Everything You Need to Know About Nylon Tubing Sourcing in 2025

Introduction: Navigating the Global Market for nylon tubing

In an increasingly interconnected world, sourcing the right nylon tubing can present significant challenges for international B2B buyers. With diverse applications spanning automotive, robotics, and agriculture, the need for high-quality, durable tubing that meets specific regulatory standards is paramount. This guide serves as a comprehensive resource for navigating the complexities of the global nylon tubing market, offering insights into various types, applications, and the critical aspects of supplier vetting.

Understanding the nuances of nylon tubing—from standard and high-pressure options to specialized varieties like super soft nylon—is essential for making informed purchasing decisions. Buyers will also find valuable information on cost considerations, ensuring they can budget effectively while securing the best products.

This guide is tailored for B2B buyers across Africa, South America, the Middle East, and Europe, including countries like Vietnam and Germany, who are seeking to enhance their supply chains with reliable nylon tubing solutions. By empowering businesses with actionable insights and strategic advice, we aim to facilitate smoother sourcing processes and foster stronger supplier relationships, ultimately driving success in diverse industrial applications.

Understanding nylon tubing Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Nylon Tubing | Lightweight, flexible, and high corrosion resistance | Pneumatic systems, automotive, robotics | Pros: Versatile, good chemical resistance. Cons: Limited pressure ratings. |

| High Pressure Nylon Tubing | Designed to withstand higher pressures | Hydraulic systems, industrial machinery | Pros: Durable under pressure, reliable. Cons: Heavier, may be costlier. |

| Super Soft Nylon Tubing | Enhanced flexibility and softer feel | Medical applications, sensitive equipment | Pros: Excellent flexibility, reduces kinking. Cons: Lower pressure tolerance. |

| D.O.T. Nylon Tubing | Compliant with Department of Transportation standards | Fuel lines, automotive brake lines | Pros: Safety compliance, suitable for automotive use. Cons: Specific certifications may limit usage. |

| Nylon Mini Coils | Compact and coiled design for easy storage and transport | Robotics, pick and place machinery, space-constrained areas | Pros: Space-efficient, easy to handle. Cons: Limited length options. |

What are the Characteristics of Standard Nylon Tubing for B2B Buyers?

Standard nylon tubing is crafted from polyamide resin, providing a lightweight yet durable solution. It boasts high corrosion resistance and flexibility, making it suitable for a variety of pneumatic applications, automotive systems, and robotics. Buyers should consider the tubing’s temperature range of -60°F to 200°F and its excellent chemical resistance when evaluating its fit for specific applications. However, while versatile, its pressure ratings may not suffice for high-stress environments.

Why Choose High Pressure Nylon Tubing for Industrial Applications?

High pressure nylon tubing is engineered to handle elevated pressure levels, making it ideal for hydraulic systems and heavy industrial machinery. With a robust construction, this type of tubing ensures reliability in demanding environments. B2B buyers should prioritize this option when dealing with applications that require enhanced durability under pressure. While it offers superior performance, it is typically heavier and may come at a higher price point.

How Does Super Soft Nylon Tubing Benefit Medical Applications?

Super soft nylon tubing is characterized by its enhanced flexibility and softer texture, making it particularly suitable for medical applications and sensitive equipment. This type of tubing reduces the risk of kinking, ensuring a smooth flow in critical environments. Buyers in the medical field should consider its flexibility and lower pressure tolerance, which can be advantageous in applications where gentle handling is essential. However, it’s important to note that its softness may limit its use in high-pressure scenarios.

What Makes D.O.T. Nylon Tubing Essential for Automotive Uses?

D.O.T. nylon tubing is specifically designed to meet Department of Transportation standards, making it a reliable choice for automotive fuel lines and brake systems. Its compliance ensures safety and performance in critical applications. B2B buyers should look for this type of tubing when selecting components for vehicles, as it guarantees adherence to regulatory requirements. However, the need for specific certifications might restrict its usage in non-automotive applications.

What Advantages Do Nylon Mini Coils Offer for Robotics and Automation?

Nylon mini coils provide a compact and coiled design, making them an excellent choice for applications in robotics and pick-and-place machinery where space is limited. Their lightweight and flexible nature allows for easy handling and installation. Buyers should consider mini coils for projects requiring efficient use of space and easy transport. Nonetheless, potential limitations in length options should be factored into purchasing decisions, ensuring they meet the specific needs of the project.

Key Industrial Applications of nylon tubing

| Industry/Sector | Specific Application of Nylon Tubing | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Fuel and Vapor Lines | High resistance to heat and chemical corrosion | Ensure compliance with automotive standards and specifications. |

| Robotics | Pneumatic Systems for Actuation | Lightweight and flexible, enhancing operational efficiency | Look for customization options for specific robotic applications. |

| Agriculture | Chemical Processing Lines | Resistant to moisture and chemicals, improving durability | Verify chemical compatibility and UV stabilization. |

| Manufacturing | Tool Lubrication Systems | Reduces wear on machinery, increasing lifespan | Consider the tubing’s temperature and pressure ratings for specific applications. |

| Packaging | Pick and Place Systems | Enhances speed and accuracy in packaging processes | Evaluate the tubing’s flexibility and compatibility with automation equipment. |

How is Nylon Tubing Used in the Automotive Sector?

In the automotive industry, nylon tubing is extensively utilized for fuel and vapor lines due to its superior heat resistance and chemical compatibility. This application addresses the challenges of fuel degradation and vapor loss, ensuring the efficient operation of vehicles. International buyers, particularly from regions with stringent automotive regulations like Germany, should prioritize sourcing nylon tubing that meets specific automotive standards and certifications to ensure safety and compliance.

What Role Does Nylon Tubing Play in Robotics?

Nylon tubing serves a critical function in robotic systems, particularly in pneumatic applications where actuation is necessary. The lightweight and flexible properties of nylon tubing enhance the efficiency of robotic movements, allowing for precise control and reduced energy consumption. Buyers in regions like South America and Africa should consider customization options that cater to specific robotic designs, ensuring the tubing fits seamlessly into their systems.

How is Nylon Tubing Beneficial in Agriculture?

In agriculture, nylon tubing is used in chemical processing lines, providing a robust solution for transporting fertilizers and pesticides. Its resistance to moisture and chemicals significantly extends the lifespan of the tubing, reducing maintenance costs and downtime. When sourcing nylon tubing for agricultural applications, buyers should ensure compatibility with various chemicals and consider UV stabilization to withstand outdoor conditions prevalent in regions like the Middle East.

Why is Nylon Tubing Important in Manufacturing?

Nylon tubing is essential in manufacturing for tool lubrication systems, where it reduces friction and wear on machinery. This application enhances the longevity of tools and equipment, leading to increased productivity and reduced operational costs. Buyers in Europe should focus on the tubing’s temperature and pressure ratings to ensure it meets the demands of high-performance manufacturing environments.

How Does Nylon Tubing Enhance Packaging Processes?

In the packaging industry, nylon tubing is integral to pick and place systems, where it facilitates the rapid movement of products. The flexibility of nylon tubing allows for smooth operation, enhancing the speed and accuracy of packaging lines. B2B buyers should evaluate the tubing’s compatibility with automation equipment, ensuring it meets the specific requirements of their packaging processes, particularly in fast-paced markets across Africa and South America.

3 Common User Pain Points for ‘nylon tubing’ & Their Solutions

Scenario 1: Inconsistent Quality Across Suppliers

The Problem: B2B buyers often face challenges when sourcing nylon tubing from multiple suppliers, leading to inconsistencies in product quality. Variations in material specifications, such as wall thickness, flexibility, and chemical resistance, can result in operational disruptions. For instance, if a buyer purchases nylon tubing intended for hydraulic applications but receives a lower quality product, it could lead to leaks, equipment failure, or even safety hazards, affecting the entire production process.

The Solution: To mitigate this risk, buyers should establish a rigorous vetting process for suppliers. This includes requesting detailed technical specifications and certifications, such as compliance with industry standards like ASTM or ISO. Additionally, implementing a supplier audit program can ensure consistent quality by evaluating manufacturing processes, quality control measures, and product testing protocols. Buyers should also consider building long-term relationships with a select few trusted suppliers to maintain consistency in material quality, thereby streamlining procurement and reducing the risk of unexpected discrepancies.

Scenario 2: Difficulty in Selecting the Right Nylon Tubing Type

The Problem: With various types of nylon tubing available—such as standard, high-pressure, and super soft—B2B buyers often struggle to determine which type best suits their specific applications. This confusion can lead to selecting the wrong tubing, resulting in performance issues, increased costs, and potential safety risks. For example, using standard nylon tubing in a high-pressure system could lead to catastrophic failures and costly downtime.

The Solution: To address this challenge, buyers should invest time in understanding the specific requirements of their applications. This includes factors such as operating pressure, temperature ranges, and chemical compatibility. Creating a comparison chart that outlines the properties and applications of different nylon tubing types can serve as a valuable reference tool. Furthermore, consulting with manufacturers or suppliers who can provide expert guidance on selecting the appropriate tubing based on application needs can enhance decision-making. Utilizing a sample testing approach before committing to larger orders can also help ensure that the chosen nylon tubing meets all operational requirements.

Scenario 3: Environmental Compliance Challenges

The Problem: As global regulations regarding environmental impact tighten, B2B buyers of nylon tubing may find it challenging to ensure that their products comply with standards such as REACH or RoHS. Failing to meet these regulations can lead to significant legal repercussions, product recalls, and damage to a company’s reputation. For example, if a manufacturer unknowingly uses nylon tubing that contains restricted substances, it could face penalties and harm its standing in the market.

The Solution: Buyers should prioritize sourcing nylon tubing from manufacturers that provide transparent information about their compliance with environmental regulations. This includes requesting documentation and certifications that confirm adherence to standards like REACH or RoHS. Implementing a compliance checklist can help buyers systematically evaluate suppliers and their products. Additionally, staying informed about evolving regulations through industry associations or legal advisories can help buyers anticipate changes and adapt their sourcing strategies accordingly. Engaging in proactive dialogue with suppliers about their sustainability practices can also foster partnerships that support compliance and environmental responsibility.

Strategic Material Selection Guide for nylon tubing

What Are the Key Properties of Common Materials Used in Nylon Tubing?

Nylon tubing is primarily made from polyamide resins, with variations that cater to specific industrial needs. The most common types include Nylon 6 and Nylon 11, each with distinct properties that influence their performance in various applications. Understanding these materials can help B2B buyers select the most suitable nylon tubing for their needs.

Nylon 6: Versatile and Cost-Effective

Nylon 6 is widely used due to its balance of strength, flexibility, and cost-effectiveness. It has a temperature rating of up to 190°C (374°F) and exhibits good resistance to abrasion and chemicals. However, it is more susceptible to moisture absorption compared to Nylon 11, which can affect its dimensional stability in humid environments.

Pros: Nylon 6 is generally less expensive and easier to manufacture, making it a popular choice for cost-sensitive applications. Its versatility allows it to be used in various sectors, including automotive and industrial machinery.

Cons: The moisture absorption can lead to swelling and loss of mechanical properties over time, particularly in humid climates. This is a significant consideration for buyers in regions like Africa and South America, where humidity levels can be high.

Nylon 11: Enhanced Performance for Specialized Applications

Nylon 11 is known for its superior flexibility and lower moisture absorption compared to Nylon 6. It can withstand temperatures up to 200°C (392°F) and offers excellent chemical resistance, making it ideal for applications involving aggressive media.

Pros: Its flexibility and chemical resistance make Nylon 11 suitable for pneumatic applications and environments where tubing is subject to bending and movement. The material’s durability also extends its lifespan, reducing replacement costs.

Cons: Nylon 11 tends to be more expensive than Nylon 6, which may deter some buyers. Additionally, its manufacturing process can be more complex, potentially leading to longer lead times for custom orders.

Nylon Tubing with Reinforcements: Strength and Durability

Reinforced nylon tubing incorporates materials like fiberglass or other polymers to enhance strength and pressure ratings. This type of tubing is particularly useful in high-pressure applications, such as hydraulic systems.

Pros: The reinforcement significantly increases the tubing’s pressure rating and durability, making it suitable for demanding environments. This can be a critical factor for industries like oil and gas or heavy machinery.

Cons: The added materials can increase the cost and complexity of manufacturing. Buyers should also consider whether the added strength is necessary for their specific application, as it may lead to over-engineering.

How Do Material Considerations Impact International B2B Buyers?

When selecting nylon tubing, international buyers must be aware of compliance with local standards such as ASTM (American Society for Testing and Materials), DIN (Deutsches Institut für Normung), and JIS (Japanese Industrial Standards). Different regions may have varying regulations regarding material safety and environmental impact, particularly in Europe, where REACH and RoHS compliance are critical.

Buyers in Africa and South America should also consider the availability of materials and local suppliers, as logistics can significantly impact lead times and costs. Understanding the specific requirements of their applications, including media compatibility and environmental conditions, is essential for making informed purchasing decisions.

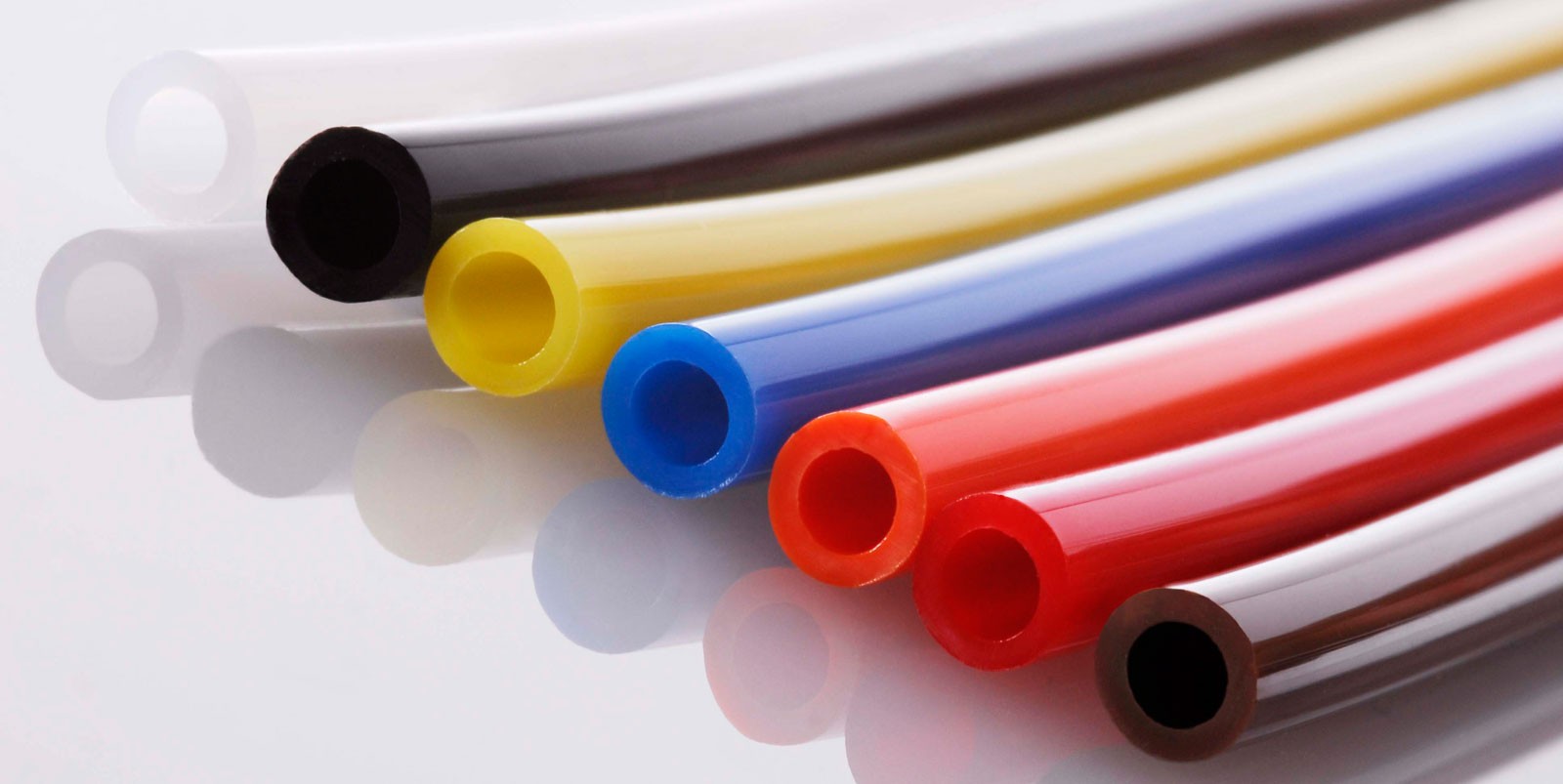

Illustrative image related to nylon tubing

Summary Table of Material Properties for Nylon Tubing

| Material | Typical Use Case for nylon tubing | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nylon 6 | General industrial applications | Cost-effective and versatile | Susceptible to moisture absorption | Low |

| Nylon 11 | Pneumatic and chemical applications | Superior flexibility and chemical resistance | Higher cost and manufacturing complexity | High |

| Reinforced Nylon | High-pressure hydraulic systems | Increased strength and pressure rating | Higher cost and potential over-engineering | Medium |

This guide provides a comprehensive overview of the materials used in nylon tubing, equipping international B2B buyers with the knowledge to make informed decisions tailored to their specific needs.

In-depth Look: Manufacturing Processes and Quality Assurance for nylon tubing

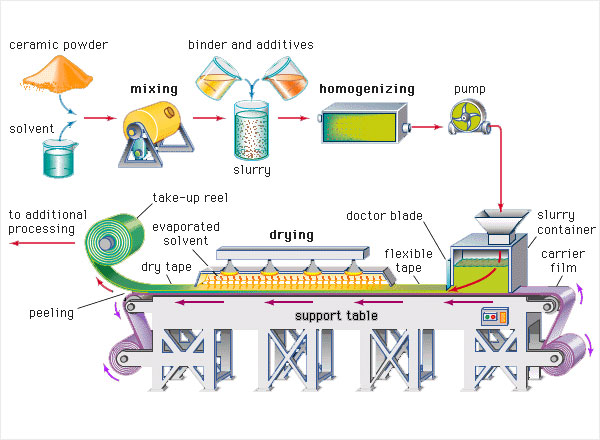

What Are the Key Stages in the Manufacturing Process of Nylon Tubing?

The manufacturing process of nylon tubing involves several critical stages, each designed to ensure the final product meets the stringent requirements of various industries. Understanding these stages is crucial for B2B buyers to assess the quality and reliability of their suppliers.

1. Material Preparation

The first step in the manufacturing process is the preparation of nylon resin, typically derived from polyamide. Manufacturers often select specific grades of nylon, such as Nylon 6 or Nylon 11, based on the intended application. The resin is dried to remove moisture, which is vital to prevent defects during the extrusion process. Suppliers often use advanced drying techniques to ensure optimal moisture content, as this can significantly affect the mechanical properties of the final tubing.

2. Forming: Extrusion Process

The core manufacturing technique for nylon tubing is extrusion. In this process, the dried nylon resin is heated and forced through a die to form a continuous tube. The extrusion process allows for precise control over the tubing’s diameter and wall thickness, which can be tailored to meet specific application needs. During this stage, manufacturers may also incorporate additives to enhance properties such as UV resistance or flexibility.

Additionally, some suppliers offer co-extrusion, where multiple layers of different materials are combined to create specialized tubing with unique properties, such as improved chemical resistance or enhanced strength.

3. Assembly: Cutting and Coiling

Once extruded, the nylon tubing is cut to the desired lengths or coiled for easier handling and transportation. This stage may include additional processes like bonding or printing, depending on customer specifications. Customization options, such as color matching or adding branding, are often available, allowing B2B buyers to align products with their corporate identity or specific project requirements.

4. Finishing: Quality Enhancements

The finishing stage includes several treatments to enhance the tubing’s performance characteristics. This may involve processes such as heat setting, which stabilizes the material and improves its resistance to deformation under stress. Manufacturers may also apply surface treatments to improve chemical resistance or enhance the aesthetic appeal of the tubing.

How Is Quality Assurance Implemented in Nylon Tubing Manufacturing?

Quality assurance (QA) is a crucial aspect of the nylon tubing manufacturing process, ensuring that products meet international standards and customer expectations. B2B buyers should be familiar with the various QA measures and standards that suppliers adhere to.

International Standards: What to Look For?

Most reputable manufacturers comply with international quality management standards such as ISO 9001. This certification indicates that the manufacturer has implemented a quality management system that focuses on continuous improvement and customer satisfaction. In addition, industry-specific certifications such as CE (for European markets) or API (for applications in the oil and gas sector) are essential indicators of product reliability and safety.

Illustrative image related to nylon tubing

What Are the Key Quality Control Checkpoints?

Quality control (QC) is integrated throughout the manufacturing process with specific checkpoints, including:

-

Incoming Quality Control (IQC): Raw materials are inspected upon receipt to ensure they meet specified standards before production begins.

-

In-Process Quality Control (IPQC): During the extrusion and assembly stages, samples are taken at regular intervals to monitor quality parameters such as dimensions, wall thickness, and surface finish. Any deviations from the standard can be addressed immediately, minimizing waste and defects.

-

Final Quality Control (FQC): After the production is complete, a thorough inspection of the finished products is conducted. This includes mechanical testing, such as tensile strength and flexibility tests, as well as visual inspections to check for surface defects.

What Testing Methods Are Commonly Used in Nylon Tubing Quality Assurance?

Manufacturers employ a variety of testing methods to ensure that nylon tubing meets industry specifications and customer requirements. Some common testing methods include:

-

Mechanical Testing: Tensile strength, elongation, and hardness tests are conducted to evaluate the material’s performance under stress.

-

Chemical Resistance Testing: Tubing is exposed to various chemicals to determine its compatibility and resistance, which is particularly important for applications in the chemical processing and food industries.

-

Thermal Analysis: Tests such as Differential Scanning Calorimetry (DSC) are used to assess the thermal properties of nylon, including melting point and thermal stability.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers adhere to rigorous quality standards, B2B buyers can implement several verification strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control measures firsthand. This can include reviewing documentation of compliance with international standards and evaluating the effectiveness of QC checkpoints.

-

Requesting Quality Reports: Buyers should request detailed quality reports that outline testing results, compliance with standards, and any non-conformance issues that may have arisen during production.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes and product compliance. This is especially useful for international transactions where buyers may not have direct oversight of the manufacturing facility.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing nylon tubing from international suppliers, particularly in regions like Africa, South America, the Middle East, and Europe, buyers should be aware of potential quality control nuances:

-

Regulatory Compliance: Different regions have varying regulatory requirements. For instance, products sold in the EU must meet CE marking standards, while those in the U.S. may need to comply with FDA regulations for specific applications. Buyers should ensure that their suppliers are knowledgeable about and compliant with these regulations.

-

Cultural Differences in Quality Standards: Quality expectations may vary between countries. It’s essential for buyers to communicate their specific quality requirements clearly and to understand the supplier’s capabilities in meeting those expectations.

-

Logistics and Supply Chain Considerations: Quality control can also be affected by logistics. Delays or mishandling during transportation can compromise product integrity. Buyers should work closely with suppliers to establish reliable logistics solutions that include quality checkpoints throughout the supply chain.

By understanding the manufacturing processes and quality assurance protocols for nylon tubing, B2B buyers can make informed decisions and foster successful partnerships with reliable suppliers.

Illustrative image related to nylon tubing

Practical Sourcing Guide: A Step-by-Step Checklist for ‘nylon tubing’

Introduction

This sourcing guide aims to equip B2B buyers with a practical checklist for procuring nylon tubing. Whether you’re in the automotive, agricultural, or chemical processing industries, understanding the critical aspects of sourcing nylon tubing will help ensure you select the right products for your needs.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly define your technical requirements. Consider factors such as the tubing’s diameter, wall thickness, and temperature resistance. Understanding these specifications will help you communicate effectively with suppliers and ensure that the products meet your operational needs.

Step 2: Research Supplier Capabilities

Conduct thorough research on potential suppliers to assess their manufacturing capabilities. Look for suppliers that specialize in nylon tubing and have experience in your industry. This ensures they can meet your specific requirements and have the necessary expertise to deliver quality products.

- Check Product Range: Ensure the supplier offers various types of nylon tubing, such as high-pressure options or custom sizes.

- Assess Innovation: A supplier that invests in R&D may provide advanced materials with superior performance characteristics.

Step 3: Evaluate Supplier Certifications

Verifying supplier certifications is crucial for ensuring product quality and compliance with industry standards. Look for certifications such as ISO 9001, RoHS, and REACH, which indicate that the supplier adheres to international quality and safety standards.

Illustrative image related to nylon tubing

- Request Documentation: Don’t hesitate to ask for copies of certifications to verify compliance.

- Understand Regulatory Compliance: Ensure that the tubing meets local regulations, especially if you are importing products to specific regions.

Step 4: Request Samples for Testing

Before making a bulk purchase, request samples of the nylon tubing. Testing samples can help you evaluate the material’s performance under real-world conditions, including flexibility, temperature tolerance, and chemical resistance.

- Conduct Rigorous Testing: Assess the samples against your specifications and operational conditions.

- Gather Feedback: Involve your technical team in the evaluation process to ensure the product meets all functional requirements.

Step 5: Compare Pricing and Terms

Once you have identified a shortlist of suppliers, compare pricing and terms. While cost is an important factor, consider the overall value, including quality, delivery times, and payment terms.

- Evaluate Total Cost of Ownership (TCO): Consider long-term costs, such as maintenance and replacement, in addition to the initial purchase price.

- Negotiate Terms: Don’t hesitate to negotiate terms, especially for larger orders, to secure better pricing or favorable payment options.

Step 6: Verify Customer Support and Service

Assess the level of customer support and service provided by the suppliers. Reliable communication and support are essential for resolving issues that may arise during the procurement process.

- Check Responsiveness: Evaluate how quickly suppliers respond to inquiries and their willingness to provide assistance.

- Review Service Options: Look for suppliers that offer after-sales support, such as troubleshooting and technical assistance.

Step 7: Finalize Contracts and Place Orders

After selecting a supplier, finalize contracts that clearly outline all agreed-upon terms, including delivery schedules, payment terms, and quality expectations. Ensure both parties have a mutual understanding to avoid disputes later.

Illustrative image related to nylon tubing

- Include Penalty Clauses: Consider including clauses that protect you in case of non-compliance with delivery or quality standards.

- Document Everything: Keep thorough records of all communications and agreements for future reference.

By following this checklist, B2B buyers can make informed decisions when sourcing nylon tubing, ultimately leading to successful procurement outcomes.

Comprehensive Cost and Pricing Analysis for nylon tubing Sourcing

What Are the Key Cost Components in Nylon Tubing Sourcing?

When sourcing nylon tubing, understanding the cost structure is crucial for effective budget management and negotiation. The primary cost components include:

-

Materials: The choice of nylon resin significantly impacts pricing. Standard nylon 6 is commonly used, but higher grades like nylon 11 may be more expensive due to their enhanced properties, such as better chemical resistance and lower moisture absorption.

-

Labor: Labor costs vary based on geographical location and the complexity of manufacturing processes. Regions with lower labor costs may offer competitive pricing, but this can also affect product quality.

-

Manufacturing Overhead: This encompasses indirect costs related to production facilities, utilities, and equipment maintenance. Efficient manufacturing processes can help reduce overhead and enhance competitiveness.

-

Tooling: Initial tooling costs for molds and specialized equipment can be substantial, particularly for custom nylon tubing. Buyers should consider these costs when evaluating overall pricing.

-

Quality Control (QC): Ensuring product quality through stringent QC measures can increase costs but is essential for compliance with industry standards, especially in sectors like automotive and medical.

-

Logistics: Shipping and handling costs are influenced by the distance from the supplier and the complexity of the supply chain. For international buyers, understanding Incoterms is vital to determine who bears these costs.

-

Margin: Suppliers typically add a markup to cover their operational costs and profit margin. Understanding the typical margin in the nylon tubing market can help buyers negotiate more effectively.

How Do Price Influencers Affect Nylon Tubing Costs?

Several factors influence pricing in the nylon tubing market:

-

Volume/MOQ: Bulk orders can significantly reduce per-unit costs. Suppliers often provide price breaks for larger quantities, making it beneficial for buyers to consolidate orders.

-

Specifications/Customization: Customized solutions tailored to specific applications often come at a premium. Buyers should weigh the need for customization against standard options to find the most cost-effective solution.

-

Materials: The choice between standard and high-performance nylon resins can lead to significant price variations. Buyers should assess their specific requirements carefully.

-

Quality and Certifications: Products that meet rigorous quality standards or certifications (e.g., ISO, RoHS) might carry higher prices. However, these certifications can also reduce long-term risks and costs associated with product failure.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge higher prices due to their proven track record, while emerging suppliers might offer lower prices to gain market share.

-

Incoterms: Understanding the shipping terms is essential for accurate cost estimation. Different Incoterms dictate who is responsible for shipping costs, insurance, and customs duties, which can affect the final price significantly.

What Are the Best Negotiation Strategies for International Buyers?

International buyers should adopt several strategies to optimize their nylon tubing sourcing:

-

Conduct Market Research: Understanding market prices and trends helps buyers negotiate effectively. Knowledge of regional pricing can provide leverage in discussions.

-

Focus on Total Cost of Ownership (TCO): Buyers should evaluate not just the purchase price but also the total cost over the product’s lifecycle, including maintenance, replacement, and logistics.

-

Negotiate Payment Terms: Flexible payment terms can alleviate cash flow pressures and enhance business relationships. Buyers should discuss options like extended payment terms or discounts for upfront payments.

-

Build Long-term Relationships: Establishing a strong partnership with suppliers can lead to better pricing, priority service, and access to new products.

-

Be Aware of Pricing Nuances: International buyers should understand the implications of currency fluctuations, tariffs, and trade agreements that may impact overall costs.

Conclusion: What Should Buyers Keep in Mind?

While sourcing nylon tubing, buyers should remain vigilant about the various cost components and pricing influencers. By leveraging negotiation strategies and focusing on the total cost of ownership, international buyers can secure more favorable terms that align with their operational needs. Keep in mind that prices can fluctuate based on market conditions and supplier dynamics, so it’s essential to stay informed and adaptable.

Alternatives Analysis: Comparing nylon tubing With Other Solutions

Understanding Alternatives to Nylon Tubing in Industrial Applications

In the realm of fluid transport and pneumatic applications, nylon tubing has established itself as a reliable solution. However, buyers may also consider alternative materials that offer different advantages depending on specific operational requirements. This section provides a comparative analysis of nylon tubing against two viable alternatives: polyurethane tubing and polyethylene tubing.

Illustrative image related to nylon tubing

| Comparison Aspect | Nylon Tubing | Polyurethane Tubing | Polyethylene Tubing |

|---|---|---|---|

| Performance | High heat resistance, good flexibility, and chemical resistance; operates effectively in temperatures from -60°F to 200°F. | Excellent flexibility and abrasion resistance; can handle moderate temperatures well. | Good chemical resistance, but limited heat resistance; operates effectively up to 180°F. |

| Cost | Moderate to high cost based on specifications and customization. | Typically higher cost due to advanced properties and durability. | Generally lower cost, making it budget-friendly for large-scale applications. |

| Ease of Implementation | Requires specific fittings and installation techniques; can be custom ordered. | Easy to install with standard fittings; available in various configurations. | Very easy to work with; often available in pre-cut lengths and rolls. |

| Maintenance | Low maintenance, but regular inspections recommended for wear. | Very low maintenance due to high durability and resistance to wear. | Low maintenance, but susceptible to UV degradation if not stabilized. |

| Best Use Case | Ideal for automotive, pneumatic, and chemical processing applications. | Best suited for applications requiring flexibility and resistance to abrasion, such as robotics and pneumatic systems. | Suitable for general fluid transport, agricultural applications, and where cost is a primary concern. |

What Are the Advantages and Disadvantages of Polyurethane Tubing?

Polyurethane tubing is known for its exceptional flexibility and durability, making it a strong contender against nylon tubing. It performs well in high-abrasion environments and can withstand moderate temperatures, making it ideal for applications in robotics and pneumatic systems. However, its higher cost can be a drawback for budget-conscious buyers. Additionally, while it offers lower maintenance needs, the need for specific fittings and potential limitations in temperature extremes can limit its applicability in some environments.

How Does Polyethylene Tubing Compare to Nylon Tubing?

Polyethylene tubing is a cost-effective alternative that is widely used in various industries. It has good chemical resistance, making it suitable for fluid transport in agricultural and industrial applications. Its ease of implementation and lower cost are significant advantages. However, it lacks the heat resistance and flexibility of nylon tubing, which may limit its use in high-temperature applications. Furthermore, without proper UV stabilization, polyethylene tubing can degrade over time when exposed to sunlight, affecting its longevity.

How to Choose the Right Tubing Solution for Your Needs

When selecting between nylon tubing and its alternatives, B2B buyers should consider several factors, including the specific application requirements, budget constraints, and the operational environment. Nylon tubing is best for applications requiring high heat resistance and chemical durability, while polyurethane offers superior flexibility and wear resistance, albeit at a higher cost. Polyethylene is an excellent choice for cost-sensitive projects where extreme heat resistance is not a priority. By carefully assessing these aspects, buyers can make informed decisions that align with their operational goals and enhance their productivity.

Essential Technical Properties and Trade Terminology for nylon tubing

What Are the Key Technical Properties of Nylon Tubing?

Understanding the technical specifications of nylon tubing is essential for B2B buyers looking to select the right product for their needs. Here are some critical properties to consider:

1. Material Grade

Nylon tubing is often produced from polyamide resins, with nylon 6 and nylon 11 being the most common grades. The choice of material grade affects the tubing’s strength, flexibility, and chemical resistance. For instance, nylon 11 is known for its superior flexibility and resistance to moisture absorption, making it ideal for applications requiring durability in varying environmental conditions.

2. Temperature Range

Nylon tubing typically operates within a temperature range of -60°F to 200°F (-51°C to 93°C). This specification is crucial for applications in extreme temperatures, such as automotive or chemical processing industries. Selecting tubing that can withstand the operational temperature ensures reliability and minimizes the risk of failure in critical systems.

3. Diameter Tolerance

Diameter tolerance refers to the allowable deviation from the specified diameter of the tubing. A common tolerance is ±0.005 inches or better, which is essential for ensuring proper fittings and connections. Inaccurate diameters can lead to leaks or inefficiencies in pneumatic systems, making this specification vital for maintaining system integrity.

4. Working Pressure

The working pressure of nylon tubing is typically rated with a safety factor of 4:1, meaning the tubing can handle pressures four times higher than its maximum working pressure. This is crucial in applications where pressure fluctuations are expected, ensuring that the tubing remains safe and effective throughout its lifecycle.

5. Chemical Resistance

Nylon tubing’s chemical resistance is determined by its molecular structure, allowing it to withstand a variety of chemicals without degrading. This property is particularly important for industries like chemical processing and oil and gas, where exposure to harsh substances is commonplace. Understanding the chemical compatibility of nylon tubing can prevent costly downtime and system failures.

What Are Common Trade Terms Used in the Nylon Tubing Industry?

Familiarity with industry jargon can enhance communication between buyers and suppliers. Here are some essential terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of nylon tubing, buyers often seek OEMs to ensure compatibility with their existing systems and to maintain quality standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQs is essential for budgeting and inventory management. Buyers must align their purchasing strategies with these requirements to avoid excess costs or supply shortages.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and terms for specific products. This process allows buyers to compare options and make informed decisions based on cost and specifications, making it a critical step in procurement.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms used in international contracts to define the responsibilities of buyers and sellers. They clarify who is responsible for shipping, insurance, and tariffs, which is vital for international B2B transactions involving nylon tubing.

5. UV Stabilized

UV stabilization refers to the treatment of nylon tubing to resist degradation from ultraviolet light. This property is especially important for applications exposed to sunlight, as it extends the life of the tubing and reduces maintenance costs.

Conclusion

By understanding the essential technical properties and trade terminology related to nylon tubing, B2B buyers can make more informed decisions. These insights enable companies to select the right products for their applications, ensuring reliability and performance in their operations.

Illustrative image related to nylon tubing

Navigating Market Dynamics and Sourcing Trends in the nylon tubing Sector

What Are the Key Market Dynamics and Trends Influencing the Nylon Tubing Sector?

The global nylon tubing market is currently experiencing robust growth, driven by increasing demand across various industries such as automotive, medical, and food processing. Factors such as the lightweight nature of nylon, its superior flexibility, and high resistance to chemicals and heat are making it a preferred choice among manufacturers. Emerging technologies like automation and IoT are reshaping sourcing strategies, with businesses increasingly leveraging data analytics to optimize supply chain operations. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are actively seeking suppliers who can offer customized solutions and quick turnaround times, reflecting a shift towards more agile sourcing practices.

In addition, sustainability is becoming a key consideration. Buyers are looking for manufacturers that provide eco-friendly options, including recycled nylon tubing and those that meet stringent environmental regulations. The rise of e-commerce has also influenced market dynamics, allowing buyers to easily compare suppliers and access a broader range of products and materials. As a result, businesses are encouraged to invest in digital platforms to enhance their visibility and reach.

How Can B2B Buyers Ensure Sustainability and Ethical Sourcing in Nylon Tubing?

Sustainability and ethical sourcing are paramount in today’s business landscape, particularly for B2B buyers looking to mitigate environmental impact. The nylon tubing sector is increasingly adopting sustainable practices by utilizing recyclable materials and reducing waste throughout the manufacturing process. Companies are now being evaluated not just on product quality but also on their commitment to sustainable practices and ethical supply chains.

Buyers should prioritize suppliers that possess certifications such as REACH and RoHS, which indicate compliance with environmental and safety standards. Additionally, exploring products made from bio-based nylon or those that have received green certifications can significantly enhance a buyer’s sustainability profile. Engaging with suppliers who demonstrate transparency in their sourcing and manufacturing processes can also help mitigate risks associated with unethical labor practices and environmental degradation. This approach not only aligns with corporate social responsibility goals but also appeals to increasingly eco-conscious consumers.

What Has Been the Historical Development of the Nylon Tubing Market?

The nylon tubing market has evolved significantly since its inception in the 1930s. Originally developed as a synthetic alternative to silk, nylon quickly gained traction due to its strength, elasticity, and resistance to wear and chemicals. The introduction of nylon 6 and nylon 11 further expanded its applications, making it a staple in various industries, including automotive and aerospace.

Illustrative image related to nylon tubing

As technological advancements progressed, the manufacturing processes for nylon tubing improved, allowing for greater customization and versatility in applications. Today, the market is characterized by a diverse range of products, including high-pressure and super-soft nylon tubing, catering to specific industry needs. This evolution highlights not only the material’s enduring relevance but also its adaptability to meet the changing demands of global markets.

Frequently Asked Questions (FAQs) for B2B Buyers of nylon tubing

-

1. How do I choose the right nylon tubing for my application?

Choosing the right nylon tubing depends on various factors including the intended application, temperature range, pressure requirements, and chemical exposure. For high-pressure applications, consider high-pressure nylon tubing, while for applications requiring flexibility, super soft nylon tubing may be ideal. Additionally, assess the tubing’s diameter and wall thickness to ensure compatibility with your fittings and system. Always consult technical specifications from manufacturers and consider conducting a sample test to evaluate performance in your specific environment. -

2. What are the key benefits of using nylon tubing in industrial applications?

Nylon tubing offers several advantages such as high flexibility, excellent chemical resistance, and a wide temperature range (-60°F to 200°F). Its lightweight nature makes it easy to handle and install, while its low moisture absorption helps maintain performance in humid conditions. Additionally, nylon tubing has a higher melting point compared to other plastics, which enhances its durability in heat-sensitive applications. These attributes make nylon tubing suitable for diverse industries, including automotive, agriculture, and robotics. -

3. What customization options are available for nylon tubing orders?

Many suppliers offer customization options for nylon tubing, including color matching, specific lengths, coiling configurations, and printed markings. Customization can enhance branding and improve identification in complex systems. When placing an order, discuss your specific requirements with the supplier to ensure they can accommodate your needs. Some manufacturers also provide prototyping services to test custom designs before full-scale production, allowing you to refine your specifications. -

4. What are the minimum order quantities (MOQs) for nylon tubing?

Minimum order quantities for nylon tubing can vary significantly by supplier and product type. While some manufacturers may allow small orders for standard products, others may require larger quantities, especially for custom items. It’s important to inquire about MOQs during your supplier selection process, as this will affect your budgeting and inventory management. If you have a smaller requirement, consider partnering with distributors who can aggregate orders to meet supplier MOQs. -

5. How do I vet suppliers when sourcing nylon tubing internationally?

Vetting suppliers is crucial to ensure quality and reliability. Start by researching potential suppliers’ reputations through customer reviews and industry ratings. Request samples to assess product quality and consistency. Additionally, verify their compliance with international standards such as ISO certifications and RoHS compliance. Conducting site visits or third-party audits can also provide insights into their manufacturing processes and quality control measures, further reducing risks associated with international sourcing. -

6. What payment terms should I expect when buying nylon tubing internationally?

Payment terms can vary based on the supplier’s policies and your business relationship. Common terms include advance payment, letters of credit, or net payment options (e.g., 30, 60, or 90 days post-delivery). Ensure you clarify payment methods and terms before finalizing the order. It’s also advisable to have a clear understanding of currency exchange rates and transaction fees, as these can impact overall costs when dealing with international suppliers. -

7. What quality assurance measures should I consider when sourcing nylon tubing?

Quality assurance is vital to ensure that the nylon tubing meets industry standards and your specific requirements. Inquire about the supplier’s quality control processes, including material testing, production inspections, and compliance with standards such as ASTM or ISO. Request documentation of certifications and test results to verify the tubing’s performance characteristics. Establishing a clear quality agreement before placing orders can also mitigate risks associated with product defects. -

8. How is logistics managed for international shipments of nylon tubing?

Logistics for international shipments of nylon tubing involves careful planning to ensure timely delivery and compliance with customs regulations. Coordinate with your supplier to understand shipping options, lead times, and costs. Consider factors like freight forwarding, incoterms, and insurance coverage to protect your investment during transit. It’s also important to stay informed about any import duties or tariffs that may apply in your country, as these can affect the overall cost and delivery timelines.

Top 7 Nylon Tubing Manufacturers & Suppliers List

1. Freelin Wade – Nylon Tubing

Domain: freelin-wade.com

Registered: 1997 (28 years)

Introduction: Nylon tubing made from polyamide resin, primarily nylon 6. Features include lighter-weight wall, greater flexibility, smaller bend radius, and higher corrosion resistance due to moisture absorption. Heat resistant with a melting point of 374°F (190°C). Specifications: Temperature range: -60° to 200°F (-51° to 93°C), Vacuum rating: to 28” Hg, Diameter tolerance: ± 0.005”, Hardness: 78 Rockwell R, W…

2. McMaster – Nylon Tubing

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Nylon Tubing, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. PolyConn – Nylon Tubing

Domain: polyconn.com

Registered: 1995 (30 years)

Introduction: Nylon tubing, also known as polyamide tubing, is designed to withstand higher temperatures, making it suitable for a variety of applications. Compared to other Nylon resins, it features a lighter weight wall, greater flexibility, and a smaller bend radius. This type of tubing is more corrosion resistant due to its moisture absorption resistance, and its heat and UV stabilization helps prevent stre…

4. NewAge Industries – NYLOTUBE® Nylon Tubing

Domain: newageindustries.com

Registered: 1998 (27 years)

Introduction: Nylon Tubing (NYLOTUBE®) is made from nylon-12 formulation, recognized for its ruggedness and lightweight properties. It offers corrosion and abrasion resistance, exceptional elastic memory, high-impact resistance even at subfreezing temperatures, and low moisture absorption to minimize dimensional instability. Suggested applications include air conditioning, chemical transfer, compressed air, coo…

5. Coilhose – Nylon Tubing

Domain: coilhose.com

Registered: 1995 (30 years)

Introduction: Nylon (PA) Tubing is known for its high pressure rating and broad temperature range. It is manufactured from high-quality resins and is heat and light stabilized. The temperature range is -60°F to 200°F. It is compatible with Coillock push to connect fittings and is made in the USA.

6. SMC – T-Metric Size Nylon Tubing

Domain: smcusa.com

Registered: 1995 (30 years)

Introduction: T-Metric Size Nylon Tubing, available in various sizes, suitable for a wide range of applications including pneumatic and hydraulic systems, resistant to abrasion and chemicals, lightweight and flexible, easy to cut and install.

7. Hudson Extrusions – Nylon Tubing

Domain: hudsonextrusions.com

Registered: 1997 (28 years)

Introduction: Nylon Tubing – Manufactured from engineering resin. Provides good abrasion resistance, high pressure, and strength at high temperatures. Common applications include hydraulic hoses, robotics, and vacuum, fuel, vapor or air lines. Types of Nylon Tubing available: Nylon 6 (FDA compliant, semi-flexible), Nylon 6/6 (higher abrasion resistance and tensile strength, semi-flexible), Nylon 11 (more flexib…

Strategic Sourcing Conclusion and Outlook for nylon tubing

In summary, strategic sourcing of nylon tubing offers substantial advantages for international B2B buyers across various industries. By prioritizing quality, durability, and compliance with global standards, businesses can enhance operational efficiency and reduce long-term costs. The versatility of nylon tubing, with its resistance to heat, chemicals, and moisture, makes it an ideal choice for applications ranging from automotive to agricultural sectors.

Investing in strategic sourcing not only ensures access to high-performance materials but also fosters supplier relationships that can lead to customized solutions tailored to specific needs. As markets in Africa, South America, the Middle East, and Europe continue to evolve, the demand for reliable and innovative tubing solutions will grow.

Looking ahead, it is crucial for B2B buyers to engage with suppliers who can provide not just products but also insights and support in navigating market trends and regulatory requirements. By doing so, businesses can position themselves advantageously in a competitive landscape. We encourage you to explore your options, connect with trusted suppliers, and leverage strategic sourcing to drive success in your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.