Top 5 Graphite Rod Suppliers (And How to Choose)

Introduction: Navigating the Global Market for graphite rod

In the ever-evolving landscape of industrial materials, sourcing graphite rods presents a unique challenge for international B2B buyers. These essential components are integral to numerous applications, from electrical conductivity in electrochemical processes to structural support in high-temperature environments. As businesses in Africa, South America, the Middle East, and Europe seek to optimize their supply chains, understanding the nuances of graphite rod procurement becomes crucial.

This comprehensive guide delves into the various types of graphite rods, including fine extruded and custom machined options, alongside their specific applications across industries. It outlines the critical factors to consider when vetting suppliers, such as quality certifications, material grades, and pricing structures. By providing in-depth insights into cost considerations and market trends, this guide empowers buyers to make informed purchasing decisions that align with their operational needs.

Moreover, the guide emphasizes the importance of understanding regional variations in sourcing practices and supplier relationships, particularly in key markets like Germany and Vietnam. With actionable strategies and expert recommendations, B2B buyers will be better equipped to navigate the complexities of the graphite rod market, ensuring they select the right materials for their projects while maximizing value and minimizing risk.

Understanding graphite rod Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fine Extruded | High purity, uniform density, available in various sizes | Electrodes, molds, heating elements | Pros: Excellent thermal and electrical conductivity. Cons: Higher cost compared to coarse grades. |

| Coarse Extruded | Lower density, less pure, typically larger diameter | Mechanical applications, bearings | Pros: Cost-effective for bulk applications. Cons: Lower performance in high-temp environments. |

| Solid Graphite | Machined from blocks, dense fine-grained structure | Heat treating, fixtures, electrodes | Pros: High compressive strength, good thermal shock resistance. Cons: Custom sizes can increase lead time. |

| Isographite | Ultra-high purity, isotropic properties | Semiconductor, aerospace industries | Pros: Exceptional electrical and thermal conductivity. Cons: Limited availability and high cost. |

| Resin-Impregnated | Enhanced strength and reduced porosity | High-performance applications | Pros: Improved durability and corrosion resistance. Cons: May not be suitable for all thermal applications. |

What Are the Key Characteristics of Fine Extruded Graphite Rods?

Fine extruded graphite rods are known for their high purity and uniform density, making them ideal for applications that require exceptional thermal and electrical conductivity. These rods are available in various sizes and grades, allowing for customization to specific needs. B2B buyers should consider the balance between performance and cost when selecting these rods, as they tend to be more expensive than their coarse counterparts. Their primary applications include use as electrodes, molds, and heating elements in industries such as metallurgy and electronics.

How Do Coarse Extruded Graphite Rods Compare?

Coarse extruded graphite rods are characterized by lower density and purity, making them suitable for less demanding mechanical applications. They are typically available in larger diameters and are more cost-effective for bulk production. While they may not perform as well in high-temperature environments, they are an excellent choice for applications such as bearings and structural components. Buyers should weigh the lower cost against potential performance limitations when considering these rods for their projects.

What Are Solid Graphite Rods and Their Applications?

Solid graphite rods are machined from blocks of graphite, offering a dense and fine-grained structure. These rods are known for their high compressive strength and excellent thermal shock resistance, making them suitable for heat treating and other high-stress applications. B2B buyers should consider the specific requirements of their applications, as solid graphite rods can be customized for size and grade, though this may increase lead times. Their versatility allows for use in a range of industries, including aerospace and manufacturing.

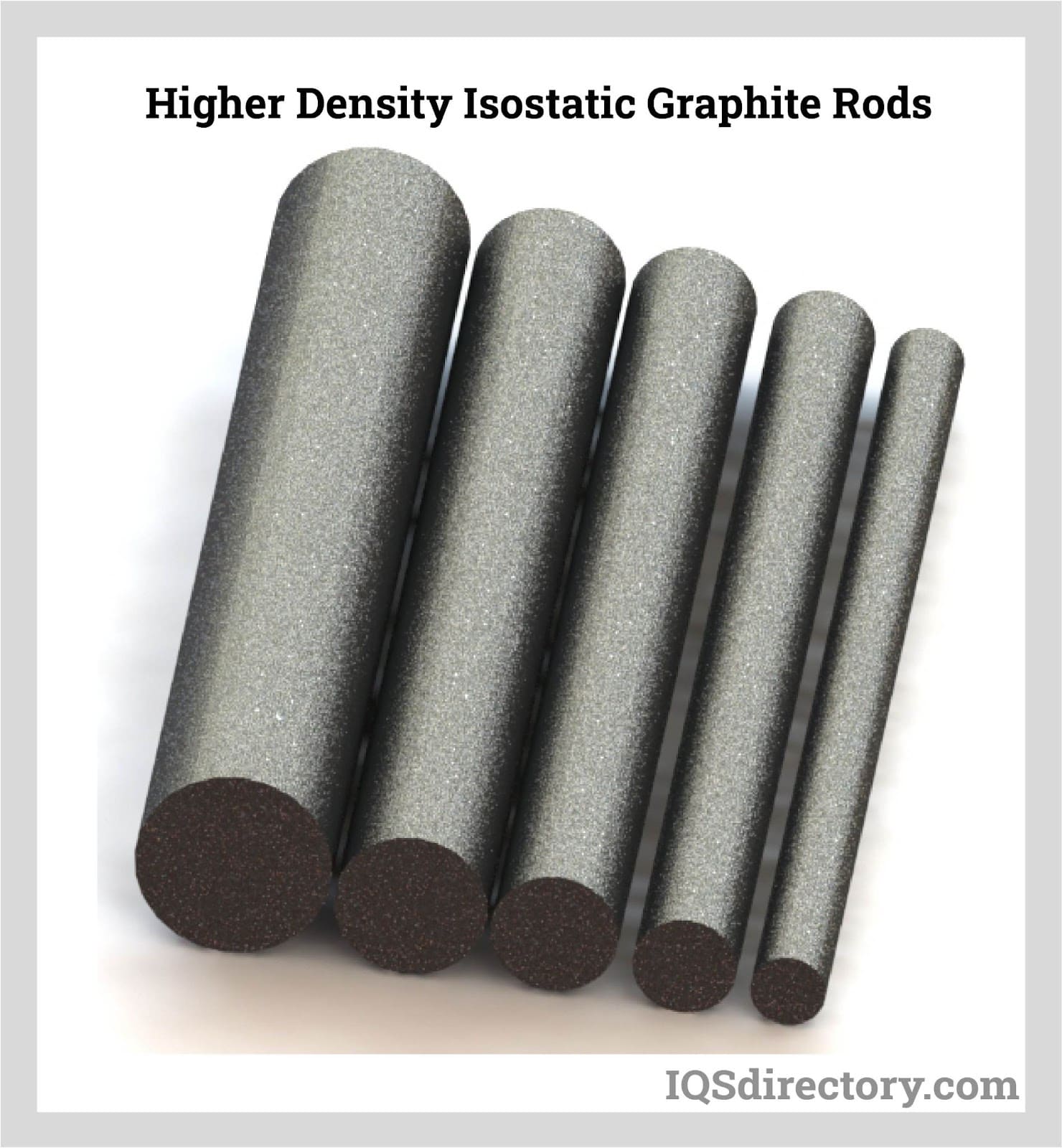

What Are the Advantages of Using Isographite?

Isographite rods are recognized for their ultra-high purity and isotropic properties, making them ideal for specialized applications in semiconductor and aerospace industries. They offer exceptional electrical and thermal conductivity, which can significantly enhance the performance of electronic components. However, buyers should be aware that isographite is often limited in availability and comes at a higher price point. This makes it crucial for B2B buyers to assess their specific application needs and budget constraints when considering isographite.

How Do Resin-Impregnated Graphite Rods Enhance Performance?

Resin-impregnated graphite rods are designed to offer enhanced strength and reduced porosity, making them suitable for high-performance applications. These rods provide improved durability and corrosion resistance, which is essential in harsh operating conditions. However, buyers should evaluate whether the resin-impregnated properties align with their application requirements, as they may not be suitable for all thermal applications. Understanding the specific environment in which these rods will be used is key to making an informed purchasing decision.

Key Industrial Applications of graphite rod

| Industry/Sector | Specific Application of graphite rod | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Heat Treating Fixtures | High thermal stability, ensuring consistent quality during manufacturing | Look for high-temperature rated graphite rods with low porosity. |

| Electronics | Electrodes for Battery Manufacturing | Enhanced conductivity and efficiency in energy storage solutions | Ensure the rods meet specific conductivity and purity standards. |

| Metal Fabrication | Molds and Dies for Casting | Improved wear resistance and longevity of manufacturing tools | Consider custom sizes and grades to match specific operational needs. |

| Automotive | Bushings and Bearings | Reduced friction and increased durability in moving parts | Verify compatibility with existing machinery and operational temperatures. |

| Renewable Energy | Components for Fuel Cells | Enhanced performance and efficiency in energy conversion | Source rods that are resistant to corrosion and high temperatures. |

How Are Graphite Rods Used in Aerospace Applications?

In the aerospace industry, graphite rods are primarily utilized as heat treating fixtures. These rods support various components during the heat treatment process, providing high thermal stability. This is critical for maintaining the integrity of parts subjected to extreme temperatures, which is essential for aircraft safety and performance. International buyers should focus on sourcing rods that can withstand high temperatures while exhibiting low porosity to prevent contamination during treatment.

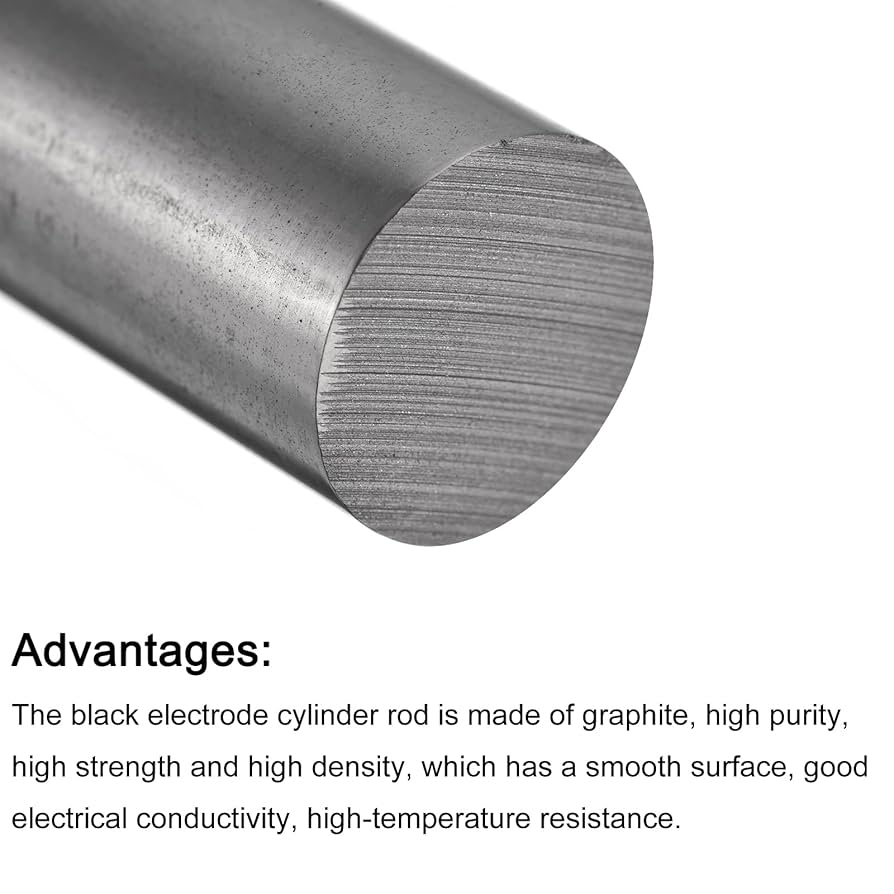

与graphite rod相关的说明性图片

What Role Do Graphite Rods Play in Electronics Manufacturing?

Graphite rods serve a vital role in the production of electrodes for battery manufacturing, particularly in lithium-ion batteries. Their excellent electrical conductivity enhances the efficiency of energy storage systems, making them indispensable in the electronics sector. Buyers in regions like Europe and South America should ensure that the graphite rods sourced meet specific conductivity requirements and purity standards to optimize battery performance.

How Are Graphite Rods Beneficial in Metal Fabrication?

In metal fabrication, graphite rods are commonly used to create molds and dies for casting processes. Their superior wear resistance and ability to withstand high temperatures ensure that molds maintain their shape and integrity over time, leading to higher quality castings. Buyers should consider custom sizes and grades of graphite rods to meet specific operational needs, particularly in industries requiring precision and durability.

What Are the Applications of Graphite Rods in the Automotive Sector?

Graphite rods are essential in the automotive industry for manufacturing bushings and bearings. Their inherent lubricating properties reduce friction in moving parts, resulting in longer-lasting components and improved vehicle performance. Buyers should verify that the graphite rods are compatible with existing machinery and can withstand the operational temperatures typical in automotive applications.

How Do Graphite Rods Enhance Renewable Energy Solutions?

In the renewable energy sector, graphite rods are utilized as components in fuel cells, where they contribute to efficient energy conversion. Their thermal and corrosion resistance ensures reliable performance under varying operational conditions. Buyers should prioritize sourcing rods that can withstand high temperatures and are resistant to corrosive environments, particularly in regions investing in renewable energy technologies.

3 Common User Pain Points for ‘graphite rod’ & Their Solutions

Scenario 1: Challenges with Material Quality and Consistency in Graphite Rods

The Problem: B2B buyers often face issues related to the quality and consistency of graphite rods. Variations in material properties can lead to failures in critical applications, particularly in industries like aerospace or electronics where precise specifications are paramount. Buyers may receive rods that do not meet the required density, thermal conductivity, or strength, resulting in operational inefficiencies and increased costs due to rework or replacement. This inconsistency can stem from a lack of standardized manufacturing processes among suppliers, especially when sourcing from different regions such as Africa or South America.

The Solution: To mitigate quality issues, it is essential for buyers to establish clear specifications and standards before procurement. Engage with suppliers who provide detailed certifications and testing results for their graphite rods, such as ASTM or ISO compliance. Additionally, consider sourcing from manufacturers with a proven track record and positive customer reviews. Conducting a small-scale trial order before committing to larger purchases can also help assess the product quality. Implementing a rigorous inspection process upon receipt of materials will further ensure that the rods meet your operational requirements.

Scenario 2: Difficulties in Custom Sizing and Specifications

The Problem: Many B2B buyers require graphite rods in specific sizes and configurations for unique applications, such as custom electrodes or machinery components. However, standard sizes may not fit their needs, leading to delays in production and additional costs. This is particularly problematic for companies in sectors like automotive or manufacturing, where specific dimensions are critical for performance and safety.

The Solution: When faced with sizing challenges, buyers should prioritize suppliers who offer custom machining capabilities and flexibility in order quantities. Communicate your precise requirements, including dimensions, tolerances, and any specific material properties needed for your application. It is beneficial to collaborate closely with the supplier’s engineering team to develop tailored solutions that meet your specifications. Some suppliers may also offer design consultations to optimize the graphite rod’s performance in your application, ensuring that you receive the exact product needed without unnecessary delays.

与graphite rod相关的说明性图片

Scenario 3: Understanding the Technical Properties of Graphite Rods

The Problem: B2B buyers often struggle to fully understand the technical properties of different graphite rods, such as thermal conductivity, electrical resistance, and mechanical strength. This lack of knowledge can lead to incorrect selections that compromise their applications, especially in high-temperature or high-stress environments. For instance, choosing a rod with inadequate thermal properties for a heat treating process can result in product failure and safety hazards.

The Solution: To effectively navigate the technical complexities of graphite rods, buyers should invest time in education about material properties and their implications for specific applications. Utilize resources such as technical datasheets, product catalogs, and supplier webinars that explain the characteristics of various graphite grades, like JC3 and JC4. Additionally, consider consulting with technical experts or engineers who specialize in material science to assist in selecting the right product based on your operational needs. By gaining a comprehensive understanding of the materials involved, you can make informed decisions that enhance performance and reliability in your applications.

Strategic Material Selection Guide for graphite rod

What Are the Key Properties of Common Graphite Rod Materials?

When selecting graphite rods for industrial applications, understanding the various materials available is crucial. Here, we analyze four common materials used for graphite rods, focusing on their properties, pros and cons, and implications for international B2B buyers.

1. Fine Extruded Graphite

Key Properties:

Fine extruded graphite rods are known for their excellent thermal conductivity and high-temperature resistance, typically rated up to 2400°C. They also exhibit good electrical conductivity, making them suitable for electrochemical applications.

与graphite rod相关的说明性图片

Pros & Cons:

The primary advantage of fine extruded graphite is its machinability, allowing for precise tolerances. However, the manufacturing process can be complex and may lead to higher costs compared to other materials. Its durability is high, but it may not withstand extreme mechanical stress.

Impact on Application:

These rods are ideal for applications requiring high thermal efficiency, such as electrodes and heating elements. They are compatible with various media, including corrosive chemicals, due to their inherent corrosion resistance.

Considerations for International Buyers:

Buyers from regions like Africa and South America should consider local regulations regarding material specifications. Compliance with international standards such as ASTM or DIN is essential for ensuring quality and performance.

2. JC3 Graphite

Key Properties:

JC3 graphite rods are dense and fine-grained, rated for high temperatures (up to 2400°C). They offer excellent electrical conductivity and high compressive strength, making them suitable for demanding applications.

Pros & Cons:

The key advantage of JC3 graphite is its superior thermal shock resistance and machinability. However, it is more expensive than other options, which could be a drawback for budget-conscious buyers.

Impact on Application:

JC3 rods are particularly effective in electrochemical processes and heat treating applications. Their robust nature allows them to perform well in environments with high thermal expansion.

Considerations for International Buyers:

For buyers in Europe, particularly Germany, adherence to local standards is crucial. Buyers should also evaluate the availability of JC3 graphite in their region to avoid supply chain disruptions.

3. JC4 Graphite

Key Properties:

JC4 graphite rods are designed for medium-temperature applications, rated up to 735°C. They possess good density and strength, making them suitable for mechanical applications.

Pros & Cons:

The primary advantage of JC4 graphite is its lower cost compared to JC3 while still offering good performance. However, its temperature rating limits its use in high-heat applications.

Impact on Application:

JC4 rods are often used in mechanical fixtures and support posts, where high thermal resistance is not critical. They are compatible with various media but may not be suitable for extreme environments.

Considerations for International Buyers:

Buyers in the Middle East should assess the compatibility of JC4 graphite with local industrial processes. Understanding the specific requirements for mechanical applications is essential for effective procurement.

4. Resin-Impregnated Graphite

Key Properties:

Resin-impregnated graphite rods enhance the material’s impermeability and strength. They can withstand moderate temperatures and offer improved wear resistance.

与graphite rod相关的说明性图片

Pros & Cons:

These rods are highly durable and resistant to chemical corrosion, making them suitable for various applications. However, the impregnation process can increase costs and complicate manufacturing.

Impact on Application:

Ideal for applications requiring enhanced durability, such as molds and bearings, resin-impregnated graphite rods excel in environments where chemical exposure is a concern.

Considerations for International Buyers:

Buyers should ensure that resin-impregnated graphite meets local standards for chemical resistance and durability. This is particularly important in regions with stringent industrial regulations.

Summary Table of Graphite Rod Materials

| Material | Typical Use Case for graphite rod | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Fine Extruded Graphite | Electrodes, heating elements | Excellent thermal conductivity | Higher manufacturing complexity | Medium |

| JC3 Graphite | Electrochemical applications | Superior thermal shock resistance | Higher cost compared to other materials | High |

| JC4 Graphite | Mechanical fixtures, support posts | Lower cost while maintaining performance | Limited high-temperature application | Medium |

| Resin-Impregnated Graphite | Molds, bearings | Enhanced durability and chemical resistance | Increased cost and complexity | Medium |

This guide provides a comprehensive overview of the strategic material selection for graphite rods, aiding international B2B buyers in making informed decisions based on their specific needs and regional considerations.

与graphite rod相关的说明性图片

In-depth Look: Manufacturing Processes and Quality Assurance for graphite rod

What Are the Key Stages in the Manufacturing Process of Graphite Rods?

The manufacturing of graphite rods involves several critical stages, each crucial for ensuring the final product meets the required specifications and performance standards. The typical process can be segmented into four main stages: material preparation, forming, assembly, and finishing.

How Is Material Prepared for Graphite Rod Production?

Material preparation is the foundational stage where high-quality graphite powder is sourced. This powder is often subjected to processes such as purification to remove impurities and improve the material’s properties. The particle size and distribution of the graphite powder are optimized to ensure uniformity in the final product. This stage may also include blending different grades of graphite to achieve desired characteristics, such as enhanced thermal conductivity or electrical properties.

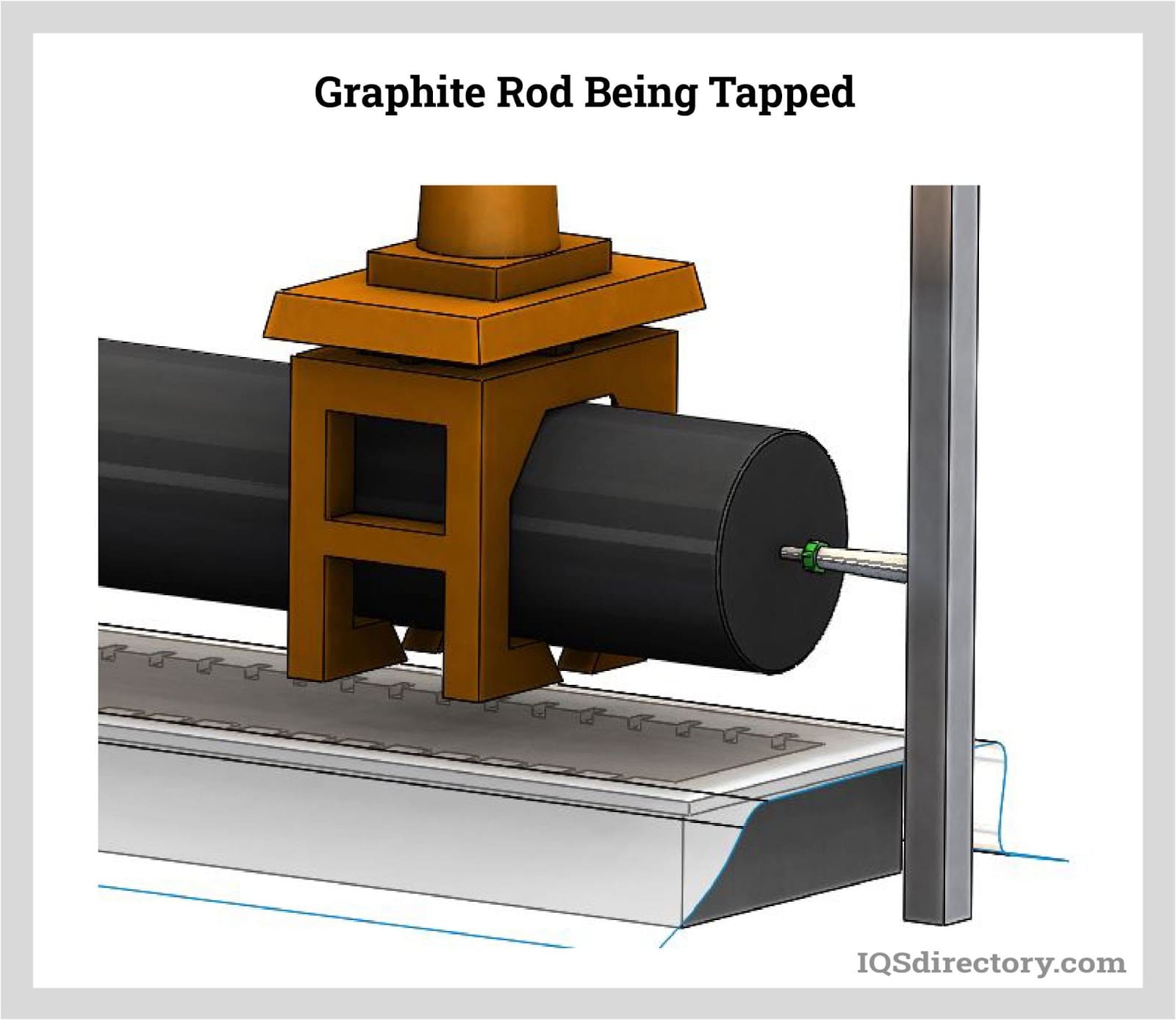

What Techniques Are Used in Forming Graphite Rods?

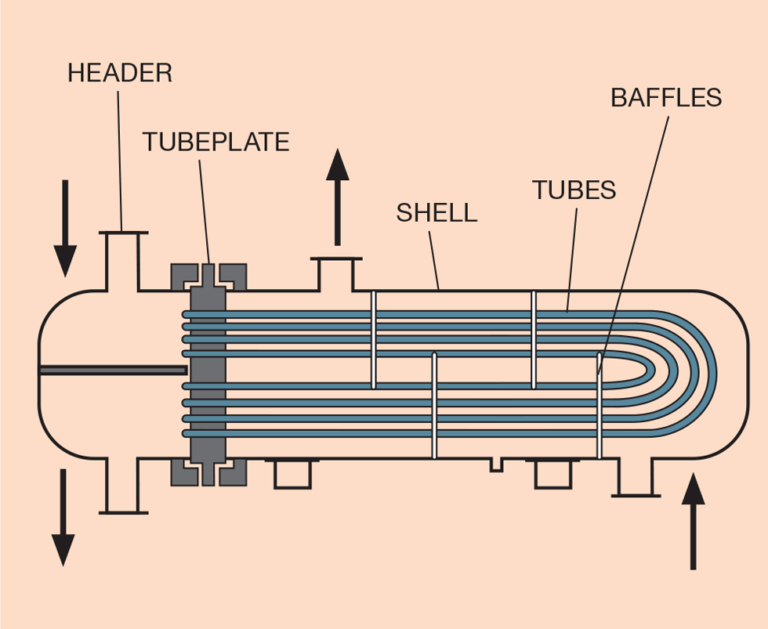

Forming is the next crucial stage where the prepared graphite material is shaped into rods. This can be achieved through various methods such as extrusion, where the graphite paste is forced through a die to create long rods of uniform cross-section. Another technique is molding, which allows for more complex geometries. The choice of method often depends on the required dimensions and properties of the rods, as well as the intended application.

How Is the Assembly Process Conducted for Graphite Rods?

In some cases, graphite rods may require assembly, particularly when they are part of a larger component or system. This may involve attaching rods to other materials or components, ensuring that the interfaces maintain the necessary thermal and electrical properties. Precision during this stage is critical, as any misalignment can lead to performance issues in the final application.

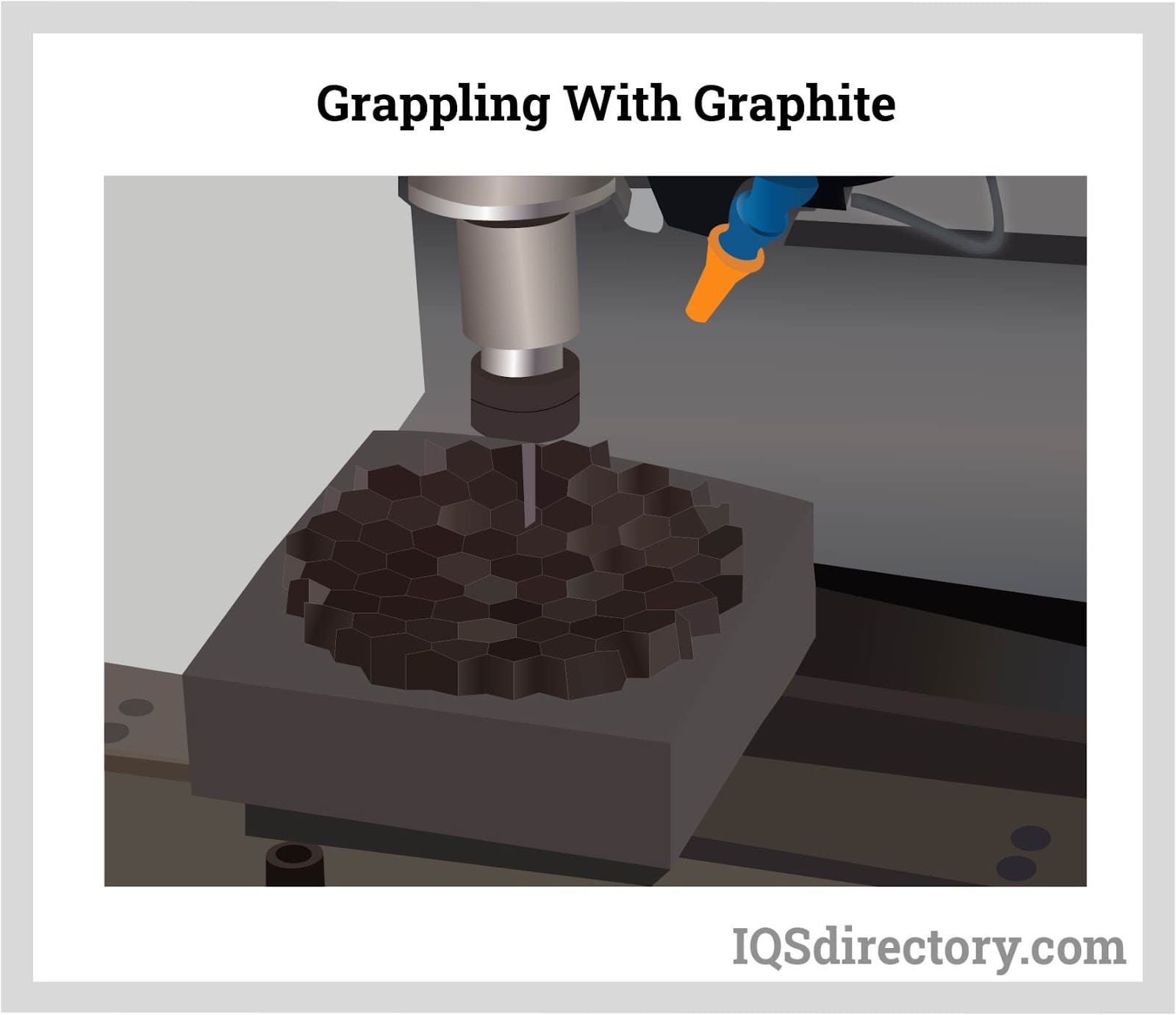

What Finishing Techniques Are Applied to Graphite Rods?

Finishing processes are applied to enhance the surface quality and dimensional accuracy of the graphite rods. Techniques such as machining, grinding, and polishing are commonly used to achieve the required tolerances and surface finishes. Additional treatments, such as impregnation with resins or other materials, can also be applied to improve the mechanical properties or to create a barrier against oxidation and corrosion.

What Quality Assurance Measures Are Essential for Graphite Rods?

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that the graphite rods meet international and industry-specific standards. Implementing robust QA measures is essential for B2B buyers looking for reliability and consistency in their suppliers.

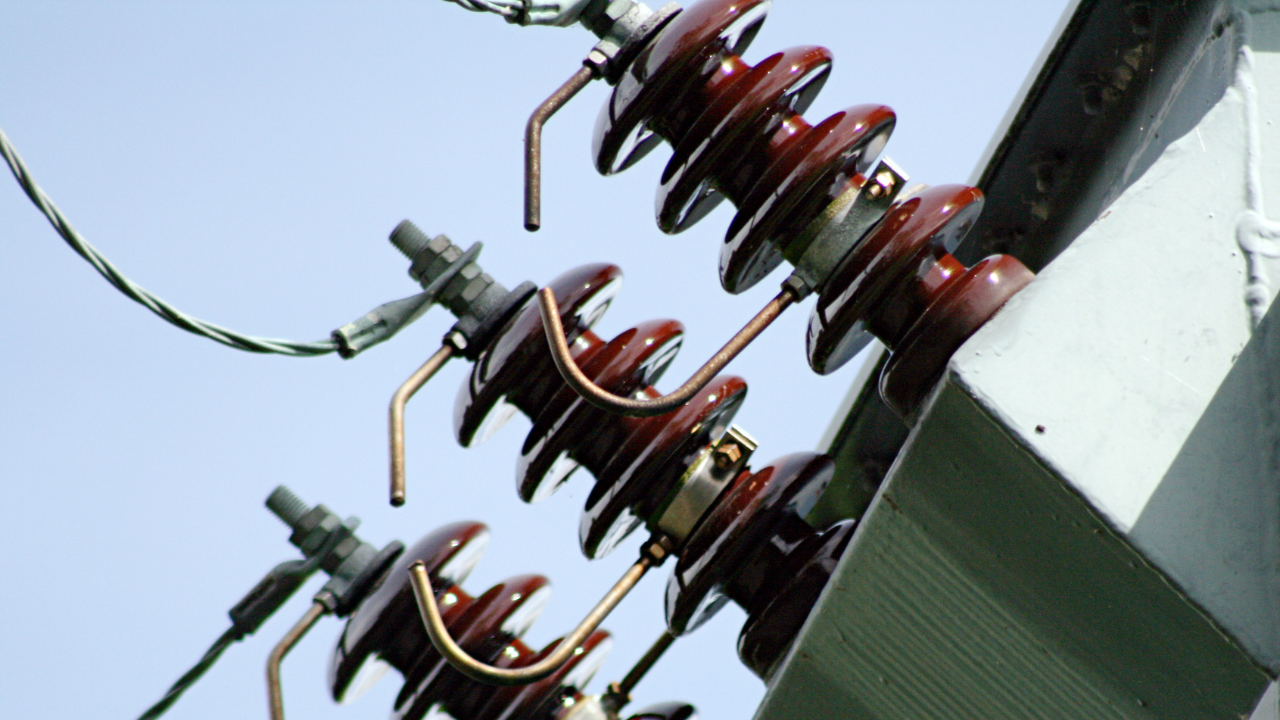

Which International Standards Are Relevant for Graphite Rods?

Key international standards include ISO 9001, which sets criteria for a quality management system, and ISO 14001 for environmental management. These certifications indicate that the manufacturer adheres to globally recognized practices in quality control and sustainability. In addition, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) are crucial for suppliers targeting specific markets, particularly in Europe and the energy sector.

与graphite rod相关的说明性图片

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are established throughout the manufacturing process to ensure product integrity. The main checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials and components upon delivery to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Monitoring is conducted during the manufacturing stages to detect any deviations from established parameters.

- Final Quality Control (FQC): This stage involves comprehensive testing of the finished graphite rods, including dimensional checks, mechanical property evaluations, and surface quality inspections.

What Common Testing Methods Are Used for Graphite Rods?

Testing methods for graphite rods typically include:

- Dimensional Inspection: Ensuring that the rods meet specified tolerances using calipers and micrometers.

- Mechanical Testing: Assessing properties such as compressive strength, tensile strength, and thermal conductivity through standardized tests.

- Chemical Analysis: Testing for purity levels and the presence of any contaminants that could affect performance.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, it’s essential to verify the quality control practices of potential suppliers. Here are actionable steps to ensure compliance:

- Supplier Audits: Conducting on-site audits can provide a firsthand look at the supplier’s manufacturing and quality assurance processes.

- Quality Reports: Requesting detailed quality assurance reports, including test results and compliance certifications, can help buyers assess the supplier’s commitment to quality.

- Third-Party Inspections: Utilizing independent third-party inspection services can offer an unbiased evaluation of the supplier’s processes and products.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International B2B buyers should be aware of specific nuances in quality control and certification that may differ by region or industry. For example, certain markets may require additional certifications, such as RoHS (Restriction of Hazardous Substances) for electronic applications or specific environmental compliance documentation.

Furthermore, the understanding of local regulations and standards is critical, as they can impact both the quality assurance processes and the acceptance of products in various markets. Buyers should also consider the logistics of compliance, as delays in certification processes can affect supply chain timelines.

Conclusion

Understanding the manufacturing processes and quality assurance measures for graphite rods is essential for B2B buyers looking to source reliable products. By focusing on detailed manufacturing stages, international standards, quality control checkpoints, testing methods, and verification processes, buyers can make informed decisions that align with their operational needs and market expectations. This comprehensive approach not only helps in selecting the right suppliers but also ensures that the products meet the rigorous demands of various applications across different industries.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘graphite rod’

Introduction

Sourcing graphite rods can be a complex process, especially for international B2B buyers. This step-by-step checklist will guide you through the essential actions required to procure high-quality graphite rods that meet your specific needs. By following these steps, you will ensure that you make informed decisions, optimize costs, and establish reliable supplier relationships.

Step 1: Define Your Technical Specifications

Before you begin sourcing, it’s vital to outline the specific technical requirements for your graphite rods. Consider factors such as the required dimensions (diameter and length), material grade (e.g., fine extruded, coarse extruded), and thermal properties based on your application needs. Clearly defined specifications will help streamline your search and facilitate accurate quotes from suppliers.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers that specialize in graphite rods. Utilize online directories, trade shows, and industry associations to compile a list of manufacturers. Pay attention to their reputation, industry experience, and customer reviews to gauge their reliability and product quality.

Step 3: Evaluate Supplier Certifications

Ensure that the suppliers you are considering possess the necessary certifications and quality standards. Look for ISO certifications or other relevant industry-specific certifications that demonstrate their commitment to quality and compliance. These certifications can provide assurance that the products meet international quality standards, which is crucial for maintaining operational integrity.

Step 4: Request Samples for Testing

Before placing a large order, request samples of the graphite rods from your shortlisted suppliers. Testing samples will allow you to evaluate the material properties, such as density, thermal conductivity, and machinability, to ensure they meet your specifications. This step minimizes the risk of investing in subpar materials that could impact your production processes.

Step 5: Compare Pricing and Terms

Once you have gathered quotes from various suppliers, compare their pricing structures and payment terms. Be mindful of additional costs such as shipping, taxes, and customs duties that may apply, particularly for international orders. A comprehensive comparison will help you identify the best value for your investment while ensuring that you do not compromise on quality.

Step 6: Check Supplier References

Before finalizing your decision, ask potential suppliers for references from previous clients, particularly those in your industry or region. Engaging with these references can provide insights into the supplier’s reliability, customer service, and product performance. This due diligence is critical for establishing a long-term partnership.

Step 7: Negotiate Contractual Terms

Once you have selected a supplier, negotiate the contractual terms to ensure mutual benefits. Discuss aspects such as pricing, delivery timelines, payment terms, and return policies. A well-defined contract protects both parties and clarifies expectations, reducing the likelihood of disputes in the future.

By following this checklist, you will be well-equipped to navigate the procurement process for graphite rods, ensuring that you secure high-quality products that align with your business needs.

Comprehensive Cost and Pricing Analysis for graphite rod Sourcing

What Are the Key Cost Components in Graphite Rod Sourcing?

When sourcing graphite rods, understanding the intricate cost structure is crucial for B2B buyers. The main components influencing the overall cost include:

与graphite rod相关的说明性图片

-

Materials: The quality and type of graphite used significantly affect pricing. Fine extruded graphite, known for its superior properties, typically commands a higher price than coarse grades. Additionally, variations like isomolded or resin-impregnated graphite can further influence costs based on their specialized applications.

-

Labor: The labor costs associated with machining and processing graphite rods vary based on the complexity of the manufacturing process. Skilled labor is often required to achieve the precision needed for high-performance applications, which can drive up costs.

-

Manufacturing Overhead: This encompasses the indirect costs of production, including facility maintenance, utilities, and equipment depreciation. Suppliers with advanced manufacturing capabilities may pass on these overhead costs, impacting the final pricing.

-

Tooling: The initial investment in tools and dies for producing specific rod sizes or shapes can be substantial. Custom tooling often leads to higher upfront costs, which are typically amortized over larger production runs.

-

Quality Control (QC): Rigorous quality assurance processes are essential, especially for applications requiring high precision and reliability. Increased QC measures can lead to higher costs, but they ensure that the product meets industry standards and customer expectations.

-

Logistics: Shipping and handling costs can vary greatly depending on the geographical location of both the supplier and the buyer. International shipping may involve additional tariffs, insurance, and freight charges, which should be factored into the total cost.

-

Margin: Suppliers add a profit margin to cover their costs and ensure sustainability. This margin can vary based on market demand, competition, and the supplier’s position in the supply chain.

How Do Price Influencers Affect Graphite Rod Pricing?

Several factors can influence the pricing of graphite rods, particularly for international B2B buyers:

-

Volume/MOQ: Suppliers often have minimum order quantities (MOQs), and pricing can become more favorable with larger orders. Bulk purchasing can lead to significant savings, so understanding these thresholds is vital.

-

Specifications and Customization: Custom sizes, grades, and specifications can increase costs due to the need for specialized production processes. Buyers should clearly communicate their requirements to avoid unexpected charges.

-

Materials and Quality Certifications: Higher quality materials, such as those certified for specific applications, typically cost more. Certifications can also add to the cost but can be crucial for industries like aerospace or automotive, where compliance is mandatory.

-

Supplier Factors: The reputation and reliability of the supplier can significantly impact pricing. Established suppliers with a track record of quality may charge a premium, while newer entrants might offer lower prices to gain market share.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can influence shipping costs and responsibilities. Understanding these terms is essential for calculating the total landed cost of the product.

What Are the Best Tips for B2B Buyers to Optimize Graphite Rod Costs?

To ensure cost efficiency when sourcing graphite rods, buyers should consider the following strategies:

-

Negotiate Effectively: Always engage suppliers in discussions about pricing. Understanding their cost structure can provide leverage in negotiations. Highlighting long-term partnerships or bulk purchasing can lead to more favorable terms.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider maintenance, operational efficiencies, and the lifespan of the rods. A slightly higher upfront cost can sometimes lead to lower overall costs if the product lasts longer or performs better.

-

Understand Pricing Nuances for International Transactions: For buyers in Africa, South America, the Middle East, and Europe, currency fluctuations, import duties, and local market conditions can significantly affect pricing. Staying informed about these variables can help in making better sourcing decisions.

-

Request Samples and Test Quality: Before committing to large orders, request samples to assess quality and performance. This can help avoid costly mistakes and ensure that the product meets the required specifications.

-

Stay Informed on Market Trends: Keeping an eye on market trends, such as fluctuations in graphite prices and changes in demand, can provide insights into the best times to purchase.

Disclaimer

The prices indicated in this analysis are for illustrative purposes only and may vary based on supplier, market conditions, and specific buyer requirements. Always obtain updated quotes from suppliers for accurate pricing.

Alternatives Analysis: Comparing graphite rod With Other Solutions

When exploring the best materials for applications such as manufacturing, electronics, and thermal management, it’s essential to consider various alternatives to graphite rods. Each alternative offers distinct advantages and limitations based on performance, cost, and application suitability. This analysis will compare graphite rods with other viable solutions to help B2B buyers make informed decisions.

Comparison Table of Graphite Rods and Alternatives

| Comparison Aspect | Graphite Rod | Silicon Carbide Rod | Copper Rod |

|---|---|---|---|

| Performance | Excellent thermal and electrical conductivity; high-temperature tolerance | High thermal conductivity; good wear resistance | Superior electrical conductivity; good thermal performance |

| Cost | Moderate, varies by size/grade | Generally higher cost | Higher cost than graphite rods |

| Ease of Implementation | Readily available in various sizes; easy to machine | Requires specialized machining | Easily available; straightforward to work with |

| Maintenance | Low maintenance; durable under high stress | Low, but can be brittle | Moderate; can corrode over time |

| Best Use Case | Electrochemical applications, molds, and heating elements | Semiconductor applications, wear parts | Electrical connections, heat sinks |

What Are the Benefits and Drawbacks of Silicon Carbide Rods?

Silicon carbide (SiC) rods are increasingly used in high-temperature and high-stress applications. They possess excellent thermal conductivity and wear resistance, making them suitable for semiconductor devices and components subjected to extreme conditions. However, they typically come at a higher cost compared to graphite rods and can be more challenging to machine due to their hardness. Their brittleness may also pose risks in applications where mechanical shock is possible.

与graphite rod相关的说明性图片

How Do Copper Rods Compare to Graphite Rods?

Copper rods are widely recognized for their superior electrical conductivity, making them the go-to choice for electrical connections and heat sinks. They offer excellent thermal performance and are relatively easy to work with. However, copper rods tend to be more expensive than graphite rods and require regular maintenance to prevent corrosion, especially in humid environments. While they excel in electrical applications, they may not withstand high temperatures as effectively as graphite rods, limiting their use in certain industrial applications.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right rod for your application depends on various factors, including performance requirements, budget constraints, and environmental conditions. Graphite rods are ideal for applications requiring high thermal and electrical conductivity at moderate costs, particularly in electrochemical settings. Silicon carbide rods are suited for high-temperature applications but come with a higher price tag and brittleness concerns. Copper rods excel in electrical conductivity but require maintenance and may not be suitable for extreme heat. By evaluating these aspects, B2B buyers can make informed choices that align with their operational needs and financial goals.

Essential Technical Properties and Trade Terminology for graphite rod

What Are the Key Technical Properties of Graphite Rods That B2B Buyers Should Know?

When considering graphite rods for industrial applications, understanding the key technical properties is crucial. Here are some essential specifications that B2B buyers should focus on:

Material Grade: What Does It Mean for Your Application?

Graphite rods are available in various material grades, such as fine extruded, coarse extruded, and isomolded graphite. Each grade has unique characteristics suited for specific applications. For instance, fine extruded rods are often preferred for high-precision applications due to their tight tolerances and excellent thermal conductivity, making them ideal for use in electrodes and molds. Selecting the right grade ensures optimal performance and durability in your specific application.

Tolerance: Why Is Precision Important in Graphite Rods?

Tolerance refers to the allowable deviation from specified dimensions. High precision in tolerance is critical for applications requiring exact fit and functionality, such as in electrical discharge machining (EDM). A tighter tolerance can lead to improved efficiency and product lifespan, which can significantly impact overall operational costs. In B2B settings, ensuring that your supplier can meet specified tolerances can prevent costly production delays and rework.

与graphite rod相关的说明性图片

Compressive Strength: How Does It Affect Performance?

Compressive strength is the ability of a graphite rod to withstand axial loads without failing. This property is vital in applications where rods are subjected to significant weight or pressure, such as in support beams or fixtures. Understanding the compressive strength helps B2B buyers choose the right product that can handle the demands of their specific operational environment without compromising safety or performance.

Thermal Conductivity: Why Is This Property Crucial?

Graphite is known for its excellent thermal conductivity, which allows for efficient heat transfer in applications like heating elements and molds. High thermal conductivity can improve process efficiency and product quality by ensuring uniform temperature distribution. For industries such as metal processing or semiconductor manufacturing, selecting a graphite rod with appropriate thermal properties is essential for achieving desired outcomes.

Density: How Does It Impact Material Selection?

Density of graphite rods can vary depending on the manufacturing process and material grade. A higher density often indicates better mechanical properties and thermal stability. For B2B buyers, understanding the density requirements for their applications can guide material selection, ensuring that the rods meet specific performance criteria while potentially reducing weight and material costs.

What Are Common Trade Terms Related to Graphite Rods That Buyers Should Understand?

In the world of B2B transactions, certain jargon and trade terms are frequently used. Familiarity with these terms can facilitate smoother communication and negotiation processes:

What Is an OEM (Original Equipment Manufacturer)?

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. For buyers, understanding OEM relationships can help ensure the quality and compatibility of graphite rods with existing systems or machinery, leading to better integration and performance.

Why Is MOQ (Minimum Order Quantity) Important?

MOQ is the minimum number of units a supplier requires a buyer to purchase. This term is significant for B2B buyers as it affects inventory management and upfront costs. Knowing the MOQ can help businesses plan their purchases more effectively and avoid excess inventory.

What Does RFQ (Request for Quotation) Entail?

An RFQ is a document that buyers send to suppliers to request pricing and terms for specific products or services. B2B buyers should use RFQs to gather competitive offers and ensure they receive the best value for their investment in graphite rods.

How Do Incoterms Affect International Trade?

Incoterms (International Commercial Terms) are standardized terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms helps B2B buyers clarify shipping costs, risk management, and delivery obligations, which is crucial when sourcing graphite rods from suppliers across different regions.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions, ultimately leading to enhanced operational efficiency and profitability.

Navigating Market Dynamics and Sourcing Trends in the graphite rod Sector

What are the Global Drivers and Key Trends Impacting the Graphite Rod Market?

The graphite rod market is witnessing significant growth, driven by several global factors. The increasing demand for lightweight and high-strength materials in industries such as aerospace, automotive, and energy is a primary driver. As nations focus on renewable energy solutions, graphite rods are becoming essential components in applications like battery manufacturing and electric vehicles. Additionally, the rise of electric arc furnaces in steel production is propelling the demand for high-quality graphite rods, especially in regions like Europe and South America.

与graphite rod相关的说明性图片

Emerging B2B technologies are reshaping sourcing trends within the graphite rod sector. Digital procurement platforms are streamlining the supply chain, allowing international buyers to connect with manufacturers more efficiently. The adoption of Industry 4.0 technologies, including AI and IoT, enhances production processes, ensuring better quality control and customization options. For buyers from Africa and the Middle East, this means access to tailored solutions that meet specific operational needs while maximizing cost-effectiveness.

Market dynamics are also shifting due to geopolitical factors and trade policies. International buyers must navigate tariffs, import regulations, and fluctuating material costs, necessitating a more strategic approach to sourcing. Building strong relationships with reliable suppliers, particularly those who offer transparency and flexibility, is crucial for mitigating risks associated with these market fluctuations.

How Can B2B Buyers Prioritize Sustainability and Ethical Sourcing in the Graphite Rod Sector?

Sustainability has become a critical concern for B2B buyers in the graphite rod market. The environmental impact of graphite mining and processing can be significant, leading to a growing emphasis on ethical sourcing practices. Buyers should prioritize suppliers who adopt responsible mining practices and have clear sustainability policies in place. This includes minimizing carbon footprints, using eco-friendly extraction methods, and ensuring fair labor practices throughout the supply chain.

与graphite rod相关的说明性图片

The importance of ethical supply chains cannot be overstated, particularly for buyers in regions with stringent environmental regulations. Companies that commit to sustainability not only enhance their brand reputation but also attract environmentally conscious customers and partners. Certifications such as ISO 14001 (Environmental Management) and adherence to the Responsible Minerals Initiative (RMI) can serve as indicators of a supplier’s commitment to sustainability.

Furthermore, the development of ‘green’ graphite materials—produced with lower environmental impact—presents an opportunity for international buyers to align their sourcing strategies with sustainability goals. By investing in suppliers who prioritize environmentally friendly practices, businesses can contribute to a more sustainable future while ensuring compliance with increasing regulatory demands.

What is the Historical Context of the Graphite Rod Market?

The history of graphite rods traces back to the early industrial era, where graphite was primarily utilized for its lubricating properties and as a refractory material. As industries evolved, the application of graphite expanded into electrical components and thermal management solutions, particularly in the 20th century. The rise of advanced manufacturing processes and technologies propelled the demand for specialized graphite products, including rods.

Over the last few decades, the graphite rod market has adapted to meet the needs of high-tech industries, leading to innovations in material formulations and processing techniques. The transition towards renewable energy sources and electric mobility has further cemented graphite’s role as a critical material in modern technology. As the market continues to evolve, understanding its historical context can provide valuable insights into future trends and opportunities for B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of graphite rod

-

How do I choose the right graphite rod for my application?

Selecting the appropriate graphite rod involves understanding your specific application requirements, such as temperature tolerance, electrical conductivity, and mechanical strength. For example, fine-grained rods like JC3 are suitable for high-temperature electrochemical applications, while JC4 rods excel in mechanical settings with moderate heat. Consider the dimensions, such as diameter and length, as well as any custom machining needs. Consulting with suppliers who can provide technical specifications and recommendations based on your unique requirements is essential. -

What are the advantages of using graphite rods in industrial applications?

Graphite rods offer numerous benefits, including excellent thermal conductivity, high compressive strength, and resistance to corrosion and thermal shock. Their inherent lubricating properties reduce friction, making them ideal for applications where moving parts are involved. Additionally, graphite rods can be machined to tight tolerances, ensuring precise fit and functionality in demanding environments. This versatility makes them suitable for various sectors, including aerospace, manufacturing, and energy. -

What minimum order quantities (MOQs) should I expect when sourcing graphite rods?

Minimum order quantities for graphite rods can vary significantly based on the supplier and specific product types. Generally, MOQs can range from a few pieces for standard sizes to larger quantities for custom orders. It’s advisable to clarify MOQs during your initial discussions with suppliers to ensure that they align with your purchasing capabilities. Some suppliers may offer flexibility on MOQs for repeat customers or bulk orders, so negotiating terms could be beneficial. -

How do I vet suppliers when sourcing graphite rods internationally?

To vet suppliers, consider factors such as their industry reputation, certifications, and experience in the graphite market. Request references or case studies from previous clients, and check online reviews and ratings. It’s also essential to verify their production capabilities, quality control processes, and compliance with international standards. Engaging in direct communication can help assess their responsiveness and willingness to accommodate your specific needs, thereby building trust in your business relationship. -

What payment terms are typically offered by suppliers of graphite rods?

Payment terms can vary widely among suppliers, often influenced by the order size and the buyer’s relationship with the supplier. Common terms include upfront payments, net 30/60/90 days, or a combination of advance and balance payments upon delivery. Discussing and negotiating payment options early in the sourcing process is crucial to ensure both parties are comfortable. Additionally, consider using secure payment methods and contracts to protect your interests in international transactions. -

What are the logistics considerations when importing graphite rods?

When importing graphite rods, key logistics considerations include shipping methods, lead times, and customs regulations. Ensure you understand the shipping options available, such as air or sea freight, and their associated costs and delivery times. Familiarize yourself with the customs documentation required for your country, including tariffs and import duties. Partnering with a reliable logistics provider can help streamline the process and mitigate potential delays or compliance issues. -

How can I ensure the quality of graphite rods before making a purchase?

To guarantee the quality of graphite rods, request product samples and detailed technical data sheets (TDS) from suppliers. Conduct thorough inspections upon receipt, focusing on aspects such as dimensions, density, and surface finish. Additionally, inquire about the supplier’s quality assurance processes, including any certifications like ISO 9001. If necessary, consider third-party testing to validate the material properties and performance specifications against your requirements. -

Can I customize graphite rods to fit specific application needs?

Yes, many suppliers offer customization options for graphite rods, including adjustments in size, shape, and grade. Customization may involve machining rods to specific dimensions or selecting particular grades of graphite based on thermal and mechanical properties required for your application. It is advisable to communicate your precise needs to the supplier early in the discussion to ensure they can meet your specifications efficiently and effectively.

Top 5 Graphite Rod Manufacturers & Suppliers List

1. Graphite Store – Fine Extruded Graphite Rods

Domain: graphitestore.com

Registered: 2002 (23 years)

Introduction: This company, Graphite Store – Fine Extruded Graphite Rods, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. eBay – Graphite Rods

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Graphite rod products for sale on eBay include various types such as graphite fishing rods, carbon graphite rods, graphite rod blanks, and tungsten carbide rods. Related searches indicate a range of specific products including 12ft fishing rods, spinning fishing rods, fly rods, and custom rods. The listings feature options for different fishing styles and applications, as well as accessories like …

3. CeraMaterials – Graphite Rods JC3 & JC4

Domain: ceramaterials.com

Registered: 2006 (19 years)

Introduction: Graphite Rods JC3 & JC4 | Stock & Custom | CeraMaterials

– Solid graphite rods machined from blocks of graphite.

– Standard sizes available, manufactured and machined from Extruded Graphite.

– Types: JC3 (dense fine grained, high temperature rated 2400℃) and JC4 (strong fine grained, medium temperature rated 735℃).

– JC3 is used for electrochemical applications; JC4 is used for mechanical applica…

4. IQS Directory – Graphite Rods

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Graphite rods are slender, elongated tools made from processed graphite, known for their durability, thermal shock resistance, and corrosion resistance. They are used in various applications, including electrical conduction, flaring tools, anodes, and components in direct current fuel cells (DCFC). Key specifications include a compressive strength of 11,000-38,000 psi and varying densities. Manufa…

5. ScienceDirect – Graphite Rods

Domain: sciencedirect.com

Registered: 1997 (28 years)

Introduction: Graphite rods are carbon-based electrodes that are inexpensive and widely used in various applications, including DNA hybridization biosensors and electrochemical devices such as batteries. They exhibit excellent chemical stability and electrical conductivity, making them suitable for use as anodes in reactors. Graphite rods can lead to increased carbon dioxide production in reactors, which enhanc…

Strategic Sourcing Conclusion and Outlook for graphite rod

In the evolving landscape of graphite rod sourcing, strategic procurement emerges as a crucial factor for international B2B buyers. Understanding the diverse applications and properties of graphite rods—such as those from grades JC3 and JC4—can significantly enhance operational efficiency and product performance. Buyers should prioritize suppliers that offer customization options and robust quality assurance processes to meet specific industrial needs.

Moreover, the ability to navigate the supply chain effectively will enable businesses to mitigate risks associated with price volatility and availability. Establishing strong relationships with suppliers in key regions—particularly in Africa, South America, the Middle East, and Europe—can lead to improved access to high-quality materials and innovative solutions tailored to unique market demands.

As we look to the future, the demand for graphite rods is anticipated to grow, driven by advancements in technology and increasing industrial applications. Now is the time for B2B buyers to engage with suppliers, leverage strategic sourcing practices, and position themselves advantageously in this competitive market. Embrace the opportunity to streamline your procurement strategy and enhance your business’s resilience and growth potential in the graphite sector.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.