How to Source Fake Industrial Piercing Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for fake industrial piercing

The global market for fake industrial piercings is rapidly evolving, presenting both opportunities and challenges for B2B buyers seeking stylish and innovative body jewelry solutions. As the demand for non-invasive accessories grows, sourcing high-quality fake industrial piercings that cater to diverse customer preferences can be a daunting task. This guide is designed to equip international buyers, especially from regions such as Africa, South America, the Middle East, and Europe—including key markets like Brazil and Germany—with the knowledge needed to navigate this dynamic landscape effectively.

Within this comprehensive resource, you will discover a variety of fake industrial piercing types, including magnetic and clip-on options that appeal to a wide audience. We delve into applications for different demographics, ensuring that you can meet the demands of your customer base, whether they are fashion-forward individuals or those seeking alternative styles. Additionally, we provide essential insights into supplier vetting processes, helping you identify reliable partners who can deliver quality products consistently.

Cost considerations are also addressed, enabling you to make informed purchasing decisions that align with your business goals. By leveraging this guide, you will gain a deeper understanding of market trends and consumer preferences, empowering you to enhance your product offerings and strengthen your competitive edge in the body jewelry sector.

Understanding fake industrial piercing Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Magnetic Industrial Piercing | Utilizes magnetic components for a no-pierce solution | Retail, Fashion Accessories, Event Promotions | Pros: Easy to wear, no need for piercings. Cons: May not be suitable for all ear shapes. |

| Clip-On Industrial Earrings | Designed to mimic the appearance of piercings without actual holes | Fashion Retail, Costume Jewelry | Pros: Versatile, wide design options. Cons: Can be less secure than other types. |

| Faux Industrial Barbells | Features a barbell design that simulates a real piercing | Body Jewelry Retail, Online Marketplaces | Pros: Realistic look, available in various materials. Cons: May require specific sizing. |

| Adjustable Industrial Styles | Customizable length and fit, often using flexible materials | Specialty Shops, Custom Jewelry | Pros: Tailored fit for different ear shapes. Cons: More complex inventory management. |

| Fashion-Forward Faux Designs | Innovative styles with unique aesthetics, appealing to trends | Trendy Boutiques, Youth-Oriented Retail | Pros: Attracts fashion-conscious consumers. Cons: Risk of quickly becoming outdated. |

What are the Key Characteristics of Magnetic Industrial Piercings?

Magnetic industrial piercings are a unique solution for those looking to achieve the look of a cartilage piercing without the commitment. They consist of two magnetic components—one on either side of the ear—holding the earring in place. This type is particularly appealing to retailers focused on fashion accessories, as it offers a trendy, no-pain alternative for consumers wary of actual piercings. When considering procurement, buyers should evaluate the quality of the magnets and materials used to ensure durability and comfort.

How Do Clip-On Industrial Earrings Stand Out?

Clip-on industrial earrings are designed to mimic the look of traditional piercings while being easy to wear. They are often favored in the fashion retail sector for their versatility and ease of use. Buyers should consider the range of styles available, as these earrings can vary significantly in design and comfort. While they offer a broad appeal, potential downsides include less security compared to other types, which could affect customer satisfaction and return rates.

What Makes Faux Industrial Barbells a Popular Choice?

Faux industrial barbells replicate the visual appeal of actual piercings with a barbell design, making them a popular choice among body jewelry retailers. They are available in various materials, including surgical stainless steel, which is essential for minimizing allergic reactions. B2B buyers should focus on the quality of materials and the realism of the design to attract customers. However, sizing considerations are crucial, as improper fit can lead to dissatisfaction.

Why Opt for Adjustable Industrial Styles?

Adjustable industrial styles allow for customization in length and fit, catering to different ear shapes and personal preferences. This flexibility makes them appealing to specialty shops and custom jewelry retailers. Buyers should assess the materials used, as well as the ease of adjustment, to ensure a positive user experience. While they offer tailored fit advantages, managing inventory for various sizes can be more complex.

What Trends Should Buyers Consider with Fashion-Forward Faux Designs?

Fashion-forward faux designs are constantly evolving to keep pace with current trends. These innovative styles often attract younger consumers looking for unique accessories. Retailers should stay updated on the latest designs to remain competitive in the market. However, the risk of these styles quickly becoming outdated means that buyers must be strategic in their purchasing decisions to avoid excess inventory.

Key Industrial Applications of fake industrial piercing

| Industry/Sector | Specific Application of fake industrial piercing | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion Accessories | Trend-driven retail for non-piercing body jewelry | Attracts a broader customer base by offering trendy alternatives | Quality materials, design variety, and compliance with safety standards |

| Event Management | Cost-effective costume accessories for themed events | Enhances event aesthetics without permanent alterations | Customization options and rapid production capabilities |

| Health & Safety | Temporary adornments for healthcare professionals | Allows expression without compromising hygiene or safety | Medical-grade materials and easy-to-clean designs |

| Entertainment & Media | Props and costumes for film, theater, and performances | Elevates character design and visual appeal | Durable materials and variety in styles for diverse character needs |

| Personal Care & Beauty | Non-invasive beauty products for salons and beauty events | Expands service offerings without the need for body alterations | Sourcing from reputable manufacturers with aesthetic appeal |

How is Fake Industrial Piercing Used in Fashion Accessories?

In the fashion accessories sector, fake industrial piercings serve as trendy alternatives for consumers who desire the aesthetic of body jewelry without the commitment of a permanent piercing. Retailers can leverage this demand by offering diverse designs that cater to various styles, from gothic to minimalist. For international buyers, especially in regions like Europe and South America, sourcing high-quality materials that comply with local fashion trends is crucial. Additionally, businesses should consider the ability to provide customization options to appeal to local markets.

What Role Does Fake Industrial Piercing Play in Event Management?

In event management, fake industrial piercings are utilized as cost-effective costume accessories for themed events, parties, and festivals. They enhance the overall aesthetic without the permanence of actual piercings, making them ideal for temporary wear. Businesses in this sector benefit from sourcing products that are visually appealing yet easy to produce in bulk. Rapid turnaround times and the ability to customize designs for specific themes can also provide a competitive edge in catering to diverse client needs.

How Does Fake Industrial Piercing Address Health & Safety Concerns?

In the health and safety sector, fake industrial piercings offer healthcare professionals a way to express individuality while adhering to strict hygiene standards. These adornments are non-invasive and can be easily removed, making them suitable for environments where traditional piercings may pose health risks. Buyers in this sector should prioritize sourcing from manufacturers that use medical-grade materials and ensure the designs are easy to clean. This approach not only meets safety regulations but also enhances employee satisfaction and morale.

In What Ways is Fake Industrial Piercing Beneficial for Entertainment & Media?

For the entertainment and media industries, fake industrial piercings are essential props for film, theater, and performance art. They help in character development by enhancing the visual appeal of costumes without the commitment of permanent modifications. Producers and costume designers can benefit from sourcing durable materials that withstand the rigors of performance while offering a variety of styles to fit diverse character needs. Understanding local cultural nuances, especially in different regions like the Middle East and Africa, can also inform design choices that resonate with audiences.

How Can Personal Care & Beauty Industries Leverage Fake Industrial Piercing?

In the personal care and beauty industry, fake industrial piercings serve as non-invasive beauty products that salons can offer during events or as part of their service menu. These accessories allow clients to experiment with their looks without undergoing actual piercings. Salons should focus on sourcing aesthetically appealing designs that align with current beauty trends and ensure that products are made from safe materials. This can enhance customer experience and expand service offerings, catering to a growing market interested in temporary beauty solutions.

3 Common User Pain Points for ‘fake industrial piercing’ & Their Solutions

Scenario 1: Sizing and Fit Issues with Fake Industrial Piercings

The Problem: Many B2B buyers face challenges in ensuring that fake industrial piercings fit their target market’s diverse ear shapes and sizes. This is particularly crucial when dealing with bulk orders for different demographics across regions like Africa and Europe, where ear anatomy can vary significantly. Incorrect sizing can lead to high return rates and dissatisfied customers, impacting brand reputation and profitability.

The Solution: To mitigate sizing issues, buyers should prioritize sourcing from manufacturers who offer customizable options. This includes varying lengths and thicknesses of the faux industrial barbell, as well as adjustable designs that can accommodate different ear structures. When placing bulk orders, request samples of various sizes to test the fit on a range of models representing your target audience. Additionally, providing detailed measurement guides and fitting instructions on your product listings can enhance customer satisfaction and reduce returns. Implementing customer feedback loops post-purchase can also inform future product adjustments and enhance the overall buying experience.

Scenario 2: Material Sensitivity and Allergies in Fake Industrial Piercing

The Problem: Material sensitivity is a significant concern, particularly for customers with sensitive skin or metal allergies. Fake industrial piercings made from substandard materials can cause skin irritation, leading to negative customer experiences and potential health risks. B2B buyers must ensure that the products they source are safe and hypoallergenic, especially in markets where consumer awareness about skin health is high.

The Solution: Buyers should prioritize sourcing fake industrial piercings made from high-quality, medical-grade materials such as surgical stainless steel or titanium, known for their anti-allergic properties. It is essential to establish clear communication with suppliers about the materials used and request certifications that verify the hypoallergenic nature of the products. Incorporating educational content about material safety into marketing materials can also reassure customers. Furthermore, offering a satisfaction guarantee that allows customers to return products that cause irritation can enhance trust and encourage repeat purchases.

Scenario 3: Risk of Accidental Ingestion of Magnetic Components

The Problem: The innovative design of magnetic fake industrial piercings, while appealing, raises safety concerns, especially in households with children or pets. The risk of accidental ingestion of small magnets can lead to serious health issues, which could result in negative publicity and liability for the businesses selling these products.

The Solution: To address this safety concern, buyers should work closely with manufacturers to ensure that all magnetic components are securely designed and have clear warnings on the packaging. Additionally, it is advisable to provide comprehensive safety information to retailers, including guidelines on how to handle and use the products safely. Consider developing a line of products that utilizes non-magnetic designs or larger magnets that are less likely to be ingested. Implementing a product recall plan can also safeguard your brand in case of safety incidents, demonstrating a commitment to customer safety and product integrity.

Illustrative image related to fake industrial piercing

Strategic Material Selection Guide for fake industrial piercing

What are the Key Materials for Fake Industrial Piercing?

When selecting materials for fake industrial piercings, it’s essential to consider their properties, advantages, and limitations. This analysis focuses on four common materials: surgical stainless steel, acrylic, titanium, and nickel-free alloys. Each material has unique characteristics that can impact product performance and marketability.

How Does Surgical Stainless Steel Perform in Fake Industrial Piercings?

Surgical stainless steel is widely regarded as the industry standard for body jewelry, including fake industrial piercings. It boasts excellent corrosion resistance and is hypoallergenic, making it suitable for sensitive skin. The material can withstand high temperatures, which is beneficial during manufacturing processes like welding or polishing.

Pros: Surgical stainless steel is durable and resistant to tarnishing, which enhances the longevity of the product. It is also relatively cost-effective, making it an attractive option for mass production.

Cons: While it is strong, surgical stainless steel can be heavier than other materials, which may affect comfort for some users. Additionally, the manufacturing complexity is moderate, requiring specialized processes for shaping and finishing.

Illustrative image related to fake industrial piercing

Impact on Application: Surgical stainless steel is compatible with various media, including sweat and moisture, ensuring it remains intact during regular wear.

Considerations for International Buyers: Compliance with international standards such as ASTM F138 is crucial for surgical stainless steel. Buyers from regions like Europe and the Middle East may also prioritize certifications that guarantee the material’s hypoallergenic properties.

What Advantages Does Acrylic Offer for Fake Industrial Piercings?

Acrylic is a lightweight plastic that is often used in fake industrial piercings due to its vibrant colors and designs. It is easy to mold and can be produced in various shapes, allowing for creative designs that appeal to a younger demographic.

Pros: The primary advantage of acrylic is its low cost and versatility in design. It is also lightweight, which enhances comfort during wear.

Cons: Acrylic is less durable than metals and can scratch easily. It also has a lower resistance to heat and chemicals, which may limit its longevity compared to other materials.

Impact on Application: While acrylic can be visually appealing, it may not be suitable for prolonged exposure to moisture or sweat, which could lead to degradation over time.

Considerations for International Buyers: Buyers should be aware of the potential for chemical leaching from acrylic materials. Compliance with safety standards, especially in the EU, is essential to avoid health risks.

Why Choose Titanium for Fake Industrial Piercings?

Titanium is known for its strength-to-weight ratio and is often used in high-end body jewelry. It is highly resistant to corrosion and is biocompatible, making it an excellent choice for sensitive skin.

Pros: Titanium is lightweight, durable, and hypoallergenic, which makes it suitable for long-term wear. It can also be anodized to produce a variety of colors without compromising its integrity.

Cons: The primary drawback is the higher cost compared to other materials like acrylic and stainless steel. Additionally, the manufacturing process for titanium can be complex, requiring specialized equipment.

Impact on Application: Titanium’s resistance to corrosion and heat makes it suitable for various environments, including humid conditions.

Considerations for International Buyers: Buyers should ensure that titanium products meet international standards such as ASTM F136. This is particularly important for markets in Europe and the Middle East, where compliance is strictly regulated.

What Role Do Nickel-Free Alloys Play in Fake Industrial Piercings?

Nickel-free alloys are increasingly popular due to growing concerns about allergies related to nickel exposure. These alloys are often made from a combination of metals that do not include nickel, making them suitable for sensitive individuals.

Pros: The primary advantage is that they are hypoallergenic, reducing the risk of skin reactions. They also offer good durability and corrosion resistance.

Cons: Nickel-free alloys can be more expensive than traditional stainless steel. Additionally, the variety of alloys available may lead to inconsistencies in quality.

Impact on Application: These alloys are suitable for users who are sensitive to nickel, making them a safer choice for a broader audience.

Considerations for International Buyers: Compliance with standards such as ASTM F2999 is essential for nickel-free alloys. Buyers from regions like Africa and South America may also seek certifications to ensure product safety.

Summary Table of Materials for Fake Industrial Piercing

| Material | Typical Use Case for fake industrial piercing | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Surgical Stainless Steel | General body jewelry, including fake piercings | Durable and corrosion-resistant | Heavier than some alternatives | Medium |

| Acrylic | Colorful, lightweight designs for casual wear | Low cost and versatile design | Less durable, scratches easily | Low |

| Titanium | High-end body jewelry for sensitive users | Lightweight and hypoallergenic | Higher cost and complex manufacturing | High |

| Nickel-Free Alloys | Jewelry for sensitive skin | Hypoallergenic and durable | More expensive than stainless steel | Medium |

This strategic material selection guide provides a comprehensive overview for B2B buyers considering fake industrial piercings, highlighting the importance of material choice in product performance and market appeal.

In-depth Look: Manufacturing Processes and Quality Assurance for fake industrial piercing

What Are the Key Stages in the Manufacturing Process of Fake Industrial Piercing?

The manufacturing process for fake industrial piercings, such as magnetic earrings, involves several critical stages that ensure both product quality and aesthetic appeal. Here’s a breakdown of the primary phases in this process:

Illustrative image related to fake industrial piercing

-

Material Preparation: The initial step involves sourcing high-quality materials, such as surgical stainless steel, which is favored for its anti-allergy, anti-rust, and anti-corrosive properties. Manufacturers often conduct thorough inspections of raw materials to ensure they meet industry standards. Suppliers should provide certifications to verify the material’s quality and safety.

-

Forming: In this phase, the prepared materials are shaped into the desired forms. Techniques such as stamping, casting, or CNC machining may be utilized depending on the design complexity. For magnetic industrial piercings, precise molding is essential to ensure that the components fit together seamlessly. Manufacturers may also employ techniques like laser cutting for intricate designs.

-

Assembly: Once the individual components are formed, they are assembled. In the case of magnetic industrial piercings, this includes attaching the magnetic plates to the barbell shaft. This stage often requires specialized tools and skilled labor to ensure that the assembly is both secure and functional.

-

Finishing: The finishing process involves polishing and coating the assembled products to enhance their visual appeal and durability. Techniques such as anodizing or electroplating may be used to provide additional protection against corrosion and wear. Quality control checks are performed at this stage to ensure the final product meets aesthetic and functional standards.

Which Quality Control Standards Should B2B Buyers Consider for Fake Industrial Piercings?

Quality assurance is paramount in the manufacturing of fake industrial piercings. B2B buyers should be aware of various international and industry-specific standards that govern product quality and safety.

-

International Standards: ISO 9001 is a widely recognized standard that outlines requirements for a quality management system (QMS). Suppliers adhering to ISO 9001 demonstrate a commitment to quality, customer satisfaction, and continuous improvement. This certification can significantly enhance buyer confidence.

-

Industry-Specific Certifications: Depending on the market, additional certifications may be relevant. For example, CE marking is essential for products sold within the European Economic Area (EEA) as it indicates compliance with safety standards. In the U.S., the American National Standards Institute (ANSI) may set requirements for certain materials used in jewelry.

-

Quality Control Checkpoints: Effective quality control involves several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This initial inspection assesses raw materials before production.

– In-Process Quality Control (IPQC): Conducted during manufacturing, this step ensures that production processes are within specified limits.

– Final Quality Control (FQC): The final inspection before products are shipped, FQC checks the finished items against design specifications and quality standards.

What Common Testing Methods Are Employed in the Quality Assurance of Fake Industrial Piercing Products?

To ensure that fake industrial piercings meet safety and quality standards, various testing methods are employed:

-

Material Testing: This includes tests for corrosion resistance, tensile strength, and allergenic reactions. Manufacturers may conduct laboratory tests to analyze the chemical composition of metals and ensure they meet safety standards.

-

Magnetic Testing: For products using magnetic components, tests are conducted to verify the strength and durability of the magnets. This ensures that the earrings can securely attach without risk of falling off.

-

Dimensional Inspection: Precision is crucial in the assembly of fake industrial piercings. Manufacturers use calipers and gauges to ensure that the dimensions of each component are within acceptable tolerances.

-

Visual Inspection: A thorough visual inspection is performed to check for any aesthetic defects, such as scratches, discoloration, or improper assembly. This step is critical for maintaining the brand’s reputation and customer satisfaction.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is vital to ensure product reliability. Here are actionable steps to consider:

Illustrative image related to fake industrial piercing

-

Supplier Audits: Conducting on-site audits provides an opportunity to evaluate the manufacturing environment, processes, and quality control measures firsthand. Buyers should develop a checklist based on industry standards to assess compliance.

-

Review of Quality Reports: Requesting detailed quality reports from suppliers can offer insights into their QC processes. These reports should outline testing methods, results, and any corrective actions taken for non-conformities.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control measures. These inspections can be scheduled at various stages of production to ensure compliance with agreed-upon standards.

-

Certifications Verification: Buyers should verify the authenticity of any quality certifications provided by suppliers. This may include checking with certifying bodies or requesting copies of relevant documents.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

When sourcing fake industrial piercings, international buyers must navigate various quality control and certification nuances:

-

Regulatory Compliance: Different regions have unique regulations regarding product safety. Buyers should familiarize themselves with local requirements in their target markets, such as REACH in Europe or FDA regulations in the U.S.

-

Cultural Sensitivities: Understanding cultural preferences and sensitivities in different regions can influence the design and material choices for fake industrial piercings. This awareness can enhance market acceptance and reduce the risk of product recalls.

-

Supply Chain Transparency: Establishing a transparent supply chain is crucial for ensuring quality. Buyers should inquire about the entire production process and any sub-suppliers involved to assess overall quality management.

By comprehensively understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing fake industrial piercings, ensuring they receive high-quality products that meet international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fake industrial piercing’

In this guide, we aim to provide B2B buyers with a comprehensive checklist for sourcing fake industrial piercings. The growing popularity of these accessories across global markets, especially in regions like Africa, South America, the Middle East, and Europe, necessitates a strategic approach to procurement. This checklist will ensure you make informed decisions, minimizing risks while maximizing product quality and supplier reliability.

Step 1: Define Your Technical Specifications

Clearly outlining your technical specifications is essential for ensuring that the products you source meet your business requirements. Consider factors such as material types, size variations, and design preferences. For example, specify whether you require surgical stainless steel for durability and hypoallergenic properties, and detail the thickness (e.g., 14G) and length variations (20mm-40mm) necessary for your target market.

Illustrative image related to fake industrial piercing

Step 2: Research Market Trends and Consumer Preferences

Understanding current trends in fake industrial piercings can provide valuable insights into what consumers are seeking. Analyze popular styles, colors, and materials that resonate with your target audience. Engaging with local fashion influencers or conducting surveys can help you gauge preferences in specific regions, ensuring that your offerings are competitive and appealing.

Step 3: Evaluate Potential Suppliers

Before committing to any supplier, a thorough evaluation is critical. Request detailed company profiles, including their manufacturing capabilities, quality control processes, and customer reviews. It’s beneficial to seek references from other B2B buyers in your industry or region to assess their reliability and product quality. This step mitigates risks associated with poor quality or unreliable delivery.

Step 4: Request Samples for Quality Assurance

Once you have shortlisted potential suppliers, request samples of their fake industrial piercings. This will allow you to inspect the quality, finish, and overall aesthetics of the products. Pay attention to the craftsmanship, as well as the comfort and safety of the items, especially if they include magnetic components that could pose risks.

Step 5: Verify Compliance with Safety Standards

Ensure that the products comply with relevant safety and health regulations in your target markets. Different regions may have specific requirements for body jewelry, particularly concerning materials and manufacturing processes. Verify if the supplier provides documentation or certifications that attest to compliance with these standards to avoid potential legal issues.

Step 6: Negotiate Terms and Conditions

After selecting a supplier, negotiate favorable terms and conditions that align with your business model. Discuss pricing structures, payment terms, minimum order quantities, and delivery timelines. Clear communication at this stage can help avoid misunderstandings later on and establish a solid foundation for a long-term partnership.

Step 7: Establish a Reliable Logistics Plan

Finally, develop a logistics plan that includes shipping methods, costs, and delivery timelines. Consider working with suppliers who have experience in international shipping and can provide tracking information. Efficient logistics are crucial for maintaining inventory levels and ensuring timely availability of products in your market.

By following this checklist, B2B buyers can navigate the complexities of sourcing fake industrial piercings effectively, ensuring that they meet customer demands while minimizing risks associated with product quality and supplier reliability.

Comprehensive Cost and Pricing Analysis for fake industrial piercing Sourcing

What Are the Key Cost Components in Fake Industrial Piercing Sourcing?

When sourcing fake industrial piercings, understanding the cost structure is crucial for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly affects pricing. Common materials include surgical stainless steel, which is anti-allergic and rust-resistant, and other metals. Prices can vary based on the quality and certification of materials used, such as medical-grade compliance.

-

Labor: Labor costs depend on the manufacturing location. Regions with lower labor costs, such as parts of Africa and South America, can offer competitive pricing, but this may impact quality. Skilled labor is essential for handmade or custom designs, which can increase costs.

-

Manufacturing Overhead: This includes costs related to utilities, rent, and administrative expenses in production facilities. Manufacturers in regions with higher overheads will likely have higher product prices.

-

Tooling: Initial tooling costs for custom designs can be significant. Buyers should inquire about tooling costs, especially for unique designs or specifications, as they can impact the overall pricing structure.

-

Quality Control (QC): Stringent QC processes can raise costs but are essential for maintaining product quality and compliance with international standards. Investing in quality assurance can prevent costly returns and enhance customer satisfaction.

-

Logistics: Shipping and handling costs vary depending on the distance, weight, and shipping method. Incoterms also play a vital role; understanding whether costs are included in the quoted price or are additional is crucial for budgeting.

-

Margin: Suppliers will add a profit margin based on their costs and market conditions. This margin can fluctuate depending on demand, competition, and buyer negotiation leverage.

How Do Price Influencers Affect Fake Industrial Piercing Costs?

Several factors can influence the pricing of fake industrial piercings, making it essential for buyers to consider these elements when negotiating.

-

Volume/MOQ: Minimum Order Quantities (MOQ) often dictate the pricing structure. Larger orders typically yield lower per-unit costs due to economies of scale. Buyers should assess their needs to negotiate better terms based on volume.

-

Specifications and Customization: Custom designs or unique specifications can significantly increase costs. Buyers should weigh the benefits of customization against potential price increases.

-

Materials and Quality Certifications: Higher quality materials and certifications can lead to increased costs but can also enhance the product’s marketability. Buyers should evaluate the trade-off between cost and quality.

-

Supplier Factors: The supplier’s reputation, reliability, and relationship with the buyer can impact pricing. Established suppliers with proven track records may charge a premium but offer better service and quality assurance.

-

Incoterms: Understanding Incoterms is vital for international shipping. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect overall costs and risk management during transit.

What Tips Can Help Buyers Optimize Costs in Fake Industrial Piercing Sourcing?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency.

-

Negotiation: Leverage volume purchases to negotiate better pricing. Building long-term relationships with suppliers can also lead to favorable terms.

-

Total Cost of Ownership (TCO): Consider all costs associated with the purchase, including shipping, duties, and storage. A lower initial price may not always equate to the best overall value.

-

Pricing Nuances: Be aware of regional pricing differences. For instance, sourcing from countries with lower production costs may provide savings, but ensure quality standards are met.

-

Market Research: Conduct thorough market research to understand price benchmarks and supplier offerings. This knowledge will empower buyers during negotiations.

-

Flexibility in Specifications: Being open to slightly modified designs or materials can lead to significant cost savings while still meeting customer expectations.

Disclaimer on Indicative Prices

Prices for fake industrial piercings can vary widely based on the factors discussed. The information provided here serves as a guideline, and buyers should conduct their due diligence to obtain accurate pricing tailored to their specific needs and circumstances.

Alternatives Analysis: Comparing fake industrial piercing With Other Solutions

Exploring Viable Alternatives to Fake Industrial Piercing Solutions

When considering the adoption of fake industrial piercings, it’s crucial for B2B buyers to evaluate various alternatives that can achieve similar aesthetic or functional goals. This analysis aims to provide insights into different solutions available in the market, comparing them based on performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | Fake Industrial Piercing | Clip-On Earrings | Magnetic Industrial Earrings |

|---|---|---|---|

| Performance | Offers realistic appearance without permanent modification. | Provides a stylish look, but may not mimic industrial piercings closely. | Similar to fake industrials, can be adjusted for comfort. |

| Cost | Typically ranges from $15-$30. | Generally less expensive, ranging from $5-$20. | Usually priced between $20-$40. |

| Ease of Implementation | No special skills needed; simply wear as an accessory. | Extremely easy to wear and remove, no tools required. | Requires adjustment for fit; some users may find the magnet tricky. |

| Maintenance | Minimal care required; clean as needed. | Very low maintenance; just keep clean. | Requires careful handling to avoid losing magnets. |

| Best Use Case | Ideal for fashion-forward individuals seeking a trendy look. | Suited for casual wear or temporary styles. | Best for those who want the industrial look without commitment. |

Detailed Breakdown of Alternatives

Clip-On Earrings

Clip-on earrings serve as a simple and cost-effective alternative to fake industrial piercings. They are easy to wear and remove, making them ideal for individuals who prefer a hassle-free approach to accessorizing. However, while clip-ons can offer a fashionable appearance, they often lack the authenticity of an industrial piercing. Their affordability makes them accessible for bulk purchases, appealing to retailers targeting budget-conscious consumers. The downside is that they may not provide the same level of comfort or style versatility as more specialized options.

Magnetic Industrial Earrings

Magnetic industrial earrings are another innovative alternative that allows wearers to achieve the appearance of an industrial piercing without any actual piercing. They feature a unique design that utilizes magnets to secure the earring in place. This method provides flexibility in adjusting the fit, making it suitable for various ear shapes. However, users must be cautious about handling the magnets, as they can be lost easily, and there is a risk of accidental ingestion, particularly around children or pets. The cost is higher than clip-ons but can justify the investment for those seeking a more authentic look.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the right solution for fake industrial piercings, B2B buyers should consider their target market and the specific preferences of their customer base. For budget-conscious consumers, clip-on earrings may be the best option due to their affordability and ease of use. Conversely, if the goal is to provide a more authentic look with adjustable comfort, magnetic industrial earrings could be the ideal choice, despite their higher price point and maintenance considerations. Ultimately, understanding the nuances of each alternative will empower buyers to make informed decisions that align with their business goals and customer needs.

Essential Technical Properties and Trade Terminology for fake industrial piercing

What Are the Key Technical Properties of Fake Industrial Piercings?

Understanding the technical specifications of fake industrial piercings is crucial for B2B buyers to ensure product quality and suitability for their target market. Here are some essential properties to consider:

1. Material Grade

The most common materials used in fake industrial piercings include surgical stainless steel, titanium, and various alloys. Surgical stainless steel is particularly valued for its anti-allergic properties, rust resistance, and durability, making it ideal for body jewelry. Buyers should ensure that materials meet international safety standards, especially for products intended for sensitive skin.

2. Gauge Thickness

The gauge thickness, typically measured in G (gauge), indicates the diameter of the piercing. A standard gauge for industrial piercings is 14G, which equates to approximately 1.6mm. Understanding gauge thickness is important for ensuring that the fake piercing fits comfortably and securely, especially for customers transitioning from traditional piercings.

3. Shaft Length

Shaft length can vary significantly, commonly ranging from 20mm to 40mm for industrial barbell designs. It’s essential for manufacturers to provide clear measurements and guidelines on how to select the appropriate length for different ear shapes and sizes. This specification helps prevent discomfort and enhances customer satisfaction.

Illustrative image related to fake industrial piercing

4. Magnetic Strength

For non-piercing designs, the strength of the magnets used is a critical property. A strong magnetic hold ensures that the fake industrial piercing remains securely in place without causing irritation. Buyers should inquire about the testing and quality assurance processes for magnetic strength to avoid product failures.

5. Design Versatility

The ability to use fake industrial piercings in various ear configurations, such as helix and conch piercings, adds value to the product line. Manufacturers should focus on creating versatile designs that cater to different styles and preferences, appealing to a broader audience.

What Are Common Trade Terms in the Fake Industrial Piercing Industry?

Familiarity with industry jargon is vital for effective communication and negotiation in the B2B marketplace. Here are several key terms to know:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or products that are sold under another brand’s name. In the context of fake industrial piercings, buyers may work with OEMs to create customized designs or branding, allowing for unique product offerings in their markets.

Illustrative image related to fake industrial piercing

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers to manage inventory effectively and ensure they meet demand without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a formal process where a buyer requests pricing and terms from suppliers. This is particularly important in B2B transactions, as it allows buyers to compare offers and negotiate better deals, ensuring cost-effectiveness.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in the shipping process. Familiarity with terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is crucial for managing logistics and understanding cost structures in international trade.

5. Lead Time

Lead time refers to the time taken from placing an order to delivery. This is a critical factor for B2B buyers as it impacts inventory management and customer satisfaction. Understanding lead times helps businesses plan better and maintain consistent stock levels.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing fake industrial piercings, ensuring they meet market demands and regulatory requirements.

Navigating Market Dynamics and Sourcing Trends in the fake industrial piercing Sector

What Are the Current Market Dynamics and Key Trends in the Fake Industrial Piercing Sector?

The global market for fake industrial piercings is driven by a blend of fashion trends, cultural influences, and the increasing popularity of body adornment as a form of self-expression. Emerging markets in Africa and South America are witnessing a surge in demand, particularly among younger demographics who are increasingly influenced by social media and celebrity culture. In Europe, countries like Germany are seeing a growing interest in non-invasive alternatives to traditional piercings, leading to a robust market for faux industrial earrings.

Additionally, technological advancements are reshaping sourcing practices. B2B buyers are leveraging e-commerce platforms to identify reliable suppliers, while innovations in materials—like surgical stainless steel and magnetic components—are enhancing product offerings. The rise of dropshipping models is also notable, enabling suppliers to reach international markets with lower overhead costs. Buyers are encouraged to stay ahead of these trends by monitoring social media platforms and fashion influencers who often dictate consumer preferences.

How Can Sustainability and Ethical Sourcing Impact B2B Practices in the Fake Industrial Piercing Sector?

Sustainability is becoming a crucial factor for B2B buyers in the fake industrial piercing sector. The environmental impact of sourcing practices is under scrutiny, prompting brands to adopt more sustainable materials and ethical supply chains. For instance, materials such as recycled metals and biodegradable packaging are gaining traction. Buyers who prioritize sustainability can differentiate themselves in a competitive market and attract environmentally-conscious consumers.

Furthermore, green certifications are becoming important indicators of a supplier’s commitment to ethical practices. B2B buyers should consider partnering with manufacturers that have certifications demonstrating their adherence to environmental standards. This not only enhances brand reputation but also fosters trust among consumers, particularly in regions like Europe, where sustainability is a key purchasing factor.

What Is the Brief Evolution and History of Fake Industrial Piercing?

The fake industrial piercing market has evolved significantly over the past two decades. Initially popularized in the early 2000s as part of the punk and alternative subcultures, fake piercings offered a non-committal way for individuals to experiment with body art without the permanence of actual piercings. As fashion trends shifted, the market expanded, incorporating innovative designs and materials that appealed to a broader audience.

Today, fake industrial piercings are not just a niche product; they have entered mainstream fashion, driven by the desire for self-expression and individuality. The evolution from simple clip-ons to sophisticated magnetic designs reflects advancements in technology and consumer preferences, paving the way for a diverse range of products that cater to various tastes and styles. B2B buyers should leverage this historical context to understand the market’s trajectory and anticipate future trends.

Frequently Asked Questions (FAQs) for B2B Buyers of fake industrial piercing

-

How do I ensure the quality of fake industrial piercings from suppliers?

To ensure the quality of fake industrial piercings, it is crucial to conduct thorough supplier vetting. Start by requesting samples to evaluate the materials and craftsmanship. Look for suppliers who use high-quality materials like surgical stainless steel to minimize allergic reactions. Additionally, check for certifications or compliance with international standards. Establish clear quality assurance protocols, including inspection processes during production and before shipping. Engaging in regular communication with the supplier can also facilitate better quality control. -

What are the best materials for fake industrial piercings?

The best materials for fake industrial piercings include surgical stainless steel, acrylic, and hypoallergenic metals. Surgical stainless steel is preferred due to its resistance to rust, corrosion, and irritation, making it suitable for sensitive skin. Acrylic offers a lightweight alternative but may not be as durable. Ensure that any material used complies with international safety standards, especially when targeting markets in Africa, South America, the Middle East, and Europe, where regulatory requirements may vary. -

What customization options are available for fake industrial piercings?

Many suppliers offer customization options for fake industrial piercings, including size, color, and design. You can request specific dimensions, such as barbell length and thickness, to cater to different customer preferences. Some manufacturers may also provide custom branding opportunities, allowing you to add your logo or packaging design. When discussing customization, ensure that you clarify minimum order quantities (MOQs) and any additional costs associated with bespoke designs. -

What is the typical MOQ for ordering fake industrial piercings?

Minimum order quantities (MOQs) for fake industrial piercings can vary significantly based on the supplier and the complexity of the order. Generally, MOQs can range from 50 to 500 pieces. It’s advisable to negotiate MOQs, especially if you are a new buyer or testing the market. Many suppliers may offer lower MOQs for specific products or during promotional periods, making it easier for you to enter the market without a large upfront investment. -

What payment terms should I expect when sourcing fake industrial piercings?

Payment terms can vary widely among suppliers, but common practices include partial upfront payments (typically 30-50%) with the balance due upon shipment. Some suppliers might offer net terms, allowing payment within 30 to 90 days after delivery. It’s crucial to clarify payment methods accepted, such as bank transfers, credit cards, or online payment platforms like PayPal. Always negotiate favorable terms that align with your cash flow and business model to minimize financial risk. -

How can I efficiently manage logistics for importing fake industrial piercings?

Efficient logistics management for importing fake industrial piercings involves choosing the right shipping method and understanding customs regulations. Evaluate options such as air freight for faster delivery or sea freight for cost-effectiveness, depending on your order size. Collaborate with a logistics partner who has experience in international shipping and can navigate customs clearance. Familiarize yourself with import duties and taxes specific to your target market to avoid unexpected costs and delays. -

What are the best practices for marketing fake industrial piercings in international markets?

To effectively market fake industrial piercings in international markets, tailor your approach to local preferences and trends. Utilize social media platforms popular in your target regions to showcase your products. Collaborating with local influencers can enhance brand visibility and credibility. Additionally, consider participating in international trade shows to connect with potential buyers and distributors. Providing quality content, such as styling tips or educational material about piercings, can also engage your audience and drive sales. -

What should I do if I encounter issues with my order of fake industrial piercings?

If you encounter issues with your order, such as defective products or shipping delays, contact your supplier immediately to discuss the problem. Maintain a professional tone and provide clear evidence of the issue, such as photos or documentation. Most reputable suppliers will have a return policy or warranty in place to address such concerns. If issues persist, consider escalating the matter through your payment platform or seeking mediation services to resolve the dispute effectively.

Top 4 Fake Industrial Piercing Manufacturers & Suppliers List

1. Etsy – Unique Handmade Industrial Decor

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: This company, Etsy – Unique Handmade Industrial Decor, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Reddit – Fake Industrial Piercing

3. Pinterest – Punk Industrial Piercing Jewelry

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Fake Industrial Piercing, Punk Industrial Piercing Jewelry, Chains, Punk Metal Dangle Piercings, Faux Industrial Piercing Chain, Silver Dangle Punk Piercings, Industrial Piercing Jewelry with Chain and Spike Dangle, Simple Industrial Piercing, Feminine Industrial Piercing, Horizontal Industrial Piercing, Pretty Industrial Piercing, Unique Industrial Piercing, Industrial Jewelry, Industrial Piercin…

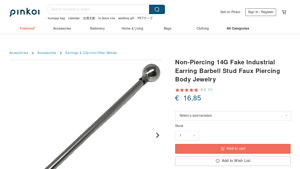

4. Pinkoi – Non-Piercing 14G Fake Industrial Earring

Domain: en.pinkoi.com

Registered: 2009 (16 years)

Introduction: {“product_name”: “Non-Piercing 14G Fake Industrial Earring Barbell Stud Faux Piercing Body Jewelry”, “price”: “US$ 19.54”, “rating”: “5.0 (1)”, “delivery_estimate”: “between 9/28~10/6”, “payment_methods”: [“Credit/debit card”, “Alipay”], “refund_policy”: {“refund_request_period”: “7 days”, “conditions”: [“Request must be made within 7 days after receiving the order”, “Designers reserve the right t…

Strategic Sourcing Conclusion and Outlook for fake industrial piercing

In the dynamic landscape of the fake industrial piercing market, strategic sourcing emerges as a crucial element for international B2B buyers. By leveraging high-quality materials such as surgical stainless steel and innovative designs like magnetic non-piercing options, businesses can enhance their product offerings while meeting the diverse preferences of consumers across regions, including Africa, South America, the Middle East, and Europe.

Understanding regional trends and consumer behaviors is essential for effective inventory management and product development. Buyers should prioritize partnerships with reliable manufacturers that emphasize craftsmanship and safety, as demonstrated by products that utilize hypoallergenic and durable materials. This not only elevates the brand’s reputation but also fosters customer loyalty in a competitive market.

Looking ahead, the demand for non-invasive body jewelry is expected to rise, driven by fashion trends and a growing awareness of body modification. B2B buyers are encouraged to explore innovative solutions and adapt to evolving consumer preferences. Embrace the opportunities within the fake industrial piercing sector by fostering relationships with strategic suppliers, ensuring your offerings remain relevant and appealing in this vibrant marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.