Top 4 Churros Machine Suppliers (And How to Choose)

Introduction: Navigating the Global Market for churros machine

In an increasingly competitive food market, sourcing the right churros machine is crucial for businesses looking to capitalize on the growing demand for this beloved treat. As churros gain popularity across continents—from the vibrant street markets of South America to the sophisticated cafes of Europe—B2B buyers face the challenge of selecting machines that not only meet production needs but also align with specific culinary traditions and consumer preferences. This guide provides a comprehensive overview of churros machines, covering various types such as manual, semi-automatic, and fully automatic options, as well as their applications in diverse settings, from food trucks to high-volume restaurants.

Understanding the nuances of the churros machine market is essential for making informed purchasing decisions. This guide equips international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, with vital insights into supplier vetting processes, cost considerations, and operational efficiencies. By highlighting key features such as energy efficiency, ease of use, and adaptability to different dough types, this resource empowers businesses to choose equipment that enhances their production capabilities and meets customer expectations. As you navigate the global market for churros machines, let this guide serve as your trusted companion in achieving culinary success and business growth.

Understanding churros machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Automatic Churro Machines | Advanced technology, programmable settings, high production speed | High-volume production for restaurants, food trucks | Pros: Efficient, consistent output; Cons: Higher initial investment. |

| Semi-Automatic Churro Machines | Combines manual and automatic controls, versatile nozzle options | Catering services, small to medium restaurants | Pros: Flexible operation; Cons: Requires some manual input. |

| Manual Churro Makers | Simple design, lever-operated cutting system, lower capacity | Small businesses, food stalls, home use | Pros: Cost-effective, easy to operate; Cons: Limited production capacity. |

| Digital Churro Makers | Touchscreen controls, customizable sizes, energy-efficient | Commercial bakeries, specialized churro shops | Pros: Precision control, energy-efficient; Cons: May require technical knowledge. |

| Churro Filling Machines | Designed for filling churros with various creams and toppings | Dessert shops, specialty food vendors | Pros: Enhances product variety; Cons: Additional equipment needed. |

What Are the Characteristics of Automatic Churro Machines?

Automatic churro machines are designed for high-volume production, making them ideal for businesses that require a consistent output of churros. These machines often feature programmable settings that allow operators to adjust cooking times and temperatures, ensuring uniform quality. They are suitable for large restaurants, food trucks, and commercial catering operations where efficiency is paramount. When considering an automatic churro machine, B2B buyers should evaluate the initial investment against potential productivity gains and return on investment.

How Do Semi-Automatic Churro Machines Operate?

Semi-automatic churro machines offer a balance between manual and automatic processes. They typically feature both automated functions and manual controls, allowing for flexibility in production. This type of machine is well-suited for catering services and small to medium-sized restaurants that may not require the full capacity of an automatic machine. Buyers should consider their specific production needs and space constraints, as well as the ease of use for staff.

Why Choose Manual Churro Makers for Small Operations?

Manual churro makers are characterized by their straightforward design and operation, often utilizing a lever mechanism for dough extrusion. They are ideal for small businesses, food stalls, or even home use, as they require a lower initial investment and minimal technical skill to operate. However, their production capacity is limited compared to automatic options. Buyers should assess their anticipated output and whether the simplicity of a manual machine aligns with their business model.

What Advantages Do Digital Churro Makers Offer?

Digital churro makers incorporate advanced technology, such as touchscreen controls, allowing for precise customization of churro sizes and cooking parameters. They are energy-efficient and suitable for commercial bakeries or specialized churro shops focused on high-quality products. While they offer significant benefits in terms of control and efficiency, buyers should be prepared for a steeper learning curve and potential technical support needs.

Illustrative image related to churros machine

How Do Churro Filling Machines Enhance Product Offerings?

Churro filling machines are specifically designed to fill churros with a variety of creams, jams, or toppings, thus expanding the product range for dessert shops and specialty food vendors. These machines can enhance customer experience by providing unique flavor combinations. However, buyers should consider the additional investment in equipment and whether their target market will appreciate the added value of filled churros.

Key Industrial Applications of churros machine

| Industry/Sector | Specific Application of churros machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Service | Restaurant and Café Churro Production | Enhances menu variety and customer satisfaction through fresh churros. | Durability, ease of cleaning, and precise temperature control are crucial. |

| Food Truck & Street Food | Mobile Churro Sales | Low investment with high-profit margins; flexibility to serve in various locations. | Compact design, portability, and energy efficiency are key factors. |

| Catering Services | Event and Party Catering | Ability to serve large quantities quickly, boosting event appeal. | Capacity, ease of operation, and quick heat-up time are essential. |

| Bakery & Confectionery | Churro Production for Dessert Items | Expands product offerings with unique dessert options. | Versatile nozzle options and customization capabilities are important. |

| Supermarkets & Retail | Pre-packaged Churros for Retail | Provides ready-to-eat options, catering to consumer convenience. | Consistency in product quality and compliance with food safety standards are critical. |

How Is the Churros Machine Used in the Food Service Industry?

In restaurants and cafés, churros machines are utilized to produce fresh churros on-site, enhancing the dessert menu and attracting customers. The ability to customize churros with various fillings and toppings caters to diverse tastes, boosting customer satisfaction. For international buyers, it is essential to consider machines that offer durability and ease of cleaning, as high-volume environments demand reliable equipment that can withstand daily use while ensuring food safety standards are met.

What Role Does the Churros Machine Play in Food Trucks and Street Food?

Food trucks and street food vendors leverage churros machines to provide a popular snack option with high-profit margins. The compact design and mobility of these machines allow vendors to serve churros at various events or locations without significant overhead costs. Buyers should prioritize energy-efficient models that require minimal space, ensuring they can operate effectively in diverse settings while maintaining consistent product quality.

How Can Catering Services Benefit from Churros Machines?

Catering services can significantly enhance their offerings by incorporating churros machines, enabling them to serve large quantities of churros at events and parties. The machines can produce churros quickly, appealing to guests and enhancing the overall experience. Buyers in this sector should focus on machines with a high capacity and ease of operation, as efficiency is crucial for meeting the demands of large gatherings while ensuring product quality.

In What Ways Are Churros Machines Used in Bakeries and Confectioneries?

Bakeries and confectioneries utilize churros machines to expand their dessert offerings, allowing them to create unique churro-based products that appeal to customers. This versatility can lead to increased sales and customer interest. Buyers should seek machines that offer various nozzle options for creating different churro shapes and sizes, as well as customization features to adapt to specific recipes or customer preferences.

How Do Supermarkets and Retailers Leverage Churros Machines?

Supermarkets and retail outlets can use churros machines to produce pre-packaged churros for consumers seeking convenient snack options. This strategy caters to the growing demand for ready-to-eat products, enhancing the store’s appeal. Key considerations for buyers in this sector include ensuring consistent product quality and compliance with food safety regulations, as well as the ability to scale production based on customer demand.

3 Common User Pain Points for ‘churros machine’ & Their Solutions

Scenario 1: High Maintenance Costs for Churro Machines

The Problem: Many B2B buyers, especially those operating in regions with limited access to high-quality maintenance services, face the challenge of high operational costs due to frequent breakdowns and repairs of churro machines. These machines are often subjected to heavy use in commercial environments, leading to wear and tear. Buyers may find that lower-quality machines require more frequent servicing, which not only increases maintenance costs but also impacts their production schedules and profitability.

The Solution: To mitigate these issues, buyers should invest in churro machines that emphasize durability and reliable build quality. Look for machines constructed with high-grade materials, such as 201 stainless steel, which can withstand the rigors of commercial use. Additionally, consider models that feature advanced heating elements for even heat distribution and precise temperature control, as these can enhance the longevity and performance of the machine. It’s also advisable to establish a maintenance schedule and partner with local service providers who specialize in food machinery to ensure timely repairs. Regular maintenance can help extend the lifespan of the equipment, reducing overall costs in the long run.

Scenario 2: Inconsistent Product Quality

The Problem: Achieving consistent product quality is a common pain point for businesses using churro machines. Variability in dough preparation, temperature settings, and frying times can lead to churros that differ in texture, taste, and appearance. This inconsistency can frustrate customers and damage a brand’s reputation, especially in competitive markets where quality is paramount.

The Solution: To ensure uniformity, buyers should invest in churro machines equipped with precise thermostat controls and advanced temperature regulation systems. Machines that allow for programmable settings can help streamline the cooking process, ensuring that every batch of churros is produced under the same conditions. Additionally, training staff on proper dough preparation techniques and machine operation is critical. Implementing a standard operating procedure (SOP) can help maintain quality control across production shifts. Buyers might also explore machines that offer multiple nozzle options for different churro shapes, allowing for greater product variety without sacrificing quality.

Illustrative image related to churros machine

Scenario 3: Limited Production Capacity

The Problem: As demand for churros grows, many businesses find their current machines unable to keep up with production needs. Whether operating a food truck or a full-scale restaurant, limited capacity can lead to long wait times for customers, ultimately affecting sales and customer satisfaction. This issue is particularly prominent in busy markets, where the ability to serve a high volume quickly can set a business apart from competitors.

The Solution: To address production capacity concerns, businesses should evaluate their current machinery against their sales projections. Investing in larger-capacity churro machines can significantly enhance output. For instance, machines with capacities ranging from 10L to 15L can produce churros more efficiently, allowing for higher volume during peak hours. Additionally, consider automated churro machines that reduce labor costs and increase efficiency by streamlining the cooking and serving process. Implementing a first-in, first-out (FIFO) system for dough can also help manage inventory and ensure freshness, maximizing production potential while minimizing waste. Regularly reviewing sales data can inform future investments, helping businesses scale their operations effectively.

Strategic Material Selection Guide for churros machine

What Are the Common Materials Used in Churros Machines?

When selecting materials for churros machines, it is crucial to consider their properties, advantages, and limitations. The right material can significantly impact the machine’s performance, durability, and overall cost-effectiveness. Below are analyses of four common materials used in churros machines: stainless steel, aluminum, cast iron, and high-temperature plastics.

Illustrative image related to churros machine

How Does Stainless Steel Perform in Churros Machines?

Stainless steel is the most prevalent material used in churros machines due to its excellent corrosion resistance and durability. It can withstand high temperatures, making it suitable for frying applications. Stainless steel typically has a temperature rating of up to 500°F (260°C) and is resistant to rust and staining, which is essential for maintaining hygiene in food processing equipment.

Pros: Stainless steel is durable, easy to clean, and compliant with food safety regulations, making it ideal for international markets. It also has a long lifespan, reducing the need for frequent replacements.

Cons: The initial cost of stainless steel components can be higher than other materials. Additionally, it may require more complex manufacturing processes, which can increase production time.

Impact on Application: Stainless steel is compatible with various media, including oils and water, making it versatile for different churro recipes.

Considerations for International Buyers: Buyers from regions such as Europe and the Middle East should ensure that the stainless steel used complies with standards like ASTM A240 or DIN 1.4301, which guarantee food-grade quality.

Illustrative image related to churros machine

What Are the Advantages of Aluminum in Churros Machines?

Aluminum is another common material used in churros machines, particularly for components that require lightweight construction. It has a lower temperature rating than stainless steel, typically around 400°F (204°C), but it offers excellent thermal conductivity, which helps in even heat distribution during frying.

Pros: Aluminum is lightweight, cost-effective, and allows for quicker heating, which can improve production efficiency. It is also easier to machine, leading to lower manufacturing complexity.

Cons: Aluminum is less durable than stainless steel and can corrode if not properly coated or anodized. This makes it less suitable for heavy-duty applications.

Impact on Application: Aluminum is compatible with frying oils, but its lower resistance to high temperatures may limit its use in certain high-heat applications.

Considerations for International Buyers: Buyers should look for anodized aluminum options to enhance corrosion resistance, especially in humid climates like those in parts of Africa and South America.

Why Is Cast Iron Used in Some Churros Machines?

Cast iron is often used in churros machines for its exceptional heat retention and even cooking properties. It can withstand high temperatures and is ideal for deep frying applications, making it a popular choice for industrial machines.

Pros: Cast iron is extremely durable and can last for decades with proper maintenance. It provides excellent heat retention, ensuring consistent cooking results.

Cons: The weight of cast iron can make machines cumbersome and less portable. Additionally, it requires regular seasoning to maintain its non-stick properties and prevent rust.

Impact on Application: Cast iron is suitable for high-temperature frying, but its heavy weight may not be ideal for all kitchen setups.

Considerations for International Buyers: Buyers should ensure that cast iron components meet local safety and health standards, particularly in regions with stringent food safety regulations.

How Do High-Temperature Plastics Fit into Churros Machines?

High-temperature plastics are increasingly being used in churros machines for non-structural components such as handles and control panels. These plastics can withstand temperatures up to 300°F (149°C) and offer good chemical resistance.

Pros: High-temperature plastics are lightweight, cost-effective, and can be molded into complex shapes, allowing for innovative designs.

Illustrative image related to churros machine

Cons: They are less durable than metals and may not withstand prolonged exposure to high heat, making them less suitable for critical cooking components.

Impact on Application: These plastics are ideal for non-contact parts, ensuring user safety while maintaining functionality.

Considerations for International Buyers: Buyers should verify that the plastics used are food-safe and compliant with regulations such as FDA or EU standards.

Summary Table of Material Selection for Churros Machines

| Material | Typical Use Case for churros machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Main structure and cooking components | Durable, corrosion-resistant, easy to clean | Higher initial cost, complex manufacturing | High |

| Aluminum | Lightweight components | Cost-effective, good thermal conductivity | Less durable, prone to corrosion | Medium |

| Cast Iron | Frying baskets and heavy-duty parts | Excellent heat retention and durability | Heavy, requires maintenance | Medium |

| High-Temperature Plastics | Handles and control panels | Lightweight, cost-effective, moldable | Less durable, limited heat resistance | Low |

This strategic material selection guide provides valuable insights for international B2B buyers, helping them make informed decisions when sourcing churros machines tailored to their specific needs and regional compliance standards.

Illustrative image related to churros machine

In-depth Look: Manufacturing Processes and Quality Assurance for churros machine

What Are the Main Stages of Manufacturing Churros Machines?

The manufacturing process of churros machines encompasses several critical stages that ensure the final product meets the needs of commercial kitchens and food service operations. Understanding these stages can help B2B buyers assess potential suppliers effectively.

Material Preparation

The initial stage involves sourcing high-quality materials such as stainless steel for durability and food safety. Stainless steel is favored due to its resistance to corrosion and ease of cleaning, which are essential in food production environments. Manufacturers typically conduct material inspections to ensure that the raw materials meet specified grades and standards. This stage may also include cutting and shaping the materials to prepare for assembly.

Forming and Assembly Techniques

After material preparation, the next step is forming the components of the churros machine. This can involve processes such as stamping, welding, and machining. For example, components like heating elements may be fabricated using advanced machining techniques to ensure precise dimensions and efficient operation.

The assembly process follows forming, where components are put together. This stage often includes the installation of critical parts such as thermostats, heating elements, and nozzles. Skilled technicians employ techniques like torque control to ensure that all components are securely fastened, preventing malfunctions during operation.

Finishing Processes

Finishing is the final stage of manufacturing, which may include surface treatment, painting, and quality checks. A common finishing technique is applying non-stick coatings to parts that come into direct contact with food. This not only enhances the performance of the machine but also ensures easy cleaning.

Quality assurance teams conduct thorough inspections during this stage to identify any defects or inconsistencies. Machines that pass these checks are often marked with certifications that indicate compliance with international standards.

How Is Quality Assurance Implemented in Churros Machine Production?

Quality assurance (QA) is a vital aspect of churros machine manufacturing, ensuring that the machines are safe, efficient, and reliable. B2B buyers should be familiar with the various QA standards and checkpoints that manufacturers typically adhere to.

What International Standards Should B2B Buyers Know?

International standards such as ISO 9001 are crucial for manufacturers aiming to demonstrate their commitment to quality management. This standard focuses on consistent product quality and customer satisfaction, which is essential in the competitive food machinery market.

Illustrative image related to churros machine

In addition to ISO certifications, other industry-specific certifications may be relevant. For instance, CE marking is important in Europe as it indicates that the machine meets EU safety, health, and environmental protection requirements. In regions like the Middle East, compliance with local standards is also essential.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are critical in the manufacturing process. Key checkpoints include:

-

Incoming Quality Control (IQC): This stage assesses raw materials upon arrival to ensure they meet required specifications before being used in production.

-

In-Process Quality Control (IPQC): Conducted during various manufacturing stages, IPQC involves monitoring processes and components to catch defects early. Techniques such as visual inspections and functional testing may be employed.

-

Final Quality Control (FQC): This final inspection ensures that the finished machines meet all design specifications and functional requirements before shipping. Common methods include performance testing and safety assessments.

What Testing Methods Are Commonly Used in Churros Machine Manufacturing?

Various testing methods are employed to validate the performance and safety of churros machines. These may include:

-

Functional Testing: Machines are operated under normal conditions to assess performance metrics such as temperature accuracy and dough consistency.

-

Durability Testing: This involves subjecting machines to prolonged use to ensure they can withstand the rigors of a commercial kitchen environment.

-

Safety Testing: Ensuring that machines comply with safety regulations, including electrical safety and food contact safety, is crucial. This may involve testing for overheating, electrical faults, and material safety.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive measures to verify the quality control practices of potential suppliers. Here are several approaches:

Conducting Supplier Audits

Performing on-site audits can provide insights into a supplier’s manufacturing processes and quality control systems. During these audits, buyers can assess compliance with international standards, review documentation, and observe production practices firsthand.

Illustrative image related to churros machine

Requesting Quality Assurance Reports

Buyers should ask for detailed quality assurance reports that outline the manufacturing process, testing methods, and results. These reports can serve as a valuable resource for understanding the supplier’s commitment to quality.

Engaging Third-Party Inspectors

Utilizing third-party inspection services can offer an unbiased evaluation of a supplier’s quality control practices. These inspectors can conduct thorough assessments and provide recommendations based on industry best practices.

What Are the QC and Certification Nuances for International Buyers?

International buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control and certification:

-

Regional Compliance Requirements: Different regions may have unique regulatory requirements. For instance, buyers in Europe must ensure CE compliance, while those in the Middle East may need to adhere to local safety standards.

-

Cultural Considerations: Understanding the cultural context of the supplier’s country can influence negotiations and expectations regarding quality. Some regions may prioritize certain certifications over others.

-

Supply Chain Transparency: In international transactions, transparency in the supply chain is critical. Buyers should seek clarity on sourcing, manufacturing, and shipping processes to mitigate risks associated with quality and compliance.

Conclusion

In summary, the manufacturing processes and quality assurance practices for churros machines are complex and multifaceted. B2B buyers must thoroughly understand these processes, international standards, and quality control measures to make informed purchasing decisions. By prioritizing quality and compliance, buyers can ensure that they invest in reliable, high-performance churros machines that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘churros machine’

This guide serves as a comprehensive checklist for B2B buyers seeking to procure churros machines. With the growing demand for churros in various markets, selecting the right equipment is crucial for ensuring quality production and operational efficiency. Follow these steps to make an informed purchasing decision.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the first step in your procurement process. Consider factors such as production capacity, machine size, and the type of churros you plan to produce (e.g., straight, looped, or thick). This clarity will help you identify machines that meet your operational needs and avoid overspending on features you won’t use.

Step 2: Research Different Types of Churros Machines

Familiarize yourself with the various types of churros machines available in the market. Options include manual, semi-automatic, and fully automatic machines, each suited for different production scales. Evaluate the advantages of each type, such as ease of use, labor costs, and production speed, to choose the best fit for your business model.

Step 3: Evaluate Potential Suppliers

Before making a purchase, thoroughly vet potential suppliers. Request company profiles, product catalogs, and customer references to gauge their reliability and quality standards. Look for suppliers that have experience in your region, as they may better understand local market conditions and compliance requirements.

Step 4: Verify Supplier Certifications

Ensure that your chosen suppliers hold relevant certifications, such as ISO or CE, which indicate adherence to quality and safety standards. This verification is crucial, especially when sourcing internationally, as it can affect product reliability and customer safety. Additionally, inquire about material quality to confirm that machines are made from safe, non-toxic materials.

Step 5: Consider Warranty and After-Sales Support

Review the warranty terms offered by suppliers and assess their after-sales support services. A robust warranty can protect your investment against defects, while effective after-sales support is essential for resolving any operational issues quickly. Inquire about the availability of spare parts and service options in your region to minimize downtime.

Step 6: Assess Delivery and Installation Options

Evaluate the supplier’s delivery and installation process, as these can significantly impact your operations. Ensure that the delivery timeline aligns with your business needs and inquire about any additional installation services provided. A smooth installation process can facilitate quicker production startup and reduce operational disruptions.

Step 7: Request Product Demonstrations

Whenever possible, request product demonstrations to assess the performance of the churros machines you are considering. A hands-on evaluation will give you insights into usability, efficiency, and product quality. This step is particularly important for high-capacity machines, where operational efficiency is critical to your business success.

Illustrative image related to churros machine

By following these steps, B2B buyers can navigate the complexities of sourcing churros machines more effectively, ensuring they select equipment that meets both their operational requirements and market demands.

Comprehensive Cost and Pricing Analysis for churros machine Sourcing

What Are the Key Cost Components in Churros Machine Sourcing?

When sourcing churros machines for commercial use, understanding the cost structure is essential for B2B buyers. The primary components influencing the total cost include:

-

Materials: The quality of materials used in manufacturing churros machines significantly affects pricing. High-grade stainless steel, for instance, ensures durability and resistance to corrosion, but it will increase upfront costs. Machines with advanced features like upgraded heating elements and nonstick coatings tend to be priced higher due to the superior materials involved.

-

Labor: Labor costs can vary based on the manufacturing location. For example, labor is generally cheaper in countries with lower wage standards, which can impact the overall pricing of the machine. However, sourcing from regions with higher labor costs often correlates with better craftsmanship and quality assurance.

-

Manufacturing Overhead: This encompasses all costs associated with the production process, such as utilities, rent, and administrative expenses. Manufacturers with efficient operations may pass on savings to buyers, while those with higher overhead will reflect these costs in their pricing.

-

Tooling: Custom machines or those with specialized features may require significant tooling investment, which can be a substantial portion of the initial cost. Buyers should consider whether they need custom specifications, as this can lead to higher tooling costs.

-

Quality Control (QC): Effective QC processes ensure that machines meet safety and performance standards. Suppliers with rigorous QC protocols may charge more, but this investment often results in higher quality and reduced maintenance costs over time.

-

Logistics: Shipping and handling costs vary based on the machine’s size, weight, and destination. For international buyers, understanding the logistics involved, including duties and tariffs, is crucial for budget planning.

-

Margin: Suppliers typically add a margin to cover their costs and profit. This can vary based on market demand, competition, and the perceived value of the machine.

How Do Price Influencers Impact Churros Machine Costs?

Several factors can influence the pricing of churros machines:

-

Volume/MOQ: The minimum order quantity (MOQ) can significantly affect pricing. Larger orders often qualify for discounts, making it more cost-effective for buyers.

-

Specifications and Customization: Machines with specific features, such as digital controls or unique nozzle designs, may come at a premium. Buyers should weigh the benefits of these features against their operational needs.

-

Quality and Certifications: Machines that meet international safety and quality standards may incur higher costs. However, they often provide peace of mind and reduce the likelihood of costly recalls or repairs.

-

Supplier Factors: Reputation and reliability of the supplier can influence pricing. Established manufacturers with a track record of quality and service may charge more but offer better support and warranty options.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for international buyers. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can impact overall costs.

What Are the Best Practices for Negotiating Churros Machine Prices?

For B2B buyers, especially in diverse markets such as Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to more favorable pricing:

-

Conduct Market Research: Familiarize yourself with pricing standards and competitor offerings. This knowledge empowers you to negotiate confidently.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also the long-term operational costs, including energy efficiency and maintenance. A higher initial investment in a quality machine could result in lower TCO.

-

Leverage Volume Discounts: If feasible, consolidate orders with other businesses to meet MOQs and unlock bulk pricing.

-

Be Clear About Specifications: Clearly define your requirements upfront to avoid costly changes later in the process.

-

Build Relationships with Suppliers: Establishing a good rapport with suppliers can lead to better negotiation outcomes and potential future discounts.

Disclaimer on Pricing

The indicative prices for churros machines vary widely based on specifications, supplier, and market conditions. Always request detailed quotes and assess the full cost implications before making a purchasing decision.

Alternatives Analysis: Comparing churros machine With Other Solutions

When considering the acquisition of a churros machine, it’s essential to evaluate various alternatives that can achieve similar objectives in producing churros or related products. This analysis will help B2B buyers make informed decisions based on performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Churros Machine | Manual Churro Maker | Automatic Dough Extruder |

|---|---|---|---|

| Performance | High output with consistent quality | Moderate output, labor-intensive | High output with customizable shapes |

| Cost | Ranges from $353 to $1,665 | Generally lower, around $200-$500 | Higher initial investment, $1,000-$5,000 |

| Ease of Implementation | Requires basic training | Simple to use, minimal training | Requires technical training |

| Maintenance | Regular cleaning; durable materials | Low maintenance; easy to clean | More complex maintenance required |

| Best Use Case | Commercial settings, food trucks | Small businesses or home use | Large-scale production facilities |

What Are the Advantages and Disadvantages of Using a Manual Churro Maker?

The manual churro maker offers a cost-effective solution for small businesses or home kitchens. These machines are generally more affordable, making them accessible for startups or individuals looking to produce churros without a significant investment. They require minimal training and are easy to clean. However, the output is limited compared to automatic machines, which may hinder production in high-demand settings. Additionally, the labor-intensive nature means that operators must be present during production, potentially increasing labor costs.

How Does an Automatic Dough Extruder Compare to a Churros Machine?

An automatic dough extruder is another viable alternative that can produce churros along with a variety of other shapes and sizes. This equipment is designed for high-volume production, making it suitable for large-scale operations such as factories or commercial bakeries. It offers consistent quality and can be programmed for different shapes, enhancing product variety. However, the initial investment is significantly higher, and it may require more technical knowledge for operation and maintenance. Businesses must weigh the benefits of versatility and efficiency against the costs and complexity involved.

Conclusion: How to Choose the Right Churro Production Solution for Your Business?

Selecting the appropriate churro production solution hinges on understanding your specific business needs and operational capacity. For businesses focused on high-volume production, a churros machine or automatic dough extruder may be the best fit despite the higher costs. Conversely, for smaller operations or those just starting, a manual churro maker can provide the necessary functionality without the financial burden. Ultimately, the decision should align with your production goals, budget constraints, and the level of automation desired in your manufacturing process.

Illustrative image related to churros machine

Essential Technical Properties and Trade Terminology for churros machine

What Are the Essential Technical Properties of a Churros Machine?

When selecting a churros machine, understanding the technical specifications is crucial for ensuring optimal performance and durability in a commercial kitchen environment. Here are some key properties to consider:

-

Material Grade

Churros machines are typically constructed from high-grade stainless steel, often 201 or 304. Stainless steel is favored for its durability, resistance to corrosion, and ease of cleaning. For B2B buyers, choosing machines made from higher-grade materials can lead to longer-lasting equipment, reducing the need for frequent replacements and maintenance. -

Heating Elements

The type of heating element can significantly impact the efficiency and consistency of churro production. Dual Incoloy heating elements are preferred as they provide rapid and even heating from both sides, ensuring that churros are cooked uniformly. This feature is vital for maintaining product quality and can enhance customer satisfaction, making it an important consideration for businesses focused on high-volume output. -

Thermostat Control

A precise thermostat control system allows for stable temperature management, which is essential for achieving consistent cooking results. Look for machines that offer advanced temperature control features. In a B2B context, reliable temperature control can minimize wastage and ensure that each churro meets the desired quality standards. -

Capacity

Churros machines come in various capacities, typically ranging from 3 liters to 15 liters. The appropriate capacity depends on the scale of production required by the business. A larger capacity machine is beneficial for high-demand environments such as food trucks and restaurants, while smaller units may suit bakeries or cafes with lower output needs. -

Ease of Cleaning

Machines with enhanced nonstick coatings and removable components facilitate easier cleaning. In a commercial setting, time is money; thus, machines that allow for quick and efficient cleaning can save labor costs and improve operational efficiency. -

Safety Features

Look for machines that incorporate safety features such as anti-return devices and effective insulation to prevent burns. These features are not only essential for compliance with health and safety regulations but also enhance the overall user experience, making them a priority for B2B buyers.

What Are Common Trade Terms in the Churros Machine Industry?

Familiarizing yourself with industry jargon can aid in effective communication and negotiation in B2B transactions. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of churros machines, an OEM may provide specialized components or entire machines that meet specific requirements for a buyer, ensuring compatibility and quality. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for buyers, as it affects inventory management and cash flow. For businesses looking to scale, negotiating favorable MOQ terms can lead to better pricing and supply reliability. -

RFQ (Request for Quotation)

An RFQ is a standard business process where a buyer requests a quote from suppliers for specific products or services. In the churros machine market, issuing an RFQ can help buyers compare costs and features among different manufacturers, ensuring that they make informed purchasing decisions. -

Incoterms (International Commercial Terms)

These are a set of rules that define the responsibilities of buyers and sellers for the delivery of goods under sales contracts. Understanding Incoterms is vital for international transactions, as they dictate shipping costs, risk transfer, and customs responsibilities, which can greatly influence the overall purchase price. -

Lead Time

This term refers to the amount of time it takes from placing an order until the product is delivered. For businesses, understanding lead times is essential for planning production schedules and managing customer expectations. -

Warranty

A warranty is a guarantee provided by the manufacturer regarding the condition of the machine and its performance over a specific period. Knowledge of warranty terms can protect buyers from unexpected costs and ensure that they receive quality equipment.

By understanding these essential properties and terms, B2B buyers can make more informed decisions when investing in churros machines, ultimately leading to better operational efficiencies and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the churros machine Sector

What Are the Key Market Dynamics and Trends Affecting the Churros Machine Sector?

The churros machine sector is experiencing significant growth, driven by the global popularity of churros as a snack and dessert option. This trend is particularly prominent in regions such as Africa, South America, the Middle East, and Europe, where churros are increasingly featured in restaurants, food trucks, and catering services. International B2B buyers are seeking machines that offer versatility, efficiency, and consistent product quality. The demand for automatic and semi-automatic churro makers is on the rise, as businesses aim to enhance production capabilities while minimizing labor costs.

Illustrative image related to churros machine

Emerging technologies are reshaping the manufacturing landscape of churros machines. Key innovations include digital controls for precise temperature regulation, energy-efficient heating elements, and user-friendly interfaces, such as touch screens. These advancements allow operators to customize the size and shape of churros, catering to diverse consumer preferences. Furthermore, the integration of IoT capabilities is gaining traction, enabling remote monitoring and maintenance of machines, which is particularly valuable for businesses operating in multiple locations.

As the market evolves, international B2B buyers are also focusing on sourcing strategies that prioritize reliability and quality. The establishment of partnerships with reputable manufacturers and suppliers ensures access to high-performance equipment that can withstand the rigors of commercial use. Additionally, buyers are increasingly considering the total cost of ownership, factoring in energy consumption, maintenance needs, and the longevity of the machines.

How Is Sustainability and Ethical Sourcing Shaping the Churros Machine Market?

Sustainability is becoming a cornerstone of the churros machine sector, reflecting the broader shift towards eco-conscious business practices. The environmental impact of manufacturing processes is under scrutiny, prompting buyers to seek machines made from sustainable materials and equipped with energy-efficient technologies. The use of stainless steel, which is not only durable but also recyclable, is becoming a standard in churros machine manufacturing.

Moreover, the importance of ethical supply chains cannot be overstated. B2B buyers are increasingly inclined to partner with suppliers who uphold fair labor practices and transparency in their operations. Certifications indicating adherence to environmental standards, such as ISO 14001, are becoming critical factors in procurement decisions. These certifications not only enhance brand reputation but also appeal to a growing consumer base that values ethical sourcing.

Investing in “green” technologies, such as machines that minimize energy consumption and waste production, is not just beneficial for the environment; it can also lead to cost savings for businesses in the long run. As consumers become more aware of sustainability issues, businesses that prioritize eco-friendly practices are likely to gain a competitive edge in the market.

Illustrative image related to churros machine

How Has the Churros Machine Sector Evolved Over Time?

The churros machine sector has a rich history that parallels the popularity of churros themselves, which trace their origins back to Spain. Initially, churros were made by hand, requiring significant labor and skill. The introduction of mechanical churros machines revolutionized the production process, allowing for consistent quality and higher output.

Over the decades, advancements in technology have led to the development of more sophisticated machines. From manual models to fully automated systems, the evolution has been driven by the need for efficiency and consistency in commercial settings. Today, manufacturers are focused on integrating digital technologies and sustainable practices, ensuring that churros machines not only meet the demands of modern food service but also align with the values of today’s consumers.

This ongoing evolution reflects a broader trend in the food equipment industry, where innovation and sustainability are key to meeting market demands and enhancing operational efficiency. As the churros market continues to grow, the machines that produce these beloved snacks will also adapt to meet the challenges and opportunities of the future.

Frequently Asked Questions (FAQs) for B2B Buyers of churros machine

-

How do I choose the right churros machine for my business?

Selecting the ideal churros machine depends on several factors including production capacity, type of churros you want to make, and your business model. For high-volume production, consider automatic machines with higher capacities (10L to 15L). If you prefer versatility, a semi-automatic machine allows for manual control while still offering automation features. Additionally, assess the machine’s features such as temperature control, nonstick surfaces, and ease of cleaning. Always review your specific needs and potential customer preferences before making a decision. -

What are the key features to look for in a churros machine?

Key features to consider include the machine’s material (stainless steel is preferable for durability), heating elements for consistent cooking, and precise temperature control for uniformity. Look for machines with nonstick coatings to ease cleaning and maintenance. If you plan to diversify your menu, consider models that come with multiple nozzle options for different churro shapes. Additionally, ensure the machine is energy-efficient to minimize operational costs, especially in regions with high energy prices. -

What is the typical lead time for ordering churros machines internationally?

Lead times for international orders can vary based on the manufacturer, shipping method, and your location. Generally, expect a lead time of 4 to 8 weeks for production and shipping. Factors such as customs clearance and local logistics can also affect delivery times. It’s advisable to communicate directly with the supplier to get precise estimates and consider using expedited shipping options if you need the equipment urgently. -

Are there minimum order quantities (MOQs) for churros machines?

Yes, many manufacturers impose minimum order quantities to ensure cost-effectiveness in production and shipping. MOQs can range from a single unit for smaller suppliers to several units for larger manufacturers. When sourcing, inquire about the MOQ and explore the possibility of negotiating lower quantities, especially if you’re just starting your business. Some suppliers may offer flexibility for first-time buyers or for specific types of machines. -

How can I verify the credibility of a churros machine supplier?

To vet a supplier, start by researching their business history, customer reviews, and any industry certifications. Request references from other B2B clients and assess their response times and customer service quality. It’s also beneficial to visit the supplier’s facility, if possible, or attend trade shows where they exhibit their products. Ensure they provide clear information about warranties, after-sales service, and technical support, which are crucial for ongoing operations. -

What payment terms should I expect when purchasing churros machines?

Payment terms can vary widely among suppliers, but common arrangements include a deposit upfront (typically 30% to 50%) with the balance due before shipping. Some suppliers may also accept letters of credit or payment through escrow services for larger transactions. Always clarify payment terms in advance and consider discussing options that align with your cash flow needs. Ensure that all terms are documented in the purchase agreement to prevent misunderstandings. -

What are the shipping and logistics considerations for importing churros machines?

When importing churros machines, consider shipping methods (air freight vs. sea freight) based on urgency and budget. Ensure you understand the total landed cost, which includes shipping, customs duties, and taxes. Engage a reliable freight forwarder to handle logistics and documentation. Familiarize yourself with local regulations regarding food equipment imports, as compliance may require specific certifications or inspections upon arrival. -

How do I ensure the quality of the churros machine before finalizing my order?

To ensure quality, request detailed product specifications and quality certifications from the supplier. If possible, ask for samples or demonstrations to evaluate the machine’s performance. Conduct thorough inspections upon delivery, checking for any damage or defects. Establish a clear return policy with the supplier in case the product does not meet your expectations. Engaging third-party quality assurance services can also provide an additional layer of verification before the machine is shipped.

Top 4 Churros Machine Manufacturers & Suppliers List

1. Ald Kitchen – Commercial Churro Makers

Domain: ald.kitchen

Introduction: High-Quality Commercial Churro Makers. Professional Churros Machine.

2. Industrias José Luis Blanco – Churro Machines & Equipment

Domain: maquinaschurros.com

Registered: 2004 (21 years)

Introduction: Industrias José Luis Blanco manufactures automatic and manual churro machines, dough mixers, and fryers. They offer a wide variety of high-tech models tailored to the needs of churro-making businesses. The company provides a 360 service including raw materials like flour and oil, and kitchen equipment essential for churro production. All machinery holds CE and FDA certifications, with some also ha…

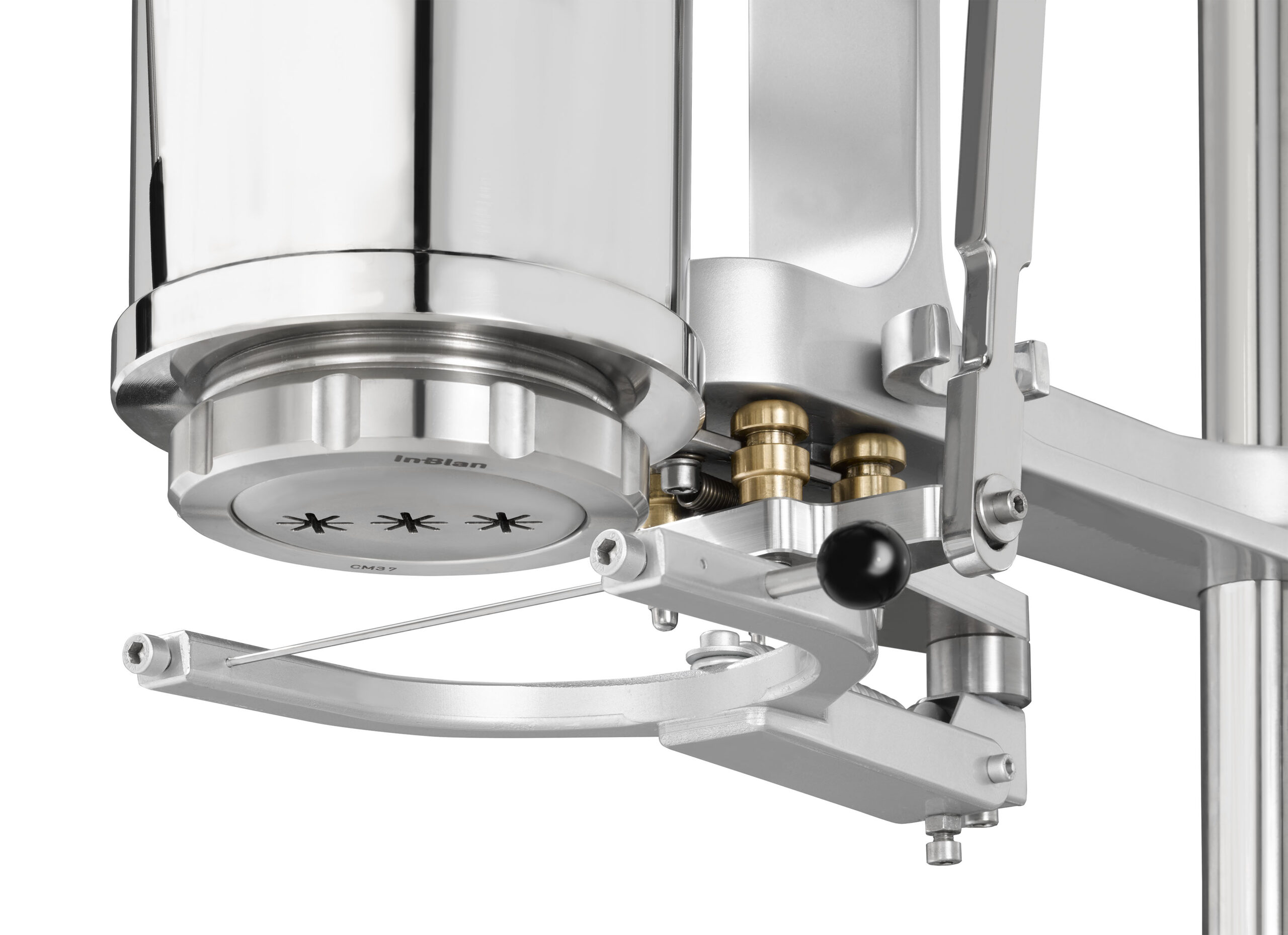

3. Inblan – Digital Automatic Churro Maker

Domain: inblan.com

Registered: 2000 (25 years)

Introduction: Digital Automatic Churro Maker designed for making straight churros, loop-shaped churros, and porras (extra-thick churros). Features include a stainless steel construction, low energy consumption, and a color touch screen for programming discharging speed and product size.

4. eBay – Commercial Churro Machines

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Commercial Churro Machines for sale on eBay include various models such as a 10L Manual Spanish Churro Machine and a 15L Electric Spanish Donuts Churrera. Prices range from $192.89 to $515.51, with options for free shipping and best offers available. The machines are categorized under Business & Industrial, specifically in Restaurant & Food Service, and are listed as brand new and unbranded.

Strategic Sourcing Conclusion and Outlook for churros machine

The global market for churro machines is evolving, driven by increasing demand for versatile, high-efficiency equipment that can enhance production capabilities. Key takeaways for B2B buyers include the importance of investing in machines that offer durability, energy efficiency, and precise control features. Advanced options like digital automatic churro makers and models with enhanced nonstick coatings not only improve product quality but also streamline operations, catering to diverse culinary needs across various regions.

Illustrative image related to churros machine

Strategic sourcing of churro machines is essential for businesses aiming to capitalize on the growing popularity of churros in various markets, including Africa, South America, the Middle East, and Europe. By choosing suppliers who prioritize quality and innovative technology, buyers can ensure a competitive edge in their respective markets.

Looking ahead, businesses should focus on building partnerships with manufacturers that understand local preferences and can offer tailored solutions. As the churro market expands, aligning with the right suppliers will be crucial in meeting consumer demands and driving profitability. Engage with leading manufacturers today to explore how the right churro machine can elevate your culinary offerings and operational efficiency.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to churros machine

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.