How to Source Premade Mini Quad Frame Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for premade mini quad frame

The global market for premade mini quad frames presents a unique opportunity for B2B buyers, yet navigating this landscape can be challenging. Whether you’re sourcing high-quality frames for recreational vehicles or looking to enhance your product line, understanding the intricacies of this market is essential. With increasing demand for compact and efficient designs, buyers must evaluate various aspects such as frame types, materials, applications, and supplier reliability to make informed purchasing decisions.

This comprehensive guide delves into the multifaceted world of premade mini quad frames, covering everything from the different types available—ranging from lightweight aluminum to robust steel constructions—to their applications in various sectors, including recreational use and motorsport. Additionally, we will explore effective strategies for vetting suppliers, assessing costs, and ensuring compliance with international standards, which is crucial for buyers from diverse regions, including Africa, South America, the Middle East, and Europe.

By equipping international B2B buyers with actionable insights and practical tools, this guide empowers you to streamline your sourcing process, mitigate risks, and ultimately enhance your business’s competitiveness in the global market. As you embark on this journey, let us help you uncover the best options that align with your specific needs and objectives.

Understanding premade mini quad frame Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Mini Quad Frame | Basic design, made from steel or aluminum, typically lightweight | Recreational use, entry-level markets | Pros: Cost-effective, easy to assemble. Cons: Limited customization options. |

| Performance Mini Quad Frame | Enhanced structural integrity, often features reinforced joints | Racing, competitive sports | Pros: Superior durability, improved handling. Cons: Higher cost, may require expert assembly. |

| Electric Mini Quad Frame | Designed for electric motors, includes battery mounts | Urban commuting, eco-friendly markets | Pros: Environmentally friendly, low maintenance. Cons: Limited range compared to gas-powered models. |

| Adjustable Mini Quad Frame | Customizable height and width settings | Adaptive sports, varied user demographics | Pros: Versatile for different riders, easy adjustments. Cons: Complexity in design may increase costs. |

| Foldable Mini Quad Frame | Compact design for easy storage, often lightweight | Rental services, travel markets | Pros: Space-saving, portable. Cons: May compromise on sturdiness compared to fixed frames. |

What Are the Key Characteristics of Standard Mini Quad Frames?

Standard mini quad frames are typically constructed from steel or aluminum, making them lightweight yet sturdy. They are designed for recreational use and cater primarily to entry-level markets. B2B buyers should consider their cost-effectiveness and ease of assembly, making them ideal for businesses targeting novice riders. However, the limited customization options may not meet the needs of more advanced users.

How Do Performance Mini Quad Frames Differ from Standard Options?

Performance mini quad frames are engineered for enhanced structural integrity, often featuring reinforced joints to withstand higher stresses during racing or competitive sports. These frames are suitable for businesses involved in high-performance markets, as they offer superior durability and improved handling capabilities. While they provide significant advantages, the higher cost and potential need for expert assembly may deter budget-conscious buyers.

Illustrative image related to premade mini quad frame

What Advantages Do Electric Mini Quad Frames Offer?

Electric mini quad frames are specifically designed to accommodate electric motors and battery packs, making them ideal for urban commuting and eco-friendly markets. Their environmental benefits and low maintenance requirements appeal to B2B buyers focused on sustainability. However, businesses should be aware of the limited range compared to gas-powered models, which may affect customer satisfaction.

Why Choose Adjustable Mini Quad Frames for Varied User Demographics?

Adjustable mini quad frames allow for customizable height and width settings, making them versatile for different riders, including those with specific needs in adaptive sports. This adaptability is a significant selling point for businesses looking to cater to a broader audience. While the complexity of design may increase costs, the potential for attracting diverse customers can justify the investment.

What Are the Benefits of Foldable Mini Quad Frames?

Foldable mini quad frames are designed for easy storage and portability, making them an excellent option for rental services and travel markets. Their compact design allows businesses to maximize space, appealing to customers who prioritize convenience. However, potential buyers should consider that these frames may compromise sturdiness compared to fixed models, which could affect performance and safety.

Key Industrial Applications of premade mini quad frame

| Industry/Sector | Specific Application of premade mini quad frame | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Custom go-kart manufacturing | Reduces production time and costs | Material durability, weight capacity, and design flexibility |

| Recreational Vehicles | Mini quad bike assembly | Enhances product offerings in recreational markets | Compliance with safety standards and local regulations |

| Education | STEM education kits | Provides hands-on learning experiences | Cost-effectiveness and ease of assembly |

| Agriculture | Utility vehicle prototypes | Supports development of agricultural solutions | Adaptability to various terrains and load capacities |

| Entertainment | Racing events and competitions | Increases engagement and participation | Speed and performance specifications |

How Are Premade Mini Quad Frames Used in Automotive Customization?

In the automotive sector, premade mini quad frames are often utilized in custom go-kart manufacturing. These frames serve as the foundational structure for various go-kart designs, enabling manufacturers to streamline their production processes. By using a premade frame, businesses can significantly reduce assembly time and costs, allowing for quicker market entry. For international buyers, especially in regions like Africa and South America, sourcing durable and lightweight materials is crucial to withstand diverse environmental conditions while maintaining performance.

What Role Do Premade Mini Quad Frames Play in Recreational Vehicle Production?

Premade mini quad frames are integral in the assembly of mini quad bikes, which are popular in recreational markets. Manufacturers leverage these frames to enhance their product offerings, catering to a growing demand for off-road recreational vehicles. The frames facilitate easy customization and adaptation for various engine types and sizes. For buyers in the Middle East and Europe, compliance with safety standards and local regulations is paramount, ensuring that the final product meets consumer expectations and legal requirements.

How Are Mini Quad Frames Beneficial for Educational Purposes?

In the education sector, premade mini quad frames are increasingly used in STEM education kits, providing students with hands-on learning experiences in engineering and design. These kits allow educators to teach fundamental principles of mechanics and physics in an engaging manner. For international buyers, particularly in developing regions, sourcing cost-effective and easy-to-assemble kits can enhance educational programs and foster interest in technical fields among students.

Why Are Premade Mini Quad Frames Important for Agricultural Innovations?

In agriculture, premade mini quad frames are utilized to prototype utility vehicles tailored for specific farming applications. These frames support the development of innovative agricultural solutions, such as small transport vehicles for crop monitoring or pest control. For agricultural businesses, especially in diverse climates like those found in Africa, the adaptability of the frame to various terrains and load capacities is essential. Buyers need to consider the frame’s durability and performance to ensure reliability in challenging environments.

How Do Premade Mini Quad Frames Enhance Entertainment and Racing Events?

In the entertainment industry, premade mini quad frames are used to create racing vehicles for events and competitions. These frames enable event organizers to increase participant engagement by providing a platform for competitive racing. The speed and performance specifications of these frames can be tailored to meet the demands of various racing formats. For businesses involved in this sector, sourcing high-performance frames that comply with event regulations is critical to ensure safety and enhance the overall racing experience.

Illustrative image related to premade mini quad frame

3 Common User Pain Points for ‘premade mini quad frame’ & Their Solutions

Scenario 1: Difficulty in Finding Compatible Components for Mini Quad Frames

The Problem:

B2B buyers often face challenges when sourcing compatible components for their premade mini quad frames. This can arise from the diverse specifications and standards across different manufacturers. For instance, a buyer in Nigeria may find that the frame they purchased from a European supplier does not fit with the local engine types or other essential parts, leading to delays in production and increased costs. Additionally, the lack of comprehensive product information can make it difficult to ascertain compatibility before making a purchase, resulting in costly mistakes.

The Solution:

To overcome compatibility issues, it is crucial to conduct thorough research before purchasing. Start by creating a detailed inventory of the components needed for your mini quad frame, including engines, wheels, and suspension parts. Use this inventory to cross-reference with product specifications from different suppliers. Partner with suppliers who provide detailed technical drawings and compatibility charts to ensure that the components will work seamlessly together. Additionally, consider establishing relationships with local distributors who can provide insights into the best-fitting components available in your region. This proactive approach will help streamline the assembly process and reduce the likelihood of returns or modifications.

Scenario 2: Limited Availability of Quality Materials

The Problem:

Another common pain point for B2B buyers is the inconsistent availability of quality materials in the production of premade mini quad frames. Buyers from South America, for instance, may struggle to find frames made from durable materials that can withstand local terrain and conditions. Inconsistent quality can lead to product failures, customer dissatisfaction, and potential damage to the company’s reputation.

The Solution:

To mitigate the risks associated with material quality, buyers should prioritize suppliers who have a proven track record in manufacturing high-quality mini quad frames. Request samples of the frames to conduct physical inspections and stress tests to ensure they meet your durability standards. Additionally, consider suppliers that offer certifications or guarantees regarding their materials, such as those that comply with ISO standards. Establishing a robust quality assurance process, including regular audits of suppliers, can also help ensure that materials remain consistent over time. This diligence will help maintain product integrity and enhance customer satisfaction.

Scenario 3: Challenges in Customization and Modifications

The Problem:

B2B buyers often encounter difficulties when it comes to customizing premade mini quad frames to meet specific market demands. For example, a company in the Middle East may need to modify frames to accommodate different engine sizes or to enhance performance for specific off-road conditions. However, many suppliers provide limited customization options, leading to frustration and potentially lost sales opportunities.

The Solution:

To address customization challenges, buyers should seek suppliers who offer modular designs or customizable options for their mini quad frames. Engage in discussions with potential suppliers about your specific needs and see if they can accommodate custom orders. It’s also beneficial to collaborate with design engineers who can assist in modifying existing designs to better fit your requirements. Furthermore, consider investing in a prototyping process that allows for testing various configurations before committing to larger orders. By fostering a collaborative relationship with suppliers and leveraging engineering expertise, buyers can effectively tailor products to meet their market’s needs, driving sales and enhancing customer satisfaction.

Illustrative image related to premade mini quad frame

Strategic Material Selection Guide for premade mini quad frame

When selecting materials for premade mini quad frames, it is essential to consider various properties that affect performance, durability, and cost. Below is an analysis of four common materials used in the manufacturing of these frames, focusing on their key properties, advantages, disadvantages, and implications for international B2B buyers.

What are the Key Properties of Steel for Mini Quad Frames?

Steel is a widely used material for mini quad frames due to its strength and versatility. It typically offers high tensile strength, making it suitable for handling significant loads and impacts. Steel frames can endure high temperatures and pressures, providing excellent structural integrity under various conditions. However, steel is prone to corrosion if not properly treated, which can be a concern in humid or coastal environments.

Pros: Steel is durable, cost-effective, and relatively easy to manufacture. It can be welded and shaped into complex designs, making it suitable for custom applications.

Cons: The primary drawback is its weight, which can affect the overall performance of the quad. Additionally, without proper coatings or treatments, steel may suffer from rust and corrosion over time.

International Considerations: Buyers should ensure compliance with international standards such as ASTM A36 for structural steel. In regions like Africa and South America, where humidity can be high, selecting galvanized or stainless steel can mitigate corrosion issues.

How Does Aluminum Compare as a Material for Mini Quad Frames?

Aluminum is another popular choice, especially for those prioritizing lightweight designs. It has a lower density than steel, which can enhance speed and maneuverability. Aluminum exhibits good corrosion resistance, making it ideal for outdoor applications. However, it has a lower tensile strength compared to steel, which may limit its use in high-stress applications.

Pros: The lightweight nature of aluminum allows for better fuel efficiency and performance. It is also resistant to rust, which is advantageous in varying climates.

Cons: The primary limitation is its cost, as aluminum tends to be more expensive than steel. Additionally, aluminum can be more challenging to weld and may require specialized techniques.

International Considerations: Compliance with standards like ASTM B221 for aluminum extrusions is crucial. Buyers in regions like the Middle East may prefer aluminum for its resistance to corrosion in arid climates.

What Role Does Carbon Fiber Play in Mini Quad Frame Construction?

Carbon Fiber is a high-performance material known for its exceptional strength-to-weight ratio. It is significantly lighter than both steel and aluminum while providing superior rigidity. Carbon fiber frames can withstand high stress and impact, making them suitable for competitive applications. However, the manufacturing process is complex and costly.

Pros: The main advantage of carbon fiber is its lightweight nature combined with high strength, which enhances performance in racing and off-road scenarios.

Cons: The high cost and complexity of manufacturing carbon fiber frames can limit their accessibility for budget-conscious buyers. Additionally, carbon fiber is less impact-resistant than metals, making it susceptible to damage from sharp impacts.

International Considerations: Buyers should be aware of compliance with specific industry standards for carbon fiber materials. In regions like Europe, adherence to EN standards for composites is essential.

How Does Plastic Composite Material Affect Mini Quad Frame Design?

Plastic Composites are increasingly used in mini quad frames due to their lightweight and corrosion-resistant properties. These materials can be molded into intricate shapes, allowing for innovative designs. However, their mechanical properties may not match those of metals, particularly under high-stress conditions.

Pros: The primary advantage is the low weight and resistance to environmental factors such as moisture and UV radiation. This makes plastic composites suitable for recreational use.

Cons: The downside is that plastic composites may not provide the same level of strength or durability as metal frames, which can be a concern for heavy-duty applications.

International Considerations: Buyers should ensure compliance with relevant standards such as ASTM D638 for plastic materials. In regions like Brazil, where environmental regulations are stringent, selecting eco-friendly composites can also be beneficial.

Summary Table of Material Selection for Mini Quad Frames

| Material | Typical Use Case for premade mini quad frame | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | General-purpose frames | High strength and durability | Prone to corrosion without treatment | Low |

| Aluminum | Lightweight performance-focused frames | Lightweight and corrosion-resistant | Higher cost and more complex to manufacture | Medium |

| Carbon Fiber | High-performance racing frames | Exceptional strength-to-weight ratio | High cost and susceptible to impact damage | High |

| Plastic Composite | Recreational and lightweight frames | Lightweight and corrosion-resistant | Lower strength compared to metals | Medium |

This strategic material selection guide provides essential insights for international B2B buyers, helping them make informed decisions based on performance, cost, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for premade mini quad frame

What are the Key Stages in the Manufacturing Process of Premade Mini Quad Frames?

The manufacturing process for premade mini quad frames involves several critical stages, each essential for ensuring structural integrity and performance.

-

Material Preparation: The process begins with sourcing high-quality materials, typically steel or aluminum, known for their strength and lightweight properties. Suppliers should provide material certifications to verify that the materials meet industry standards. Pre-cutting and machining of raw materials are performed to achieve the necessary dimensions and specifications.

-

Forming: This stage involves various techniques such as bending, welding, and stamping. Advanced CNC (Computer Numerical Control) machines are often utilized for precision cutting and shaping. For welded frames, MIG (Metal Inert Gas) welding is commonly used due to its efficiency and strength. Ensuring uniformity in the forming process is crucial to maintain consistency across production batches.

-

Assembly: After forming, components are assembled to create the frame structure. This may involve the use of jigs and fixtures to hold parts in place during the welding process. The assembly stage must be meticulously managed to avoid misalignment, which can affect the final product’s performance.

-

Finishing: The finishing stage includes surface treatments such as powder coating or galvanizing to enhance durability and corrosion resistance. This step not only improves aesthetics but also extends the lifespan of the quad frames. Quality checks during this stage ensure that the finish is uniform and free from defects.

How is Quality Assurance Implemented in the Production of Mini Quad Frames?

Quality assurance (QA) is a vital component of the manufacturing process, ensuring that the final products meet or exceed industry standards.

-

International Standards: Adhering to recognized international standards like ISO 9001 is essential. This standard focuses on quality management systems and ensures consistent product quality. Additionally, compliance with industry-specific standards such as CE marking for safety in the EU or API (American Petroleum Institute) standards is crucial for buyers in different markets.

-

Quality Control Checkpoints:

– Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival. Buyers should expect suppliers to conduct tests for material properties and certifications.

– In-Process Quality Control (IPQC): During manufacturing, periodic inspections ensure that processes are followed correctly, and any deviations are addressed immediately. This includes verifying dimensions and the quality of welds.

– Final Quality Control (FQC): At the end of the production line, finished products undergo thorough inspections. This can include visual checks and functional tests to ensure that the frames meet specified performance criteria. -

Common Testing Methods: Various testing methods are employed throughout the manufacturing process. These can include:

– Non-Destructive Testing (NDT): Techniques such as ultrasonic testing or X-ray inspection help detect internal flaws without damaging the product.

– Destructive Testing: Samples may undergo stress tests to ensure they can withstand operational loads.

– Dimensional Checks: Utilizing calipers and gauges to confirm that all dimensions adhere to specified tolerances.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial for ensuring product reliability.

-

Supplier Audits: Conducting regular audits of suppliers can provide insight into their quality management systems and manufacturing processes. This can be done in person or through third-party auditing services that specialize in manufacturing quality assurance.

-

Quality Assurance Reports: Requesting detailed quality assurance reports from suppliers can help buyers assess compliance with international standards. These reports should outline quality control measures, test results, and any corrective actions taken for defects.

-

Third-Party Inspections: Engaging third-party inspection agencies can offer an unbiased assessment of the manufacturing process and product quality. These agencies can perform inspections at various stages of production, providing added assurance to buyers.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must be aware of specific nuances related to quality control that can vary by region.

-

Cultural Differences in Quality Expectations: Different regions may have varying standards and expectations regarding quality. For instance, European buyers may prioritize strict adherence to CE standards, while buyers from Africa may focus more on durability under harsh conditions. Understanding these differences can help buyers communicate their needs effectively.

-

Regulatory Compliance: Buyers should be informed about local regulations that may impact product requirements. For example, certain regions may mandate specific safety features or materials that need to be incorporated into the design of mini quad frames.

-

Logistical Considerations: International shipping introduces additional challenges related to quality control. Buyers should work with suppliers who have robust packaging and shipping processes to minimize the risk of damage during transit. Additionally, understanding the logistics of importing goods can help buyers navigate potential customs issues that might affect quality.

Conclusion

In summary, the manufacturing process and quality assurance for premade mini quad frames involve meticulous attention to detail, adherence to international standards, and effective communication between suppliers and buyers. By understanding the key stages of manufacturing and the importance of quality control, international B2B buyers can make informed decisions and establish partnerships that ensure high-quality products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘premade mini quad frame’

Introduction

Sourcing a premade mini quad frame can be a strategic move for businesses looking to enhance their product offerings in the recreational vehicle market. This guide provides a step-by-step checklist to help B2B buyers effectively procure mini quad frames, ensuring quality, compliance, and value for money. By following these steps, you can streamline your sourcing process and make informed purchasing decisions.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of a successful procurement process. Identify the dimensions, materials, weight capacity, and design features required for your mini quad frame. This will help you communicate effectively with suppliers and ensure that the products you receive meet your operational needs.

- Considerations: Include aspects such as frame geometry, mounting points for engines, and compatibility with other components.

- Documentation: Create a detailed specification sheet to share with potential suppliers.

Step 2: Research and Shortlist Suppliers

Conduct thorough research to identify potential suppliers who specialize in mini quad frames. Look for manufacturers with a proven track record in producing high-quality frames that meet your specifications.

- Sources: Utilize industry directories, trade shows, and online platforms to find reputable suppliers.

- Criteria: Focus on suppliers with positive reviews, solid customer service, and a history of timely deliveries.

Step 3: Evaluate Supplier Certifications

Before moving forward, verify that your shortlisted suppliers hold relevant certifications and comply with industry standards. Certifications such as ISO 9001 can indicate a commitment to quality management.

- Importance: Compliance ensures that the products meet safety and quality benchmarks, which is particularly crucial in the recreational vehicle market.

- Documentation Request: Ask suppliers to provide copies of their certifications and any compliance documentation.

Step 4: Request Samples

Requesting samples of the premade mini quad frames is a critical step in the evaluation process. This allows you to assess the quality, durability, and overall design of the frames.

Illustrative image related to premade mini quad frame

- Evaluation: Examine the samples for craftsmanship, material quality, and adherence to your specifications.

- Cost Consideration: Factor in any shipping costs associated with obtaining samples when budgeting.

Step 5: Negotiate Terms and Pricing

Once you are satisfied with the samples, initiate negotiations regarding pricing, payment terms, and lead times. Clear communication during this phase is essential to establish a mutually beneficial agreement.

- Pricing Structure: Inquire about bulk discounts, shipping costs, and potential hidden fees.

- Payment Terms: Discuss payment options and conditions, such as deposits or payment upon delivery.

Step 6: Finalize the Order and Confirm Delivery Details

After reaching an agreement, finalize your order and confirm all delivery details. Ensure that both parties have a clear understanding of the expectations regarding timelines and quantities.

- Documentation: Obtain a formal purchase order and confirm the delivery schedule in writing.

- Follow-Up: Establish a point of contact for any queries or updates throughout the delivery process.

Step 7: Conduct Quality Control Upon Receipt

Upon receiving the mini quad frames, conduct a thorough inspection to ensure they meet your specifications and quality standards. This step is vital to prevent issues down the line.

- Checklist: Use a quality control checklist to evaluate dimensions, finishes, and any other critical factors.

- Reporting Issues: If discrepancies are found, document them and communicate with the supplier for resolution.

By following this checklist, B2B buyers can navigate the complexities of sourcing premade mini quad frames with confidence, ensuring a successful procurement process that supports their business objectives.

Comprehensive Cost and Pricing Analysis for premade mini quad frame Sourcing

What Are the Key Cost Components for Premade Mini Quad Frames?

Understanding the cost structure of premade mini quad frames is crucial for international B2B buyers. The main cost components include:

-

Materials: The choice of materials significantly impacts the cost. Common materials include steel, aluminum, and composite materials. High-quality materials that offer durability and performance often come at a premium.

-

Labor: Labor costs can vary widely based on the region of production. Countries with lower wage rates may offer competitive pricing, but it’s essential to consider the skill level of the labor force, which can affect the quality of the finished product.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help minimize overhead costs, allowing for more competitive pricing.

-

Tooling: Tooling costs are associated with the machinery and tools required to produce mini quad frames. Custom tooling can be expensive but is necessary for producing unique designs or specifications.

-

Quality Control (QC): Implementing rigorous QC processes is vital to ensure product reliability. While this adds to the cost, it can prevent costly defects and returns, ultimately benefiting the buyer.

-

Logistics: Shipping and handling costs can vary significantly depending on the supplier’s location and the buyer’s destination. International shipping may involve customs duties and tariffs, which should be factored into the total cost.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure business viability. This margin can vary based on market competition and the supplier’s business model.

How Do Price Influencers Affect the Cost of Mini Quad Frames?

Several factors influence the pricing of premade mini quad frames:

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly affect pricing. Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should consider negotiating MOQs to align with their needs while optimizing costs.

-

Specifications and Customization: Custom designs and specifications can increase costs. Buyers should clearly define their requirements to avoid unexpected pricing changes later in the process.

-

Materials: The choice of materials not only affects durability but also pricing. Buyers should balance cost with the desired quality to ensure they get value for their investment.

-

Quality and Certifications: Frames that meet international quality standards or certifications may carry higher prices. However, these certifications can be critical for markets with stringent regulations.

-

Supplier Factors: The supplier’s reputation, reliability, and service quality can impact pricing. Established suppliers may charge more but offer better quality assurance and customer service.

-

Incoterms: Understanding Incoterms is vital for international buyers. They define the responsibilities of buyers and sellers in shipping and logistics, impacting overall costs. For example, choosing FOB (Free on Board) may lead to lower shipping costs compared to CIF (Cost, Insurance, and Freight).

What Are Effective Buyer Tips for Negotiating Prices on Mini Quad Frames?

To secure the best pricing on premade mini quad frames, international buyers should consider the following strategies:

-

Negotiation: Engage in open discussions with suppliers about pricing, especially if you have long-term purchasing plans. Building a strong relationship can lead to better terms.

-

Cost-Efficiency: Analyze the total cost of ownership, which includes purchase price, shipping, customs duties, and potential maintenance costs. This holistic view can help you make informed decisions.

-

Pricing Nuances for International Markets: Be aware of the unique market dynamics in regions like Africa, South America, the Middle East, and Europe. Factors such as local demand, currency fluctuations, and trade agreements can influence pricing.

-

Seek Multiple Quotes: Obtaining quotes from various suppliers allows for comparison and can provide leverage in negotiations. Ensure you are comparing similar specifications and terms to make an informed choice.

Disclaimer on Indicative Prices

Pricing for premade mini quad frames can fluctuate based on market conditions, material availability, and supplier pricing strategies. Therefore, the figures mentioned in this analysis are indicative and should not be considered fixed. Buyers are encouraged to conduct thorough market research and engage directly with suppliers to obtain accurate and up-to-date pricing information.

Illustrative image related to premade mini quad frame

Alternatives Analysis: Comparing premade mini quad frame With Other Solutions

Exploring Alternative Solutions to the Premade Mini Quad Frame

In the realm of mini quad frames, the premade option is a popular choice among manufacturers and hobbyists alike. However, various alternatives exist that can serve similar purposes. This analysis aims to provide B2B buyers with a comprehensive comparison of the premade mini quad frame against other viable solutions, enabling informed decision-making tailored to specific operational needs.

| Comparison Aspect | Premade Mini Quad Frame | Custom-Built Frame | Modular Frame Kits |

|---|---|---|---|

| Performance | High stability and durability for recreational use | Variable; can be optimized for specific performance needs | Moderate; depends on the components used |

| Cost | Higher initial investment | Variable costs depending on materials and labor | Moderate; costs depend on selected components |

| Ease of Implementation | Simple assembly; ready to use | Requires skilled labor for construction | User-friendly, but requires assembly skills |

| Maintenance | Generally low maintenance | Maintenance can be high depending on material choice | Moderate; dependent on quality of components |

| Best Use Case | Recreational and casual use | High-performance racing or custom applications | Versatile for DIY enthusiasts and small manufacturers |

What Are the Benefits and Drawbacks of a Custom-Built Frame?

Custom-built frames offer flexibility in design, allowing manufacturers to optimize performance for specific applications, such as racing or specialized recreational use. The primary advantage lies in tailoring the frame to meet precise specifications, which can enhance performance and durability. However, the drawbacks include potentially higher costs due to the need for skilled labor and custom materials, as well as longer lead times for production. This option is best suited for businesses with specific performance criteria or those willing to invest in a tailored solution.

How Do Modular Frame Kits Compare to Premade Mini Quad Frames?

Modular frame kits present a versatile option for DIY enthusiasts and small manufacturers who may prefer a hands-on approach. These kits typically come with a variety of components that can be assembled according to individual preferences, allowing for a degree of customization. The ease of assembly is a significant benefit, making it accessible for those with basic mechanical skills. However, the performance can vary based on the quality of components selected, and the assembly process may require time and patience. This solution works well for businesses looking to engage customers in the assembly process or for those needing a cost-effective alternative.

Making the Right Choice: Which Solution Should B2B Buyers Opt For?

When selecting the appropriate frame solution, B2B buyers should consider their operational needs, budget constraints, and the intended application of the quad frame. For those seeking a reliable, ready-to-use option with minimal maintenance, the premade mini quad frame is ideal. Conversely, businesses that prioritize high-performance specifications or wish to engage in a custom design process may find that a custom-built frame meets their needs better. Modular frame kits cater to those looking for flexibility and the ability to involve their customers in the assembly process.

In conclusion, understanding the strengths and weaknesses of each alternative enables buyers to make informed choices that align with their business goals. Whether opting for a premade mini quad frame, a custom-built solution, or a modular kit, aligning the choice with specific requirements will lead to greater satisfaction and operational success.

Essential Technical Properties and Trade Terminology for premade mini quad frame

What Are the Key Technical Properties of a Premade Mini Quad Frame?

When considering the purchase of premade mini quad frames, understanding the essential technical properties is crucial for ensuring compatibility, durability, and performance. Here are some critical specifications to consider:

-

Material Grade

The material used for the frame typically includes steel or aluminum. Steel frames are known for their strength and durability, making them suitable for rugged terrains. Aluminum, on the other hand, is lighter and resistant to corrosion, which can enhance the agility of the quad. Selecting the right material impacts the weight, strength, and overall performance of the vehicle, crucial for buyers focused on specific applications. -

Weld Quality and Tolerance

The precision of welds is vital for the structural integrity of the frame. High-quality welding ensures that the joints can withstand stress during operation. Tolerance levels specify how much deviation from the ideal measurements is acceptable, affecting the fit of components. Understanding these factors helps buyers assess the frame’s durability and performance under various conditions. -

Weight Capacity

Each mini quad frame is designed to support a specific weight limit, which includes both the rider and any additional cargo. Knowing the weight capacity is essential for safety and performance. Exceeding this limit can lead to frame deformation or failure, making this a key specification for commercial buyers. -

Dimensions

The frame dimensions, including length, width, and height, determine compatibility with various engines and components. Buyers must ensure that the dimensions align with their intended use and any existing parts they wish to integrate. Accurate dimensions are crucial for ensuring that the mini quad operates efficiently and safely. -

Finish and Coating

The surface finish of a mini quad frame, such as powder coating or paint, affects both aesthetics and durability. A good finish provides resistance to corrosion, abrasion, and UV damage, extending the frame’s lifespan. Buyers should consider the finish type based on the environmental conditions where the quad will be used. -

Assembly Requirements

Understanding the assembly requirements, including the need for additional hardware or tools, is essential for efficient setup. Some frames come pre-assembled, while others require complete assembly. This impacts the time and resources needed for deployment, particularly for businesses that prioritize quick turnaround times.

What Are Common Trade Terms in the Premade Mini Quad Frame Industry?

Familiarity with industry jargon is essential for effective communication and negotiation. Here are several common trade terms relevant to the procurement of premade mini quad frames:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce components that are used in another company’s end products. For buyers, understanding OEM specifications ensures they are sourcing parts that meet the original design standards, which is vital for maintaining product quality. -

MOQ (Minimum Order Quantity)

The minimum quantity that a supplier is willing to sell in a single order. Knowing the MOQ is crucial for budget management and inventory planning, especially for businesses looking to maintain a steady supply without overextending their resources. -

RFQ (Request for Quotation)

A document sent to suppliers requesting pricing and terms for specific products or services. An RFQ allows buyers to gather competitive pricing information and assess potential suppliers before making purchasing decisions. -

Incoterms (International Commercial Terms)

A set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping responsibilities, costs, and risks involved in importing frames from different countries. -

Lead Time

The amount of time from placing an order to receiving the product. Understanding lead times is essential for project planning and ensures that production schedules align with delivery timelines. -

Certification Standards

Certifications like ISO or CE indicate compliance with specific industry standards for safety and quality. Buyers should look for certified products to ensure they meet regulatory requirements and industry best practices.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing premade mini quad frames, ensuring that they meet their operational needs and quality expectations.

Navigating Market Dynamics and Sourcing Trends in the premade mini quad frame Sector

What Are the Key Market Drivers for Premade Mini Quad Frames?

The global market for premade mini quad frames is experiencing dynamic growth driven by several factors. The increasing popularity of recreational and utility vehicles, particularly among younger demographics in regions like Africa, South America, and the Middle East, is a major catalyst. These regions are witnessing a surge in demand for affordable and customizable quad frames, which facilitate both leisure and practical applications. Moreover, technological advancements in manufacturing processes are enabling suppliers to produce high-quality, lightweight, and durable frames that cater to various customer preferences.

Emerging B2B tech trends, such as digital marketplaces and e-commerce platforms, are also reshaping the sourcing landscape. International buyers are increasingly leveraging online platforms to connect with manufacturers and suppliers, streamlining their procurement processes. The integration of supply chain management software is enhancing inventory tracking and order fulfillment, providing real-time data that helps businesses make informed sourcing decisions. Additionally, the trend towards modular designs in quad frames allows for greater customization options, appealing to a broader audience.

How Is Sustainability Influencing the Sourcing of Premade Mini Quad Frames?

The emphasis on sustainability and ethical sourcing is becoming increasingly important in the premade mini quad frame sector. Environmental concerns regarding the manufacturing process and the lifecycle of materials used in production have led many companies to seek eco-friendly alternatives. Buyers are prioritizing suppliers who utilize sustainable materials, such as recycled metals and biodegradable composites, in their quad frame manufacturing.

Furthermore, obtaining green certifications can significantly enhance a supplier’s reputation in the market. Certifications such as ISO 14001 for environmental management or LEED for sustainable building practices not only demonstrate a commitment to minimizing environmental impact but also attract eco-conscious buyers. International buyers are encouraged to inquire about the sustainability practices of their suppliers and consider those who have transparent supply chains that align with ethical sourcing principles. This focus on sustainability not only contributes to a healthier planet but can also lead to cost savings through efficient resource management.

What Is the Historical Context of the Premade Mini Quad Frame Market?

The premade mini quad frame market has evolved significantly over the past few decades. Initially, quad frames were primarily custom-built by enthusiasts, limiting accessibility for the average consumer. However, as demand grew, manufacturers began to standardize production processes, making premade options available at competitive prices. The introduction of lightweight materials and advanced manufacturing techniques has further transformed the sector, allowing for enhanced performance and durability.

In recent years, the global market has seen an influx of players, particularly from Asia, which has driven innovation and cost reductions. This evolution has made it easier for international B2B buyers to source high-quality quad frames tailored to various needs, reflecting the shifting preferences of consumers and the growing importance of recreational vehicles in diverse markets. As the industry continues to adapt to consumer trends and technological advancements, the future of premade mini quad frames looks promising.

Frequently Asked Questions (FAQs) for B2B Buyers of premade mini quad frame

-

How do I ensure the quality of premade mini quad frames from suppliers?

To ensure the quality of premade mini quad frames, conduct thorough supplier vetting. Request samples and certifications to verify compliance with international standards. Additionally, consider suppliers that provide detailed specifications and quality assurance processes. Regular audits and inspections during production can further guarantee the quality of the frames. Establishing a clear communication channel with the supplier will help address any concerns promptly. -

What is the best material for premade mini quad frames?

The best materials for premade mini quad frames are typically high-strength steel or aluminum. Steel offers durability and strength, making it ideal for off-road applications, while aluminum provides a lighter frame, enhancing speed and maneuverability. When selecting materials, consider the intended use, weight requirements, and environmental conditions. Ensure that your supplier can provide detailed material specifications to meet your performance needs. -

What customization options are available for premade mini quad frames?

Many suppliers offer customization options for premade mini quad frames, including size, color, and design features. You can request specific modifications such as additional mounting points or adjustments to frame geometry. Discuss your requirements with the supplier to understand the extent of customization they can provide. Be aware that significant alterations may affect lead times and pricing. -

What is the minimum order quantity (MOQ) for premade mini quad frames?

Minimum order quantities (MOQs) for premade mini quad frames vary by supplier and can range from a few units to several hundred. It’s essential to clarify the MOQ with potential suppliers early in discussions. Some manufacturers may offer flexibility for first-time buyers or bulk orders, so negotiating based on your purchasing needs could lead to better terms. -

What payment terms should I expect when sourcing mini quad frames internationally?

Payment terms for international purchases of mini quad frames can vary significantly. Common arrangements include a deposit upfront (usually 30% to 50%) with the balance due before shipment or upon delivery. Some suppliers may offer credit terms for established buyers. Always ensure that payment terms are documented clearly in your purchase agreement to avoid any misunderstandings. -

How can I navigate international shipping logistics for mini quad frames?

Navigating international shipping logistics involves understanding customs regulations, freight options, and delivery times. Collaborate with your supplier to determine the best shipping method, whether air or sea freight, based on urgency and cost. Ensure all necessary documentation, such as invoices and customs declarations, is prepared in advance. Working with a logistics partner familiar with your destination country’s regulations can streamline the process. -

What certifications should I look for when sourcing mini quad frames?

When sourcing mini quad frames, look for certifications that demonstrate compliance with safety and quality standards. Common certifications include ISO 9001 for quality management systems and CE marking for compliance with European safety regulations. Additionally, check for specific certifications relevant to your target market, such as ASTM standards in the US. These certifications can help ensure that the products meet industry expectations. -

How do I handle disputes with suppliers regarding mini quad frame orders?

Handling disputes with suppliers requires clear communication and documentation. Start by discussing the issue directly with your supplier to seek an amicable resolution. If needed, refer to your contract to clarify terms and responsibilities. If a resolution cannot be reached, consider mediation or arbitration as alternatives to litigation. Maintaining a professional relationship and documenting all communications can facilitate smoother dispute resolution processes.

Top 5 Premade Mini Quad Frame Manufacturers & Suppliers List

1. GoPowerSports – Frame Kits and Parts

Domain: gopowersports.com

Registered: 2003 (22 years)

Introduction: Frame Kits include various options such as Bolt Go-Kart Kits, Go-Kart Plans, Mini Bike Kits, and specific models like Lil’ Rascal Minibike Kits, Mega Moto Minibike Kits, and Rascal GT Minibike Kits. The product range also features Weld On Frame Parts and is compatible with brands like GoPowerSports, Manco, Comet, and Tillotson. Specific components mentioned include frame groups, steering assemblie…

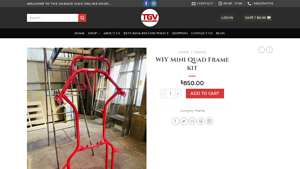

2. The Garage Vlog Shop – Lightweight Mini Quad Frame Kit

Domain: thegaragevlogshop.com

Registered: 2024 (1 years)

Introduction: Lightweight Mini Quad Frame Kit for Mini Quad Bikes, Price: $850.00, Category: Frames, Key Features: Durable materials (aluminum or carbon fiber), easy assembly and disassembly, compatibility with various components, includes necessary hardware, designed for stability and handling. Key Components: Main frame, arms, shock mounts, battery trays, motor mounts, landing gear. Frame Thickness Options: 3…

3. Progressive RC – Free Shipping & Easy Returns

Domain: progressiverc.com

Registered: 2007 (18 years)

Introduction: This company, Progressive RC – Free Shipping & Easy Returns, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Go Karts USA – American Racer 215 Minibike Frame

Domain: gokartsusa.com

Registered: 2003 (22 years)

Introduction: Go Kart Frames and Mini Bike Frames available for purchase. Key products include:

1. American Racer 215 Minibike Frame – $395.00, accommodates Honda GX200 Engine, heavy-duty frame, 5-degree engine mount.

2. AFX Mini Bike Fenders – $32.35, fits 8 in. wheels, includes mounting holes.

3. Drag Daddy 44 Dragster Mini Bike Kit – $916.92, designed for track use, features double loop frame, 1 inch mild s…

5. Facebook – Mini Quad Frame Kits

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Mini Quad Frame Kits, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for premade mini quad frame

In summary, the strategic sourcing of premade mini quad frames presents significant opportunities for international B2B buyers. By leveraging a global supply chain, businesses can access high-quality products that meet diverse market demands while optimizing costs. The importance of establishing strong relationships with manufacturers cannot be overstated; it ensures not only competitive pricing but also reliability in supply and quality assurance.

To enhance procurement strategies, buyers should focus on suppliers that offer customization options and robust support services. Engaging with manufacturers who understand regional compliance and market trends can provide an added advantage, particularly in dynamic regions like Africa, South America, the Middle East, and Europe.

As you navigate this evolving landscape, consider how strategic sourcing can elevate your product offerings and expand your market reach. Take proactive steps today to explore partnerships that align with your business goals and drive innovation in your offerings. The future of the mini quad frame market is ripe with potential—position your business to capitalize on it.

Illustrative image related to premade mini quad frame

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to premade mini quad frame