Top 4 Perspex Sheet 8 X 4 Suppliers (And How to Choose)

Introduction: Navigating the Global Market for perspex sheet 8 x 4

In an increasingly interconnected world, sourcing high-quality perspex sheet 8 x 4 can present a significant challenge for B2B buyers. The need for a versatile, durable, and lightweight alternative to traditional glass is paramount across various industries, including construction, signage, and retail displays. This comprehensive guide addresses the key aspects of navigating the global market for perspex sheets, providing insights into types, applications, supplier vetting, and cost considerations.

By exploring the diverse applications of perspex sheets—ranging from custom furniture to protective barriers—this guide empowers international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, including regions like Nigeria and Saudi Arabia. It equips decision-makers with the knowledge necessary to make informed purchasing choices, ensuring they select the right product to meet their specific needs.

Furthermore, the guide emphasizes the importance of understanding supplier credibility and product specifications, which can significantly impact project outcomes. By leveraging the insights provided, buyers can confidently navigate the complexities of sourcing perspex sheets, enabling them to enhance their product offerings and optimize operational efficiency. As the demand for innovative materials continues to rise, this guide stands as a crucial resource for businesses aiming to stay ahead in a competitive market.

Understanding perspex sheet 8 x 4 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Clear Cast Acrylic | High optical clarity, UV resistant, shatter-proof | Signage, displays, aquariums | Pros: Excellent clarity, durable. Cons: Higher cost compared to extruded variants. |

| Extruded Acrylic | Lightweight, lower cost, good impact resistance | Retail displays, furniture, protective barriers | Pros: Cost-effective, easy to cut. Cons: Less clarity and strength than cast. |

| Opaque Acrylic | Non-transparent, available in various colors | Decorative applications, privacy screens | Pros: Offers privacy, aesthetic options. Cons: Limited applications compared to clear. |

| Frosted Acrylic | Diffuses light, semi-transparent | Office partitions, decorative panels | Pros: Reduces glare, stylish. Cons: Less visibility than clear sheets. |

| Tinted Acrylic | Available in various colors, reduces glare | Automotive, architectural elements | Pros: Enhances aesthetics, UV protection. Cons: Color may limit design options. |

What Are the Key Characteristics of Clear Cast Acrylic Sheets?

Clear cast acrylic sheets are recognized for their exceptional optical clarity and durability. They are UV resistant, making them suitable for outdoor applications, such as signage and displays that require long-lasting visibility. Their shatter-proof nature provides an added safety feature, which is crucial for environments where breakage could pose risks. When purchasing, B2B buyers should consider the thickness and size required for their specific applications, as well as the potential for custom cutting.

How Do Extruded Acrylic Sheets Differ from Other Types?

Extruded acrylic sheets are lightweight and generally more affordable than their cast counterparts. They offer good impact resistance, making them a popular choice for various applications, including retail displays and protective barriers. However, they may not have the same level of clarity or strength as cast acrylic sheets. Buyers should evaluate the cost-effectiveness of extruded sheets versus the performance needs of their projects, especially in high-traffic or high-visibility areas.

In What Applications Are Opaque Acrylic Sheets Most Effective?

Opaque acrylic sheets are non-transparent and come in a variety of colors, making them ideal for decorative applications and privacy screens. They are widely used in environments where visibility is not a priority, such as in partitioning spaces or creating artistic displays. When sourcing opaque acrylic, B2B buyers should assess the color options and thicknesses available, as well as the sheet’s compatibility with their design needs.

Why Choose Frosted Acrylic Sheets for Office Spaces?

Frosted acrylic sheets provide a stylish solution for office partitions and decorative panels, as they diffuse light while maintaining a level of privacy. This type of acrylic is particularly effective in settings that require a balance between openness and seclusion. B2B buyers should consider the aesthetic appeal and light-diffusing properties of frosted sheets, as well as their durability and ease of maintenance in a corporate environment.

What Advantages Do Tinted Acrylic Sheets Offer in Design?

Tinted acrylic sheets come in various colors and are particularly effective in reducing glare while providing UV protection. They are often used in automotive and architectural applications where aesthetics are essential. Buyers should evaluate the color options available, as well as the specific performance characteristics that tinted sheets can offer, ensuring they align with the overall design and functional requirements of their projects.

Key Industrial Applications of perspex sheet 8 x 4

| Industry/Sector | Specific Application of perspex sheet 8 x 4 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail Displays | Point of Purchase (POP) Displays | Enhances product visibility and customer engagement | Ensure clarity, thickness options, and customization capabilities. |

| Construction & Architecture | Glazing for Windows and Skylights | Provides natural light while being shatter-resistant | Consider UV resistance and thermal insulation properties. |

| Marine & Automotive | Interior and Exterior Panels | Lightweight and durable alternative to traditional materials | Assess marine-grade specifications and resistance to corrosion. |

| Signage | Custom Signage and Displays | High visibility and weather resistance for outdoor use | Verify color options and surface finishes for branding consistency. |

| Aquariums | Tank Construction | Offers a clear, safe alternative to glass for aquatic environments | Check for thickness and clarity to ensure optimal viewing. |

How is Perspex Sheet 8 x 4 Used in Retail Displays?

In the retail sector, perspex sheet 8 x 4 is commonly utilized for Point of Purchase (POP) displays. These displays are crucial for attracting customer attention and enhancing the visibility of products. The lightweight nature of acrylic allows for easy installation and repositioning, while its clarity ensures that the products showcased are front and center. International buyers should consider the sheet’s thickness and customization options to align with their branding needs.

What Role Does Perspex Play in Construction and Architecture?

In construction and architecture, perspex sheet 8 x 4 serves as an excellent glazing solution for windows and skylights. Its shatter-resistant properties provide safety without compromising on aesthetics, allowing for abundant natural light in commercial and residential spaces. Buyers from regions with extreme weather should prioritize UV resistance and thermal insulation features to ensure longevity and energy efficiency.

Why is Perspex Preferred in Marine and Automotive Industries?

The marine and automotive industries leverage perspex sheet 8 x 4 for interior and exterior panels due to its lightweight yet durable nature. It is an ideal substitute for glass, reducing overall vehicle weight and enhancing fuel efficiency. Buyers should focus on sourcing marine-grade acrylic that meets specific resistance standards against corrosion and environmental wear, especially in coastal areas.

How is Perspex Used for Signage Applications?

For signage, perspex sheet 8 x 4 is favored for its high visibility and weather-resistant qualities, making it suitable for both indoor and outdoor displays. The material can be easily cut and customized, allowing businesses to create signs that are not only functional but also visually appealing. B2B buyers should consider the various color options and surface finishes available to ensure their signage aligns with their brand identity.

What Benefits Does Perspex Offer for Aquariums?

In the aquarium industry, perspex sheet 8 x 4 is utilized for tank construction, providing a clear and safe alternative to traditional glass. Its impact strength ensures that tanks can withstand internal pressure while offering unobstructed views of aquatic life. Buyers should assess the thickness and clarity of the sheets to ensure they meet the specific requirements for their aquarium designs, especially in regions where aesthetics play a significant role in consumer purchasing decisions.

3 Common User Pain Points for ‘perspex sheet 8 x 4’ & Their Solutions

Scenario 1: Sourcing Quality Perspex Sheets for Diverse Applications

The Problem: B2B buyers often encounter challenges when sourcing high-quality perspex sheets. In regions such as Africa and South America, the availability of reliable suppliers can be limited, leading to concerns about product authenticity and quality. Buyers may struggle with inconsistent thickness, clarity, and UV resistance, which can significantly impact their end products, such as signage, display cases, or protective barriers. The fear of investing in subpar materials can deter businesses from making necessary purchases.

The Solution: To ensure quality, buyers should prioritize sourcing from reputable manufacturers or distributors who specialize in acrylic products. Conduct thorough research by checking certifications, product specifications, and customer reviews. It’s beneficial to request samples before placing large orders to assess the clarity and thickness firsthand. Additionally, consider suppliers that offer detailed product descriptions, including molecular weight and UV resistance ratings. Establishing a long-term relationship with a trusted supplier can also lead to better pricing and reliable product availability, ensuring consistent quality for your projects.

Scenario 2: Handling Difficulties with Custom Cutting and Machining

The Problem: Custom cutting and machining of perspex sheets can pose a significant challenge for B2B buyers, especially when the specifications are complex. Inadequate tools or lack of knowledge about proper cutting techniques can lead to jagged edges, chips, or even cracks, rendering the sheets unusable. This not only wastes materials but also delays project timelines and increases costs, particularly for businesses that rely on precise dimensions for applications like retail displays or architectural features.

The Solution: To overcome cutting and machining difficulties, buyers should invest in proper tools designed specifically for acrylic. Using a fine-toothed saw or laser cutting technology can yield cleaner edges. It’s advisable to consult with suppliers who offer cutting services or provide resources such as instructional videos on best practices for cutting perspex sheets. Additionally, buyers should consider ordering sheets cut to size directly from suppliers, which can save time and reduce the risk of damage during the cutting process. Regular training for staff on handling and working with acrylic can further minimize errors and enhance overall efficiency.

Scenario 3: Understanding Thickness and Its Impact on Application

The Problem: B2B buyers often struggle with understanding the appropriate thickness of perspex sheets required for their specific applications. Misjudging the thickness can lead to structural failures, especially in high-stress environments like aquariums or outdoor installations. For instance, a buyer might choose a sheet that is too thin for a protective barrier, resulting in potential safety hazards and additional costs for replacements or repairs.

The Solution: To accurately determine the required thickness, buyers should assess the intended use of the perspex sheet and consult with technical experts or supplier representatives. They should consider factors such as load-bearing requirements, environmental conditions, and any regulatory standards that might apply. Most suppliers provide guidelines or charts to help buyers match sheet thickness with application needs. Additionally, creating prototypes or conducting stress tests can provide valuable insights into the performance of the chosen thickness, allowing for informed decisions that ensure safety and durability in the final product.

Strategic Material Selection Guide for perspex sheet 8 x 4

What Are the Key Properties of Common Materials for Perspex Sheet 8 x 4?

When selecting materials for perspex sheets, particularly the 8 x 4 size, it is essential to understand the properties of the most commonly used materials. Each material has unique characteristics that affect its performance in various applications. Below, we analyze four prevalent materials: clear cast acrylic, extruded acrylic, polycarbonate, and glass.

Clear Cast Acrylic: What Makes It a Preferred Choice?

Clear cast acrylic is known for its excellent optical clarity and superior strength, making it an ideal choice for applications requiring transparency and durability. It has a temperature resistance of up to 80°C (176°F) and is highly resistant to UV light, preventing yellowing over time.

Pros: The material is lightweight, easy to fabricate, and can be polished to a high gloss. It is also shatter-resistant, making it suitable for safety applications.

Cons: The primary downside is its susceptibility to scratching, which can affect aesthetics and functionality. Additionally, it is more expensive than extruded acrylic.

Impact on Application: Clear cast acrylic is perfect for high-end displays, aquariums, and signage where clarity is paramount.

Considerations for International Buyers: Compliance with standards such as ASTM and DIN is crucial. Buyers in regions like Africa and the Middle East may also need to consider local regulations regarding material safety and environmental impact.

Extruded Acrylic: When Is It More Suitable?

Extruded acrylic offers a more cost-effective solution while still providing good optical clarity and impact resistance. It typically has a lower temperature resistance of around 70°C (158°F) compared to cast acrylic.

Pros: The manufacturing process allows for larger sheets at a lower cost, making it a popular choice for bulk applications. It is also easier to work with in terms of cutting and shaping.

Cons: However, it is less durable than cast acrylic and can warp under high temperatures. Its lower scratch resistance is also a concern for applications requiring high clarity.

Impact on Application: Extruded acrylic is commonly used for internal signage, displays, and protective barriers.

Considerations for International Buyers: Buyers should ensure that the extruded acrylic meets local safety standards and consider the potential for material degradation in extreme climates.

Polycarbonate: What Are Its Unique Benefits?

Polycarbonate is a robust alternative to acrylic, known for its high impact resistance—up to 250 times stronger than glass. It can withstand temperatures ranging from -40°C to 120°C (-40°F to 248°F), making it suitable for various environments.

Pros: Its extreme durability makes it ideal for applications where safety is a concern, such as in riot shields or safety glasses. It is also lightweight and easy to fabricate.

Cons: The main disadvantage is its susceptibility to scratching, although it can be coated for added protection. Polycarbonate also tends to be more expensive than acrylic.

Impact on Application: This material is perfect for applications requiring high durability, such as in security installations and outdoor signage.

Considerations for International Buyers: Compliance with international safety standards is essential, especially in regions with stringent regulations like Europe.

Glass: When Is It Still Relevant?

While glass is not a plastic, it is still a common material for applications requiring high clarity and scratch resistance. It can withstand high temperatures and is chemically resistant.

Pros: Glass offers unmatched optical clarity and scratch resistance, making it ideal for high-end applications.

Cons: Its weight and fragility are significant drawbacks, making it less suitable for mobile applications or where safety is a concern.

Impact on Application: Glass is often used in architectural applications, high-end displays, and where aesthetic appeal is critical.

Considerations for International Buyers: Buyers should be aware of shipping costs and local regulations regarding glass safety and installation.

Summary Table of Material Selection for Perspex Sheet 8 x 4

| Material | Typical Use Case for perspex sheet 8 x 4 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Clear Cast Acrylic | Aquariums, high-end displays | Superior optical clarity | Susceptible to scratching | High |

| Extruded Acrylic | Internal signage, displays | Cost-effective and easy to fabricate | Less durable than cast acrylic | Medium |

| Polycarbonate | Safety shields, outdoor signage | Extremely high impact resistance | Susceptible to scratching | High |

| Glass | Architectural applications, high-end displays | Unmatched optical clarity | Heavy and fragile | Medium |

This guide provides a comprehensive overview of material options for perspex sheets, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for perspex sheet 8 x 4

The manufacturing process for perspex sheets, particularly the widely sought-after 8 x 4 dimensions, involves several critical stages that ensure the final product meets the high standards expected by B2B buyers across various industries. This section outlines the key manufacturing processes and quality assurance measures relevant to these acrylic sheets, providing insights that international buyers, especially from Africa, South America, the Middle East, and Europe, can leverage when evaluating suppliers.

What Are the Main Stages of the Manufacturing Process for Perspex Sheets?

The production of perspex sheets typically involves four main stages: material preparation, forming, assembly, and finishing.

Material Preparation: How Are Raw Materials Selected and Processed?

The primary raw material used in the production of perspex sheets is polymethyl methacrylate (PMMA). This thermoplastic polymer is chosen for its exceptional clarity, UV resistance, and shatterproof qualities. During the material preparation stage, PMMA is sourced from reputable suppliers who adhere to international standards. Quality checks are conducted to ensure that the raw materials meet specified criteria before moving forward.

The raw PMMA is then processed into sheets through a combination of extrusion or casting methods. In the extrusion process, PMMA pellets are heated until molten and then forced through a die to form sheets. Alternatively, in the casting process, PMMA is poured into molds and allowed to cure, resulting in sheets that often have superior optical clarity and strength.

Forming: What Techniques Are Used to Shape Perspex Sheets?

Once the material is prepared, the next step is forming. This involves cutting the sheets to the desired dimensions, such as the standard 8 x 4 feet size. Techniques such as laser cutting, CNC machining, and saw cutting are commonly employed. Laser cutting offers precision and clean edges, making it a preferred method for intricate designs or customized shapes.

After cutting, the sheets may undergo further shaping processes such as bending or thermoforming. These techniques allow manufacturers to create specific profiles or curves that may be necessary for particular applications, such as displays, signage, or furniture.

Assembly: Are Additional Components Integrated into the Sheets?

While perspex sheets are often used as standalone products, they can also be assembled with other materials or components to create complex structures. For instance, when manufacturing display cases or aquariums, the acrylic sheets might be bonded with adhesives that are specifically formulated for PMMA. The assembly process is critical, as the integrity of the final product hinges on the quality of the joints and seals.

What Quality Assurance Measures Are Implemented During Production?

Quality assurance (QA) is a vital component of the manufacturing process, particularly for B2B buyers who require reliable and high-quality products. Manufacturers typically adhere to various international standards, such as ISO 9001, which outlines requirements for a quality management system. Additionally, industry-specific certifications like CE marking or API certification can further assure product quality and compliance with regional regulations.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is integrated at several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials as they arrive at the manufacturing facility. Suppliers should provide documentation that verifies compliance with specified standards.

-

In-Process Quality Control (IPQC): During production, ongoing assessments are conducted to monitor processes and ensure they remain within defined parameters. This includes checking the thickness and clarity of the sheets at various stages.

-

Final Quality Control (FQC): Once the sheets are completed, they undergo a thorough inspection to ensure they meet all specifications. This includes visual inspections for defects, measurements for dimensional accuracy, and tests for impact resistance and UV stability.

How Can B2B Buyers Verify Supplier Quality Control Processes?

International B2B buyers should take proactive steps to verify the quality control processes of potential suppliers. Here are some strategies:

-

Request Audits and Reports: Buyers can ask suppliers for access to their quality management system documentation, including audit reports. These documents should reflect adherence to international standards and provide insights into the supplier’s QA processes.

-

Third-Party Inspections: Engaging independent third-party inspection agencies can provide an unbiased evaluation of a supplier’s manufacturing and quality assurance practices. This can be particularly beneficial for buyers unfamiliar with local suppliers.

-

Sample Testing: Before placing large orders, buyers can request samples of the perspex sheets. Conducting tests on these samples for clarity, thickness, and impact resistance can help assess the product’s quality.

What Are the Nuances of Quality Control for International Buyers?

For buyers from different regions, especially Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is crucial. Variations in manufacturing practices and standards can affect product quality. Buyers should be aware of regional compliance requirements and ensure that suppliers can meet these specifications.

Additionally, language barriers and differences in business practices may complicate communications regarding quality assurance. Establishing clear channels of communication and mutual understanding can help mitigate these challenges.

Conclusion: Ensuring Quality in Perspex Sheet Procurement

In summary, the manufacturing processes and quality assurance measures for perspex sheets, particularly in the 8 x 4 size, are complex yet essential to producing a reliable product. B2B buyers should leverage the information provided in this guide to assess potential suppliers critically. By understanding the manufacturing stages, quality control checkpoints, and verification methods, buyers can make informed decisions that align with their quality expectations and operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘perspex sheet 8 x 4’

Introduction

Sourcing ‘perspex sheet 8 x 4’ for your business needs requires a strategic approach to ensure that you obtain the right quality and specifications at a competitive price. This checklist will guide you through each critical step of the procurement process, helping you make informed decisions that align with your operational requirements and budget constraints.

Step 1: Define Your Technical Specifications

Before beginning your sourcing process, clearly outline the technical specifications of the perspex sheets you need. Consider factors such as thickness, color, clarity, and any special features like UV resistance or impact strength. Defining these parameters upfront helps streamline supplier selection and ensures that the products meet your application needs.

- Thickness Options: Common thicknesses range from 1/8″ (3mm) to 1″ (24mm). Identify which thickness best suits your application.

- Color and Clarity: Decide whether you require clear, frosted, or tinted sheets based on the intended use.

Step 2: Identify Reputable Suppliers

Conduct thorough research to identify potential suppliers who specialize in acrylic products. Look for companies with a solid reputation in the industry and positive reviews from previous customers. This step is essential to ensure reliability and quality in your procurement process.

- Online Directories: Utilize platforms like Alibaba or ThomasNet to find verified suppliers.

- Industry Recommendations: Seek recommendations from industry peers or trade associations to discover trusted suppliers.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to vet them thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website; due diligence can save you from potential issues down the line.

- Certifications: Check for certifications that indicate quality standards, such as ISO certifications.

- Samples: Request samples of the perspex sheets to evaluate quality firsthand.

Step 4: Compare Pricing and Terms

Once you have shortlisted suppliers, compare their pricing structures and payment terms. Ensure you understand what is included in the price, such as shipping costs, taxes, and potential discounts for bulk purchases.

- Bulk Discounts: Inquire about pricing tiers based on order quantities to maximize your budget.

- Payment Terms: Understand the payment methods accepted and any credit options available.

Step 5: Confirm Shipping and Delivery Logistics

Shipping logistics can significantly impact your procurement process, especially when sourcing internationally. Confirm the shipping methods, delivery timelines, and associated costs with your chosen supplier.

- Freight Options: Discuss whether the supplier offers freight shipping and the implications for delivery times.

- Customs and Duties: Understand any customs requirements or duties that may apply when importing materials into your country.

Step 6: Negotiate and Finalize Contracts

Once you’ve decided on a supplier, negotiate the terms of the contract to ensure they align with your business needs. This includes confirming pricing, delivery schedules, and quality assurance processes.

- Contract Clarity: Ensure that all terms are clearly outlined in the contract to avoid misunderstandings.

- Quality Assurance: Establish terms for quality checks and returns in case the products do not meet the agreed specifications.

Step 7: Monitor and Evaluate Supplier Performance

After the procurement process is complete, continue to monitor the supplier’s performance regarding quality, delivery, and service. This ongoing evaluation will help you determine if you should maintain or adjust your supplier relationships in the future.

- Feedback Mechanism: Implement a system to gather feedback from your team on the product quality and supplier responsiveness.

- Regular Reviews: Schedule periodic reviews to reassess supplier performance and explore new sourcing options if necessary.

By following this checklist, you can enhance your sourcing strategy for perspex sheets, ensuring that you make informed decisions that benefit your business in the long run.

Comprehensive Cost and Pricing Analysis for perspex sheet 8 x 4 Sourcing

What Are the Key Cost Components in Sourcing Perspex Sheet 8 x 4?

When sourcing Perspex sheets (8 x 4 feet), understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The price of raw acrylic material (PMMA) significantly influences overall costs. Variations in quality and source can lead to price fluctuations.

-

Labor: The workforce involved in cutting, shaping, and finishing the sheets adds to the overall cost. Skilled labor can command higher wages, particularly in regions with stringent labor laws.

-

Manufacturing Overhead: This encompasses the costs of maintaining machinery, facilities, and utilities. Efficient manufacturing processes can minimize these costs, but they still represent a significant portion of the total price.

-

Tooling: Custom molds or tools for specific sheet designs can incur additional costs. Buyers should consider these when requesting custom sizes or shapes.

-

Quality Control (QC): Implementing stringent QC processes ensures product integrity but also adds to costs. Certifications (like ISO) may be required, especially for specific applications.

-

Logistics: Transportation costs can vary widely based on the shipping method, distance, and weight of the materials. International shipments may involve customs duties and tariffs, which should be factored into the total cost.

-

Margin: Suppliers typically build a margin into their pricing to cover risks and profit. Understanding the market average can help buyers gauge if a price is reasonable.

How Do Price Influencers Affect Perspex Sheet Costs?

Several factors influence pricing for Perspex sheets, which can vary significantly across regions, especially in Africa, South America, the Middle East, and Europe.

-

Volume/MOQ: Purchasing in larger quantities often leads to lower per-unit costs. Many suppliers offer tiered pricing based on minimum order quantities (MOQs), which can lead to significant savings.

-

Specifications and Customization: Custom specifications, such as thickness, color, or finish, can impact pricing. Clear cast sheets generally command higher prices than extruded alternatives due to their superior quality.

-

Material Quality and Certifications: Higher-grade acrylic with certifications may cost more but can offer enhanced durability and UV resistance, which may be essential for specific applications.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge a premium due to their track record of quality and service.

-

Incoterms: The choice of Incoterms affects who bears the costs and risks during shipping. Understanding these terms can lead to better negotiation outcomes and cost management.

What Buyer Tips Can Enhance Cost-Efficiency in Perspex Sheet Sourcing?

For international B2B buyers, especially from regions like Nigeria and Saudi Arabia, several strategies can enhance cost-efficiency:

-

Negotiate Effectively: Leverage volume orders and long-term relationships to negotiate better terms. Be prepared to discuss payment terms, delivery timelines, and price adjustments.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but the total cost, including logistics, potential wastage, and installation. Sometimes, a higher upfront cost can lead to lower long-term expenses due to durability.

-

Be Aware of Pricing Nuances: Prices can fluctuate based on exchange rates, local taxes, and tariffs. Staying informed about these factors can help buyers make timely purchasing decisions.

-

Research Supplier Backgrounds: Investigate potential suppliers’ financial stability and reputation. This helps in assessing risk and ensuring a reliable supply chain.

Disclaimer on Indicative Prices

Pricing for Perspex sheets can vary based on market conditions, and the figures provided are for illustrative purposes only. Always consult with suppliers for the most accurate and current pricing tailored to your specific needs and circumstances.

Alternatives Analysis: Comparing perspex sheet 8 x 4 With Other Solutions

When considering materials for various applications, it’s essential to evaluate alternatives that can fulfill similar roles as the perspex sheet 8 x 4. This analysis will help B2B buyers identify which material best suits their project requirements, whether it’s for construction, display, or protective applications.

Comparison Table

| Comparison Aspect | Perspex Sheet 8 x 4 | Acrylic Sheet (Clear Cast) | Polycarbonate Sheet |

|---|---|---|---|

| Performance | Strong, lightweight, UV resistant | Excellent clarity, shatter-resistant | Extremely impact resistant |

| Cost | Moderate cost | Generally higher cost | Variable; can be higher than acrylic |

| Ease of Implementation | Easy to cut, shape, and install | Requires special tools for cutting | Requires specific tools for cutting |

| Maintenance | Low maintenance | Low maintenance | Low maintenance, but can scratch |

| Best Use Case | Signage, furniture, displays | Aquariums, POP displays, furniture | Safety barriers, protective equipment |

Detailed Breakdown of Alternatives

Acrylic Sheet (Clear Cast)

Clear cast acrylic sheets are an alternative that offers excellent optical clarity and is shatter-resistant. They are ideal for applications where visibility and aesthetics are critical, such as aquariums and high-end displays. However, they can be more expensive than standard perspex sheets and may require specialized cutting tools, increasing the complexity of implementation. Their versatility makes them suitable for both indoor and outdoor use, but care must be taken to avoid scratching the surface.

Polycarbonate Sheet

Polycarbonate sheets are renowned for their exceptional impact resistance, making them a superior choice for environments that demand durability, such as safety barriers or protective equipment. They can withstand significant force without breaking, which is advantageous in high-traffic areas. However, they can be more expensive than both perspex and acrylic sheets, depending on the thickness and brand. Polycarbonate also tends to scratch more easily, which can detract from its appearance over time. Despite this, their strength and resilience often justify the investment for applications requiring robust materials.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right material depends on the specific requirements of your project. If you prioritize cost-effectiveness and ease of installation, the perspex sheet 8 x 4 is a solid choice for a variety of applications, including signage and furniture. For projects that demand higher clarity and aesthetics, consider clear cast acrylic, while polycarbonate is the go-to option for maximum durability and impact resistance. By assessing the unique needs of your application—be it performance, budget constraints, or maintenance considerations—you can make an informed decision that aligns with your operational goals.

Essential Technical Properties and Trade Terminology for perspex sheet 8 x 4

What Are the Key Technical Properties of Perspex Sheet 8 x 4?

-

Material Grade

Perspex, also known as acrylic or PMMA (polymethyl methacrylate), is renowned for its high clarity and UV resistance. The material grade refers to the quality of the acrylic, which can affect durability, transparency, and impact resistance. Higher-grade acrylic sheets are typically more suitable for demanding applications like aquariums or high-traffic displays, where strength and aesthetics are paramount. -

Thickness Tolerance

Thickness tolerance is critical in applications requiring precision, such as signage or display cases. For 8 x 4 acrylic sheets, typical tolerances range from ±10%, with most variations being less than ±5%. Understanding these tolerances helps buyers ensure that the sheets will fit within specific framing or mounting systems, preventing costly errors during installation. -

Impact Resistance

Acrylic sheets are approximately 17 times stronger than glass, making them an ideal choice for environments where shattering is a concern. This property is particularly important for B2B buyers in sectors like construction or retail, where safety and durability are vital. A high impact resistance means less likelihood of replacements and lower long-term costs. -

Moisture Resistance

Perspex sheets have excellent moisture resistance, which makes them suitable for various indoor and outdoor applications, from signage to protective barriers. This property is especially beneficial for businesses in humid climates, such as those in parts of Africa and South America, ensuring the longevity of products without degradation. -

UV Resistance

UV resistance is crucial for applications exposed to sunlight, as it prevents yellowing and degradation over time. This is particularly relevant for outdoor signage and displays. B2B buyers should prioritize UV-resistant acrylic sheets to maintain aesthetic quality and structural integrity in sunlit environments. -

Optical Clarity

The optical clarity of acrylic sheets is superior to that of glass, with a light transmission rate of over 90%. This property is essential for applications requiring transparency, such as display cases or windows. Buyers looking to enhance visibility and appeal in their products should consider acrylic sheets for their high-quality optical performance.

What Are Common Trade Terms Related to Perspex Sheet 8 x 4?

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of perspex sheets, understanding OEM relationships can help buyers source materials that meet specific performance standards for their products. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it affects inventory management and cost efficiency. Buyers should be aware of MOQs to avoid overstocking or incurring higher per-unit costs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. For perspex sheets, submitting an RFQ can help businesses compare suppliers and negotiate better terms, ensuring they receive competitive pricing for their bulk orders. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and risk management. Familiarity with Incoterms is essential for B2B buyers importing perspex sheets, as it impacts overall costs and logistics. -

Lead Time

Lead time refers to the time between placing an order and receiving the product. For perspex sheets, understanding lead times helps businesses plan their projects and manage customer expectations, which is vital in industries with tight deadlines. -

Cut-to-Size

This term describes the service where suppliers cut sheets to specific dimensions as per the buyer’s requirements. Cut-to-size services are valuable for B2B buyers who need customized dimensions for their applications, reducing the need for additional labor and waste.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they select the right perspex sheet 8 x 4 for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the perspex sheet 8 x 4 Sector

What Are the Key Market Dynamics and Trends for Perspex Sheets 8 x 4?

The global market for perspex sheets, particularly the 8 x 4 size, is witnessing significant growth driven by several factors. The demand for lightweight, durable, and versatile materials across various sectors—such as construction, signage, automotive, and retail—is a key driver. The increasing need for sustainable building materials, coupled with the rising popularity of acrylic in decorative applications, is pushing businesses to explore innovative solutions. Emerging technologies, such as advanced laser cutting and CNC machining, are enhancing the capabilities of perspex sheets, allowing for intricate designs and custom solutions that cater to specific industry needs.

International B2B buyers, especially those from Africa, South America, the Middle East, and Europe, are increasingly prioritizing suppliers that offer not only high-quality products but also efficient logistics and supply chain transparency. In regions like Nigeria and Saudi Arabia, where infrastructure development is rapidly progressing, the demand for reliable perspex sheet suppliers is expected to rise. Moreover, the expansion of e-commerce platforms is facilitating easier access to suppliers across borders, enabling businesses to source materials more effectively.

How Is Sustainability Influencing the Sourcing of Perspex Sheets?

Sustainability is becoming a cornerstone of B2B purchasing decisions in the perspex sheet sector. With growing awareness of environmental issues, buyers are increasingly seeking suppliers who adhere to ethical sourcing practices and offer eco-friendly materials. The environmental impact of acrylic production, including energy consumption and waste generation, is prompting manufacturers to adopt greener methods, such as using recycled materials and reducing carbon footprints.

Moreover, certifications such as ISO 14001 for environmental management systems and other green certifications are becoming essential for suppliers aiming to establish credibility in the market. B2B buyers are now more inclined to collaborate with manufacturers that can demonstrate their commitment to sustainability through responsible sourcing and production practices. This shift not only aligns with corporate social responsibility goals but also appeals to consumers who are increasingly favoring sustainable products.

How Has the Market for Perspex Sheets Evolved Over Time?

The evolution of the perspex sheet market reflects significant advancements in material technology and changing consumer preferences. Initially developed as a substitute for glass, perspex sheets have grown in popularity due to their superior impact resistance, lightweight properties, and versatility. Over the decades, manufacturers have improved the quality and range of acrylic sheets, introducing various thicknesses and finishes to meet diverse application needs.

In recent years, the focus has shifted toward customization and sustainability, with suppliers investing in technology to provide tailored solutions that cater to specific industry requirements. As environmental concerns gain prominence, the industry is also moving toward more sustainable practices, marking a significant shift in how perspex sheets are produced and marketed. This evolution highlights the importance of adaptability in meeting the demands of a dynamic global market while maintaining a commitment to quality and sustainability.

Frequently Asked Questions (FAQs) for B2B Buyers of perspex sheet 8 x 4

-

How do I choose the right thickness of perspex sheet 8 x 4 for my project?

Selecting the appropriate thickness of perspex sheet depends on the intended application. For lightweight structures like signage or displays, a thickness of 1/8″ (3mm) is often sufficient. However, for applications requiring durability, such as protective barriers or furniture, consider thicker sheets (up to 1″ or 25mm). Always evaluate factors like environmental exposure and load-bearing requirements to ensure optimal performance. -

What are the benefits of using perspex sheets instead of glass?

Perspex sheets, or acrylic sheets, offer numerous advantages over glass, including lower weight, higher impact resistance, and shatterproof properties. They are also easier to cut and shape, allowing for greater design flexibility. Additionally, perspex is UV resistant, making it suitable for outdoor applications without significant degradation over time. -

What customization options are available for perspex sheets?

Many suppliers offer customization options for perspex sheets, including cutting to specific dimensions, thickness variations, and color choices. Some manufacturers also provide surface treatments such as frosted or mirrored finishes. When sourcing, inquire about custom capabilities to meet your project specifications, ensuring you get precisely what you need. -

What is the minimum order quantity (MOQ) for perspex sheets?

MOQs for perspex sheets can vary significantly based on the supplier and the specific product. Many international suppliers may set an MOQ of 100 sheets, while others might allow smaller orders for customized products. It’s essential to discuss your needs with potential suppliers to understand their policies and negotiate suitable terms. -

How can I vet suppliers for perspex sheets in international markets?

To vet suppliers effectively, consider reviewing their certifications, customer reviews, and product samples. Request references from past clients, and assess their manufacturing capabilities and quality control processes. Additionally, ensure they comply with international trade regulations and have experience exporting to your region, which is crucial for smooth logistics. -

What payment terms are typically offered by suppliers for perspex sheets?

Payment terms can vary, but common arrangements include upfront payment, net 30, or letters of credit for larger orders. It’s advisable to negotiate terms that align with your cash flow and risk tolerance. Ensure to clarify the payment methods accepted, such as bank transfers or credit cards, to streamline the transaction process. -

What quality assurance measures should I expect from suppliers?

Reputable suppliers should implement robust quality assurance measures, including material testing for clarity, thickness, and impact resistance. Request documentation of their quality control processes, such as ISO certifications. Additionally, inquire about warranties or guarantees for the sheets, ensuring you are covered against defects. -

How is shipping handled for international orders of perspex sheets?

Shipping for perspex sheets typically involves freight services due to their size. Discuss shipping options with suppliers, including costs, delivery timelines, and insurance coverage. It’s crucial to understand customs regulations in your country and any potential tariffs or duties that may apply to ensure a smooth import process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 4 Perspex Sheet 8 X 4 Manufacturers & Suppliers List

1. Shapes Plastics – 1/4 Clear Cast Acrylic Sheet

Domain: shapesplastics.com

Registered: 2019 (6 years)

Introduction: {“product_name”: “1/4\” Clear Cast Acrylic Sheet”, “dimensions”: “48\” x 96\””, “price”: “$134.95”, “bulk_pricing”: [{“quantity”: 2, “price”: “$128.20”}, {“quantity”: 5, “price”: “$121.46”}, {“quantity”: 10, “price”: “$114.71”}], “sku”: “23324142”, “material_type”: “Acrylic/Plexiglass”, “features”: [“lightweight”, “impact-resistant”, “transparent”, “high impact strength”], “applications”: [“storm …

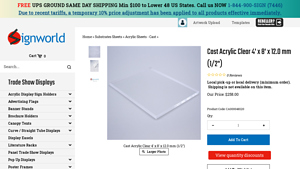

2. Display Wholesale – Clear Cast Acrylic Sheet 4′ x 8′ x 12mm

Domain: display-wholesale.com

Registered: 2008 (17 years)

Introduction: Cast Acrylic Clear 4′ x 8′ x 12.0 mm (1/2″)

Price: $258.00

Shipping: FREE UPS GROUND SAME DAY SHIPPING for orders over $100 to Lower 48 US States. Local pick-up or delivery available within 50 miles of California office.

Features:

– Low Internal Stress Level

– Lightweight (half the weight of glass)

– Good chemical resistance

– Maximum light transmission without hot spots, suitable for edge lighti…

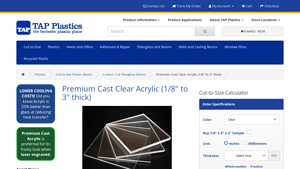

3. Tap Plastics – Acrylic Sheets

Domain: tapplastics.com

Registered: 1999 (26 years)

Introduction: Acrylic Sheets – Cast Clear, available in various sizes, ideal for a range of applications including displays, signage, and protective barriers. Offers high clarity, UV resistance, and is lightweight yet durable.

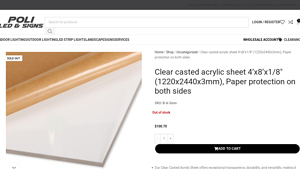

4. PoliLed Signs – Clear Cast Acrylic Sheet

Domain: poliledsigns.com

Registered: 2018 (7 years)

Introduction: Clear casted acrylic sheet 4’x8’x1/8″ (1220x2440x3mm), Paper protection on both sides, Exceptional transparency, durability, and versatility, Suitable for signage, displays, glazing, and architectural projects, Weather-resistant, Easy to cut and install, SKU: B-A-3mm, Price: $100.70

Strategic Sourcing Conclusion and Outlook for perspex sheet 8 x 4

What Are the Key Benefits of Strategic Sourcing for Perspex Sheets?

In conclusion, strategic sourcing of 8 x 4 perspex sheets offers significant advantages for international B2B buyers. By prioritizing high-quality acrylic materials that are lightweight, durable, and versatile, businesses can ensure they meet diverse application needs—from construction and signage to retail displays. The ability to customize thickness and finish further enhances the adaptability of these materials, making them suitable for various environments and climates.

Moreover, engaging with reliable suppliers can lead to cost efficiencies and improved supply chain resilience. Buyers from regions like Africa, South America, the Middle East, and Europe should actively explore partnerships with manufacturers and distributors who understand local market dynamics and can provide competitive pricing without compromising quality.

How Can You Prepare for Future Opportunities in the Acrylic Market?

Looking ahead, the demand for acrylic products is expected to grow as industries increasingly recognize their value. Businesses should stay informed about innovations in acrylic technology and seek out sustainable sourcing options to align with global trends. By proactively engaging in strategic sourcing, companies can position themselves to capitalize on emerging opportunities in the perspex sheet market. Take action today to enhance your procurement strategy and ensure your business remains competitive in a rapidly evolving landscape.