A B2B Buyer’s Guide to Iron Bracket: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for iron bracket

In the ever-evolving landscape of global manufacturing, sourcing durable and reliable iron brackets poses a significant challenge for international B2B buyers. With a myriad of options available, from decorative shelf brackets to heavy-duty supports, understanding the nuances of quality, application, and supplier credibility is essential for making informed purchasing decisions. This comprehensive guide delves into the diverse types of iron brackets, their various applications across industries, and the critical factors to consider when vetting suppliers.

As businesses in Africa, South America, the Middle East, and Europe—such as Vietnam and Saudi Arabia—seek to enhance their operational capabilities, this guide serves as a vital resource. It not only outlines the cost implications associated with different types of iron brackets but also provides insights into the latest trends in design and functionality. By equipping buyers with knowledge about load capacities, installation requirements, and aesthetic considerations, this guide empowers them to select the most suitable products for their specific needs.

Navigating the global market for iron brackets doesn’t have to be daunting; with the right information at hand, you can ensure that your investments yield the highest returns in performance and durability.

Understanding iron bracket Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| L Brackets | Simple, right-angled design, often heavy-duty | Shelving, countertops, and furniture | Pros: Easy installation, versatile; Cons: Limited aesthetic appeal. |

| Floating Brackets | Concealed mounting, creating a “floating” effect | Modern shelving solutions and displays | Pros: Clean appearance, maximizes space; Cons: Requires precise installation. |

| Corbels | Decorative support, often elaborately designed | Architectural applications, mantels | Pros: Aesthetic appeal, high load capacity; Cons: Can be more expensive. |

| Heavy-Duty Brackets | Engineered for high loads, thicker materials | Industrial shelving, commercial applications | Pros: Exceptional strength, durable; Cons: Heavier, may require more installation effort. |

| Decorative Brackets | A variety of styles and finishes available | Home decor, retail displays | Pros: Enhances visual appeal, diverse options; Cons: May not support as much weight as heavy-duty types. |

What Are L Brackets and Their B2B Suitability?

L brackets are one of the most commonly used iron brackets, characterized by their straightforward right-angle design. They are typically made from heavy-duty materials, ensuring stability and support for various applications such as shelving and countertops. For B2B buyers, L brackets offer ease of installation and versatility, making them ideal for both commercial and residential settings. However, their simplistic design might not appeal to businesses looking for decorative options.

How Do Floating Brackets Enhance Modern Spaces?

Floating brackets are designed to be hidden from view, allowing shelves to appear as if they are suspended in mid-air. This type of bracket is particularly suited for modern shelving solutions and retail displays where aesthetics are paramount. B2B buyers should consider the precise installation requirements of floating brackets, as they must be mounted correctly to support the intended load. While they provide a sleek look, the need for accuracy in installation can be a drawback for some.

What Makes Corbels a Popular Choice in Architecture?

Corbels are decorative brackets that provide both support and visual interest, often found in architectural applications such as mantels and overhangs. They come in various styles, from ornate to minimalist, making them suitable for a wide range of design themes. For B2B buyers, corbels offer the dual benefit of aesthetic enhancement and structural support. However, their cost can be higher than simpler bracket types, which is an important consideration for budget-conscious projects.

Why Choose Heavy-Duty Brackets for Industrial Applications?

Heavy-duty brackets are engineered to withstand substantial loads, making them ideal for industrial shelving and commercial applications. Constructed from thicker materials, these brackets are designed for durability and long-term use. B2B buyers should prioritize heavy-duty brackets when high load capacity is essential, such as in warehouses or manufacturing settings. The trade-off for their strength is the increased weight, which may complicate installation compared to lighter options.

How Do Decorative Brackets Cater to Aesthetic Needs?

Decorative brackets come in a wide variety of styles, colors, and finishes, allowing businesses to enhance visual appeal in homes, retail spaces, and offices. They can serve as functional supports while also acting as design elements. B2B buyers should consider the balance between aesthetics and load capacity, as decorative brackets may not hold as much weight as their heavy-duty counterparts. This makes them suitable for lighter applications, such as picture frames or small shelves.

Key Industrial Applications of iron bracket

| Industry/Sector | Specific Application of Iron Bracket | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Building | Structural support in commercial buildings | Provides stability and safety in load-bearing applications | Ensure compliance with local building codes and load ratings |

| Retail & Display | Shelving systems for product displays | Enhances product visibility and maximizes space efficiency | Consider customization options for branding and aesthetics |

| Furniture Manufacturing | Support for shelving and cabinetry | Increases durability and design flexibility | Focus on weight capacity and finish options to match furniture styles |

| Home Improvement & DIY | Brackets for residential shelving | Facilitates efficient use of space and organization | Look for easy installation guides and compatibility with various materials |

| Hospitality & Food Service | Support for countertops and shelving in restaurants | Ensures functionality and aesthetic appeal in dining spaces | Prioritize heavy-duty options for high-traffic environments |

How is Iron Bracket Used in Construction & Building?

In the construction and building industry, iron brackets serve as essential structural supports for various applications, including load-bearing walls and shelving systems. They provide the necessary strength to ensure stability and safety in commercial buildings, particularly where heavy materials or equipment are involved. International buyers should verify that the brackets meet local building codes and load ratings, as these can vary significantly by region. Additionally, sourcing from reputable manufacturers who adhere to quality standards is crucial to avoid structural failures.

What Role Do Iron Brackets Play in Retail & Display?

In retail environments, iron brackets are commonly used to create shelving systems that display products effectively. These brackets enhance product visibility while maximizing space efficiency, allowing retailers to showcase a wider range of items. For B2B buyers in this sector, it’s important to consider customization options that align with brand aesthetics and ensure that the brackets can support the intended load without compromising safety. Sourcing durable and visually appealing designs can significantly impact customer engagement and sales.

Illustrative image related to iron bracket

How Do Furniture Manufacturers Utilize Iron Brackets?

Furniture manufacturers frequently incorporate iron brackets into their designs for shelving and cabinetry. These brackets not only provide robust support but also allow for greater design flexibility, enabling manufacturers to create stylish and functional pieces. Buyers should focus on the weight capacity of the brackets, as well as finish options that complement various furniture styles. Additionally, ensuring that the brackets are compatible with different materials will help in streamlining production processes and meeting customer demands.

Why Are Iron Brackets Important for Home Improvement & DIY Projects?

In the home improvement and DIY sectors, iron brackets are invaluable for installing residential shelving and storage solutions. They facilitate the efficient use of space and help homeowners organize their belongings effectively. B2B buyers in this market should seek brackets that come with easy installation guides and are compatible with various materials, such as wood and drywall. Furthermore, understanding the weight capacity and durability of the brackets is essential to ensure long-lasting performance in home applications.

How Are Iron Brackets Utilized in Hospitality & Food Service?

In the hospitality and food service industry, iron brackets are critical for supporting countertops and shelving in restaurants and cafes. They ensure both functionality and aesthetic appeal, contributing to the overall dining experience. For international buyers, prioritizing heavy-duty options is essential, especially in high-traffic environments where durability is paramount. Additionally, sourcing brackets that are easy to clean and resistant to wear and tear will enhance the longevity and appearance of dining spaces.

3 Common User Pain Points for ‘iron bracket’ & Their Solutions

Scenario 1: Weight Capacity Concerns for Heavy Loads

The Problem: B2B buyers often face challenges when selecting iron brackets for projects involving heavy loads, such as shelves in commercial spaces or supports for countertops. Many buyers may not fully understand the weight limits of different bracket types, leading to potential safety risks and costly damages. For instance, installing a bracket rated for 150 lbs to support a shelf intended to hold heavy equipment can result in failure, causing not only loss of materials but also possible injuries.

The Solution: To effectively address weight capacity concerns, B2B buyers should prioritize sourcing iron brackets that are specifically engineered for heavy-duty applications. When evaluating products, consider brackets with a tested load capacity exceeding the total anticipated weight. It’s essential to choose brackets that have undergone rigorous testing, with documented load ratings—look for specifications that indicate they can support at least 300 lbs per pair. Additionally, ensure that the installation method is appropriate for the weight being supported; this may involve using multiple brackets or reinforcing the wall behind them. Investing in high-quality, heavy-duty brackets will not only improve safety but also enhance the longevity of the installation.

Scenario 2: Incompatibility with Wall Types

The Problem: Another prevalent issue for B2B buyers is the incompatibility of iron brackets with various wall types. For example, a buyer may plan to install shelving in a facility with drywall, brick, or concrete walls and may not know how to properly anchor the brackets in these different materials. Using inappropriate mounting techniques can lead to instability and shelf collapse.

The Solution: To solve this problem, buyers should assess the wall type before selecting iron brackets and their mounting hardware. For drywall, it’s crucial to avoid relying solely on toggle bolts; instead, opt for brackets that can be anchored into wall studs or reinforced with backer boards for added support. For brick or concrete walls, use masonry anchors designed for those materials, ensuring that the brackets are securely fastened to avoid any risk of failure. Additionally, consulting installation guides specific to each wall type can provide critical insights into the best practices for mounting iron brackets effectively.

Scenario 3: Aesthetic Versus Functional Requirements

The Problem: B2B buyers often struggle to balance the aesthetic appeal and functional performance of iron brackets, especially in environments where design plays a significant role, such as retail spaces or high-end commercial establishments. Many buyers may find themselves choosing visually appealing brackets that do not meet the necessary load-bearing requirements, leading to a mismatch between design and functionality.

The Solution: To navigate this challenge, it’s essential for buyers to explore a variety of iron bracket styles that combine both aesthetics and strength. Look for suppliers that offer customizable options or a range of designs that suit your project’s visual requirements while maintaining structural integrity. When selecting brackets, consider both the visual design and the engineering specifications—brackets should be made from durable materials and designed to handle the expected load. Conducting a thorough review of product specifications, as well as consulting with manufacturers about the best combinations of design and performance, will enable buyers to make informed decisions that fulfill both functional and aesthetic needs. Additionally, visiting showrooms or obtaining samples can help visualize how different designs will fit into the overall project.

Strategic Material Selection Guide for iron bracket

When selecting materials for iron brackets, it is crucial to consider various factors that influence performance, durability, and suitability for specific applications. Below, we analyze four common materials used in the production of iron brackets, highlighting their properties, advantages, disadvantages, and considerations for international B2B buyers.

What Are the Key Properties of Cast Iron for Iron Brackets?

Cast iron is a widely used material for iron brackets due to its excellent strength and durability. It has a high melting point, making it suitable for applications involving elevated temperatures. Additionally, cast iron exhibits good corrosion resistance, particularly when coated or treated. However, it can be brittle, which may lead to cracking under high stress or impact.

Pros and Cons: The primary advantage of cast iron is its ability to withstand heavy loads, making it ideal for structural applications. It is also cost-effective compared to other metals. However, its brittleness can be a limitation, especially in dynamic environments where flexibility is required.

Illustrative image related to iron bracket

Impact on Application: Cast iron brackets are suitable for heavy-duty shelving and support structures. They are often used in industrial settings where robust support is necessary.

Considerations for International Buyers: Buyers should ensure compliance with local standards such as ASTM or DIN, particularly regarding load-bearing capabilities and safety regulations. In regions like Africa and the Middle East, where environmental conditions can vary, corrosion resistance is a significant factor.

How Does Steel Compare as a Material for Iron Brackets?

Steel, particularly carbon steel, is another common choice for iron brackets. It offers a high tensile strength and is less brittle than cast iron, providing greater flexibility under stress. Steel also has good corrosion resistance when galvanized or coated.

Pros and Cons: The key advantage of steel is its versatility and strength-to-weight ratio, making it suitable for a wide range of applications. However, untreated steel can corrode easily, necessitating protective coatings, which can increase manufacturing complexity and cost.

Impact on Application: Steel brackets are ideal for both residential and commercial shelving systems, as they can accommodate varying load requirements.

Considerations for International Buyers: Buyers should be aware of the different grades of steel and their compliance with international standards. In Europe, for instance, EN standards are prevalent, while in South America, local certifications may be required.

Illustrative image related to iron bracket

What Are the Benefits of Wrought Iron for Iron Brackets?

Wrought iron is known for its malleability and resistance to corrosion, making it an aesthetically pleasing option for decorative brackets. It can be easily shaped and welded, allowing for intricate designs.

Pros and Cons: The primary advantage of wrought iron is its aesthetic appeal, making it suitable for decorative applications. However, it is generally more expensive than cast iron and steel, which can limit its use in budget-sensitive projects.

Impact on Application: Wrought iron is often used in architectural applications, such as railings and decorative shelving, where appearance is as important as strength.

Considerations for International Buyers: Buyers should consider the availability of wrought iron in their region and the associated costs. Compliance with aesthetic and structural standards is also essential, especially in regions with strict building codes.

How Do Composite Materials Perform for Iron Brackets?

Composite materials, often a blend of metals and polymers, are increasingly being used for brackets due to their lightweight and corrosion-resistant properties. They can be engineered to specific performance criteria, such as load-bearing capacity and environmental resistance.

Pros and Cons: The main advantage of composites is their lightweight nature, which can reduce shipping costs and ease installation. However, they may not offer the same level of strength as traditional metals, limiting their use in heavy-duty applications.

Impact on Application: Composite brackets are suitable for lighter shelving and applications where weight is a concern, such as in mobile installations.

Considerations for International Buyers: Buyers should evaluate the specific performance characteristics of composite materials and ensure they meet local standards. Additionally, understanding the environmental impact and recyclability of composites can be crucial for sustainability-focused companies.

Summary Table of Material Selection for Iron Brackets

| Material | Typical Use Case for iron bracket | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cast Iron | Heavy-duty shelving | Excellent load-bearing capacity | Brittle, may crack under stress | Low |

| Steel | Residential and commercial shelving | Versatile and strong | Prone to corrosion without coating | Medium |

| Wrought Iron | Decorative architectural elements | Aesthetic appeal and malleability | Higher cost, less common availability | High |

| Composite Materials | Lightweight shelving | Lightweight and corrosion-resistant | Limited strength for heavy loads | Medium |

This guide serves as a comprehensive overview for international B2B buyers, providing insights into material selection that align with their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for iron bracket

The manufacturing process for iron brackets involves several critical stages, each designed to ensure the final product meets stringent quality and performance standards. For B2B buyers, understanding these processes not only helps in evaluating suppliers but also in making informed purchasing decisions.

What are the Main Stages in the Manufacturing Process of Iron Brackets?

Material Preparation: How is Raw Material Selected and Processed?

The manufacturing process begins with the careful selection of raw materials, typically high-quality steel or cast iron. Suppliers often source materials compliant with international standards to ensure durability and strength. The raw steel is inspected for defects before being cut into required dimensions. This initial stage is crucial, as the quality of the material directly influences the performance of the final product.

How are Iron Brackets Formed and Assembled?

Forming Techniques: What Methods are Used to Shape Iron Brackets?

Once the materials are prepared, the forming process begins. This may involve techniques such as laser cutting, bending, and welding. Laser cutting is particularly favored for its precision, allowing for intricate designs while maintaining structural integrity. After cutting, the brackets are bent into shape using hydraulic or mechanical presses.

For assembly, components may be welded or bolted together, depending on the design and intended load capacity. Heavy-duty brackets often require additional reinforcement, such as gussets, which are welded to increase strength. This assembly stage is critical, as improper techniques can lead to structural weaknesses.

Illustrative image related to iron bracket

What Finishing Processes Enhance Durability and Aesthetics?

Surface Treatment: How is the Final Appearance of Iron Brackets Achieved?

The finishing stage involves surface treatments that enhance both the durability and aesthetic appeal of iron brackets. Common methods include powder coating, galvanizing, and painting. Powder coating provides a protective layer that resists corrosion and wear, making it suitable for various environments. Galvanizing, on the other hand, involves coating the iron with zinc to prevent rust, particularly in humid or coastal areas.

This stage not only ensures longevity but also allows for customization in color and texture, catering to diverse market preferences.

What Quality Control Measures are Essential in Iron Bracket Manufacturing?

What International Standards Should Buyers Be Aware Of?

Quality assurance is a fundamental aspect of the manufacturing process for iron brackets. Suppliers often adhere to international standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with such standards indicates that the manufacturer maintains consistent quality and is committed to continuous improvement.

In addition to ISO standards, industry-specific certifications, such as CE marking for products sold in Europe, ensure that the brackets meet safety and performance criteria. For buyers in regions like Africa and South America, understanding these certifications can aid in the selection of reliable suppliers.

How are Quality Control Checkpoints Implemented?

What are the Key Quality Control Checkpoints in the Manufacturing Process?

The quality control process typically involves several checkpoints: Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

Illustrative image related to iron bracket

-

Incoming Quality Control (IQC): This initial checkpoint assesses the raw materials for compliance with specified standards before they enter the manufacturing process.

-

In-Process Quality Control (IPQC): During production, random samples are tested to ensure that the manufacturing processes are yielding products that meet predefined criteria. This may include dimensional checks and strength testing.

-

Final Quality Control (FQC): Once production is complete, the final products undergo rigorous testing to verify their performance and safety. This may include load testing to ensure that the brackets can support the intended weight.

What Testing Methods Ensure the Integrity of Iron Brackets?

What Common Testing Methods are Used in Quality Assurance?

Common testing methods for iron brackets include tensile testing, load testing, and visual inspections. Tensile testing evaluates the material’s strength and ductility, while load testing assesses the bracket’s ability to support specified weights without permanent deformation. Visual inspections focus on identifying surface defects, weld quality, and overall finish.

B2B buyers should inquire about the specific testing methods employed by suppliers to ensure that the products meet their operational requirements.

How Can B2B Buyers Verify Supplier Quality Control Processes?

What Steps Can Buyers Take to Ensure Supplier Quality Assurance?

To verify the quality control processes of suppliers, B2B buyers can take several steps:

-

Request Documentation: Ask for quality assurance documentation, including ISO certifications, test reports, and inspection records. This information provides insight into the supplier’s commitment to quality.

-

Conduct Audits: If feasible, conduct on-site audits to assess the manufacturing processes and quality control measures in place. This firsthand evaluation can help identify potential issues before purchasing.

-

Engage Third-Party Inspectors: Consider hiring third-party inspection services to evaluate the quality of products before shipment. These inspectors can provide unbiased assessments of compliance with specified standards.

What Nuances Should International Buyers Consider Regarding Quality Control?

How Do Regional Differences Impact Quality Assurance in Iron Bracket Manufacturing?

International buyers, particularly from diverse markets like Africa, South America, the Middle East, and Europe, should be aware of regional differences in manufacturing practices and quality assurance standards.

For instance, in markets with emerging industries, suppliers may not always adhere to stringent quality controls, making it essential for buyers to perform due diligence. Understanding local regulations and standards can also help buyers navigate potential challenges related to product compliance and safety.

By being informed about the manufacturing processes and quality assurance practices of iron brackets, B2B buyers can make better purchasing decisions, ensuring that they select reliable suppliers who meet their quality expectations. This knowledge not only safeguards their investment but also contributes to the long-term success of their projects.

Illustrative image related to iron bracket

Practical Sourcing Guide: A Step-by-Step Checklist for ‘iron bracket’

Introduction

Sourcing iron brackets for your business requires a methodical approach to ensure you acquire high-quality products that meet your specifications. This guide outlines essential steps to streamline your procurement process, helping you make informed decisions that align with your operational needs.

Step 1: Define Your Technical Specifications

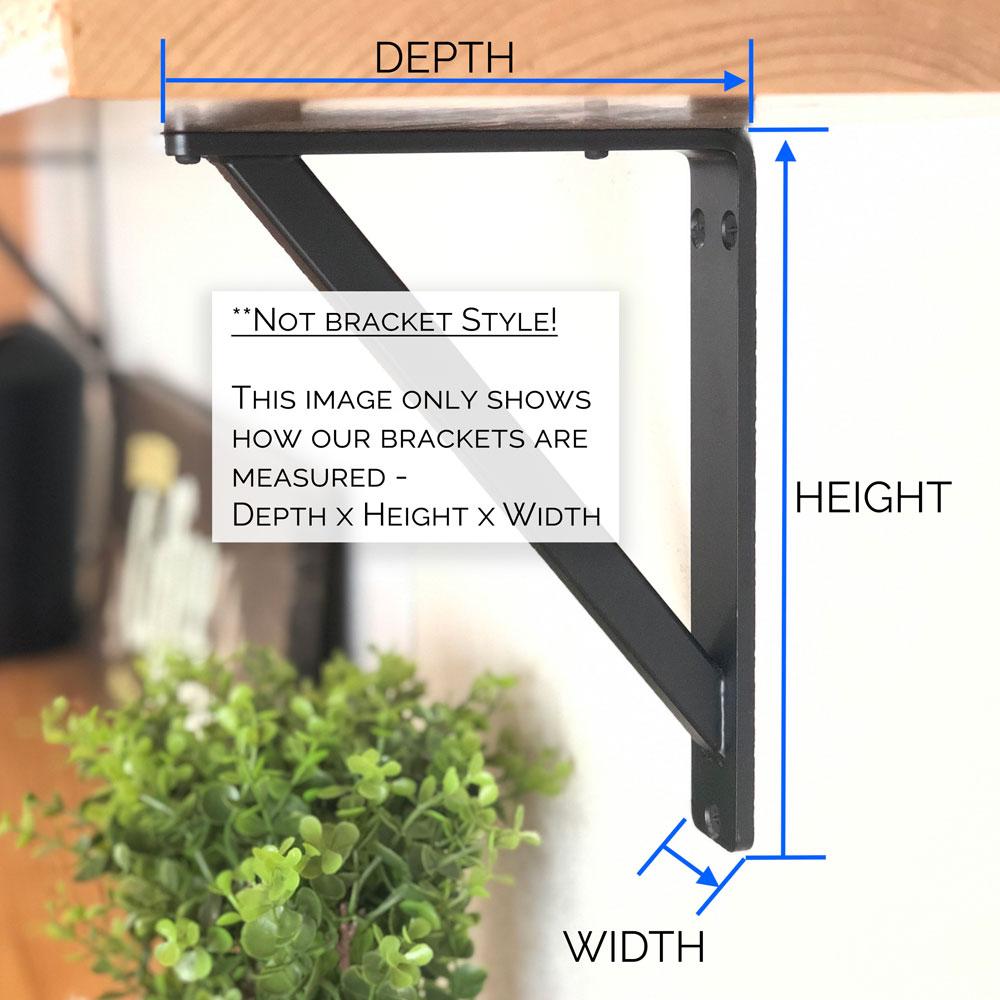

Establish clear technical requirements for the iron brackets you need. This includes dimensions, load capacity, material grade, and finish. Knowing these specifications upfront will help narrow down your options and ensure that the brackets will effectively support the intended applications.

- Consider load requirements: Determine the weight the brackets will need to support.

- Identify installation conditions: Assess whether the brackets will be used indoors or outdoors, as this may affect material selection.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in iron brackets. Look for companies with a robust reputation in your industry and positive customer feedback. Supplier reliability is crucial to ensure timely delivery and consistent quality.

- Check online platforms: Utilize B2B marketplaces and trade directories to find suppliers.

- Review customer testimonials: Analyze feedback from other businesses to gauge supplier performance.

Step 3: Evaluate Supplier Certifications

Before proceeding with any supplier, verify their certifications and compliance with industry standards. Certifications can indicate the quality and safety of the products, as well as the supplier’s commitment to best practices.

- Look for ISO certifications: These indicate adherence to international quality management standards.

- Check for environmental compliance: Ensure the supplier meets relevant environmental regulations, especially if you operate in regions with strict guidelines.

Step 4: Request Samples for Testing

Always request product samples before placing a bulk order. Testing samples allows you to assess the quality, finish, and functionality of the brackets firsthand. This step is crucial for preventing costly mistakes.

- Conduct load tests: Ensure that the samples can support the specified weight without deformation.

- Inspect for defects: Look for any manufacturing flaws or inconsistencies in finish.

Step 5: Negotiate Terms and Conditions

Once you have selected a supplier, engage in negotiations to establish favorable terms. Discuss pricing, payment terms, delivery schedules, and warranty conditions. Clarity on these points can prevent misunderstandings later.

- Understand pricing structures: Inquire about bulk discounts and additional fees.

- Clarify warranty policies: Ensure you know the terms of any warranties offered for the brackets.

Step 6: Finalize Your Order and Monitor Delivery

After agreeing on terms, finalize your order with the supplier. Keep communication open to monitor the progress of your order and ensure timely delivery. This proactive approach can help address any issues before they escalate.

Illustrative image related to iron bracket

- Establish a point of contact: Designate someone from your team to liaise with the supplier.

- Track shipment: Use tracking tools provided by the supplier to stay informed about delivery timelines.

Step 7: Post-Purchase Review

After receiving your order, conduct a thorough review of the products. Ensure they meet your specifications and quality expectations. This evaluation will help you assess supplier performance for future orders.

- Gather feedback from your team: Collect insights from those who will be using the brackets in their daily operations.

- Document any issues: Record any discrepancies for future reference and discussion with the supplier.

By following these steps, you can ensure a smooth sourcing process for iron brackets that meets your business needs effectively.

Comprehensive Cost and Pricing Analysis for iron bracket Sourcing

What Are the Key Cost Components in Iron Bracket Manufacturing?

When sourcing iron brackets, understanding the cost structure is vital for making informed purchasing decisions. The primary cost components include:

-

Materials: The quality and type of iron used significantly impact the cost. Higher-grade alloys or treated materials may incur additional expenses but provide better durability and performance.

-

Labor: Labor costs can vary based on geographical location. Regions with higher wages will naturally lead to increased production costs. Skilled labor is often required for precision manufacturing, especially for customized designs.

-

Manufacturing Overhead: This encompasses costs associated with the facilities, equipment, and utilities needed for production. Overhead can vary widely depending on the scale of production and the efficiency of the manufacturing process.

-

Tooling: The initial investment in tooling for molds and dies can be substantial, particularly for custom bracket designs. This upfront cost is often amortized over large production runs.

-

Quality Control (QC): Ensuring that iron brackets meet specified standards requires a dedicated QC process, which adds to overall costs. Certifications for quality assurance may also be necessary, depending on the target market.

-

Logistics: Transportation costs can fluctuate based on distance, shipping method, and the chosen Incoterms. These factors are crucial for international buyers, especially those in regions like Africa and South America, where infrastructure may vary.

-

Margin: Suppliers typically add a margin to cover their costs and ensure profitability. This margin can be influenced by market demand, competition, and the perceived value of the product.

How Do Price Influencers Affect Iron Bracket Costs?

Several factors influence the pricing of iron brackets, particularly for international B2B buyers:

-

Volume/MOQ: Purchasing in bulk often leads to lower per-unit costs. Suppliers may offer discounts based on Minimum Order Quantities (MOQs), which can significantly impact pricing for large projects.

-

Specifications/Customization: Customized designs or specific requirements (like load-bearing capacity) can increase costs. Off-the-shelf brackets are generally less expensive than those requiring special tooling or unique materials.

-

Materials: The choice of iron type and any additional coatings (like rust-resistant finishes) will affect pricing. Higher-quality materials typically result in a higher upfront cost but can lead to lower Total Cost of Ownership (TCO) due to increased longevity.

-

Quality and Certifications: Products that meet international quality standards may command higher prices. Certifications can enhance credibility, especially in markets with strict regulatory requirements.

-

Supplier Factors: Supplier reliability, reputation, and service levels can influence pricing. Established suppliers with strong track records may charge more due to their ability to deliver consistent quality and service.

-

Incoterms: The chosen Incoterms dictate who bears responsibility for shipping and logistics costs. Understanding these terms can help buyers manage costs effectively.

What Negotiation Tips Can Help Buyers Secure Better Pricing?

Navigating the complexities of iron bracket sourcing requires strategic negotiation and an understanding of cost-efficiency:

-

Research and Benchmarking: Analyze market prices and gather quotes from multiple suppliers. This will provide a solid basis for negotiation.

-

Focus on Total Cost of Ownership (TCO): Highlight the long-term benefits of investing in higher-quality brackets, which may reduce replacement and maintenance costs over time.

-

Be Clear on Specifications: Clearly define your requirements to avoid misunderstandings that could lead to additional costs. This clarity will also help suppliers provide more accurate quotes.

-

Explore Flexible Payment Terms: Negotiating payment terms can alleviate upfront costs. Consider options such as installment payments or extended credit terms.

-

Consider Local Suppliers: For buyers in regions like Africa or South America, sourcing from local manufacturers may reduce shipping costs and lead times, enhancing overall cost efficiency.

What Are the Pricing Nuances for International B2B Buyers?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, specific pricing nuances should be considered:

-

Currency Fluctuations: Exchange rates can significantly affect pricing. Locking in prices or using forward contracts may mitigate risks associated with currency volatility.

-

Import Duties and Taxes: Understanding applicable tariffs and taxes is essential for calculating the true cost of imported goods. These additional charges can impact overall budgeting.

-

Cultural Considerations: Different regions may have varying expectations regarding negotiation and pricing transparency. Being culturally aware can facilitate smoother transactions.

-

Logistical Challenges: International shipping can introduce delays and unforeseen costs. Building strong relationships with logistics partners can streamline this process.

In conclusion, the comprehensive analysis of costs and pricing for iron brackets involves understanding a multitude of factors. By considering these elements, B2B buyers can make informed decisions that align with their budgetary constraints and project requirements. Always remember that prices are indicative and can vary based on specific circumstances and negotiations.

Alternatives Analysis: Comparing iron bracket With Other Solutions

In the world of shelving and structural support, choosing the right bracket solution is crucial for stability, aesthetics, and cost-effectiveness. While iron brackets are a popular choice due to their strength and durability, there are viable alternatives that may better suit specific needs depending on the application. This section compares iron brackets with two alternative solutions: aluminum brackets and wooden brackets, providing insights into their respective advantages and disadvantages.

| Comparison Aspect | Iron Bracket | Aluminum Bracket | Wooden Bracket |

|---|---|---|---|

| Performance | High load capacity, durable, resistant to rust and corrosion. | Lightweight, good load capacity, resistant to corrosion. | Variable load capacity, depends on wood type, can warp over time. |

| Cost | Moderate to high cost depending on design and weight capacity. | Generally lower cost than iron, but varies with quality. | Low to moderate cost, depending on wood type and finish. |

| Ease of Implementation | Requires proper installation techniques to ensure stability. | Easy to install, often lighter and easier to handle. | Can be easy to install, but requires careful handling to prevent damage. |

| Maintenance | Low maintenance; resistant to environmental factors. | Low maintenance; may require periodic checks for stability. | Higher maintenance; can require refinishing or replacement due to wear. |

| Best Use Case | Ideal for heavy-duty applications in commercial settings. | Suitable for residential and light commercial use. | Best for aesthetic applications and lighter loads in residential settings. |

What Are the Advantages and Disadvantages of Using Aluminum Brackets?

Aluminum brackets are a lightweight alternative to iron, making them easier to handle and install. They offer good load-bearing capabilities while resisting rust and corrosion, which is particularly beneficial in humid environments. However, aluminum may not support as much weight as iron, making it less suitable for heavy-duty applications. Additionally, while typically less expensive than iron, the cost can vary significantly based on the quality and design of the aluminum brackets.

How Do Wooden Brackets Compare to Iron Brackets in Performance?

Wooden brackets provide an aesthetic appeal that is often unmatched by metal options, making them ideal for decorative applications. They can be less expensive than both iron and aluminum, depending on the type of wood used. However, their performance can be inconsistent; the load capacity depends on the wood species and quality. Wooden brackets are also more susceptible to warping and damage from moisture, which may necessitate more frequent maintenance or replacement.

How Can B2B Buyers Choose the Right Bracket Solution?

When selecting the right bracket solution, B2B buyers should consider several factors, including the load requirements, installation environment, and aesthetic preferences. Iron brackets excel in high-stress environments and provide long-lasting durability, making them the preferred choice for heavy-duty applications. In contrast, aluminum brackets are great for lighter applications where ease of installation and cost-effectiveness are priorities. Wooden brackets can enhance the aesthetic appeal of a space but may require more maintenance and careful consideration regarding load capacity. By assessing these factors and understanding the specific needs of their projects, buyers can make informed decisions that align with their operational requirements.

Essential Technical Properties and Trade Terminology for iron bracket

What Are the Key Technical Properties of Iron Brackets?

When selecting iron brackets for various applications, understanding their technical specifications is crucial for ensuring performance and durability. Here are some essential properties to consider:

-

Material Grade

– Iron brackets are typically made from different grades of steel or wrought iron. The material grade affects strength, corrosion resistance, and suitability for specific environments. For example, A36 steel is commonly used for its excellent weldability and structural integrity, making it ideal for heavy-duty applications. -

Load Capacity

– This specification indicates the maximum weight an iron bracket can support without bending or breaking. Load capacities can vary significantly, with standard brackets supporting 100 lbs each, while heavy-duty options can handle upwards of 600 lbs per pair. Knowing the load capacity is critical for ensuring safety and functionality in shelving and countertop applications. -

Finish and Coating

– The finish of an iron bracket, whether powder-coated or galvanized, affects its resistance to rust and wear. A powder-coated finish provides a protective layer that enhances durability, especially in humid or outdoor environments. This property is particularly important for international buyers in regions with varied climates. -

Tolerance

– Tolerance refers to the permissible limit of variation in dimensions. For iron brackets, precise tolerances ensure that they fit properly during installation and can handle the intended loads without failure. Poor tolerance can lead to installation difficulties and compromise structural integrity. -

Dimensions

– The size and shape of iron brackets are vital for compatibility with shelving or countertop designs. Key dimensions include arm length, width, and height. Properly sized brackets ensure optimal load distribution and aesthetic alignment with the overall design. -

Installation Type

– Different installation types, such as wall-mounted, floating, or under-counter brackets, dictate the bracket’s application. Understanding the installation requirements helps buyers choose the right type for their specific project needs.

Which Trade Terms Are Commonly Used in Iron Bracket Transactions?

Navigating the purchasing process for iron brackets involves familiarizing oneself with key trade terminology. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

– OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of iron brackets, understanding OEM relationships can help buyers identify reliable sources for high-quality products. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. Buyers need to consider MOQs when planning purchases, especially for bulk orders, to ensure they meet supplier requirements without over-committing resources. -

RFQ (Request for Quotation)

– An RFQ is a document used by buyers to solicit price quotes from suppliers. This process is critical in B2B transactions, as it allows buyers to compare prices, terms, and specifications before making a purchasing decision. -

Incoterms (International Commercial Terms)

– Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers in international trade. Understanding Incoterms is essential for determining who is responsible for shipping, insurance, and tariffs during the transport of iron brackets. -

Lead Time

– This term refers to the time it takes from placing an order to receiving the product. Knowing the lead time is crucial for project planning, especially in industries where timely delivery is essential. -

Certification

– Certifications, such as ISO or ASTM, indicate that a product meets specific quality and safety standards. For buyers, certification can provide assurance of product reliability and compliance with local regulations.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing iron brackets, ultimately ensuring their projects are successful and cost-effective.

Navigating Market Dynamics and Sourcing Trends in the iron bracket Sector

What Are the Current Market Dynamics and Key Trends in the Iron Bracket Sector?

The iron bracket market is currently experiencing robust growth, driven by several global factors. The construction and home improvement sectors are burgeoning, especially in emerging markets across Africa, South America, the Middle East, and Europe. This growth is fueled by urbanization, rising disposable incomes, and increased demand for durable and aesthetically pleasing home fixtures. Additionally, the rise of e-commerce platforms is transforming traditional sourcing methods, allowing international buyers to access a broader range of suppliers and products. B2B tech advancements, including the use of AI and data analytics for inventory management and demand forecasting, are optimizing supply chain efficiencies, making it easier for buyers to make informed decisions.

Moreover, sustainability is becoming a significant factor in purchasing decisions. Buyers are increasingly looking for suppliers who prioritize environmentally friendly practices, such as using recycled materials or reducing carbon footprints in manufacturing processes. The demand for customization is also on the rise, with businesses seeking unique designs that reflect local cultural aesthetics. These trends are reshaping the market landscape, compelling suppliers to innovate and adapt quickly.

How Is Sustainability Influencing Sourcing Practices for Iron Brackets?

As global awareness of environmental issues grows, sustainability is becoming a cornerstone of sourcing strategies in the iron bracket sector. The environmental impact of manufacturing processes cannot be overlooked; traditional iron production is energy-intensive and contributes significantly to greenhouse gas emissions. B2B buyers are now prioritizing suppliers who demonstrate a commitment to sustainable practices, such as utilizing recycled steel and minimizing waste.

Ethical sourcing is equally important, as buyers increasingly seek transparent supply chains that ensure fair labor practices and compliance with international labor standards. Certifications like ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) are becoming essential for suppliers aiming to attract eco-conscious buyers. Moreover, the adoption of ‘green’ materials and processes not only fulfills regulatory requirements but also enhances brand reputation, potentially leading to increased sales and customer loyalty. By aligning sourcing strategies with sustainability goals, businesses can create a competitive advantage in a rapidly evolving market.

What Is the Historical Context of Iron Bracket Manufacturing?

The evolution of iron bracket manufacturing reflects broader trends in industrialization and design preferences. Initially, iron brackets were primarily functional, designed to support shelves and structures without consideration for aesthetics. However, as the Industrial Revolution progressed in the 18th and 19th centuries, advancements in metallurgy and manufacturing techniques allowed for more intricate designs and increased durability.

In the late 20th century, the rise of DIY culture and home improvement movements led to a surge in demand for both standard and decorative iron brackets. This shift prompted manufacturers to diversify their product lines, offering a variety of styles, finishes, and load capacities to cater to different consumer needs. Today, the market continues to evolve, influenced by technological innovations, sustainability concerns, and changing consumer preferences, shaping the way iron brackets are designed and sourced globally.

Frequently Asked Questions (FAQs) for B2B Buyers of iron bracket

-

How do I choose the right iron bracket for my shelving needs?

Selecting the appropriate iron bracket involves considering both the shelf depth and the expected load. A general rule is to choose a bracket arm that extends about two-thirds of the shelf depth to prevent sagging. For instance, if you have a 10-inch deep shelf, an arm of approximately 7 inches is ideal. Additionally, check the weight capacity of the brackets; heavy-duty options can support upwards of 300 lbs per pair. Ensure that the brackets are mounted securely into wall studs or solid materials to maintain safety and durability. -

What are the weight limits for iron brackets?

The weight capacity of iron brackets varies based on their design and construction. Standard brackets typically hold around 100 lbs each, while heavy-duty brackets can support up to 300 lbs or more per pair. It’s crucial to consider the distribution of weight on the shelf, as well as the mounting method. For maximum strength, always anchor brackets into studs rather than drywall, and avoid overloading them to ensure longevity and safety. -

What customization options are available for iron brackets?

Many suppliers offer customization options for iron brackets, including size, finish, and design. Businesses can request specific dimensions to fit unique shelving requirements or select finishes that align with their branding or aesthetic preferences. Additionally, some manufacturers may provide options for adding logos or custom patterns. When seeking customization, communicate your requirements clearly and inquire about lead times and any additional costs involved. -

What is the minimum order quantity (MOQ) for purchasing iron brackets?

The minimum order quantity for iron brackets can vary significantly between suppliers. Some manufacturers may allow small orders for trial purposes, while others may have a higher MOQ, often ranging from 50 to 500 units. It’s advisable to discuss your needs with potential suppliers and explore options for smaller quantities if necessary. Establishing a relationship with a supplier may also lead to more flexible terms in future orders. -

What payment terms should I expect when sourcing iron brackets internationally?

Payment terms for international transactions typically include various options such as upfront payments, letters of credit, or payment upon delivery. Suppliers may require a deposit (often 30% to 50%) before production begins, with the balance due before shipment. It’s essential to clarify payment terms upfront and ensure that they align with your cash flow requirements. Additionally, consider discussing currency exchange rates and potential fees associated with international transactions. -

How can I ensure the quality of iron brackets before making a purchase?

To ensure the quality of iron brackets, request samples from suppliers before placing a large order. Conduct a thorough review of the materials and manufacturing processes used, such as the type of steel and fabrication techniques. Certifications and quality assurance documentation are also critical; reputable suppliers should provide evidence of compliance with international standards. Additionally, consider seeking customer reviews or references to gain insights into the supplier’s reliability and product performance. -

What logistics considerations should I keep in mind when importing iron brackets?

When importing iron brackets, it’s crucial to consider shipping methods, transit times, and customs regulations. Discuss the most efficient shipping options with your supplier, including air or sea freight, and factor in delivery times that align with your project schedules. Be aware of import duties and taxes, which can significantly affect overall costs. It’s also advisable to work with a freight forwarder or logistics expert to navigate the complexities of international shipping and ensure a smooth delivery process. -

How do I vet potential suppliers for iron brackets?

Vetting suppliers is essential to ensure reliability and product quality. Start by researching the supplier’s reputation, including reviews and testimonials from previous clients. Verify their manufacturing capabilities, certifications, and quality control processes. It may also be beneficial to request references or case studies from similar projects. Lastly, consider visiting the manufacturing facility if possible, or using third-party inspection services to assess their operations firsthand.

Top 4 Iron Bracket Manufacturers & Suppliers List

1. IronSupports – Designer Metal Shelf Brackets

Domain: ironsupports.com

Registered: 2017 (8 years)

Introduction: Designer Metal Shelf Brackets, hand-crafted in America, engineered for load capacity, available in various designs from ornate to minimal. Key features include:

– Made from ¼-inch plate steel with solid gusset support

– Load tested past 300 lb

– Multiple sizes and finishes

– Fast shipping, in-stock items ship within 1 business day

– Lifetime guarantee

– Suitable for various applications incl…

2. Cascade Iron Co – Heavy Duty Shelf Bracket

Domain: cascadeironco.com

Registered: 2018 (7 years)

Introduction: Cascade Iron Co specializes in high-quality metal shelf brackets and fixtures made in the USA from domestic steel. Key products include: 1. Heavy Duty Shelf Bracket for Floating Shelves – Starting at $14.00 2. L Bracket – Metal Shelving Support – Starting at $8.00 3. Double J Hook – $16.00 4. Towel Bar – Metal Rack – $30.00 5. Metal Paper Towel Holder – Under Mount – $40.00 6. Floating Metal Shelf…

3. RCH Hardware – Decorative Shelf Brackets

Domain: rchhardware.com

Registered: 2015 (10 years)

Introduction: Decorative shelf brackets made of solid cast iron, heavy-duty and versatile. Available in various finishes to match other hardware. Suitable for vintage, rustic, cottage, country farmhouse, modern, industrial, and art deco styles. Includes matching mounting screws. Bulk pricing available.

4. Black Dog Ironworks – Classic Forged Shelf Bracket

Domain: blackdogironworks.com

Registered: 2015 (10 years)

Introduction: {“name”: “Classic Forged Shelf Bracket”, “price”: “$39.99”, “sold_individually”: true, “production_time”: “5-7 days”, “material”: “solid steel”, “techniques”: “modern and traditional blacksmithing techniques”, “features”: [“time honored rivets”, “classic twist”, “rugged design”], “decor_style”: “rustic modern”, “sizes_available”: [“6 Inch”, “8 Inch”, “10 Inch”, “12 Inch”], “custom_sizes”: “availab…

Strategic Sourcing Conclusion and Outlook for iron bracket

Iron brackets have emerged as a vital component in various sectors, including construction, retail, and home improvement. Their durability, aesthetic appeal, and versatility make them an essential choice for B2B buyers looking to enhance structural integrity and design in their projects. Strategic sourcing of iron brackets not only ensures access to high-quality materials but also fosters long-term relationships with suppliers, ultimately leading to cost savings and improved supply chain efficiency.

As international markets continue to evolve, particularly in regions such as Africa, South America, the Middle East, and Europe, it is essential for businesses to stay ahead of industry trends and demand fluctuations. Engaging with reliable manufacturers and suppliers can provide insights into emerging innovations and sustainable practices, which are increasingly valued in today’s market.

Looking forward, the demand for iron brackets is expected to grow as construction projects expand globally. B2B buyers are encouraged to prioritize partnerships with suppliers who offer robust product lines, competitive pricing, and exemplary customer service. By making informed sourcing decisions, businesses can not only meet their current needs but also position themselves for future success in a competitive landscape. Take the next step in your sourcing strategy today and explore the vast opportunities that quality iron brackets can offer.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.