Container House Price: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for container house price

In today’s rapidly evolving construction landscape, the challenge of sourcing affordable and sustainable container houses is becoming increasingly pressing for international B2B buyers. Understanding container house prices is not merely about the initial purchase; it encompasses a myriad of factors including design variations, material choices, and local regulations. This guide is designed to provide a comprehensive overview of container house pricing, tailored specifically for businesses and investors from diverse regions such as Africa, South America, the Middle East, and Europe, including key markets like Nigeria and Germany.

Within these pages, you will discover detailed insights into various types of container homes—from prefabricated models to custom builds—along with their typical applications in residential and commercial sectors. Additionally, we will navigate the essential steps for vetting suppliers, ensuring compliance with local building codes, and budgeting for hidden costs that can significantly impact the overall investment. By arming you with the knowledge needed to make informed purchasing decisions, this guide aims to empower your organization to capitalize on the advantages of container housing solutions, enhancing your portfolio while addressing pressing housing needs in your target markets. Let’s embark on this journey together and unlock the potential of container homes in a global marketplace.

Understanding container house price Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Container Homes | Built from one or more standard shipping containers; modular design | Affordable housing, temporary offices | Pros: Cost-effective, quick assembly. Cons: Limited customization options. |

| Custom Container Homes | Tailored designs; various sizes and layouts; higher-end finishes | Luxury housing, bespoke projects | Pros: Unique designs, high customization. Cons: Higher costs, longer build times. |

| Prefabricated Container Homes | Manufactured off-site; fixed sizes and layouts; quicker delivery | Affordable housing, disaster relief | Pros: Lower labor costs, rapid deployment. Cons: Limited options for customization. |

| Stacked Container Homes | Multi-story designs; several containers stacked vertically | Urban housing, student accommodations | Pros: Maximizes space, innovative aesthetics. Cons: Complex structural requirements. |

| Hybrid Container Homes | Combination of containers with traditional building materials | Eco-friendly projects, commercial spaces | Pros: Versatile design, improved insulation. Cons: Potentially higher costs and longer timelines. |

What Are Standard Container Homes and Their Suitability for B2B Buyers?

Standard container homes are primarily constructed using one or more shipping containers, offering a modular design that allows for flexibility in size and layout. They are ideal for affordable housing solutions and temporary office spaces, making them attractive for businesses looking to minimize costs while providing functional living or working environments. B2B buyers should consider the ease of assembly and lower costs, but be aware of the limitations in customization options that may not suit specific branding or operational needs.

How Do Custom Container Homes Meet Unique Business Requirements?

Custom container homes are designed to meet specific buyer requirements, allowing for a wide range of sizes, layouts, and finishes. This flexibility makes them suitable for luxury housing projects or bespoke commercial endeavors, where unique aesthetics are essential. While they offer significant customization advantages, B2B buyers must account for higher costs and longer construction timelines, which can impact project budgets and delivery schedules.

What Advantages Do Prefabricated Container Homes Offer for Quick Deployment?

Prefabricated container homes are manufactured off-site, featuring fixed sizes and layouts that streamline the building process. This makes them particularly appealing for affordable housing initiatives and disaster relief efforts, where rapid deployment is crucial. B2B buyers benefit from lower labor costs and quicker setup times, although they should note the limited customization options, which may not cater to specific design visions or branding requirements.

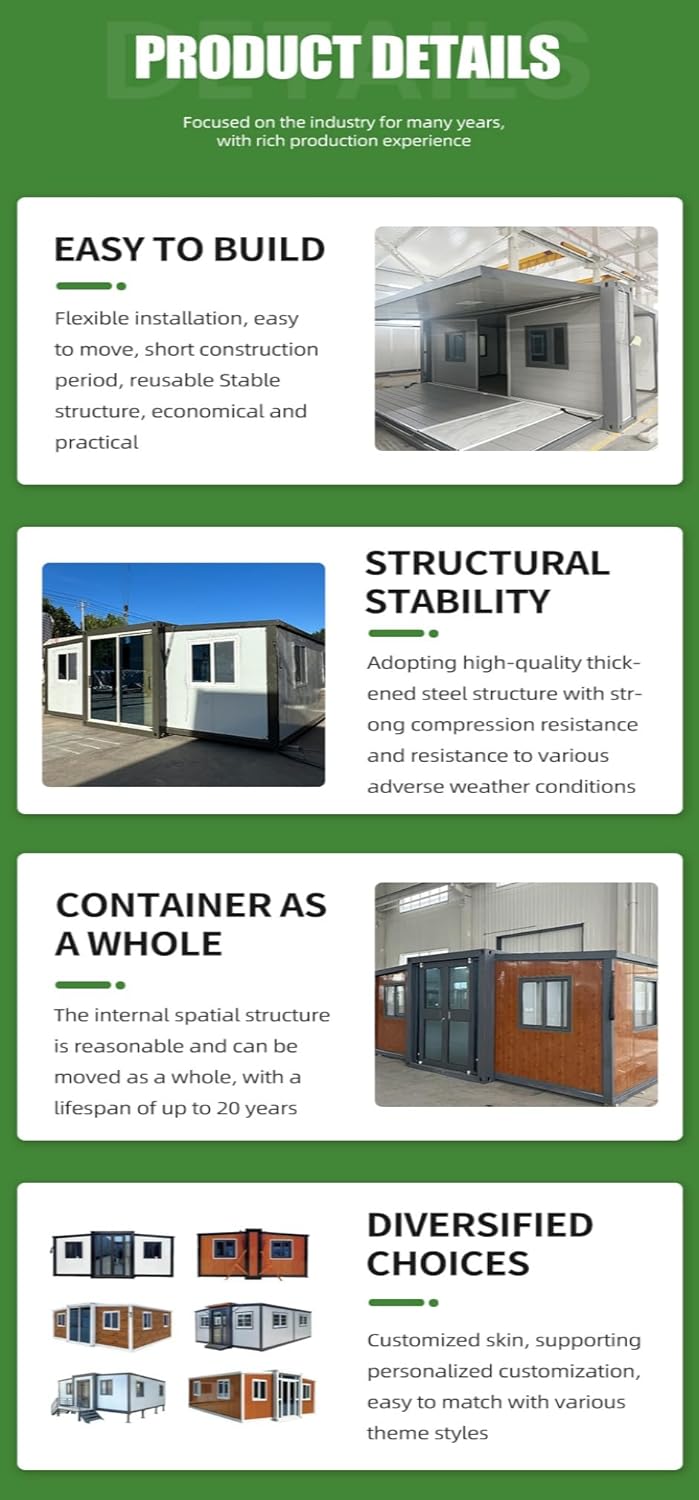

Illustrative image related to container house price

Why Consider Stacked Container Homes for Urban Projects?

Stacked container homes utilize multiple containers arranged vertically, optimizing space in urban environments. This innovative design is well-suited for student accommodations and urban housing projects, where land is at a premium. B2B buyers can appreciate the creative use of space and modern aesthetics, but must also consider the complex structural requirements and potential zoning challenges associated with multi-story builds.

How Do Hybrid Container Homes Combine Benefits for Eco-Friendly Projects?

Hybrid container homes integrate shipping containers with traditional building materials, offering a versatile design that promotes sustainability. They are ideal for eco-friendly projects and commercial spaces that prioritize green building practices. B2B buyers will find benefits in the improved insulation and aesthetic appeal, though they should be prepared for potentially higher costs and longer timelines due to the complexity of combining different materials and construction methods.

Key Industrial Applications of container house price

| Industry/Sector | Specific Application of Container House Price | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Temporary site offices for construction projects | Reduces overhead costs while providing functional spaces | Consider local regulations, transportation costs, and durability of containers. |

| Hospitality | Modular hotels or eco-lodges for tourism | Offers a unique lodging experience with lower initial costs | Evaluate design flexibility, sustainability certifications, and local market demand. |

| Education | Classrooms or dormitories in remote areas | Provides quick and affordable educational facilities | Assess land preparation needs, utility connections, and compliance with educational standards. |

| Healthcare | Mobile clinics or temporary healthcare facilities | Enhances access to healthcare services in underserved areas | Investigate local health regulations, necessary medical equipment, and logistical support. |

| Retail | Pop-up shops or mobile retail units | Enables businesses to enter new markets with minimal investment | Analyze foot traffic potential, local zoning laws, and customization options for branding. |

How is Container House Price Used in Construction Projects?

In the construction industry, container houses serve as temporary site offices or storage units. They provide a cost-effective solution for managing project logistics without the need for permanent structures. B2B buyers must consider local regulations regarding site offices, the transportation costs of containers, and the durability of the units, especially in adverse weather conditions. The flexibility in design allows for customization based on specific project needs, making them an attractive option for construction firms.

Illustrative image related to container house price

What Role Do Container Houses Play in the Hospitality Sector?

The hospitality industry has embraced container houses for creating modular hotels or eco-lodges. This innovative approach allows businesses to offer unique accommodations at a lower initial investment compared to traditional buildings. B2B buyers should focus on design flexibility to meet market trends and sustainability certifications to appeal to eco-conscious travelers. Additionally, understanding local market demand is crucial for success in this sector, as it influences the overall investment and potential returns.

How Can Container Houses Enhance Educational Facilities?

In the education sector, container houses can be transformed into classrooms or dormitories, particularly in remote or underserved areas. This application addresses the urgent need for educational infrastructure while being cost-effective. Buyers must evaluate land preparation requirements and utility connections to ensure the facilities meet educational standards. Compliance with local educational regulations is also essential to avoid disruptions and ensure the long-term viability of the investment.

What Benefits Do Container Houses Offer Healthcare Providers?

Healthcare providers utilize container houses as mobile clinics or temporary healthcare facilities, especially in areas lacking adequate medical services. This innovative solution enhances access to healthcare for underserved populations, providing essential services where they are most needed. B2B buyers should investigate local health regulations and the necessary medical equipment to ensure compliance and functionality. Logistical support for transportation and setup is also a critical consideration for healthcare applications.

Illustrative image related to container house price

How Are Container Houses Transforming Retail Opportunities?

In the retail sector, container houses are increasingly used as pop-up shops or mobile retail units, allowing businesses to enter new markets with minimal investment. This approach provides flexibility and adaptability to changing consumer trends. B2B buyers should analyze foot traffic potential in target locations and local zoning laws that may affect the operation of mobile retail units. Customization options for branding and design can further enhance the appeal of these innovative retail solutions.

3 Common User Pain Points for ‘container house price’ & Their Solutions

Scenario 1: Navigating Cost Variability in Container Home Pricing

The Problem:

B2B buyers often encounter significant variability in container home prices, which can lead to budgeting challenges. For instance, a construction firm in Nigeria may receive quotes ranging from $25,000 to $400,000 for similar container homes due to differences in container quality, local labor costs, and additional features. This unpredictability can complicate project planning and financial forecasting, making it difficult for buyers to secure appropriate funding and manage stakeholder expectations.

The Solution:

To mitigate this issue, buyers should conduct thorough market research and establish a clear budget that includes a detailed cost breakdown. Engage multiple suppliers and contractors to obtain quotes, ensuring that each proposal includes the same specifications for comparison. Additionally, consider creating a checklist of essential features—such as insulation, foundation type, and utility installations—to ensure consistency across bids. Utilize tools like online cost calculators or consult with industry experts who can provide insights into typical expenses in different regions. This approach not only fosters transparency but also helps identify potential hidden costs early in the process.

Illustrative image related to container house price

Scenario 2: Understanding Regulatory Impacts on Container Home Costs

The Problem:

Regulatory challenges can significantly impact the overall cost of container homes, especially in regions with stringent building codes or zoning laws. A construction company in Germany may find that local regulations require additional permits or modifications to container designs, which can lead to unexpected increases in costs and delays in project timelines. This can be frustrating for buyers who have already allocated a budget based on initial estimates.

The Solution:

To navigate these regulatory hurdles effectively, buyers should invest time in understanding local zoning laws and building codes before making purchases. Collaborate with local authorities or hire a consultant who specializes in container home regulations to ensure compliance from the outset. Additionally, consider integrating these regulatory costs into the initial budget, allowing for a more accurate financial assessment. Establishing a good relationship with local contractors familiar with the permitting process can also streamline approvals and reduce potential delays.

Scenario 3: Managing Additional Costs Beyond the Initial Container Purchase

The Problem:

Many B2B buyers underestimate the additional costs associated with converting a shipping container into a livable space. A developer in South America may initially budget for the container itself but overlook expenses related to site preparation, foundation work, utilities, and interior finishes. This oversight can result in budget overruns and project delays, ultimately impacting profitability and project viability.

Illustrative image related to container house price

The Solution:

To address this pain point, buyers should adopt a comprehensive approach to budgeting that accounts for all phases of the project. Begin by creating a detailed project plan that outlines every stage of development, from land clearing to final inspections. Consult with experienced contractors who can provide estimates for site preparation, foundation work, and utility connections, as these costs can vary widely based on location and site conditions. Incorporating contingency funds—typically 10-15% of the total project cost—can also help manage unforeseen expenses. By taking a holistic view of the project and engaging in proactive planning, buyers can better control costs and ensure that their container home projects remain on track and within budget.

Strategic Material Selection Guide for container house price

What Are the Key Materials Affecting Container House Pricing?

When considering the construction of container homes, the selection of materials plays a critical role in determining the overall cost, durability, and functionality of the final product. Here, we analyze four common materials used in container house construction, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Steel Influence Container House Costs?

Steel is the primary material used in shipping containers, providing structural integrity and durability. Key properties include high tensile strength, resistance to deformation, and excellent corrosion resistance when treated with appropriate coatings.

Pros: Steel is incredibly durable and can withstand harsh environmental conditions, making it suitable for various climates, including those found in Africa and the Middle East. Additionally, steel containers are often readily available and can be sourced locally, reducing transportation costs.

Illustrative image related to container house price

Cons: The primary disadvantage of steel is its susceptibility to rust if not properly maintained. Moreover, the initial cost can be high, especially for high-quality, treated steel. The manufacturing complexity can also increase costs if custom modifications are required.

Impact on Application: Steel’s strength allows for multi-story designs and the ability to support heavy loads, making it ideal for larger container homes. However, buyers must consider local environmental conditions when selecting steel grades and coatings.

Considerations for International Buyers: Compliance with local building codes and standards, such as ASTM in the U.S. or DIN in Germany, is crucial. Buyers should also be aware of local availability and pricing of steel to avoid unexpected costs.

What Role Does Insulation Play in Container Home Pricing?

Insulation is essential for energy efficiency and comfort in container homes. Common insulation materials include spray foam, fiberglass, and rigid foam boards.

Pros: Effective insulation can significantly reduce energy costs by maintaining indoor temperatures, which is particularly beneficial in regions with extreme climates. Spray foam insulation, for example, provides excellent thermal resistance and air sealing.

Cons: Some insulation materials, like spray foam, can be expensive and require specialized installation. Additionally, improper installation can lead to moisture issues, which can damage the container structure over time.

Impact on Application: The choice of insulation affects the home’s energy efficiency and comfort levels. In hotter climates, reflective insulation can help keep interiors cooler, while in colder regions, thicker insulation may be necessary.

Illustrative image related to container house price

Considerations for International Buyers: Different countries have varying insulation standards and energy efficiency requirements. Buyers should ensure that their insulation choices comply with local regulations to avoid penalties.

How Do Finishing Materials Affect Container Home Costs?

Finishing materials, including drywall, flooring, and fixtures, contribute significantly to the overall aesthetic and functionality of container homes.

Pros: High-quality finishes can enhance the appeal and value of the home, making it more marketable. Options like eco-friendly materials can attract environmentally conscious buyers.

Cons: The cost of finishing materials can vary widely, and high-end finishes can significantly increase the overall budget. Additionally, sourcing unique or luxury materials may lead to longer lead times and increased shipping costs.

Impact on Application: The choice of finishes can affect durability and maintenance requirements. For instance, water-resistant flooring is essential in humid climates, while durable surfaces are preferable in high-traffic areas.

Illustrative image related to container house price

Considerations for International Buyers: Buyers should consider local preferences for materials and styles, as well as availability. Compliance with local building codes regarding fire safety and material sustainability is also essential.

What is the Importance of Foundation Materials in Container House Construction?

The foundation is a critical component for any container home, often requiring concrete or steel piers for stability.

Pros: A solid foundation ensures the longevity and safety of the container home, especially in areas prone to flooding or seismic activity. Concrete provides excellent load-bearing capacity and can be customized for various soil conditions.

Cons: The cost of foundation materials can be significant, particularly if extensive excavation or grading is required. Additionally, the foundation must be designed to accommodate the specific weight and distribution of the container structure.

Impact on Application: The foundation type can influence the overall design and layout of the container home. For example, elevated foundations may be necessary in flood-prone areas.

Considerations for International Buyers: Local soil conditions and building codes will dictate the type of foundation required. Buyers should also consider the availability of materials and skilled labor for foundation construction.

Illustrative image related to container house price

Summary Table of Material Considerations

| Material | Typical Use Case for container house price | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural framework | High durability and availability | Susceptible to rust without proper treatment | High |

| Insulation | Thermal and acoustic barrier | Energy efficiency and comfort | Can be expensive and requires proper installation | Medium |

| Finishing Materials | Interior and exterior aesthetics | Enhances appeal and value | Can significantly increase overall budget | Medium to High |

| Foundation Materials | Stability and support | Ensures longevity and safety | High initial cost and design complexity | Medium to High |

This strategic material selection guide empowers B2B buyers to make informed decisions regarding container house pricing, ensuring compliance with local standards and optimizing overall project costs.

In-depth Look: Manufacturing Processes and Quality Assurance for container house price

What Are the Key Manufacturing Processes Involved in Container House Production?

The manufacturing of container houses involves a series of well-defined stages, each critical to ensuring the structural integrity and overall quality of the final product. Here’s a breakdown of the main stages in the manufacturing process:

How Is Material Prepared for Container House Construction?

Material preparation is the first step in the manufacturing process. This phase typically involves sourcing high-quality shipping containers, which are often made from Corten steel, known for its durability and resistance to corrosion. Once containers are procured, they undergo inspection to assess structural integrity and any pre-existing damage.

Post-inspection, containers are cleaned and prepared for modifications. This includes removing any rust, paint, or contaminants and conducting necessary repairs. For B2B buyers, selecting suppliers that prioritize sourcing containers from reputable shipping lines can ensure that the materials used are of high quality.

What Techniques Are Used in Forming Container Houses?

The forming stage involves modifying the containers to meet specific design and functional requirements. Key techniques include cutting, welding, and reinforcing the containers.

-

Cutting: Sections are cut out for doors, windows, and other openings using plasma or laser cutting technologies, which provide precision and minimize structural damage.

-

Welding: After modifications, the sections are welded back together. This step is crucial for maintaining the structural integrity of the container. Advanced welding techniques like MIG (Metal Inert Gas) or TIG (Tungsten Inert Gas) are often employed to ensure strong joints.

-

Reinforcement: Additional steel reinforcements may be added to support larger openings or to enhance load-bearing capabilities, especially for multi-story configurations.

What Does the Assembly Process Involve for Container Houses?

The assembly phase is where the modified containers are combined to create a functional living space. This can involve connecting multiple containers, often requiring careful planning to ensure that the overall structure is sound.

During assembly, interior layouts are defined, and utilities (plumbing, electrical, HVAC) are integrated. This stage often utilizes modular construction techniques, which can expedite the building process. B2B buyers should ensure that their suppliers have experience with modular assembly to reduce lead times and costs.

How Are Finishing Touches Applied to Container Houses?

Finishing involves the installation of interior and exterior elements, including insulation, drywall, flooring, and roofing. The choice of finishes can significantly impact both aesthetics and energy efficiency.

Illustrative image related to container house price

-

Insulation: Proper insulation is vital for climate control, especially in regions with extreme temperatures. Common materials include spray foam and rigid foam boards.

-

Interior Fixtures: Installation of plumbing fixtures, electrical systems, and HVAC components occurs during this stage. Buyers should inquire about the quality of materials and brands used for these installations.

-

Exterior Treatments: Exterior finishes may include paint, cladding, or landscaping, enhancing the visual appeal and protecting against environmental factors.

What Quality Assurance Measures Should B2B Buyers Consider?

Quality assurance (QA) is an integral part of the container house manufacturing process, ensuring that products meet both international standards and customer expectations.

Which International Standards Should Be Adhered to in Container House Production?

B2B buyers should look for suppliers who comply with international quality standards such as ISO 9001, which sets the criteria for a quality management system. Additionally, certifications like CE (Conformité Européenne) for European markets and API (American Petroleum Institute) for specific industrial applications may also be relevant.

These certifications assure buyers that the manufacturing processes are regularly audited and that the products meet safety and performance criteria.

What Are the Key Quality Control Checkpoints in Container House Manufacturing?

Quality control (QC) checkpoints are vital in maintaining high standards throughout the manufacturing process. The typical QC checkpoints include:

-

Incoming Quality Control (IQC): Inspects raw materials and components upon arrival to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): Ongoing inspections during manufacturing to identify defects early in the process. This may include checks on welding quality, structural integrity, and proper installation of utilities.

-

Final Quality Control (FQC): A thorough inspection of the completed container house before delivery, ensuring it meets all specifications and is free of defects.

What Common Testing Methods Are Used to Ensure Quality in Container Houses?

Testing methods can vary based on design and intended use but typically include:

- Structural Load Testing: Ensures the integrity of the building under expected loads.

- Thermal Imaging: Checks for insulation efficiency and identifies potential heat loss areas.

- Water Infiltration Testing: Assesses the effectiveness of seals and roofing materials against leaks.

How Can B2B Buyers Verify Supplier Quality Control Processes?

Verifying a supplier’s QC processes is crucial for B2B buyers, especially when sourcing internationally. Here are several strategies:

Illustrative image related to container house price

-

Audits: Conducting on-site audits of the manufacturing facility can provide insights into their quality management practices and overall capabilities.

-

Quality Reports: Requesting documentation of QC processes, including inspection reports and certifications, can help buyers gauge reliability.

-

Third-party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the manufacturing processes and final products.

What Are the Quality Control Nuances for International Buyers?

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of specific nuances:

- Regulatory Compliance: Different regions have varying building codes and regulations. Buyers should ensure that their suppliers are knowledgeable about local compliance requirements.

- Language Barriers: Clear communication is essential. Consider suppliers who provide documentation and support in multiple languages.

- Cultural Differences: Understanding cultural approaches to business and quality can facilitate smoother transactions and partnerships.

In summary, understanding the manufacturing processes and quality assurance measures for container houses is essential for B2B buyers. By focusing on these aspects, buyers can ensure they partner with reliable suppliers who deliver high-quality products that meet international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘container house price’

In the rapidly evolving market for container homes, understanding pricing and procurement strategies is essential for B2B buyers. This step-by-step guide will help you navigate the complexities of sourcing container houses, ensuring you make informed decisions that align with your project requirements and budget constraints.

Step 1: Define Your Project Requirements

Before delving into pricing, clearly outline what you need from a container home. Consider factors such as size, layout, number of containers, and intended use (e.g., residential, office, or temporary housing). Knowing your specifications upfront helps you communicate effectively with suppliers and ensures that you receive accurate quotes.

Step 2: Research Local Regulations and Zoning Laws

Understanding local building codes and zoning laws is crucial, as they can significantly impact your project. Check whether container homes are permissible in your desired area and identify any specific requirements for permits. Non-compliance can lead to costly delays and modifications, so thorough research is a must.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Ensure that the suppliers have experience with container homes and can provide insights into local regulations and construction practices.

- Look for certifications: Verify if suppliers have relevant industry certifications, which can indicate quality and reliability.

- Assess delivery capabilities: Ensure that the supplier can deliver containers efficiently to your project site, considering logistics and transportation costs.

Step 4: Request Detailed Quotes

Once you’ve shortlisted suppliers, request detailed quotes that break down the costs associated with your container home. Look for transparency in pricing, including the cost of containers, labor, and any additional materials or services.

- Compare price per square foot: This will help you gauge value and identify any outliers in your quotations.

- Inquire about bulk discounts: If you’re purchasing multiple containers, ask if there are discounts available for larger orders.

Step 5: Assess Quality and Condition of Containers

When sourcing containers, inspect their quality and condition. New containers will cost more but offer durability and fewer modifications. Used containers can be more cost-effective but may require additional repairs or modifications.

- Check for structural integrity: Ensure containers are free from rust, dents, and structural damage.

- Request inspection reports: A reputable supplier should provide documentation verifying the condition of their containers.

Step 6: Consider Additional Costs

Beyond the initial purchase price, factor in additional costs such as land preparation, foundation work, utility connections, and interior finishing. These expenses can significantly affect your overall budget.

- Budget for professional services: Include costs for architects, contractors, and other specialists who may be required for installation.

- Plan for landscaping and utilities: These elements are often overlooked but are essential for a functional living space.

Step 7: Finalize Agreements and Contracts

Once you’ve selected a supplier, ensure all agreements are clearly documented. Contracts should outline delivery timelines, payment terms, and warranty information.

- Review cancellation and modification policies: Understand the terms if you need to make changes or cancel your order.

- Establish clear communication channels: Ensure you have a designated point of contact for any issues or queries during the procurement process.

By following these steps, you will be well-equipped to navigate the container home pricing landscape effectively, making informed decisions that align with your business objectives.

Comprehensive Cost and Pricing Analysis for container house price Sourcing

What Are the Key Cost Components of Container House Pricing?

When sourcing container houses, understanding the various cost components is crucial for making informed purchasing decisions. The cost structure typically includes materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margin.

-

Materials: The choice of materials significantly impacts pricing. Standard steel shipping containers range from $1,200 to $10,000 each, depending on size and condition (new or used). Additional materials for insulation, plumbing, electrical systems, and finishes can add thousands to the overall cost.

-

Labor: Labor costs can vary widely based on geographic location and the complexity of the build. Labor for skilled trades such as electricians and plumbers can range from $45 to $150 per hour. It is essential to account for not just the general contractor but also specialized labor that may be required to ensure compliance with local building codes.

-

Manufacturing Overhead and Tooling: These costs include factory expenses and the equipment needed to modify or assemble the containers into livable spaces. Efficient manufacturing processes can reduce overhead but may require upfront investment in tooling.

-

Quality Control (QC): Ensuring that the container homes meet safety and building standards involves additional QC costs. This might include inspections and certifications, which are particularly important for international buyers to ensure compliance with local regulations.

-

Logistics: Transporting containers can be a significant cost, especially when sourcing internationally. Shipping fees, customs duties, and local delivery costs should be factored into the total cost. For buyers in regions such as Africa or South America, these logistics costs can add considerable expenses, especially if shipping to remote locations.

-

Margin: Suppliers typically add a margin to cover their costs and ensure profitability. The margin can vary based on the supplier’s overhead, market demand, and competitive landscape.

What Factors Influence Container House Pricing for B2B Buyers?

Several key price influencers can affect container house pricing, particularly for international B2B buyers.

-

Volume and Minimum Order Quantity (MOQ): Suppliers may offer better pricing for larger orders. Understanding the MOQ is critical, as ordering in bulk can significantly reduce per-unit costs.

-

Specifications and Customization: Customizing container homes to meet specific needs can increase costs. Buyers should clearly outline their specifications to avoid unexpected expenses later in the process.

-

Material Quality and Certifications: The quality of materials used, including insulation and finishes, can influence pricing. Additionally, certifications for sustainability or safety can also affect costs, especially in markets that prioritize eco-friendly construction.

-

Supplier Factors: Reliability, reputation, and experience of the supplier can impact costs. Established suppliers might charge higher prices due to their proven track record, but they often provide better service and quality assurance.

-

Incoterms: Understanding the terms of trade is essential for international buyers. Incoterms dictate who is responsible for shipping, insurance, and tariffs, which can significantly impact the total cost of ownership.

What Are the Best Negotiation Tips for Container House Pricing?

For B2B buyers, negotiating container house prices effectively can yield substantial savings. Here are some tips:

-

Research Market Prices: Being informed about the market rates for both containers and construction services helps buyers negotiate confidently.

-

Leverage Volume Discounts: If possible, consolidate orders to achieve better pricing. Suppliers are often willing to negotiate on larger volumes.

-

Clarify Total Cost of Ownership: When negotiating, consider not just the initial price but also the ongoing costs, such as maintenance, insurance, and utilities. A slightly higher upfront cost could lead to lower long-term expenses.

-

Be Flexible with Specifications: If you can be flexible on certain specifications or materials, it may open the door to cost savings.

-

Establish Long-term Relationships: Building a good relationship with suppliers can lead to better deals and more favorable terms in the future.

Conclusion

Understanding the cost structure and pricing influencers of container houses is essential for B2B buyers, particularly in diverse markets like Africa, South America, the Middle East, and Europe. By considering factors such as materials, labor, and logistics, along with effective negotiation strategies, buyers can optimize their purchasing decisions. Always remember that the prices mentioned are indicative and can vary based on specific circumstances and local market conditions.

Alternatives Analysis: Comparing container house price With Other Solutions

Exploring Alternatives to Container House Pricing

As the demand for affordable and sustainable housing solutions grows, many businesses are considering alternatives to container houses. While container homes provide a unique combination of durability and eco-friendliness, various other options are available in the market. This analysis aims to compare container house pricing with two viable alternatives: prefabricated modular homes and traditional brick-and-mortar construction. Understanding these options helps B2B buyers make informed decisions based on their specific needs.

| Comparison Aspect | Container House Price | Prefabricated Modular Homes | Traditional Brick-and-Mortar Construction |

|---|---|---|---|

| Performance | High durability, energy-efficient | Good thermal performance, customizable | High structural integrity, long lifespan |

| Cost | $25,000 – $250,000 | $100,000 – $300,000 | $150,000 – $500,000 |

| Ease of Implementation | Moderate; requires site preparation | Easy; built off-site, quick assembly | Challenging; requires extensive site work |

| Maintenance | Low; resistant to weather | Moderate; requires regular upkeep | High; susceptible to wear and structural issues |

| Best Use Case | Affordable housing, eco-friendly projects | Quick deployment for temporary or permanent housing | Long-term residential or commercial buildings |

What Are the Advantages and Disadvantages of Prefabricated Modular Homes?

Prefabricated modular homes are constructed in a factory setting and then transported to the site for assembly. They offer a faster build time compared to traditional methods, often taking a few months from order to completion. Their cost typically ranges from $100,000 to $300,000, making them a more expensive option than container homes but generally less costly than traditional construction. One of the main advantages is the variety of designs and configurations available, allowing for customization. However, these homes may require more maintenance than container houses, as they are not as inherently resilient to harsh weather conditions.

How Does Traditional Brick-and-Mortar Construction Compare?

Traditional brick-and-mortar construction is the most established method for building homes and commercial buildings. With costs ranging from $150,000 to $500,000, this option is generally the most expensive. However, the durability and longevity of brick-and-mortar structures are unparalleled, often lasting for decades with proper maintenance. This method allows for complete customization but involves a longer construction timeline, often taking several months to over a year to complete. While it offers a high level of structural integrity, it requires significant site preparation and ongoing maintenance, making it less appealing for businesses seeking a quick and cost-effective housing solution.

Illustrative image related to container house price

How Should B2B Buyers Choose the Right Solution?

When choosing between container homes, prefabricated modular homes, and traditional construction, B2B buyers should consider their specific project requirements, budget constraints, and desired timelines. Container homes may be ideal for businesses focused on sustainability and lower initial costs, while prefabricated modular homes are better suited for those needing quick assembly and flexibility in design. Traditional brick-and-mortar construction remains the best option for long-term investment in structural integrity and customization, albeit at a higher price point. By carefully evaluating these factors, buyers can select the most appropriate housing solution for their needs.

Essential Technical Properties and Trade Terminology for container house price

What Are the Key Technical Properties Impacting Container House Pricing?

Understanding the essential technical properties of container houses is crucial for B2B buyers in making informed purchasing decisions. Here are some key specifications that directly influence the cost and feasibility of shipping container homes:

-

Material Grade

Container homes are typically constructed from high-strength steel, which is rated by its yield strength. The most common grade is Corten steel, known for its durability and weather resistance. For B2B buyers, selecting the right material grade is vital; higher-grade steel may incur higher upfront costs but offers better long-term performance and lower maintenance expenses. -

Container Dimensions

Standard shipping containers come in various sizes, with the most common being 20-foot and 40-foot lengths. The dimensions not only affect the cost but also the design possibilities of the home. Buyers must evaluate the size that meets their needs while balancing the cost per square foot, which typically ranges from $150 to $350. -

Structural Integrity

The structural integrity of a container home is paramount. This involves understanding load-bearing capacities and compliance with local building codes. For B2B buyers, ensuring that a container home can withstand environmental stresses—such as heavy winds, seismic activity, or snow loads—can prevent costly modifications or repairs later. -

Insulation and Energy Efficiency

Containers are metal structures that require proper insulation to maintain comfortable living conditions. The insulation type (e.g., spray foam, rigid board) affects both initial costs and energy efficiency. For businesses, investing in better insulation can lead to lower heating and cooling costs, enhancing overall property value. -

Foundation Requirements

Container homes generally need a solid foundation, which can significantly impact the total cost. The type of foundation (e.g., concrete slab, piers) determines not just initial expenses but also long-term stability. B2B buyers should assess the site conditions and select a foundation that minimizes future issues. -

Finishing Specifications

The choice of interior and exterior finishes, including flooring, roofing, and fixtures, can vary widely in cost. Buyers should consider the total cost of these finishes when budgeting, as they can significantly affect the overall price. High-quality finishes may enhance appeal and resale value, making them a worthy investment.

What Are Common Trade Terms Related to Container House Pricing?

Familiarity with industry jargon is essential for effective communication and negotiation in the container home market. Here are several key terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of container homes, OEMs often supply pre-fabricated components or materials. Understanding OEM relationships can help buyers secure quality products at competitive prices. -

MOQ (Minimum Order Quantity)

MOQ defines the smallest quantity of a product that a supplier is willing to sell. For container homes, knowing the MOQ is essential for budgeting and planning, especially if purchasing multiple containers or custom features. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing for specific products or services. B2B buyers should utilize RFQs to compare costs across different suppliers, ensuring they receive competitive bids for container homes. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms can help buyers navigate shipping costs, risks, and insurance responsibilities when importing container homes or materials. -

FF&E (Furniture, Fixtures, and Equipment)

This term refers to the movable items within a container home that are not permanently attached. For B2B buyers, considering FF&E in budgeting is crucial as it can significantly affect the overall cost and functionality of the living space. -

Zoning Regulations

These are local laws that dictate how land can be used and developed. Understanding zoning regulations is crucial for B2B buyers to avoid legal complications and ensure that the container home can be legally placed and occupied in the desired location.

By grasping these technical properties and industry terms, B2B buyers can navigate the complexities of container home pricing more effectively, ultimately leading to better purchasing decisions.

Navigating Market Dynamics and Sourcing Trends in the container house price Sector

What Are the Key Trends Shaping the Container House Price Market?

The container house market is experiencing significant growth driven by urbanization, rising housing costs, and the need for sustainable living solutions. As cities become more congested, container homes offer an innovative way to maximize space at a lower price point compared to traditional housing. The average cost for constructing a container home ranges from $25,000 to $250,000, influenced by factors such as size, design, and location. For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding local market dynamics is crucial. In regions like Nigeria, where affordable housing is a pressing issue, container homes present a viable solution that aligns with economic constraints.

Emerging technologies are shaping sourcing trends in this sector, with advancements in modular construction techniques and digital platforms facilitating easier procurement processes. Buyers can now access suppliers and manufacturers through online marketplaces that provide competitive pricing and transparency in sourcing materials. Additionally, the integration of Building Information Modeling (BIM) allows for efficient project planning and execution, reducing costs associated with labor and materials. This trend is particularly relevant for buyers in Europe and the Middle East, where efficiency and compliance with local regulations are paramount.

How Can Sustainability and Ethical Sourcing Impact Container House Prices?

The importance of sustainability and ethical sourcing in the container house sector cannot be overstated. As global awareness of environmental issues rises, B2B buyers are increasingly seeking materials and suppliers that adhere to green building standards. The use of recycled shipping containers not only reduces waste but also lowers the carbon footprint associated with traditional construction methods. Consequently, investing in ‘green’ certifications can enhance a brand’s reputation and appeal to environmentally-conscious consumers.

Furthermore, ethical supply chains are vital for ensuring that materials are sourced responsibly. Buyers should prioritize suppliers who demonstrate transparency in their sourcing practices, ensuring that labor conditions are fair and that local communities benefit from the economic activity generated by container home production. This trend is particularly relevant in regions like South America and Africa, where social responsibility can significantly impact brand loyalty and market penetration.

Illustrative image related to container house price

How Has the Container House Market Evolved Over Time?

The container house market has evolved significantly over the past two decades, transitioning from a niche concept to a mainstream housing alternative. Initially, shipping containers were primarily utilized for storage and transportation. However, as urban living conditions became more challenging, innovative architects and builders began repurposing these containers into functional living spaces. This evolution was driven by a combination of factors, including the need for affordable housing, the rise of sustainable living, and the appeal of minimalist design.

As the market has matured, the introduction of prefabricated container homes has made it easier for B2B buyers to enter this space. These homes offer standardized designs that streamline the construction process while reducing costs, making them particularly attractive for developers and investors. The focus on customization and sustainability continues to shape the trajectory of the container house market, ensuring its relevance in a rapidly changing global landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of container house price

-

How do I determine the total cost of a container house?

To accurately estimate the total cost of a container house, consider various factors including the size of the container, the number of containers required, and additional features such as insulation, plumbing, and electrical systems. Typically, costs range from $25,000 to $250,000, depending on the complexity of the build and customization. It’s also crucial to factor in land preparation, foundation work, and any local zoning regulations that may affect pricing. -

What is the best way to source shipping containers for my project?

When sourcing shipping containers, look for reputable suppliers with experience in container homes. Verify their certifications and inspect the containers for structural integrity. It’s often beneficial to purchase used containers to save costs, but ensure you conduct thorough inspections to avoid hidden damages. Additionally, consider suppliers who offer customization options to meet your specific design needs. -

What factors should I consider when choosing a supplier for container homes?

Evaluate suppliers based on their experience in manufacturing container homes, customer reviews, and the range of customization options they provide. It’s essential to assess their quality assurance processes, after-sales support, and compliance with local building codes. Request case studies or references from previous clients to gauge their reliability and service quality. -

What are the minimum order quantities (MOQ) for container houses?

Minimum order quantities can vary widely by supplier and region. Some manufacturers may allow single-unit purchases, while others may require orders of multiple units, especially for custom designs. Always clarify MOQs during initial discussions and consider negotiating terms that align with your project needs and budget. -

What payment terms are typical for international container house purchases?

Payment terms for container house purchases can differ significantly among suppliers. Common arrangements include a deposit upfront (often 30-50%), with the remainder due upon delivery or after installation. Ensure to discuss and agree on payment methods that provide security, such as letters of credit or escrow services, especially in international transactions. -

How do I ensure quality assurance for my container home project?

To ensure quality, select suppliers who adhere to international standards and provide warranties for their products. Request detailed specifications and quality control procedures before production begins. Additionally, consider hiring third-party inspectors to assess the containers during manufacturing and before shipment, ensuring compliance with your requirements. -

What logistics considerations should I be aware of when importing container houses?

Logistics play a crucial role in the timely delivery of container houses. Be mindful of shipping methods, potential customs regulations, and import duties in your destination country. Collaborate with logistics experts to navigate shipping routes and ensure containers are transported safely. It’s also advisable to account for lead times in your project schedule. -

How can I customize my container house to meet local regulations and preferences?

Customization should align with local building codes, climate conditions, and cultural preferences. Engage architects or designers familiar with container construction and local regulations to ensure compliance. Discuss your specific needs with the supplier to explore design options, finishes, and layouts that reflect your vision while meeting safety standards.

Top 5 Container House Price Manufacturers & Suppliers List

1. Reddit – Container Cost Overview

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Container cost: approximately $4,000 each for 40-foot containers; total for 3-5 containers around $20,000. Additional costs include ground preparation, foundation (estimated $5,000-$15,000), utilities (water/sewer, grid/solar connections), equipment rental, lumber, drywall, flooring, insulation, paint, furnishing, and labor. Total estimated cost for four containers: $100,000-$150,000 depending on …

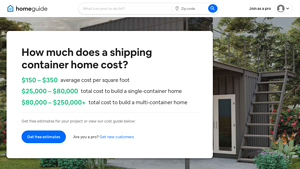

2. HomeGuide – Shipping Container Home Costs

Domain: homeguide.com

Registered: 1995 (30 years)

Introduction: Shipping Container Home Cost: $150 – $350 average cost per square foot; $25,000 – $80,000 total cost for a single-container home; $80,000 – $250,000+ total cost for a multi-container home. Container prices: $1,200 – $10,000 for the container alone. Sizes and costs: Home office (80-100 sq ft, 1 container, $10,000 – $20,000), Studio (160 sq ft, 1 container, $15,000 – $25,000), 1 bed 1 bath (320 sq f…

3. Bobs Containers – Container Homes

Domain: bobscontainers.com

Registered: 2019 (6 years)

Introduction: Container Homes – 20 ft, 40 ft, Multi-unit

– 20 ft Container Homes

– 40 ft Container Homes

– Multi-Unit Container Homes

– 1 Bedroom Homes

– 2 Bedroom Homes

– 3 Bedroom Homes

– Affordable Homes

– Container Dorms

– Container Restrooms

– Container Offices

– Container Bars

– Container Pool

– Ready to Ship

– Container Parts & Accessories

– Pricing for various models:

– “The Porter” Model: 40 ft Luxur…

4. House Beautiful – Shipping Container Homes

Domain: housebeautiful.com

Registered: 1995 (30 years)

Introduction: Shipping container homes start around $25,000 for a single-container tiny home. Average costs range from $150 to $350 per square foot. Standard shipping container sizes and costs include: 80 sq ft (10 ft long) = $12k to $28k, 160 sq ft (20 ft long) = $24k to $56k, 320 sq ft (40 ft long) = $48k to $112k. A lone shipping container costs between $1,200 and $10,000. General guidance for home sizes: St…

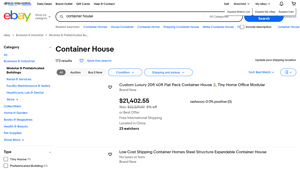

5. eBay – Key Product Details for Container Houses

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Key product details for Container Houses on eBay include: 1. Types: Prefabricated Building, Tiny House, Modular Home, Kit Home, Cabin. 2. Sizes: Width options of 20 ft, 30 ft, 40 ft; Length options of 20 ft, 30 ft, 40 ft. 3. Number of Bedrooms: 1, 2, 3. 4. Materials: Steel, Metal, Aluminum, Plastic, Wood. 5. Features: Dual Pane Windows, Modern Architecture, Smart Living, Universal Design, Water So…

Strategic Sourcing Conclusion and Outlook for container house price

In navigating the landscape of container house pricing, international B2B buyers must consider several critical factors that can significantly impact overall costs. The price range for container homes typically spans from $25,000 to over $250,000, influenced by variables such as size, location, and desired features. Strategic sourcing of materials and labor not only enhances cost-effectiveness but also ensures compliance with local regulations, which can vary significantly across regions like Africa, South America, the Middle East, and Europe.

Understanding the breakdown of costs—from container acquisition and site preparation to utilities and interior finishes—will enable buyers to make informed decisions that align with their budget and project goals. Additionally, opting for used containers and prefabricated designs can lead to substantial savings, further emphasizing the importance of strategic sourcing in this sector.

Illustrative image related to container house price

Looking ahead, the demand for sustainable and innovative housing solutions is expected to rise, making container homes an attractive option for diverse markets. International buyers are encouraged to leverage strategic partnerships with suppliers and contractors to capitalize on these trends, ensuring they remain competitive in a rapidly evolving industry. Engage with local experts and explore financing options to position your projects for success in the container housing market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.