where other materials might fail.

Considerations for International Buyers: Compliance with safety and environmental standards is crucial, particularly in regions with strict regulations. Buyers should also consider the availability of local suppliers for maintenance and replacement.

What Role Do Metal Form Tubes Play?

Key Properties: Metal form tubes, often made from steel or aluminum, provide exceptional strength and durability. They are resistant to corrosion and can handle high loads and pressures.

Pros & Cons: The key advantage of metal tubes is their long lifespan and ability to withstand harsh conditions. However, they are typically the most expensive option and may require additional treatments to prevent rust and corrosion.

Impact on Application: Metal tubes are ideal for heavy construction projects, including bridges and high-rise buildings, where structural integrity is critical.

Considerations for International Buyers: Buyers must ensure that metal tubes meet local building codes and standards, which can vary significantly across regions. Additionally, the cost of transportation and availability of local suppliers should be factored into purchasing decisions.

Summary Table of Material Options for 48-Inch Diameter Concrete Form Tubes

| Material | Typical Use Case for 48 Diameter Concrete Form Tubes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cardboard | Residential and light commercial structures | Cost-effective and easy to handle | Single-use and limited durability | Low |

| Plastic | Heavy-duty applications, large commercial structures | Durable and reusable | Higher cost and specialized handling | Medium |

| Fiberglass | Demanding environments, coastal areas | Excellent strength and corrosion resistance | Complex manufacturing and high cost | High |

| Metal | Heavy construction projects, bridges | Exceptional strength and longevity | Most expensive and requires treatments | High |

This strategic material selection guide provides B2B buyers with the necessary insights to make informed decisions regarding the procurement of 48-inch diameter concrete form tubes, ensuring compliance with regional standards and suitability for specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for 48 diameter concrete form tubes

What Are the Main Stages of Manufacturing 48-Inch Diameter Concrete Form Tubes?

The manufacturing process of 48-inch diameter concrete form tubes involves several key stages, each critical to ensuring the final product meets the required specifications for strength, durability, and usability.

Material Preparation

The process begins with material selection. Most concrete form tubes are made from high-quality recycled cardboard, which offers both structural integrity and environmental sustainability. The cardboard is treated with moisture-resistant adhesives to enhance durability and protect against precipitation. This treatment is essential, as concrete form tubes often need to withstand various weather conditions during construction.

Once the materials are selected, they undergo a preprocessing phase where they are cut into sheets of appropriate sizes. These sheets will later be formed into tubes. Quality checks at this stage include verifying the moisture content and thickness of the cardboard, ensuring that they conform to industry standards.

How Are 48-Inch Diameter Concrete Form Tubes Formed?

The next phase involves the actual forming of the tubes. The cut sheets are passed through a forming machine that rolls and molds them into cylindrical shapes. This machine uses hydraulic pressure to ensure that the seams are tightly sealed, preventing leaks during the concrete pouring process.

Key techniques employed during this stage include:

- Spiral Winding: This technique allows for the efficient creation of cylindrical shapes while maintaining structural integrity.

- Heat Treatment: Some manufacturers may apply heat to enhance the adhesive properties of the cardboard, ensuring a robust bond between layers.

What Is the Assembly Process for Concrete Form Tubes?

Following the forming stage, the tubes are assembled. This may involve additional layers of cardboard for enhanced strength, especially for larger diameters like 48 inches. Each layer is meticulously aligned and bonded together using high-quality adhesives.

Quality control measures during assembly include visual inspections to check for any imperfections or misalignments. Tubes that do not meet the specifications are either reprocessed or discarded.

Illustrative image related to 48 diameter concrete form tubes

What Finishing Techniques Are Used for Concrete Form Tubes?

The final stage in the manufacturing process is finishing. This involves applying a protective coating to the outer surface of the tubes, enhancing their moisture resistance and ensuring they can withstand harsh environmental conditions.

Finishing techniques may also include:

- Surface Treatment: A final treatment can be applied to improve the aesthetic appeal of the tubes.

- Labeling: Each tube is labeled with important information, including size, weight, and manufacturer details, which is crucial for inventory management and regulatory compliance.

How Is Quality Assurance Implemented in Manufacturing Concrete Form Tubes?

Quality assurance (QA) is vital in the manufacturing of concrete form tubes, ensuring that products meet both international and industry-specific standards.

What Are the Relevant International Standards for Quality Assurance?

Manufacturers of concrete form tubes often adhere to international standards such as ISO 9001, which outlines the criteria for a quality management system. Compliance with ISO standards ensures that products are consistently produced and that quality is continuously improved.

Additionally, region-specific certifications such as CE marking in Europe and API standards in the oil and gas sector may also apply, depending on the intended use of the tubes.

Illustrative image related to 48 diameter concrete form tubes

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is integrated at multiple checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This is performed on raw materials upon delivery. Inspections ensure that materials meet specified standards for thickness, moisture resistance, and overall quality.

-

In-Process Quality Control (IPQC): During manufacturing, QC personnel monitor the forming and assembly processes, checking for adherence to specifications and standards.

-

Final Quality Control (FQC): After the finishing stage, a thorough inspection is conducted. This includes checking for dimensional accuracy, surface quality, and adherence to strength specifications.

What Common Testing Methods Are Used for Quality Assurance?

Testing methods for concrete form tubes may include:

- Compression Testing: Ensures the tubes can withstand the weight of the concrete without collapsing.

- Moisture Resistance Testing: Verifies that the tubes can endure exposure to moisture without degrading.

- Dimensional Verification: Ensures that the tubes meet specified diameter and length requirements.

How Can B2B Buyers Verify Supplier Quality Assurance?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality assurance practices is crucial.

What Steps Can Buyers Take to Audit Suppliers?

-

Request Certifications: Buyers should request copies of relevant certifications (ISO, CE, etc.) and assess their validity and relevance to the product.

-

Conduct Audits: Regular audits of suppliers can provide insight into their manufacturing processes and adherence to quality standards. Buyers may choose to conduct these audits themselves or hire third-party inspectors.

-

Review Quality Reports: Suppliers should provide regular quality reports detailing testing results and any corrective actions taken to address quality issues.

-

Engage with Third-Party Inspection Services: Utilizing independent inspection services can help verify that the supplier adheres to the necessary quality standards throughout the manufacturing process.

What Are the Quality Control Nuances for International B2B Buyers?

When dealing with suppliers from different countries, B2B buyers must be aware of regional differences in quality standards and regulations. For example, compliance with local building codes and safety regulations may vary significantly.

Buyers should also consider the logistics of transporting products internationally, which can impact the integrity of the tubes. Ensuring that suppliers have robust packaging and shipping practices is essential to avoid damage during transit.

By understanding the manufacturing processes and quality assurance measures in place for 48-inch diameter concrete form tubes, B2B buyers can make informed decisions that align with their project requirements and standards. This knowledge not only aids in selecting reliable suppliers but also helps ensure that the final products perform as expected in critical construction applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ’48 diameter concrete form tubes’

Introduction

This guide serves as a comprehensive checklist for B2B buyers seeking to procure 48-inch diameter concrete form tubes. Sourcing these materials effectively is essential for ensuring quality, cost-efficiency, and timely project execution. By following the steps outlined below, buyers can make informed decisions that align with their project needs and operational standards.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your procurement process. Consider factors such as wall thickness, material type, and length. This clarity will help you communicate effectively with suppliers and ensure that the products meet your project requirements.

- Wall Thickness: Determine if you need standard or heavy-duty options based on the structural demands.

- Material Type: Consider whether you prefer fiber, cardboard, or other composite materials for durability and cost-effectiveness.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in concrete form tubes. Evaluate their market presence, product offerings, and reputation within the industry. This step is vital to finding reliable partners who can meet your specific needs.

- Supplier Directories: Utilize industry-specific directories and platforms to find reputable manufacturers and distributors.

- Online Reviews: Check reviews and testimonials from previous clients to gauge reliability and product quality.

Step 3: Verify Supplier Certifications

Before finalizing any agreements, verify that your chosen suppliers have the necessary certifications and compliance with industry standards. This ensures that the products you receive meet safety and quality benchmarks, reducing the risk of project delays or failures.

- Quality Certifications: Look for ISO or ASTM certifications that validate product standards.

- Environmental Compliance: Ensure that suppliers follow sustainable practices and regulations, especially if sourcing in environmentally sensitive regions.

Step 4: Request Samples for Evaluation

Before committing to a bulk order, request samples of the concrete form tubes. This allows you to assess the quality, durability, and suitability of the products for your specific applications. Testing samples can prevent costly mistakes later in the project.

Illustrative image related to 48 diameter concrete form tubes

- Physical Inspection: Evaluate the samples for structural integrity, moisture resistance, and overall quality.

- Performance Testing: Consider conducting tests to see how the tubes perform under your project conditions.

Step 5: Negotiate Terms and Pricing

Once you have identified suitable suppliers and evaluated their products, engage in negotiations to secure favorable terms. Discuss pricing, payment options, lead times, and delivery logistics to ensure that all aspects of the procurement are clearly understood.

- Bulk Discounts: Inquire about discounts for larger orders to maximize cost savings.

- Payment Flexibility: Discuss payment terms that align with your cash flow requirements, such as installment plans or credit options.

Step 6: Establish a Delivery Schedule

Coordinate with your supplier to establish a clear delivery schedule that aligns with your project timelines. Timely delivery is crucial to avoid project delays and maintain workflow efficiency.

- Lead Time Expectations: Confirm the expected lead times for production and shipping.

- Contingency Plans: Discuss potential delays and how they will be managed to ensure that your project remains on track.

Step 7: Review and Finalize Purchase Agreement

Before finalizing the order, review all contractual terms and conditions carefully. Ensure that all agreed-upon specifications, delivery timelines, and pricing structures are documented to prevent misunderstandings.

- Contractual Clarity: Pay attention to cancellation policies, warranty details, and dispute resolution clauses.

- Confirmation of Order: Obtain a written confirmation of your order to safeguard against any discrepancies.

By following this checklist, B2B buyers can navigate the procurement process for 48-inch diameter concrete form tubes with confidence, ensuring they secure the right products for their projects.

Comprehensive Cost and Pricing Analysis for 48 diameter concrete form tubes Sourcing

Analyzing the cost and pricing structure for 48-inch diameter concrete form tubes requires an understanding of several key components that influence both manufacturing costs and final pricing for international B2B buyers.

What Are the Key Cost Components in 48-Inch Concrete Form Tubes?

-

Materials: The primary material used for concrete form tubes is often recycled cardboard or other composite materials. The cost of these raw materials can fluctuate based on market demand, availability, and quality. Sustainable sourcing can also impact pricing, as eco-friendly materials may carry a premium.

-

Labor: Labor costs encompass the wages paid to workers involved in the manufacturing process, including assembly, quality control, and packaging. Regions with higher labor costs will see increased pricing, while countries with lower labor costs can offer more competitive pricing.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can help reduce overhead costs, directly influencing the final price.

-

Tooling: The initial investment in tooling for production can be significant, especially for custom sizes or specifications. This cost is typically amortized over the production volume, which means larger orders can benefit from reduced per-unit costs.

-

Quality Control (QC): Ensuring the durability and reliability of concrete form tubes involves rigorous testing and quality assurance processes. Compliance with international standards or certifications can increase costs but is essential for maintaining product integrity, especially in demanding environments.

-

Logistics: Shipping and transportation costs are crucial, particularly for international buyers. Factors such as distance, shipping method, and customs duties can significantly affect the total cost. Incoterms play a vital role in determining who bears these costs and responsibilities.

-

Margin: Suppliers will add a profit margin to cover their expenses and ensure a return on investment. This margin can vary widely based on market competition, brand reputation, and perceived value.

What Influences Pricing for International B2B Buyers?

Several factors can influence the pricing of concrete form tubes for international buyers, especially in regions like Africa, South America, the Middle East, and Europe.

-

Volume and Minimum Order Quantity (MOQ): Higher volumes typically lead to better pricing. Suppliers often have set MOQs, and negotiating these can yield significant savings.

-

Specifications and Customization: Custom orders may incur additional costs due to tooling and material variations. Standard sizes usually have lower costs due to established production processes.

-

Quality and Certifications: Products that meet specific quality standards or certifications (such as ASTM or ISO) may command higher prices. Buyers should assess whether these certifications are necessary for their projects.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may offer higher-quality products but at a premium.

-

Incoterms: Understanding the shipping terms can affect the overall cost. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who pays for shipping and insurance, which can influence the final price.

What Tips Can Help Buyers Optimize Costs?

-

Negotiation: Leverage volume purchases or long-term contracts to negotiate better pricing. Building a strong relationship with suppliers can also lead to favorable terms.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes not just the purchase price but also shipping, handling, and potential wastage. Opting for durable, high-quality tubes may save costs in the long run.

-

Pricing Nuances for International Buyers: Understand regional differences in pricing and logistics. Factors such as local tariffs, shipping routes, and currency fluctuations can impact costs. Working with a local distributor can help mitigate some of these challenges.

Conclusion

The sourcing of 48-inch diameter concrete form tubes involves a complex interplay of cost components and pricing influencers. By understanding these factors, international B2B buyers can make informed decisions that balance quality, cost, and logistics. Always consult with multiple suppliers and consider the total cost of ownership to ensure the best value for your investment.

Illustrative image related to 48 diameter concrete form tubes

Alternatives Analysis: Comparing 48 diameter concrete form tubes With Other Solutions

Exploring Alternatives to 48 Diameter Concrete Form Tubes

In the construction industry, choosing the right formwork solution is crucial for ensuring project efficiency and structural integrity. While 48 diameter concrete form tubes offer a reliable option for creating circular columns, various alternatives exist that might better suit specific project needs. This section examines these alternatives, comparing their performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | 48 Diameter Concrete Form Tubes | Aluminum Forms | 3D Printed Formwork |

|---|---|---|---|

| Performance | Excellent for round columns; strong and stable | High precision; reusable and durable | Innovative shapes and designs possible; variable material strengths |

| Cost | Moderate; generally affordable for single-use | Higher initial cost; cost-effective over time | Potentially high setup costs; savings in labor and material for complex shapes |

| Ease of Implementation | Easy to transport and install; single-use | Requires skilled labor for setup; heavier | Requires specialized equipment and expertise; complex setup |

| Maintenance | No maintenance; single-use | Requires cleaning and maintenance for reusability | Minimal maintenance; depends on materials used |

| Best Use Case | Ideal for quick, one-time applications like light poles | Suitable for repetitive, large-scale projects | Best for complex, customized structures where traditional forms fail |

What Are the Advantages and Disadvantages of Using Aluminum Forms?

Aluminum forms are a robust alternative to concrete form tubes. They are designed for repeated use, making them an excellent option for contractors who need to form concrete in various projects. The precision of aluminum forms allows for tight tolerances, resulting in high-quality finishes. However, the initial investment is significantly higher than that of concrete form tubes, which can be a deterrent for smaller projects or companies. Additionally, their weight requires skilled labor for proper handling and assembly, which can increase labor costs.

How Does 3D Printed Formwork Compare to Traditional Options?

3D printed formwork represents a cutting-edge solution that enables the creation of complex and customized shapes that traditional formwork cannot easily achieve. This technology can significantly reduce material waste and labor costs in the long run, particularly for intricate designs. However, the technology requires specialized equipment and expertise, which can lead to high initial setup costs. Furthermore, the durability of the printed material must be assessed based on the specific project requirements, as not all 3D printing materials are suitable for heavy structural applications.

Illustrative image related to 48 diameter concrete form tubes

Conclusion: How Should B2B Buyers Choose the Right Formwork Solution?

When selecting the right formwork solution, B2B buyers must consider their specific project requirements, including the complexity of the design, budget constraints, and the expected duration of use. For projects requiring quick setups with minimal investment, 48 diameter concrete form tubes are a practical choice. Conversely, for larger projects where reusability is paramount, aluminum forms may prove more economical over time. Meanwhile, for innovative designs that demand flexibility, 3D printed formwork could be the best solution, provided the buyer is prepared for the associated costs and technical requirements. Ultimately, aligning the choice with project goals will ensure optimal performance and cost-effectiveness.

Essential Technical Properties and Trade Terminology for 48 diameter concrete form tubes

What Are the Key Technical Properties of 48-Inch Diameter Concrete Form Tubes?

When selecting 48-inch diameter concrete form tubes, understanding their technical properties is crucial for ensuring optimal performance in construction projects. Here are some critical specifications that should be considered:

-

Material Composition

– Most concrete form tubes are made from a high-quality cardboard or composite material, designed to withstand moisture and provide structural integrity. The choice of material affects the tube’s durability and resistance to environmental factors, which is vital for maintaining the quality of the poured concrete. -

Wall Thickness

– The wall thickness of a form tube directly influences its strength and load-bearing capacity. Commonly available options range from lightweight to heavy-duty configurations. A thicker wall is essential for applications requiring greater support, particularly in commercial constructions where structural stability is paramount. -

Length Tolerance

– Length tolerance is the permissible variation in the tube’s specified length. For instance, a typical tolerance might be ±1/8 inch. This specification is significant in ensuring that the tubes fit seamlessly into the construction framework, reducing the risk of errors during the pouring and setting of concrete. -

Moisture Resistance

– High-quality form tubes feature moisture-resistant coatings that allow them to endure wet conditions for extended periods—often up to 72 hours. This property is particularly important in regions with unpredictable weather, as it prevents the degradation of the tubes before the concrete sets. -

Weight and Handling

– The weight of the tubes affects their handling and transportation. Lighter tubes are easier to manage on-site, which can lead to reduced labor costs and faster installation times. Buyers should consider the weight-to-strength ratio to determine the best fit for their specific project needs. -

Load Capacity

– Each form tube has a specified load capacity, which indicates how much weight it can support before buckling or collapsing. This specification is essential for ensuring safety and compliance with building codes, particularly in large-scale construction projects.

What Common Trade Terms Should Buyers Know About Concrete Form Tubes?

Understanding trade terminology is vital for effective communication and negotiation in the procurement process. Here are some key terms relevant to 48-inch diameter concrete form tubes:

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of concrete form tubes, an OEM may provide proprietary designs or specifications that ensure compatibility with specific construction requirements. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest number of units that a supplier is willing to sell. Understanding MOQ is crucial for buyers as it impacts inventory management and cost calculations. For large projects, negotiating a lower MOQ can lead to significant savings. -

RFQ (Request for Quotation)

– An RFQ is a document that solicits price quotes from suppliers. It usually includes detailed specifications, quantities, and terms of purchase. Crafting a clear and comprehensive RFQ is essential for receiving accurate and competitive pricing from multiple vendors. -

Incoterms (International Commercial Terms)

– These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is crucial for ensuring clarity in shipping and delivery agreements. -

Lead Time

– This term refers to the amount of time between placing an order and the delivery of the goods. Understanding lead times is essential for project planning, as delays can impact construction schedules and overall project timelines. -

Certification Standards

– Many concrete form tubes are manufactured to meet specific certification standards (e.g., ASTM, ISO). These certifications assure buyers of the quality and reliability of the products, which is particularly important in regulated markets.

By mastering these technical properties and trade terminologies, international B2B buyers can make informed decisions when sourcing 48-inch diameter concrete form tubes, ensuring their projects are completed on time and within budget.

Navigating Market Dynamics and Sourcing Trends in the 48 diameter concrete form tubes Sector

What Are the Current Market Dynamics and Key Trends in the 48-Inch Diameter Concrete Form Tubes Sector?

The global market for 48-inch diameter concrete form tubes is witnessing significant growth driven by several factors. The booming construction and infrastructure development sectors in emerging economies, particularly in Africa, South America, and the Middle East, are pushing demand for innovative and efficient construction solutions. Countries such as Nigeria and Vietnam are increasingly investing in infrastructure, necessitating the use of reliable construction materials like concrete form tubes, which are essential for erecting columns and supports in various building applications.

A key trend influencing sourcing decisions is the shift towards digitization and technology adoption in the procurement processes. B2B buyers are leveraging e-commerce platforms and digital supply chains to streamline their sourcing activities, allowing them to compare prices, assess product specifications, and evaluate supplier reliability more effectively. Additionally, the adoption of Building Information Modeling (BIM) in construction projects is enhancing collaboration among stakeholders, further promoting the demand for precise and standardized construction materials.

Furthermore, sustainability is becoming a central theme in market dynamics. Buyers are increasingly prioritizing suppliers that can demonstrate environmentally friendly practices, including the use of recycled materials and energy-efficient manufacturing processes. This shift is particularly relevant in regions where environmental regulations are tightening, prompting buyers to seek out suppliers who can provide compliant products.

How Important Is Sustainability and Ethical Sourcing in the B2B Concrete Form Tube Market?

Sustainability and ethical sourcing are critical considerations for B2B buyers of 48-inch diameter concrete form tubes. The construction industry is under growing scrutiny regarding its environmental impact, and buyers are increasingly aware of their role in fostering sustainable practices. Concrete form tubes made from recycled cardboard, for instance, not only reduce waste but also align with the circular economy principles that many companies are striving to adopt.

Additionally, ethical supply chains are gaining importance, as buyers seek to partner with suppliers who adhere to fair labor practices and transparency. Certifications such as FSC (Forest Stewardship Council) and ISO standards are becoming essential benchmarks for evaluating potential suppliers. These certifications not only assure buyers of the sustainability of materials but also enhance their brand reputation in a market that increasingly values corporate social responsibility.

Moreover, the environmental impact of construction activities has prompted a demand for ‘green’ products that minimize carbon footprints. The use of moisture-resistant adhesives and innovative designs in concrete form tubes can enhance their durability, reducing the need for replacements and thus contributing to lower overall environmental impact. As a result, B2B buyers are encouraged to prioritize suppliers who can provide products that meet these sustainability criteria.

How Has the 48-Inch Diameter Concrete Form Tubes Sector Evolved Over Time?

The evolution of the 48-inch diameter concrete form tubes sector reflects broader trends in construction and materials science. Initially, concrete form tubes were predominantly made from wood, which required significant labor and resources for assembly and disassembly. However, the introduction of fiber and cardboard-based tubes has revolutionized the market by offering lightweight, easy-to-handle alternatives that reduce labor costs and time on-site.

Over the years, technological advancements have led to improvements in the manufacturing processes of concrete form tubes, allowing for greater moisture resistance and structural integrity. These innovations have made it possible to use form tubes in a wider range of applications, from residential buildings to large-scale commercial projects. The focus on sustainability has also prompted manufacturers to invest in eco-friendly materials and practices, ensuring that the industry continues to adapt to the growing demand for responsible sourcing and environmental stewardship.

In summary, the 48-inch diameter concrete form tubes sector is undergoing significant transformation driven by market dynamics, sustainability initiatives, and technological advancements. B2B buyers are encouraged to stay informed about these trends to make strategic sourcing decisions that align with their business goals and values.

Illustrative image related to 48 diameter concrete form tubes

Frequently Asked Questions (FAQs) for B2B Buyers of 48 diameter concrete form tubes

-

How do I ensure the quality of 48 diameter concrete form tubes from suppliers?

To ensure quality, start by vetting suppliers through their certifications and industry standards compliance, such as ISO certifications. Request product samples to evaluate material integrity and construction standards. Additionally, consider conducting factory audits or using third-party inspection services to assess manufacturing processes. Reviews and testimonials from previous clients can also provide insight into reliability and performance. Establishing clear quality assurance protocols in your purchase agreement is essential to mitigate risks. -

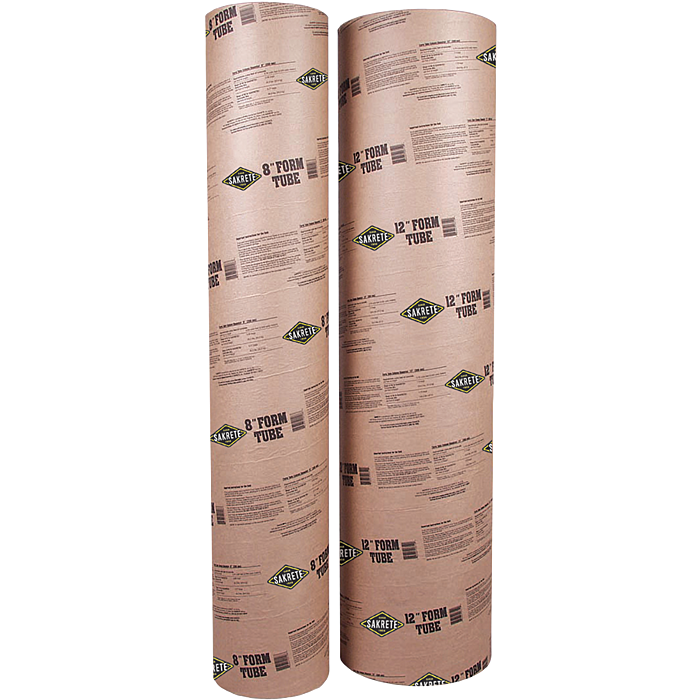

What is the best material for 48 diameter concrete form tubes?

The best materials for 48 diameter concrete form tubes typically include high-strength cardboard or composite materials that offer moisture resistance and structural integrity. Cardboard tubes are lightweight, easy to handle, and cost-effective for single-use applications. For projects requiring durability under harsh conditions, consider tubes with moisture-resistant coatings. Evaluate the intended use and environmental conditions to select the most suitable material that balances performance with cost. -

What are the typical lead times for ordering 48 diameter concrete form tubes?

Lead times for ordering 48 diameter concrete form tubes can vary significantly based on supplier location, production capacity, and order size. Generally, expect lead times to range from 2 to 6 weeks. For international orders, factors such as customs clearance and shipping logistics may extend this timeframe. It’s advisable to confirm lead times with suppliers upfront and consider placing orders well in advance to accommodate any potential delays. -

What are the minimum order quantities (MOQ) for concrete form tubes?

Minimum order quantities (MOQ) for 48 diameter concrete form tubes differ among suppliers and may depend on factors like production capabilities and shipping arrangements. Common MOQs can range from a few dozen to several hundred units. When sourcing internationally, it’s essential to discuss MOQs with potential suppliers to ensure they align with your project needs and budget constraints. Negotiating MOQs may also be possible, especially for larger or recurring orders. -

How can I customize 48 diameter concrete form tubes for my project?

Customization options for 48 diameter concrete form tubes may include varying lengths, wall thicknesses, and surface treatments to enhance moisture resistance. Many suppliers offer bespoke solutions tailored to specific project requirements. Engage directly with suppliers to discuss your needs, and request prototypes if necessary. Ensure that the customization aligns with your structural specifications and complies with local building codes. -

What payment terms are typically offered for international orders of concrete form tubes?

Payment terms for international orders of 48 diameter concrete form tubes can vary widely based on supplier policies and buyer-seller relationships. Common arrangements include advance payment, letter of credit, or payment upon delivery. It’s crucial to negotiate terms that provide security for both parties. Always clarify currency, payment methods, and any potential fees associated with international transactions to avoid surprises. -

What are the logistics considerations when importing concrete form tubes?

Logistics considerations for importing 48 diameter concrete form tubes include shipping methods, customs clearance, and delivery timelines. Choose a reliable freight forwarder familiar with handling construction materials to ensure compliance with international regulations. Assess shipping costs and delivery times to make informed decisions about transport modes (air vs. sea). Prepare all necessary documentation to facilitate smooth customs processing and avoid delays. -

How do I handle issues with damaged or defective concrete form tubes upon delivery?

Handling issues with damaged or defective concrete form tubes requires prompt communication with your supplier. Document the damages with photographs and detailed descriptions, then notify the supplier immediately. Review your purchase agreement for terms related to returns and replacements. A reputable supplier will typically have a process for addressing such issues, which may include sending replacements or issuing credits. Always maintain clear records of communications for accountability.

Top 4 48 Diameter Concrete Form Tubes Manufacturers & Suppliers List

1. Sonoco-Darragh – 48 IN. X 12 FT. Concrete Forming Tube

Domain: darraghcompany.com

Registered: 2000 (25 years)

Introduction: Product Name: 48 IN. X 12 FT. CONCRETE FORMING TUBE

Product Code: 356019

Manufacturer: Sonoco-Darragh

2. Deco-Crete Supply – Sonotube by the Foot

Domain: deco-cretesupply.com

Registered: 2006 (19 years)

Introduction: Sonotube – By the Foot, Price: $5.85, Available Sizes: 12″ and 8″ Diameter, Heavy Duty, Can be used with form liners to create fire pits or columns, Quantity: By the foot, Contact for sizes not listed online: (330) 641-8059.

3. Formtech Inc – Sonotube® Concrete Column Forms

Domain: formtechinc.com

Registered: 2000 (25 years)

Introduction: Sonotube® Concrete Paperboard Column Forming Tubes are lightweight, single-use alternatives to fiberglass and steel column forms. Sourced from Greif® and Sonoco, common products include Greif® EasyPour™ and Sonoco Sonotube®. Available diameters: 8″, 14″, 18″, 24″, 28″, 30″, 36″, 42″, 48″ with a standard height of 12′. Custom diameter sizes from 6″ to 60″ upon request. Applications include columns …

4. Cox Hardware – Concrete Form Tube 48 In

Domain: coxhardware.com

Registered: 1999 (26 years)

Introduction: Concrete Form Tube 48 In (Diameters) – A one-time fiber form tube that reduces the cost of pouring piers, round columns, piles, and supports. Use when building piers, storage buildings, decks, fences, mailboxes, pilings, and mobile home supports. Not available for shipping due to size limitations. Available sizes: 8 In ID x 48 In Long, 10 In ID x 48 In Long, 12 In ID x 48 In Long. Pricing: 8 In – …

Strategic Sourcing Conclusion and Outlook for 48 diameter concrete form tubes

In the evolving landscape of construction and infrastructure development, strategic sourcing of 48-inch diameter concrete form tubes is essential for international buyers aiming to enhance project efficiency and sustainability. These form tubes, available in various lengths and materials, offer significant advantages, including easy handling, moisture resistance, and reduced labor costs. Buyers should prioritize suppliers that provide high-quality products, reliable delivery schedules, and competitive pricing to ensure that their projects remain on time and within budget.

As the demand for durable and efficient building solutions continues to rise, investing in strategic sourcing can provide a competitive edge in the global marketplace. Buyers from regions such as Africa, South America, the Middle East, and Europe are encouraged to explore diverse suppliers and material options that align with their specific project needs.

Looking ahead, the trend towards environmentally friendly materials and construction practices will likely influence the sourcing of concrete form tubes. Engaging with suppliers who prioritize sustainability can further enhance your brand’s reputation while contributing to global efforts in reducing environmental impact. Take the next step in optimizing your supply chain by connecting with trusted suppliers today, ensuring your projects are built on a solid foundation.

Illustrative image related to 48 diameter concrete form tubes

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.