Pontoon Boat Door Latch Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for pontoon boat door latch

In the competitive landscape of marine accessories, sourcing a reliable pontoon boat door latch can be a significant challenge for international B2B buyers. A high-quality latch is not only essential for ensuring the safety and security of boat passengers but also plays a crucial role in enhancing the overall user experience on the water. This comprehensive guide delves into the various types of pontoon boat door latches, their specific applications, and the critical factors to consider when selecting suppliers.

Understanding the nuances of pontoon boat door latch options, including material durability, compatibility with different gate configurations, and ease of installation, is vital for making informed purchasing decisions. Additionally, we will explore supplier vetting processes and pricing structures tailored to different regions, including Africa, South America, the Middle East, and Europe, with specific insights for markets such as Nigeria and Saudi Arabia.

By equipping B2B buyers with actionable insights and a deep understanding of the pontoon boat door latch market, this guide aims to empower businesses to make strategic purchasing decisions that not only meet their operational needs but also drive long-term satisfaction and loyalty among their customers. Whether you are looking to enhance safety features or improve functionality, this guide serves as your roadmap to navigating the global market for pontoon boat door latches.

Understanding pontoon boat door latch Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Gate Latch | Fits 1″, 1 1/8″, or 1 1/4″ square tube; nylon construction | General pontoon boat access control | Pros: Durable, easy installation. Cons: Limited security features. |

| Slam Latch | Self-locking mechanism; quick access; robust design | High-traffic pontoon areas | Pros: Fast operation, secure closure. Cons: May require more maintenance. |

| Safety Gate Latch | Designed for right or left-side installation; prevents inward swing | Safety-focused applications | Pros: Enhances safety, reliable. Cons: Slightly more complex installation. |

| Locking Gate Latch | Integrated lock for added security; fits standard tube sizes | Security-sensitive environments | Pros: Increased security, peace of mind. Cons: Higher cost, may require keys. |

| Adjustable Gate Latch | Customizable fit for various gate sizes; adaptable design | Versatile applications across different boats | Pros: Flexibility in installation, accommodates various designs. Cons: Potentially higher complexity in fitting. |

What are the Characteristics of Standard Gate Latches for Pontoon Boats?

Standard gate latches are commonly used in pontoon boats due to their straightforward design and ease of installation. They typically accommodate square tube sizes of 1″, 1 1/8″, and 1 1/4″, making them suitable for various boat models. Made from durable nylon, these latches prevent rattling and ensure longevity. B2B buyers should consider their reliability and cost-effectiveness, as they provide essential access control without complex mechanisms.

How Do Slam Latches Enhance Access in High-Traffic Areas?

Slam latches are designed for rapid access, making them ideal for high-traffic areas on pontoon boats. Their self-locking mechanism ensures that gates close securely without the need for manual locking, which is beneficial in busy environments. B2B buyers should evaluate their operational efficiency and durability, as these latches often require minimal maintenance while providing robust functionality.

Why Choose Safety Gate Latches for Enhanced Security?

Safety gate latches are essential for ensuring the security of pontoon boats, especially in environments where safety is paramount. These latches prevent inward swinging, which can be a safety hazard. They are suitable for right or left-side installation, making them versatile for various boat designs. B2B purchasers should prioritize these latches in applications where safety regulations are stringent or where they cater to family-oriented customers.

What Advantages Do Locking Gate Latches Offer?

Locking gate latches provide an added layer of security for pontoon boats, making them ideal for environments where theft or unauthorized access is a concern. They fit standard tube sizes and are designed to integrate seamlessly into existing gate structures. While they offer peace of mind for boat owners, B2B buyers must consider the higher initial investment and the potential need for keys, which can complicate access for multiple users.

How Do Adjustable Gate Latches Cater to Diverse Boat Designs?

Adjustable gate latches are designed to accommodate various gate sizes, making them a flexible option for different pontoon boat configurations. Their adaptability allows for customization during installation, which is beneficial for manufacturers producing a range of boat models. B2B buyers should assess the installation complexity and potential adjustments required, as these latches can offer significant advantages in terms of versatility and customer satisfaction.

Key Industrial Applications of pontoon boat door latch

| Industry/Sector | Specific Application of pontoon boat door latch | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Marine Manufacturing | Installation in pontoon boat gates for secure access | Enhances safety and ease of access for passengers and crew | Durability against marine conditions, compatibility with gate sizes |

| Recreational Boating | Integration into rental pontoon boats for customer use | Improves user experience by ensuring secure and reliable operation | Cost-effectiveness, ease of installation, and maintenance |

| Tourism and Hospitality | Usage in pontoon boats for leisure and sightseeing tours | Provides safety and convenience, enhancing customer satisfaction | Aesthetic appeal, reliability, and compliance with safety regulations |

| Commercial Fishing | Application in fishing pontoons for secure gear storage | Protects equipment and ensures efficient operations | Robustness, resistance to corrosion, and ease of use |

| Boat Repair and Maintenance | Replacement parts for existing pontoon boats | Reduces downtime and maintenance costs | Availability of spare parts, warranty, and quality assurance |

How Are Pontoon Boat Door Latches Used in Marine Manufacturing?

In the marine manufacturing sector, pontoon boat door latches are essential components that provide secure access to boat gates. These latches are designed to operate on both right and left hinged gates and are compatible with various square tube sizes. By preventing gates from swinging inward, they enhance safety for passengers and crew. For international buyers, especially in regions like Africa and South America, sourcing durable latches that withstand marine environments is crucial. Manufacturers must consider the materials used, ensuring they resist corrosion and provide longevity.

What Role Do Pontoon Boat Door Latches Play in Recreational Boating?

Recreational boating often includes rental services where pontoon boats are made available to the public. Here, door latches are vital for ensuring a secure environment for users. They prevent accidental openings while the boat is in motion, promoting safety. For B2B buyers in the Middle East and Europe, the focus should be on cost-effectiveness and ease of installation to maintain operational efficiency and minimize downtime. Reliable latches contribute to a positive user experience, which is essential in the competitive rental market.

How Do Pontoon Boat Door Latches Enhance Tourism and Hospitality?

In the tourism and hospitality industry, pontoon boats are frequently used for sightseeing tours and leisure activities. The integration of high-quality door latches ensures that passengers can board and disembark safely, which is pivotal for customer satisfaction. Buyers from regions like Saudi Arabia and Nigeria should prioritize latches that not only offer functionality but also align with aesthetic preferences, enhancing the overall appearance of the vessel. Compliance with safety regulations is also a key consideration in this sector.

Why Are Pontoon Boat Door Latches Important for Commercial Fishing?

In commercial fishing, pontoon boats serve as vital platforms for gear storage and operations. Reliable door latches protect valuable equipment from the elements, ensuring that everything remains secure during transport. For international buyers, sourcing robust latches that can withstand harsh marine conditions is essential. The focus should be on durability and ease of use, as these factors directly impact operational efficiency and reduce maintenance costs.

What Considerations Are There for Boat Repair and Maintenance?

For boat repair and maintenance businesses, pontoon boat door latches often need to be replaced due to wear and tear. Having access to quality replacement parts is crucial for minimizing downtime and keeping maintenance costs low. Buyers should consider the availability of spare parts and the warranties offered by suppliers. Ensuring that the latches meet high standards of quality is essential for maintaining the integrity and safety of pontoon boats in service.

3 Common User Pain Points for ‘pontoon boat door latch’ & Their Solutions

Scenario 1: Compatibility Issues with Different Pontoon Boat Designs

The Problem: Many B2B buyers face challenges when sourcing pontoon boat door latches that are compatible with various boat designs. Given the diversity in pontoon boat sizes and construction materials, a latch that fits one model may not work for another. This can lead to delays in production and increased costs due to returns or replacements. Buyers may also find it difficult to ascertain whether a latch will suit their specific needs without physical samples or extensive product specifications.

The Solution: To address compatibility issues, B2B buyers should prioritize sourcing latches that offer adjustable sizing and versatile compatibility. When evaluating suppliers, look for products that specifically mention compatibility with multiple square tube sizes (e.g., 1″, 1 1/8″, and 1 1/4″). It’s also beneficial to request detailed specifications and installation guides from manufacturers to ensure that the latches will fit various pontoon designs. Establishing relationships with reliable suppliers who can provide technical support and customization options can further enhance compatibility, reducing the likelihood of costly mistakes.

Scenario 2: Durability and Performance Under Harsh Marine Conditions

The Problem: The marine environment poses unique challenges that can compromise the performance and lifespan of door latches. Buyers often encounter latches that corrode, break, or fail due to exposure to saltwater, UV rays, and extreme temperatures. Such failures not only jeopardize safety but can also lead to unexpected maintenance costs and downtime for the vessels, impacting overall business operations.

The Solution: When sourcing pontoon boat door latches, prioritize materials that are specifically engineered for marine applications. Look for latches made from high-quality nylon or other corrosion-resistant materials that can withstand the harsh marine environment. Additionally, buyers should consider latches that come with warranties, indicating the manufacturer’s confidence in their durability. Conducting thorough market research and requesting samples to test the latches in real-world conditions can also help ensure that the chosen products meet performance expectations over time.

Scenario 3: Installation Challenges Leading to Operational Delays

The Problem: Installation difficulties are a significant pain point for B2B buyers, especially when the latches are complex or require specialized tools. Complicated installation processes can lead to delays in project timelines, increased labor costs, and frustration among teams. If latches are not installed correctly, they may fail to perform, necessitating additional adjustments or replacements.

The Solution: To mitigate installation challenges, buyers should seek out pontoon boat door latches that emphasize ease of installation. Products that come with comprehensive installation instructions and all necessary hardware can streamline the process. Additionally, consider working with suppliers that offer technical support or training sessions for installation teams. Investing in latches that are designed for straightforward, tool-free installation can further reduce the likelihood of errors and improve operational efficiency. Engaging with suppliers who provide clear communication and support can also facilitate a smoother installation process, ensuring that projects stay on schedule.

Strategic Material Selection Guide for pontoon boat door latch

What Materials Are Commonly Used for Pontoon Boat Door Latches?

When selecting materials for pontoon boat door latches, it is essential to consider the unique environmental challenges and performance requirements associated with marine applications. Here, we analyze four common materials: nylon, stainless steel, aluminum, and brass, focusing on their properties, advantages, disadvantages, and implications for international buyers.

How Does Nylon Perform in Marine Applications?

Nylon is a popular choice for pontoon boat door latches due to its lightweight and durable nature. Key properties include excellent resistance to corrosion and UV degradation, making it suitable for prolonged exposure to marine environments. Nylon also offers a temperature tolerance that allows it to perform well in various climates.

Pros: Nylon latches are generally cost-effective and easy to install, with minimal manufacturing complexity. Their lightweight nature reduces overall boat weight, which can improve fuel efficiency.

Cons: While nylon is durable, it can be prone to wear over time, especially under extreme conditions. Its mechanical properties may degrade at elevated temperatures, limiting its use in hotter climates.

International Considerations: Buyers from regions like Africa and the Middle East should ensure compliance with local standards for marine materials, as well as consider the availability of replacement parts in their markets.

What Are the Benefits of Stainless Steel for Door Latches?

Stainless steel is renowned for its exceptional strength and corrosion resistance, making it an ideal material for pontoon boat door latches. It withstands harsh marine environments and can handle significant mechanical stress.

Pros: The durability of stainless steel latches ensures a long lifespan, reducing the need for frequent replacements. They also offer a sleek aesthetic that appeals to many boat owners.

Cons: The primary drawback is the higher cost compared to other materials like nylon or aluminum. Additionally, stainless steel can be heavier, potentially impacting the overall weight of the boat.

International Considerations: Buyers should verify that the stainless steel used meets international standards such as ASTM or DIN, especially in regions with strict regulations regarding marine hardware.

Why Choose Aluminum for Pontoon Boat Door Latches?

Aluminum is another viable material for pontoon boat door latches, known for its lightweight and corrosion-resistant properties. It is often used in marine applications where weight savings are critical.

Pros: Aluminum latches are typically less expensive than stainless steel and provide a good balance between weight and strength. They are also resistant to rust, making them suitable for freshwater and saltwater applications.

Cons: While aluminum is durable, it may not offer the same level of strength as stainless steel, making it less suitable for high-stress applications. Additionally, it can be prone to scratches and dents.

International Considerations: Buyers in Europe and South America should consider the local availability of aluminum grades that comply with marine standards to ensure product reliability.

What Role Does Brass Play in Latch Manufacturing?

Brass is often used for its aesthetic appeal and corrosion resistance, particularly in decorative applications. It is less common for structural components but can be found in some marine latches.

Pros: Brass offers a classic look and is resistant to corrosion, particularly in freshwater environments. Its antimicrobial properties can also be beneficial in maintaining hygiene.

Illustrative image related to pontoon boat door latch

Cons: The primary limitation of brass is its susceptibility to dezincification, especially in saltwater, which can compromise its structural integrity. It is also generally more expensive than nylon and aluminum.

International Considerations: Buyers should ensure that brass latches meet specific international standards, particularly in regions with high salinity levels, to avoid premature failure.

Summary Table of Material Selection for Pontoon Boat Door Latches

| Material | Typical Use Case for pontoon boat door latch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nylon | General-purpose latches for lightweight applications | Corrosion-resistant, lightweight | Prone to wear under extreme conditions | Low |

| Stainless Steel | Heavy-duty latches for high-stress applications | Exceptional strength and durability | Higher cost, heavier weight | High |

| Aluminum | Lightweight latches for performance boats | Cost-effective, good corrosion resistance | Less strength than stainless steel | Medium |

| Brass | Decorative latches for aesthetic applications | Attractive appearance, antimicrobial | Susceptible to dezincification in saltwater | Medium to High |

This analysis provides a comprehensive overview of material options for pontoon boat door latches, enabling international B2B buyers to make informed decisions based on performance, cost, and regional compliance.

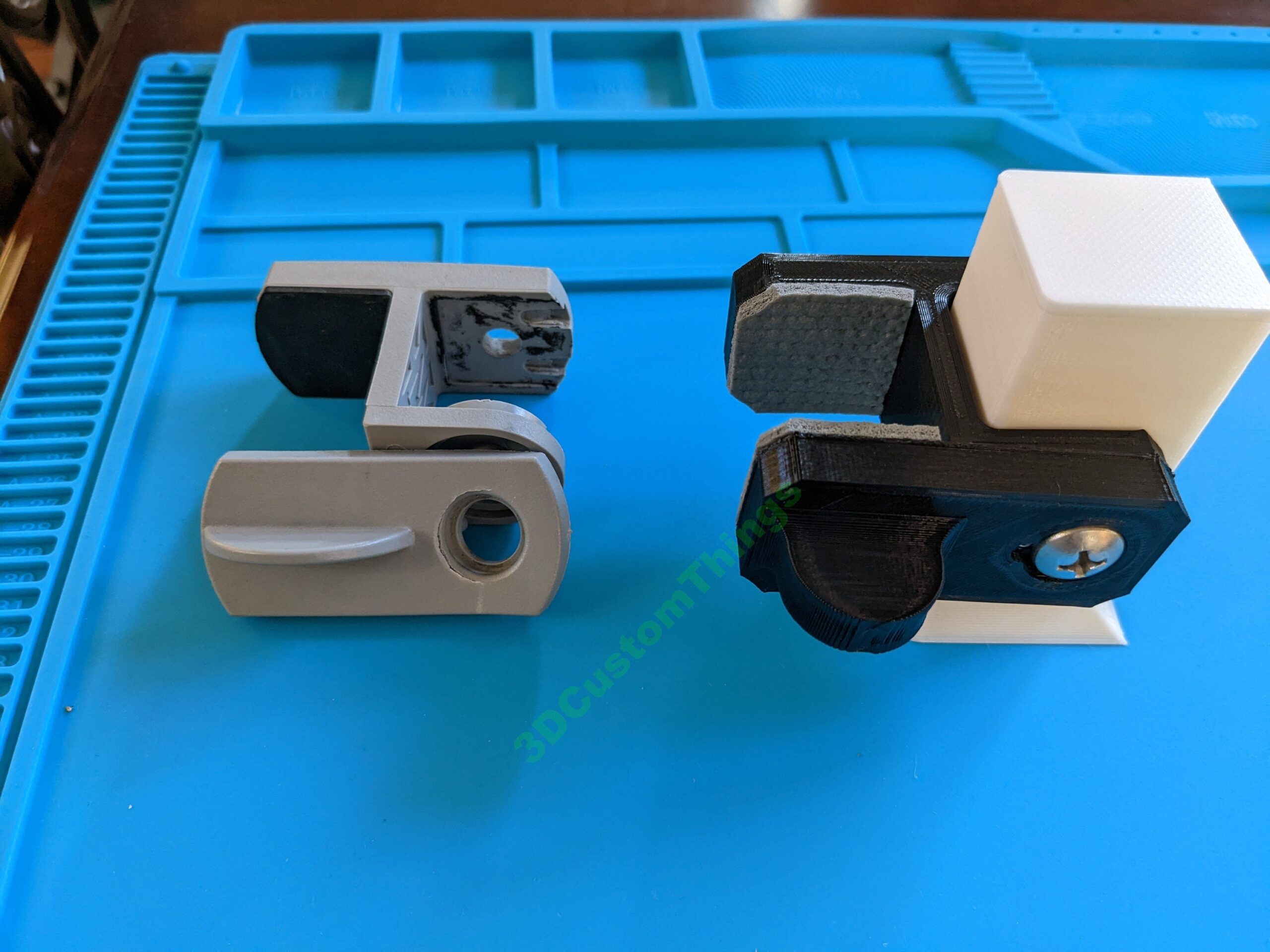

Illustrative image related to pontoon boat door latch

In-depth Look: Manufacturing Processes and Quality Assurance for pontoon boat door latch

What Are the Main Stages in the Manufacturing Process of Pontoon Boat Door Latches?

The manufacturing process for pontoon boat door latches involves several critical stages, ensuring that the final product meets quality, durability, and functionality standards essential for marine environments.

Material Preparation: What Materials Are Used?

The initial phase involves selecting high-quality materials that can withstand marine conditions. Common materials include:

- Nylon: This is often used for its lightweight and corrosion-resistant properties. It provides durability while reducing noise and rattling.

- Stainless Steel: For components requiring additional strength, stainless steel is commonly used due to its resistance to rust and corrosion.

- Aluminum: Sometimes used in combination with nylon or steel, aluminum is lightweight and offers good resistance to the elements.

Once materials are selected, they undergo thorough inspection to ensure they meet predefined specifications.

How Are Pontoon Boat Door Latches Formed?

The forming stage utilizes various techniques to shape the raw materials into functional components. This often includes:

- Injection Molding: Primarily used for nylon parts, this process involves injecting molten plastic into molds to create complex shapes that are consistent and precise.

- Stamping: For metal components, stamping is a common method where sheets of metal are cut and shaped using high-pressure machines. This ensures uniformity across batches.

- Machining: Precision machining may be employed for components that require exact dimensions and tolerances, particularly in stainless steel parts.

These techniques ensure that each part meets the design specifications necessary for effective functionality.

What Does the Assembly Process Entail?

Once individual components are formed, they undergo assembly. This typically includes:

- Component Integration: Each part, whether nylon, metal, or aluminum, is assembled using screws, rivets, or clips. The assembly process must ensure that all parts work seamlessly together.

- Testing During Assembly: As components are assembled, functional tests may be performed to check for proper operation, such as ensuring that the latch engages and disengages smoothly.

This stage is crucial, as any misalignment or improper assembly can lead to product failure.

What Finishing Techniques Are Applied to Ensure Quality?

After assembly, finishing processes enhance the durability and aesthetics of the pontoon boat door latches. Common finishing techniques include:

- Surface Treatments: Parts may undergo anodizing or powder coating to improve corrosion resistance, especially for aluminum components.

- Quality Inspections: Before packaging, latches are subjected to visual inspections and functional tests to verify that they meet quality standards.

These finishing touches not only enhance the product’s appearance but also extend its lifespan in challenging marine environments.

How Is Quality Assurance Implemented in the Manufacturing of Pontoon Boat Door Latches?

Quality assurance is a vital component in the manufacturing of pontoon boat door latches, ensuring that products meet both international and industry-specific standards.

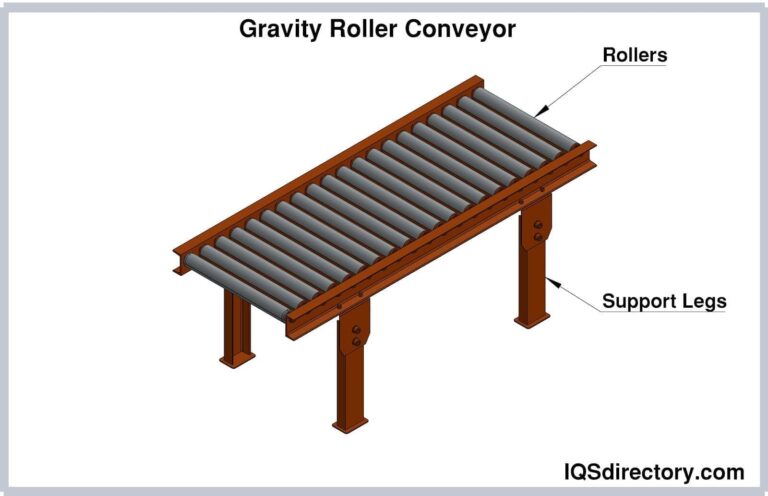

Illustrative image related to pontoon boat door latch

What International Standards Are Relevant to Quality Control?

B2B buyers should be aware of the key international standards that govern quality assurance, including:

- ISO 9001: This is a globally recognized standard for quality management systems. It ensures that manufacturers adhere to consistent quality processes and customer satisfaction.

- CE Marking: In Europe, products must comply with health, safety, and environmental protection standards. CE marking indicates that a product meets these requirements.

- API Standards: For components used in marine applications, adherence to American Petroleum Institute (API) standards may be necessary, especially for materials used in harsher environments.

These certifications not only validate the quality of the product but also enhance the credibility of the supplier.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integral throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): This initial inspection ensures that raw materials meet quality specifications before production begins.

- In-Process Quality Control (IPQC): During manufacturing, ongoing inspections verify that processes are being followed and that components are being produced to specification.

- Final Quality Control (FQC): After assembly, a final inspection checks the completed product for any defects or functional issues before shipping.

These checkpoints help identify and rectify issues early in the process, reducing the risk of defective products reaching customers.

What Common Testing Methods Are Employed?

Several testing methods are employed to ensure that pontoon boat door latches perform as expected:

- Functional Testing: This assesses whether the latch operates correctly under various conditions, including temperature and humidity.

- Durability Testing: Latches may undergo stress tests to simulate real-world usage, ensuring they can withstand forces without failure.

- Corrosion Testing: For metal components, salt spray tests may be conducted to evaluate resistance to corrosion, a critical factor in marine environments.

These tests help verify that the latches will perform reliably over time.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, especially from regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential for ensuring product reliability.

What Methods Can Be Used for Supplier Audits?

- Supplier Audits: Conducting on-site audits of manufacturing facilities allows buyers to assess the production environment, equipment, and processes firsthand.

- Requesting Quality Reports: Suppliers should provide documentation of their quality control processes, including results from IQC, IPQC, and FQC tests.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality assurance processes and product quality.

These methods help buyers build trust in their suppliers and ensure that they are receiving high-quality products.

What Quality Control Nuances Should International Buyers Consider?

International buyers should also be aware of specific nuances that could affect quality control:

- Cultural Differences: Understanding the local manufacturing culture can provide insights into potential challenges or advantages in quality management.

- Regulatory Compliance: Ensure that suppliers comply with local regulations and standards that may differ from international norms, which can affect the product’s usability in different markets.

- Communication Barriers: Clear communication regarding quality expectations and specifications is crucial. Using a common language or translation services can help mitigate misunderstandings.

By considering these factors, B2B buyers can enhance their procurement strategies and ensure the quality of pontoon boat door latches meets their requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pontoon boat door latch’

In the competitive landscape of pontoon boat accessories, sourcing the right door latch is essential for ensuring safety, functionality, and customer satisfaction. This guide provides a step-by-step checklist to assist B2B buyers in procuring high-quality pontoon boat door latches that meet specific operational needs.

Step 1: Define Your Technical Specifications

Understanding the precise requirements for your pontoon boat door latch is crucial. Consider factors such as the gate size, hinge orientation (left or right), and the type of materials (e.g., nylon or metal) used in the latch. Make sure the latch is compatible with the square tube sizes of 1″, 1 1/8″, or 1 1/4″, as different models may have varying specifications.

Step 2: Research Reliable Suppliers

Conduct thorough research to identify suppliers with a solid reputation in the marine accessories market. Look for suppliers who specialize in pontoon boat parts, as they are more likely to offer quality products tailored to your needs. Utilize online platforms, trade shows, and industry publications to gather information about potential suppliers.

Step 3: Evaluate Supplier Certifications

Before finalizing any deals, ensure that your potential suppliers have the necessary certifications and quality assurance processes in place. Certifications may include ISO standards or compliance with marine safety regulations. This step is vital to guarantee that the latches are not only functional but also safe and durable for end-users.

Step 4: Request Product Samples

Always ask for samples of the pontoon boat door latches you are considering. This will allow you to assess the quality, durability, and ease of installation firsthand. Testing the product before a bulk purchase can save you from costly mistakes and ensure that the latch meets your performance expectations.

Step 5: Check Warranty and After-Sales Support

Inquire about the warranty period and the after-sales support provided by the supplier. A robust warranty indicates confidence in the product’s durability, while good after-sales support can be crucial for troubleshooting and maintenance. Ensure that the warranty covers a reasonable timeframe, ideally 6 years or more, which is common for quality marine products.

Step 6: Compare Pricing and Payment Terms

Analyze pricing structures from different suppliers and consider the total cost of ownership, including shipping and import duties if applicable. Transparent pricing helps in budgeting and ensures you are not overpaying for similar products. Additionally, clarify payment terms to avoid unexpected charges or issues.

Step 7: Finalize the Order and Monitor Delivery

Once you have selected a supplier, finalize your order and set clear expectations regarding delivery timelines. Monitor the shipment closely to ensure it arrives as scheduled. This step is vital for maintaining your inventory levels and fulfilling customer orders promptly.

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing pontoon boat door latches, ensuring that they make informed decisions that align with their operational requirements and business goals.

Comprehensive Cost and Pricing Analysis for pontoon boat door latch Sourcing

What Are the Key Cost Components of Sourcing Pontoon Boat Door Latches?

When evaluating the cost structure for pontoon boat door latches, several components come into play. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the supplier’s profit margin.

-

Materials: The choice of materials significantly impacts cost. Common options include nylon and various metals. Nylon, while cost-effective and resistant to corrosion, may be less durable than metals, which can drive up prices but provide longer-lasting solutions.

-

Labor: Labor costs can vary depending on the region of production. Countries with lower labor costs may offer competitive pricing, but this may sometimes compromise quality. Understanding the labor market in your supplier’s location is crucial.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and equipment maintenance. These costs are typically factored into the per-unit price of the latches.

-

Tooling: Custom tooling for specific designs can be a significant upfront cost, especially for unique or highly specialized latches. It’s essential to consider these costs when ordering custom products.

-

Quality Control: Ensuring product quality through rigorous QC processes can incur additional costs. Suppliers that invest in quality assurance may charge higher prices, reflecting the reliability of their products.

-

Logistics: Transporting latches from the manufacturer to the buyer adds another layer of cost. This includes shipping, customs duties, and any tariffs that may apply, especially for international buyers.

-

Margin: Finally, suppliers will add a profit margin to cover their operational costs and ensure profitability. Understanding the market dynamics will help buyers negotiate better prices.

How Do Pricing Influencers Affect the Cost of Pontoon Boat Door Latches?

Several factors influence the pricing of pontoon boat door latches, particularly for international buyers in regions such as Africa, South America, the Middle East, and Europe.

-

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk can lead to significant discounts. Suppliers often have MOQs, and exceeding these can reduce per-unit costs.

-

Specifications and Customization: Customized latches that meet specific requirements can increase costs. Buyers should clearly communicate their needs to avoid unexpected expenses.

-

Material Quality and Certifications: Higher quality materials and industry certifications (e.g., ISO, CE) can increase costs but are essential for ensuring product reliability and compliance with local regulations.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers with a track record of quality may charge more but offer assurance of product performance.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international transactions. They dictate who bears the cost and risk at various stages of transport, affecting the overall pricing structure.

What Buyer Tips Can Help Optimize Costs When Sourcing Pontoon Boat Door Latches?

To maximize cost-efficiency when sourcing pontoon boat door latches, buyers should consider the following strategies:

-

Negotiate Pricing: Leverage volume purchases and establish long-term relationships with suppliers to negotiate better terms. Being informed about market prices can enhance negotiation power.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also shipping, maintenance, and replacement costs. A cheaper latch might incur higher long-term costs due to lower durability.

-

Understand Pricing Nuances for International Buyers: Currency fluctuations, import duties, and regional tariffs can significantly affect costs. Buyers should factor these elements into their budgeting and pricing strategies.

-

Research and Compare Suppliers: Don’t settle for the first quote. Compare multiple suppliers to find the best balance between price and quality. Online platforms and trade shows can be valuable resources for this research.

Disclaimer on Indicative Prices

Prices for pontoon boat door latches can vary widely based on the factors mentioned above. The indicative prices range from $9.99 to $32.99, depending on specifications and supplier. It is advisable to obtain quotes from multiple suppliers to ensure competitive pricing tailored to your specific needs and circumstances.

Alternatives Analysis: Comparing pontoon boat door latch With Other Solutions

When considering the best solutions for securing doors on pontoon boats, various alternatives to traditional pontoon boat door latches exist. These alternatives can offer different functionalities, costs, and ease of use, making it essential for B2B buyers to assess their specific needs against available options. Below, we compare the standard pontoon boat door latch with two viable alternatives: the slam latch and the locking hasp.

| Comparison Aspect | Pontoon Boat Door Latch | Slam Latch | Locking Hasp |

|---|---|---|---|

| Performance | Reliable, prevents inward swinging of gates | Quick closure, ideal for frequent use | Provides security with locking mechanism |

| Cost | $9.99 – $21.99 | $32.99 | $7.99 – $14.69 |

| Ease of Implementation | Simple installation, mounts directly on gate | Easy to install, may require more space | Requires drilling for installation |

| Maintenance | Minimal maintenance required | Low maintenance, durable materials | Regular checks needed for lock mechanism |

| Best Use Case | Ideal for general pontoon boat usage | Best for high-traffic areas or quick access | Suitable for areas requiring extra security |

What are the Pros and Cons of the Slam Latch as an Alternative?

The slam latch offers a fast and efficient method for securing pontoon boat gates, making it particularly suitable for high-traffic areas where quick access is essential. This type of latch allows users to simply close the gate without needing to turn a handle, which is beneficial for busy environments. However, its design may require additional space for installation and may not prevent inward swinging as effectively as traditional latches. Additionally, slam latches can be more costly, which may deter budget-conscious buyers.

How Does the Locking Hasp Compare as an Alternative?

The locking hasp provides an added layer of security, making it an excellent choice for pontoon boats that may be left unattended or in high-risk areas. It allows users to secure the gate with a padlock, which can deter unauthorized access effectively. However, installation can be more complex, often requiring drilling into the boat’s frame, and regular maintenance is necessary to ensure the lock functions properly. The cost is generally lower than that of a slam latch, making it an appealing option for buyers looking for budget-friendly security solutions.

Conclusion: How Can B2B Buyers Choose the Right Solution?

Selecting the appropriate door latch for pontoon boats depends on several factors, including the specific operational needs of the boat, budget constraints, and security requirements. Buyers should consider the traffic frequency of the gate, the importance of security, and the ease of installation when making their decision. While the standard pontoon boat door latch is a reliable and cost-effective choice for many, alternatives like the slam latch and locking hasp may be better suited for specialized applications. Ultimately, evaluating these options against the operational context will help B2B buyers make informed decisions that enhance the functionality and safety of their pontoon boats.

Essential Technical Properties and Trade Terminology for pontoon boat door latch

What Are the Key Technical Properties of a Pontoon Boat Door Latch?

When selecting a pontoon boat door latch, understanding its technical specifications is crucial for ensuring durability, reliability, and compatibility with your boat’s design. Here are some key properties to consider:

-

Material Composition:

Most pontoon boat door latches are constructed from nylon or marine-grade plastics. These materials are favored for their resistance to corrosion, UV rays, and impact, which is essential for marine applications. For B2B buyers, investing in high-quality materials can lead to longer product lifespans and reduced replacement costs. -

Size Compatibility:

The latches typically fit square tubing sizes of 1″, 1 1/8″, and 1 1/4″. This versatility allows the latch to be compatible with various pontoon models and designs. B2B buyers should ensure that the latch fits the specific dimensions of their boats to avoid installation issues. -

Hinge Orientation:

Many latches are designed to operate with both right and left hinged gates. This feature enhances flexibility and ease of installation, making it easier for manufacturers to cater to diverse customer preferences. From a purchasing perspective, this adaptability can streamline inventory management and reduce the need for multiple products. -

Preventive Features:

Effective latches often include mechanisms to prevent gates from swinging inward or rattling. Such features contribute to the safety and comfort of boat users. Buyers should prioritize latches that offer these enhancements, as they can significantly improve the user experience on the water. -

Installation Simplicity:

Latches that are designed for easy installation, with all parts mounting directly on the gate, are beneficial for both manufacturers and end-users. This attribute reduces labor costs and installation time, making it an important consideration in B2B transactions. -

Warranty and Durability:

A manufacturer-backed warranty, such as a six-year guarantee, indicates confidence in the product’s durability. B2B buyers should evaluate warranty offerings as they reflect the manufacturer’s commitment to quality and customer satisfaction.

What Are the Common Trade Terms Related to Pontoon Boat Door Latches?

Familiarity with industry terminology is essential for effective communication and negotiation in B2B transactions. Here are several key terms relevant to the pontoon boat door latch market:

-

OEM (Original Equipment Manufacturer):

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reliable suppliers who can provide quality latches compatible with their boat designs. -

MOQ (Minimum Order Quantity):

MOQ defines the smallest number of units a supplier is willing to sell. For buyers, knowing the MOQ is crucial for budgeting and inventory planning, especially when entering new markets or launching new products. -

RFQ (Request for Quotation):

An RFQ is a document sent to suppliers asking for price quotes on specific products. It is a vital tool for buyers to compare prices and terms from multiple vendors, ensuring they secure the best deal for pontoon boat latches. -

Incoterms:

Short for International Commercial Terms, these terms define the responsibilities of buyers and sellers regarding shipping and delivery. Familiarity with Incoterms helps buyers understand shipping costs and risks, which can significantly impact overall pricing. -

Lead Time:

This term refers to the time between placing an order and receiving the product. Understanding lead times is essential for planning inventory and ensuring timely availability of pontoon boat latches for customer demands. -

Durability Testing:

This refers to the assessment of a product’s lifespan under various conditions. Buyers should inquire about durability testing results to ensure that the latches can withstand harsh marine environments.

By focusing on these technical specifications and trade terms, B2B buyers can make informed decisions when sourcing pontoon boat door latches, ensuring they choose the right products for their needs.

Navigating Market Dynamics and Sourcing Trends in the pontoon boat door latch Sector

What Are the Key Market Dynamics and Trends in the Pontoon Boat Door Latch Sector?

The pontoon boat door latch market is witnessing notable growth, driven by a surge in recreational boating and leisure activities globally. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe increasingly invest in marine equipment, understanding key market dynamics becomes essential. The demand for reliable and durable door latches is on the rise due to heightened safety standards and the need for effective gate management systems on pontoon boats.

Emerging trends indicate a shift towards advanced materials and designs that enhance functionality while maintaining aesthetic appeal. Manufacturers are increasingly adopting nylon and other lightweight materials, which not only improve durability but also reduce noise—a common issue with traditional metal latches. Additionally, innovations in manufacturing processes, such as 3D printing, are enabling companies to create customized solutions that meet specific regional needs, thus enhancing buyer engagement.

International buyers should also be aware of regional preferences and requirements. For instance, buyers from Nigeria may prioritize cost-effectiveness and ease of installation, while those in Saudi Arabia might focus on high durability and design aesthetics. Understanding these nuances can help suppliers tailor their offerings to meet diverse market demands, ultimately fostering stronger B2B relationships.

How Can Sustainability and Ethical Sourcing Impact the Pontoon Boat Door Latch Market?

Sustainability is becoming a pivotal factor in the pontoon boat door latch sector, as environmental concerns influence purchasing decisions. Buyers are increasingly looking for products that minimize environmental impact, emphasizing the importance of ethical sourcing and sustainable practices. This trend is particularly relevant in markets like Europe, where consumers are more conscious of the ecological footprint of their purchases.

Incorporating ‘green’ certifications and materials can significantly enhance the appeal of pontoon boat door latches. For instance, using recycled plastics or responsibly sourced materials not only appeals to environmentally conscious buyers but can also qualify products for green certifications, enhancing marketability. Suppliers that prioritize sustainability in their manufacturing processes may find themselves at a competitive advantage, as they can cater to a growing segment of buyers who prioritize eco-friendly practices.

Moreover, establishing transparent supply chains is essential. Buyers are increasingly demanding visibility into the sourcing of materials and the ethical standards of manufacturers. Companies that can demonstrate commitment to ethical labor practices and environmental stewardship will likely foster trust and loyalty among B2B customers, resulting in long-term partnerships.

What Is the Evolution of the Pontoon Boat Door Latch Sector?

The evolution of pontoon boat door latches reflects broader trends in marine hardware development. Historically, door latches were primarily made from metal, focusing on functionality and security. However, as boating has transitioned into a leisure activity for many, aesthetics, ease of use, and noise reduction have gained prominence.

In the past two decades, advancements in materials technology have introduced durable alternatives like nylon, which offers advantages in weight and noise reduction while maintaining strength. This shift has been driven by the need for better performance in diverse marine environments, particularly in regions with varying weather conditions, such as the Middle East and South America.

Furthermore, the integration of technology into marine hardware is on the rise, with smart latching systems beginning to emerge. These innovations not only improve security but also enhance user experience, paving the way for future developments in the pontoon boat door latch market. As the industry continues to evolve, B2B buyers must stay informed about these trends to make strategic sourcing decisions that align with their business goals.

Frequently Asked Questions (FAQs) for B2B Buyers of pontoon boat door latch

-

How do I select the right pontoon boat door latch for my needs?

Choosing the right pontoon boat door latch involves considering the gate’s size and hinge orientation. Most latches fit square tubes of 1″, 1 1/8″, or 1 1/4″. Ensure compatibility with both right and left-hinged gates, as this flexibility can be crucial for installation. Additionally, consider the material; nylon latches are durable and help prevent rattling. Review product specifications from various suppliers to ensure they meet your operational requirements, and don’t hesitate to reach out for samples if necessary. -

What is the best material for a pontoon boat door latch?

Nylon and stainless steel are among the best materials for pontoon boat door latches. Nylon latches are lightweight, resistant to corrosion, and effective in preventing rattling, making them ideal for marine environments. Stainless steel offers superior strength and durability, providing added security. When sourcing latches, consider the specific conditions they will face, such as exposure to saltwater or heavy usage, to choose the most suitable material. -

What are the common features to look for in pontoon boat door latches?

Key features to consider include compatibility with various gate sizes, ease of installation, and the ability to prevent inward swinging. Look for latches that can be installed entirely on the gate, as this simplifies the installation process. Additional features such as anti-rattle designs and warranties can also enhance product reliability. Always review technical specifications and customer feedback to ensure the latch meets your specific boating requirements. -

How can I ensure the quality of pontoon boat door latches from suppliers?

To ensure quality, conduct thorough supplier vetting. Start by checking their certifications and quality assurance processes. Request samples to evaluate the product firsthand and review customer testimonials or case studies. Additionally, consider suppliers that offer warranties, as this indicates confidence in their products. Engaging in direct communication with suppliers about their manufacturing processes can also provide insights into their quality control measures. -

What are the typical minimum order quantities (MOQs) for pontoon boat door latches?

Minimum order quantities can vary significantly between suppliers, often ranging from 50 to 500 units. Some manufacturers may accommodate smaller orders, particularly for new buyers or trial orders. It’s essential to discuss MOQs upfront during negotiations to ensure they align with your purchasing strategy. Additionally, consider the potential for bulk purchasing discounts, which can lead to cost savings over time. -

What payment terms should I expect when sourcing pontoon boat door latches internationally?

Payment terms can vary based on the supplier and your negotiation. Common practices include payment in advance, letters of credit, or 30-60 days net payment terms after delivery. It’s crucial to establish clear terms before finalizing the order, as this can impact your cash flow. Be cautious about upfront payments; consider using escrow services for larger orders to mitigate risks. -

How do I handle logistics and shipping for pontoon boat door latches?

When planning logistics, consider the shipping method that best balances cost and delivery time. Air freight is faster but more expensive, while sea freight is economical for larger orders but takes longer. Work with suppliers who have experience in international shipping and can provide necessary documentation like bills of lading and customs paperwork. Also, factor in duties and tariffs that may apply to your region to avoid unexpected costs. -

What should I do if there are issues with my order of pontoon boat door latches?

In case of issues, promptly contact the supplier to discuss the problem, whether it involves defective products or incorrect quantities. Most reputable suppliers have return and exchange policies, so familiarize yourself with these terms beforehand. Document the issues with photos and detailed descriptions to facilitate resolution. If the supplier does not respond satisfactorily, consider escalating the matter through relevant trade organizations or consumer protection agencies.

Top 3 Pontoon Boat Door Latch Manufacturers & Suppliers List

1. Overton’s – Pontoon Boat Safety Gate Latches

Domain: overtons.com

Registered: 1996 (29 years)

Introduction: This company, Overton’s – Pontoon Boat Safety Gate Latches, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. T-H Marine Supplies – Pontoon Gate Latch

Domain: thmarinesupplies.com

Registered: 2017 (8 years)

Introduction: Pontoon Gate Latch by T-H Marine Supplies, SKU: GL-1-DP. Features easy installation and reliable functionality for boat gates. Compatible with right or left hinged gates and fits square tubes of 1″, 1 1/8″, or 1 1/4″. Made from nylon to prevent rattling and ensure durability. All parts install directly on the gate. Requires #10 x 1 1/4″ phillips oval stainless screws and one #10 1 1/2″ phillips ov…

3. Boat Outfitters – Marine Latches

Domain: boatoutfitters.com

Registered: 2002 (23 years)

Introduction: Marine latches are essential for securing boat doors, lids, and hatches. Types include: 1. Flush/Slam Latches – for storage unit doors, livewell lids, console and access doors. 2. Push Button Latches – for smaller access doors like electronic box lids and glove boxes. 3. Cam/Compression Latches – for larger access doors and deck hatches, allowing access with one hand. 4. Draw Latches – for hatch h…

Strategic Sourcing Conclusion and Outlook for pontoon boat door latch

As the global demand for pontoon boats continues to rise, the importance of strategic sourcing for components like door latches becomes increasingly clear. Buyers should prioritize suppliers that offer durable, reliable products tailored for various gate configurations, ensuring they meet the needs of diverse markets. The emphasis on quality materials, such as nylon molded parts that prevent rattling and enhance longevity, is essential for maintaining customer satisfaction and minimizing returns.

Moreover, understanding regional preferences and compliance with local maritime regulations can enhance sourcing strategies, especially for international markets in Africa, South America, the Middle East, and Europe. Engaging with suppliers who provide comprehensive warranties, such as the 6-year guarantees seen in some products, can further strengthen buyer confidence and promote long-term partnerships.

Illustrative image related to pontoon boat door latch

Looking ahead, as the pontoon boat industry evolves, it is crucial for B2B buyers to stay informed about emerging trends and innovations in marine hardware. By fostering strong relationships with manufacturers and leveraging strategic sourcing practices, businesses can not only enhance their product offerings but also position themselves as leaders in a competitive market. Now is the time to take action—explore reliable suppliers and invest in high-quality pontoon boat door latches to meet the growing demands of your customers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.