Top 4 Burn Barrells Suppliers (And How to Choose)

Introduction: Navigating the Global Market for burn barrells

In today’s dynamic global market, sourcing burn barrels poses unique challenges for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. The need for efficient waste management solutions has never been more critical, with businesses seeking reliable options to incinerate waste while adhering to environmental regulations. This guide aims to illuminate the complexities of the burn barrel market, providing insights into various types, applications, and the importance of selecting the right suppliers.

As you navigate through this comprehensive resource, you will discover essential information regarding the different burn barrel designs, including traditional models and advanced incinerators tailored for enhanced efficiency. We will delve into the diverse applications of burn barrels across industries, from agriculture to construction, highlighting their role in promoting sustainable waste disposal practices. Additionally, this guide will equip you with practical tips for vetting suppliers, understanding cost structures, and ensuring compliance with local regulations.

By empowering international B2B buyers with actionable insights and detailed knowledge, this guide will facilitate informed purchasing decisions that align with your operational needs and environmental goals. Whether you are in Vietnam or Nigeria, understanding the global landscape of burn barrels will enable you to leverage the best options available, ultimately enhancing your business’s efficiency and sustainability.

Understanding burn barrells Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Metal Barrel | Typically made from steel, holds 55 gallons, often has a removable lid. | Waste management, agricultural burning. | Pros: Cost-effective, durable. Cons: Can rust, may emit smoke if not used correctly. |

| Stainless Steel Incinerator | Made of high-quality stainless steel, designed for high-temperature burns. | Industrial waste disposal, document incineration. | Pros: Long-lasting, efficient burn, cleaner emissions. Cons: Higher upfront cost. |

| Burn Cage | Open design for better airflow, often portable. | Yard debris disposal, outdoor events. | Pros: Easy to use, reduces smoke. Cons: Less effective for small debris, requires supervision. |

| Customizable Burn Barrel | Options for size, material, and additional features like covers and grates. | Specialized waste management, unique business needs. | Pros: Tailored solutions, versatile. Cons: May require longer lead times for production. |

| Eco-Friendly Burn Barrel | Designed with sustainable materials and features to minimize emissions. | Green waste management, environmentally-conscious businesses. | Pros: Reduces environmental impact, compliant with regulations. Cons: Often more expensive than traditional options. |

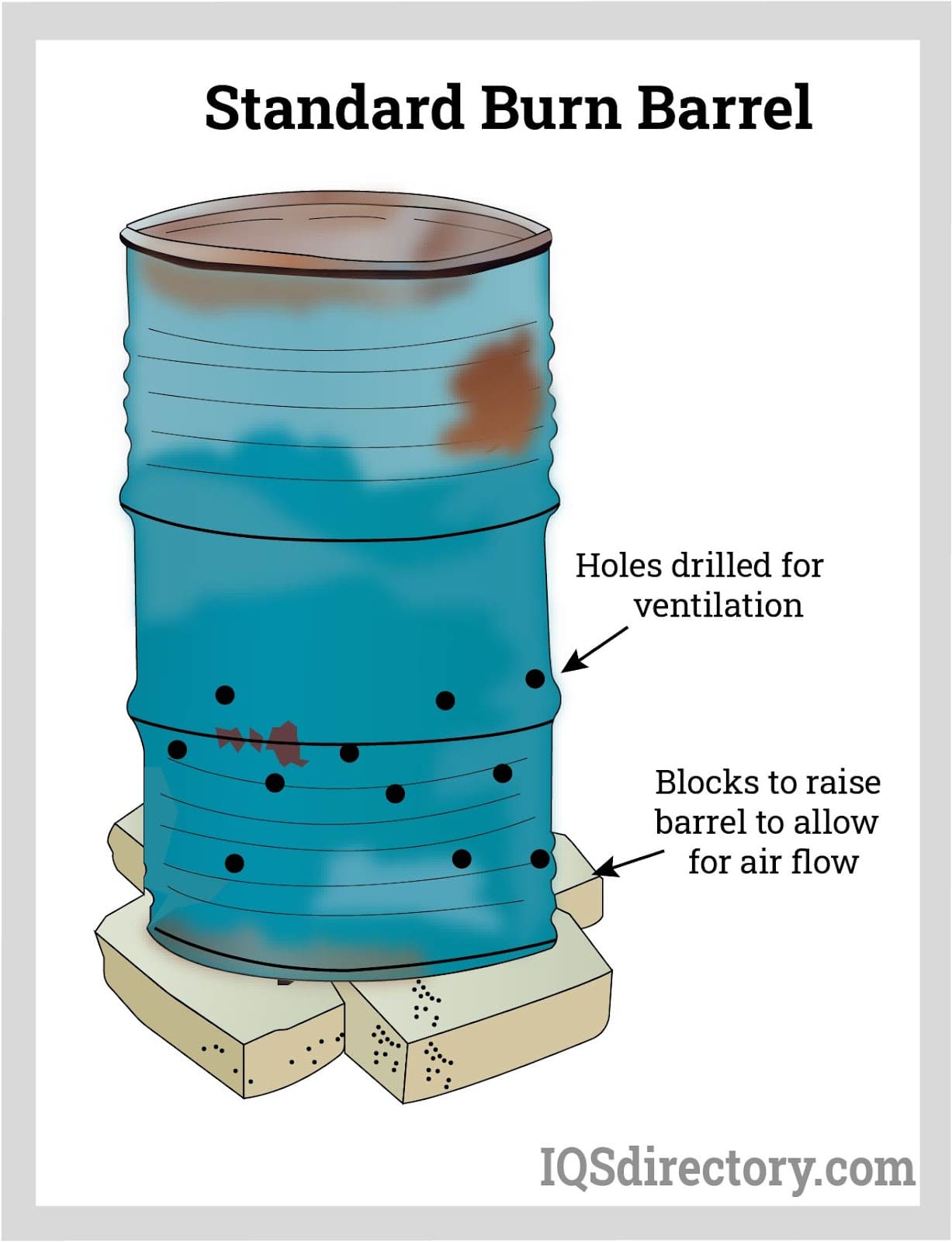

What Are the Characteristics of Standard Metal Barrels?

Standard metal burn barrels are typically constructed from durable steel and have a capacity of 55 gallons. They often feature a removable lid for easy access and burning of waste materials. These barrels are widely used in agricultural settings and waste management due to their affordability and robust nature. However, buyers should consider that they may rust over time and can produce smoke if not properly maintained or used.

How Do Stainless Steel Incinerators Stand Out?

Stainless steel incinerators are engineered for high-temperature burns, often exceeding 1800°F, which allows for efficient waste disposal and minimal smoke emissions. Their construction ensures longevity and resistance to warping, making them ideal for industrial applications, including document destruction and hazardous waste disposal. While the initial investment is higher than that of standard barrels, the long-term savings on maintenance and environmental compliance can be significant for businesses.

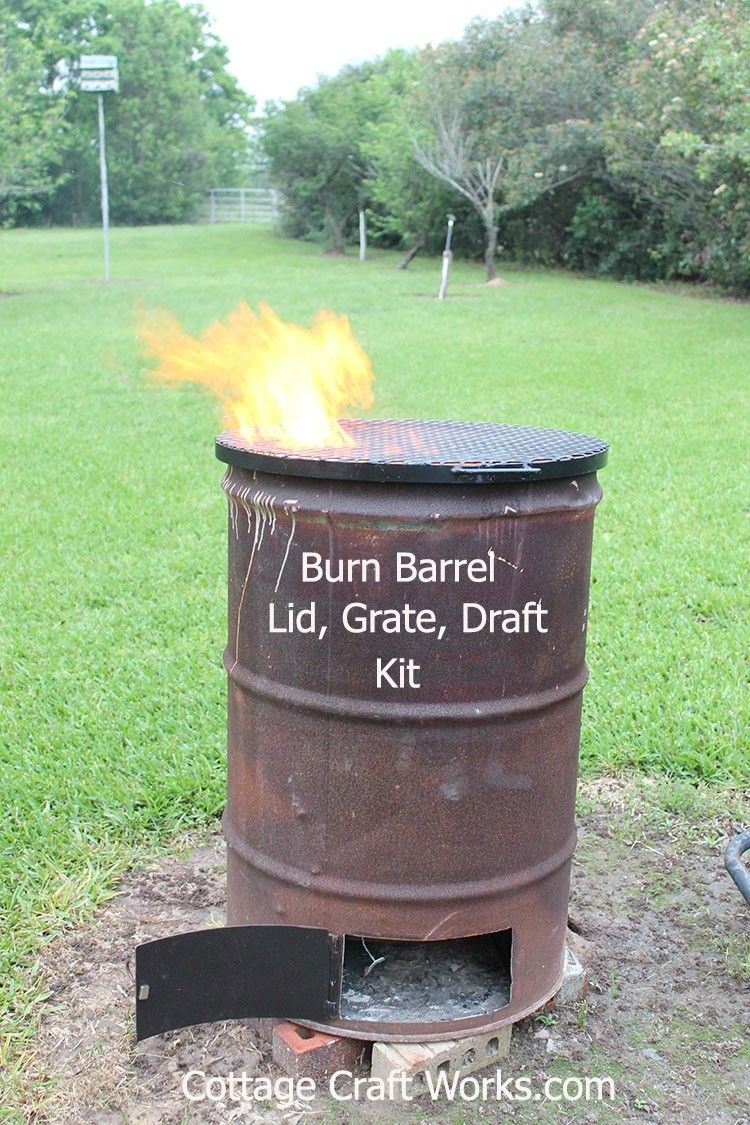

Illustrative image related to burn barrells

What Benefits Do Burn Cages Offer for Outdoor Use?

Burn cages feature an open design that enhances airflow, allowing for a more efficient burn and reduced smoke output. They are particularly useful for disposing of yard debris and are often portable, making them suitable for various outdoor events. However, their effectiveness diminishes with smaller debris, and they require supervision during use to ensure safety. Businesses should weigh the convenience of these units against their limitations in handling different waste types.

Why Choose Customizable Burn Barrels?

Customizable burn barrels provide businesses with the flexibility to select sizes, materials, and features such as covers and grates tailored to specific waste management needs. This adaptability makes them ideal for specialized applications, ensuring compliance with local regulations and operational requirements. However, potential buyers should be prepared for longer lead times and possibly higher costs compared to off-the-shelf options.

What Makes Eco-Friendly Burn Barrels a Smart Choice?

Eco-friendly burn barrels are designed with sustainable materials and technologies that minimize emissions and environmental impact. They cater to businesses focused on green practices and compliance with environmental regulations. While they may come at a premium price, the investment can enhance a company’s reputation and appeal to environmentally-conscious customers. These barrels are ideal for organizations looking to demonstrate their commitment to sustainability while managing waste effectively.

Key Industrial Applications of burn barrells

| Industry/Sector | Specific Application of Burn Barrels | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Disposal of agricultural waste and debris | Reduces waste management costs and promotes sustainability | Compliance with local environmental regulations; material durability |

| Construction | Incineration of construction waste | Efficient waste disposal; minimizes site clutter | Sourcing from reliable manufacturers; capacity and size options |

| Waste Management | Processing of non-recyclable materials | Enhances waste processing efficiency; reduces landfill use | Certifications for safety; emission controls; local regulations |

| Forestry | Burning of brush and tree debris | Prevents wildfire risks; clears land for new growth | Material quality; fire safety features; transport logistics |

| Municipal Services | Community waste disposal and incineration | Cost-effective waste management for municipalities | Bulk purchasing options; compliance with health and safety standards |

How Are Burn Barrels Used in Agriculture for Waste Disposal?

In the agricultural sector, burn barrels are employed for the incineration of organic waste, such as crop residues and plant debris. This practice not only reduces the volume of waste but also minimizes the risk of pest infestations and disease spread. For international buyers, especially in regions like Africa and South America, it is crucial to consider local environmental regulations regarding open burning. Additionally, sourcing burn barrels made from durable materials ensures they withstand the rigors of outdoor use.

What Role Do Burn Barrels Play in Construction Waste Management?

In construction, burn barrels are utilized for the disposal of non-hazardous waste materials, such as wood scraps and packaging debris. This method provides a quick and efficient solution to minimize clutter on job sites, leading to safer working conditions. Buyers in the construction industry should prioritize barrels that comply with local waste management laws and have sufficient capacity to handle the volume of waste generated. Furthermore, selecting robust designs can enhance longevity and performance.

How Are Burn Barrels Beneficial for Waste Management Companies?

Waste management companies leverage burn barrels to process non-recyclable materials, effectively reducing the amount of waste sent to landfills. This not only contributes to environmental sustainability but also improves operational efficiency. For B2B buyers in this sector, it is essential to consider sourcing barrels that meet safety and emission standards, as well as those that are certified for use in their specific geographic regions. This ensures compliance and minimizes potential liabilities.

Illustrative image related to burn barrells

Why Are Burn Barrels Important in Forestry Practices?

In forestry, burn barrels are critical for the safe disposal of brush and tree debris, particularly after land clearing or storm damage. By incinerating this waste, forestry operations can reduce wildfire risks and promote healthier land management practices. Buyers should focus on barrels that feature fire safety measures and are made from materials capable of withstanding high temperatures. Understanding local regulations regarding outdoor burning is also vital for compliance and operational success.

How Do Municipal Services Utilize Burn Barrels for Community Waste Management?

Municipalities often utilize burn barrels for community waste disposal, particularly in rural areas where traditional waste management services may be limited. This approach provides a cost-effective solution for managing organic waste and reduces the burden on landfill sites. When sourcing burn barrels for municipal applications, it is important to consider bulk purchasing options and ensure that the products adhere to health and safety standards. This not only enhances community health but also fosters trust in public services.

3 Common User Pain Points for ‘burn barrells’ & Their Solutions

Scenario 1: Navigating Regulatory Compliance for Waste Management

The Problem: Many B2B buyers, especially those in industrial sectors, face the challenge of adhering to local and international regulations surrounding waste management and incineration. This is particularly pertinent in regions such as Africa and South America, where waste disposal regulations can vary significantly. Buyers may find themselves uncertain about the legal implications of using burn barrels, risking penalties or damaging their reputations by failing to comply with environmental standards. Furthermore, the materials being burned may require specific handling to avoid toxic emissions.

The Solution: To navigate these regulatory waters, buyers should conduct thorough research on the regulations governing waste incineration in their respective regions. This includes understanding what materials are permissible for incineration and the required emissions standards. Collaborating with local environmental agencies can provide clarity and ensure compliance. When sourcing burn barrels, opt for models that are designed with advanced airflow systems and high-temperature capabilities, as these features often lead to more efficient burns and reduced emissions. Additionally, consider investing in training for staff on proper burning techniques and safety protocols to further mitigate compliance risks.

Illustrative image related to burn barrells

Scenario 2: Inefficient Burning Leading to Increased Costs

The Problem: A common pain point for B2B buyers using burn barrels is the inefficiency of the burning process, which can result in higher operational costs. Inefficient burns may lead to incomplete combustion, leaving behind unburned waste that requires additional disposal methods, thus increasing overall waste management costs. This is particularly problematic for businesses dealing with large volumes of waste, as the expenses can quickly add up.

The Solution: To enhance the efficiency of burning processes, buyers should invest in high-quality burn barrels that feature innovative designs, such as those with enhanced airflow systems. These designs promote hotter burns, ensuring that waste is fully incinerated. Buyers should also regularly maintain their burn barrels, checking for blockages and wear that can impede airflow and reduce burning efficiency. Incorporating an ash catcher can help manage residue and keep the burning area cleaner, further reducing the time and effort spent on waste management. Finally, establishing a regular schedule for waste burning can optimize operations and reduce costs associated with excess waste handling.

Scenario 3: Safety Hazards Associated with Burn Barrels

The Problem: Safety is a paramount concern for B2B buyers using burn barrels, especially in industrial settings or rural areas where open burning may pose risks. The potential for fires to spread or accidents to occur during the burning process can create hazardous situations, endangering workers and surrounding communities. Additionally, improper handling or malfunctioning equipment can lead to injuries or environmental damage, which can severely impact a company’s bottom line and reputation.

The Solution: To mitigate safety hazards, buyers must prioritize the selection of burn barrels that are designed with safety features, such as flame arrestors and stable bases. It is essential to provide adequate training for employees on safe operating procedures, including the correct methods for loading waste and monitoring the burn process. Implementing strict safety protocols, such as keeping a fire extinguisher on-site and maintaining a safe distance from flammable materials, can further minimize risks. Additionally, conducting regular safety audits and drills can help ensure that all personnel are prepared to handle emergencies effectively. By fostering a culture of safety, companies can protect their workforce and reduce the likelihood of incidents related to burn barrel use.

Illustrative image related to burn barrells

Strategic Material Selection Guide for burn barrells

When selecting materials for burn barrels, it is essential to consider the performance characteristics, cost implications, and regulatory compliance specific to different regions. Here, we analyze four common materials used in burn barrel manufacturing: steel, stainless steel, aluminum, and high-density polyethylene (HDPE). Each material has distinct properties and suitability for various applications, particularly for international B2B buyers.

What are the Key Properties of Steel for Burn Barrels?

Steel is a widely used material for burn barrels due to its strength and durability. It typically has a high-temperature rating, allowing it to withstand the intense heat generated during burning. Steel is also relatively affordable, making it a cost-effective option for manufacturers. However, it is prone to corrosion, especially when exposed to moisture, which can compromise its structural integrity over time.

Pros: High strength, cost-effective, readily available.

Cons: Susceptible to rust and corrosion, which may require additional protective coatings.

Impact on Application: Suitable for burning solid waste but may not be ideal for corrosive materials.

Considerations for International Buyers: Compliance with local environmental regulations is crucial, as some regions may have restrictions on burning certain materials.

How Does Stainless Steel Compare for Burn Barrels?

Stainless steel offers superior corrosion resistance compared to regular steel, making it an excellent choice for burn barrels that will be exposed to harsh weather conditions. It can withstand high temperatures without warping, ensuring longevity and performance. Although stainless steel is more expensive than regular steel, its durability can lead to lower lifecycle costs.

Pros: Excellent corrosion resistance, high-temperature tolerance, long lifespan.

Cons: Higher initial cost, which may deter budget-conscious buyers.

Impact on Application: Ideal for a variety of waste types, including those with corrosive properties.

Considerations for International Buyers: Buyers should ensure that the stainless steel grade meets local standards, such as ASTM or DIN specifications.

Illustrative image related to burn barrells

What are the Benefits of Using Aluminum for Burn Barrels?

Aluminum is lightweight and resistant to corrosion, making it a practical option for burn barrels, especially in regions with high humidity. Its thermal conductivity allows for efficient heat distribution, which can enhance burning efficiency. However, aluminum has a lower melting point than steel and stainless steel, which may limit its use in high-temperature applications.

Pros: Lightweight, corrosion-resistant, good heat distribution.

Cons: Lower melting point, which may affect performance under extreme conditions.

Impact on Application: Suitable for light waste materials but may not be ideal for heavy-duty applications.

Considerations for International Buyers: Ensure compliance with local regulations regarding aluminum usage, particularly in waste management practices.

Why Choose High-Density Polyethylene (HDPE) for Burn Barrels?

HDPE is a plastic material known for its high strength-to-density ratio and excellent chemical resistance. While it is not typically used for high-temperature applications, it can be effective for specific uses, such as burning non-hazardous waste. HDPE is also resistant to corrosion and does not rust, making it a low-maintenance option.

Pros: Lightweight, corrosion-resistant, low maintenance.

Cons: Limited temperature tolerance, not suitable for all waste types.

Impact on Application: Best for non-hazardous waste; caution is advised with flammable materials.

Considerations for International Buyers: Buyers should verify that HDPE barrels meet local waste disposal regulations and standards.

Summary Table of Material Selection for Burn Barrels

| Material | Typical Use Case for burn barrells | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | General waste burning | High strength, cost-effective | Prone to corrosion | Medium |

| Stainless Steel | Corrosive waste and heavy-duty use | Excellent durability and longevity | Higher initial cost | High |

| Aluminum | Lightweight waste materials | Lightweight and corrosion-resistant | Lower melting point | Medium |

| High-Density Polyethylene (HDPE) | Non-hazardous waste | Low maintenance and chemical resistance | Limited temperature tolerance | Low |

This strategic material selection guide provides insights into the key properties, advantages, and limitations of various materials used in burn barrels, aiding international B2B buyers in making informed decisions tailored to their specific needs and regional compliance requirements.

Illustrative image related to burn barrells

In-depth Look: Manufacturing Processes and Quality Assurance for burn barrells

What Are the Key Stages in the Manufacturing Process of Burn Barrels?

The manufacturing process of burn barrels involves several critical stages, each essential for producing a durable and efficient product.

-

Material Preparation: The primary materials used in burn barrel manufacturing are typically heavy-duty steel or stainless steel. In this phase, raw materials are sourced and inspected for quality. Steel sheets are cut to size using laser cutting or plasma cutting techniques, ensuring precision and minimal waste.

-

Forming: This stage involves shaping the cut steel into cylindrical forms. Techniques such as rolling and welding are commonly employed. The edges of the steel sheets are often welded to create a seamless barrel, enhancing its structural integrity. Advanced manufacturers may utilize automated machinery to improve consistency and speed.

-

Assembly: After forming, various components such as lids, handles, and air intake vents are assembled. This process can include welding, bolting, or using high-strength adhesives, depending on the design. Attention to detail during assembly is crucial to ensure that all parts fit correctly and function as intended.

-

Finishing: The finishing stage includes surface treatments such as painting or powder coating to enhance corrosion resistance and aesthetic appeal. High-temperature-resistant paints may be used to withstand the intense heat generated during burning. A thorough cleaning process is also conducted to remove any contaminants before the final coating.

What International Standards and Quality Control Measures Should B2B Buyers Consider?

Quality control (QC) is paramount in the manufacturing of burn barrels, especially for international buyers who require assurance of product reliability and safety.

-

International Standards: Compliance with standards such as ISO 9001 is essential. This standard outlines criteria for a quality management system, emphasizing consistent quality and customer satisfaction. Additional certifications relevant to burn barrels may include CE marking for products sold in Europe and API standards for those used in industrial applications.

-

Quality Control Checkpoints: Effective quality assurance involves several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This involves the inspection of raw materials upon receipt to ensure they meet specified standards.

– In-Process Quality Control (IPQC): During manufacturing, periodic inspections are conducted to monitor processes and ensure adherence to specifications.

– Final Quality Control (FQC): Once the product is completed, a thorough inspection is performed to verify that the burn barrels meet all quality and safety standards before they are shipped. -

Testing Methods: Common testing methods for burn barrels include:

– Pressure Testing: Ensuring the barrel can withstand high temperatures and pressures.

– Load Testing: Checking the structural integrity under various weight conditions.

– Corrosion Resistance Testing: Evaluating the barrel’s ability to resist rust and degradation over time.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, it is crucial to ensure that suppliers maintain robust quality control processes. Here are actionable steps to verify supplier QC:

-

Supplier Audits: Conducting regular audits of the manufacturing facility can provide firsthand insight into the QC processes in place. An audit should assess compliance with international standards and evaluate the effectiveness of the supplier’s quality management system.

-

Quality Reports: Requesting detailed quality reports from suppliers can help buyers understand the QC measures implemented. These reports should include data on defect rates, testing outcomes, and any corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can offer an impartial assessment of the supplier’s quality practices. These inspections can occur at various stages of production, ensuring that the burn barrels meet the specified standards before shipment.

What Are the Unique QC Challenges for International Buyers?

International buyers face specific challenges regarding quality control that can affect the sourcing of burn barrels:

-

Regulatory Variations: Different countries have varying regulations and standards for product safety and quality. Understanding these differences is crucial for compliance and market acceptance.

-

Logistical Issues: Shipping and handling can impact the quality of burn barrels, especially if not packed correctly. Ensuring that suppliers use appropriate packaging can mitigate risks during transit.

-

Communication Barriers: Language differences and cultural nuances can lead to misunderstandings regarding quality expectations. Establishing clear communication channels and documentation can help bridge these gaps.

Conclusion: Ensuring Quality in Burn Barrel Manufacturing

In summary, the manufacturing process of burn barrels is intricate, involving various stages from material preparation to finishing. For B2B buyers, understanding these processes and the associated quality control measures is vital for sourcing high-quality products. By focusing on international standards, implementing thorough verification methods, and being aware of unique challenges, buyers can ensure that they partner with reliable suppliers who meet their quality expectations.

Illustrative image related to burn barrells

Practical Sourcing Guide: A Step-by-Step Checklist for ‘burn barrells’

To assist B2B buyers in the procurement of burn barrels, this guide offers a comprehensive checklist designed to streamline the sourcing process. By following these steps, you can ensure that you make informed decisions that meet your operational needs and compliance standards.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, clarify the technical specifications of the burn barrels you require. This includes material (e.g., stainless steel versus galvanized steel), size (commonly 55-gallon drums), and design features (such as airflow systems for better combustion). Having clear specifications helps in comparing products accurately and ensures that you select barrels that meet your operational requirements.

Step 2: Research Regulatory Compliance Requirements

Different regions have varying regulations regarding the use of burn barrels, especially concerning environmental impact and safety. Investigate local laws and standards to ensure that the barrels you intend to purchase comply with these regulations. This step is crucial to avoid legal repercussions and ensure safe usage in your specific market.

Step 3: Evaluate Potential Suppliers

Prior to making a commitment, thoroughly vet potential suppliers. Request detailed company profiles, product specifications, and customer references. Look for suppliers with experience in your region, as they are more likely to understand local market conditions and regulatory requirements. Online reviews and testimonials can also provide insights into their reliability and product quality.

Illustrative image related to burn barrells

Step 4: Request Samples or Product Demonstrations

Whenever possible, request samples or demonstrations of the burn barrels from shortlisted suppliers. This allows you to assess the quality, durability, and functionality of the products firsthand. During demonstrations, inquire about the combustion efficiency and safety features, as these are vital for effective and responsible use.

Step 5: Compare Pricing and Total Cost of Ownership

While price is a significant factor, it is essential to consider the total cost of ownership, which includes installation, maintenance, and operational costs. Gather quotes from multiple suppliers and compare not only the initial purchase price but also the longevity and efficiency of the burn barrels. A higher upfront cost may be justified if it results in lower operational costs over time.

Step 6: Check for After-Sales Support and Warranty

Confirm that the supplier offers comprehensive after-sales support and a warranty for their products. Reliable customer service can be invaluable, particularly if issues arise post-purchase. A solid warranty indicates confidence in the product’s quality and can save you significant costs in case of defects or failures.

Illustrative image related to burn barrells

Step 7: Finalize Your Purchase Agreement

Once you have selected a supplier, ensure that you finalize a clear purchase agreement that outlines all terms, including pricing, delivery timelines, and payment terms. A well-drafted agreement protects both parties and sets clear expectations. Additionally, confirm the logistics of delivery to ensure timely receipt of the burn barrels.

By following this structured checklist, B2B buyers can effectively navigate the procurement process for burn barrels, ensuring they secure the best products that meet their operational and compliance needs.

Comprehensive Cost and Pricing Analysis for burn barrells Sourcing

What Are the Key Cost Components in Burn Barrel Sourcing?

When sourcing burn barrels, understanding the cost structure is crucial for B2B buyers. The primary components influencing costs include:

-

Materials: The choice of material significantly affects the price. Common options include steel, which is durable but pricier, and plastic, which is lighter and often cheaper. High-quality stainless steel, for instance, is favored for its longevity and resistance to warping, but it will increase the overall cost.

-

Labor: Labor costs vary by region and manufacturing process. For instance, countries with lower labor costs may provide a competitive edge, but quality control might suffer without stringent oversight.

-

Manufacturing Overhead: This includes utilities, rent, and equipment depreciation. Manufacturers with advanced technologies may have higher overheads, but they often deliver superior products.

-

Tooling: Customization requires specialized tooling, which can significantly add to initial costs. Buyers should assess the necessity of custom designs versus standard options.

-

Quality Control (QC): Rigorous QC processes ensure the product meets safety and performance standards, impacting both costs and the final pricing.

-

Logistics: Shipping costs can vary greatly depending on the distance, mode of transport, and weight of the barrels. International buyers must consider these factors when calculating total costs.

-

Margin: Suppliers generally add a margin to their costs to ensure profitability. This can vary widely based on competition and market demand.

How Do Price Influencers Affect Burn Barrel Costs?

Several factors influence pricing beyond the basic cost components:

-

Volume/MOQ: Bulk orders typically result in lower per-unit costs. Buyers should negotiate minimum order quantities (MOQ) that align with their needs to maximize cost efficiency.

-

Specifications and Customization: Custom features such as specialized lids or integrated safety mechanisms can drive up costs. Buyers should weigh the benefits of customization against their budget constraints.

-

Materials and Quality Certifications: Products with certifications (e.g., ISO, safety standards) often come at a premium. Buyers should evaluate the necessity of these certifications based on regulatory requirements in their respective markets.

-

Supplier Factors: Established suppliers with a strong reputation may command higher prices due to perceived quality. However, emerging suppliers might offer competitive pricing to gain market entry.

-

Incoterms: Understanding Incoterms is essential for international transactions. These terms define responsibilities and costs related to shipping, insurance, and tariffs, significantly impacting the total landed cost.

What Tips Can Help Buyers Optimize Burn Barrel Sourcing?

To ensure cost-effective sourcing, buyers should consider the following strategies:

-

Negotiate Effectively: Engage suppliers in discussions about pricing, especially for large orders. Highlighting potential for future business can leverage better terms.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the lifespan, maintenance, and disposal costs of burn barrels. Investing in higher-quality barrels may lead to lower TCO in the long run.

-

Understand Pricing Nuances for International Sourcing: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of local market conditions, potential tariffs, and logistical challenges. Building relationships with local distributors can also aid in navigating these complexities.

-

Request Samples and Compare: Before committing to a supplier, request samples to assess quality. This can prevent costly mistakes and ensure that the barrels meet operational needs.

Disclaimer for Indicative Prices

Pricing for burn barrels can fluctuate based on market conditions, supplier negotiations, and regional factors. The figures mentioned are indicative and may vary. Buyers should conduct thorough research and obtain quotes from multiple suppliers to ensure competitive pricing.

Illustrative image related to burn barrells

Alternatives Analysis: Comparing burn barrells With Other Solutions

Exploring Alternatives to Burn Barrels for Waste Management

In the realm of waste management, burn barrels are a common solution for incinerating unwanted materials. However, as businesses seek more efficient, sustainable, and compliant methods, it’s essential to explore viable alternatives. This analysis compares burn barrels with two other solutions: incinerators and composting systems, providing insights into their respective benefits and drawbacks.

| Comparison Aspect | Burn Barrels | Incinerators | Composting Systems |

|---|---|---|---|

| Performance | Effective for small volumes; can produce smoke and emissions. | High-efficiency combustion; reduces waste volume significantly. | Converts organic waste into valuable compost; slower process. |

| Cost | Low initial investment; around $100-$700 depending on design. | Higher upfront costs; $1,500-$10,000+ for commercial units. | Moderate costs; $200-$1,500 for residential/commercial setups. |

| Ease of Implementation | Simple setup; requires minimal space and tools. | Requires professional installation; more complex. | Requires space and time; needs proper management for efficiency. |

| Maintenance | Low maintenance; occasional cleaning needed. | Regular maintenance required; professional servicing recommended. | Requires ongoing management; regular turning and monitoring needed. |

| Best Use Case | Suitable for rural areas with limited waste management options. | Ideal for industrial settings with high waste volumes. | Best for organic waste in urban or agricultural settings. |

In-Depth Analysis of Alternatives

How Do Incinerators Compare to Burn Barrels?

Incinerators represent a significant upgrade in waste management technology compared to burn barrels. They provide high-efficiency combustion, capable of reaching temperatures above 1800°F, which ensures complete waste incineration and minimizes harmful emissions. While the initial investment for an incinerator can be substantial—ranging from $1,500 to over $10,000—the long-term benefits of reduced waste volume and compliance with environmental regulations can offset these costs. However, the complexity of installation and the need for regular professional maintenance can be a barrier for some businesses.

What Are the Advantages of Composting Systems?

Composting systems offer a sustainable alternative for managing organic waste. They transform food scraps, yard waste, and other biodegradable materials into nutrient-rich compost, which can enhance soil quality and support plant growth. The initial investment for composting setups varies, typically ranging from $200 to $1,500, depending on the scale and technology used. While composting is environmentally friendly and promotes circular economy practices, it requires more time and management than burn barrels or incinerators. Businesses must actively manage the composting process to ensure efficiency and avoid odors or pests.

How Should B2B Buyers Choose the Right Waste Management Solution?

When selecting a waste management solution, B2B buyers should assess their specific needs, including the volume and type of waste generated, budget constraints, and regulatory compliance requirements. For companies in rural areas with limited waste disposal options, burn barrels may still be a viable choice. However, businesses in industrial sectors should consider investing in incinerators for their efficiency and compliance benefits. Meanwhile, organizations focused on sustainability and organic waste should explore composting systems, which not only reduce waste but also contribute positively to the environment.

In conclusion, understanding the pros and cons of each alternative can empower B2B buyers to make informed decisions that align with their operational goals and sustainability initiatives.

Illustrative image related to burn barrells

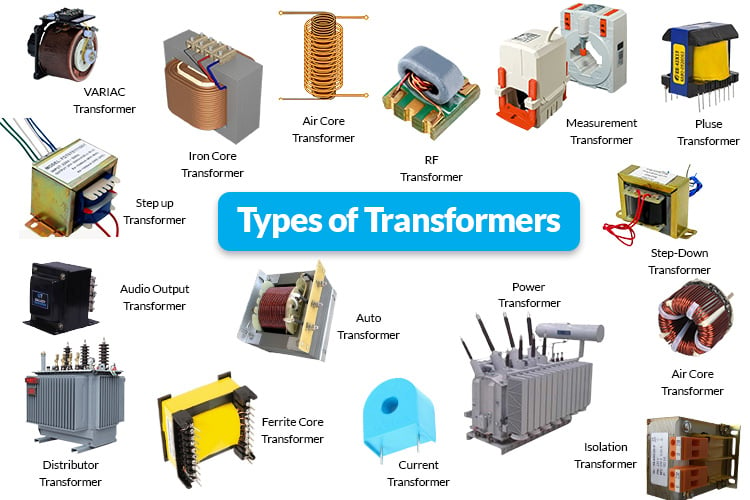

Essential Technical Properties and Trade Terminology for burn barrells

What Are the Key Technical Properties of Burn Barrels?

When considering burn barrels for industrial or agricultural applications, several technical properties are essential for ensuring efficiency, safety, and compliance with environmental regulations. Below are critical specifications that B2B buyers should evaluate:

-

Material Composition

Burn barrels are primarily constructed from either steel or high-density polyethylene (HDPE). Steel barrels are favored for their durability and ability to withstand high temperatures, while HDPE barrels are lightweight and resistant to rust and corrosion. Understanding the material’s properties is crucial as it directly impacts the barrel’s longevity and effectiveness in waste incineration. -

Heat Resistance

The ability of a burn barrel to withstand high temperatures is vital for efficient burning. Many models can achieve temperatures above 1800°F, which ensures complete incineration of waste and minimizes smoke emissions. For B2B buyers, choosing a barrel with high heat resistance can significantly reduce operational costs and improve environmental compliance. -

Capacity and Dimensions

Burn barrels typically come in standard sizes, such as 55-gallon drums. However, the dimensions can vary based on specific applications. A barrel’s capacity affects how much waste can be incinerated at one time, influencing both efficiency and productivity. Selecting the appropriate size is critical for optimizing waste management processes. -

Ventilation Design

An effective burn barrel will incorporate a well-designed ventilation system that allows for optimal airflow. This feature not only enhances combustion efficiency but also reduces smoke output. B2B buyers should prioritize models with patented airflow designs to ensure cleaner burning and compliance with local environmental regulations. -

Safety Features

Safety is paramount when dealing with incineration. Features such as flame arrestors, covers, and handles enhance user safety and operational efficiency. Understanding these features helps buyers assess the overall safety profile of a burn barrel, which is particularly important in regions with strict safety regulations. -

Durability and Warranty

The durability of a burn barrel is often indicated by its warranty period. A longer warranty typically reflects the manufacturer’s confidence in the product’s longevity. Buyers should consider barrels with robust construction and extended warranties to ensure they are making a wise investment.

What Common Trade Terms Should B2B Buyers Know About Burn Barrels?

Navigating the procurement process for burn barrels requires familiarity with specific industry jargon. Here are several key terms that are crucial for B2B transactions:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce components or products that are used in another company’s end products. When sourcing burn barrels, understanding whether a supplier is an OEM can influence quality assurance and reliability. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for B2B buyers to plan their inventory and budget effectively, especially in regions where storage capacity may be limited. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers asking for price quotes on specific products. For burn barrels, submitting an RFQ can help buyers compare prices and terms from multiple suppliers, ensuring they get the best deal. -

Incoterms (International Commercial Terms)

These are a set of predefined commercial terms published by the International Chamber of Commerce, which outline the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for B2B buyers engaged in cross-border trade, as it affects shipping costs and risk management. -

Lead Time

This term refers to the time it takes from placing an order to receiving the product. Understanding lead times is vital for inventory management, especially in industries that require timely waste disposal solutions. -

Certification Standards

Many regions have specific environmental and safety standards that burn barrels must meet. Familiarizing oneself with these certification requirements can help buyers avoid compliance issues and potential legal challenges.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and regulatory requirements in the procurement of burn barrels.

Navigating Market Dynamics and Sourcing Trends in the burn barrells Sector

What Are the Key Market Dynamics and Trends in the Burn Barrels Sector?

The global burn barrels market is shaped by various factors that influence sourcing strategies and buyer behaviors, particularly in regions such as Africa, South America, the Middle East, and Europe. One significant driver is the increasing need for efficient waste management solutions, driven by urbanization and rising population density. This has led to a growing demand for products that facilitate safe and effective disposal of refuse, including burn barrels designed for outdoor burning of organic waste.

Emerging technologies are reshaping the burn barrel landscape, with manufacturers adopting innovations like improved airflow systems and materials that enhance durability and efficiency. Stainless steel barrels, for instance, are gaining traction due to their longevity and resistance to warping, which reduces the need for frequent replacements. Additionally, the integration of e-commerce platforms is making it easier for international buyers to source products from manufacturers across the globe, ensuring they can access a variety of options tailored to their specific needs.

Illustrative image related to burn barrells

Market dynamics are also influenced by regional regulations on waste disposal, particularly in urban areas where environmental concerns are paramount. Buyers must navigate these regulations to ensure compliance, which may lead them to prefer suppliers who provide certified environmentally friendly products. This trend towards regulatory adherence is especially pronounced in Europe, where stringent waste management laws require more sustainable solutions.

How Are Sustainability and Ethical Sourcing Impacting the Burn Barrels Market?

The environmental impact of burn barrels is a critical concern for many businesses, particularly those in environmentally conscious markets. The traditional use of burn barrels for waste disposal can contribute to air pollution and greenhouse gas emissions if not managed properly. Thus, buyers are increasingly seeking products that minimize these impacts, driving demand for burn barrels designed with sustainability in mind.

Ethical sourcing practices are becoming paramount as businesses aim to enhance their corporate social responsibility (CSR) profiles. Buyers are more inclined to partner with manufacturers that demonstrate a commitment to sustainable practices, such as using recyclable materials and ensuring safe labor conditions. Certifications like ISO 14001 for environmental management and other “green” credentials are becoming essential for suppliers aiming to attract international buyers.

Furthermore, the focus on sustainability is prompting innovations in burn barrel design, with manufacturers exploring alternative materials and production methods that reduce environmental footprints. For instance, some companies are developing burn barrels that incorporate recycled materials or are made from biodegradable substances. This shift not only meets buyer demand for eco-friendly options but also aligns with global efforts to combat climate change.

What Is the Historical Context of Burn Barrels in the B2B Sector?

Burn barrels have evolved significantly since their inception, originally serving as rudimentary tools for waste disposal. Early models were often made from repurposed industrial drums, primarily designed for practical use rather than efficiency or environmental safety. As urbanization increased and waste management became a pressing issue, the need for more effective burning solutions emerged.

In the late 20th century, innovations in materials and design led to the development of more sophisticated burn barrels. Manufacturers began to focus on improving combustion efficiency and reducing emissions, aligning with growing environmental awareness. Today, the sector has seen the emergence of advanced burn barrels that not only serve their primary purpose but also meet stringent environmental regulations, catering to the demands of a more eco-conscious global market.

In summary, the burn barrels sector is undergoing a transformative phase, driven by technological advancements, sustainability concerns, and evolving buyer expectations. International B2B buyers must remain informed about these dynamics to effectively navigate sourcing strategies and establish partnerships that align with their operational goals and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of burn barrells

-

How do I ensure compliance with local regulations when sourcing burn barrels?

To ensure compliance with local regulations, start by researching the specific laws governing the use of burn barrels in your country or region. This may include environmental regulations, safety standards, and waste disposal laws. Engage with local authorities or industry associations for guidance. Additionally, when selecting suppliers, inquire about their adherence to these regulations and request documentation that verifies compliance. Regular audits and reviews of supplier practices can further mitigate risks associated with non-compliance. -

What are the most suitable materials for burn barrels in various climates?

The best materials for burn barrels depend on the climate and intended usage. For humid or coastal areas, stainless steel is recommended due to its corrosion resistance. In arid regions, heavy-duty galvanized steel may suffice as it withstands extreme heat. Customization options, such as adding protective coatings, can enhance durability. Ensure that the chosen material aligns with your burning needs, whether for yard waste, documents, or other materials, to maximize efficiency and safety. -

What factors should I consider when vetting suppliers of burn barrels?

Vetting suppliers requires a comprehensive approach. Evaluate their manufacturing capabilities, experience in the industry, and reputation through reviews or testimonials. Check for certifications that demonstrate compliance with international standards and regulations. Request samples to assess product quality and durability. Additionally, consider their ability to meet your specific requirements, such as customization options and minimum order quantities (MOQs). Establishing clear communication channels is also crucial for ongoing collaboration. -

What customization options are available for burn barrels?

Many suppliers offer a range of customization options for burn barrels, including size, material, and features. Common customizations include additional vents for improved airflow, lids for safety, and specific coatings for weather resistance. You may also request branding options, such as logos or colors. Discuss your specific needs with potential suppliers to explore available options and ensure the final product meets your operational requirements. -

What are typical minimum order quantities (MOQs) for burn barrels?

Minimum order quantities (MOQs) for burn barrels can vary significantly among suppliers. Generally, MOQs range from a few dozen to several hundred units, depending on the manufacturer’s production capacity and business model. When negotiating with suppliers, consider your budget and storage capabilities, and be open to discussing flexible terms if you require smaller quantities initially. Building a long-term relationship may also lead to more favorable MOQs in the future. -

What payment terms are standard in international trade for burn barrels?

Payment terms in international trade typically include options like advance payment, letters of credit, or open account terms. Common arrangements involve a deposit upon order confirmation, followed by the balance before shipping. It’s crucial to clarify these terms with your supplier early in the negotiation process to avoid misunderstandings. Consider using secure payment methods that offer protection against fraud, especially when dealing with new suppliers. -

How do I handle logistics and shipping for burn barrels?

Logistics and shipping for burn barrels involve several steps. First, determine the best shipping method based on cost, speed, and destination. Collaborate with your supplier to choose reliable freight forwarders who are experienced in handling large items. Ensure that all customs documentation is prepared in advance to avoid delays at the border. Additionally, factor in potential tariffs and duties when budgeting for the overall cost of importing burn barrels. -

What quality assurance practices should I expect from suppliers?

Quality assurance practices vary by supplier, but reputable manufacturers typically implement rigorous testing and inspection processes. Look for suppliers that adhere to international quality standards, such as ISO certifications. They should provide documentation demonstrating product testing results, including durability and safety assessments. Establishing clear quality expectations in your contract can help ensure that the products meet your specifications and reduce the likelihood of defects.

Top 4 Burn Barrells Manufacturers & Suppliers List

1. Burn Right® – Small Incinerator

Domain: burnrightproducts.com

Registered: 2003 (22 years)

Introduction: Burn Right® Products offers a range of incinerators and burn barrels, including:

1. **Small Incinerator** – Price: $429.00

– Features: Designed for backyard use, effective for burning yard debris.

2. **XL Burn Barrel Incinerator** – Price: $699.00

– Features: Patented design, made of 100% stainless steel, warp-resistant, efficient burn temperatures over 1800°F.

3. **Accessories:**

– An…

2. Reddit – Burn Barrels and Health Concerns

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Burn barrels are used for burning yard waste such as twigs, small branches, and leaves. Some users express concern about burning trash that includes plastics and Styrofoam due to health risks. The PACT Act of 2022 highlights health issues associated with burn pits, including various types of cancer and respiratory illnesses. Users also mention alternative waste management practices, such as recycl…

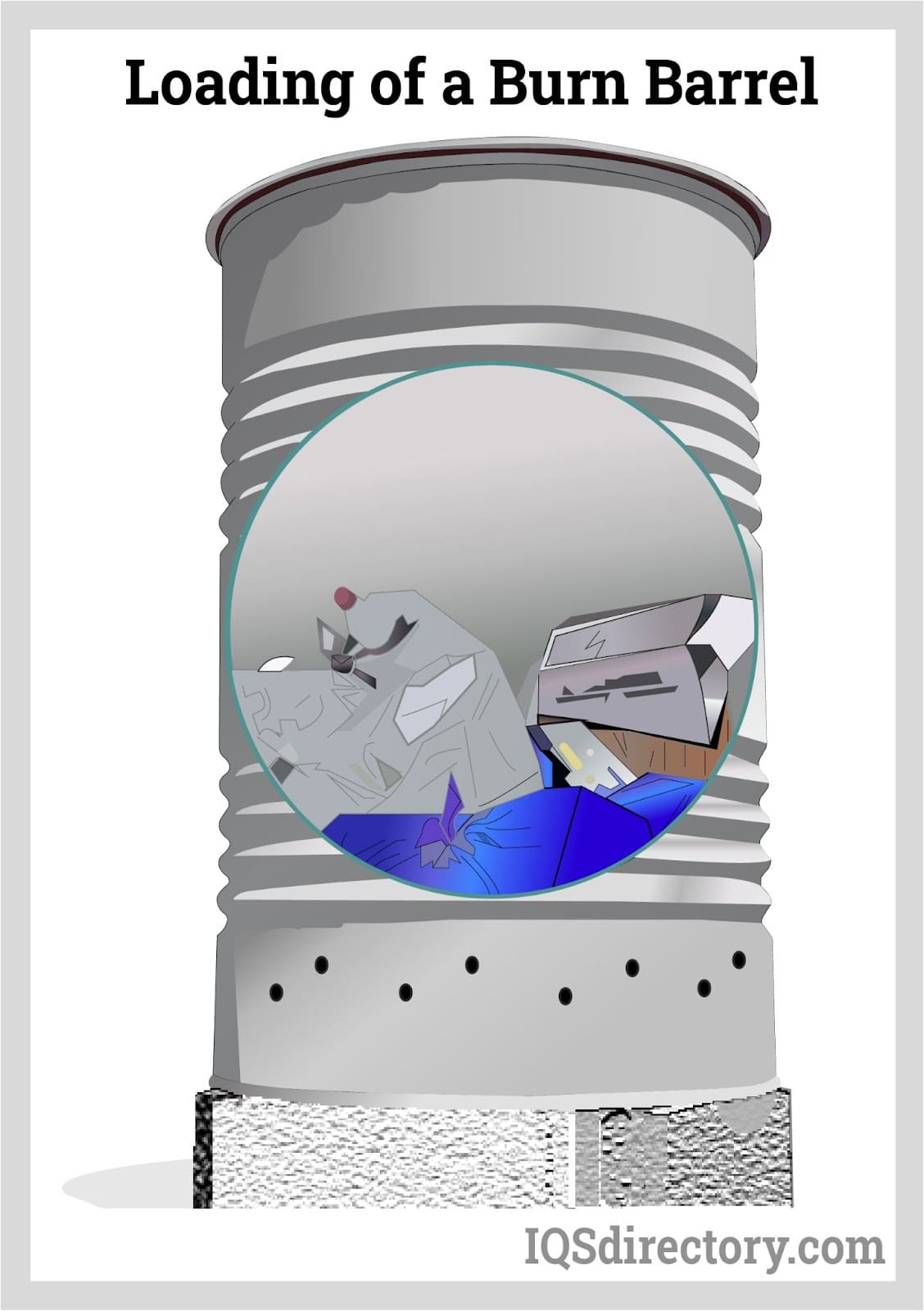

3. IQS Directory – Burn Barrels

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Burn barrels are repurposed metal drums, typically 55-gallon, used for incinerating combustible waste. They are designed for safety and effectiveness, minimizing landfill waste, and are commonly used in rural areas without trash collection services. Their use is regulated, with specific protocols varying by state and county. Types of burn barrels include: 1. Yard Waste Burn Barrels: For incinerati…

4. Hearth – 55 Gallon Steel Drum with Airflow Holes

Domain: hearth.com

Registered: 1995 (30 years)

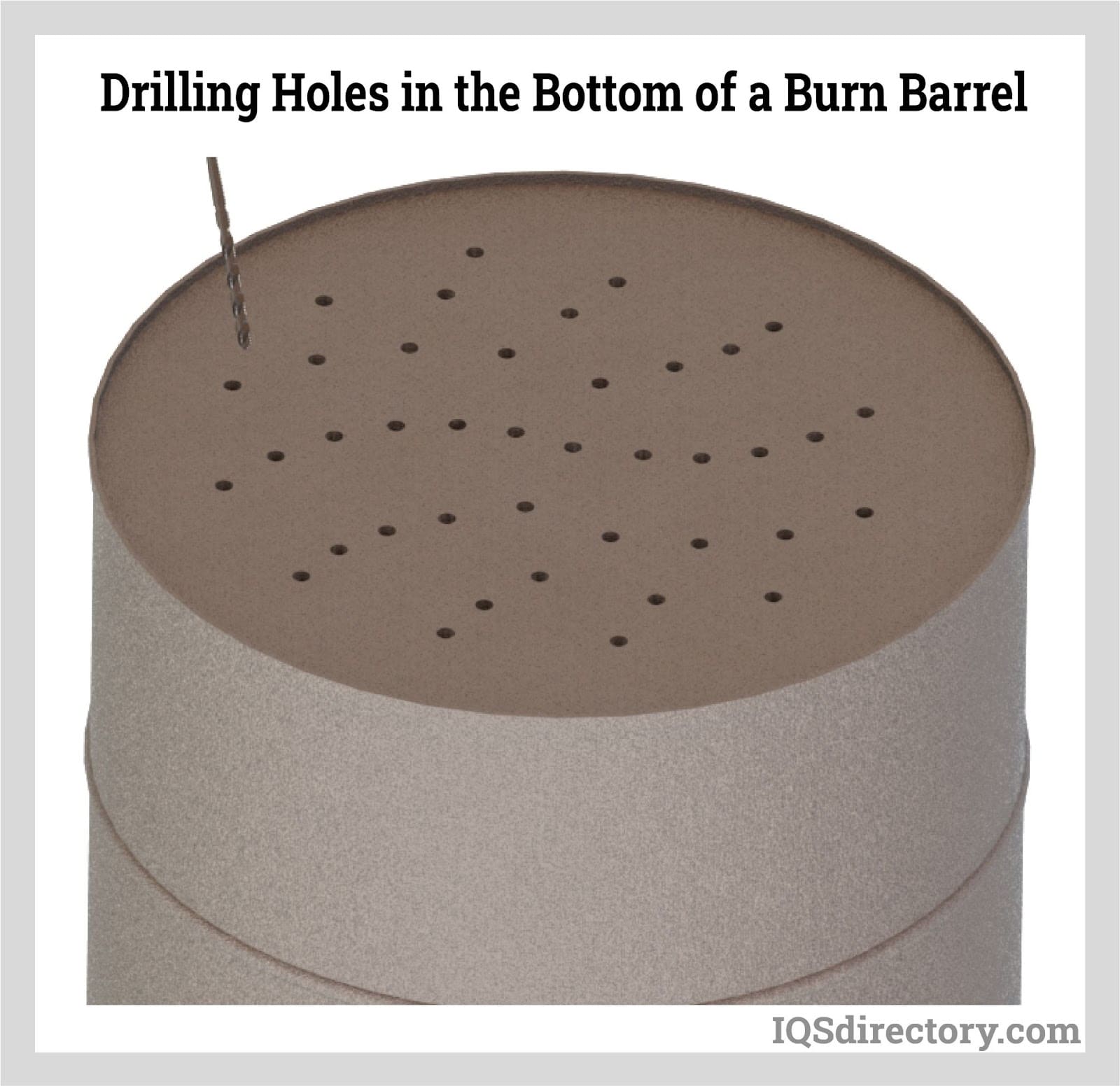

Introduction: 55 gallon steel drum, drilled a dozen 3/8″ holes around the base (6″ from the bottom) for air flow.

Strategic Sourcing Conclusion and Outlook for burn barrells

In the evolving landscape of waste management and environmental sustainability, strategic sourcing of burn barrels has emerged as a critical component for businesses across various regions, including Africa, South America, the Middle East, and Europe. By focusing on high-quality, efficient burn barrels, companies can significantly enhance their operational efficiency while adhering to regulatory standards. The choice of materials, such as stainless steel, and innovative designs that promote cleaner burning not only contribute to environmental goals but also offer long-term cost savings.

As international B2B buyers consider their sourcing strategies, it is essential to evaluate suppliers based on their product durability, safety features, and compliance with local regulations. Building relationships with reputable manufacturers can lead to better pricing structures, improved supply chain reliability, and access to advanced technologies.

Illustrative image related to burn barrells

Looking ahead, the demand for effective waste disposal solutions will continue to grow. Businesses must proactively engage with suppliers who are committed to innovation and sustainability. By prioritizing strategic sourcing of burn barrels, companies can position themselves as leaders in environmental stewardship while meeting the needs of their communities. Take the next step in your sourcing strategy and explore the latest offerings in burn barrel technology to stay ahead in this competitive market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to burn barrells