Metal Spinner: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for metal spinner

In an increasingly interconnected world, sourcing high-quality metal spinners for diverse applications presents a significant challenge for international B2B buyers. Whether you are looking to enhance outdoor spaces or create unique decorative items, understanding the intricacies of the global market for metal spinners is essential. This guide provides a comprehensive overview of the types, applications, and design variations of metal spinners, enabling buyers to make informed purchasing decisions that align with their specific needs.

From decorative wind spinners that add aesthetic value to gardens and patios, to functional pieces that serve as kinetic art, the applications of metal spinners are vast and varied. This resource also delves into critical aspects of supplier vetting, including assessing manufacturing quality, understanding lead times, and evaluating shipping logistics, particularly for buyers from Africa, South America, the Middle East, and Europe, such as Germany and Vietnam.

By equipping yourself with the knowledge contained in this guide, you can navigate the complexities of sourcing metal spinners effectively, ensuring that your investments yield high returns in both quality and customer satisfaction. Prepare to discover actionable insights that will empower your procurement strategies and enhance your competitive edge in the global marketplace.

Understanding metal spinner Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Kinetic Wind Spinners | Feature rotating elements that create motion and visual interest. | Landscaping, garden decor, outdoor events | Pros: Eye-catching, enhances aesthetics. Cons: Can be more expensive. |

| Decorative Garden Spinners | Often themed designs (animals, patterns) made from durable metals. | Retail gift shops, home improvement stores | Pros: Diverse designs appeal to various markets. Cons: Limited functionality beyond decor. |

| Functional Wind Spinners | Designed for practical use, such as wind direction indicators. | Agriculture, weather stations | Pros: Practical utility, helps with outdoor activities. Cons: Less visually appealing. |

| Solar-Powered Spinners | Incorporate solar technology for illumination at night. | Eco-friendly retailers, outdoor exhibitions | Pros: Energy-efficient, dual function as decor and light. Cons: Higher upfront costs. |

| Custom Metal Spinners | Tailored designs based on client specifications and branding. | Corporate gifts, promotional events | Pros: Unique branding opportunities. Cons: Longer lead times for production. |

What Are Kinetic Wind Spinners and Their Applications in B2B?

Kinetic wind spinners are designed to create dynamic movement, often featuring multiple rotating elements that catch the wind. These spinners are commonly used in landscaping and garden décor, appealing to businesses that focus on outdoor aesthetics. When considering a purchase, B2B buyers should evaluate the spinner’s durability, materials used, and design complexity, as these factors can influence both longevity and visual appeal.

Illustrative image related to metal spinner

How Do Decorative Garden Spinners Differ in Design and Use?

Decorative garden spinners are characterized by their thematic designs, which can range from whimsical animals to intricate patterns. These spinners serve primarily as decorative items in retail settings or home improvement stores. Buyers should consider the target market’s preferences when selecting designs, as trends can vary by region. The ability to offer a wide variety of styles can enhance a retailer’s inventory and appeal.

Why Choose Functional Wind Spinners for Practical Applications?

Functional wind spinners are designed with utility in mind, often serving as indicators for wind direction or speed. These spinners find their primary applications in agriculture and weather stations, where accurate weather data is crucial. B2B buyers should prioritize spinners that offer reliability and visibility, ensuring they meet the practical needs of their end-users while also considering aesthetic aspects for outdoor settings.

What Are the Benefits of Solar-Powered Spinners in Eco-Friendly Markets?

Solar-powered spinners are an innovative solution that combines art with technology, utilizing solar energy to provide illumination at night. They are particularly popular among eco-friendly retailers and outdoor exhibitions that emphasize sustainable practices. Buyers should weigh the initial investment against long-term energy savings and consider the spinner’s design to ensure it meets both aesthetic and functional requirements.

How Can Custom Metal Spinners Enhance Branding Opportunities?

Custom metal spinners allow businesses to create unique designs tailored to specific branding needs, making them ideal for corporate gifts and promotional events. These spinners can serve as effective marketing tools that enhance brand visibility. However, B2B buyers should be prepared for longer lead times and potentially higher costs associated with customization, which may impact inventory planning and cash flow.

Illustrative image related to metal spinner

Key Industrial Applications of metal spinner

| Industry/Sector | Specific Application of Metal Spinner | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Wind Spinners for Crop Pollination | Enhances pollination rates, leading to higher yields | Durability against weather, material quality, and size |

| Renewable Energy | Kinetic Wind Spinners for Energy Generation | Provides sustainable energy solutions | Efficiency in wind capture, maintenance requirements |

| Outdoor Decor & Landscaping | Decorative Wind Spinners for Gardens and Parks | Improves aesthetic appeal, attracts customers | Design variety, weather resistance, and customization options |

| Manufacturing & Machinery | Component in Kinetic Energy Devices | Enhances product functionality and appeal | Precision in manufacturing, material strength, and weight |

| Retail & Gift Industry | Unique Gift Items and Home Decor | Differentiates product offerings, increases sales | Packaging, shipping logistics, and design trends |

How is Metal Spinner Used in Agriculture for Crop Pollination?

In the agricultural sector, metal spinners are used as wind spinners to attract pollinators such as bees and butterflies. By creating a visually engaging environment, these spinners can significantly enhance pollination rates, leading to improved crop yields. For international buyers, especially from regions like Africa and South America, sourcing durable spinners that withstand harsh weather conditions is crucial. Additionally, the choice of materials, such as rust-resistant metals, ensures longevity and performance in diverse climates.

What Role do Kinetic Wind Spinners Play in Renewable Energy?

Kinetic wind spinners are increasingly being utilized in the renewable energy sector as part of wind energy generation systems. These spinners can harness wind energy to convert it into usable power, contributing to sustainable energy solutions. For businesses in Europe and the Middle East looking to invest in renewable technologies, it is essential to consider the efficiency of the spinner design and its capacity to withstand varying wind speeds. Maintenance requirements and the availability of replacement parts are also key factors in the sourcing process.

How do Decorative Wind Spinners Enhance Outdoor Spaces?

In the outdoor decor and landscaping industry, decorative metal wind spinners are popular for enhancing the aesthetic appeal of gardens and parks. These spinners not only serve as visual focal points but also attract visitors, boosting foot traffic and sales for businesses in this sector. Buyers should focus on sourcing spinners that are weather-resistant and available in a variety of designs to cater to diverse customer preferences. Customization options can also provide a competitive edge in the market.

In What Ways are Metal Spinners Used in Manufacturing and Machinery?

Metal spinners find applications in manufacturing and machinery as components in kinetic energy devices. These devices often rely on the spinning motion to enhance functionality, making metal spinners an integral part of the design. For international buyers, particularly in regions with advanced manufacturing capabilities like Germany, precision in manufacturing is critical. Sourcing spinners made from high-strength materials ensures reliability, while considerations around weight can impact the overall efficiency of machinery.

Illustrative image related to metal spinner

How are Unique Gift Items Created Using Metal Spinners?

The retail and gift industry has embraced metal spinners as unique gift items and home decor products. Their eye-catching designs make them ideal for attracting customers looking for distinctive decorative pieces. Businesses should consider sourcing spinners that are well-packaged for shipping, as this can enhance the overall customer experience. Additionally, staying updated on design trends can help retailers ensure that their offerings remain relevant and appealing to consumers across various markets.

3 Common User Pain Points for ‘metal spinner’ & Their Solutions

Scenario 1: Sourcing High-Quality Metal Spinners for Outdoor Decor

The Problem: B2B buyers often face difficulties in sourcing high-quality metal spinners that can withstand various weather conditions while maintaining aesthetic appeal. This challenge is particularly pronounced in regions with extreme weather fluctuations, where products may rust, fade, or deteriorate quickly. Buyers may also struggle with inconsistent quality from suppliers, leading to dissatisfaction among end customers and potential returns that can impact their bottom line.

The Solution: To effectively source high-quality metal spinners, buyers should prioritize suppliers that specialize in outdoor decor and have a proven track record of using durable materials. Look for products made from 18-gauge steel or aluminum, which offer better resistance to corrosion and wear. Buyers should also ask for samples or detailed product specifications, including information on coatings such as baked-on powder coats that enhance durability and color retention. Establishing a relationship with reliable manufacturers who provide warranties can also help mitigate risks associated with product quality. Implementing a quality assurance process, such as inspecting products upon receipt and before sale, can further ensure that only the best items reach the market.

Scenario 2: Customization Needs for Unique Market Demands

The Problem: Many B2B buyers encounter challenges when trying to meet the specific aesthetic or functional needs of their target markets. For instance, a buyer may need custom designs that resonate with local cultural themes or seasonal trends, but not all suppliers offer customization services, leading to missed sales opportunities and customer dissatisfaction.

The Solution: Buyers should seek out manufacturers who provide bespoke services and are willing to collaborate on design projects. This may involve sharing detailed design briefs, including dimensions, materials, and desired finishes. Establishing a partnership with a metal spinner company that can accommodate such requests will enhance the product lineup and cater to unique customer preferences. Additionally, buyers can utilize design software or collaborate with local artists to create prototypes, ensuring that the final products are both appealing and culturally relevant. Regular communication with suppliers throughout the customization process can help streamline production and ensure timely delivery, ultimately enhancing customer satisfaction and loyalty.

Scenario 3: Managing Inventory and Supply Chain Fluctuations

The Problem: B2B buyers often struggle with managing inventory levels and navigating supply chain issues that can lead to delays or stockouts. This is particularly critical for businesses that sell seasonal products like garden decor, where demand can surge suddenly during certain times of the year. Inconsistent supply can disrupt sales cycles and negatively affect revenue.

The Solution: Implementing an effective inventory management system that forecasts demand based on historical sales data can significantly alleviate these challenges. Buyers should work closely with suppliers to establish minimum order quantities and lead times, ensuring that stock levels are adequate to meet customer demand without overextending resources. Utilizing just-in-time inventory practices can also help minimize holding costs while ensuring timely availability of products. Additionally, diversifying the supplier base by establishing relationships with multiple manufacturers can provide flexibility and reduce the risk of stockouts due to unforeseen supply chain disruptions. Regularly reviewing supplier performance and market trends can help buyers remain proactive in their inventory management strategies.

Strategic Material Selection Guide for metal spinner

What Are the Key Properties of Common Materials Used in Metal Spinners?

In the metal spinning industry, the choice of material significantly influences the performance, durability, and cost-effectiveness of the final product. Below, we analyze four common materials used in metal spinners, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Steel Perform as a Material for Metal Spinners?

Key Properties: Steel, particularly stainless steel, offers exceptional strength and durability. It can withstand high temperatures and pressures, making it suitable for outdoor applications. Its corrosion resistance, especially in stainless variants, ensures longevity in various environmental conditions.

Pros & Cons: The primary advantage of steel is its robustness and ability to be manufactured into intricate designs. However, it can be heavier than other materials, which may complicate installation and shipping. The manufacturing complexity can also increase costs, particularly for custom designs.

Impact on Application: Steel spinners are compatible with a wide range of media, including wind and moisture, making them ideal for outdoor decor. They are often used in garden settings, where durability is paramount.

Considerations for International Buyers: Compliance with international standards such as ASTM or DIN is crucial. Buyers from regions like Europe may prefer materials that meet stringent environmental regulations, while those in Africa and South America might prioritize cost-effectiveness.

What Are the Benefits of Aluminum in Metal Spinners?

Key Properties: Aluminum is lightweight yet strong, with good corrosion resistance. It has a lower melting point compared to steel, which allows for easier shaping during the manufacturing process.

Pros & Cons: The main advantage of aluminum is its lightweight nature, making it easier to transport and install. However, it may not be as durable as steel under extreme conditions, and its cost can be higher depending on the alloy used.

Illustrative image related to metal spinner

Impact on Application: Aluminum spinners are often used in decorative applications where weight is a concern. They are suitable for environments with moderate weather conditions.

Considerations for International Buyers: Buyers should be aware of the varying standards for aluminum alloys, particularly in Europe (EN standards) and the Middle East. Understanding local preferences for aluminum grades can help in selecting the right material.

Why Choose Copper for Metal Spinners?

Key Properties: Copper is known for its excellent thermal and electrical conductivity, as well as its natural resistance to corrosion. It develops a patina over time, which can enhance its aesthetic appeal.

Illustrative image related to metal spinner

Pros & Cons: The key advantage of copper is its unique appearance and resistance to corrosion, which makes it suitable for artistic applications. However, it is generally more expensive than both steel and aluminum, and its softness can lead to wear over time.

Impact on Application: Copper spinners are often used in artistic installations or high-end decorative pieces where aesthetics are prioritized over durability.

Considerations for International Buyers: Buyers should consider the cost implications of copper and its compliance with local regulations regarding metal sourcing. In Europe, for instance, there are strict guidelines around the use of copper in outdoor applications.

What Role Does Iron Play in Metal Spinners?

Key Properties: Iron is a strong and durable material, often used in traditional metalworking. It has a high tensile strength and can be finished in various ways to enhance its appearance and resistance to rust.

Pros & Cons: Iron’s primary advantage is its strength and cost-effectiveness. However, it is prone to rusting if not properly coated or maintained, which can limit its suitability for outdoor applications.

Illustrative image related to metal spinner

Impact on Application: Iron spinners are often used in decorative garden settings but require protective coatings to ensure longevity in outdoor environments.

Considerations for International Buyers: Buyers should consider the availability of iron and its compliance with local standards. In regions like Africa and South America, where iron ore is abundant, sourcing may be more cost-effective.

Summary Table of Material Selection for Metal Spinners

| Material | Typical Use Case for metal spinner | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Outdoor decor, garden spinners | High durability and strength | Heavier, complex manufacturing | Medium |

| Aluminum | Decorative applications | Lightweight, easy to shape | Less durable than steel | High |

| Copper | Artistic installations | Unique aesthetic, corrosion-resistant | Expensive, softer material | High |

| Iron | Traditional garden decor | Cost-effective, strong | Prone to rust, requires coating | Low |

This strategic material selection guide provides a comprehensive overview for international B2B buyers, helping them make informed decisions based on performance, cost, and compliance considerations.

Illustrative image related to metal spinner

In-depth Look: Manufacturing Processes and Quality Assurance for metal spinner

What are the Main Stages in the Manufacturing Process of Metal Spinners?

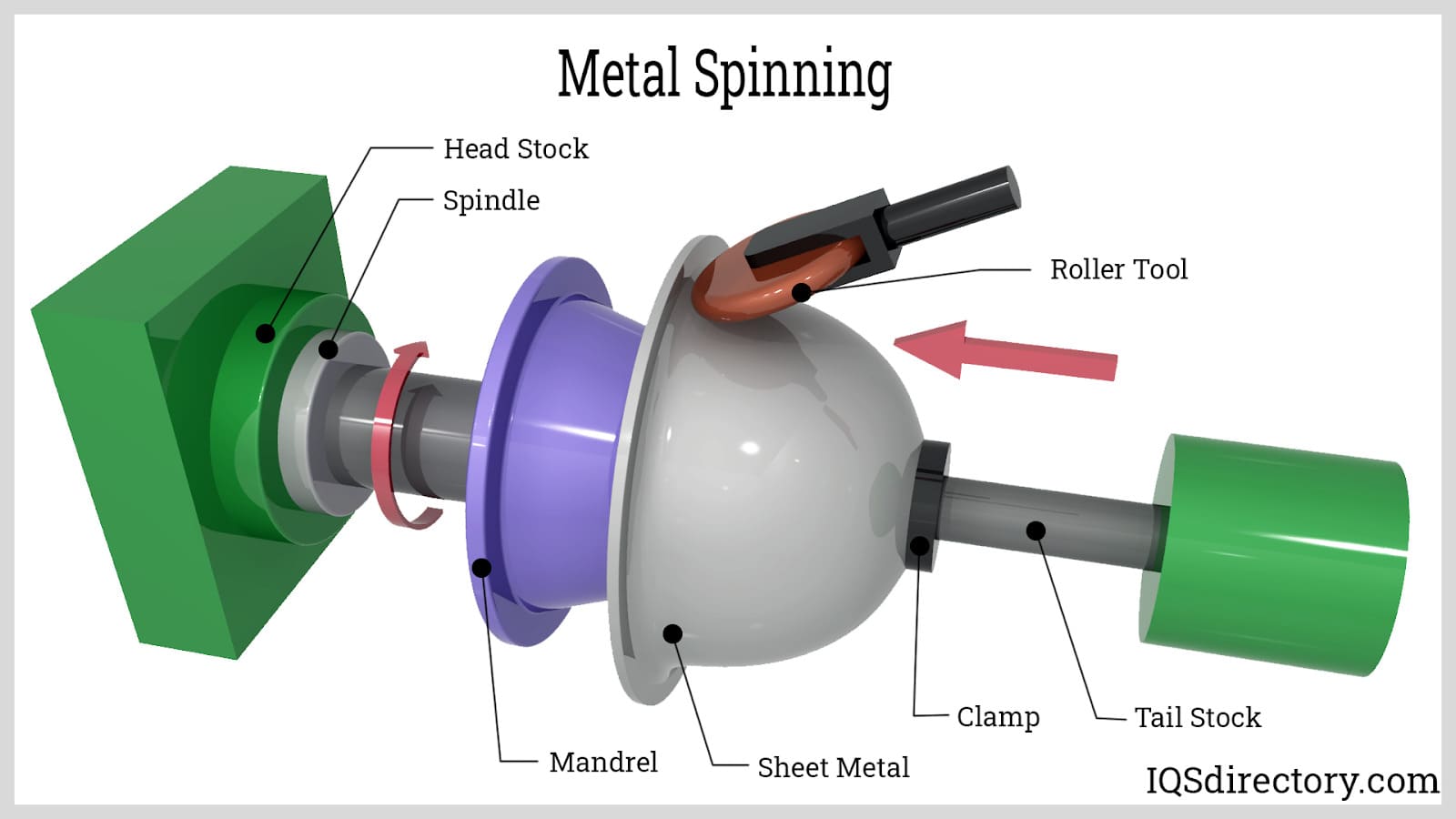

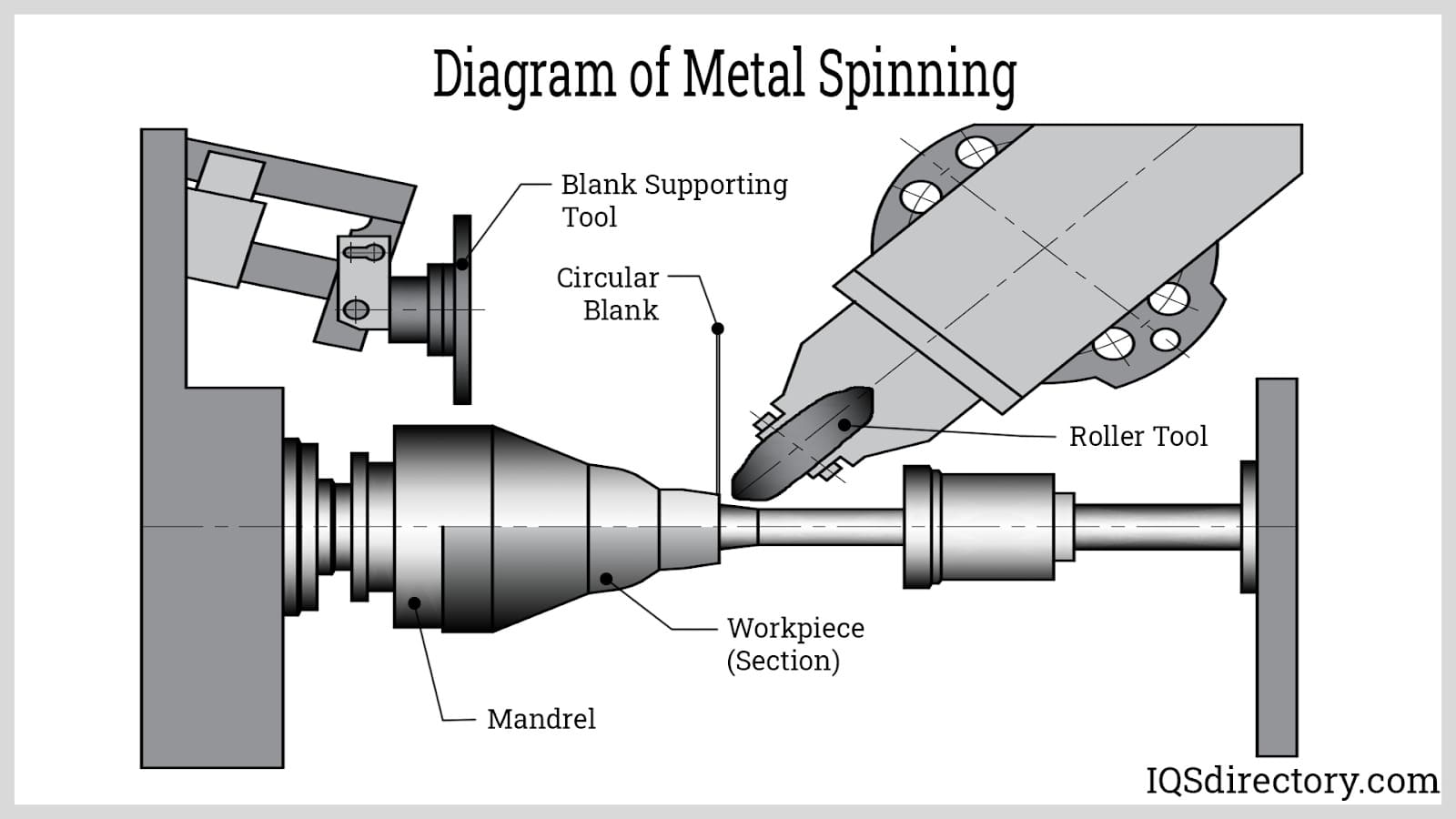

The manufacturing of metal spinners is a multi-stage process that begins with material preparation and culminates in finishing. Each stage is critical to ensure the final product meets quality standards and customer specifications.

-

Material Preparation: The process typically starts with selecting high-quality materials, often 18-gauge steel or aluminum, known for their durability and resistance to the elements. Raw materials undergo cutting and shaping to form the initial components of the spinner. Precision is essential at this stage to ensure parts fit together seamlessly during assembly.

-

Forming: This stage involves various techniques such as CNC machining, stamping, or laser cutting to create the desired shapes and designs. Advanced technologies like 3D printing are also emerging in the industry, allowing for intricate designs that were previously challenging to achieve. The forming stage is crucial for maintaining the aesthetic appeal and functional performance of the spinners.

-

Assembly: Once the components are formed, they are assembled using techniques such as welding, riveting, or mechanical fastening. This stage requires skilled labor to ensure that the assembly is robust and that moving parts, such as bearings, are installed correctly for smooth operation.

-

Finishing: The final stage involves surface treatment processes such as powder coating, painting, or galvanizing. These treatments enhance the spinner’s aesthetic appeal and provide protection against corrosion and weathering. A high-quality finish not only improves durability but also increases the product’s marketability.

How is Quality Assurance Implemented in Metal Spinner Manufacturing?

Quality assurance (QA) is vital in the production of metal spinners to ensure they meet international standards and customer expectations. Here are the key aspects of QA in the manufacturing process:

-

International Standards Compliance: Many manufacturers adhere to ISO 9001 standards, which outline requirements for a quality management system. Compliance with these standards assures buyers of consistent product quality and operational efficiency. Additionally, certifications such as CE and API may be relevant for specific markets or applications, particularly in Europe and the Middle East.

-

Quality Control Checkpoints: The QA process typically includes several checkpoints:

– Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before they enter production. Suppliers are required to provide certificates of compliance and material test reports.

– In-Process Quality Control (IPQC): During manufacturing, inspections are conducted to ensure that the production process adheres to specified quality standards. This includes monitoring equipment and processes to prevent defects.

– Final Quality Control (FQC): After assembly, the finished product undergoes rigorous testing for functionality, appearance, and durability. This may involve performance tests, visual inspections, and stress tests to ensure reliability. -

Common Testing Methods: Testing methods can vary depending on the product specifications and intended use. Common techniques include:

– Visual Inspection: Checking for surface defects, scratches, and overall finish.

– Mechanical Testing: Assessing strength and durability through tensile and fatigue tests.

– Environmental Testing: Simulating conditions such as humidity and temperature to evaluate corrosion resistance.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial. Here are actionable insights on how to conduct effective verification:

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the supplier’s manufacturing processes and quality control measures firsthand. This includes reviewing documentation, inspecting facilities, and assessing equipment used in production.

-

Requesting Quality Reports: Buyers should ask suppliers for detailed quality reports that include data on inspection results, compliance certifications, and any corrective actions taken for past issues. This transparency fosters trust and ensures accountability.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s quality control practices. These organizations can conduct random inspections and testing on behalf of the buyer, ensuring adherence to international standards.

-

Certification Verification: Buyers should verify the authenticity of certifications claimed by suppliers. This may involve checking with certification bodies or requesting proof of compliance documentation.

What Nuances Should International B2B Buyers Consider in Quality Control?

When dealing with international suppliers, B2B buyers must navigate various nuances in quality control:

-

Cultural Differences: Different regions may have varying standards and practices regarding quality control. Understanding these cultural differences can help buyers set realistic expectations and foster better communication with suppliers.

-

Regulatory Compliance: Buyers must be aware of the regulatory requirements specific to their region or industry. This includes understanding local standards for materials and manufacturing processes, which may differ from international norms.

-

Logistical Considerations: Quality assurance can also be affected by logistics and transportation. Buyers should ensure that suppliers have robust packaging and shipping processes to minimize damage during transit.

-

Long-Term Relationships: Establishing long-term partnerships with reliable suppliers can enhance quality consistency. Continuous monitoring and feedback can help suppliers improve their processes over time, benefiting both parties.

In conclusion, understanding the manufacturing processes and quality assurance protocols for metal spinners is essential for B2B buyers seeking high-quality products. By focusing on manufacturing stages, implementing rigorous quality control measures, and verifying supplier practices, buyers can ensure they are sourcing durable and appealing metal spinners that meet their market needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘metal spinner’

In the competitive world of metal spinning, a systematic approach to sourcing is essential for B2B buyers, especially those in diverse markets like Africa, South America, the Middle East, and Europe. This guide provides a practical checklist to streamline your procurement process, ensuring you select the best suppliers and products for your needs.

Step 1: Define Your Technical Specifications

Clearly outline the specifications for the metal spinners you need, including dimensions, materials, and design requirements. This step is critical because it ensures that potential suppliers can meet your exact needs and helps avoid misunderstandings later in the procurement process. Additionally, having detailed specifications will aid in comparing offerings from different suppliers.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in metal spinning. Look for companies with a strong track record in your industry, and prioritize those with experience in international shipping if you’re sourcing from different continents. Utilize platforms like trade directories, industry publications, and networking events to gather a list of potential suppliers.

Illustrative image related to metal spinner

Step 3: Evaluate Supplier Capabilities

Before making a commitment, assess the capabilities of your shortlisted suppliers. Request detailed company profiles, including their production capacity, technology used, and quality control processes. This evaluation is vital to ensure that the supplier can handle your order volume and meet quality standards consistently.

- Key considerations:

- Production equipment and technology.

- Staff expertise and experience in metal spinning.

- Quality assurance practices.

Step 4: Check References and Reviews

Reach out to previous clients or read online reviews to gauge the reliability of potential suppliers. This step is important for validating claims made by suppliers about their service quality and product performance. Look for feedback regarding delivery times, communication, and product quality.

- Focus on:

- Testimonials from clients in similar industries.

- Any common issues reported by past customers.

Step 5: Verify Compliance and Certifications

Ensure that the suppliers comply with relevant industry standards and certifications. This step is crucial for guaranteeing product quality and adherence to safety regulations, particularly if you’re operating in markets with strict compliance requirements. Verify certifications such as ISO, CE, or specific industry-related standards.

Step 6: Request Samples or Prototypes

Before finalizing your order, request samples or prototypes of the metal spinners. This allows you to assess the quality and suitability of the products firsthand. Evaluating samples can also provide insight into the supplier’s attention to detail and ability to meet your specifications.

Step 7: Negotiate Terms and Finalize Contracts

Once you’ve selected a supplier, engage in negotiations to establish favorable terms regarding pricing, delivery schedules, and payment conditions. Clear contracts help avoid misunderstandings and protect both parties in the transaction. Ensure that all agreed-upon terms are documented to facilitate a smooth procurement process.

Illustrative image related to metal spinner

By following this comprehensive checklist, B2B buyers can effectively navigate the sourcing landscape for metal spinners, ensuring they partner with reliable suppliers who meet their specific needs.

Comprehensive Cost and Pricing Analysis for metal spinner Sourcing

What Are the Key Cost Components in Metal Spinner Manufacturing?

When sourcing metal spinners, understanding the cost structure is crucial for effective budgeting and negotiation. The primary cost components include:

-

Materials: The choice of metal significantly impacts the cost. Common materials include stainless steel, aluminum, and coated metals. Higher quality materials enhance durability and aesthetic appeal but come at a premium.

-

Labor: Labor costs vary by region and depend on the complexity of the spinner’s design. Skilled labor for intricate designs may increase production costs, while simpler designs can be produced more efficiently.

-

Manufacturing Overhead: This encompasses expenses related to utilities, rent, and equipment maintenance. Efficient manufacturing processes can help mitigate these costs.

-

Tooling: The cost of molds and tools required for production must be considered, especially for custom designs. Initial tooling investments can be significant but are amortized over larger production runs.

-

Quality Control (QC): Implementing robust QC measures ensures product consistency and meets international standards, which can add to the overall cost but is essential for maintaining quality.

-

Logistics: Shipping and handling costs are critical, especially for international transactions. These can fluctuate based on distance, shipping method, and the weight of the product.

-

Margin: Suppliers typically apply a margin to cover their costs and profit. Understanding the markup can help buyers negotiate better deals.

How Do Price Influencers Affect Metal Spinner Costs?

Several factors influence the pricing of metal spinners:

-

Volume/MOQ: Larger orders often lead to reduced prices per unit due to economies of scale. Buyers should evaluate their needs and negotiate minimum order quantities (MOQ) for better pricing.

-

Specifications/Customization: Custom designs and specifications can significantly increase costs. Buyers should consider whether customization is necessary or if standard designs meet their needs.

-

Materials: The choice of materials impacts not only the cost but also the spinner’s longevity and appeal. Higher-grade materials, while more expensive, can provide a better return on investment.

-

Quality/Certifications: Certifications (e.g., ISO, CE) can affect pricing. While they may add initial costs, they also enhance credibility and marketability.

-

Supplier Factors: The supplier’s location, reputation, and production capabilities can influence pricing. Building relationships with reliable suppliers can lead to better terms and pricing.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is essential for determining who is responsible for shipping, insurance, and tariffs, which can affect the total landed cost.

What Tips Can Help B2B Buyers Negotiate Better Prices for Metal Spinners?

For international buyers, especially from regions like Africa, South America, the Middle East, and Europe, the following tips can enhance cost-efficiency:

-

Negotiate Effectively: Leverage volume orders and establish long-term relationships with suppliers to negotiate better pricing. Don’t hesitate to ask for discounts based on order size or frequency.

-

Consider Total Cost of Ownership (TCO): Evaluate the long-term costs associated with the product, including maintenance, potential replacements, and shipping fees. A lower upfront cost may not always translate to savings.

-

Understand Pricing Nuances: Be aware of seasonal pricing, currency fluctuations, and geopolitical factors that can impact costs. Staying informed can provide leverage during negotiations.

-

Seek Multiple Quotes: Obtaining quotes from various suppliers can help identify competitive pricing and highlight potential cost-saving opportunities.

-

Evaluate Supplier Reliability: Look for suppliers with a strong track record of quality and delivery. A slightly higher price may be justified by better reliability and service.

Disclaimer

The prices mentioned in various sources range from approximately $25 to $315, depending on the design, size, and material quality. These figures are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough research and obtain updated quotes before finalizing orders.

Alternatives Analysis: Comparing metal spinner With Other Solutions

Exploring Alternatives to Metal Spinners for Outdoor Decoration

When considering outdoor decorative solutions, it’s essential to evaluate various options that can fulfill similar aesthetic and functional roles. Metal spinners are popular for their kinetic beauty and durability, but several alternatives offer unique advantages. This analysis will compare metal spinners against two viable alternatives: wind chimes and kinetic sculptures, providing insights into their respective benefits and drawbacks.

| Comparison Aspect | Metal Spinner | Wind Chimes | Kinetic Sculptures |

|---|---|---|---|

| Performance | High; spins in light wind | Moderate; sound varies with wind strength | High; dynamic movement attracts attention |

| Cost | Moderate ($30 – $50) | Low to Moderate ($20 – $100) | High ($50 – $500+) |

| Ease of Implementation | Simple; requires minimal setup | Easy; just hang from a hook | Moderate; may need a stable base |

| Maintenance | Low; resistant to rust and fading | Moderate; needs occasional cleaning | Low to Moderate; depends on materials |

| Best Use Case | Gardens, patios, and outdoor events | Patios, porches, and serene environments | Public spaces, art installations, and gardens |

What Are the Benefits and Drawbacks of Wind Chimes?

Wind chimes are a classic outdoor decorative option that offers auditory appeal along with visual charm. They perform well in moderate winds, producing soothing sounds that enhance the outdoor ambiance. The cost of wind chimes varies widely, making them accessible for different budgets. However, their performance heavily depends on wind strength, and they may require occasional maintenance to keep them clean and free of debris. Wind chimes are best suited for spaces where sound can be appreciated, such as porches and gardens.

How Do Kinetic Sculptures Compare to Metal Spinners?

Kinetic sculptures are artistic installations that utilize wind or mechanical energy to create movement, often becoming a focal point in gardens or public spaces. They generally perform exceptionally well, capturing attention with their dynamic forms. However, they can be more expensive and may require a more involved setup, particularly if a stable base or installation method is needed. Maintenance can vary based on the materials used; while some are designed to withstand the elements, others may need more care. Kinetic sculptures are ideal for artistic expression and can significantly enhance the aesthetic value of larger outdoor areas.

How Can B2B Buyers Choose the Right Outdoor Decorative Solution?

In selecting the appropriate outdoor decorative solution, B2B buyers should assess their specific needs, budget, and intended use case. Metal spinners offer an appealing balance of performance, cost, and ease of installation, making them suitable for a variety of settings. Wind chimes may be the right choice for those seeking auditory elements alongside visual ones, while kinetic sculptures cater to those looking for a more artistic statement. By understanding the strengths and weaknesses of each alternative, buyers can make informed decisions that align with their aesthetic and functional objectives.

Essential Technical Properties and Trade Terminology for metal spinner

What Are the Key Technical Properties of Metal Spinners?

Understanding the technical specifications of metal spinners is crucial for B2B buyers looking to make informed purchasing decisions. Here are several critical properties to consider:

-

Material Grade

Metal spinners are typically made from various grades of steel or aluminum, which significantly impacts their durability and suitability for different applications. For example, 18-gauge steel is commonly used for outdoor spinners due to its balance of strength and weight. Choosing the right material ensures that the product can withstand environmental conditions, thereby enhancing longevity and reducing replacement costs. -

Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension. In metal spinning, tight tolerances are essential for ensuring the precision of the final product. A tolerance of ±0.01 inches may be required in high-precision applications. Maintaining proper tolerances is vital for ensuring product compatibility with other components, minimizing assembly issues, and achieving customer satisfaction. -

Finish

The finish of a metal spinner, often achieved through processes like powder coating, impacts both aesthetics and functionality. A baked-on powder coat not only provides a vibrant look but also offers corrosion resistance, which is crucial for outdoor applications. Buyers should consider finishes that align with their branding and durability requirements, as these factors can influence the perceived quality of the product. -

Weight

The weight of a metal spinner can affect its stability and ease of installation. For instance, heavier spinners may perform better in windy conditions but can also be more challenging to transport. Understanding the weight requirements based on the intended use and installation site is essential for optimal performance and customer satisfaction. -

Ball Bearing Mechanism

Many high-quality wind spinners incorporate stainless-steel ball bearing swivels that allow for smooth rotation even in light breezes. This feature not only enhances the spinner’s functionality but also contributes to its longevity by reducing wear on the spinning mechanism. Buyers should look for spinners that employ robust bearing systems to ensure optimal performance.

What Are Common Trade Terms in the Metal Spinner Industry?

Familiarity with industry terminology is vital for B2B buyers to navigate the procurement process effectively. Here are several key terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of metal spinners, an OEM might provide custom designs for specific client needs, ensuring that the product meets unique specifications. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of an item that a supplier is willing to sell. Understanding MOQ is crucial for buyers to manage inventory effectively and ensure that they are not overcommitting financially. This term often influences purchasing decisions, especially for smaller businesses. -

RFQ (Request for Quotation)

An RFQ is a formal document used to solicit price quotes from suppliers. It typically outlines the specifications, quantities, and delivery requirements for the desired products. Submitting a well-structured RFQ can lead to better pricing and terms, making it a critical tool in the procurement process. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce that define the responsibilities of buyers and sellers in international transactions. Understanding these terms helps buyers navigate shipping, insurance, and risk management effectively, ensuring smooth cross-border transactions. -

KPI (Key Performance Indicator)

KPIs are measurable values that demonstrate how effectively a company is achieving key business objectives. For buyers in the metal spinner market, relevant KPIs might include delivery times, product quality, and customer satisfaction metrics, all of which can inform future purchasing decisions.

By grasping these technical properties and trade terms, B2B buyers can enhance their purchasing strategies, ensuring they select the right products while effectively managing their procurement processes.

Navigating Market Dynamics and Sourcing Trends in the metal spinner Sector

What Are the Key Market Drivers and Trends in the Metal Spinner Sector?

The metal spinner sector is experiencing dynamic growth, driven by several global factors. Increasing consumer interest in outdoor aesthetics, coupled with the rise of home gardening and landscaping trends, has significantly boosted demand for decorative metal spinners. Notably, international markets in Africa, South America, the Middle East, and Europe are increasingly embracing these products, which serve both functional and decorative purposes.

Illustrative image related to metal spinner

Emerging technologies in manufacturing, such as automation and advanced CNC machining, are reshaping the production landscape. These innovations enable manufacturers to enhance precision, reduce lead times, and lower production costs, making high-quality metal spinners more accessible to B2B buyers worldwide. Additionally, the integration of e-commerce platforms has streamlined the purchasing process, allowing buyers from different regions to access a wider array of products with ease.

Key sourcing trends include a shift towards customization, as buyers increasingly seek unique designs tailored to specific cultural preferences or seasonal themes. This trend is particularly evident in regions like Europe and the Middle East, where traditional motifs often influence design choices. Furthermore, the rise of direct-to-consumer sales models is prompting manufacturers to adapt their strategies, focusing on building strong online presences and engaging marketing campaigns to reach international buyers effectively.

How Does Sustainability Impact Sourcing in the Metal Spinner Industry?

Sustainability and ethical sourcing are becoming critical considerations for B2B buyers in the metal spinner sector. The environmental impact of manufacturing processes—particularly those involving metal—has raised concerns about resource depletion and waste generation. Companies are increasingly pressured to adopt sustainable practices, such as utilizing recycled materials and minimizing energy consumption during production.

Moreover, buyers are showing a preference for suppliers who can demonstrate commitment to ethical supply chains. Certifications such as ISO 14001 (Environmental Management) and Fair Trade are gaining traction, offering assurance that products are sourced responsibly. This shift towards green certifications not only enhances brand image but also aligns with the growing consumer demand for sustainable products.

Incorporating sustainable materials, such as powder-coated steel that reduces the need for harmful paints, is another trend that buyers should consider. By prioritizing environmentally friendly options, B2B buyers can not only contribute to the global sustainability movement but also potentially reduce costs associated with waste management and regulatory compliance.

Illustrative image related to metal spinner

What Is the Historical Context of Metal Spinners in B2B Markets?

The history of metal spinners dates back several centuries, with roots in traditional metalworking practices. Initially, metal spinning was a manual process, often utilized for creating functional items such as cookware and industrial components. Over time, the craft evolved into an art form, giving rise to decorative pieces that enhance outdoor spaces.

In recent decades, technological advancements have transformed metal spinning from a labor-intensive craft to a highly efficient industrial process. This evolution has enabled the production of more intricate designs and larger quantities, catering to the growing demand from both retail and wholesale markets. As the sector continues to innovate, B2B buyers are presented with an expanding array of options, reflecting changing consumer preferences and the increasing importance of aesthetics in outdoor decor.

Frequently Asked Questions (FAQs) for B2B Buyers of metal spinner

-

How do I select the right metal spinner for my business needs?

Selecting the right metal spinner involves understanding your target market and the specific applications of the product. Consider factors such as design, size, durability, and aesthetic appeal. Research the preferences of your customers in regions like Africa or Europe, as cultural factors may influence design choices. Additionally, evaluate the material quality and manufacturing processes of potential suppliers to ensure longevity and compliance with local regulations. -

What are the common materials used in metal spinners?

Metal spinners are typically made from materials such as stainless steel, aluminum, and iron. Stainless steel offers excellent corrosion resistance and durability, making it ideal for outdoor use. Aluminum is lightweight and rust-resistant, suitable for intricate designs, while iron provides strength and sturdiness. When sourcing, consider the specific environmental conditions of your target market to choose the most appropriate material. -

What customization options should I consider when sourcing metal spinners?

Customization options for metal spinners may include design alterations, size variations, color finishes, and branding elements such as logos. Many manufacturers offer bespoke solutions, allowing you to cater to specific market demands. It is essential to discuss these options with suppliers upfront, as customization can impact lead times, pricing, and minimum order quantities (MOQs). -

What is the typical MOQ for metal spinners in B2B transactions?

Minimum order quantities (MOQs) for metal spinners can vary significantly depending on the supplier and the complexity of the design. Generally, MOQs can range from 50 to several hundred units. When negotiating with suppliers, consider your budget, storage capacity, and sales forecasts. Some manufacturers may offer flexible MOQs for first-time orders or for standard designs, so it’s worthwhile to inquire about these possibilities. -

How can I ensure the quality of metal spinners from international suppliers?

To ensure quality, it is crucial to conduct thorough supplier vetting. Look for manufacturers with established reputations, positive reviews, and relevant certifications (such as ISO). Request samples to assess craftsmanship and materials before placing a bulk order. Additionally, consider implementing quality assurance protocols, such as third-party inspections, especially for large orders, to verify compliance with your specifications. -

What payment terms should I negotiate with metal spinner suppliers?

Payment terms can vary widely across international suppliers. Common arrangements include full payment upfront, a deposit with the balance due upon shipment, or net payment terms after delivery. To mitigate risk, consider negotiating payment terms that provide a balance between security for the supplier and flexibility for your business. Using trusted payment platforms can also enhance security in international transactions. -

What shipping options are available for importing metal spinners?

Shipping options for importing metal spinners typically include sea freight, air freight, and express courier services. Sea freight is cost-effective for large shipments but involves longer transit times, while air freight is faster but more expensive. Evaluate your delivery timelines and budget constraints when selecting a shipping method. Additionally, consider customs duties and regulations in your country to ensure compliance upon arrival. -

How can I effectively communicate with suppliers in different regions?

Effective communication with suppliers across different regions requires understanding cultural nuances and language barriers. Use clear, concise language and avoid idioms or jargon that may not translate well. Tools like video conferencing and instant messaging can facilitate real-time discussions. If necessary, consider hiring a local intermediary who understands both the market and the language to enhance clarity and foster strong relationships.

Top 6 Metal Spinner Manufacturers & Suppliers List

1. Spinfinity – Teal Butterfly 3D Metal Spinner

Domain: kiteloft.com

Registered: 1996 (29 years)

Introduction: [{‘name’: ‘Teal Butterfly 3D Metal Spinner’, ‘brand’: ‘Spinfinity’, ‘size’: ’12″‘, ‘price’: ‘$39.99’}, {‘name’: ‘Hummingbird Animated Wind Spinner’, ‘brand’: ‘Spinfinity’, ‘size’: ’12” Diameter’, ‘price’: ‘$39.99’}, {‘name’: ‘Sepia Dragonfly Animated Metal Spinner’, ‘brand’: ‘Spinfinity’, ‘size’: ’12″‘, ‘price’: ‘$39.99’}, {‘name’: ‘Palm Tree Metal Spinner’, ‘brand’: ‘Spinfinity’, ‘size’: ’12″‘, ‘…

2. Inspired by the Outdoors – Metal Garden Wind Spinners

Domain: inspiredbytheoutdoors.com

Registered: 2016 (9 years)

Introduction: Metal Garden Wind Spinners made of 18-gauge steel with baked-on powder coat high gloss paint. Features a stainless-steel ball bearing swivel for spinning in light breezes. Available in various designs including bear, moose, lighthouse, American Flag, bird house, and loon. Each piece is made to order with a processing time of up to 7 days. Prices range from $25.95 to $39.95, with discounts availabl…

3. Final Fantasy XIV – Metal Spinner

Domain: na.finalfantasyxiv.com

Registered: 2000 (25 years)

Introduction: {“name”: “Metal Spinner”, “type”: “Fishing Tackle”, “required_level”: 55, “item_level”: 136, “description”: “This particularly clever invention relies on a fish’s natural tendency to snag its face on spinning, jagged objects.”, “sell_price”: 41, “obtained_from”: [{“npc”: “Anna”, “location”: “The Firmament”, “coordinates”: “(X:14.2 Y:12.6)”}, {“npc”: “Diana”, “location”: “The Firmament”, “coordinat…

4. Plow & Hearth – Wind Spinners Collection

Domain: plowhearth.com

Registered: 1996 (29 years)

Introduction: Wind Spinners Collection from Plow & Hearth includes 85 products. Key details include: 1. Price Range: $34.95 to $214.50. 2. Types: Various designs including Copper Lily, Hydro, Sunflower, Oceanic Dimensions, and more. 3. Features: Some are solar-powered and include lighted options. 4. Materials: Predominantly metal, with some glass and plastic. 5. Sizes: Heights range from 20″ to 91″. 6. Styles: …

5. Metal Spinners – Precision Metal Forming Solutions

Domain: metalspinners.com

Registered: 1996 (29 years)

Introduction: Metal Spinners offers precision metal forming solutions, specializing in metal spinning and hydroforming services for various industries including airflow/air-movement, agriculture, automotive, and industrial products. Hydroforming provides lightweight, high-performance parts, while metal spinning focuses on strong, cost-effective cylindrical components capable of withstanding high pressure. The c…

6. Addictive Fidget Toys – EDC Stainless Steel or Aluminum Turbine Fidget Spinner

Domain: addictivefidgettoys.com

Registered: 2016 (9 years)

Introduction: [{‘name’: ‘EDC Stainless Steel or Aluminum Turbine Fidget Spinner’, ‘price_range’: ‘$14.99 – $34.99’, ‘rating’: 4.62}, {‘name’: ‘EDC Brass Small Dual Bar Fidget Spinner’, ‘price_range’: ‘$9.99 – $14.99’, ‘rating’: 5.0}, {‘name’: ‘EDC Propeller Fidget Spinner’, ‘price_range’: ‘$4.99’, ‘rating’: 5.0}, {‘name’: ‘Wagon Wheel Fidget Spinner’, ‘price_range’: ‘$7.99’, ‘rating’: 4.43}, {‘name’: ‘Brass Sku…

Strategic Sourcing Conclusion and Outlook for metal spinner

In the ever-evolving landscape of metal spinner production, strategic sourcing emerges as a critical factor for B2B buyers seeking to enhance their supply chains. By prioritizing quality materials, such as 18-gauge steel with durable finishes, and leveraging innovative manufacturing processes, businesses can ensure they deliver high-quality products that meet consumer expectations. Additionally, establishing relationships with reliable suppliers not only reduces costs but also improves lead times, fostering a more agile response to market demands.

As international B2B buyers from Africa, South America, the Middle East, and Europe navigate this competitive market, it is essential to remain informed about emerging trends and technologies that can impact sourcing decisions. Emphasizing sustainability and design diversity will resonate with environmentally conscious consumers, making it imperative for companies to adapt their product offerings accordingly.

Illustrative image related to metal spinner

Looking ahead, the demand for unique, aesthetically pleasing metal spinners will continue to grow. Buyers are encouraged to take proactive steps in evaluating their sourcing strategies, exploring new partnerships, and investing in product innovation to stay ahead of the curve. By embracing these principles, companies can position themselves for success in the global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to metal spinner