Fixed Guard Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for fixed guard

In today’s competitive global landscape, sourcing effective fixed guards for machinery safety is a crucial challenge for B2B buyers across various industries. The need for robust protective barriers that mitigate workplace hazards while complying with international safety standards cannot be overstated. This comprehensive guide delves into the intricacies of fixed guards, outlining the different types available, their specific applications, and the critical factors to consider when evaluating suppliers.

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, including countries such as Brazil and Nigeria, will find valuable insights into how to effectively vet suppliers and understand the cost implications associated with fixed guards. With an emphasis on safety compliance and operational efficiency, this guide empowers businesses to make informed purchasing decisions that not only enhance workplace safety but also contribute to overall productivity.

By equipping yourself with the knowledge presented in this guide, you will be better positioned to navigate the complexities of the global market for fixed guards, ensuring that your organization is not only compliant but also competitive in an increasingly safety-conscious world. Let’s explore the essential elements that will drive your sourcing strategy for fixed guards.

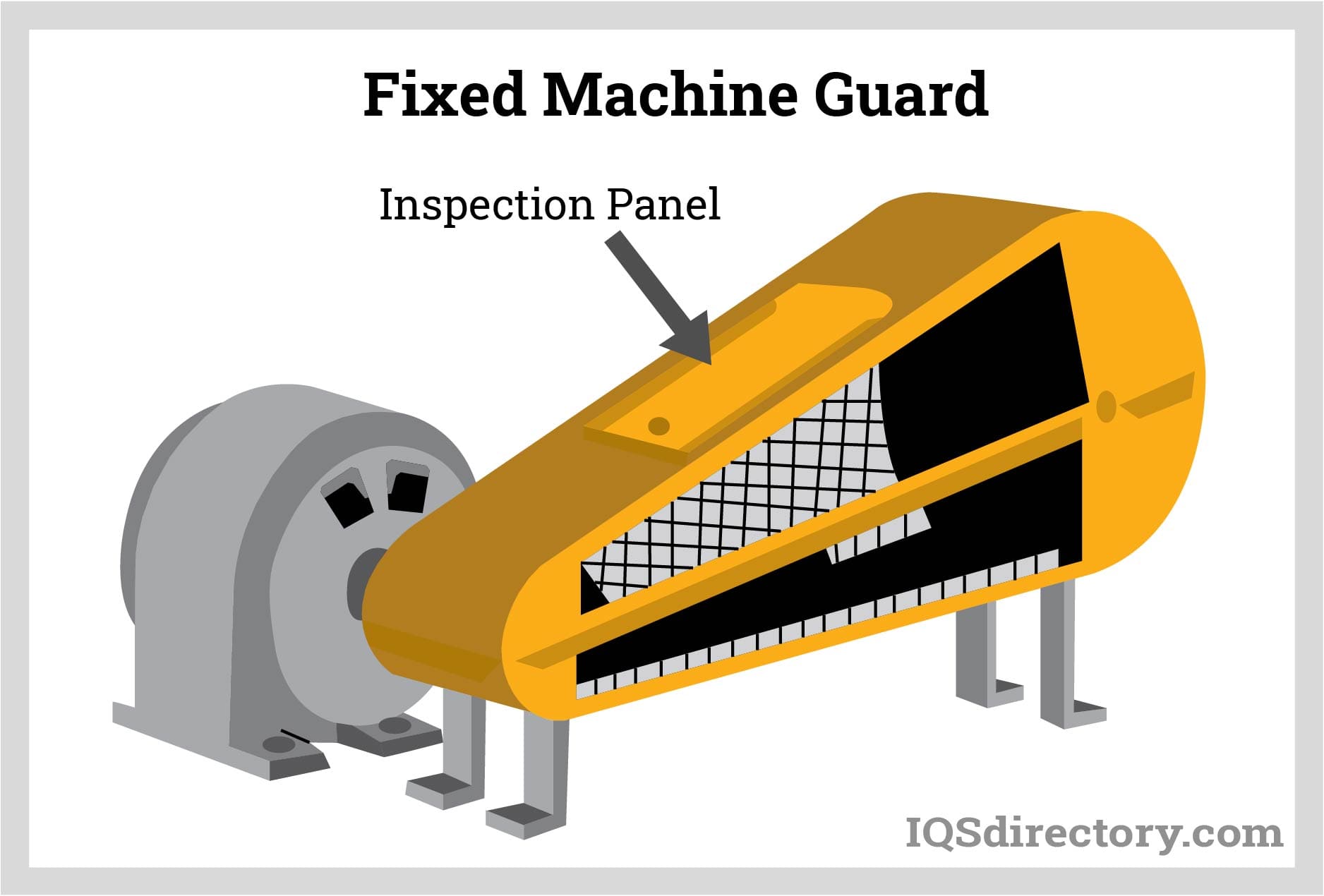

Understanding fixed guard Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

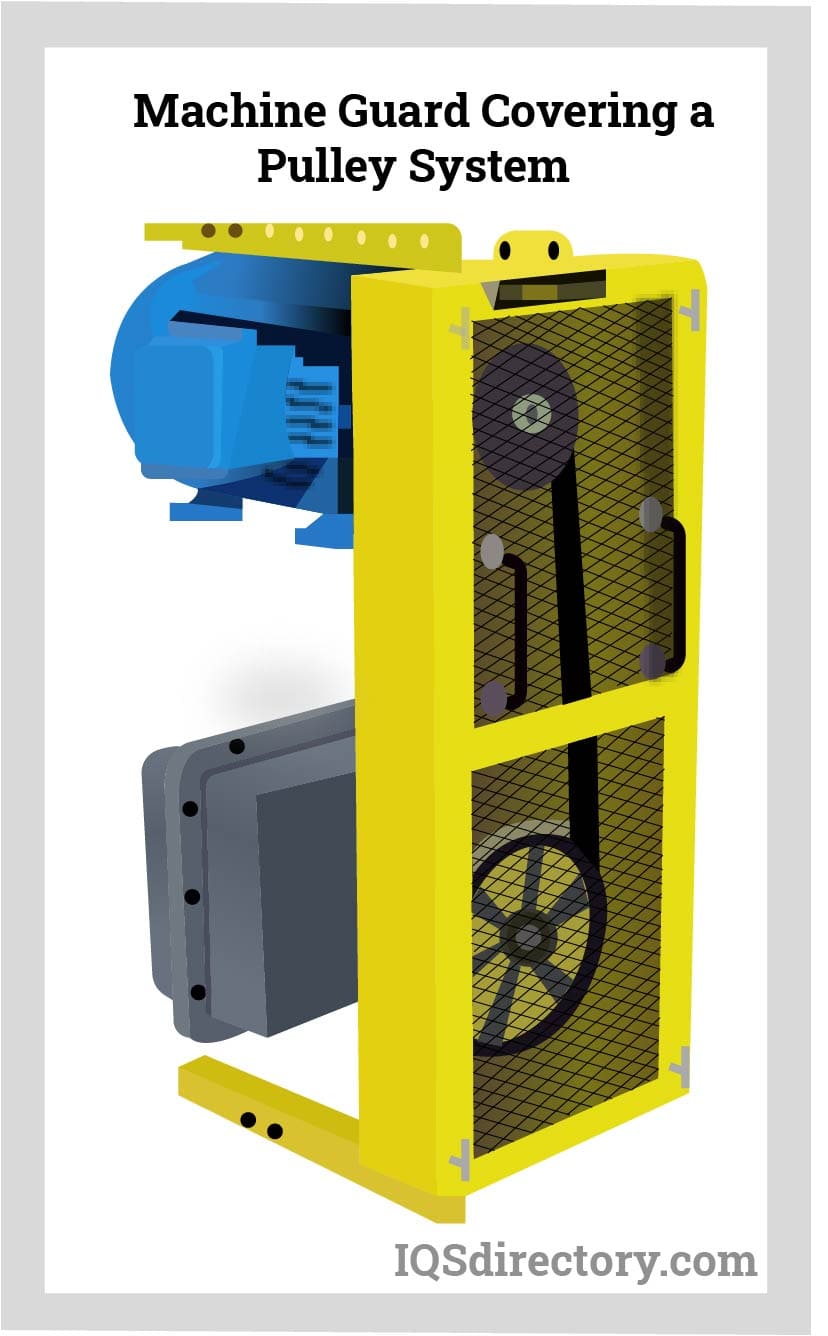

| Fixed Mesh Guards | Made of durable mesh, allowing visibility while providing protection. | Manufacturing, warehousing, assembly lines | Pros: Enhanced visibility; lightweight. Cons: Less robust than solid guards. |

| Solid Barrier Guards | Constructed from solid materials like metal, providing high durability. | Heavy machinery, industrial equipment | Pros: Excellent protection; withstands harsh environments. Cons: Limited visibility; can be heavier. |

| Safety Covers | Designed to shield specific moving parts, such as blades or gears. | Woodworking, metal fabrication | Pros: Targeted protection; prevents accidental contact. Cons: May require specific installation. |

| Perimeter Guards | Establish a boundary around a hazard zone but do not completely enclose it. | Construction sites, outdoor machinery | Pros: Allows for access control; versatile. Cons: May not provide full safety without additional measures. |

| Modular Guarding Systems | Composed of interchangeable panels, allowing customization for different setups. | Robotics, automated production lines | Pros: Flexible design; easy to adapt to changes. Cons: Initial setup can be complex. |

What Are Fixed Mesh Guards and Their B2B Suitability?

Fixed mesh guards are lightweight yet durable barriers made from mesh materials. They allow visibility while effectively protecting personnel from potential hazards. Ideal for environments where monitoring operations is essential, such as manufacturing and warehousing, these guards can be employed to safeguard assembly lines without obstructing the view of workers. When considering a purchase, buyers should evaluate the mesh material’s durability, the guard’s mounting options, and whether the level of protection meets safety regulations.

How Do Solid Barrier Guards Enhance Safety in Industrial Settings?

Solid barrier guards are constructed from robust materials like metal, offering high durability and protection in demanding environments. They are particularly suitable for heavy machinery and industrial equipment, where the risk of injury is significant. Buyers should consider the thickness and material of the guard, as well as its ability to withstand environmental factors such as temperature and moisture. While they provide excellent protection, the trade-off includes limited visibility, which may necessitate additional safety measures.

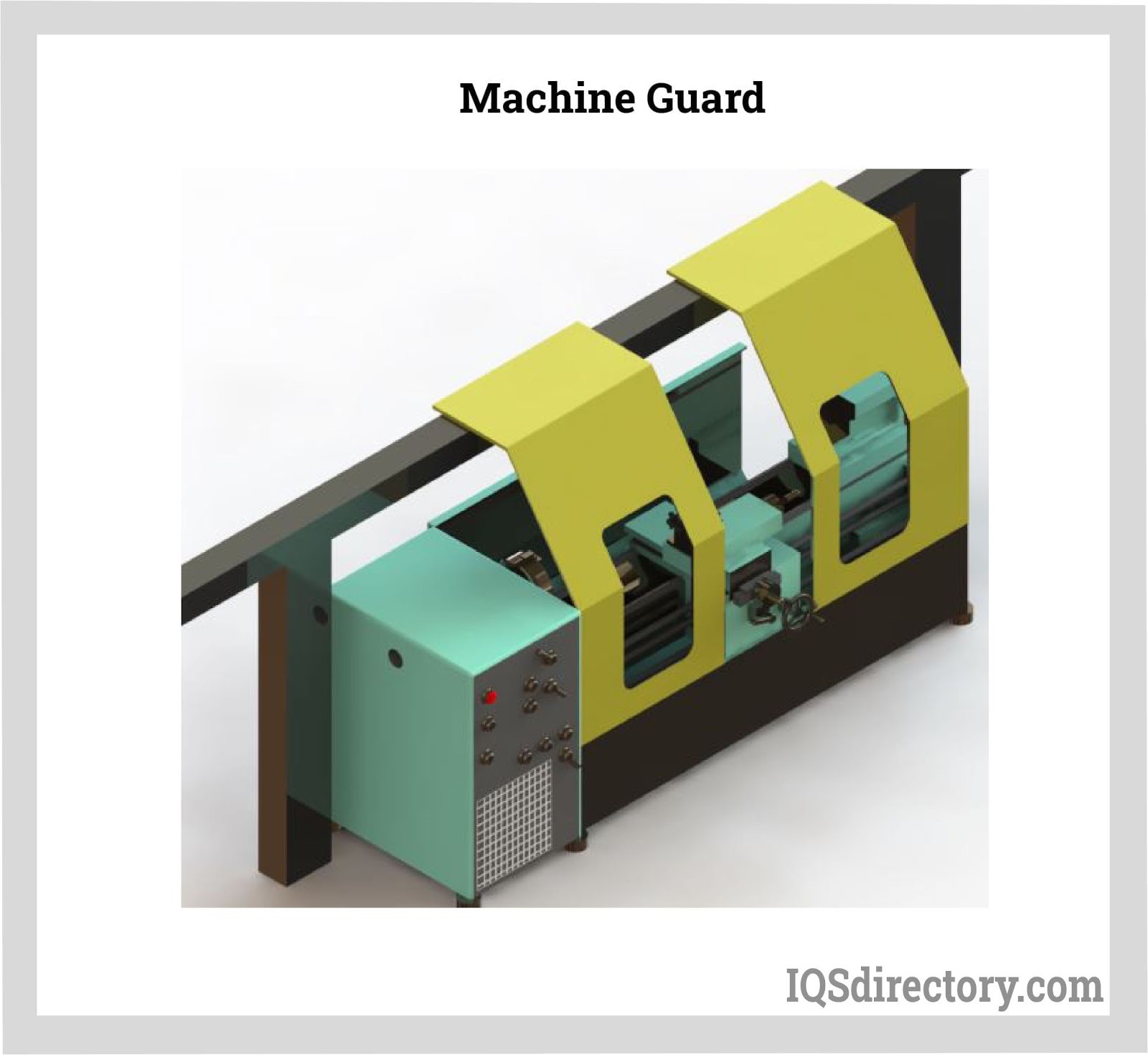

Illustrative image related to fixed guard

What Are the Benefits of Using Safety Covers in Specific Applications?

Safety covers are designed to shield specific moving parts of machinery, such as blades or gears, making them particularly useful in woodworking and metal fabrication industries. Their primary function is to prevent accidental contact with hazardous components while allowing for efficient operation. When purchasing safety covers, businesses should focus on the compatibility with existing machinery, ease of installation, and compliance with safety standards. Although they provide targeted protection, the installation process can sometimes require specialized knowledge or tools.

How Do Perimeter Guards Function in Hazardous Areas?

Perimeter guards serve as a boundary around a hazard zone without completely enclosing it, making them suitable for construction sites and outdoor machinery setups. These guards help to control access and mitigate risks by creating a defined space around potentially dangerous areas. Buyers should assess the height and design of perimeter guards to ensure they meet safety requirements while allowing for necessary access. While they are versatile and can be used in various applications, they may not offer complete safety on their own and should be part of a broader safety strategy.

Why Choose Modular Guarding Systems for Dynamic Work Environments?

Modular guarding systems consist of interchangeable panels that can be customized to fit different setups, making them ideal for robotics and automated production lines. This flexibility allows businesses to adapt their safety measures as operations evolve. When considering modular systems, buyers should evaluate the ease of assembly, the quality of materials used, and compatibility with existing equipment. While these systems provide significant adaptability, their initial setup can be complex and may require careful planning to ensure optimal safety and efficiency.

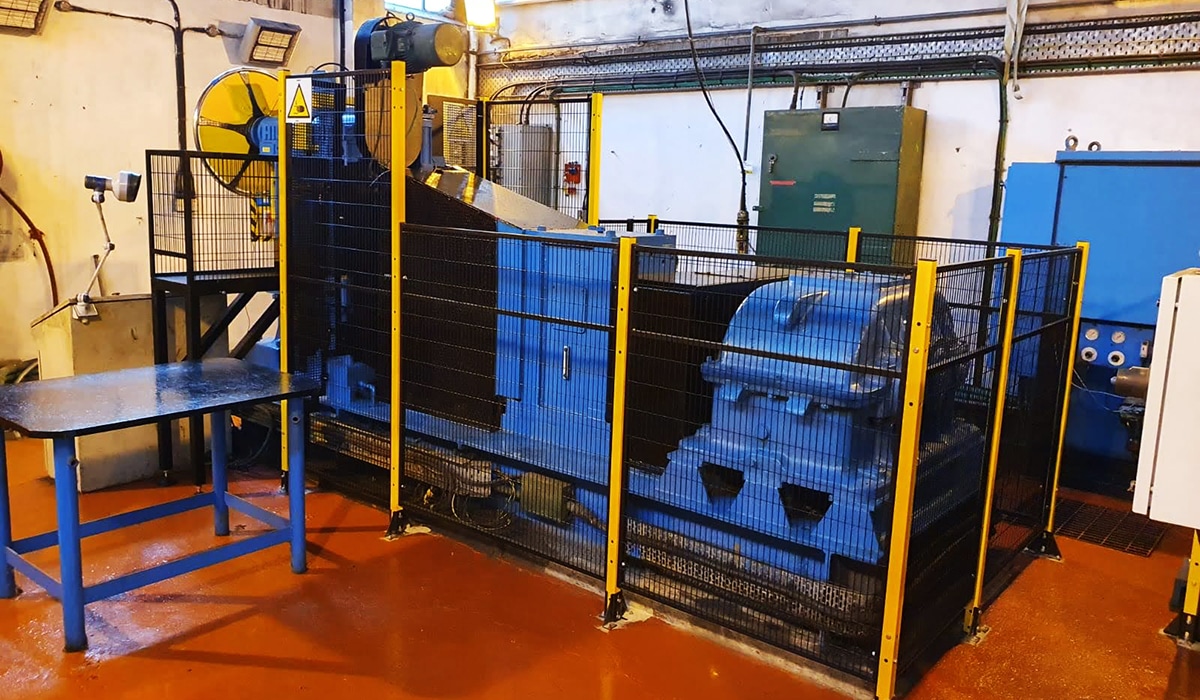

Illustrative image related to fixed guard

Key Industrial Applications of fixed guard

| Industry/Sector | Specific Application of fixed guard | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Protecting moving parts of machinery | Enhances worker safety and reduces accident rates | Compliance with local safety regulations, durability under heavy use |

| Food Processing | Securing equipment in food production lines | Prevents contamination and ensures product safety | Material compliance with food safety standards, ease of cleaning |

| Mining | Guarding machinery in extraction processes | Minimizes risk of injuries in hazardous environments | Resistance to harsh conditions, customizable designs for specific equipment |

| Construction | Protecting workers from heavy machinery operations | Reduces liability and enhances site safety | Adaptability to various machinery, easy installation and removal |

| Logistics/Warehousing | Securing automated systems and conveyor belts | Increases operational efficiency and safety | Compatibility with existing systems, modular designs for flexibility |

How is Fixed Guard Used in Manufacturing?

In the manufacturing sector, fixed guards are crucial for protecting workers from moving parts of machinery, such as conveyor belts and cutting tools. These guards serve as permanent barriers, effectively minimizing the risk of injuries caused by accidental contact. For international B2B buyers, sourcing fixed guards requires adherence to local safety regulations and standards, ensuring that the materials used can withstand the rigors of continuous operation. Additionally, considering the durability and maintenance needs of these guards is essential to sustain long-term safety and compliance.

What Role Does Fixed Guard Play in Food Processing?

In food processing plants, fixed guards are employed to secure machinery involved in the production and packaging of food products. They help prevent contamination by ensuring that only authorized personnel can access sensitive areas. For buyers in this industry, it’s vital to select guards made from materials that comply with food safety standards, are easy to clean, and can withstand the unique conditions of food processing environments. Understanding local regulations regarding food safety is essential for ensuring the right choice of fixed guards.

How is Fixed Guard Applied in Mining Operations?

In the mining industry, fixed guards are used to protect workers from the moving parts of heavy machinery, such as excavators and conveyor systems. These guards are designed to withstand harsh environmental conditions, thereby enhancing worker safety in hazardous settings. Buyers from regions like Africa and South America should prioritize sourcing fixed guards that are customizable to fit various types of mining equipment while also considering their durability against extreme weather and operational demands.

Why is Fixed Guard Important in Construction Sites?

Construction sites often involve heavy machinery, making fixed guards vital for protecting workers from accidents. These guards provide a stable barrier around dangerous equipment, which helps reduce liability for companies and enhances overall site safety. For buyers in the construction sector, it’s important to choose guards that are adaptable to different machinery and can be easily installed or removed as needed. Furthermore, understanding the specific safety regulations in their region is crucial to ensure compliance and worker safety.

How Does Fixed Guard Improve Safety in Logistics and Warehousing?

In logistics and warehousing, fixed guards are utilized to secure automated systems and conveyor belts, ensuring that workers are kept at a safe distance from moving parts. This not only enhances operational efficiency but also significantly reduces the risk of workplace accidents. Buyers in this sector should look for fixed guards that are compatible with existing systems and can be customized to accommodate various layouts. Additionally, modular designs can offer flexibility in adapting to changing operational needs, making them a smart investment for businesses aiming to improve safety and productivity.

3 Common User Pain Points for ‘fixed guard’ & Their Solutions

Scenario 1: The Challenge of Compliance with Safety Standards

The Problem: In many regions, including Africa and South America, manufacturers face strict safety regulations that require the implementation of effective machine guarding solutions. A B2B buyer might struggle to ensure that the fixed guards they purchase meet local and international safety standards. This can lead to potential legal liabilities, employee injuries, and costly fines. The pressure to maintain compliance while also keeping production efficient can be overwhelming, especially when buyers are uncertain about which products will meet these rigorous standards.

The Solution: To navigate compliance challenges, B2B buyers should start by thoroughly researching the relevant regulations in their industry and region. Engaging with reputable suppliers who provide fixed guards certified for safety standards, such as ISO or ANSI, can simplify the procurement process. When specifying fixed guards, ensure they are designed to provide adequate coverage for all hazardous zones while allowing for easy inspection and maintenance. Additionally, consider requesting documentation from suppliers that verify compliance with safety regulations. Establishing a close working relationship with your chosen supplier can also facilitate ongoing support and updates on regulatory changes, ensuring your facility remains compliant and safe.

Scenario 2: Difficulty in Customizing Fixed Guards for Unique Machinery

The Problem: Different manufacturing environments and machinery types often present unique challenges that standard fixed guards may not address. A B2B buyer in a specialized industry—such as food processing or pharmaceuticals—might find that off-the-shelf fixed guards do not fit their specific machinery or operational needs. This can lead to gaps in safety coverage and increased risk of accidents, which not only endangers employees but can also disrupt production processes.

The Solution: To overcome customization challenges, buyers should collaborate closely with suppliers who offer tailored fixed guard solutions. Before purchasing, conduct a thorough assessment of your machinery to identify specific risk areas and operational requirements. Many suppliers provide consultation services to help design fixed guards that fit your unique machinery while ensuring compliance with safety standards. When discussing options with suppliers, emphasize the need for custom measurements, materials that meet industry-specific requirements (like corrosion resistance in food processing), and flexibility in design to accommodate changes in machinery or processes. This proactive approach will enhance safety while maintaining operational efficiency.

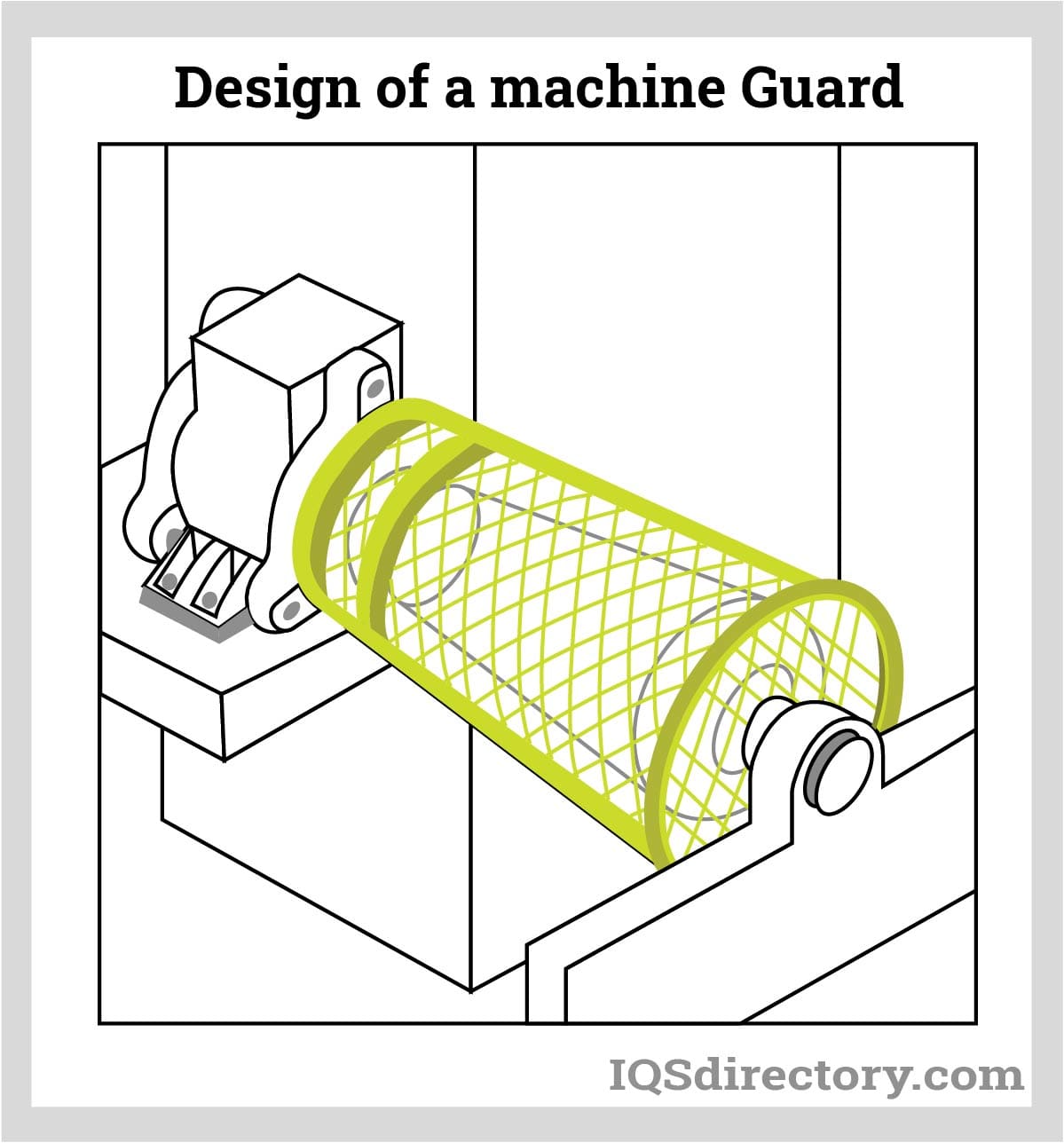

Illustrative image related to fixed guard

Scenario 3: The Cost-Benefit Dilemma of Investing in Fixed Guards

The Problem: Many B2B buyers are faced with the dilemma of investing in fixed guards versus other safety measures. With tight budgets and competing priorities, some companies may view fixed guards as an unnecessary expense rather than a critical investment in workplace safety. This mindset can lead to inadequate safety measures, resulting in higher long-term costs due to accidents, employee downtime, and potential legal repercussions.

The Solution: To justify the investment in fixed guards, B2B buyers should conduct a comprehensive cost-benefit analysis that highlights the long-term savings associated with enhanced safety measures. Calculate potential costs related to accidents, including medical expenses, lost productivity, and legal fees, against the upfront investment in high-quality fixed guards. Additionally, emphasize the value of employee safety and morale—safe work environments can lead to increased productivity and lower turnover rates. When discussing fixed guards with stakeholders, focus on case studies or testimonials from similar industries that demonstrate how investing in safety equipment has resulted in tangible benefits. This strategic approach will help align safety investments with overall business goals, making a compelling case for procurement.

Strategic Material Selection Guide for fixed guard

What Are the Key Properties of Common Materials Used for Fixed Guards?

When selecting materials for fixed guards, it is crucial to consider their properties, performance characteristics, and suitability for specific applications. Here, we analyze four common materials: steel, aluminum, polycarbonate, and stainless steel, focusing on their performance, pros and cons, and implications for international B2B buyers.

Illustrative image related to fixed guard

How Does Steel Perform as a Material for Fixed Guards?

Steel is a widely used material for fixed guards due to its high strength and durability. It typically has excellent temperature resistance and can withstand significant pressure, making it suitable for heavy-duty applications. However, steel is prone to corrosion, especially in humid or chemically aggressive environments unless treated with protective coatings.

Pros: Steel offers superior strength and impact resistance, making it ideal for high-risk environments. It is also relatively cost-effective and widely available.

Cons: The main drawback is its susceptibility to rust and corrosion, which can lead to increased maintenance costs. Additionally, manufacturing complexity may arise when fabricating intricate designs.

Illustrative image related to fixed guard

Impact on Application: Steel is compatible with various media, including oils and chemicals, but may require protective coatings in harsh environments.

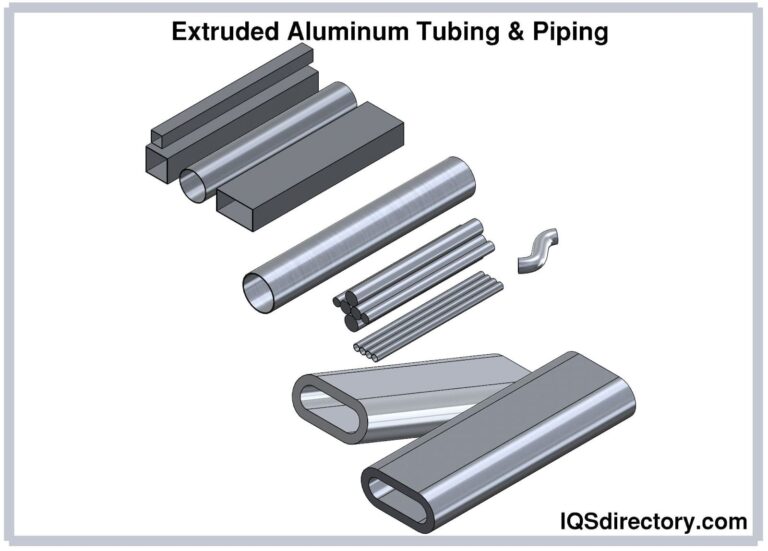

What Are the Advantages of Using Aluminum for Fixed Guards?

Aluminum is another popular choice for fixed guards, known for its lightweight and corrosion-resistant properties. It performs well in environments where weight is a critical factor, such as in mobile machinery or equipment.

Pros: Aluminum is lightweight, resistant to corrosion, and easy to fabricate, allowing for versatile designs. It is also non-magnetic, which can be an advantage in certain applications.

Cons: While aluminum is durable, it is not as strong as steel and may not withstand heavy impacts as effectively. The cost can also be higher than that of standard steel.

Impact on Application: Aluminum is suitable for environments where moisture is present, but it may not be the best choice for applications involving high temperatures or heavy mechanical stress.

Why Consider Polycarbonate as a Material for Fixed Guards?

Polycarbonate is a thermoplastic material known for its high impact resistance and transparency. It is often used in applications where visibility is essential, such as in safety guards for machinery.

Pros: Polycarbonate is lightweight, shatter-resistant, and provides excellent visibility. It is also easy to clean and maintain, making it suitable for environments requiring hygiene.

Cons: The material can be more expensive than metals and may degrade under prolonged exposure to UV light unless treated. Its temperature resistance is also lower compared to metals.

Impact on Application: Polycarbonate is ideal for environments where visibility and safety are paramount, such as in food processing or pharmaceutical industries.

What Benefits Does Stainless Steel Offer for Fixed Guards?

Stainless steel is an alloy known for its corrosion resistance and aesthetic appeal. It is particularly suitable for environments that require hygiene and cleanliness, such as food processing and pharmaceuticals.

Pros: Stainless steel is highly durable, resistant to corrosion, and easy to clean, making it ideal for sanitary applications. It also has a high strength-to-weight ratio.

Cons: The main drawback is its cost, which is typically higher than that of other materials. Additionally, it can be challenging to work with due to its hardness.

Impact on Application: Stainless steel is compatible with a wide range of media, including water and chemicals, making it versatile for various industrial applications.

Summary of Material Selection for Fixed Guards

| Material | Typical Use Case for fixed guard | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy machinery protection | High strength and impact resistance | Susceptible to corrosion | Medium |

| Aluminum | Lightweight machinery and mobile equipment | Lightweight and corrosion-resistant | Lower strength than steel | Medium |

| Polycarbonate | Safety guards in visible areas | Shatter-resistant and transparent | Higher cost and UV degradation | High |

| Stainless Steel | Food processing and sanitary environments | Corrosion-resistant and easy to clean | Higher cost and manufacturing complexity | High |

This guide provides a comprehensive overview of material options for fixed guards, helping international B2B buyers make informed decisions tailored to their specific operational needs and environmental conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for fixed guard

What Are the Main Stages of Manufacturing Fixed Guards?

The manufacturing process for fixed guards involves several critical stages, each essential to ensuring the final product meets both safety and quality standards. These stages typically include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Fixed Guards?

Material preparation begins with selecting high-quality raw materials that meet industry standards for strength and durability. Common materials used include steel, aluminum, and specialized polymers. These materials must undergo rigorous testing to ensure they can withstand operational stresses and environmental conditions.

Once the materials are selected, they are cut to size using precision cutting techniques such as laser cutting or CNC machining. This ensures that each piece is uniform and fits together correctly during assembly. Effective inventory management practices are crucial at this stage to minimize waste and ensure timely production.

Illustrative image related to fixed guard

What Forming Techniques Are Used in Fixed Guard Manufacturing?

The forming stage involves shaping the prepared materials into the desired configurations. Techniques such as bending, stamping, and welding are commonly employed. For instance, steel guards may be bent into shape using hydraulic presses, while aluminum may be stamped for lighter applications.

Welding is particularly significant in this process, as it creates strong, permanent joints that are critical for the structural integrity of the guard. Manufacturers often utilize MIG or TIG welding, depending on the material and application, to ensure the joints are robust and reliable.

How Are Fixed Guards Assembled?

Assembly is where the individual components come together to form the final product. This stage may involve fastening parts using screws, nuts, or rivets, which must be applied with precision to ensure stability and safety. Automated assembly lines can enhance efficiency and consistency, allowing for faster production rates without compromising quality.

Illustrative image related to fixed guard

Quality checks are often integrated into the assembly process, ensuring that each unit meets specifications before it proceeds to finishing. This might include visual inspections and functional tests to confirm that all moving parts are free from obstruction and that the guard is securely fitted.

What Finishing Processes Are Applied to Fixed Guards?

Finishing processes enhance the durability and aesthetic appeal of fixed guards. Common techniques include powder coating, painting, or galvanizing, which provide corrosion resistance and improve the product’s lifespan. The choice of finishing method often depends on the operating environment; for example, guards used in outdoor settings may require more robust protective coatings.

In addition to protective finishes, labeling and branding are also applied during this stage, ensuring that the product meets regulatory requirements and is easily identifiable for maintenance and safety purposes.

How Is Quality Assurance Implemented in Fixed Guard Manufacturing?

Quality assurance (QA) is a critical aspect of fixed guard manufacturing, ensuring that products comply with international and industry-specific standards. A robust QA process encompasses various checkpoints and testing methods throughout the production cycle.

Illustrative image related to fixed guard

Which International Standards Are Relevant for Fixed Guard Quality?

Fixed guards must often comply with international standards such as ISO 9001, which outlines criteria for quality management systems. Additionally, industry-specific certifications like CE marking in Europe or API standards in the oil and gas sector may apply, depending on the intended use of the guards.

These certifications not only demonstrate adherence to safety and quality standards but also enhance the product’s marketability. B2B buyers should verify that suppliers have the necessary certifications and that their products are compliant with relevant regulations in their region.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to monitor quality and consistency. Typical checkpoints include:

-

Incoming Quality Control (IQC): This initial checkpoint verifies the quality of raw materials upon receipt, ensuring they meet specified standards before production begins.

-

In-Process Quality Control (IPQC): During the manufacturing stages, IPQC checks focus on the quality of the production process itself. This might involve random sampling of products for dimensional checks or functional testing.

-

Final Quality Control (FQC): Once the guards are assembled and finished, FQC ensures that each unit meets all specifications and is free from defects before shipment.

How Can B2B Buyers Verify Supplier Quality Assurance Practices?

B2B buyers can take several steps to verify a supplier’s quality assurance practices. Conducting regular audits of potential suppliers is one of the most effective methods. These audits can assess compliance with quality standards and the efficacy of their QA processes.

Illustrative image related to fixed guard

Additionally, requesting quality reports and certifications can provide insights into a supplier’s commitment to quality. Third-party inspections are another valuable resource, offering an independent verification of the supplier’s adherence to industry standards.

What Nuances Should International B2B Buyers Consider Regarding QC?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances when it comes to quality assurance. Variations in regulatory requirements across countries can impact the compliance of fixed guards. For example, while CE marking is essential in Europe, other regions may have different safety standards.

Furthermore, logistical considerations such as shipping and customs can affect product quality if not managed properly. Buyers should ensure that suppliers have established protocols for maintaining quality during transportation, including appropriate packaging and handling procedures.

Illustrative image related to fixed guard

Understanding these factors will enable B2B buyers to make informed decisions when sourcing fixed guards, ensuring they select suppliers who prioritize quality and compliance. By focusing on these manufacturing processes and quality assurance practices, businesses can enhance safety in their operations while ensuring they meet legal and market expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fixed guard’

In the quest for enhanced workplace safety, procuring fixed guards is a crucial step for businesses across various industries. This guide serves as a comprehensive checklist to aid international B2B buyers in sourcing effective fixed guards that comply with safety regulations and meet operational needs.

Step 1: Define Your Technical Specifications

Before beginning the procurement process, clearly outline the technical specifications required for your fixed guards. Consider factors such as the type of machinery, the specific hazards present, and the environment in which the guards will be installed. This will guide your search and ensure that the guards provide adequate protection.

- Material Requirements: Determine if you need guards made from steel, plastic, or other materials based on durability and environmental conditions.

- Size and Dimensions: Measure the hazard zones to ensure that the guards will fit correctly and provide complete coverage.

Step 2: Research Regulatory Compliance

Understanding the regulatory landscape is essential when sourcing fixed guards. Different regions may have specific safety standards that your equipment must meet to ensure compliance and avoid penalties.

- Local Regulations: Familiarize yourself with OSHA guidelines or equivalent local regulations in your target markets, such as EN standards in Europe or ABNT in Brazil.

- Certification Requirements: Look for suppliers whose products are certified to these safety standards, ensuring that the guards will provide the necessary protection.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct a thorough evaluation. This step is vital to ensure that you partner with a reputable company that can deliver quality products.

Illustrative image related to fixed guard

- Company Profiles: Request detailed company profiles and check their history in manufacturing fixed guards.

- References and Case Studies: Ask for references from other businesses in similar industries or regions to gauge their reliability and product performance.

Step 4: Request Samples and Specifications

Once you have shortlisted potential suppliers, request samples or detailed specifications of their fixed guards. This will allow you to assess the quality and suitability of the products for your specific needs.

- Material and Build Quality: Examine the materials used and the overall build quality. Ensure they meet your durability and safety requirements.

- Ease of Installation: Review the installation process to determine if additional tools or expertise are necessary, which could impact your operational timelines.

Step 5: Compare Pricing and Terms

With several samples and specifications in hand, compare pricing structures and terms from different suppliers. This is crucial to ensure you receive the best value for your investment.

- Total Cost of Ownership: Consider not just the upfront cost, but also installation, maintenance, and potential replacement costs.

- Payment Terms: Assess the payment terms and conditions, ensuring they align with your financial capabilities and procurement policies.

Step 6: Verify After-Sales Support and Warranty

Finally, ensure that the supplier offers robust after-sales support and warranty terms. This can significantly impact the long-term satisfaction and performance of the fixed guards.

Illustrative image related to fixed guard

- Technical Support: Confirm that the supplier provides technical support for installation and maintenance queries.

- Warranty Coverage: Understand the warranty terms to protect your investment against defects or issues that may arise post-purchase.

By following this structured checklist, B2B buyers can effectively navigate the complexities of sourcing fixed guards, ensuring that they choose the best solutions for their safety needs while adhering to regulatory standards.

Comprehensive Cost and Pricing Analysis for fixed guard Sourcing

What Are the Key Cost Components in Sourcing Fixed Guards?

When sourcing fixed guards, understanding the cost structure is crucial for effective budgeting and procurement. The main cost components include:

-

Materials: The type of materials used, such as steel or aluminum, significantly influences costs. Higher quality materials that comply with international safety standards may incur a premium but ensure longevity and safety.

-

Labor: Labor costs encompass wages for skilled workers involved in the design, manufacturing, and installation of fixed guards. Labor expenses can vary widely based on geographic location and the complexity of the installation.

-

Manufacturing Overhead: This includes costs related to factory utilities, equipment depreciation, and indirect labor. Efficient manufacturing processes can help reduce overhead costs, allowing for more competitive pricing.

-

Tooling: Initial setup and tooling costs for custom fixed guards can be substantial. This cost is particularly relevant for specialized designs that require specific molds or machinery.

-

Quality Control (QC): Implementing stringent quality control measures adds to the overall cost but is essential for ensuring compliance with safety regulations. Investing in QC can prevent costly recalls or safety incidents in the future.

-

Logistics: Shipping and handling costs vary depending on the distance from the supplier, shipping method, and import duties. International buyers should factor in these logistics costs to avoid budget overruns.

-

Margin: Suppliers typically include a margin to cover their operational costs and profit. Understanding the margin can aid buyers in evaluating the reasonableness of pricing.

How Do Price Influencers Affect Fixed Guard Costs?

Several factors can influence the pricing of fixed guards, including:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide discounts for bulk orders. Understanding MOQ can help buyers negotiate better pricing, especially for larger projects.

-

Specifications and Customization: Custom designs or specifications may lead to higher costs due to additional engineering and production processes. Buyers should assess whether customization is necessary for their operational needs.

-

Material Quality and Certifications: Premium materials that offer enhanced durability or specific certifications (e.g., ISO, OSHA compliance) will typically cost more. Buyers should weigh the long-term benefits against the initial price.

-

Supplier Factors: The supplier’s reputation, reliability, and track record can affect pricing. Established suppliers may command higher prices but offer better quality assurance and customer service.

-

Incoterms: Different Incoterms (International Commercial Terms) can significantly impact the total landed cost. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) will help buyers calculate the total cost of acquiring fixed guards.

What Are the Best Negotiation Tips for International Buyers?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, negotiation strategies can lead to significant cost savings:

-

Understand Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, operational costs, and potential downtime. A higher upfront investment may yield better long-term savings.

-

Leverage Long-Term Relationships: Building relationships with suppliers can lead to better pricing, terms, and service. Consider multi-year contracts to secure favorable rates.

-

Be Clear About Specifications: Clearly defining specifications and requirements minimizes misunderstandings and unexpected costs. This clarity helps suppliers provide accurate quotes.

-

Explore Local Suppliers: Sourcing from local manufacturers may reduce shipping costs and lead times. Investigate regional suppliers who can meet your quality standards.

-

Stay Informed About Market Trends: Understanding current market conditions, material costs, and industry standards can strengthen your negotiation position. Keep abreast of trends affecting the supply chain.

Conclusion: Why Are Indicative Prices Important in Fixed Guard Sourcing?

While understanding the cost structure and pricing nuances is crucial, it’s essential to note that prices can fluctuate based on market conditions, material costs, and supplier pricing strategies. Always seek indicative prices as a starting point, but be prepared to negotiate and adjust based on your specific requirements and the supplier’s capabilities. Engaging in thorough market research and supplier evaluations will ensure informed decision-making and optimal procurement outcomes.

Alternatives Analysis: Comparing fixed guard With Other Solutions

Exploring Alternative Machine Guarding Solutions: Fixed Guard vs. Other Technologies

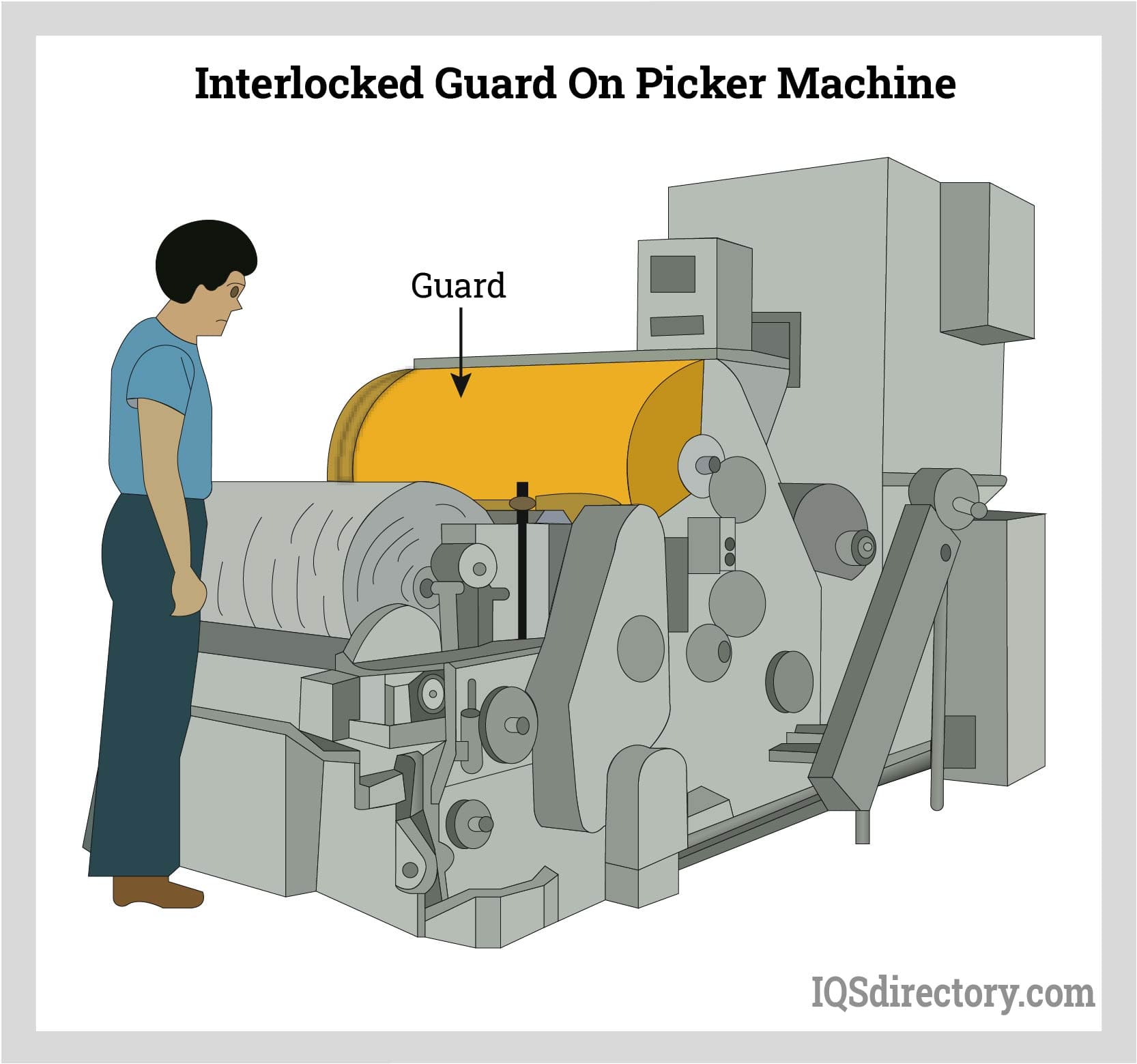

In the realm of machine safety, fixed guards serve as a fundamental barrier to protect workers from potential hazards. However, businesses must evaluate whether fixed guards are the best solution for their specific needs. In this analysis, we will compare fixed guards with two viable alternatives: interlocking guards and adjustable guards. This comparison will help B2B buyers understand the strengths and weaknesses of each option to make informed purchasing decisions.

Illustrative image related to fixed guard

| Comparison Aspect | Fixed Guard | Interlocking Guards | Adjustable Guards |

|---|---|---|---|

| Performance | Provides a permanent barrier against hazards. | Prevents machine operation if guard is not in place, enhancing safety. | Flexible protection, can adapt to various operations. |

| Cost | Generally lower initial investment. | Higher cost due to integration with machine controls. | Moderate cost, varies based on adjustment mechanisms. |

| Ease of Implementation | Simple installation, often requires basic tools. | More complex, requiring integration with machine systems. | Installation can be straightforward but depends on the setup. |

| Maintenance | Low maintenance; infrequent checks needed. | Requires regular checks to ensure proper function. | Maintenance needed for adjustment mechanisms. |

| Best Use Case | Ideal for stable operations with minimal variability. | Best for dynamic environments where machine access is frequent. | Suitable for operations with varying sizes and types of stock. |

What Are the Pros and Cons of Interlocking Guards?

Interlocking guards provide a significant safety advantage by ensuring that machinery cannot operate unless the guard is securely in place. This integration with machine control systems reduces the risk of accidental starts, offering an elevated level of protection. However, the complexity of installation and higher costs can be drawbacks, especially for smaller operations or facilities with budget constraints. Regular maintenance is also essential to ensure the system functions correctly, which could add to operational downtime.

How Do Adjustable Guards Compare?

Adjustable guards offer flexibility, allowing users to modify the guard to accommodate different tasks or materials. This adaptability makes them ideal for manufacturing environments with varied production needs. However, the cost can vary widely based on the adjustment mechanisms, and they may require more frequent maintenance compared to fixed guards. The complexity in adjusting them correctly can also lead to potential safety risks if not managed properly.

How to Choose the Right Machine Guarding Solution for Your Business?

Selecting the appropriate machine guarding solution requires a careful assessment of your operational needs, budget constraints, and safety regulations. Fixed guards are best for stable environments where hazards are constant and predictable, offering a cost-effective solution with low maintenance. Conversely, interlocking guards are optimal for facilities requiring stringent safety measures and have the budget for more complex systems. Adjustable guards serve well in dynamic operations that demand flexibility but may require more oversight and maintenance.

In conclusion, B2B buyers should prioritize understanding their unique safety requirements, operational flexibility, and financial capabilities when choosing between fixed guards and alternative solutions. Evaluating these factors will ensure that the chosen guarding system not only complies with safety regulations but also enhances operational efficiency and worker safety.

Illustrative image related to fixed guard

Essential Technical Properties and Trade Terminology for fixed guard

What Are the Critical Technical Properties of Fixed Guards?

When evaluating fixed guards for machinery safety, several key technical properties should be considered to ensure optimal performance and compliance with safety regulations. Here are four critical specifications:

-

Material Grade

Fixed guards are typically constructed from materials such as steel, aluminum, or high-strength plastics. The material grade directly affects durability, corrosion resistance, and overall strength. For instance, galvanized steel is often used for outdoor applications due to its rust-resistant properties, making it suitable for various environmental conditions. Selecting the right material ensures the guard can withstand wear and tear, thereby enhancing safety and longevity. -

Thickness and Gauge

The thickness of the material used for fixed guards is crucial for its structural integrity. A thicker gauge (lower gauge number) usually indicates a stronger guard that can withstand impacts and resist deformation. This is particularly important in high-traffic industrial environments where machinery operates continuously. The right thickness not only ensures safety but also affects the guard’s weight and installation requirements, which can impact overall project costs. -

Tolerance Levels

Tolerance refers to the allowable deviation from specified dimensions in the guard’s construction. Precise tolerances are essential for ensuring that guards fit correctly and function as intended. Poorly fitted guards can lead to gaps that may expose operators to hazards. In B2B procurement, specifying tight tolerances can prevent costly rework and ensure compliance with safety standards. -

Load Capacity

Understanding the load capacity of a fixed guard is essential, especially in environments where heavy machinery operates. This specification indicates how much weight the guard can support without failure, which is critical for maintaining safety during operation. Manufacturers should provide clear guidelines on load limits to help buyers select appropriate guards for their specific applications.

What Are Common Trade Terms Associated with Fixed Guards?

Familiarity with industry jargon is essential for effective communication and procurement in the B2B environment. Here are some common terms related to fixed guards:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can be crucial when sourcing fixed guards, as it often impacts product quality and compatibility with existing machinery. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. Knowing the MOQ is vital for buyers, especially in international procurement, as it affects inventory management and overall costs. Buyers should negotiate MOQs that align with their operational needs to avoid excess inventory or stock shortages. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for price proposals for specific products or services. When procuring fixed guards, issuing an RFQ allows buyers to compare pricing, specifications, and lead times from multiple suppliers, facilitating informed decision-making. -

Incoterms

International Commercial Terms (Incoterms) define the responsibilities of buyers and sellers in international trade. Understanding these terms is crucial for determining who bears the cost of shipping, insurance, and duties when importing fixed guards. Clear knowledge of Incoterms helps mitigate risks associated with international transactions. -

Compliance Standards

Compliance standards are regulations set by governing bodies (e.g., OSHA in the U.S.) that dictate safety requirements for machinery guarding. Familiarity with these standards is essential for ensuring that fixed guards meet legal requirements, thereby minimizing liability and enhancing workplace safety.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when procuring fixed guards, ensuring safety, compliance, and cost-effectiveness in their operations.

Navigating Market Dynamics and Sourcing Trends in the fixed guard Sector

What are the Current Market Dynamics and Key Trends for Fixed Guard Solutions?

The fixed guard sector is experiencing significant growth driven by increasing global safety regulations and a heightened focus on workplace safety. As industries such as manufacturing, construction, and logistics expand, the demand for effective machine guarding solutions has surged. In regions like Africa, South America, the Middle East, and Europe, particularly in countries like Brazil and Nigeria, the push for compliance with safety standards is a key driver. Buyers are increasingly looking for fixed guards that not only meet regulatory requirements but also enhance operational efficiency.

Emerging technologies are reshaping how businesses approach sourcing fixed guard solutions. Innovations such as smart sensors and IoT (Internet of Things) integration allow for real-time monitoring of machine safety, providing B2B buyers with advanced data analytics capabilities. This trend towards automation and data-driven decision-making is particularly appealing to international buyers looking to optimize safety protocols while reducing operational costs. Additionally, the rise of e-commerce platforms has made it easier for businesses to source fixed guard products from global suppliers, facilitating competitive pricing and diverse options.

Moreover, the increasing importance of customization in fixed guarding solutions reflects a growing trend. Buyers are now seeking tailored solutions that can adapt to specific machinery and operational requirements, leading to a demand for modular designs and adjustable guards. This shift is particularly noticeable in diverse markets where machinery types and operational practices vary widely, making fixed guards a critical component of safety strategies across different sectors.

How is Sustainability and Ethical Sourcing Impacting the Fixed Guard Sector?

In the context of fixed guards, sustainability is becoming a vital consideration for B2B buyers. The environmental impact of manufacturing processes, coupled with a growing consumer preference for eco-friendly products, is leading companies to seek suppliers who prioritize sustainable practices. This includes the use of recycled materials and the implementation of energy-efficient manufacturing processes.

Ethical sourcing is equally important, as businesses are increasingly held accountable for their supply chain practices. Buyers are looking for partners who can demonstrate a commitment to ethical labor practices and environmental stewardship. Certifications such as ISO 14001 for environmental management and compliance with local labor laws are critical factors in the sourcing decision. Additionally, the use of ‘green’ materials in fixed guard production not only enhances brand reputation but also aligns with the corporate social responsibility (CSR) goals of many organizations.

Illustrative image related to fixed guard

Furthermore, international buyers are now more inclined to engage with suppliers who can provide transparency throughout the supply chain. This transparency ensures that ethical and sustainable practices are upheld, which can significantly influence purchasing decisions, particularly in regions where consumers are increasingly conscious of their environmental footprint.

What is the Evolution and Historical Context of Fixed Guard Solutions?

The evolution of fixed guard solutions is deeply intertwined with advancements in industrial safety standards and technological innovations. Historically, the concept of machine guarding emerged in the early 20th century as industries began to recognize the dangers associated with machinery operations. Initial solutions focused on basic barriers to prevent access to hazardous areas, but as industrial processes became more complex, so too did the designs of safety guards.

Over the decades, the introduction of regulatory bodies such as OSHA (Occupational Safety and Health Administration) in the United States has shaped the standards for machine safety, leading to more sophisticated fixed guard designs. Today, fixed guards are engineered not only to comply with safety regulations but also to enhance operational efficiency and minimize downtime. This evolution reflects a broader trend in industrial safety, where proactive measures are prioritized to protect workers while optimizing productivity. As the market continues to grow and evolve, fixed guard solutions will likely incorporate even more advanced technologies and materials, further enhancing their role in workplace safety.

Frequently Asked Questions (FAQs) for B2B Buyers of fixed guard

-

How do I ensure compliance with safety regulations when sourcing fixed guards?

To ensure compliance, familiarize yourself with the safety standards relevant to your industry and region, such as OSHA guidelines in the U.S. or local regulations in Africa, South America, the Middle East, and Europe. Request documentation from suppliers that demonstrate adherence to these standards. It’s also beneficial to conduct a risk assessment of your facility to determine specific guarding needs. Engage with suppliers who have experience in your region and can provide compliant products tailored to your operations. -

What is the best type of fixed guard for my machinery?

The best type of fixed guard depends on your specific machinery and hazard zones. Fixed guards are ideal for providing a permanent barrier for stationary machinery, while interlocking guards may be better for machines requiring access during operation. Consider factors like the nature of the work, frequency of access needed, and the level of risk involved. Consulting with safety experts or suppliers can help you determine the most suitable option based on your operational requirements. -

How can I customize fixed guards to fit my machinery?

Customization options vary by supplier, but many offer tailored solutions based on your machinery specifications and safety needs. When discussing customization, provide detailed measurements, operational parameters, and any specific features required, such as materials or color coding. Ensure that the supplier can accommodate your requests and verify their experience with custom projects. Request samples or prototypes to assess fit and functionality before finalizing the order. -

What are the minimum order quantities (MOQ) for fixed guards?

MOQs for fixed guards can vary significantly depending on the supplier and the complexity of the product. Some manufacturers may have a low MOQ for standard designs, while custom orders may require higher quantities. It’s advisable to discuss your needs with potential suppliers and negotiate terms that align with your procurement strategy. Some suppliers may offer flexibility for first-time buyers or bulk orders, so it’s worth exploring these options. -

What payment terms should I expect when purchasing fixed guards internationally?

Payment terms can differ based on the supplier’s policies and your negotiation. Common terms include full payment upfront, a deposit with the balance upon delivery, or payment after delivery for established relationships. Ensure that you clarify payment methods accepted (e.g., bank transfer, credit card, letters of credit) and consider currency exchange rates, which can impact costs. It’s prudent to review the supplier’s credibility and history before agreeing to terms. -

How do I evaluate the quality assurance processes of a fixed guard supplier?

To evaluate a supplier’s quality assurance processes, request details about their manufacturing practices, certifications, and inspection protocols. Look for suppliers who adhere to international quality standards such as ISO 9001. Ask about their testing methods for durability and safety, and if they provide warranties or guarantees for their products. Additionally, seeking references or customer testimonials can provide insight into their quality and reliability. -

What logistical considerations should I keep in mind when sourcing fixed guards?

Logistical considerations include shipping methods, lead times, and import regulations specific to your country. Understand the delivery timelines to ensure that the guards arrive when needed, and inquire about the supplier’s ability to handle customs paperwork. Assess the total landed cost, including shipping fees, taxes, and duties. Establish clear communication with the supplier regarding tracking shipments and managing potential delays. -

How can I establish a long-term partnership with a fixed guard supplier?

Building a long-term partnership with a supplier involves open communication, regular evaluations of product performance, and providing feedback on their service. Engage in discussions about future needs and potential product innovations. Consider placing consistent orders to demonstrate commitment, and participate in joint projects or collaborations that align with both parties’ interests. Building trust through transparency and reliability will strengthen the partnership over time.

Top 5 Fixed Guard Manufacturers & Suppliers List

1. WireCrafters – RapidGuard® II Machine Guarding

Domain: machineguarding.com

Registered: 2002 (23 years)

Introduction: RapidGuard® II Machine Guarding by Wirecrafters includes various products such as Machine Guard Locks & Safety Switches, Machine Guarding Panels, Machine Guarding Doors, and Accessories. Specific items mentioned are the RapidGuard® II Cut-Down Kit, RapidGuard® II Panel Splice Kit, WireCrafters GuardLock Light Curtain Enclosures, and WireCrafters RapidGuard® II Switch Enclosure Post. The system is …

2. Axelent – Machine Guards

Domain: axelent.com

Registered: 2002 (23 years)

Introduction: Axelent is a leading manufacturer of machine guards, providing a complete system that meets current directives and standards. Key product details include:

– Fixed guards that prevent access to hazards, suitable for areas accessed less than once per week.

– Fixed guards must be strong enough for expected hazards, removable only with tools, and designed to prevent loss of fasteners.

– They must n…

3. Pilz – Fixed Guards

4. OSH Academy – Machine Safeguarding Course

Domain: oshacademy.com

Registered: 2006 (19 years)

Introduction: 154 Machine Safeguarding: Basic course covers various types of machine guards including Fixed Guards, Adjustable Guards, and Interlocked Guards. Fixed Guards are permanent and made from durable materials, providing simplicity and permanence. Adjustable Guards offer flexibility for different stock sizes. Interlocked Guards ensure safety by shutting off the machine when the guard is removed. The cou…

5. Safeopedia – Machine Safeguarding Solutions

Domain: safeopedia.com

Registered: 2010 (15 years)

Introduction: Fixed Interlocked Automatic & Trip refers to various methods of machine safeguarding. A fixed guard is a permanent part of the machine, not reliant on moving parts. An interlocking guard uses a tripping device to automatically power off the machine when triggered. Adjustable guards offer flexibility based on stock size, while trip guards have barriers that open and close with stock movement. The c…

Strategic Sourcing Conclusion and Outlook for fixed guard

In summary, effective strategic sourcing for fixed guards is essential for enhancing workplace safety and ensuring compliance with international standards. By understanding the various types of machine guarding—fixed, interlocking, adjustable, and self-adjusting—B2B buyers can make informed decisions tailored to their specific operational needs. Investing in high-quality fixed guards not only mitigates risks associated with machinery hazards but also contributes to overall operational efficiency and employee well-being.

Illustrative image related to fixed guard

As global markets continue to evolve, particularly in regions like Africa, South America, the Middle East, and Europe, the demand for robust safety solutions will only increase. Companies should prioritize sourcing strategies that emphasize quality, durability, and adaptability to meet diverse industrial requirements.

Looking ahead, the implementation of innovative safety technologies and rigorous compliance with safety regulations will be pivotal in driving competitive advantage. International B2B buyers are encouraged to engage with reputable suppliers who can offer tailored solutions and expert insights. This proactive approach will not only safeguard your workforce but also fortify your brand reputation in an increasingly safety-conscious marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.