Everything You Need to Know About In Line Centrifugal Pump Sourcing in 2025

Introduction: Navigating the Global Market for in line centrifugal pump

In the rapidly evolving global market, sourcing the right in-line centrifugal pump can be a daunting challenge for international B2B buyers. With diverse applications ranging from HVAC systems to potable water management, the need for reliable and efficient pumps is paramount. Buyers in regions such as Africa, South America, the Middle East, and Europe—countries like Vietnam and Germany—face unique obstacles, including varying regulatory standards, supply chain complexities, and the necessity for localized support. This guide aims to address these challenges head-on, providing a comprehensive overview of in-line centrifugal pumps, their types, applications, and critical considerations for supplier vetting.

Throughout this guide, you will gain valuable insights into the nuances of in-line centrifugal pump technologies, enabling you to make informed purchasing decisions. We will explore various pump designs, including flex coupled, close coupled, and split coupled models, and detail their specific applications in different industrial sectors. Furthermore, we will delve into essential factors such as cost analysis, maintenance requirements, and performance metrics, all tailored to meet the demands of international markets. By equipping you with the knowledge needed to navigate this complex landscape, this guide empowers you to enhance operational efficiency, reduce downtime, and ultimately drive business success.

Understanding in line centrifugal pump Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Flex Coupled | Flexible coupling design, allows for easier maintenance | HVAC systems, water distribution | Pros: Easy to install and maintain. Cons: May require more space than other designs. |

| Close Coupled | Compact design with motor directly attached to the pump | Potable water, industrial processes | Pros: Space-saving, efficient. Cons: Limited accessibility for repairs. |

| Split Coupled | Separate motor and pump, allowing for flexible installation | Large commercial applications | Pros: Easy maintenance, versatile placement. Cons: More complex installation process. |

| Bronze Construction | All-bronze body for corrosion resistance | Marine applications, chemical processing | Pros: High durability, ideal for corrosive fluids. Cons: Higher upfront cost. |

| Circulator Pumps | Designed for low flow and low head applications | Residential heating, cooling systems | Pros: Energy-efficient, compact. Cons: Limited to specific flow requirements. |

What are the Characteristics of Flex Coupled In-Line Pumps?

Flex coupled in-line pumps feature a flexible coupling that connects the motor and pump. This design allows for easier maintenance and alignment, making it a popular choice for HVAC systems and water distribution networks. B2B buyers should consider the installation space, as these pumps may require more room than others. Additionally, the flexibility in maintenance can result in reduced downtime, making them a cost-effective option for businesses focused on reliability.

How Do Close Coupled In-Line Pumps Stand Out?

Close coupled in-line pumps are characterized by their compact design, with the motor directly attached to the pump. This design is ideal for applications requiring limited space, such as potable water systems and industrial processes. Buyers should weigh the benefits of efficiency and space-saving against the potential challenge of accessibility for repairs, as the compact nature can make servicing more difficult.

What Are the Benefits of Split Coupled In-Line Pumps?

Split coupled in-line pumps feature a separate motor and pump, allowing for flexible installation options. This design is particularly advantageous in large commercial applications where maintenance and replacement are common. B2B purchasers should consider the ease of maintenance and installation versatility when selecting this type. However, the more complex installation process may require skilled labor, which can increase initial costs.

Why Choose Bronze Construction Pumps for Corrosive Applications?

Bronze construction in-line pumps are designed for high durability and corrosion resistance, making them suitable for marine applications and chemical processing. The all-bronze body ensures longevity in harsh environments. Buyers interested in these pumps should be prepared for a higher upfront investment but can benefit from lower long-term maintenance costs due to the pump’s durability.

What Makes Circulator Pumps Ideal for Residential Applications?

Circulator pumps are specifically designed for low flow and low head applications, making them perfect for residential heating and cooling systems. Their energy-efficient design and compact size make them an attractive option for B2B buyers focused on sustainability and cost savings. However, it’s important to note that their flow capabilities are limited, which may not suit all commercial applications.

Key Industrial Applications of in line centrifugal pump

| Industry/Sector | Specific Application of in line centrifugal pump | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| HVAC | Circulation of water in heating and cooling systems | Efficient temperature control, energy savings | Reliability, energy efficiency ratings, compatibility with existing systems |

| Water Treatment | Pumping clean water and chemicals for treatment processes | Improved water quality, compliance with health standards | Material compatibility, flow rate requirements, maintenance support |

| Agriculture | Irrigation systems for efficient water distribution | Enhanced crop yield, optimized resource management | Durability, adaptability to varying water quality, energy efficiency |

| Food and Beverage | Transfer of liquids in processing and packaging | Ensures product quality, minimizes contamination risk | Sanitary design, regulatory compliance, ease of cleaning |

| Chemical Processing | Moving chemicals through production lines | Safe handling of hazardous materials, process efficiency | Material resistance to chemicals, pressure handling capabilities, safety certifications |

How are In-Line Centrifugal Pumps Used in HVAC Systems?

In HVAC applications, in-line centrifugal pumps are crucial for circulating water in heating and cooling systems. These pumps ensure consistent temperature control across buildings, significantly enhancing comfort while reducing energy consumption. For international buyers, particularly in diverse climates like those in Africa and the Middle East, sourcing pumps with high reliability and energy efficiency ratings is essential to manage operational costs effectively.

What Role Do In-Line Centrifugal Pumps Play in Water Treatment?

In water treatment facilities, in-line centrifugal pumps are utilized to transport clean water and chemicals necessary for purification processes. Their ability to maintain consistent flow rates ensures compliance with health standards, which is vital for public health. Buyers in regions such as South America and Europe must consider factors like material compatibility and maintenance support to ensure longevity and reliability in their systems.

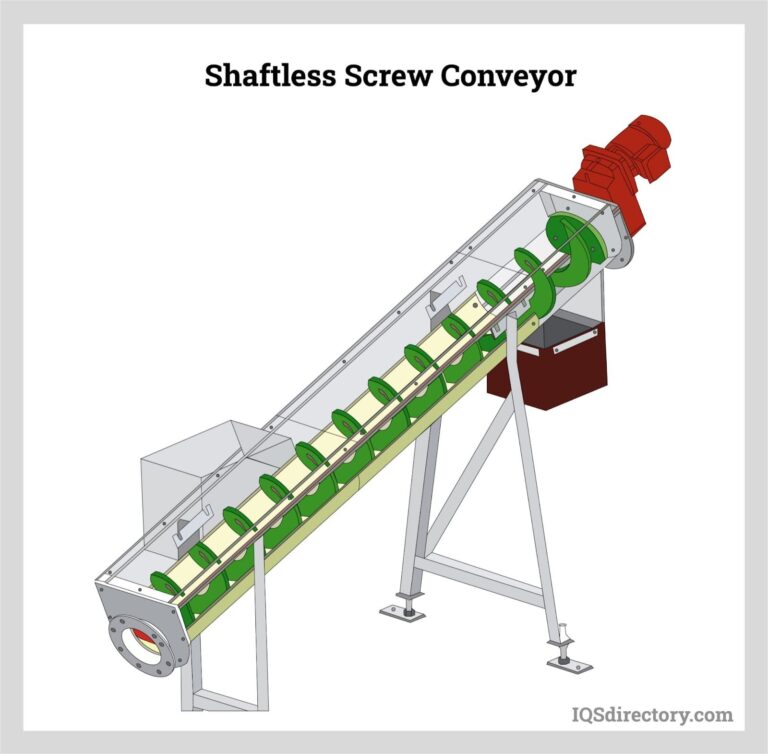

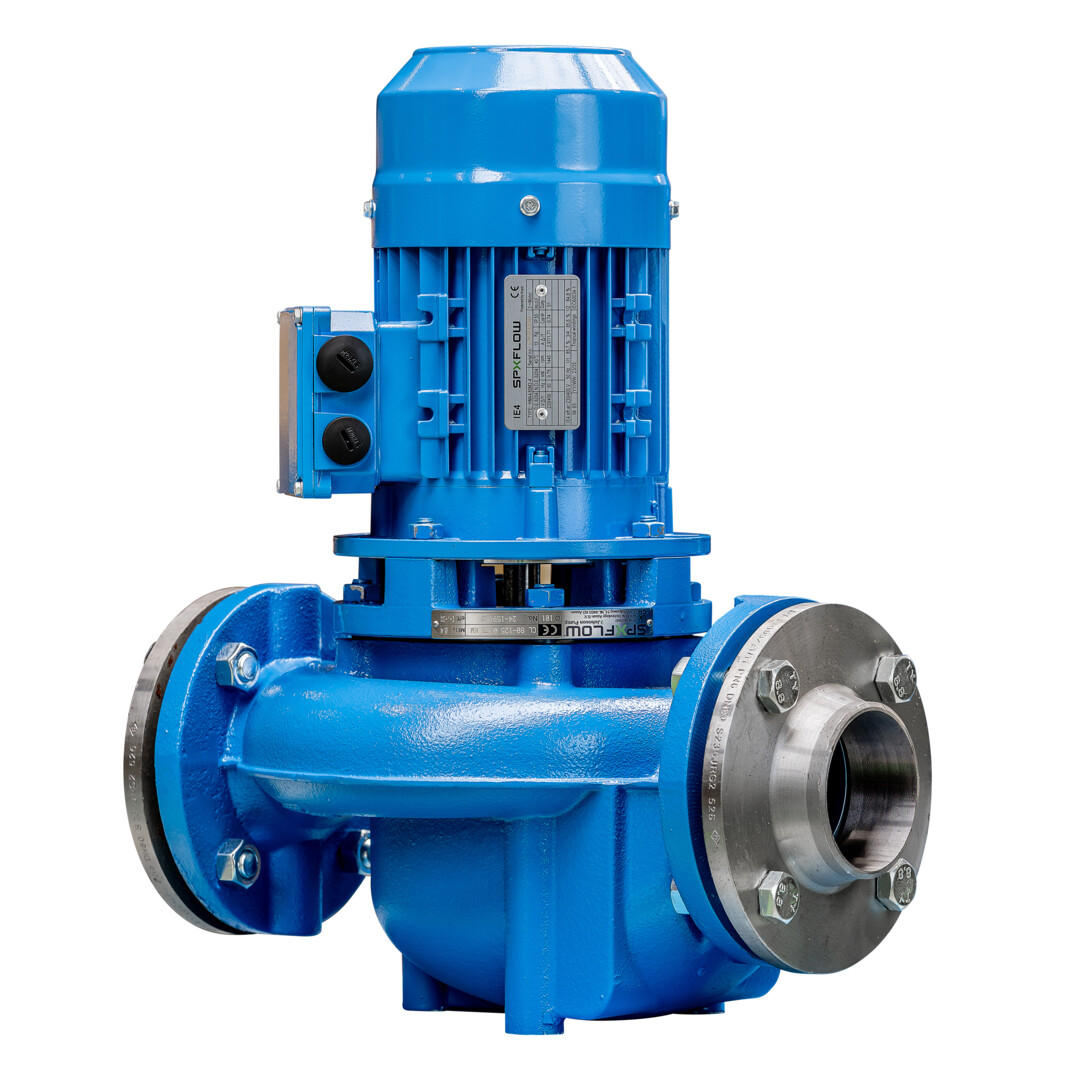

Illustrative image related to in line centrifugal pump

How Do In-Line Centrifugal Pumps Benefit Agriculture?

In agriculture, these pumps are integral to irrigation systems, facilitating efficient water distribution across fields. By optimizing water use, they contribute to enhanced crop yields and better resource management. Buyers in areas with variable water quality, like parts of Africa and South America, should prioritize durability and the pump’s adaptability to different water conditions when sourcing.

Why Are In-Line Centrifugal Pumps Important in Food and Beverage Processing?

In the food and beverage sector, in-line centrifugal pumps are essential for transferring liquids during processing and packaging. Their design minimizes the risk of contamination, ensuring product quality. International buyers must focus on sanitary designs that comply with regulatory standards, as well as ease of cleaning to maintain hygiene.

What Are the Key Considerations for In-Line Centrifugal Pumps in Chemical Processing?

In chemical processing, in-line centrifugal pumps facilitate the movement of various chemicals through production lines. Their robust design enables the safe handling of hazardous materials while enhancing process efficiency. Buyers should prioritize pumps with materials resistant to specific chemicals and those with adequate pressure handling capabilities to ensure safety and compliance with industry regulations.

3 Common User Pain Points for ‘in line centrifugal pump’ & Their Solutions

Scenario 1: Inefficient Pump Performance Leading to Increased Operational Costs

The Problem: A common challenge faced by B2B buyers is the inefficient performance of in-line centrifugal pumps, which can lead to increased energy consumption and higher operational costs. This inefficiency often arises from improper sizing or selection of the pump for specific applications. For instance, using a pump that is either too large or too small for the intended flow rate can result in energy wastage, excessive wear and tear, and ultimately, a reduction in the lifespan of the pump. Buyers may find themselves dealing with escalating utility bills and frequent maintenance costs, which can significantly impact their bottom line.

The Solution: To overcome this issue, it is critical for buyers to conduct a thorough analysis of their system requirements before selecting an in-line centrifugal pump. Engage with pump manufacturers or distributors to obtain detailed specifications and performance curves for different models. Utilize tools such as flow rate calculators and pressure drop assessments to ensure the pump is appropriately sized for the application. Additionally, consider implementing energy-efficient models that comply with international standards, as these can significantly reduce energy consumption. Regularly scheduled maintenance and monitoring of pump performance can also help identify inefficiencies early, allowing for timely adjustments.

Scenario 2: Frequent Pump Failures and Downtime

The Problem: Frequent failures and unplanned downtime of in-line centrifugal pumps can be a major headache for B2B buyers, especially in industries where continuous operation is crucial, such as manufacturing or HVAC systems. Buyers often struggle with understanding the root causes of these failures, which may include factors such as cavitation, poor installation practices, or inadequate maintenance. The resulting downtime can lead to lost production, delayed projects, and substantial financial losses.

The Solution: To mitigate the risk of pump failures, it is essential to invest in proper installation and ongoing maintenance practices. Collaborate with experienced technicians during the installation process to ensure that the pump is set up correctly, following the manufacturer’s guidelines. Implement a routine maintenance schedule that includes regular inspections, vibration analysis, and monitoring of operating conditions to detect any early signs of trouble. Additionally, consider integrating advanced monitoring systems that can provide real-time data on pump performance, allowing for predictive maintenance strategies that can prevent unexpected breakdowns.

Scenario 3: Difficulty in Finding Reliable Suppliers

The Problem: In many regions, particularly in developing markets in Africa and South America, buyers often face challenges in sourcing reliable suppliers for in-line centrifugal pumps. This issue can stem from a lack of local availability, inconsistent quality of products, or difficulties in obtaining timely support and replacement parts. Buyers may find themselves navigating a complex landscape of suppliers, leading to uncertainty about product performance and after-sales service.

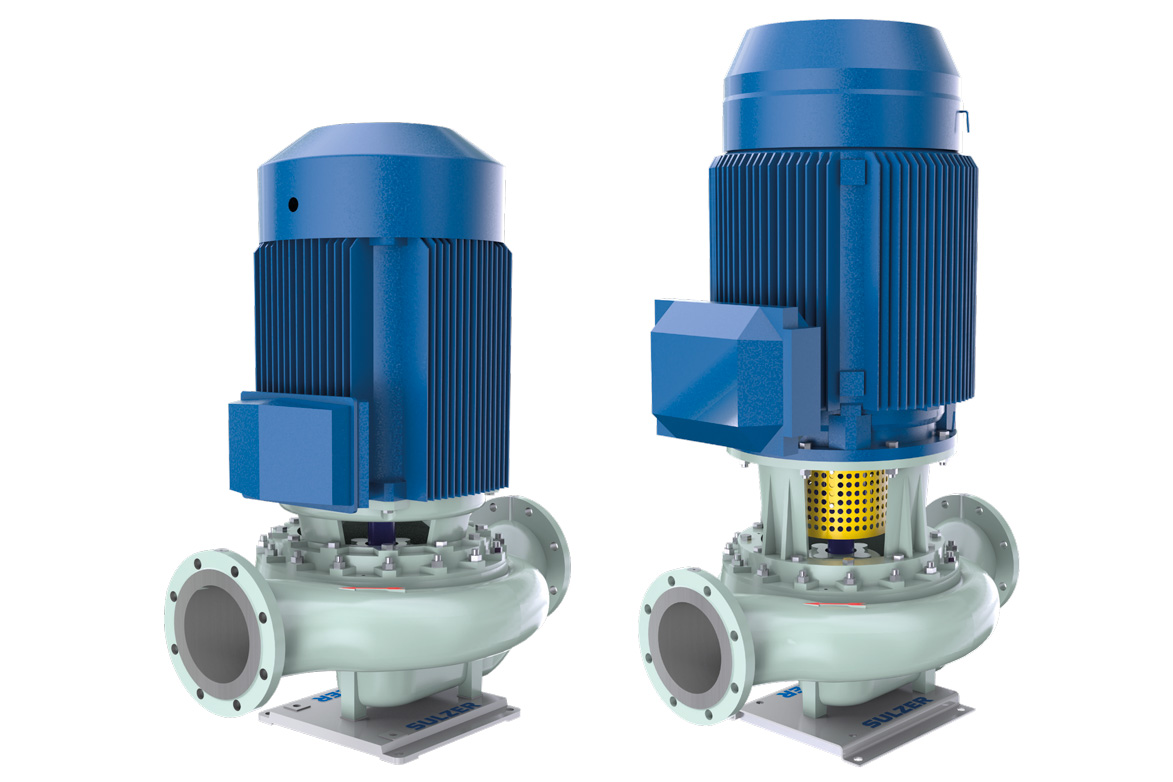

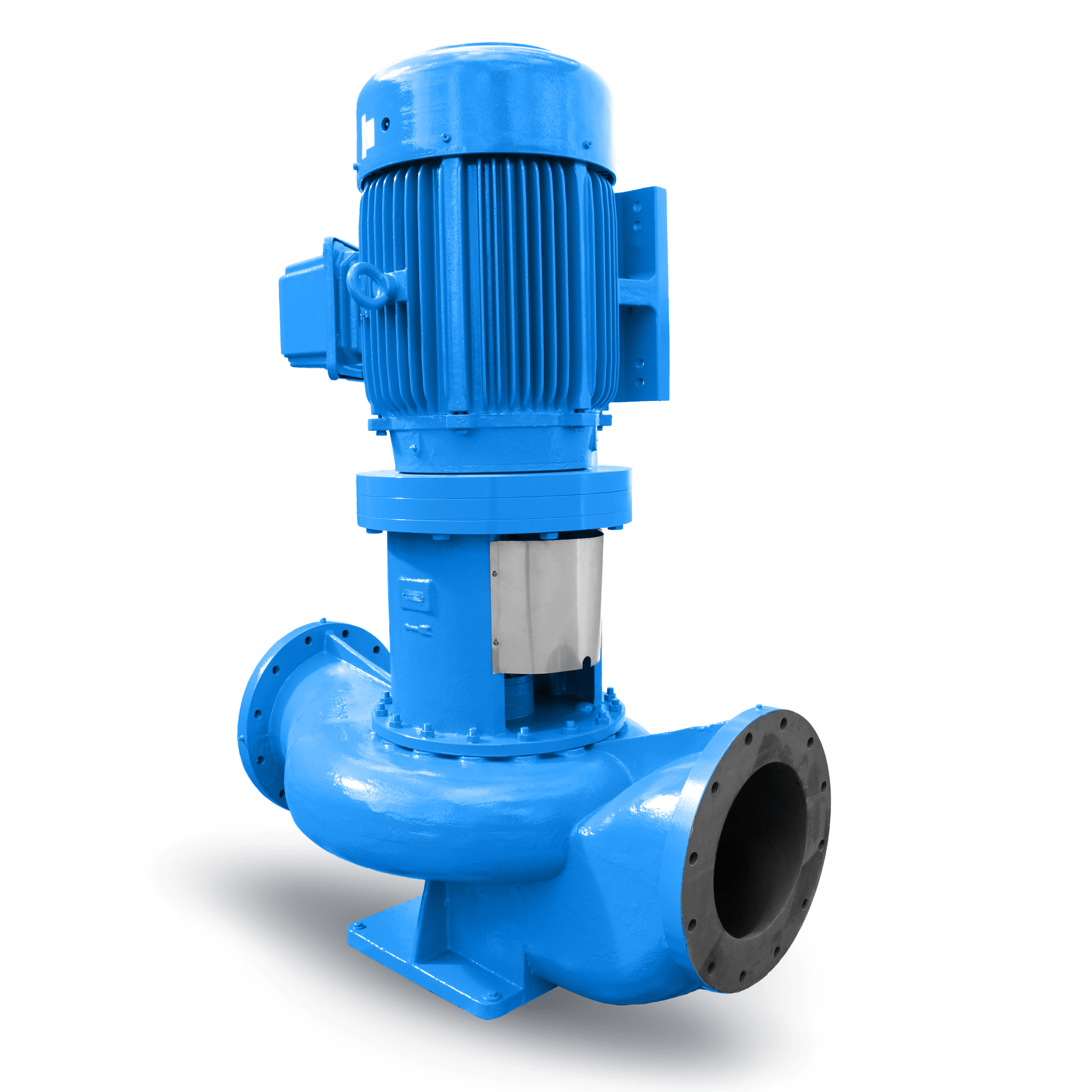

Illustrative image related to in line centrifugal pump

The Solution: To address this sourcing challenge, buyers should prioritize building relationships with reputable suppliers who have a proven track record in the industry. Conduct thorough research by seeking out reviews, case studies, and testimonials from other customers. Attend industry trade shows and networking events to connect with suppliers directly and assess their offerings. Additionally, consider partnering with suppliers that provide comprehensive support services, including installation, maintenance, and training. Establishing long-term partnerships with reliable suppliers can ensure consistent quality and availability, helping to streamline procurement processes and reduce the risk of downtime.

Strategic Material Selection Guide for in line centrifugal pump

What Are the Key Materials Used in In-Line Centrifugal Pumps?

In-line centrifugal pumps are critical components in various industrial applications, and the choice of material significantly impacts their performance, durability, and cost-effectiveness. Below, we analyze four common materials used in the construction of these pumps, focusing on their properties, advantages, disadvantages, and specific considerations for international buyers.

How Does Cast Iron Perform in In-Line Centrifugal Pumps?

Key Properties: Cast iron is known for its excellent strength and durability, with a temperature rating up to 400°F (204°C) and a pressure rating of around 250 PSI. It also has good wear resistance, making it suitable for handling abrasive fluids.

Pros & Cons: The primary advantage of cast iron is its cost-effectiveness and high tensile strength. However, it is prone to corrosion, especially when exposed to aggressive chemicals, which can lead to a shorter lifespan in certain applications. Additionally, cast iron is heavier than other materials, which may complicate installation and maintenance.

Impact on Application: Cast iron is suitable for applications involving water, oil, and some chemicals but may not be ideal for highly corrosive environments. Buyers must consider the specific media being pumped to ensure compatibility.

Considerations for International Buyers: Cast iron pumps often comply with ASTM standards, making them a reliable choice for buyers in regions like Europe and the Middle East. However, buyers in Africa and South America should be aware of local corrosion rates and environmental conditions that may affect performance.

What Are the Benefits of Stainless Steel in Centrifugal Pumps?

Key Properties: Stainless steel offers excellent corrosion resistance and can withstand temperatures up to 1,500°F (815°C) and pressures exceeding 300 PSI, depending on the grade. Its smooth surface reduces friction and enhances flow efficiency.

Pros & Cons: The key advantage of stainless steel is its durability and resistance to corrosion, making it suitable for a wide range of fluids, including aggressive chemicals. However, it is generally more expensive than cast iron, and its manufacturing process can be complex, leading to higher production costs.

Impact on Application: Stainless steel is ideal for applications involving food and beverage processing, pharmaceuticals, and other industries where hygiene is critical. Its compatibility with a broad range of media makes it a versatile choice.

Considerations for International Buyers: Buyers in Europe and Germany often prefer stainless steel due to stringent hygiene standards. Compliance with DIN standards is crucial, while buyers in Africa and South America should consider local regulations regarding food safety and chemical handling.

Why Choose Bronze for In-Line Centrifugal Pumps?

Key Properties: Bronze is known for its excellent corrosion resistance, particularly in marine environments. It can handle temperatures up to 400°F (204°C) and pressures around 175 PSI.

Pros & Cons: The primary advantage of bronze is its resistance to corrosion and biofouling, making it suitable for seawater applications. However, bronze is more expensive than cast iron and can be subject to dezincification in certain conditions, which may compromise its integrity.

Impact on Application: Bronze is particularly well-suited for applications involving seawater, potable water, and other corrosive fluids. Its properties make it a preferred choice for marine and offshore applications.

Illustrative image related to in line centrifugal pump

Considerations for International Buyers: Buyers in coastal regions, such as those in South America and the Middle East, may favor bronze pumps for their durability against saltwater. Compliance with ASTM standards is essential for ensuring quality and performance.

What Role Does Plastic Play in Centrifugal Pump Construction?

Key Properties: Plastic materials, such as PVC and polypropylene, are lightweight and resistant to a wide range of chemicals. They can typically handle temperatures up to 140°F (60°C) and pressures around 150 PSI.

Pros & Cons: The main advantage of plastic is its low cost and excellent chemical resistance, making it suitable for various applications. However, plastics may not withstand high temperatures and pressures as effectively as metals, limiting their use in more demanding environments.

Illustrative image related to in line centrifugal pump

Impact on Application: Plastic pumps are ideal for applications involving corrosive chemicals, such as acids and bases. They are commonly used in laboratories, chemical processing, and wastewater treatment.

Considerations for International Buyers: Buyers in regions with stringent chemical handling regulations, such as Europe, should ensure that plastic pumps meet relevant standards. In Africa and South America, local availability and cost can be significant factors in material selection.

Summary of Material Selection for In-Line Centrifugal Pumps

| Material | Typical Use Case for in line centrifugal pump | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cast Iron | Water, oil, and some chemicals | Cost-effective and durable | Prone to corrosion | Low |

| Stainless Steel | Food processing, pharmaceuticals | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Bronze | Marine applications, potable water | Corrosion and biofouling resistance | Expensive, risk of dezincification | Med |

| Plastic | Chemical processing, wastewater treatment | Lightweight and chemical resistant | Limited temperature and pressure range | Low |

This guide provides a comprehensive overview of material selection for in-line centrifugal pumps, helping international B2B buyers make informed decisions based on their specific applications and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for in line centrifugal pump

What Are the Key Stages in the Manufacturing Process of In-Line Centrifugal Pumps?

The manufacturing process of in-line centrifugal pumps involves several critical stages, each designed to ensure the final product meets high standards of performance and durability.

Material Preparation: What Materials Are Commonly Used?

The process begins with the careful selection and preparation of materials. Common materials include cast iron, bronze, and stainless steel, selected for their corrosion resistance, strength, and ability to withstand high pressures. These materials undergo rigorous quality checks to ensure they meet international standards, with inspections focusing on chemical composition, tensile strength, and surface finish.

How Are In-Line Pumps Formed?

Once materials are prepared, the forming stage takes place. This typically involves casting and machining processes. In casting, molten metal is poured into molds to create pump components like the casing and impeller. After casting, these components are machined to precise specifications, ensuring smooth surfaces and accurate dimensions essential for optimal performance. Techniques such as CNC machining are commonly employed to achieve high precision.

What Assembly Techniques Are Used in Pump Manufacturing?

The assembly stage involves the careful integration of all components, including the impeller, motor, and casing. This process often uses specialized tools to ensure tight tolerances are maintained. Each assembly is carried out in a clean environment to prevent contamination. Manufacturers may employ both manual and automated assembly techniques, depending on the complexity of the pump design and the volume of production.

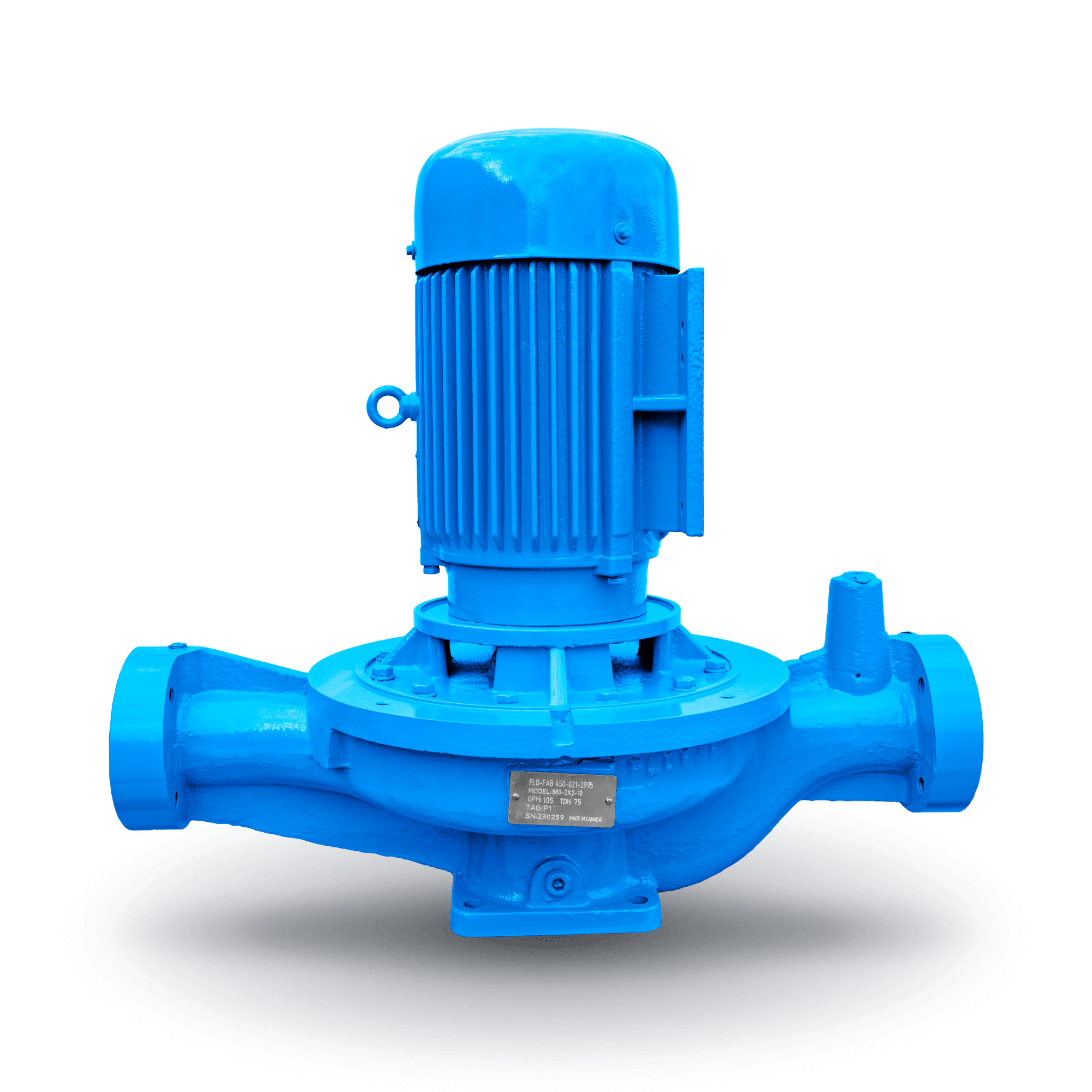

Illustrative image related to in line centrifugal pump

What Finishing Processes Enhance Pump Performance?

Finishing processes are crucial for enhancing the performance and longevity of in-line centrifugal pumps. These processes may include surface treatments, such as coating for corrosion resistance, and polishing to improve hydraulic efficiency. Quality checks during this stage focus on the aesthetic and functional aspects of the pump, ensuring that the final product not only looks good but also performs optimally in its intended application.

How Is Quality Assurance Implemented in In-Line Pump Manufacturing?

Quality assurance (QA) is paramount in ensuring that in-line centrifugal pumps meet industry standards and customer expectations.

What International Standards Govern Pump Manufacturing?

Manufacturers often adhere to international quality management standards such as ISO 9001, which focuses on improving customer satisfaction and ensuring consistent product quality. Additionally, industry-specific certifications such as CE (Conformité Européenne) for European markets and API (American Petroleum Institute) standards for pumps used in the oil and gas sector are critical. These certifications serve as a guarantee that the pumps have been tested and meet stringent quality criteria.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process. Key stages include:

Illustrative image related to in line centrifugal pump

- Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon delivery to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During production, regular inspections are conducted to monitor the manufacturing process and detect any deviations from quality standards.

- Final Quality Control (FQC): Once assembly is complete, the final product undergoes rigorous testing to ensure it performs to specifications.

What Testing Methods Are Commonly Used for In-Line Pumps?

Common testing methods for in-line centrifugal pumps include performance testing, pressure testing, and leakage testing. Performance testing evaluates the pump’s flow rate and efficiency under various operating conditions, while pressure testing ensures that the pump can withstand its rated pressure without failure. Leakage testing verifies the integrity of seals and joints, preventing fluid loss in operation.

How Can B2B Buyers Verify Supplier Quality Control Measures?

B2B buyers must take proactive steps to verify the quality control measures of potential suppliers, especially when sourcing from international markets.

What Auditing Practices Should Buyers Consider?

Conducting audits is an effective way to assess a supplier’s manufacturing and quality assurance practices. Buyers should look for suppliers who are transparent about their QA processes and are willing to provide documentation and access for on-site inspections. Audits can reveal the supplier’s adherence to international standards and their commitment to quality.

How Important Are Quality Reports and Certifications?

Buyers should request quality reports and certifications from suppliers. These documents provide insight into the supplier’s quality management systems and compliance with international standards. Certifications from recognized bodies can serve as a significant assurance of product quality, particularly for B2B buyers in regions with strict regulatory requirements.

Illustrative image related to in line centrifugal pump

What Role Do Third-Party Inspections Play in Quality Assurance?

Engaging third-party inspection services can further enhance confidence in product quality. These independent organizations can conduct thorough inspections and testing, providing impartial verification of the supplier’s claims. This is particularly important for B2B buyers from regions like Africa and South America, where local regulations may differ significantly from those in Europe or the Middle East.

What Are the Unique QC Considerations for International B2B Buyers?

When sourcing in-line centrifugal pumps from international suppliers, B2B buyers must consider various nuances in quality control.

How Do Regional Standards Affect Pump Quality?

Different regions have unique regulatory standards that can affect pump design and performance. For instance, pumps destined for the European market must comply with CE marking requirements, while those for the Middle Eastern market may need to meet specific local standards. Buyers should ensure that their suppliers are familiar with and compliant with the relevant standards for their target market.

What Should Buyers Know About Warranty and Service Agreements?

Understanding warranty and service agreements is vital for B2B buyers. A robust warranty can indicate the manufacturer’s confidence in their product quality. Buyers should seek clarity on the terms of warranty, including coverage for defects and the process for claiming repairs or replacements. Additionally, service agreements that outline maintenance and support can enhance the longevity and reliability of the pumps in operation.

Illustrative image related to in line centrifugal pump

In conclusion, the manufacturing processes and quality assurance practices for in-line centrifugal pumps are critical components that B2B buyers must thoroughly evaluate. By understanding these aspects, buyers can make informed decisions and select suppliers that meet their quality expectations and regulatory requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘in line centrifugal pump’

In the competitive landscape of industrial procurement, sourcing an in-line centrifugal pump requires careful consideration and strategic planning. This guide offers a practical checklist to help B2B buyers navigate the complexities of selecting the right pump for their needs, ensuring a successful purchase that meets both operational and budgetary requirements.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the first and most critical step in the procurement process. Consider factors such as flow rate, head pressure, and the fluid being pumped. Different applications may require different materials or pump configurations, so it’s essential to align your requirements with the specific characteristics of the in-line centrifugal pump.

- Flow Rate: Determine the required gallons per minute (GPM) based on your system’s demands.

- Head Pressure: Calculate the total dynamic head (TDH) to ensure the pump can effectively move fluid through your system.

Step 2: Research and Compare Manufacturers

Identifying reputable manufacturers is vital for ensuring quality and reliability. Look for companies with a proven track record in producing in-line centrifugal pumps. Compare their product lines, focusing on performance, durability, and customer reviews.

- Industry Reputation: Seek out manufacturers with certifications and endorsements from industry organizations.

- Product Range: Ensure the manufacturer offers a variety of models that can cater to different applications and needs.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s crucial to vet potential suppliers thoroughly. Request comprehensive company profiles, case studies, and references from buyers in similar industries or regions. This due diligence will provide insights into the supplier’s reliability and customer service.

- References: Contact previous clients to gauge their satisfaction and the supplier’s after-sales support.

- Case Studies: Look for documented success stories that illustrate the supplier’s capability in solving similar challenges.

Step 4: Verify Compliance with Industry Standards

Ensure that the pumps comply with relevant industry standards and regulations, particularly regarding safety, environmental impact, and performance. Compliance not only guarantees product quality but also mitigates risks associated with non-compliance.

- Certifications: Look for ISO certifications or other industry-specific standards applicable in your region.

- Environmental Impact: Assess any certifications related to energy efficiency or sustainability, which may be increasingly relevant in global markets.

Step 5: Request Quotes and Evaluate Pricing

Gather quotes from multiple suppliers to understand the market pricing for your specified pump. Be cautious of prices that seem too good to be true; they may indicate lower quality or hidden costs.

- Breakdown of Costs: Request detailed pricing that includes installation, shipping, and any additional fees.

- Warranty and Service Agreements: Ensure that the quotes outline warranty terms and the availability of maintenance services.

Step 6: Assess Delivery Times and Availability

Understanding the lead times and availability of the pumps is essential for planning your operations. Delays can significantly impact your project timelines, so verify the supplier’s ability to meet your delivery requirements.

- Lead Times: Inquire about typical delivery times and any factors that might cause delays.

- Inventory Levels: Check if the supplier has the required pumps in stock or if they will be manufacturing them on demand.

Step 7: Finalize Purchase and Review Contract Terms

Once you’ve selected a supplier, review the purchase contract thoroughly. Ensure that all terms, including payment schedules, delivery dates, and warranty details, are clear and agreed upon.

- Contract Clarity: Look for any ambiguous terms that could lead to misunderstandings.

- Payment Terms: Understand the payment structure to avoid cash flow issues post-purchase.

By following these steps, B2B buyers can confidently navigate the sourcing process for in-line centrifugal pumps, ensuring that they make informed decisions that align with their operational needs and budget constraints.

Comprehensive Cost and Pricing Analysis for in line centrifugal pump Sourcing

What Are the Key Cost Components of In-Line Centrifugal Pumps?

When sourcing in-line centrifugal pumps, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The type of materials used significantly affects the overall cost. Common materials include cast iron, stainless steel, and bronze, each with varying price points. Higher-quality materials can improve durability and efficiency but will increase initial costs.

-

Labor: Labor costs encompass the wages of skilled workers involved in manufacturing and assembly. Regions with higher labor costs, such as parts of Europe, may lead to increased pricing compared to manufacturers in lower-cost areas like parts of South America or Africa.

-

Manufacturing Overhead: This includes expenses related to facility operations, utilities, and indirect labor. Efficient manufacturing processes can reduce overhead, positively impacting pricing.

-

Tooling: Initial tooling costs are necessary for custom designs or specifications. If a buyer requires unique features, these costs can escalate, influencing the overall pricing structure.

-

Quality Control (QC): Implementing stringent QC processes ensures the reliability of the pumps, but it also adds to the overall cost. Buyers should seek suppliers with robust QC practices to ensure product quality.

-

Logistics: Shipping and transportation costs vary widely based on the distance from the supplier and the chosen Incoterms. Buyers should consider these costs when evaluating total expenses.

-

Margin: Supplier margins can vary based on market conditions and competition. Understanding supplier pricing strategies can provide leverage during negotiations.

How Do Price Influencers Affect In-Line Centrifugal Pump Costs?

Several factors can influence the pricing of in-line centrifugal pumps:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders often lead to discounts. Buyers should assess their demand to negotiate better pricing structures based on volume.

-

Specifications and Customization: Custom features, such as specific motor types or specialized materials, will increase costs. Buyers should weigh the necessity of customizations against potential price increases.

-

Material Quality and Certifications: Pumps with certifications (e.g., ISO, CE) or made from higher-grade materials typically command higher prices. Buyers should consider the long-term benefits of investing in certified products.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium for their brand, but they often provide better support and warranties.

-

Incoterms: Understanding Incoterms is vital for cost management. They dictate who bears the shipping and insurance costs, which can significantly impact the final price.

What Buyer Tips Can Optimize Sourcing Costs?

To effectively manage costs when sourcing in-line centrifugal pumps, consider the following tips:

-

Negotiate Wisely: Engage in open discussions with suppliers about pricing, especially for large orders. Highlight your potential for future business to negotiate better terms.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes not only the purchase price but also operational costs, maintenance, and longevity of the pumps. A slightly higher initial investment in a more durable pump can lead to significant savings over time.

-

Understand Pricing Nuances for International Buyers: Different regions may have varying pricing strategies based on local market conditions. For instance, suppliers in Africa and South America may offer competitive pricing due to lower labor costs, but consider potential trade tariffs or logistics challenges when importing.

-

Stay Informed on Market Trends: Regularly review market conditions that could affect pricing, such as material shortages or economic changes. Being informed allows you to time your purchases more effectively.

Disclaimer on Pricing

The prices mentioned in various listings can fluctuate based on market conditions, supplier changes, and specific buyer requirements. It is advisable to confirm current pricing directly with suppliers to ensure accuracy and avoid unexpected costs.

Alternatives Analysis: Comparing in line centrifugal pump With Other Solutions

Exploring Alternatives to In-Line Centrifugal Pumps: A Comparative Analysis

When considering the best pumping solution for industrial applications, it’s essential to evaluate various technologies that can meet specific operational needs. In-line centrifugal pumps are popular for their efficiency and versatility; however, other solutions may offer distinct advantages depending on the application context. This section compares in-line centrifugal pumps with two viable alternatives: positive displacement pumps and submersible pumps.

| Comparison Aspect | In-Line Centrifugal Pump | Positive Displacement Pump | Submersible Pump |

|---|---|---|---|

| Performance | High flow rates, moderate pressure | Low flow rates, high pressure | Variable flow rates, high head |

| Cost | Moderate initial cost, ongoing energy costs | Higher initial cost, lower operational costs | Moderate initial cost, high installation costs |

| Ease of Implementation | Generally straightforward, requires piping alignment | Requires careful design to accommodate flow | Installation can be complex due to depth |

| Maintenance | Regular checks needed, easy access | Requires more frequent maintenance, may need specialized service | Regular maintenance needed, but generally robust |

| Best Use Case | HVAC, water circulation, clean water applications | High-viscosity fluids, precise dosing | Wastewater management, deep well applications |

What Are the Advantages and Disadvantages of Positive Displacement Pumps?

Positive displacement pumps operate by trapping a fixed amount of fluid and forcing it into the discharge pipe. This method allows for precise flow control, making them ideal for applications involving viscous fluids or when accurate dosing is required.

Pros:

– High efficiency with high-viscosity fluids.

– Excellent for applications requiring precise flow rates.

– Less affected by variations in pressure.

Cons:

– Generally more expensive to purchase and install compared to in-line centrifugal pumps.

– More complex maintenance needs due to moving parts.

– Not suitable for low-viscosity applications, as they can cause cavitation.

How Do Submersible Pumps Compare in Functionality and Use Cases?

Submersible pumps are designed to operate underwater, making them ideal for applications such as draining, sewage pumping, and deep well extraction. They work by pushing fluid to the surface rather than pulling it, which is beneficial in certain scenarios.

Pros:

– Highly efficient in pumping water from deep wells or flooded areas.

– Self-priming, eliminating the need for additional priming systems.

– Typically robust and can handle various types of liquids, including solids.

Illustrative image related to in line centrifugal pump

Cons:

– Installation can be complicated and costly, especially in deep wells.

– Regular maintenance is required to prevent clogging and wear.

– Limited application in high-pressure systems compared to centrifugal pumps.

How Should B2B Buyers Choose the Right Pumping Solution?

When selecting a pumping solution, B2B buyers must consider several factors, including the specific application requirements, the nature of the fluid being pumped, and the overall cost of ownership. In-line centrifugal pumps are often suitable for standard applications with clean fluids, while positive displacement pumps may be better for specialized scenarios requiring precision. Submersible pumps serve well in environments where deep water extraction is necessary but can entail higher installation costs.

Ultimately, the choice should be guided by a detailed assessment of operational needs, budget constraints, and the long-term maintenance implications of each option. By carefully analyzing these factors, buyers can ensure they select a solution that not only meets their immediate requirements but also supports their operational efficiency and cost-effectiveness in the long run.

Essential Technical Properties and Trade Terminology for in line centrifugal pump

What Are the Key Technical Properties of In-Line Centrifugal Pumps?

In-line centrifugal pumps are critical in various applications, from HVAC systems to water treatment. Understanding their technical specifications can significantly impact your purchasing decision. Here are some essential properties:

-

Material Grade

The material used in pump construction (e.g., cast iron, stainless steel, bronze) affects durability and compatibility with various fluids. For example, stainless steel is often preferred for potable water applications due to its corrosion resistance. B2B buyers should consider the specific environment in which the pump will operate to ensure longevity and performance. -

Pump Size and Flow Rate

The physical dimensions of the pump, often denoted in inches (e.g., 2x2x5.25), are crucial for installation space considerations. The flow rate, typically measured in gallons per minute (GPM), determines how much fluid can be moved within a given time. Understanding these metrics helps buyers match the pump to their system requirements effectively. -

Power and Efficiency Ratings

Motor horsepower (HP) indicates the power required to operate the pump. Efficient pumps can save on energy costs over time, making it essential to evaluate energy efficiency ratings. This is particularly important for international buyers focused on sustainability and operational costs. -

Working Pressure

Measured in pounds per square inch (PSI), the maximum working pressure indicates the pump’s ability to handle system pressures without failure. This specification is vital for ensuring safety and reliability in high-pressure applications. -

Impeller Diameter

The impeller diameter significantly influences the pump’s performance characteristics, including its capacity and efficiency. A larger impeller can typically move more fluid but may require more power. Buyers should consider the implications of impeller size on system design and energy consumption. -

Phase and Voltage Ratings

Pumps are available in single-phase or three-phase configurations, impacting their compatibility with different electrical systems. Voltage ratings (e.g., 115/230V or 230/460V) dictate where and how the pump can be operated. Understanding these ratings is crucial for seamless integration into existing systems.

What Are Common Trade Terms Related to In-Line Centrifugal Pumps?

Navigating the procurement process for in-line centrifugal pumps involves understanding several industry-specific terms. Here are some key definitions:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications can help buyers ensure that they are sourcing compatible and high-quality components. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is particularly important for B2B buyers looking to manage inventory levels and costs effectively. Knowing the MOQ can help in budgeting and supply chain planning. -

RFQ (Request for Quotation)

An RFQ is a document that solicits price proposals from suppliers for specific products or services. When purchasing in-line centrifugal pumps, submitting an RFQ can help buyers obtain competitive pricing and detailed product information. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in shipping and freight. Familiarity with these terms helps B2B buyers understand shipping costs and responsibilities, ensuring smooth logistics. -

Hydraulic Performance Curve

This term refers to a graph that illustrates the pump’s performance characteristics, including flow rate versus head (pressure). Understanding this curve is essential for buyers to evaluate if a pump meets their operational requirements. -

Centrifugal Pump Efficiency

This term describes the ratio of the pump’s hydraulic energy output to the mechanical energy input. High efficiency is a critical factor for B2B buyers focused on energy savings and long-term operational costs.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions when procuring in-line centrifugal pumps, ensuring they meet both operational and financial objectives.

Navigating Market Dynamics and Sourcing Trends in the in line centrifugal pump Sector

What Are the Key Trends Influencing the In-Line Centrifugal Pump Market?

The in-line centrifugal pump sector is experiencing a notable transformation driven by several global factors. The increasing demand for efficient water management solutions, particularly in agricultural and industrial applications, is propelling the market forward. In regions like Africa and South America, where water scarcity is a pressing issue, in-line pumps are becoming essential for irrigation and water distribution systems. Meanwhile, in Europe and the Middle East, strict regulations on energy efficiency and emissions are influencing buyers to seek pumps that meet eco-friendly standards.

Emerging technologies such as IoT (Internet of Things) and AI (Artificial Intelligence) are reshaping how in-line pumps are sourced and utilized. Real-time monitoring and predictive maintenance capabilities are now available, allowing businesses to optimize performance and reduce operational costs. Furthermore, the trend towards modularity in pump design enables buyers to customize solutions tailored to specific applications, enhancing flexibility and scalability.

International buyers are also increasingly prioritizing partnerships with suppliers who can provide comprehensive service packages, including installation, maintenance, and support. This shift underscores the importance of sourcing from manufacturers that not only deliver quality products but also understand local market dynamics and regulations.

How Is Sustainability Shaping Sourcing Decisions in the In-Line Pump Sector?

Sustainability is no longer a mere buzzword; it has become a critical factor influencing sourcing decisions in the in-line centrifugal pump market. The environmental impact of pump manufacturing and operation is under scrutiny, prompting buyers to prioritize suppliers who adhere to sustainable practices. This includes using eco-friendly materials, minimizing waste during production, and implementing energy-efficient technologies in their products.

Ethical supply chains are gaining traction, especially among international buyers who are increasingly aware of the socio-economic implications of their purchasing decisions. Certifications such as ISO 14001 for environmental management and ENERGY STAR ratings for energy efficiency are becoming essential criteria in supplier selection. Buyers from regions like Europe are particularly vigilant about ensuring that their supply chains reflect corporate social responsibility.

Illustrative image related to in line centrifugal pump

Moreover, the transition to ‘green’ materials, such as corrosion-resistant alloys and recyclable components, is influencing product design and sourcing strategies. By investing in sustainable technologies and materials, businesses can not only reduce their carbon footprint but also enhance their market reputation among environmentally conscious consumers.

What Is the Historical Context of the In-Line Centrifugal Pump Industry?

The in-line centrifugal pump has evolved significantly since its inception in the early 20th century. Initially designed for basic fluid transfer, advancements in engineering and materials have transformed these pumps into high-efficiency machines suited for a variety of applications, including HVAC systems, water treatment, and industrial processes.

Over the decades, the introduction of advanced materials such as stainless steel and specialized polymers has improved durability and resistance to corrosion, making in-line pumps more reliable in demanding environments. As industries began to prioritize energy efficiency and sustainability, manufacturers responded by integrating innovative technologies that enhance performance while reducing energy consumption.

Today, the in-line centrifugal pump market is characterized by a blend of tradition and innovation, with manufacturers focusing on developing smarter, more efficient solutions that meet the evolving needs of global buyers. This historical context is crucial for B2B buyers as they navigate the complexities of sourcing pumps that align with both their operational requirements and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of in line centrifugal pump

-

1. How do I select the right in-line centrifugal pump for my application?

Selecting the appropriate in-line centrifugal pump involves assessing several key factors including flow rate, head pressure, and the type of fluid being pumped. Start by determining the specific requirements of your application, such as temperature and viscosity of the fluid, as well as the system layout. Consult with manufacturers to understand the pump’s specifications, and consider the pump’s efficiency and energy consumption. Ensure that the pump’s materials are compatible with the fluid to prevent corrosion or contamination. -

2. What are the key features to look for in an in-line centrifugal pump?

When sourcing an in-line centrifugal pump, consider essential features such as pump design (flex coupled, close coupled, or split coupled), efficiency ratings, and maintenance requirements. Look for options that offer adjustable speed drives to optimize performance based on varying demand. Additionally, evaluate the manufacturer’s warranty and support services, as well as the availability of spare parts. It’s also beneficial to choose pumps that are tested for reliability in your specific industry application. -

3. What are the typical minimum order quantities (MOQs) for in-line centrifugal pumps?

Minimum order quantities (MOQs) can vary significantly among suppliers. Generally, MOQs for in-line centrifugal pumps may range from one unit for specialized suppliers to several dozen for larger manufacturers. It’s advisable to communicate your needs directly with potential suppliers to negotiate terms that suit your purchasing strategy, especially if you are looking to test a new product in your market. Custom orders may have different MOQ policies, so clarify those as well. -

4. How can I vet suppliers when sourcing in-line centrifugal pumps?

To effectively vet suppliers, start by researching their reputation in the industry through reviews, case studies, and client testimonials. Verify their production capabilities, certifications, and adherence to international quality standards like ISO. Request samples of previous work or product prototypes, and engage in direct communication to gauge their responsiveness and customer service. Attending trade shows or industry conferences can also provide insights into supplier credibility and product offerings. -

5. What payment terms should I expect when purchasing in-line centrifugal pumps internationally?

International payment terms can vary widely but typically include options like advance payment, letter of credit, or payment upon delivery. Ensure that you understand the payment schedule and any associated fees, such as currency conversion charges. It’s wise to establish clear terms before finalizing a purchase to avoid misunderstandings. Utilizing escrow services can add an additional layer of security for large transactions, providing protection for both parties. -

6. How do I ensure quality assurance for my in-line centrifugal pump purchases?

Quality assurance can be ensured by requesting detailed product specifications, certifications, and compliance documents from the supplier. Consider implementing a quality control process that includes inspections and testing of pumps upon arrival. Establishing a good relationship with the supplier can also facilitate open communication about quality issues and product performance. Additionally, inquire about their manufacturing processes and whether they conduct regular audits or third-party inspections. -

7. What logistics considerations should I keep in mind when importing in-line centrifugal pumps?

Logistics play a crucial role in the timely delivery of in-line centrifugal pumps. Evaluate shipping methods, costs, and delivery times, and ensure the supplier can meet your deadlines. Be aware of customs regulations in your country, including import duties and taxes, as these can impact overall costs. Additionally, consider working with logistics partners who have experience in handling industrial equipment to streamline the process and mitigate potential delays. -

8. Can in-line centrifugal pumps be customized for specific applications?

Yes, many manufacturers offer customization options for in-line centrifugal pumps to meet specific application needs. Customizations can include modifications in size, material, or performance features such as impeller design or motor type. When discussing customization with suppliers, clearly outline your requirements and applications to ensure that the final product aligns with your operational needs. Keep in mind that customization may affect lead times and pricing, so plan accordingly.

Top 4 In Line Centrifugal Pump Manufacturers & Suppliers List

1. Xylem – Series e-80 Close-Coupled Centrifugal Pumps

Domain: xylem.com

Registered: 1999 (26 years)

Introduction: This company, Xylem – Series e-80 Close-Coupled Centrifugal Pumps, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Bell and Gossett – In-line Pumps

Domain: nationalpumpsupply.com

Registered: 2012 (13 years)

Introduction: Bell and Gossett In-line Pumps for Heating Systems include various models such as B&G Series e-60, e-80, e-90, and e-1510. They offer options like bronze fitted pumps, all bronze pumps, ECM pumps, and smart pumps. The product range also features double suction pumps, multi-stage pumps, and glycol make-up units. Accessories and parts for these pumps are available, including seal kits, bearing assem…

3. Barmesapumps – BVL Series Vertical In-Line Centrifugal Pumps

Domain: barmesapumps.com

Registered: 2014 (11 years)

Introduction: Vertical In-Line Centrifugal Pumps – BVL Series: Key features include discharge sizes from 1.5″ to 14″, power ratings up to 500 HP, flow rates up to 12,000 GPM, heads up to 560 ft, and a working pressure of 175 PSIG. Standard features are same-size suction/discharge connections, short shaft design, and a small installation footprint with low/reduced noise. Common applications include HVAC systems,…

4. Grundfos – In-line Single-Stage Pumps

Domain: product-selection.grundfos.com

Registered: 1995 (30 years)

Introduction: This company, Grundfos – In-line Single-Stage Pumps, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for in line centrifugal pump

In the competitive landscape of industrial procurement, strategic sourcing for in-line centrifugal pumps is crucial for ensuring operational efficiency and cost-effectiveness. By leveraging a comprehensive understanding of product specifications, supplier capabilities, and market dynamics, international buyers can make informed decisions that align with their unique requirements. Emphasizing the importance of reliability and performance, buyers should prioritize suppliers who offer robust warranties and comprehensive support services.

Moreover, as global supply chains continue to evolve, sourcing from reputable manufacturers in regions like Europe and North America can mitigate risks associated with quality and availability. Engaging with local distributors and partners in Africa, South America, and the Middle East can also enhance logistical efficiency and reduce lead times.

Looking ahead, the demand for energy-efficient and environmentally sustainable solutions in the pumping industry will only intensify. Buyers are encouraged to stay abreast of technological advancements and regulatory changes that may impact their sourcing strategies. By adopting a proactive approach to sourcing in-line centrifugal pumps, businesses can position themselves for success in a rapidly changing market landscape. Embrace the opportunity to optimize your supply chain today—your operational excellence depends on it.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.