Bebco Industries Inc: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for bebco industries inc

In today’s complex global market, sourcing reliable hazardous area electronic enclosures and modular building solutions from Bebco Industries, Inc. can be a daunting task for international B2B buyers. With a plethora of options available, identifying the right products that meet stringent industry standards while addressing unique regional needs can pose significant challenges. This guide aims to provide a comprehensive overview of Bebco Industries, including the types of enclosures and modular buildings offered, their diverse applications across various sectors, and essential supplier vetting criteria.

Bebco Industries is recognized for its commitment to quality and innovation, catering to industries such as oil and gas, chemicals, pharmaceuticals, and food processing. Buyers will gain insights into the customization options available, allowing for tailored solutions that fit specific operational requirements. Furthermore, we will explore factors influencing cost, ensuring that businesses can make informed purchasing decisions without compromising on safety or functionality.

By navigating this guide, B2B buyers from Africa, South America, the Middle East, and Europe—regions with unique market dynamics—will be empowered to evaluate their options effectively. Whether in Saudi Arabia or Germany, understanding Bebco’s offerings and service commitment will enhance procurement strategies, leading to successful project outcomes and long-term partnerships.

Understanding bebco industries inc Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hazardous Area Enclosures | Designed for explosive environments, made from durable materials like stainless steel and fiberglass. | Oil and gas, chemical processing, pharmaceuticals | Pros: High durability, customizable options. Cons: Higher initial costs, potential regulatory complexities. |

| Modular Buildings | Prefabricated structures that are customizable and scalable, built in a controlled environment. | Temporary and permanent office spaces, healthcare, education | Pros: Quick installation, flexibility in design. Cons: Limited customization post-installation, transport logistics. |

| Security Booths & Shelters | Portable, modular units designed for security and surveillance purposes. | Retail, corporate offices, construction sites | Pros: Easy relocation, quick setup. Cons: May require additional security features, limited space. |

| Environmental Test Chambers | Controlled environments for testing products under various conditions. | Electronics, pharmaceuticals, automotive | Pros: Precise testing conditions, customizable setups. Cons: High maintenance costs, requires technical expertise. |

| EMI/RF Shielded Enclosures | Enclosures that prevent electromagnetic interference for sensitive devices. | Telecommunications, aerospace, defense | Pros: Protects sensitive equipment, enhances reliability. Cons: Higher cost, specific design requirements. |

What are Hazardous Area Enclosures and Their Key Features?

Hazardous area enclosures are critical for industries operating in environments with flammable gases or dust, such as oil and gas or chemical processing. These enclosures are constructed from robust materials like stainless steel and fiberglass, ensuring they withstand harsh conditions. When considering a purchase, buyers should evaluate compliance with industry standards (NEMA, IECEx, ATEX) and the customization options available to meet specific operational needs.

How Do Modular Buildings Cater to Diverse Business Needs?

Modular buildings are versatile structures that can be tailored for various applications, including offices, healthcare facilities, and educational institutions. Built in a factory setting, these buildings offer quick assembly and the ability to adapt to changing business requirements. Buyers should consider factors such as scalability, energy efficiency, and the potential for future modifications when investing in modular solutions.

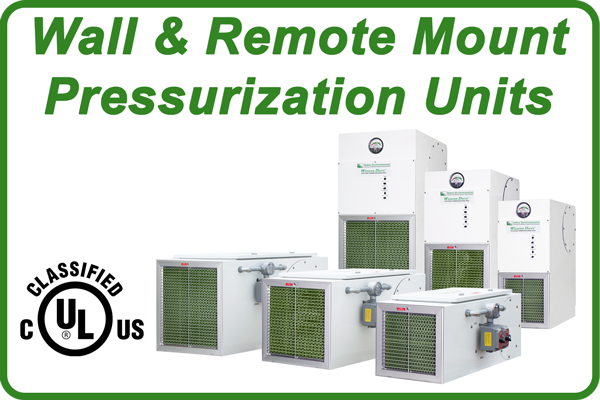

Illustrative image related to bebco industries inc

What Are the Benefits of Security Booths and Shelters?

Security booths and shelters are designed to enhance safety at various locations, including retail and corporate environments. Their modular nature allows for easy relocation and rapid setup, making them ideal for temporary security needs. Buyers should assess the specific security features required, such as surveillance capabilities, and the potential need for additional modifications based on site conditions.

Why Choose Environmental Test Chambers for Product Testing?

Environmental test chambers provide controlled conditions for testing products under various environmental factors like temperature and humidity. This is essential for industries like electronics and pharmaceuticals where reliability is paramount. When purchasing, companies should consider the testing range, customization options, and maintenance requirements to ensure the chamber meets their specific testing protocols.

What Are EMI/RF Shielded Enclosures and Their Importance?

EMI/RF shielded enclosures are essential for protecting sensitive electronic equipment from electromagnetic interference, which can disrupt operations in sectors such as telecommunications and aerospace. These enclosures are designed to create a barrier against unwanted signals, ensuring operational integrity. Buyers need to evaluate the specific shielding effectiveness required and the associated costs of custom designs when considering these solutions.

Key Industrial Applications of bebco industries inc

| Industry/Sector | Specific Application of bebco industries inc | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil and Gas | Hazardous area electronic enclosures | Protects sensitive electronics from explosive environments, ensuring operational safety and compliance. | Ensure compliance with NEMA, IECEx, and ATEX standards; consider customization options for specific equipment. |

| Chemical Processing | Customized modular buildings for chemical plants | Provides flexible and safe workspaces, enhancing productivity and safety in hazardous settings. | Evaluate materials for chemical resistance; assess site preparation and installation services. |

| Pharmaceutical | Secure enclosures for sensitive electronic devices | Safeguards critical equipment, ensuring reliability and compliance with health regulations. | Confirm adherence to industry standards; prioritize rapid delivery and installation capabilities. |

| Food Processing | Enclosures for food processing equipment | Ensures hygiene and safety, protecting machinery from contamination and environmental factors. | Investigate certifications for food safety; consider options for easy cleaning and maintenance. |

| Construction and Infrastructure | Modular buildings for site offices and facilities | Offers quick setup and adaptability, reducing downtime and project delays. | Look for scalable solutions; assess logistics for transportation and assembly on-site. |

How Does Bebco Industries Inc. Serve the Oil and Gas Sector?

In the oil and gas industry, Bebco Industries provides hazardous area electronic enclosures specifically designed to protect sensitive electronic components in explosive environments. These enclosures ensure compliance with stringent safety regulations, thereby minimizing risks of accidents and enhancing operational reliability. International buyers, particularly from regions like the Middle East where oil extraction is prevalent, should prioritize enclosures that meet NEMA, IECEx, and ATEX standards, ensuring they are equipped for the unique challenges of their environments.

Illustrative image related to bebco industries inc

What Modular Solutions Does Bebco Offer for Chemical Processing Facilities?

Bebco Industries specializes in providing customized modular buildings tailored for chemical processing plants. These structures are designed to create flexible and safe workspaces that can adapt to evolving business needs. By utilizing modular construction, companies can enhance productivity while ensuring compliance with health and safety regulations. Buyers in Africa and South America should consider the chemical resistance of materials used and the availability of site preparation and installation services to ensure a seamless integration into their operations.

Why Are Secure Enclosures Critical in the Pharmaceutical Industry?

In the pharmaceutical sector, Bebco’s secure enclosures safeguard sensitive electronic devices that are crucial for research and production. These enclosures not only protect against environmental factors but also ensure compliance with stringent health regulations, which is vital in maintaining product integrity. Buyers from Europe, particularly Germany, known for its rigorous pharmaceutical standards, should confirm that the enclosures adhere to industry certifications and prioritize rapid delivery and installation to maintain production schedules.

How Does Bebco Support Food Processing Operations?

Bebco Industries provides enclosures specifically designed for food processing equipment, ensuring that hygiene and safety standards are met. These enclosures protect machinery from contamination while also offering durability against environmental factors. For buyers in regions like South America, where food safety is paramount, it is essential to investigate certifications for food safety and consider options for easy cleaning and maintenance to uphold quality standards.

What Modular Solutions Are Available for Construction and Infrastructure Projects?

In construction and infrastructure, Bebco’s modular buildings serve as site offices and facilities that can be rapidly deployed to enhance project efficiency. These structures allow for quick setup and adaptability, significantly reducing downtime and project delays. International buyers should look for scalable solutions that can be easily transported and assembled on-site, ensuring they can meet the dynamic needs of construction projects while adhering to budgetary constraints.

3 Common User Pain Points for ‘bebco industries inc’ & Their Solutions

Scenario 1: Navigating Regulatory Compliance in Hazardous Environments

The Problem: B2B buyers in sectors such as oil and gas, chemicals, and pharmaceuticals often face significant challenges in ensuring compliance with stringent industry regulations. These regulations dictate the specifications for equipment used in hazardous environments, and non-compliance can lead to safety hazards, legal repercussions, and costly delays. Buyers may struggle to identify enclosures that not only meet these regulations but also fit their specific application needs.

The Solution: To overcome this challenge, buyers should engage with Bebco Industries, Inc. early in the project planning phase. Bebco offers a wide range of enclosures designed to meet various industry standards, including NEMA, IECEx, ATEX, and UL ratings. Buyers should leverage Bebco’s expertise by consulting their knowledgeable sales and support staff, who can guide them in selecting the right enclosure for their specific requirements. Providing detailed information about the intended application, environmental conditions, and regulatory demands will enable Bebco to offer tailored solutions. Additionally, consider requesting documentation that verifies compliance with relevant standards to ensure that all equipment will pass regulatory inspections seamlessly.

Scenario 2: Customization Needs for Unique Applications

The Problem: Many B2B buyers encounter difficulties when standard enclosures do not meet their unique application requirements. For instance, companies in specialized industries may require custom cutouts, specific materials, or unique branding options that off-the-shelf solutions cannot provide. This lack of customization can lead to operational inefficiencies, increased costs, and delays in project timelines.

The Solution: Buyers should take advantage of Bebco Industries’ customization capabilities. When discussing project specifications, clearly outline your needs, including size, material preferences, and any unique features required for your application. Bebco’s team of experienced engineers and technicians can collaborate with you to design and manufacture enclosures tailored to your exact specifications. This proactive engagement will not only ensure that the final product meets your operational requirements but also enhances efficiency and reduces the risk of future modifications or replacements. Moreover, leveraging Bebco’s design expertise can often lead to innovative solutions that improve functionality.

Scenario 3: Managing Lead Times and Installation Challenges

The Problem: In fast-paced industries, delays in obtaining necessary equipment can lead to significant project setbacks. B2B buyers often find themselves in situations where lead times for critical enclosures are longer than anticipated, which can disrupt operations and lead to increased costs. Additionally, the installation process can be complicated, requiring specialized knowledge that may not be readily available in-house.

Illustrative image related to bebco industries inc

The Solution: To mitigate these risks, buyers should establish clear timelines and communicate their urgency to Bebco Industries from the outset. Bebco is known for its fast turnaround times and can often accommodate expedited requests when informed early. It is also beneficial to discuss installation requirements upfront; Bebco offers comprehensive support throughout the entire project lifecycle, including site preparation and installation assistance. Consider including installation training for your team as part of the procurement process to ensure that they are well-equipped to handle the enclosures efficiently. By planning ahead and utilizing Bebco’s resources, buyers can significantly reduce delays and ensure smoother project execution.

Strategic Material Selection Guide for bebco industries inc

What Are the Key Properties of Common Materials Used by Bebco Industries, Inc.?

Bebco Industries, Inc. utilizes a variety of materials in their products, particularly hazardous area enclosures and modular buildings. Understanding the properties and implications of these materials is crucial for international B2B buyers. Below, we analyze four common materials: stainless steel, aluminum, fiberglass, and carbon steel.

How Does Stainless Steel Benefit Hazardous Area Enclosures?

Stainless steel is renowned for its exceptional corrosion resistance and durability, making it an ideal choice for enclosures in harsh environments. It can withstand high temperatures and pressures, which is critical in industries like oil and gas. The primary advantage of stainless steel is its long lifespan and low maintenance requirements, which can significantly reduce total cost of ownership.

Illustrative image related to bebco industries inc

However, stainless steel can be more expensive than other materials, which may deter some buyers. Additionally, its weight can complicate installation and transportation. For applications involving corrosive media, stainless steel is highly compatible, ensuring the integrity of sensitive electronic components.

International buyers, particularly from regions with stringent compliance standards like Germany and Saudi Arabia, should note that stainless steel enclosures can meet various international standards, including ASTM and DIN. This compliance can facilitate smoother import processes and enhance market acceptance.

What Role Does Aluminum Play in Modular Building Solutions?

Aluminum is lightweight yet strong, offering excellent corrosion resistance, making it suitable for modular buildings that may face environmental challenges. It is easily fabricated, allowing for complex designs and customizations, which is beneficial for unique project requirements.

The primary downside of aluminum is its lower strength compared to stainless steel, which may limit its use in high-stress applications. Additionally, while generally cost-effective, aluminum can be more expensive than other metals, depending on market fluctuations. Its compatibility with various media is generally favorable, but care should be taken when using it in highly corrosive environments.

For international buyers, especially in Africa and South America, the lightweight nature of aluminum can reduce shipping costs and installation time. Compliance with local building codes and standards, such as JIS in Japan or ASTM in the U.S., should also be considered to ensure project viability.

Illustrative image related to bebco industries inc

How Does Fiberglass Contribute to Product Performance?

Fiberglass is a composite material that offers excellent chemical resistance and is lightweight, making it suitable for hazardous environments. Its non-conductive properties are advantageous in electrical applications, providing safety in explosive atmospheres. Fiberglass enclosures can also be molded into complex shapes, allowing for innovative designs.

On the downside, fiberglass can be less durable than metals in terms of impact resistance, which may be a concern in high-traffic areas. Additionally, it may not be suitable for extremely high-temperature applications. Fiberglass is compatible with various chemicals, making it ideal for the chemical and pharmaceutical industries.

International buyers should be aware of the varying standards for fiberglass products across different regions. Compliance with local regulations, such as ATEX in Europe, is crucial for ensuring safety and reliability in hazardous applications.

Illustrative image related to bebco industries inc

What Are the Advantages of Carbon Steel in Industrial Applications?

Carbon steel is known for its strength and durability, making it a popular choice for structural components in modular buildings. It is cost-effective and readily available, which can be a significant advantage for large-scale projects.

However, carbon steel is prone to corrosion, necessitating protective coatings or treatments to enhance its longevity. This can increase manufacturing complexity and costs. Its compatibility with various media is generally good, but caution is advised in corrosive environments.

For B2B buyers in the Middle East and Africa, the cost-effectiveness of carbon steel can be appealing, particularly for large projects. Buyers should ensure that the coatings used comply with local standards to mitigate corrosion risks.

Summary Table of Material Selection for Bebco Industries, Inc.

| Material | Typical Use Case for bebco industries inc | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Hazardous area enclosures | Exceptional corrosion resistance | Higher cost and weight | High |

| Aluminum | Modular buildings | Lightweight and easy to fabricate | Lower strength compared to steel | Medium |

| Fiberglass | Chemical storage enclosures | Excellent chemical resistance | Less durable in high-impact scenarios | Medium |

| Carbon Steel | Structural components in modular buildings | Cost-effective and strong | Susceptible to corrosion | Low |

This strategic material selection guide provides essential insights for international B2B buyers, ensuring informed decisions that align with their specific project requirements and regional compliance standards.

Illustrative image related to bebco industries inc

In-depth Look: Manufacturing Processes and Quality Assurance for bebco industries inc

What Are the Key Stages in the Manufacturing Process at Bebco Industries Inc.?

Bebco Industries Inc. employs a meticulous manufacturing process designed to deliver high-quality hazardous area enclosures and modular buildings. The process can be broken down into four main stages: material preparation, forming, assembly, and finishing.

Material Preparation

The manufacturing journey begins with the careful selection and preparation of raw materials. Bebco utilizes high-grade materials such as stainless steel, aluminum, and fiberglass, which are chosen for their superior resistance to corrosion, impact, and environmental stressors. The materials undergo thorough inspections to ensure they meet the stringent specifications required for hazardous environments. This initial stage sets the foundation for quality and durability in the final products.

Forming Techniques

Once the materials are prepared, they enter the forming stage, where advanced techniques such as precision sheet metal fabrication are employed. This involves cutting, bending, and shaping the materials into the desired configurations. Bebco utilizes state-of-the-art machinery and technology to ensure accuracy and efficiency in this stage. The forming process is crucial, as it directly impacts the structural integrity and functionality of the enclosures.

Assembly Process

Following the forming stage, the components are assembled into complete units. This step is carried out by skilled technicians who follow strict assembly protocols to ensure that every enclosure meets the specific requirements of its intended application. Customization options, such as cutouts and branding, can be integrated during this stage, allowing Bebco to cater to the unique needs of its B2B clients. Attention to detail during assembly is vital to prevent any potential issues in the product’s performance.

Finishing Touches

The final stage of manufacturing involves finishing processes that enhance both aesthetics and durability. This can include surface treatments, coatings, and quality checks to ensure that the enclosures can withstand the harsh conditions they are designed for. The finishing touches also contribute to the overall brand presentation, as many clients require specific colors and branding for their enclosures.

Illustrative image related to bebco industries inc

How Does Quality Assurance Work at Bebco Industries Inc.?

Quality assurance is a cornerstone of Bebco Industries Inc.’s operations, ensuring that every product meets both international standards and industry-specific requirements. The company adheres to several quality control checkpoints throughout the manufacturing process, which are essential for maintaining high standards.

What International Standards Does Bebco Adhere To?

Bebco is committed to quality management and meets ISO 9001 standards, which focus on consistent quality and customer satisfaction. Additionally, the company complies with industry-specific certifications such as CE, API, ATEX, and UL ratings. These certifications validate that Bebco’s products are suitable for use in hazardous areas, assuring international B2B buyers of their safety and reliability.

What Are the Key Quality Control Checkpoints?

The quality control process at Bebco includes several key checkpoints:

Illustrative image related to bebco industries inc

- Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet required specifications.

- In-Process Quality Control (IPQC): During the manufacturing process, regular checks are conducted to monitor adherence to quality standards. This ensures that any deviations are caught early.

- Final Quality Control (FQC): Before products leave the facility, they undergo a final inspection to verify that they meet all specifications and standards. This includes functional testing and visual inspections.

What Testing Methods Are Commonly Used?

Bebco employs a range of testing methods to ensure product reliability. Common methods include environmental testing, where products are subjected to conditions that mimic real-world scenarios, and performance testing to verify that enclosures function as intended. Additionally, electrical safety tests and corrosion resistance tests are routinely conducted to ensure compliance with industry standards.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers like Bebco is crucial. Here are several actionable steps buyers can take:

Conduct Supplier Audits

Buyers should consider conducting on-site audits of the manufacturing facility to assess quality control processes firsthand. This provides insights into the supplier’s commitment to quality and adherence to standards.

Illustrative image related to bebco industries inc

Request Quality Control Reports

Bebco can provide detailed quality control reports that outline their processes, testing results, and compliance with international standards. These documents offer transparency and assurance to potential buyers regarding the quality of the products.

Engage Third-Party Inspections

Utilizing third-party inspection services can add an additional layer of verification. Independent inspectors can evaluate the manufacturing process and product quality, ensuring that suppliers meet the required standards.

Understanding Quality Certification Nuances

International buyers should familiarize themselves with the specific certifications required for their regions. For example, European clients may prioritize CE certification, while Middle Eastern clients may look for compliance with local safety standards. Understanding these nuances can help buyers make informed decisions.

Illustrative image related to bebco industries inc

What Are the Benefits of Bebco’s Quality Assurance Processes for International Buyers?

The rigorous quality assurance processes at Bebco Industries Inc. provide numerous benefits to international B2B buyers. These include:

-

Confidence in Product Reliability: Buyers can trust that the enclosures will perform as expected in hazardous environments, reducing the risk of operational failures.

-

Compliance with Regulations: Bebco’s adherence to international and industry-specific standards ensures that buyers remain compliant with local regulations, facilitating smoother operations.

-

Customization Assurance: With a strong quality control framework, buyers can be assured that customized solutions will meet their specifications without compromising on quality.

-

Long-Term Cost Savings: Investing in high-quality enclosures leads to reduced maintenance costs and improved operational efficiency, providing long-term value for buyers.

In summary, Bebco Industries Inc. employs a comprehensive and robust manufacturing and quality assurance process that not only meets but exceeds industry standards. This commitment to quality ensures that international B2B buyers receive reliable, durable, and compliant products tailored to their unique needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bebco industries inc’

Introduction

This sourcing guide is designed to assist international B2B buyers in effectively procuring products from Bebco Industries, Inc. With a focus on hazardous area electronic enclosures and modular building solutions, this checklist will provide actionable insights to ensure a smooth procurement process. By following these steps, buyers can make informed decisions that align with their operational needs and industry standards.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, it is essential to establish clear technical specifications for the enclosures or modular buildings you require. This includes dimensions, materials (such as stainless steel or fiberglass), and compliance with industry standards (NEMA, IECEx, ATEX).

– Consider the environment where the products will be used, as this will impact material selection and design features.

Step 2: Research Bebco Industries’ Product Range

Familiarize yourself with the full spectrum of products offered by Bebco Industries. Their offerings include various sizes and configurations of enclosures suitable for hazardous environments as well as customizable modular buildings.

– Look for customization options that can meet your specific operational needs, such as branding or unique cutouts.

Illustrative image related to bebco industries inc

Step 3: Verify Supplier Certifications

It’s crucial to ensure that Bebco Industries holds the necessary certifications relevant to your industry and region. Certifications such as UL ratings and compliance with international safety standards are indicators of product reliability and safety.

– Request documentation that verifies these certifications to avoid potential compliance issues down the line.

Step 4: Evaluate Supplier Experience and Reputation

Assess Bebco Industries’ track record in your specific industry sector. Look for case studies or testimonials from clients in similar fields, such as oil and gas or pharmaceuticals.

– Consider their longevity in the market and any awards or recognitions they have received, which can reflect their commitment to quality and service.

Step 5: Engage in Direct Communication

Reach out to Bebco Industries’ sales and support team to discuss your requirements in detail. This engagement can provide insights into their responsiveness and customer service approach.

– Prepare a list of questions regarding product features, lead times, and after-sales support to gauge their capability to meet your needs.

Illustrative image related to bebco industries inc

Step 6: Request a Quote and Compare Pricing

Once you have gathered all necessary information, request a formal quote from Bebco Industries. Compare this with quotes from other suppliers to ensure competitive pricing.

– Take note of any additional costs such as shipping or customization fees, which can impact the total procurement budget.

Step 7: Plan for Installation and Maintenance

Consider the logistics of installation and ongoing maintenance of the products you procure. Discuss with Bebco Industries about their installation services and any maintenance support they offer.

– Evaluate whether their offerings include training for your team, which can enhance the longevity and effectiveness of the products in your operations.

By following this comprehensive checklist, B2B buyers can effectively navigate the procurement process with Bebco Industries, ensuring that they select the right products tailored to their specific needs while also fostering a reliable partnership.

Comprehensive Cost and Pricing Analysis for bebco industries inc Sourcing

What Are the Key Cost Components for Sourcing from Bebco Industries, Inc.?

When considering sourcing from Bebco Industries, Inc., understanding the cost structure is essential for effective budgeting and decision-making. The primary cost components include:

Illustrative image related to bebco industries inc

-

Materials: Bebco utilizes high-quality materials such as stainless steel, aluminum, and fiberglass, which are essential for producing durable and reliable enclosures. The choice of materials can significantly impact the cost, especially when sourcing specialty materials or those with specific certifications.

-

Labor: Skilled labor is crucial for the fabrication and assembly of enclosures and modular buildings. Labor costs can vary based on the complexity of the designs and the expertise required for customization.

-

Manufacturing Overhead: This encompasses the costs associated with running the manufacturing facility, including utilities, equipment maintenance, and administrative expenses. Efficient manufacturing processes can help mitigate overhead costs.

-

Tooling: Initial tooling costs can be a significant investment, especially for custom projects. This includes molds and fixtures necessary for production, which can be amortized over large orders.

-

Quality Control (QC): Bebco emphasizes high standards of quality, which includes rigorous QC processes. This ensures that products meet various industry standards, such as NEMA, IECEx, ATEX, and UL ratings, which may add to the overall cost.

-

Logistics: Shipping and handling costs can vary based on the destination, size of the order, and chosen Incoterms. Understanding these factors is vital for accurate cost estimation.

-

Margin: Finally, the profit margin for Bebco will depend on the overall cost structure and market competition. Transparent pricing strategies can help build trust with international buyers.

How Do Price Influencers Affect Sourcing Costs from Bebco Industries?

Several factors influence the pricing structure when sourcing from Bebco:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically lead to lower per-unit costs due to economies of scale. However, buyers must be aware of any MOQs set by Bebco, as these can affect initial investment levels.

-

Specifications and Customization: Custom solutions will generally incur higher costs due to the added complexity in design and production. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Material Choices: The selection of materials can affect both cost and lead time. For instance, opting for premium materials for enhanced durability may lead to increased costs, but can offer long-term savings in terms of maintenance and longevity.

-

Quality and Certifications: Compliance with international standards can influence pricing. Buyers in regions such as Europe or the Middle East may require specific certifications, which can add to the overall cost.

-

Supplier Factors: Supplier relationships and market conditions can impact pricing. Long-term partnerships may lead to better pricing structures, while fluctuating market demands can affect availability and costs.

-

Incoterms: Understanding the chosen Incoterms is essential, as they dictate the responsibilities of both parties in terms of shipping, insurance, and customs clearance. This can significantly influence the total landed cost.

What Are the Best Negotiation Tips for International B2B Buyers?

When negotiating with Bebco Industries, consider the following strategies to maximize cost-efficiency:

-

Emphasize Volume Orders: Highlight your potential for larger orders to negotiate better pricing. Suppliers often provide discounts for bulk purchases.

-

Request Detailed Quotations: Ask for itemized quotes that break down costs by components. This transparency helps identify potential areas for negotiation.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the upfront costs but also long-term factors like durability, maintenance, and energy efficiency. A higher initial investment may yield better returns over time.

-

Understand Regional Pricing Nuances: Be aware of currency fluctuations, tariffs, and shipping costs specific to your region. This understanding can provide leverage during negotiations.

-

Build Relationships: Developing a strong relationship with Bebco’s sales team can lead to better support and pricing options. Regular communication fosters trust and may provide access to exclusive deals.

Disclaimer on Pricing

Please note that the prices discussed are indicative and can vary based on current market conditions, material availability, and specific buyer requirements. Always consult directly with Bebco Industries for the most accurate and up-to-date pricing information tailored to your needs.

Alternatives Analysis: Comparing bebco industries inc With Other Solutions

Understanding Alternatives in the Context of Bebco Industries Inc.

In the competitive landscape of hazardous area enclosures and modular building solutions, B2B buyers often seek alternatives that can meet their unique requirements. Evaluating different options not only helps in identifying the best fit for a specific application but also provides insights into performance, cost-effectiveness, and suitability for various environments. This analysis compares Bebco Industries Inc. with two viable alternatives: Hubbell Wiegmann and Panel Built Inc.

Illustrative image related to bebco industries inc

Comparison Table

| Comparison Aspect | Bebco Industries Inc. | Hubbell Wiegmann | Panel Built Inc. |

|---|---|---|---|

| Performance | High-quality enclosures with robust protection for electronics in hazardous environments. | Reliable enclosures designed for diverse applications, including harsh environments. | Versatile modular buildings, customizable for various uses. |

| Cost | Competitive pricing with options for customization. | Generally higher price point due to brand reputation and premium materials. | Cost-effective modular solutions, often lower than traditional construction. |

| Ease of Implementation | Quick turnaround with a focus on customer collaboration for custom solutions. | Standard designs may limit customization but ensure quick deployment. | Modular approach allows for fast assembly and relocation. |

| Maintenance | Designed for durability; low maintenance with high resistance to environmental factors. | Durable but may require more frequent inspections and maintenance due to complexity. | Low maintenance with easy reconfiguration options. |

| Best Use Case | Ideal for oil and gas, chemical, and pharmaceutical industries needing robust hazardous enclosures. | Suitable for various industrial applications requiring dependable enclosure solutions. | Best for businesses needing flexible, expandable office or facility space. |

Detailed Breakdown of Alternatives

Hubbell Wiegmann

Hubbell Wiegmann is recognized for its comprehensive range of electrical enclosures that cater to demanding industrial environments. The strength of their offerings lies in the brand’s strong reputation and commitment to quality. However, their products often come at a higher price point, which may be a deterrent for budget-conscious buyers. While their designs are robust, the lack of customization options compared to Bebco might limit their adaptability for specific needs.

Panel Built Inc.

Panel Built specializes in modular building solutions that provide a cost-effective alternative to traditional construction methods. Their products are particularly advantageous for businesses requiring flexibility, as they allow for easy reconfiguration and expansion. However, while their pricing is competitive, some buyers may find that the quality and aesthetics do not match those of Bebco. Additionally, their focus on modularity means that they may not offer the same level of specialized protection found in Bebco’s hazardous area enclosures.

Conclusion: How to Choose the Right Solution for Your Needs

When evaluating alternatives to Bebco Industries Inc., it is essential for B2B buyers to consider their specific operational requirements. Factors such as the environment where the enclosure will be used, budget constraints, and the need for customization play a crucial role in decision-making. Buyers should weigh the performance and durability of Bebco’s offerings against the flexibility and cost advantages of alternatives like Hubbell Wiegmann and Panel Built. Ultimately, the right choice will align with the buyer’s long-term goals, ensuring a reliable and effective solution that meets the demands of their industry.

Illustrative image related to bebco industries inc

Essential Technical Properties and Trade Terminology for bebco industries inc

What Are the Essential Technical Properties of Bebco Industries, Inc. Products?

Understanding the key specifications of Bebco Industries, Inc. products is crucial for B2B buyers looking to invest in reliable hazardous area enclosures and modular building solutions. Here are some critical technical properties that define the quality and performance of Bebco’s offerings:

-

Material Composition

Bebco’s enclosures are constructed from high-quality materials such as stainless steel, aluminum, and fiberglass. Each material provides distinct advantages: stainless steel offers exceptional corrosion resistance, aluminum is lightweight and easy to work with, and fiberglass is ideal for environments susceptible to chemical exposure. Choosing the right material is vital for ensuring durability and longevity in hazardous environments, making it a key consideration for international buyers. -

NEMA Ratings

Bebco’s products adhere to various National Electrical Manufacturers Association (NEMA) ratings, which specify the level of protection offered against environmental factors such as dust, water, and corrosion. For example, a NEMA 4X rating indicates protection against corrosion and water ingress. Understanding these ratings allows buyers to select enclosures suited to their specific operational conditions, ensuring compliance with safety standards. -

Customizability Options

Bebco offers extensive customization, allowing buyers to tailor enclosures to their unique requirements. This includes custom cutouts for cables, specific color finishes, and branding options. Customizability is essential for B2B buyers, as it enables them to integrate products seamlessly into their existing systems and branding strategies. -

Impact Resistance

The enclosures are designed to withstand significant impacts, which is critical in environments where physical damage is a risk. Buyers must consider impact resistance when selecting enclosures for industrial applications, as it directly affects the reliability and safety of sensitive electronic components housed within. -

Thermal Management

Bebco’s enclosures incorporate thermal management features to prevent overheating of electronic components. Effective thermal management is crucial in maintaining operational efficiency and extending the lifespan of equipment, making it a vital property for buyers in industries like oil and gas or pharmaceuticals. -

Electromagnetic Interference (EMI) Shielding

Many of Bebco’s enclosures feature EMI shielding to protect sensitive electronics from interference. This property is particularly important for buyers in sectors that rely on precise electronic signals, as it helps to ensure operational integrity in challenging environments.

What Are Common Trade Terms Relevant to Bebco Industries, Inc.?

Familiarity with industry jargon is essential for effective communication and decision-making in B2B transactions. Here are several common trade terms that buyers should understand:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. For buyers, understanding OEM relationships can be crucial for sourcing high-quality components or enclosures that meet specific industry standards. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is important for buyers to assess their budget and inventory needs, especially when considering large-scale projects. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and availability for specific products. It is an essential tool for buyers to compare offerings and negotiate better terms with suppliers like Bebco. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Understanding these terms is vital for buyers operating in global markets to avoid unexpected costs and ensure smooth logistics. -

Lead Time

Lead time refers to the period from placing an order to receiving the product. For B2B buyers, being aware of lead times is crucial for planning and ensuring that projects stay on schedule, particularly in industries with tight deadlines. -

Warranty

A warranty is a guarantee provided by the manufacturer regarding the condition of the product and the commitment to repair or replace it if necessary. Buyers should carefully review warranty terms to understand their rights and the level of support they can expect from Bebco.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing products from Bebco Industries, Inc., ensuring they meet their operational needs while maintaining compliance with industry standards.

Navigating Market Dynamics and Sourcing Trends in the bebco industries inc Sector

What Are the Current Market Dynamics and Key Trends for Bebco Industries, Inc.?

The global market for hazardous area enclosures and modular buildings is witnessing significant growth, driven by increasing safety regulations and the demand for efficient, adaptable structures across various industries, particularly in oil and gas, chemical, pharmaceutical, and food processing sectors. International buyers, especially from regions such as Africa, South America, the Middle East, and Europe (notably Saudi Arabia and Germany), are increasingly looking for suppliers that can deliver high-quality, customizable solutions. This shift is propelled by the rising emphasis on safety and compliance with stringent industry standards, such as NEMA, IECEx, ATEX, and UL ratings.

Illustrative image related to bebco industries inc

Emerging B2B tech trends are shaping sourcing strategies, with buyers prioritizing digital platforms for procurement, enabling streamlined communication and faster decision-making processes. Additionally, there is a growing inclination towards using advanced materials that offer enhanced durability and resistance to environmental factors, which is critical in hazardous locations. The modular building sector is also evolving, with a notable trend towards prefabrication, allowing for rapid deployment and reduced construction timelines. This flexibility is particularly appealing to businesses in fast-growing markets, where the ability to scale operations quickly can confer a competitive advantage.

How Is Sustainability Influencing B2B Sourcing Decisions in the Bebco Industries Sector?

Sustainability is becoming an essential consideration for B2B buyers, with an increasing focus on minimizing environmental impact throughout the supply chain. Bebco Industries, Inc. is well-positioned to meet this demand by offering eco-friendly modular building solutions that incorporate sustainable materials and energy-efficient technologies. Buyers are now seeking suppliers who demonstrate a commitment to environmental stewardship, which can include certifications for green materials and adherence to sustainable manufacturing practices.

The importance of ethical sourcing cannot be overstated, as businesses recognize the need to align their operations with broader corporate social responsibility goals. This trend has led to a demand for transparency in supply chains, where buyers want assurance that their suppliers are not only compliant with environmental regulations but are also actively reducing their carbon footprint. By prioritizing partnerships with companies like Bebco that emphasize sustainability, international buyers can enhance their brand reputation and appeal to eco-conscious consumers.

What Is the Historical Context of Bebco Industries, Inc. in B2B Markets?

Founded in 1982, Bebco Industries, Inc. has a rich history rooted in the manufacturing of hazardous area electronic enclosures and modular buildings. Over the decades, the company has established itself as a trusted provider in these sectors, adapting to market demands and technological advancements. The firm’s commitment to quality and customer service has enabled it to build a strong global network of distributors and partners, facilitating its reach into diverse markets across Africa, South America, the Middle East, and Europe. This evolution reflects Bebco’s agility in responding to changing industry dynamics, positioning it as a reliable partner for B2B buyers seeking high-quality, customizable solutions in challenging environments.

Frequently Asked Questions (FAQs) for B2B Buyers of bebco industries inc

-

How do I choose the right hazardous area enclosure for my application?

Selecting the appropriate hazardous area enclosure requires a thorough understanding of your specific environment and requirements. Consider factors such as the type of materials that will be housed, the environmental conditions (e.g., temperature, humidity), and compliance with industry standards like NEMA, IECEx, or ATEX. It’s advisable to consult with Bebco’s experienced engineers who can guide you through the customization options to ensure the enclosure meets your operational needs and safety standards. -

What customization options are available for Bebco’s enclosures?

Bebco Industries offers extensive customization options to tailor enclosures to your specific requirements. Customizations can include cutouts for cable management, specific dimensions, finishes, and colors, as well as branding options. Collaborating closely with Bebco’s design team can help ensure that your enclosure is not only functional but also aligns with your brand identity and operational needs. -

What are the minimum order quantities (MOQs) for Bebco’s products?

The minimum order quantity for Bebco’s enclosures and modular buildings can vary based on the specific product line and customization requirements. Typically, larger orders can benefit from economies of scale, potentially reducing per-unit costs. It’s best to contact Bebco’s sales team directly to discuss your needs and determine the most suitable MOQ for your project. -

What payment terms does Bebco Industries offer for international buyers?

Bebco Industries provides flexible payment terms tailored to meet the needs of international buyers. Options may include upfront payments, letters of credit, or installment plans depending on the order size and buyer’s creditworthiness. It’s advisable to discuss your preferred payment method with Bebco’s finance team to establish terms that align with your procurement process. -

How does Bebco ensure quality assurance for its products?

Bebco Industries adheres to stringent quality assurance protocols throughout the manufacturing process. This includes rigorous testing for durability, compliance with industry standards, and inspections at various stages of production. Additionally, their commitment to continuous improvement ensures that all products not only meet but exceed customer expectations for performance and reliability. -

What logistics options are available for shipping Bebco products internationally?

Bebco Industries offers a range of logistics solutions to facilitate international shipping. This includes working with trusted freight partners to ensure timely and safe delivery of products to your location. Depending on your needs, Bebco can assist with shipping documentation, customs clearance, and delivery tracking, ensuring a smooth procurement experience. -

How can I evaluate the reliability of Bebco as a supplier?

To assess Bebco Industries’ reliability as a supplier, consider their track record in the industry, customer testimonials, and certifications that demonstrate compliance with international standards. Engaging in discussions with existing clients and reviewing case studies can provide insight into their service quality, product performance, and commitment to customer support. -

What industries does Bebco primarily serve, and can they support diverse applications?

Bebco Industries primarily serves industries such as oil and gas, chemical, pharmaceutical, and food processing. Their expertise in creating hazardous area enclosures and modular buildings allows them to support diverse applications, from temporary facilities to permanent installations. Their engineering team is equipped to adapt solutions to meet specific sector needs, ensuring optimal functionality and safety across various environments.

Top 6 Bebco Industries Inc Manufacturers & Suppliers List

1. Bebco Environmental – Explosion-Proof Air Conditioners

Domain: exphvac.com

Registered: 2015 (10 years)

Introduction: Bebco Environmental offers explosion-proof air conditioners designed for industrial HVAC, pressurization, and room air filtration solutions. These units are suitable for electrical enclosures, shelters, and buildings in hazardous environments such as oil refineries, chemical manufacturing plants, and offshore rigs. Key features include: competitive pricing, comprehensive two-year parts and field l…

2. Bebco Industries – Hazardous Area Electronic Enclosures

Domain: enclosuremanufacturers.com

Registered: 2001 (24 years)

Introduction: Bebco Industries, Inc. specializes in hazardous area electronic enclosures for industries such as oil and gas, chemical, pharmaceutical, and food processing. Founded in 1982, the company offers a variety of enclosures, including wall-mount, floor-mount, and free-standing options. Their enclosures are constructed from high-quality materials like stainless steel, aluminum, and fiberglass, ensuring r…

3. Bebco – Instrument Panel Solutions

Domain: linkedin.com

Registered: 2002 (23 years)

Introduction: This company, Bebco – Instrument Panel Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Bebco Industries – Modular & Portable Buildings

Domain: thebluebook.com

Registered: 1995 (30 years)

Introduction: Bebco Industries, Inc. specializes in the following product lines: Buildings–Modular & Portable, Metal Enclosures, and Offices–In-Plant. They offer various types of modular buildings including hospitality unit modules, apartment unit modules, and dormitory unit modules. Additionally, they provide fabricated structures such as control booths and substation control rooms. Their services also inclu…

5. Bebco Industries Inc – Blast Resistant Buildings

Domain: bloomberg.com

Registered: 1993 (32 years)

Introduction: Bebco Industries Inc offers blast resistant buildings, industrial duty metal shelters, instrument racks, sheds and canopies, and accessories including lighting, raised flooring, suspended ceilings, laboratory environments, crew quarters, and storage amenities.

6. Bebco Industries – Electronic Enclosures

Domain: electronicenclosures.net

Registered: 2015 (10 years)

Introduction: Bebco Industries, Inc. is a leading manufacturer of electronic enclosures and environmental control systems for hazardous locations. Key product details include:

– Types of Enclosures: Explosion-proof, dust-tight, water-tight enclosures, NEMA 4X, NEMA 7, and NEMA 9 enclosures.

– Industries Served: Oil and gas, petrochemical, and pharmaceutical plants.

– Custom Solutions: Experienced engineering…

Strategic Sourcing Conclusion and Outlook for bebco industries inc

In conclusion, Bebco Industries, Inc. stands out as a premier provider of hazardous area electronic enclosures and modular building solutions. With a legacy of innovation since 1982, the company is committed to delivering high-quality products that meet the rigorous demands of industries such as oil and gas, pharmaceuticals, and food processing. Their customizable enclosures and modular buildings not only ensure safety and durability but also offer clients the flexibility to adapt to evolving market needs.

Illustrative image related to bebco industries inc

Strategic sourcing with Bebco means partnering with a trusted supplier that prioritizes quality, efficiency, and customer satisfaction. Their experienced team is dedicated to providing tailored solutions, fast turnaround times, and exceptional service, making them an ideal choice for international B2B buyers. As markets in Africa, South America, the Middle East, and Europe continue to grow, the demand for reliable and innovative construction solutions will only increase.

We encourage prospective buyers to explore Bebco’s offerings and consider the advantages of strategic sourcing with a leader in the enclosure and modular building sectors. By choosing Bebco Industries, you are not just securing a supplier; you are investing in a partnership that empowers your business to thrive in any environment.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to bebco industries inc