How to Source Aluminum Sheet Metal 4X8 Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for aluminum sheet metal 4×8

In the dynamic landscape of international trade, sourcing aluminum sheet metal 4×8 can pose significant challenges for B2B buyers, particularly those operating in diverse markets across Africa, South America, the Middle East, and Europe. With varying standards, suppliers, and applications, navigating this global marketplace requires a thorough understanding of the product’s specifications and potential uses. This guide aims to demystify the complexities of sourcing aluminum sheet metal, equipping decision-makers with the insights needed to make informed purchasing choices.

Throughout this comprehensive guide, we will explore various types of aluminum sheets, including popular alloys like 3003, 5052, and 6061, each suited for distinct applications ranging from automotive to construction. We will delve into practical applications, highlighting how different grades and finishes can enhance product functionality and aesthetic appeal. Furthermore, the guide will provide a framework for vetting suppliers, ensuring that buyers can confidently select partners who meet their quality and service expectations.

In addition to cost considerations, we will address logistical challenges, such as shipping and lead times, that can impact procurement decisions. By the end of this guide, international B2B buyers will be empowered to navigate the complexities of the aluminum sheet metal market, fostering successful sourcing strategies that align with their operational goals and regional requirements.

Understanding aluminum sheet metal 4×8 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 3003 Aluminum Sheet | Good corrosion resistance, excellent workability, moderate strength | Cooking utensils, chemical equipment | Pros: Lightweight, easy to fabricate. Cons: Lower strength compared to other alloys. |

| 5052 Aluminum Sheet | High strength, excellent corrosion resistance, good weldability | Marine applications, automotive parts | Pros: Superior durability, ideal for harsh environments. Cons: More expensive than 3003. |

| 6061 Aluminum Sheet | Versatile, good mechanical properties, excellent weldability | Structural applications, aerospace | Pros: High strength-to-weight ratio, good corrosion resistance. Cons: Requires more processing. |

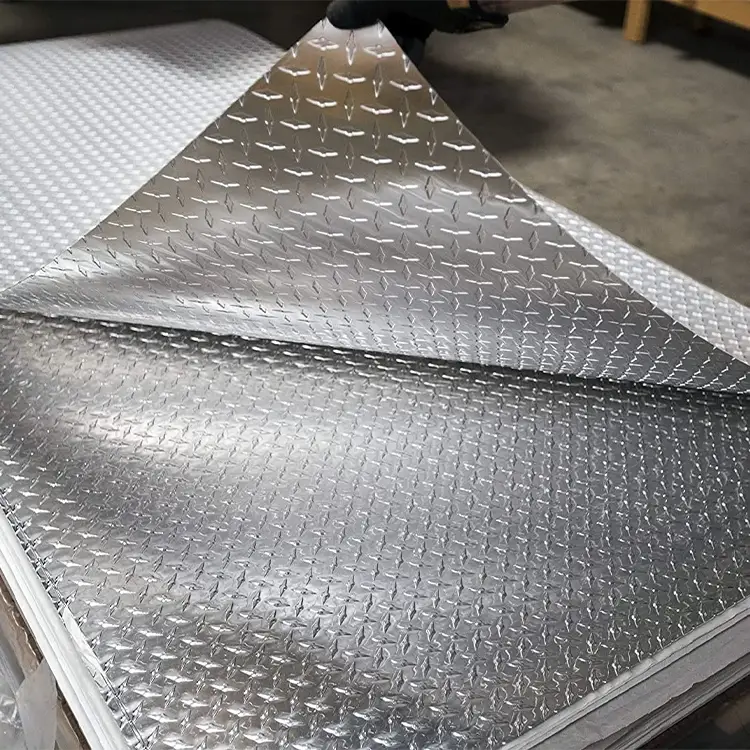

| Embossed Aluminum | Textured surface for aesthetic appeal and slip resistance | Decorative applications, wall coverings | Pros: Enhances appearance, easy to install. Cons: May have limited structural applications. |

| Diamond Plate | Raised surface pattern for enhanced grip and durability | Flooring, truck beds, industrial uses | Pros: Highly durable, slip-resistant. Cons: Heavier and may be more challenging to cut. |

What Are the Characteristics of 3003 Aluminum Sheets?

3003 aluminum sheets are known for their excellent workability and moderate strength. With a good balance of corrosion resistance, these sheets are commonly used in applications such as cooking utensils and chemical equipment. When considering B2B purchases, buyers should note that while 3003 sheets are lightweight and easy to fabricate, they do not offer the same strength as other aluminum alloys, making them less suitable for heavy-duty applications.

Why Choose 5052 Aluminum Sheets for B2B Applications?

5052 aluminum sheets are recognized for their high strength and superior corrosion resistance, making them ideal for marine and automotive applications. Their excellent weldability allows for versatile fabrication options. For B2B buyers, the durability of 5052 sheets in harsh environments is a significant advantage; however, they come at a higher price point than 3003 sheets, which could affect budget considerations.

What Makes 6061 Aluminum Sheets a Popular Choice?

6061 aluminum sheets are versatile and exhibit good mechanical properties, making them suitable for structural applications and aerospace components. Their excellent weldability and corrosion resistance enhance their appeal in various industries. B2B buyers should consider that while 6061 sheets provide a high strength-to-weight ratio, they may require more processing time and costs, impacting overall project timelines.

How Can Embossed Aluminum Sheets Enhance Aesthetic Appeal?

Embossed aluminum sheets feature a textured surface that not only provides aesthetic appeal but also enhances slip resistance, making them popular for decorative applications and wall coverings. For B2B buyers, these sheets are easy to install and can significantly elevate the visual impact of a project. However, their structural capabilities are limited compared to standard aluminum sheets, which should be considered when selecting materials.

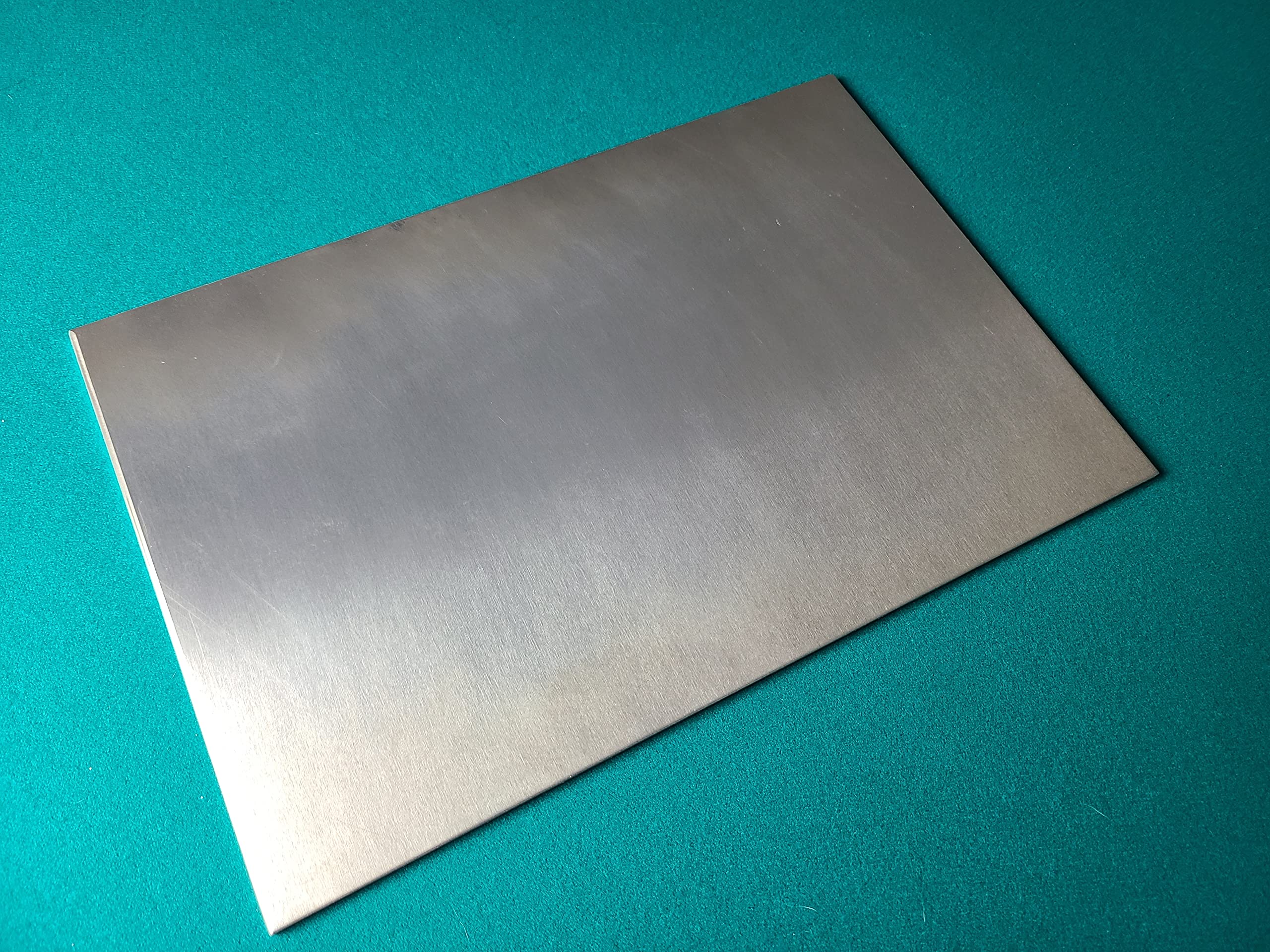

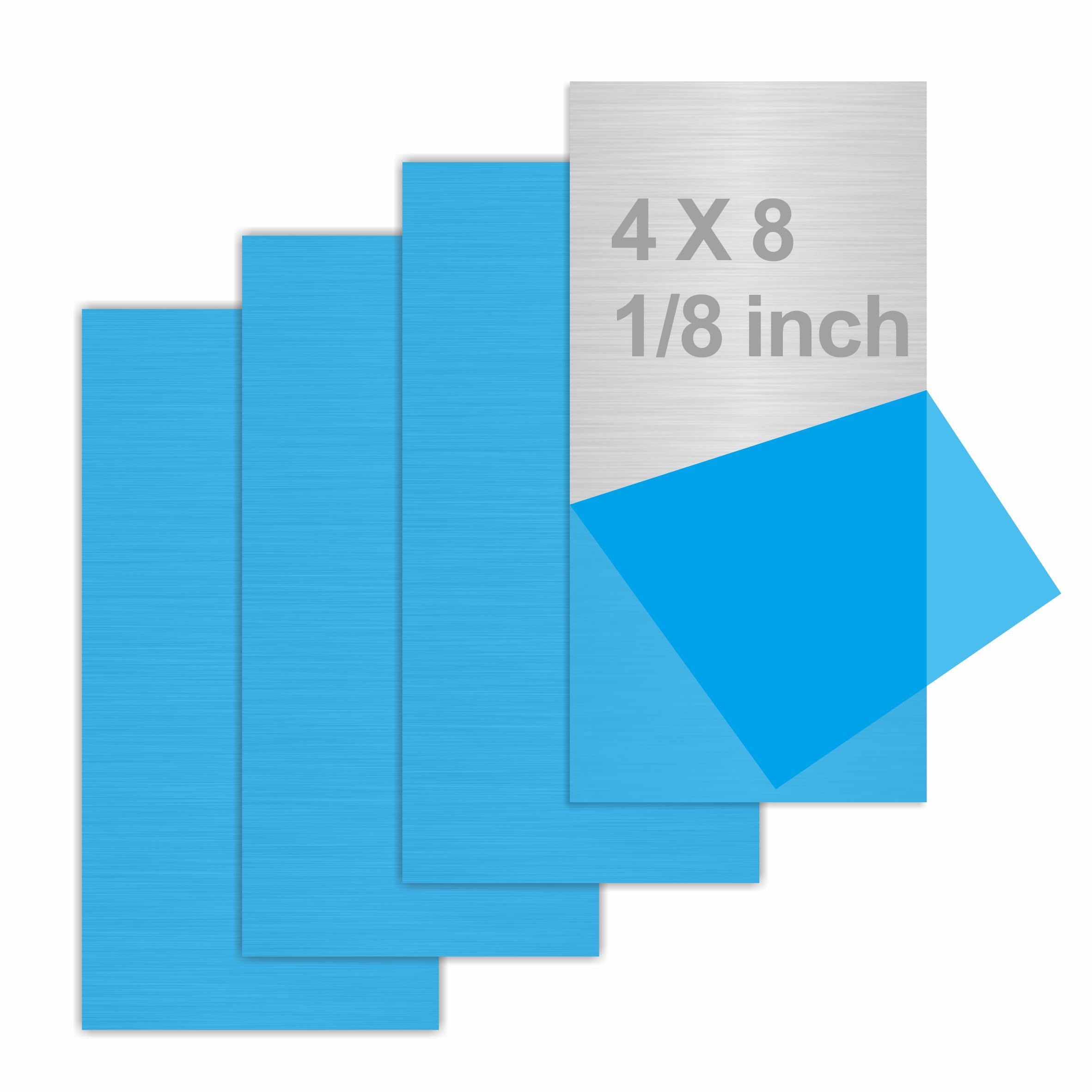

Illustrative image related to aluminum sheet metal 4×8

When Should You Use Diamond Plate Aluminum Sheets?

Diamond plate aluminum sheets are characterized by their raised surface pattern, which offers enhanced grip and durability, making them ideal for flooring and industrial applications. B2B buyers appreciate the slip-resistant properties and robustness of diamond plates; however, they are heavier and may be more challenging to cut compared to other aluminum types. This could influence logistics and installation processes in various projects.

Key Industrial Applications of aluminum sheet metal 4×8

| Industry/Sector | Specific Application of aluminum sheet metal 4×8 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Body panels and structural components | Lightweight, corrosion-resistant materials enhance vehicle efficiency and lifespan. | Ensure compliance with local regulations and quality standards. |

| Construction | Wall cladding and roofing systems | Provides durability and aesthetic appeal, reducing maintenance costs over time. | Look for suppliers with customizable options and local delivery capabilities. |

| Marine | Boat hulls and components | Excellent corrosion resistance in harsh marine environments extends product life. | Source from manufacturers with experience in marine-grade materials. |

| Food Processing | Equipment and structural supports | Non-reactive properties ensure food safety and hygiene. | Verify certifications for food-grade applications and easy cleaning. |

| HVAC | Ductwork and enclosures | Lightweight yet strong, improving energy efficiency and installation ease. | Consider thermal conductivity and insulation properties in sourcing. |

How is Aluminum Sheet Metal 4×8 Used in the Automotive Industry?

In the automotive sector, aluminum sheet metal 4×8 is predominantly utilized for body panels and structural components. The lightweight nature of aluminum contributes to enhanced fuel efficiency, while its corrosion resistance ensures a longer lifespan for vehicles. International buyers, particularly from regions like Europe and South America, must ensure that the materials meet local safety and quality standards, which can vary significantly by country. Sourcing from reputable suppliers who can provide certifications and compliance documentation is crucial.

What Role Does Aluminum Sheet Metal 4×8 Play in Construction?

In construction, aluminum sheet metal 4×8 serves as wall cladding and roofing material, offering both durability and aesthetic appeal. Its resistance to rust and corrosion significantly reduces maintenance costs, making it a cost-effective choice for long-term projects. For B2B buyers in Africa and the Middle East, it’s vital to consider local climatic conditions when selecting aluminum grades and finishes. Additionally, sourcing partners should be able to provide customized solutions to meet specific architectural designs.

Why is Aluminum Sheet Metal 4×8 Essential in the Marine Sector?

The marine industry heavily relies on aluminum sheet metal 4×8 for constructing boat hulls and various components due to its superior corrosion resistance in saltwater environments. This property not only extends the life of marine vessels but also minimizes maintenance needs, which is a significant cost-saving factor for businesses. International buyers should prioritize sourcing from manufacturers experienced in producing marine-grade aluminum, ensuring the materials meet stringent maritime regulations.

How is Aluminum Sheet Metal 4×8 Used in Food Processing?

In food processing facilities, aluminum sheet metal 4×8 is used for equipment and structural supports, thanks to its non-reactive properties that ensure food safety and hygiene. This application is critical in maintaining compliance with health regulations. Buyers in this sector, especially in regions like South America and Africa, should verify that the aluminum sourced is certified for food-grade applications and can withstand rigorous cleaning processes.

What are the Benefits of Aluminum Sheet Metal 4×8 in HVAC Applications?

In HVAC systems, aluminum sheet metal 4×8 is commonly used for ductwork and enclosures. Its lightweight yet strong composition enhances energy efficiency and simplifies installation processes. For businesses in Europe and the Middle East, it is essential to consider the thermal conductivity and insulation properties of the aluminum when sourcing. Working with suppliers who understand local HVAC standards can lead to better product performance and reduced energy costs.

3 Common User Pain Points for ‘aluminum sheet metal 4×8’ & Their Solutions

Scenario 1: Difficulty in Finding the Right Thickness for Specific Applications

The Problem: B2B buyers often struggle to determine the appropriate thickness of aluminum sheet metal for their projects. Selecting a sheet that is too thin can compromise structural integrity, while choosing one that is too thick may lead to unnecessary costs and difficulties in handling. This is especially true for industries like construction, automotive, and manufacturing, where specific material properties are crucial for performance and safety.

The Solution: To effectively address this issue, buyers should first assess their project requirements, including load-bearing capacity, environmental conditions, and the intended use of the aluminum sheets. For instance, if the application involves high-stress environments, opting for a thicker gauge (such as 0.063 inches for heavy-duty applications) is advisable. Buyers can leverage product specifications from reputable suppliers, comparing options such as 3003, 5052, and 6061 alloys to find the right balance of strength, weight, and cost. It’s beneficial to consult with suppliers who offer customization services, allowing for tailored solutions that meet exact specifications. Additionally, using tools such as load calculators can help in making informed decisions on thickness.

Illustrative image related to aluminum sheet metal 4×8

Scenario 2: Long Lead Times and Availability Issues

The Problem: Many B2B buyers face frustration when dealing with long lead times and stock availability, particularly when sourcing 4×8 aluminum sheets from international suppliers. Delays can disrupt production schedules, leading to increased costs and missed deadlines, which can ultimately impact client satisfaction and business reputation.

The Solution: To mitigate this challenge, buyers should establish relationships with multiple suppliers across different regions. By diversifying their sourcing strategy, they can better manage supply chain disruptions and ensure quicker access to materials. It’s also advisable to maintain an inventory of essential materials to avoid production halts. When placing orders, buyers should inquire about lead times upfront and consider negotiating contracts that include expedited shipping options. Utilizing local suppliers, when feasible, can also reduce shipping times and costs. Lastly, staying informed about market trends and potential supply chain issues can help buyers anticipate delays and plan accordingly.

Scenario 3: Challenges in Fabrication and Customization

The Problem: B2B buyers often encounter difficulties when it comes to fabricating aluminum sheets to meet specific design requirements. Challenges may arise in cutting, bending, or finishing the aluminum, particularly for complex projects that demand precision. This can lead to wasted materials and increased labor costs, impacting overall project efficiency.

The Solution: To overcome fabrication challenges, buyers should consider working with suppliers that offer value-added services, such as custom cutting, CNC machining, or fabrication support. These services can save time and reduce material waste. Additionally, buyers should familiarize themselves with the best practices for working with aluminum, including the appropriate tools and techniques for cutting and forming. For example, using laser cutting can provide clean edges and precise dimensions, while ensuring that the correct type of adhesive or fasteners are used can enhance the integrity of assembled structures. Investing in training for staff on aluminum handling and processing techniques can also yield significant efficiency gains and improve overall project outcomes.

Strategic Material Selection Guide for aluminum sheet metal 4×8

What Are the Key Properties of Common Aluminum Alloys for Sheet Metal Applications?

When selecting aluminum sheet metal, particularly in the 4×8 size, understanding the properties of various alloys is essential for ensuring optimal performance in specific applications. The most common alloys used in aluminum sheet metal include 3003, 5052, and 6061. Each alloy has unique characteristics that make it suitable for different uses.

Illustrative image related to aluminum sheet metal 4×8

How Do Aluminum Alloys 3003, 5052, and 6061 Compare in Terms of Performance?

3003 Aluminum Alloy

3003 is a commercially pure aluminum alloy known for its excellent workability and moderate strength. It exhibits good corrosion resistance and is easily welded and formed. However, it is not suitable for applications requiring high strength or heat treatment. This alloy is often used in chemical and food processing industries due to its non-toxic nature and resistance to corrosion.

Pros:

– Excellent corrosion resistance

– Good formability and weldability

– Cost-effective for moderate strength applications

Cons:

– Limited strength compared to other alloys

– Not suitable for high-temperature applications

Impact on Application:

Ideal for applications involving food and chemical processing, where corrosion resistance is critical.

Considerations for International Buyers:

Compliance with standards like ASTM and DIN is crucial, especially in industries with strict regulations. Buyers in regions like Europe may prefer materials that meet specific environmental and safety standards.

Illustrative image related to aluminum sheet metal 4×8

5052 Aluminum Alloy

5052 is known for its high strength and excellent corrosion resistance, particularly in marine environments. It is often used in applications requiring durability and resistance to saltwater. The alloy also has good weldability and formability, making it suitable for complex shapes.

Pros:

– Superior corrosion resistance

– High strength and durability

– Excellent weldability

Cons:

– Higher cost compared to 3003

– Limited availability in certain regions

Impact on Application:

Well-suited for marine and automotive applications where strength and resistance to harsh environments are necessary.

Considerations for International Buyers:

Buyers should ensure that the 5052 alloy meets local standards and certifications, particularly in maritime applications where compliance with international maritime regulations is essential.

Illustrative image related to aluminum sheet metal 4×8

6061 Aluminum Alloy

6061 is a versatile alloy that offers good mechanical properties and is commonly used in structural applications. It has excellent corrosion resistance and can be heat-treated to enhance its strength. This alloy is widely used in construction, automotive, and aerospace applications.

Pros:

– High strength-to-weight ratio

– Excellent corrosion resistance

– Suitable for heat treatment

Cons:

– More expensive than 3003 and 5052

– Requires more complex manufacturing processes

Impact on Application:

Ideal for applications requiring structural integrity and lightweight materials, such as in aerospace and automotive industries.

Considerations for International Buyers:

Ensure that the alloy meets relevant international standards for structural applications, such as ASTM and JIS, especially in regions like Germany where stringent regulations are enforced.

Summary of Material Selection for Aluminum Sheet Metal 4×8

| Material | Typical Use Case for aluminum sheet metal 4×8 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| 3003 | Food processing, chemical handling | Excellent corrosion resistance | Limited strength | Low |

| 5052 | Marine and automotive applications | High strength and corrosion resistance | Higher cost | Medium |

| 6061 | Structural applications in aerospace and automotive | High strength-to-weight ratio | More complex manufacturing | High |

This guide provides a comprehensive overview of the key aluminum alloys used in 4×8 sheet metal applications, highlighting their properties, advantages, and limitations. By understanding these factors, international B2B buyers can make informed decisions that align with their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for aluminum sheet metal 4×8

What Are the Main Stages in the Manufacturing Process of Aluminum Sheet Metal 4×8?

The manufacturing process of aluminum sheet metal, particularly the 4×8 size, involves several critical stages. Understanding these stages is essential for B2B buyers to ensure they are sourcing high-quality materials.

Material Preparation

The first stage in the manufacturing process is material preparation, where raw aluminum ingots are melted and cast into slabs. The aluminum alloy is selected based on the desired properties, such as strength, corrosion resistance, and workability. Common alloys for sheet metal production include 3003, 5052, and 6061, each offering unique characteristics suitable for various applications.

Once the aluminum is cast, it is rolled into sheets. This rolling process can be hot or cold, depending on the desired thickness and mechanical properties. Hot rolling is typically used for thicker sheets, while cold rolling is preferred for achieving tighter tolerances and a finer surface finish.

Forming Techniques

After material preparation, the next stage is forming, which involves shaping the aluminum sheets into the required dimensions. Common techniques used in this stage include:

Illustrative image related to aluminum sheet metal 4×8

-

Stamping: This method uses a die to cut and shape the aluminum sheets into specific forms. It is particularly useful for producing complex shapes and is often employed in automotive and aerospace applications.

-

Shearing: A process that involves cutting the aluminum sheets to size using a shear machine. This technique is efficient for producing straight cuts and is widely used in fabricating components.

-

Bending: This process involves applying force to the aluminum sheets to create angles or curves. Bending is crucial for applications that require specific geometries, such as brackets and frames.

Assembly and Finishing Processes

Once the sheets are formed, they may undergo assembly processes if they are part of larger components or products. Assembly may involve welding, riveting, or using adhesives, depending on the application.

The finishing stage includes surface treatments to enhance durability and aesthetics. Common finishing processes for aluminum sheets include:

-

Anodizing: This electrochemical process increases corrosion resistance and allows for various color finishes.

-

Painting: Applying a protective and decorative layer using powder coating or liquid paint enhances the appearance and durability of aluminum sheets.

-

Brushing or Polishing: These techniques improve the surface finish and are often used for decorative applications.

What Quality Assurance Measures Are Essential for Aluminum Sheet Metal?

Quality assurance (QA) is paramount in the manufacturing of aluminum sheet metal, especially for international B2B buyers. It ensures that the materials meet specific standards and specifications, which is critical for performance and safety.

International and Industry-Specific Standards

Aluminum sheet manufacturers typically adhere to several international standards to ensure quality. The ISO 9001 standard is widely recognized and focuses on quality management systems, ensuring consistent quality in products and services. Additionally, industry-specific standards such as CE marking in Europe and API standards in oil and gas applications provide further assurance of quality.

Quality Control Checkpoints

Quality control (QC) checkpoints are implemented throughout the manufacturing process to maintain high standards. Key checkpoints include:

-

Incoming Quality Control (IQC): This initial stage checks raw materials upon arrival to ensure they meet specified requirements.

-

In-Process Quality Control (IPQC): Ongoing inspections are conducted during the manufacturing process to identify defects or deviations in real-time. This proactive approach minimizes waste and ensures consistent quality.

-

Final Quality Control (FQC): Once the manufacturing process is complete, a final inspection is performed to verify that the finished aluminum sheets meet all specifications and standards before shipping.

Common Testing Methods for Quality Assurance

Various testing methods are employed to assess the quality of aluminum sheet metal. These may include:

-

Mechanical Testing: Assessing properties such as tensile strength, yield strength, and elongation to determine the material’s performance under stress.

-

Chemical Analysis: Verifying the composition of the aluminum alloy to ensure it meets the specified standards.

-

Visual Inspection: Conducting a thorough examination of the surface for defects, such as scratches, dents, or discoloration.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is crucial. Here are actionable steps to ensure quality assurance:

Conduct Supplier Audits

Regular audits of potential suppliers can provide insights into their manufacturing processes, quality control measures, and compliance with international standards. These audits can be performed in person or through remote assessments, depending on logistical considerations.

Request Quality Reports and Certifications

Buyers should request quality reports and certifications from suppliers, including ISO 9001 and any relevant industry-specific certifications. These documents provide evidence of the supplier’s commitment to quality and adherence to international standards.

Utilize Third-Party Inspection Services

Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control processes. These services can perform inspections at various stages of production, ensuring that the materials meet the buyer’s specifications before shipment.

What Are the QC and Certification Nuances for International B2B Buyers?

International buyers must navigate specific nuances when it comes to quality control and certification. Here are key considerations:

-

Understanding Regional Standards: Different regions may have varying standards and regulations. For instance, CE marking is crucial for products sold in Europe, while other regions may have their own specific requirements.

-

Documentation for Customs: Proper documentation, including certificates of conformity and quality reports, is essential for smooth customs clearance. International buyers should ensure that their suppliers provide all necessary documentation.

-

Cultural Considerations: Building strong relationships with suppliers can facilitate better communication regarding quality expectations and standards. Understanding cultural nuances can aid in negotiations and foster trust.

By thoroughly understanding the manufacturing processes and quality assurance measures in the production of aluminum sheet metal, B2B buyers can make informed decisions and ensure they are sourcing high-quality materials that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘aluminum sheet metal 4×8’

This guide is designed to assist B2B buyers in the effective sourcing of aluminum sheet metal in the standard 4×8 size. By following these actionable steps, you can ensure a streamlined procurement process that meets your technical needs and aligns with your business objectives.

Step 1: Define Your Technical Specifications

Understanding your technical requirements is crucial for selecting the right aluminum sheet metal. Consider factors such as the alloy type (e.g., 3003, 5052, 6061) and thickness (common options include .025″, .063″, and .125″). Each alloy has specific properties; for instance, 5052 offers superior corrosion resistance, making it ideal for marine applications.

Step 2: Determine Your Quantity Needs

Before reaching out to suppliers, assess how much aluminum sheet metal you require. Bulk orders often lead to better pricing and more favorable shipping terms. Be clear about whether you need standard sheets or custom sizes, as this can affect lead times and availability.

Step 3: Research Potential Suppliers

Conduct thorough research on potential suppliers to ensure they meet your quality and service standards. Look for companies that specialize in aluminum products and have a proven track record in your industry. Key aspects to evaluate include:

– Company history and reputation.

– Customer reviews and testimonials.

– Certifications (e.g., ISO) that indicate adherence to quality standards.

Step 4: Request Samples

Before making a large commitment, request samples of the aluminum sheets to assess quality and suitability for your application. This step allows you to evaluate the material’s finish, thickness, and overall performance. Ensure that the supplier can provide samples in the exact specifications you require.

Step 5: Verify Supplier Certifications

Ensure that your chosen suppliers hold the necessary certifications and comply with international standards. Certifications such as ISO 9001 for quality management systems can be indicators of a reliable supplier. This step mitigates risks associated with poor-quality materials that could impact your end products.

Step 6: Assess Pricing and Payment Terms

Gather quotes from multiple suppliers to compare pricing. Be sure to consider not just the base price but also shipping costs and payment terms. Some suppliers may offer discounts for bulk orders or favorable payment conditions that can improve your cash flow.

Illustrative image related to aluminum sheet metal 4×8

Step 7: Evaluate Lead Times and Delivery Options

Understanding lead times is essential for planning your production schedules. Discuss delivery options with potential suppliers, especially if you have tight deadlines. Inquire about their capacity to handle urgent orders and ensure that they have robust logistics in place for international shipping.

By systematically following these steps, you can effectively navigate the procurement of aluminum sheet metal 4×8, ensuring that you choose the right materials and suppliers for your business needs.

Comprehensive Cost and Pricing Analysis for aluminum sheet metal 4×8 Sourcing

What Are the Key Cost Components for Sourcing Aluminum Sheet Metal 4×8?

When analyzing the cost structure for aluminum sheet metal 4×8, several key components come into play. These include material costs, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the supplier’s margin.

Material Costs: The base cost of aluminum varies based on the alloy grade (e.g., 3003, 5052, or 6061) and the thickness of the sheet. Prices typically range from $40 to $150 per sheet, depending on these factors.

Labor and Manufacturing Overhead: Labor costs will depend on the location of the manufacturing facility. For instance, labor is generally more expensive in Europe compared to regions in Africa and South America. Manufacturing overhead includes costs related to utilities, equipment depreciation, and facility maintenance, which can also vary significantly by region.

Tooling and Quality Control: Tooling costs are incurred for the setup and maintenance of machinery required to cut and shape the aluminum sheets. Quality control processes ensure that the sheets meet specific standards and certifications, which may add to the overall cost.

Logistics: Transportation and shipping costs can greatly affect the final price. Factors such as distance, shipping method, and the chosen Incoterms (e.g., FOB, CIF) will influence logistics expenses. Buyers should consider both local and international shipping rates when calculating total costs.

Supplier Margin: Each supplier will have its pricing strategy and margin built into the cost. This margin can vary based on the supplier’s market position, reputation, and demand for aluminum sheet metal.

How Do Price Influencers Impact the Cost of Aluminum Sheet Metal?

Several factors can influence the pricing of aluminum sheet metal, particularly for international buyers.

Volume and Minimum Order Quantity (MOQ): Purchasing larger quantities often leads to lower per-unit prices. Suppliers may offer discounts for bulk orders, making it advantageous for businesses to assess their needs and negotiate accordingly.

Specifications and Customization: Custom requirements such as specific dimensions, finishes, or additional treatments can lead to increased costs. Buyers should clearly define their needs upfront to avoid unexpected expenses later in the procurement process.

Quality and Certifications: Higher quality aluminum sheets, particularly those with certifications like ISO or ASTM standards, may command higher prices. It’s essential for buyers to balance quality with cost, especially if the sheets will be used in critical applications.

Supplier Factors: The reliability and reputation of a supplier can affect pricing. Established suppliers may offer better quality and service but at a premium. It’s crucial to conduct thorough due diligence on potential suppliers to ensure they meet your quality and pricing expectations.

What Tips Can Help International Buyers Optimize Costs?

For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, several strategies can enhance cost efficiency:

Negotiation: Always engage in negotiations with suppliers. Understanding the cost breakdown can empower buyers to negotiate better pricing or terms. Highlighting long-term relationships or repeat business can also strengthen your position.

Total Cost of Ownership (TCO): Consider the total cost beyond the purchase price, including logistics, installation, and maintenance. A lower upfront cost might lead to higher expenses down the line if quality is compromised.

Pricing Nuances: Be aware of currency fluctuations, import duties, and taxes that can impact the overall cost when sourcing internationally. Establishing a clear understanding of these factors can help in budgeting effectively.

Local Sourcing: If possible, consider sourcing from local suppliers to minimize logistics costs and simplify the procurement process. This can also lead to faster turnaround times.

Disclaimer on Indicative Prices

The prices mentioned are indicative and may vary based on market conditions, location, and supplier negotiations. It is advisable for buyers to conduct their research and obtain quotes from multiple suppliers to ensure they are getting the best deal.

Alternatives Analysis: Comparing aluminum sheet metal 4×8 With Other Solutions

Introduction: Understanding Alternatives in Material Selection

When it comes to selecting materials for construction or manufacturing, aluminum sheet metal 4×8 is a popular choice due to its lightweight, durability, and corrosion resistance. However, it is crucial for B2B buyers to explore alternative solutions that may offer similar or enhanced benefits tailored to specific applications. This analysis compares aluminum sheet metal 4×8 with two viable alternatives: galvanized steel sheets and composite aluminum panels.

Comparison Table

| Comparison Aspect | Aluminum Sheet Metal 4×8 | Galvanized Steel Sheets | Composite Aluminum Panels |

|---|---|---|---|

| Performance | High corrosion resistance, lightweight, excellent thermal conductivity | Strong, resistant to rust, heavier | Lightweight, good insulation, aesthetic flexibility |

| Cost | Moderate to high | Generally lower | Higher initial investment |

| Ease of Implementation | Easy to cut and install | Requires specialized tools for cutting | More complex installation due to panel bonding |

| Maintenance | Minimal, but may require surface treatment | Moderate, needs periodic painting to prevent rust | Low, requires occasional cleaning |

| Best Use Case | Automotive, aerospace, and architectural applications | Industrial applications, roofing, and fencing | High-end architectural projects, signage, and interior design |

Detailed Breakdown of Alternatives

Galvanized Steel Sheets

Galvanized steel is steel that has been coated in zinc to prevent rusting, making it a robust alternative to aluminum. The primary advantages of galvanized steel sheets are their strength and lower cost, making them a budget-friendly option for large-scale applications like industrial roofing and fencing. However, they are heavier than aluminum and may require specialized tools for cutting and installation, which can increase labor costs. Additionally, while galvanized steel offers decent corrosion resistance, it may not perform as well as aluminum in highly corrosive environments, such as coastal areas.

Composite Aluminum Panels

Composite aluminum panels consist of two thin layers of aluminum enclosing a non-aluminum core, providing enhanced durability and insulation properties. These panels are often used in high-end architectural projects due to their aesthetic appeal and versatility in design. The lightweight nature of composite panels makes them easy to handle, but their installation can be more complex, often requiring specialized bonding techniques. While they tend to have a higher upfront cost compared to aluminum sheet metal, their longevity and low maintenance can make them a cost-effective solution in the long run, especially in applications where appearance is a critical factor.

Conclusion: Choosing the Right Material for Your Needs

Selecting the right material requires a thorough understanding of the specific application and operational context. Aluminum sheet metal 4×8 offers a balance of lightweight construction and corrosion resistance, making it ideal for a range of applications. However, alternatives like galvanized steel and composite aluminum panels may provide unique benefits that align better with specific project requirements, such as cost considerations or aesthetic preferences. B2B buyers should evaluate these factors meticulously, considering both short-term costs and long-term performance to make informed purchasing decisions.

Essential Technical Properties and Trade Terminology for aluminum sheet metal 4×8

What Are the Essential Technical Properties of Aluminum Sheet Metal 4×8?

When sourcing aluminum sheet metal, especially in the 4×8 size, understanding its technical properties is crucial for making informed purchasing decisions. Here are some key specifications that B2B buyers should consider:

1. Material Grade

Aluminum sheets are available in various grades, with 3003, 5052, and 6061 being the most common. Each grade has distinct characteristics:

– 3003: Known for its excellent workability and corrosion resistance, this grade is often used in applications requiring moderate strength.

– 5052: Offers higher strength and is particularly resistant to saltwater, making it ideal for marine environments.

– 6061: A versatile alloy that combines good mechanical properties with excellent corrosion resistance, suitable for structural applications.

Understanding the appropriate grade helps buyers select the right material for specific applications, ensuring durability and performance.

Illustrative image related to aluminum sheet metal 4×8

2. Thickness

The thickness of aluminum sheets is measured in gauge, with common options for 4×8 sheets ranging from 0.025 inches to 0.125 inches. Thickness impacts both the weight and strength of the material. Thicker sheets provide greater strength and durability, which is essential for structural applications, while thinner sheets are lighter and easier to handle, often used for decorative purposes.

3. Tolerance

Tolerance refers to the permissible limit of variation in dimensions. For aluminum sheets, standard tolerances can range from ±0.005 inches to ±0.010 inches. Accurate tolerances are vital for applications where precise fit is necessary, such as in machining or fabrication processes, ensuring that components fit together seamlessly.

4. Surface Finish

Aluminum sheets come in various surface finishes, including brushed, polished, and embossed. The finish can affect aesthetics, corrosion resistance, and the ability to paint or adhere to other materials. Buyers should consider the intended use and desired appearance when selecting the surface finish.

5. Weight

The weight of aluminum sheets is an important factor, particularly in applications where weight savings are critical, such as in aerospace or automotive industries. The density of aluminum is approximately 0.0975 lb/in³. Understanding the weight helps in logistics planning and cost estimation, particularly in shipping and handling.

What Are Common Trade Terms in the Aluminum Sheet Metal Industry?

Navigating the aluminum sheet metal industry involves familiarizing oneself with specific trade terminology. Here are some essential terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. For buyers, understanding OEM relationships is crucial for ensuring that they are sourcing high-quality materials that meet industry standards.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units that a supplier is willing to sell. This term is important for buyers to understand as it impacts inventory management and budget planning. Knowing the MOQ can help in negotiating better terms or exploring options for bulk purchasing.

Illustrative image related to aluminum sheet metal 4×8

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing for specific quantities and specifications. This process helps buyers compare costs and options, ensuring they receive competitive pricing for their projects.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, particularly concerning shipping and delivery. Familiarity with these terms is essential for managing logistics and understanding cost implications, especially when sourcing from different regions.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. Understanding lead times is critical for project planning, allowing buyers to schedule production and delivery effectively.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions that align with their specific needs and project requirements in the aluminum sheet metal market.

Navigating Market Dynamics and Sourcing Trends in the aluminum sheet metal 4×8 Sector

What Are the Key Trends Influencing the Global Aluminum Sheet Metal 4×8 Market?

The aluminum sheet metal 4×8 market is experiencing significant growth driven by several global factors. The increasing demand for lightweight materials in sectors such as automotive, aerospace, and construction is a primary driver. Aluminum’s excellent strength-to-weight ratio and corrosion resistance make it an attractive option for manufacturers looking to enhance fuel efficiency and reduce emissions. Additionally, emerging markets in Africa and South America, particularly in countries like Brazil, are investing in infrastructure projects, further driving the demand for aluminum products.

Technological advancements are reshaping sourcing trends in the B2B aluminum sector. The rise of digital platforms and e-commerce is facilitating easier access for international buyers to source aluminum sheet metal directly from manufacturers. This trend is particularly beneficial for buyers in regions with limited local suppliers, allowing them to compare prices, quality, and delivery times effectively. Furthermore, the adoption of automated processes in manufacturing is enhancing efficiency and reducing lead times, which is crucial for businesses that operate on tight schedules.

Moreover, sustainability is becoming a core component of sourcing strategies. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to eco-friendly practices, including recycling and reduced carbon footprints. As a result, aluminum suppliers are focusing on improving their sustainability credentials, offering certified green materials that appeal to environmentally conscious buyers in Europe and the Middle East.

How Is Sustainability Shaping the Aluminum Sheet Metal 4×8 Supply Chain?

Sustainability has emerged as a critical consideration in the sourcing of aluminum sheet metal 4×8. The environmental impact of aluminum production is significant, with high energy consumption and greenhouse gas emissions being notable concerns. Consequently, international buyers are increasingly seeking suppliers that adhere to sustainable practices. This includes using recycled aluminum, which can reduce energy use by up to 95% compared to virgin aluminum production.

Ethical sourcing is also gaining traction, with buyers demanding transparency in the supply chain. Certifications such as the Aluminium Stewardship Initiative (ASI) provide assurance that products are sourced responsibly, considering both environmental and social factors. Buyers from regions like Europe, known for their stringent environmental regulations, are particularly focused on these certifications as part of their procurement criteria.

The trend towards sustainability extends to product offerings as well. Manufacturers are developing “green” aluminum materials that boast lower environmental impacts throughout their lifecycle. This includes products with certifications such as LEED (Leadership in Energy and Environmental Design), which can enhance the marketability of aluminum sheet metal in eco-conscious projects.

What Is the Historical Context of the Aluminum Sheet Metal 4×8 Market?

The aluminum sheet metal market has evolved significantly over the past few decades. Initially, aluminum was primarily utilized in the aerospace sector due to its lightweight and durable properties. However, as manufacturing techniques improved and the costs of production decreased, aluminum found its way into a wider array of applications, including automotive, construction, and consumer goods.

The introduction of new aluminum alloys, such as the 3003, 5052, and 6061 grades, expanded the material’s versatility and usability, allowing it to meet various performance requirements across different industries. The 4×8 sheet size became a standard in many markets, facilitating easier handling and installation for a multitude of applications.

Today, the aluminum sheet metal 4×8 market is characterized by a focus on innovation, sustainability, and the integration of technology in sourcing and manufacturing processes, reflecting the broader shifts within the global materials landscape. As international demand continues to grow, particularly in emerging markets, the aluminum sector is poised for further evolution.

Frequently Asked Questions (FAQs) for B2B Buyers of aluminum sheet metal 4×8

-

How do I choose the right aluminum sheet metal thickness for my project?

Selecting the appropriate thickness of aluminum sheet metal is crucial for ensuring durability and functionality. Common thicknesses for 4×8 sheets range from 0.025 inches to 0.063 inches. Consider the specific application: for structural support, thicker sheets (0.063 inches) may be necessary, while decorative applications might suffice with thinner options. Evaluate the environment as well; corrosive settings may require thicker, more resistant materials. Always consult with suppliers for recommendations based on your project’s requirements. -

What is the best aluminum alloy for my industrial application?

For industrial applications, the choice of aluminum alloy significantly impacts performance. The 5052 alloy is favored for its corrosion resistance and strength, making it ideal for marine and automotive uses. The 3003 alloy is a good option for applications requiring moderate strength and excellent workability. If you need high weldability, the 6061 alloy is also a strong contender. Assess your application’s specific needs, such as exposure to chemicals or the requirement for bending and shaping, to determine the best alloy. -

What are the typical minimum order quantities (MOQs) for aluminum sheet metal?

Minimum order quantities for aluminum sheet metal can vary widely by supplier and region. Generally, MOQs range from 100 to 500 sheets for bulk orders. However, some suppliers may accommodate smaller orders, particularly for custom cuts or specialty items. When negotiating with suppliers, inquire about their flexibility on MOQs, especially if your project involves smaller-scale requirements or trial runs. -

What payment terms should I expect when sourcing aluminum sheet metal internationally?

International payment terms can differ significantly based on the supplier and your location. Common terms include advance payment, letters of credit, or payment upon delivery. It’s advisable to establish clear terms before placing an order to avoid misunderstandings. Consider using secure payment methods such as PayPal or bank transfers that offer buyer protection. Always confirm currency conversion rates and any additional fees that may apply to international transactions. -

How do I verify the quality of aluminum sheet metal before purchase?

To ensure quality, request certifications such as ASTM or ISO standards from your supplier. You can also ask for material test reports that detail the mechanical properties and chemical composition of the aluminum. If possible, request samples before placing a bulk order to assess the material firsthand. Additionally, check supplier reviews and ratings from previous customers to gauge reliability and product quality. -

What logistics considerations should I keep in mind when importing aluminum sheet metal?

Logistics for importing aluminum sheet metal involves several factors, including shipping methods, customs duties, and delivery timelines. Choose a reliable freight forwarder experienced in handling metal shipments to navigate customs efficiently. Be aware of potential tariffs or import taxes that may apply in your country. Establish a clear communication channel with your supplier regarding shipping schedules and tracking to ensure timely delivery. -

Can I customize the size and finish of aluminum sheet metal orders?

Yes, many suppliers offer customization options for size, thickness, and finishes of aluminum sheet metal. Common finishes include brushed, polished, or anodized, depending on the intended use. When requesting a custom order, provide detailed specifications to the supplier to ensure accuracy. Be prepared to discuss lead times, as custom orders may require additional processing time. -

What are the common uses of 4×8 aluminum sheet metal in various industries?

4×8 aluminum sheet metal is versatile and used across numerous industries. In construction, it serves as wall cladding, roofing, and flooring material. The automotive industry utilizes it for body panels and structural components due to its lightweight and strength. In marine applications, aluminum sheets resist corrosion, making them ideal for boat building. Additionally, the signage and display sectors favor aluminum for its durability and aesthetic appeal. Understanding your industry’s specific needs will help you leverage aluminum sheet metal effectively.

Top 6 Aluminum Sheet Metal 4X8 Manufacturers & Suppliers List

1. Metals Depot – Aluminum Sheet 3003, 5052, 6061

Domain: metalsdepot.com

Registered: 1999 (26 years)

Introduction: Aluminum Sheet – 3003, 5052, 6061

3003-H14 Aluminum Sheet – (ASTM B209, QQ-A-250/2)

– Excellent weldability and formability

– Good corrosion resistance

– Applications: fuel tanks, food & chemical handling, trailer siding & roofing

– Mill Finish – Not Polished

– Non-magnetic

– Brinell = 40, Tensile = 22,000, Yield = 21,000 (+/-)

5052-H32 Aluminum Sheet – (ASTM B209, QQ-A-250/8)

– Superior corrosio…

2. Cuts Metal – 48 x 96 Aluminum Diamond Plate

Domain: cutsmetal.net

Registered: 2005 (20 years)

Introduction: {“Product Name”: “48” x 96″ Aluminum Diamond Plate”, “Size”: “4′ x 8′ (48″ x 96″)”, “Material”: “Embossed Aluminum Diamond Plate Sheet”, “Thickness”: “.025 inches (little less than 1/32″ thick)”, “Price”: “$115.00”, “Features”: [“Cheaper, lighter, and more flexible than other diamond plate sheets”, “Easy to handle and install”, “Ideal for wainscoting or wall guard”, “Available in multiple colors i…

3. Elite Garage Floors – Brushed Aluminum Sheet

Domain: elitegaragefloors.com

Registered: 2012 (13 years)

Introduction: Brushed Aluminum Sheet, Dimensions: 48″ x 96″, Thickness: 14 Gauge (.063″), Alloy: 5052 H32, Finish: Brushed Mill Finish

4. Alro Steel – Aluminum Sheet

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Aluminum sheet, approximately 4’x8′, pricing around $4 per pound in Indianapolis, IN. Alternative suggestions include contacting local suppliers like Alro Steel and Metal Supermarket for better pricing and availability.

5. Metal Supermarkets – Aluminum Sheet

Domain: metalsupermarkets.com

Registered: 1996 (29 years)

Introduction: Aluminum sheet is a thin, flat piece of aluminum with various applications. It is a non-ferrous metal, meaning it doesn’t rust when exposed to moisture. Available grades include 1100, 2024, 3003, 5052, 6061, and 7075. Typical applications for each grade are: 1100 (spun hollowware, heat exchanger fins, cooking utensils), 2024 (aircraft fittings, structural components), 3003 (chemical tanks, trim), …

6. Chalco Aluminum – 4×8 Aluminum Sheet

Domain: chalcoaluminum.com

Registered: 2017 (8 years)

Introduction: 4×8 Aluminum Sheet

– Free Samples: Available for most products

– Bulk Purchase Discount: 5% discount on bulk purchases

– Manufacture: China

– Global Sea Freight Services

– Quick Response: Inquiries answered within 24 hours

Specifications:

– Alloy Series: 1000, 2000, 3000, 5000, 6000, 7000 series

– Temper: O-H112, T3-T8, T351-T851, H111, H112, H12-H18, H22-H28, H32-H38

– Thickness: 1/16″, 1/8″, 3/…

Strategic Sourcing Conclusion and Outlook for aluminum sheet metal 4×8

In conclusion, strategic sourcing of aluminum sheet metal 4×8 represents a critical opportunity for international B2B buyers, particularly in Africa, South America, the Middle East, and Europe. By leveraging the diverse qualities of aluminum alloys such as 3003, 5052, and 6061, businesses can enhance their product offerings, ensuring durability and versatility across various applications, from construction to automotive manufacturing.

The cost-effectiveness and lightweight nature of aluminum sheets make them ideal for a multitude of industries, facilitating ease of transport and installation. Buyers should prioritize partnerships with reliable suppliers that can provide not only high-quality materials but also the flexibility to accommodate custom orders and timely delivery.

As global demand for aluminum products continues to rise, staying informed about market trends and potential supply chain disruptions is essential. By embracing a strategic sourcing approach, companies can position themselves for growth and innovation.

We encourage international buyers to explore partnerships with trusted suppliers and to consider the myriad applications of aluminum sheet metal. The future is bright for those willing to invest in quality materials that drive efficiency and performance.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.