A Deep Dive into In-Line Flow Switch Solution

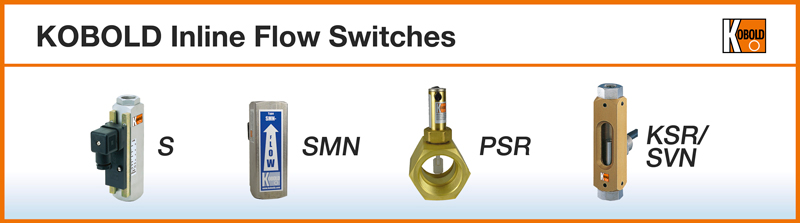

Introduction: Navigating the Global Market for in-line flow switch

In the ever-evolving landscape of industrial automation, sourcing reliable in-line flow switches presents a significant challenge for B2B buyers across the globe. The need for precision in monitoring fluid flow is paramount, especially in sectors such as manufacturing, water treatment, and HVAC. This comprehensive guide is designed to equip international buyers, particularly those from emerging markets in Africa, South America, the Middle East, and Europe—including Nigeria and Brazil—with the knowledge necessary to navigate the complexities of sourcing in-line flow switches.

Within this guide, we delve into various types of in-line flow switches, their applications across different industries, and the critical factors to consider when selecting a supplier. We provide insights on how to effectively vet suppliers to ensure product quality and reliability, along with a detailed analysis of costs associated with different types of flow switches. By empowering buyers with this information, we aim to facilitate informed purchasing decisions that enhance operational efficiency and reduce downtime.

As you explore the intricacies of in-line flow switches, you will find actionable insights that not only address your immediate sourcing needs but also position your business for sustained success in an increasingly competitive global market.

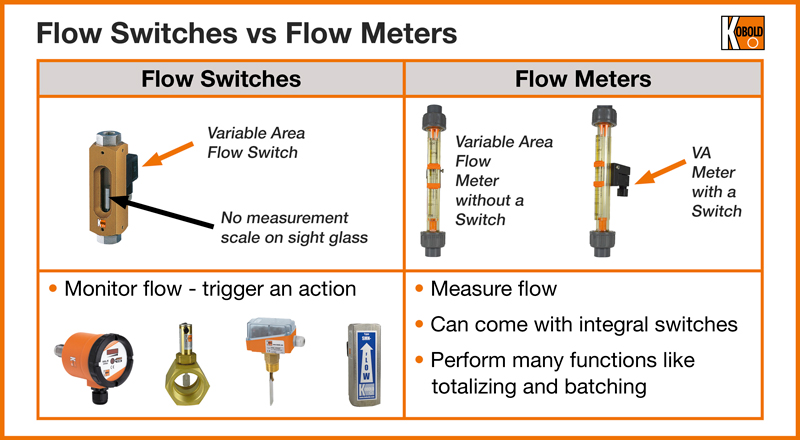

Understanding in-line flow switch Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Paddle Wheel Flow Switch | Utilizes a rotating paddle to detect flow; compact design. | Water treatment, HVAC systems, chemical processing. | Pros: Compact, reliable for moderate flow rates. Cons: Limited to certain flow conditions. |

| Vane Flow Switch | Employs a vane that moves with flow; suitable for larger pipes. | Industrial pumps, cooling systems, HVAC. | Pros: Versatile for various pipe sizes, robust. Cons: More complex installation and maintenance. |

| Thermal Dispersion Flow Switch | Measures flow via thermal sensors; ideal for low flow detection. | Chillers, boilers, and filtration systems. | Pros: High sensitivity, adjustable settings. Cons: May not be suitable for high-viscosity fluids. |

| Positive Displacement Flow Switch | Operates by measuring the volume of fluid; very accurate. | Food and beverage, pharmaceuticals. | Pros: High accuracy, excellent for low flow rates. Cons: Higher cost, requires regular calibration. |

| Magnetic Flow Switch | Uses magnetic fields to detect flow; non-intrusive. | Water and wastewater management, chemical processing. | Pros: Non-invasive, suitable for various fluids. Cons: Requires specific fluid characteristics for accuracy. |

What Are the Characteristics of Paddle Wheel Flow Switches?

Paddle wheel flow switches are designed with a rotating paddle that detects flow through mechanical movement. They are compact and ideal for applications where space is limited, such as in water treatment facilities and HVAC systems. When considering a paddle wheel flow switch, B2B buyers should evaluate the flow range and ensure compatibility with their existing systems. While they are reliable for moderate flow rates, they may not perform optimally under extreme conditions.

How Do Vane Flow Switches Operate and Where Are They Used?

Vane flow switches utilize a vane that pivots in response to fluid flow, making them suitable for larger pipe diameters. These switches are commonly found in industrial pumps and cooling systems, where they provide robust performance. Buyers should consider the installation complexity and potential maintenance needs, as vane flow switches can be more intricate than simpler designs. Their versatility in handling various pipe sizes is a significant advantage, but they require careful consideration for specific applications.

What Makes Thermal Dispersion Flow Switches Unique?

Thermal dispersion flow switches operate by detecting changes in temperature caused by fluid flow, making them particularly effective for low flow detection. They are frequently used in applications such as chillers and boilers. B2B buyers should assess the sensitivity and adjustability of these switches, especially in systems requiring precise flow monitoring. While they offer high sensitivity, their effectiveness may diminish with high-viscosity fluids, which is a crucial consideration for industries like food processing.

Why Choose Positive Displacement Flow Switches?

Positive displacement flow switches measure the volume of fluid passing through, offering exceptional accuracy and reliability. They are particularly well-suited for industries requiring precise flow measurement, such as food and beverage or pharmaceuticals. Buyers must be aware of the higher costs associated with these switches and the need for regular calibration to maintain accuracy. Their ability to handle low flow rates effectively makes them a popular choice in high-precision applications.

What Are the Benefits and Limitations of Magnetic Flow Switches?

Magnetic flow switches operate using magnetic fields to detect the flow of conductive fluids without direct contact, making them non-intrusive. They are widely used in water and wastewater management and chemical processing. B2B buyers should consider the specific fluid characteristics required for optimal performance, as these switches may not work effectively with non-conductive fluids. While their non-invasive nature is a significant benefit, ensuring compatibility with the fluid type is essential for reliable operation.

Key Industrial Applications of in-line flow switch

| Industry/Sector | Specific Application of in-line flow switch | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Water Treatment | Monitoring flow in filtration systems | Ensures optimal filtration efficiency and reduces downtime. | Compatibility with various water types and required certifications. |

| Oil and Gas | Flow monitoring in pipeline systems | Enhances safety by detecting leaks and maintaining flow rates. | High pressure and temperature ratings, and chemical resistance. |

| Food and Beverage | Flow control in ingredient processing | Guarantees accurate ingredient proportions for product quality. | Compliance with food safety regulations and material certifications. |

| HVAC Systems | Flow detection in heating and cooling systems | Improves energy efficiency and system reliability. | Operating temperature range and environmental ratings (NEMA). |

| Chemical Processing | Monitoring flow in chemical mixing and transfer | Prevents overflows and maintains process integrity. | Material compatibility with various chemicals and safety certifications. |

How is an in-line flow switch used in water treatment applications?

In water treatment facilities, in-line flow switches are crucial for monitoring the flow of water through filtration systems. They ensure that the water flow remains within specified parameters, optimizing filtration efficiency and preventing system overloads. For buyers in regions such as Nigeria or Brazil, sourcing switches that can withstand varying water qualities and comply with local environmental regulations is essential to maintain effective operations and regulatory compliance.

What role do in-line flow switches play in the oil and gas industry?

In the oil and gas sector, in-line flow switches are employed to monitor fluid flow in pipelines, ensuring safety and operational efficiency. These devices can detect leaks or flow interruptions, allowing for immediate corrective actions to prevent hazardous situations. International buyers should prioritize flow switches with high pressure and temperature ratings, as well as robust chemical resistance, to ensure reliability in harsh environments common in oil and gas operations.

How do in-line flow switches enhance food and beverage processing?

In the food and beverage industry, in-line flow switches are vital for controlling the flow of ingredients during processing. They help maintain accurate proportions, ensuring product consistency and quality. Buyers in this sector must consider sourcing switches that comply with food safety regulations, including materials that are FDA-approved, to guarantee that they meet hygiene standards and avoid contamination risks.

Why are in-line flow switches important for HVAC systems?

In HVAC systems, in-line flow switches monitor the flow of air and liquids, ensuring optimal performance of heating and cooling units. By detecting flow conditions, these switches help improve energy efficiency and system reliability, contributing to lower operational costs. When sourcing these devices, buyers should look for models with appropriate temperature ratings and environmental protection standards, such as NEMA ratings, to ensure durability in diverse climates.

How do in-line flow switches contribute to chemical processing?

In chemical processing, in-line flow switches are essential for monitoring the flow of various chemicals during mixing and transfer operations. They prevent overflow and ensure that processes remain within safe operational limits, protecting both equipment and personnel. Buyers in this industry need to consider the compatibility of flow switches with specific chemicals and ensure that they have the necessary safety certifications to comply with industry regulations.

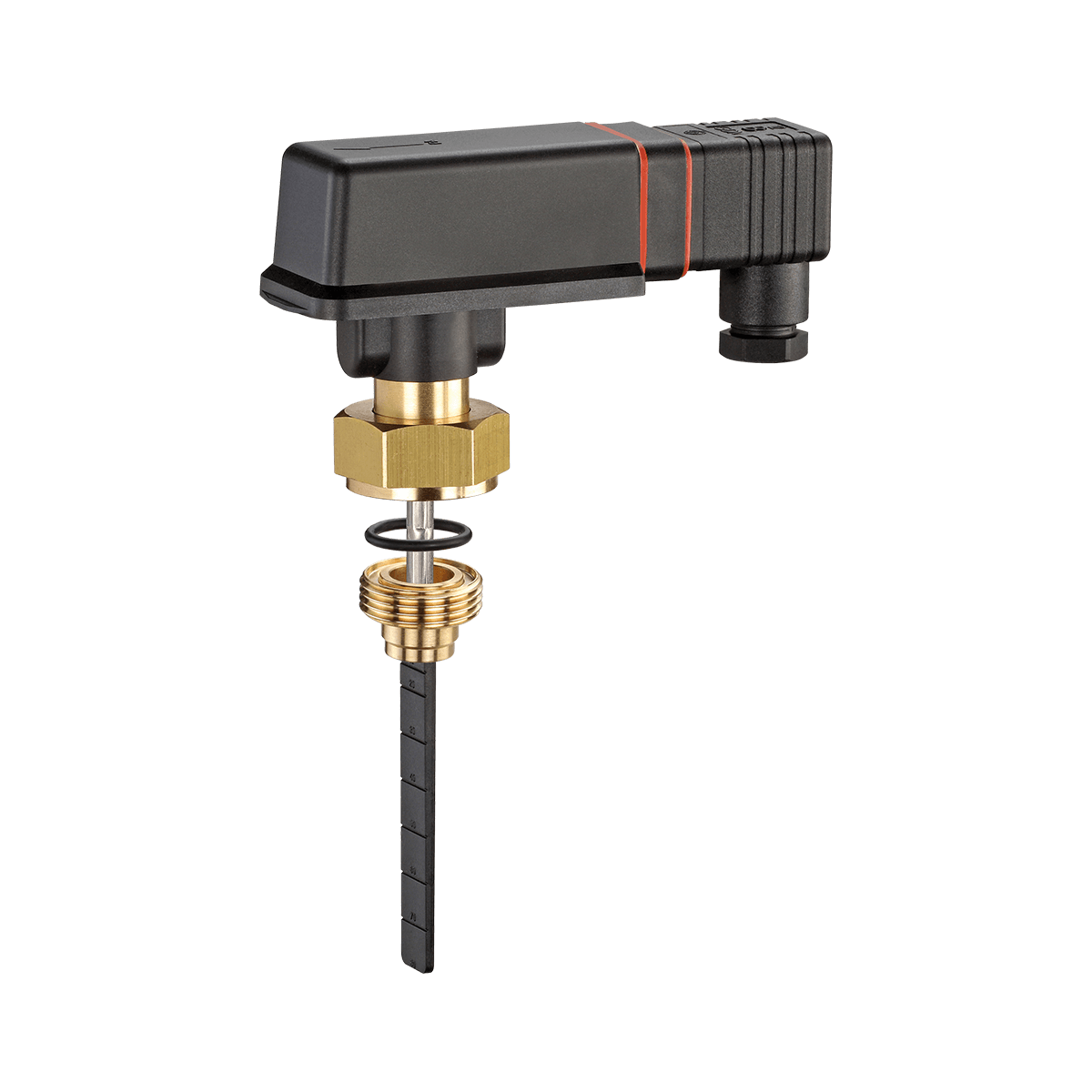

Illustrative image related to in-line flow switch

3 Common User Pain Points for ‘in-line flow switch’ & Their Solutions

Scenario 1: Inaccurate Flow Measurements Leading to System Failures

The Problem: Many B2B buyers face the challenge of inaccurate flow measurements due to poor-quality or improperly calibrated in-line flow switches. This can result in equipment failures, system inefficiencies, and increased operational costs. For instance, in a manufacturing plant, if the flow switch does not accurately detect the fluid flow rate, it may lead to pump cavitation or overheating, causing extensive downtime and costly repairs. Buyers often find themselves frustrated when they realize that their equipment is not performing optimally due to unreliable flow measurements.

The Solution: To mitigate these risks, it is crucial to source high-quality in-line flow switches that are appropriate for the specific application. Buyers should prioritize devices with adjustable calibration settings and high accuracy ratings. When selecting a flow switch, consider factors such as the type of media being measured, the required flow range, and the environmental conditions. It’s advisable to consult with manufacturers to understand their calibration processes and request data sheets that detail the accuracy specifications. Regular maintenance and recalibration of flow switches can also enhance reliability; implement a routine check every six months to ensure accurate performance.

Scenario 2: Difficulty in Integration with Existing Systems

The Problem: Another common issue for B2B buyers is the challenge of integrating new in-line flow switches with existing systems. Many industrial environments utilize legacy equipment, and finding flow switches that are compatible with these systems can be a daunting task. Buyers often encounter issues such as mismatched connection sizes, incompatible signal outputs, or even software integration problems. This not only delays project timelines but also adds unanticipated costs due to the need for additional adapters or modifications.

The Solution: To streamline the integration process, buyers should conduct thorough compatibility assessments before purchasing new flow switches. This includes evaluating the existing system’s specifications and identifying the required connection types, sizes, and signal outputs. Engage with suppliers who offer a range of customizable options and technical support. It may also be beneficial to opt for modular flow switches that allow for various configurations and can be adjusted to fit different setups. Additionally, consider partnering with a systems integrator who specializes in flow measurement technologies; they can help ensure seamless integration and offer solutions tailored to specific operational needs.

Scenario 3: High Maintenance Costs and Downtime

The Problem: High maintenance costs and unplanned downtime are significant pain points for businesses using in-line flow switches. Over time, wear and tear, especially in harsh industrial environments, can lead to frequent failures. This not only incurs high replacement costs but also disrupts production schedules, ultimately impacting profitability. B2B buyers often struggle to justify the expense of premium flow switches when faced with these ongoing maintenance issues.

The Solution: To reduce maintenance costs and enhance the longevity of in-line flow switches, buyers should invest in durable models designed for specific environmental conditions. Look for features such as robust materials that resist corrosion and wear, and choose flow switches that have proven track records in similar applications. Implementing a predictive maintenance strategy can also be beneficial; using data analytics to monitor flow switch performance will help identify potential issues before they lead to failures. Additionally, establish a maintenance contract with the supplier for regular inspections and servicing, which can prevent unexpected breakdowns and extend the life of the equipment.

Strategic Material Selection Guide for in-line flow switch

What Are the Key Materials Used in In-line Flow Switches?

In-line flow switches are critical components in various industrial applications, and the choice of material significantly impacts their performance and durability. Below, we analyze four common materials used in the construction of in-line flow switches, focusing on their properties, advantages, disadvantages, and implications for international buyers.

How Does Stainless Steel Perform in In-line Flow Switches?

Stainless steel is a popular choice for in-line flow switches due to its excellent corrosion resistance and high strength. It typically has a temperature rating of up to 200°C and can withstand high pressures, making it suitable for demanding environments. The primary advantage of stainless steel is its durability; it can endure harsh chemicals and extreme conditions without degrading.

However, stainless steel can be relatively expensive compared to other materials, which may impact the overall cost of the flow switch. Additionally, manufacturing processes involving stainless steel can be complex, leading to longer lead times. For international buyers, compliance with standards such as ASTM and DIN is crucial, especially in regions like Europe and the Middle East, where stringent regulations are common.

What Role Does PVC Play in In-line Flow Switches?

Polyvinyl chloride (PVC) is widely used in applications where cost-effectiveness is a priority. It is lightweight and offers good chemical resistance, particularly against acids and bases, making it suitable for water treatment and chemical processing applications. PVC flow switches typically operate effectively at temperatures up to 60°C and pressures around 10 bar.

The main advantage of PVC is its low cost, which makes it an attractive option for budget-conscious projects. However, its limitations include lower temperature and pressure ratings compared to metals, which may restrict its use in high-performance applications. For buyers in regions like Africa and South America, where cost constraints are often significant, PVC can be a viable option, but they should be aware of potential limitations in extreme conditions.

How Does Brass Compare in In-line Flow Switch Applications?

Brass is another common material used in in-line flow switches, favored for its good mechanical properties and resistance to corrosion, particularly in water applications. It typically supports temperatures up to 120°C and moderate pressures, making it suitable for various industrial applications, including HVAC and plumbing.

One of the key advantages of brass is its excellent machinability, allowing for intricate designs and customizations. However, brass can be more expensive than plastic options and may not be suitable for highly corrosive environments. International buyers should consider local regulations regarding brass usage, particularly in the food and beverage industry, where compliance with standards like FDA and EU regulations is essential.

What Are the Benefits of Using Polypropylene in In-line Flow Switches?

Polypropylene is a thermoplastic material known for its excellent chemical resistance and lightweight properties. It is commonly used in applications involving corrosive chemicals, such as in the chemical processing industry. Polypropylene flow switches typically have a temperature rating of up to 80°C and can handle moderate pressures.

The primary advantage of polypropylene is its resistance to a wide range of chemicals, making it ideal for specialized applications. However, its mechanical strength is lower than that of metals, which may limit its use in high-pressure scenarios. For international buyers, especially in regions with diverse industrial needs, polypropylene can be an effective material choice, provided that the application does not exceed its physical limitations.

Summary of Material Selection for In-line Flow Switches

| Material | Typical Use Case for in-line flow switch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | High-pressure and high-temperature applications | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| PVC | Water treatment and chemical processing | Cost-effective and lightweight | Limited temperature and pressure ratings | Low |

| Brass | HVAC and plumbing systems | Good machinability and corrosion resistance | More expensive and not suitable for highly corrosive environments | Med |

| Polypropylene | Chemical processing and corrosive environments | Excellent chemical resistance | Lower mechanical strength | Med |

In conclusion, selecting the appropriate material for in-line flow switches is crucial for ensuring optimal performance and longevity. Buyers should carefully consider the specific requirements of their applications, including environmental conditions and compliance with regional standards, to make informed purchasing decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for in-line flow switch

What Are the Key Stages in the Manufacturing Process of In-line Flow Switches?

The manufacturing process for in-line flow switches involves several critical stages, each designed to ensure that the final product meets high-performance standards. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation

The first step in manufacturing in-line flow switches is the selection and preparation of materials. Common materials include stainless steel, brass, and various polymers, chosen for their durability and compatibility with different media. Quality raw materials are sourced from reputable suppliers, and incoming materials undergo inspection to ensure they meet specified standards. This is often the first checkpoint in the quality control process. -

Forming Techniques

Various techniques are employed to shape the materials into components of the flow switch. For metal components, processes such as CNC machining, stamping, and casting are commonly used. Plastic components may be produced through injection molding. Precision in these forming techniques is crucial to ensure that the components fit together correctly, contributing to the overall efficiency and accuracy of the flow switch. -

Assembly Process

Once the individual components are formed, they are assembled into the final flow switch unit. This may involve both manual and automated processes. During assembly, critical components such as sensors, actuators, and electronic displays are integrated. The assembly line typically includes several quality checkpoints where components are verified for proper fit and functionality. -

Finishing Techniques

The final stage of manufacturing involves finishing processes that enhance the product’s durability and appearance. This may include surface treatments such as anodizing, plating, or applying protective coatings. Additionally, final assembly may include the installation of seals and gaskets to ensure leak-proof operation. Finishing not only improves the aesthetic quality but also extends the lifespan of the flow switch.

How Is Quality Assurance Implemented in the Manufacturing of In-line Flow Switches?

Quality assurance (QA) is integral to the manufacturing of in-line flow switches, ensuring that products meet both internal and external standards. The implementation of QA involves adherence to international standards, systematic checkpoints, and rigorous testing methods.

-

Adherence to International Standards

Most manufacturers of in-line flow switches comply with international quality standards such as ISO 9001, which outlines requirements for a quality management system. Certifications such as CE mark, which indicates conformity with health, safety, and environmental protection standards, and API standards for products used in the oil and gas sector, are also common. These certifications not only assure product quality but also facilitate market access, particularly in regions like Europe, Africa, and South America. -

Quality Control Checkpoints

Quality control is typically structured around three main checkpoints:

– Incoming Quality Control (IQC): This stage involves the inspection of raw materials and components upon arrival at the manufacturing facility. Materials that do not meet specifications are rejected.

– In-Process Quality Control (IPQC): During the manufacturing process, ongoing checks are conducted to monitor the quality of components and assemblies. This ensures that any defects are identified and rectified promptly.

– Final Quality Control (FQC): Before shipment, each in-line flow switch undergoes a final inspection to verify functionality, performance, and compliance with specified standards. This may involve pressure testing, flow testing, and electrical testing. -

Testing Methods for In-line Flow Switches

Common testing methods include:

– Hydraulic Testing: To ensure that the flow switch can withstand the pressure of the media it will monitor.

– Flow Calibration: To verify that the flow switch accurately detects and responds to flow changes.

– Electrical Testing: To ensure that electronic components function correctly and safely.

– Environmental Testing: To assess the product’s performance under various environmental conditions, including temperature extremes and humidity.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For B2B buyers, particularly in international markets, verifying a supplier’s quality control measures is critical to ensuring product reliability and compliance. Here are several strategies to effectively assess supplier quality:

-

Supplier Audits

Conducting supplier audits is one of the most effective ways to evaluate quality control processes. This can include both on-site visits and remote assessments. During an audit, buyers can review the manufacturer’s quality management systems, inspection protocols, and compliance with international standards. -

Requesting Quality Reports

Buyers should request documentation that outlines the supplier’s quality control processes, including inspection reports, testing results, and certifications. This documentation should provide insight into the supplier’s adherence to standards and their ability to maintain consistent quality. -

Third-Party Inspections

Engaging a third-party inspection agency can provide an unbiased assessment of the manufacturer’s quality control practices. These agencies can conduct random checks during production and final inspections before shipment, ensuring that the products meet the agreed-upon specifications. -

Understanding QC and Certification Nuances

It is essential for buyers to be aware of the specific certifications and quality control nuances relevant to their region. For instance, CE certification is vital for products entering the European market, while UL certification may be required for electrical components in North America. Buyers should confirm that suppliers possess the necessary certifications for their target markets, especially when sourcing from regions with differing regulatory environments, such as Africa or South America.

Conclusion

In-line flow switches play a crucial role across various industries, and understanding the manufacturing processes and quality assurance measures is essential for B2B buyers. By focusing on material preparation, forming techniques, assembly processes, and rigorous quality control standards, buyers can make informed decisions. Moreover, implementing effective verification strategies will ensure that suppliers maintain high quality and compliance, ultimately leading to reliable and efficient operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘in-line flow switch’

In the competitive landscape of B2B procurement, sourcing an in-line flow switch requires a structured approach to ensure quality, reliability, and compatibility with your specific applications. This checklist serves as a practical guide to navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Before beginning your search, clearly outline the technical requirements for the in-line flow switch. Consider factors such as flow rate, media compatibility, operating temperature, and pressure ratings. This step is crucial as it ensures that the chosen switch meets the operational demands of your application.

- Flow Rate: Determine the expected flow range to ensure the switch can handle your specific requirements.

- Temperature and Pressure: Specify maximum and minimum operating conditions to avoid equipment failure.

Step 2: Research and Shortlist Potential Suppliers

Conduct thorough research to identify suppliers that specialize in in-line flow switches. Look for companies with a strong reputation in your industry and geographical area.

- Industry Experience: Prioritize suppliers with a proven track record in similar applications or industries.

- Product Range: A diverse product range indicates a supplier’s capability to meet various needs, enhancing your options.

Step 3: Evaluate Supplier Certifications and Standards

Verify that potential suppliers adhere to industry standards and possess relevant certifications. This step is critical to ensure product quality and compliance with regulations.

- ISO Certifications: Look for ISO 9001 or other quality management certifications, which indicate a commitment to quality control.

- Local Compliance: Ensure the products meet local regulatory requirements, especially if you’re sourcing from international suppliers.

Step 4: Request Samples and Technical Documentation

Before making a bulk order, request samples of the in-line flow switches along with detailed technical documentation. This allows you to assess the product quality firsthand.

- Sample Testing: Conduct tests under your operational conditions to verify performance.

- Documentation Review: Analyze data sheets and manuals to ensure proper installation and maintenance.

Step 5: Assess Pricing and Payment Terms

Gather pricing information from your shortlisted suppliers and compare it against your budget. Understanding payment terms is also essential for financial planning.

- Cost Comparison: Evaluate the total cost of ownership, including shipping and handling, not just the unit price.

- Flexible Payment Options: Seek suppliers who offer favorable payment terms that align with your cash flow.

Step 6: Check Customer Support and After-Sales Service

Evaluate the level of customer support and after-sales service provided by potential suppliers. Reliable support can significantly impact your experience post-purchase.

- Technical Support: Ensure the supplier offers accessible technical support for installation and troubleshooting.

- Warranty and Returns Policy: Review warranty terms and the return process in case of defective products.

Step 7: Finalize the Purchase Agreement

Once you have assessed all factors, proceed to finalize the purchase agreement with your chosen supplier. Ensure all terms are clearly defined to avoid misunderstandings.

- Contract Clarity: Include detailed specifications, delivery timelines, and payment terms in the agreement.

- Legal Review: Consider having your legal team review the contract to safeguard your interests.

By following this step-by-step checklist, you can streamline the sourcing process for in-line flow switches, ensuring you make informed decisions that meet your operational needs and budget constraints.

Comprehensive Cost and Pricing Analysis for in-line flow switch Sourcing

What Are the Key Cost Components for Sourcing In-Line Flow Switches?

When evaluating the cost structure for sourcing in-line flow switches, several components play a significant role. The primary cost elements include:

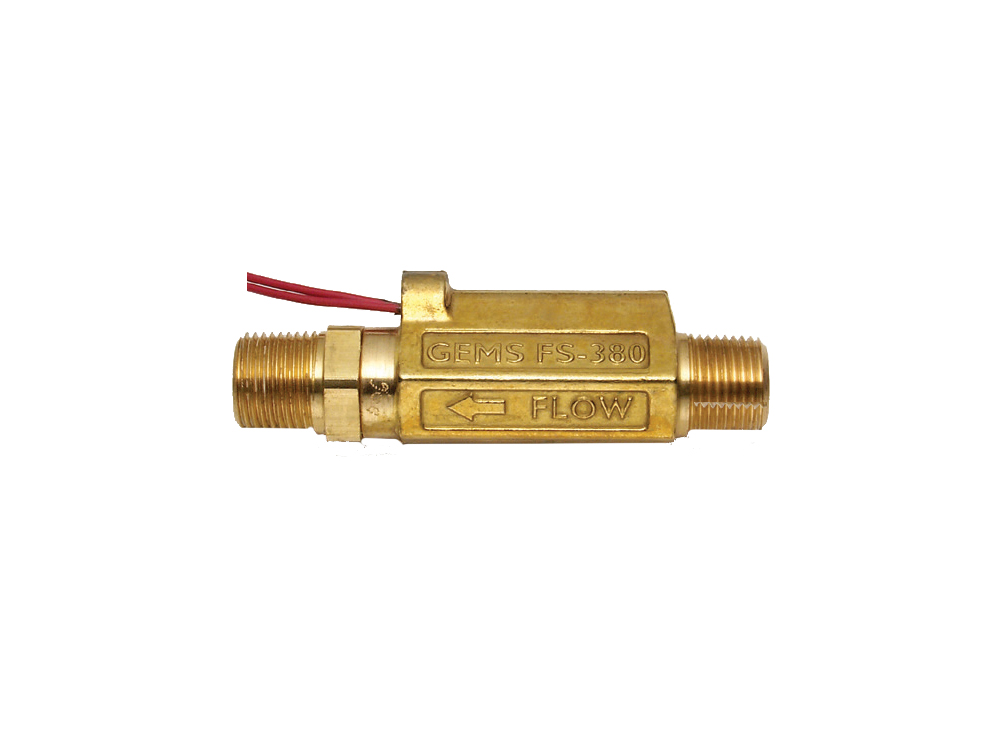

Illustrative image related to in-line flow switch

-

Materials: The choice of materials significantly impacts pricing. High-quality stainless steel or specialized plastics used in flow switches can lead to higher costs, but they often ensure better durability and performance.

-

Labor: Labor costs vary depending on the manufacturing location. Countries with lower labor costs may offer competitive pricing, but quality assurance and craftsmanship must be considered to avoid future operational issues.

-

Manufacturing Overhead: This encompasses costs related to factory operations, including utilities, equipment maintenance, and administrative expenses. Efficient manufacturing processes can reduce overhead, thus lowering overall costs.

-

Tooling: Custom tooling for specific designs can be a significant upfront investment. Buyers should consider whether the tooling costs can be amortized over large orders to reduce per-unit costs.

-

Quality Control (QC): Investing in quality control measures is essential for ensuring product reliability. Suppliers that implement stringent QC processes may have higher prices, but they can offer better long-term value through reduced failure rates.

-

Logistics: Shipping costs can vary widely based on distance, freight methods, and Incoterms. For international buyers, understanding logistics is crucial to avoid unexpected expenses.

-

Margin: Supplier profit margins can influence pricing. Established suppliers may have higher margins due to brand reputation and reliability, while newer entrants might offer lower prices to gain market share.

How Do Price Influencers Affect In-Line Flow Switch Costs?

Several factors influence the pricing of in-line flow switches, which buyers should consider when negotiating:

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically result in lower per-unit costs due to economies of scale. Buyers should assess their requirements and negotiate MOQ terms that align with their operational needs.

-

Specifications and Customization: Custom features or specifications can significantly increase costs. Buyers should clearly define their needs to avoid unnecessary expenses associated with additional customizations.

-

Materials: As previously mentioned, the choice of materials can affect pricing. Buyers should balance the cost with the performance characteristics required for their specific applications.

-

Quality and Certifications: Certifications such as ISO or industry-specific compliance can raise costs but are often essential for ensuring product reliability and safety. Buyers in regulated industries must prioritize suppliers that meet these standards.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge a premium, but they often provide better customer service and support.

-

Incoterms: Understanding Incoterms is vital for international sourcing. These terms define the responsibilities of buyers and sellers in shipping, which can affect overall costs. Buyers should ensure they understand who bears the shipping costs, duties, and risks.

What Tips Can Buyers Use to Optimize Costs When Sourcing In-Line Flow Switches?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, can employ several strategies to optimize sourcing costs:

-

Negotiate Terms: Building strong relationships with suppliers can lead to better pricing, payment terms, and volume discounts. Don’t hesitate to negotiate to achieve a more favorable cost structure.

-

Focus on Total Cost of Ownership (TCO): Consider not just the purchase price but also maintenance, operation, and potential failure costs. A lower upfront cost may lead to higher TCO if the product is less reliable.

-

Evaluate Pricing Nuances: Be aware of currency fluctuations, import duties, and local taxes that can affect pricing. Researching these factors can help avoid unforeseen expenses.

-

Conduct Supplier Audits: Before finalizing contracts, perform due diligence on suppliers. Assess their manufacturing capabilities, quality control processes, and customer feedback to ensure they meet your standards.

-

Leverage Technology: Use digital platforms to compare prices and specifications across multiple suppliers. This can provide insights into competitive pricing and help in making informed decisions.

Disclaimer on Indicative Prices

It is essential to note that the prices of in-line flow switches can vary widely based on the factors discussed above. Buyers are encouraged to seek quotations from multiple suppliers and consider all cost components for accurate budgeting.

Alternatives Analysis: Comparing in-line flow switch With Other Solutions

Exploring Alternatives to In-Line Flow Switches: A Comparative Analysis

In the realm of flow measurement and control, in-line flow switches are widely used for their reliability and precision. However, there are alternative solutions that can also serve similar purposes, each with its unique advantages and drawbacks. Understanding these alternatives is crucial for B2B buyers looking to make informed decisions tailored to their operational needs.

| Comparison Aspect | In-Line Flow Switch | Turbine Flow Meter | Ultrasonic Flow Meter |

|---|---|---|---|

| Performance | High accuracy; suitable for various fluids | High accuracy; best for clean liquids | Non-intrusive; works well with dirty fluids |

| Cost | Moderate initial investment | Higher initial cost; requires calibration | Higher upfront cost; no moving parts reduce maintenance |

| Ease of Implementation | Relatively easy to install | Requires precise installation and calibration | Installation can be complex; requires skilled labor |

| Maintenance | Low maintenance; periodic checks needed | Moderate; requires calibration and potential replacement of moving parts | Minimal; no moving parts reduce wear |

| Best Use Case | General industrial applications, HVAC systems | Oil and gas, chemical processing | Water treatment, wastewater management |

What are the Benefits and Drawbacks of Turbine Flow Meters?

Turbine flow meters utilize a rotating blade to measure the flow rate of liquids. They are known for their high accuracy and ability to handle a wide range of flow rates. However, their performance can be impacted by the viscosity and density of the fluid, making them less effective for non-Newtonian fluids. Additionally, turbine meters often have a higher initial cost and require regular calibration to maintain accuracy, which can lead to increased operational costs over time.

How Do Ultrasonic Flow Meters Compare?

Ultrasonic flow meters use sound waves to measure the flow of liquids, offering a non-invasive solution that can be particularly advantageous for dirty or corrosive fluids. Their lack of moving parts results in minimal maintenance requirements, which can significantly reduce long-term costs. However, they tend to have a higher upfront cost and can be more complex to install compared to in-line flow switches. Ultrasonic meters also require skilled personnel for setup and calibration, which may not be readily available in all regions.

Conclusion: How to Choose the Right Flow Measurement Solution?

Selecting the appropriate flow measurement technology depends on various factors, including the specific application, fluid characteristics, budget constraints, and maintenance capabilities. In-line flow switches are ideal for general use with moderate costs and low maintenance requirements. In contrast, turbine flow meters excel in high-accuracy applications but come with higher costs and complexity. Ultrasonic flow meters offer versatility and minimal maintenance but require skilled installation. B2B buyers should evaluate these aspects carefully to choose a solution that aligns with their operational needs and financial considerations.

Essential Technical Properties and Trade Terminology for in-line flow switch

What Are the Key Technical Properties of an In-Line Flow Switch?

When considering the purchase of an in-line flow switch, understanding its technical properties is crucial for ensuring it meets operational needs. Here are some essential specifications:

1. Flow Rate

This specification indicates the maximum and minimum flow rates that the switch can handle, usually measured in gallons per minute (GPM) or liters per minute (LPM). Selecting a flow switch with an appropriate flow rate ensures that it accurately monitors the fluid dynamics within your system, preventing potential issues such as pump damage or system failure.

2. Operating Temperature Range

The operating temperature range defines the extremes within which the flow switch can function effectively, often noted in degrees Celsius or Fahrenheit. This property is particularly important for industries dealing with high-temperature fluids, such as chemicals or steam. Proper temperature ratings prevent equipment malfunction and ensure longevity.

3. Material Composition

The materials used in the construction of the flow switch, such as stainless steel, brass, or plastic, affect its durability, compatibility with various fluids, and resistance to corrosion. Selecting the right material is essential to ensure that the switch can withstand the specific conditions of your application, including exposure to aggressive chemicals or high pressures.

4. Enclosure Rating

Enclosure ratings, often specified by the NEMA or IP standards, indicate the level of protection against environmental factors like dust and moisture. A higher rating (e.g., NEMA 4X) is crucial for applications in harsh conditions, such as outdoor installations or industrial environments, ensuring reliable operation and reducing maintenance costs.

5. Switch Type and Rating

Flow switches can come in different types, such as mechanical, thermal, or magnetic, and each has its own switch rating (e.g., SPDT, DPDT). Understanding these types helps in choosing a switch that provides the desired level of sensitivity and reliability for your application, which can significantly impact process control.

6. Actuation Set Point

The actuation set point is the specific flow rate at which the switch will trigger an action, such as an alarm or system shutdown. This specification is vital for applications requiring precise flow control to prevent overflow, dry running of pumps, or other critical failures.

What Are Common Trade Terms Related to In-Line Flow Switches?

Navigating the procurement landscape involves understanding industry jargon. Here are some common terms that are particularly relevant:

1. OEM (Original Equipment Manufacturer)

An OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the flow switch market, knowing whether a product is OEM can indicate quality and reliability, as these products are often built to specific industry standards.

2. MOQ (Minimum Order Quantity)

MOQ specifies the smallest quantity of an item that a supplier is willing to sell. Understanding MOQ is crucial for budgeting and inventory management, especially for international buyers who may need to import larger quantities to meet supplier requirements.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit pricing and terms for a specific quantity of goods. This term is essential for B2B transactions, as it initiates the procurement process and helps buyers compare offers from different suppliers.

4. Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with these terms ensures that buyers understand shipping costs, risks, and obligations associated with their purchases.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to its delivery. In industries where flow switches are critical to operations, knowing lead times helps in planning and avoiding delays in production or project timelines.

6. Calibration

Calibration is the process of adjusting the accuracy of a flow switch against a known standard. This term is vital for ensuring that the measurement of flow rates is accurate, which directly impacts the efficiency and safety of operations.

By familiarizing yourself with these technical properties and trade terminologies, you will be better equipped to make informed decisions when sourcing in-line flow switches for your business needs.

Navigating Market Dynamics and Sourcing Trends in the in-line flow switch Sector

What Are the Current Market Dynamics and Key Trends Influencing the In-Line Flow Switch Sector?

The in-line flow switch market is witnessing significant growth driven by various global factors. The rise in industrial automation, particularly in manufacturing and process industries, is a major driver. Countries in Africa, South America, the Middle East, and Europe are increasingly investing in automation technologies to enhance operational efficiency and reduce labor costs. This trend is coupled with the growing demand for real-time monitoring and control systems, which in-line flow switches facilitate effectively.

Emerging technologies such as IoT (Internet of Things) and Industry 4.0 are transforming how businesses approach flow measurement and control. International B2B buyers are now looking for flow switches that not only offer reliable performance but also integrate seamlessly with smart systems. For instance, flow switches equipped with advanced features like digital displays, remote monitoring capabilities, and compatibility with various media types are gaining traction.

Illustrative image related to in-line flow switch

Moreover, the market is seeing a shift towards customization and flexibility in product offerings. Suppliers are increasingly providing configurable solutions tailored to specific industry requirements, allowing businesses to optimize their processes. This demand for tailored solutions is particularly prominent in regions with diverse industrial needs, such as Nigeria and Brazil, where applications vary widely from water treatment to chemical processing.

How Is Sustainability Shaping the In-Line Flow Switch Supply Chain?

Sustainability and ethical sourcing have become paramount considerations for B2B buyers in the in-line flow switch sector. The environmental impact of manufacturing processes is under scrutiny, pushing companies to seek suppliers that prioritize eco-friendly practices. This shift is particularly evident in Europe, where regulatory frameworks demand compliance with stringent environmental standards.

Buyers are increasingly favoring suppliers who utilize sustainable materials and production methods. For instance, in-line flow switches made from recyclable materials or those that have received ‘green’ certifications are becoming more desirable. Additionally, companies are looking for transparency in their supply chains to ensure that their procurement practices do not contribute to environmental degradation or unethical labor practices.

The emphasis on sustainability is not just about compliance; it also serves as a competitive advantage. Companies that adopt sustainable practices can enhance their brand reputation and appeal to environmentally-conscious consumers. Furthermore, as the global market moves towards sustainability, B2B buyers who align their sourcing strategies with these trends may benefit from reduced costs and increased market share.

What Is the Historical Context Behind the Evolution of In-Line Flow Switches?

The evolution of in-line flow switches dates back to the early industrial age when the need for precise flow measurement became essential for process control. Initially, mechanical flow switches dominated the market, relying on simple mechanical components to detect flow conditions. As technology advanced, the introduction of electronic flow switches provided greater accuracy and reliability, paving the way for the sophisticated devices available today.

In recent years, the integration of digital technology has further transformed the landscape. Modern in-line flow switches now feature advanced functionalities such as digital displays, remote monitoring capabilities, and programmable settings, catering to the increasingly complex demands of industrial applications. This evolution reflects the broader trend of automation and digitalization within the industrial sector, positioning in-line flow switches as critical components in contemporary process management systems.

As the market continues to evolve, B2B buyers can expect ongoing advancements that enhance performance, sustainability, and adaptability to meet the changing needs of diverse industries.

Frequently Asked Questions (FAQs) for B2B Buyers of in-line flow switch

-

How do I choose the right in-line flow switch for my application?

Choosing the right in-line flow switch involves evaluating several key factors. First, consider the type of fluid (liquid, gas) and its properties, such as viscosity and temperature range. Next, assess the required flow rate and pipe size to ensure compatibility. Additionally, look for features such as adjustable set points and sensor material that can withstand the specific environmental conditions. Lastly, consider certifications for safety and compliance with international standards, particularly if you are operating in regulated industries. -

What are the common applications for in-line flow switches?

In-line flow switches are widely used in various industries, including HVAC, water treatment, food and beverage, and chemical processing. They are essential for monitoring flow rates, protecting pumps, and preventing system failures. Common applications include boiler feedwater systems, irrigation systems, and liquid transfer processes. Understanding your specific application will help you identify the most suitable flow switch that meets your operational needs. -

How can I customize an in-line flow switch to fit my specific needs?

Many manufacturers offer customization options for in-line flow switches, allowing you to tailor features such as size, material, and sensing technology. When discussing customization, specify your requirements clearly, including flow rate, temperature range, and any unique environmental conditions. Some suppliers may also provide programmable features for alarm settings or output signals. Ensure that you communicate your needs during the inquiry process to receive accurate quotes and lead times. -

What is the minimum order quantity (MOQ) for in-line flow switches?

The MOQ for in-line flow switches varies by manufacturer and can depend on the specific model and customization options. Generally, MOQs can range from as low as 10 units to hundreds for specialized designs. When sourcing internationally, inquire directly with suppliers about their MOQs, as they may offer flexibility for first-time buyers or bulk orders. Additionally, consider discussing your long-term needs to establish a more favorable relationship. -

What payment terms should I expect when purchasing in-line flow switches?

Payment terms for in-line flow switches can vary widely based on the supplier and the region. Common terms include payment in advance, net 30, or net 60 days after delivery. Some suppliers might also accept letters of credit for larger orders. It is crucial to clarify payment methods upfront and ensure they align with your budgeting and cash flow processes. Always review the terms in the contract to avoid any misunderstandings. -

How do I ensure the quality and reliability of in-line flow switches from international suppliers?

To ensure quality and reliability, conduct thorough research on potential suppliers. Look for certifications such as ISO 9001 or industry-specific approvals that demonstrate adherence to quality standards. Request samples for testing and evaluate their performance in your specific application. Additionally, consider reading reviews or seeking references from other clients to gauge their experiences with the supplier. Establishing a clear quality assurance process will help mitigate risks. -

What are the logistics considerations when importing in-line flow switches?

When importing in-line flow switches, consider logistics factors such as shipping methods, lead times, and customs regulations in your country. Choose a reliable freight forwarder who understands the specific requirements for your region. Be aware of any import duties, taxes, and compliance documentation needed to clear customs. It is also wise to plan for potential delays in shipping, especially if you are sourcing from different continents. -

How can I compare different suppliers for in-line flow switches effectively?

To compare suppliers effectively, create a checklist of key criteria, including product specifications, pricing, lead times, and customer service. Request quotes from multiple suppliers and assess their responsiveness and willingness to accommodate your needs. Evaluate their track record in terms of delivery reliability and after-sales support. Also, consider the total cost of ownership, which includes not just the purchase price but also shipping, installation, and potential maintenance costs over time.

Top 7 In-Line Flow Switch Manufacturers & Suppliers List

1. Burkert – Inline Flow Switch SE32

Domain: burkert-usa.com

Registered: 1996 (29 years)

Introduction: Inline flow switch with display Type SE32 / Article Number 560547. Flow rate: 12.0 V – 36 V, Temperature range: 0.00 °C – 100.00 °C, Measurement technology: Paddle wheel / oval gear, Magnetic, Relay, Compact design.

2. McMaster – Inline and Insertion Flow Switches

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Inline and Insertion Flow Switches, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Dwyer – Delivery Flow Switches

Domain: dwyeromega.com

Registered: 2022 (3 years)

Introduction: This company, Dwyer – Delivery Flow Switches, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Flows – Flow Switches & Sensors

Domain: flows.com

Registered: 1995 (30 years)

Introduction: Flow Switches include: Air Flow Switch, Insertion Flow Switch, Paddle Flow Switch, Thermal Flow Switch, Water Flow Switch, Deduct Water Meter, Temperature Sensors, Sight Flow Indicators.

5. Fluid Components – FLT93L Flow Switch

Domain: fluidcomponents.com

Registered: 1996 (29 years)

Introduction: FLT93L Flow Switch is an inline type FlexSwitch for flow and temperature monitoring. It features temperature compensation for set point accuracy with process temperature variations up to ± 100°F. The device is field-configurable or factory preset, offering flexibility, accuracy, and stability for multiple process sensing and switching requirements. Applications include pump protection, cooling wat…

6. Burkert – Type 8010 Inline Paddle Wheel Flow Switch

Domain: burkert.com

Registered: 1995 (30 years)

Introduction: Type 8010 – Inline Paddle Wheel Flow Switch

– Designed for use in pure and water resembling fluids, free from air bubbles and magnetizable particles.

– Monitors minimum/maximum values of flow.

– Composed of a sensor-fitting (Type S010) and a transmitter (Type SE10), connected by a Quarter-Turn.

– Indicates flow presence by switching the Reed contact in the transmitter.

– Adjustable switching poin…

7. Orange Research – 30000 Series Flow Switches

Domain: orangeresearch.com

Registered: 1998 (27 years)

Introduction: Fixed Set-Point Flow Switches, 30000 Series, factory-preset settings, compact size, low-cost OEM design, suitable for limited space applications, rugged materials for high-pressure use, stainless steel springs, brass or stainless steel pistons and pressure bodies, applications include lubricating systems, chillers, coolers, heat exchangers. Flow range: 0.1 to 1.5 GPM, maximum pressure: 1000 psig (…

Strategic Sourcing Conclusion and Outlook for in-line flow switch

In the rapidly evolving landscape of industrial automation, selecting the right in-line flow switch is crucial for operational efficiency and reliability. Key considerations include compatibility with various media, accurate measurement capabilities, and robust design suited for diverse environmental conditions. Strategic sourcing enables buyers to leverage competitive pricing, ensure compliance with regional standards, and select products that align with their specific operational needs.

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding local market dynamics and supplier capabilities is essential. Engaging with reputable manufacturers and distributors can facilitate access to innovative technologies that enhance flow monitoring and control processes.

As industries continue to prioritize sustainability and efficiency, investing in high-quality in-line flow switches will not only optimize processes but also contribute to long-term cost savings. Now is the time to evaluate your sourcing strategies and consider partnerships that can provide cutting-edge solutions tailored to your operational requirements. Embrace the opportunity to enhance your systems with reliable and efficient flow measurement solutions that drive success in your business endeavors.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to in-line flow switch

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.