Fixed Wheels: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for fixed wheels

In the fast-evolving landscape of global commerce, sourcing high-quality fixed wheels poses a significant challenge for international B2B buyers, particularly those operating in dynamic markets such as Africa, South America, the Middle East, and Europe. With the growing demand for fixed gear, track, and single-speed bicycles, understanding the intricacies of these specialized products is crucial. This guide aims to equip buyers with essential insights into the diverse types of fixed wheels available, their various applications, and the factors influencing cost and supplier selection.

Within these pages, you will discover a comprehensive overview of the fixed wheel market, including the latest trends, innovative designs, and performance specifications. We will also explore effective strategies for vetting suppliers, ensuring product quality, and navigating logistics challenges unique to your region. By addressing these key areas, this guide empowers B2B buyers to make informed purchasing decisions that align with their operational needs and budget constraints.

Whether you are a bicycle manufacturer looking to enhance your product line or a retailer seeking reliable wheelsets to meet customer demand, this resource will provide valuable guidance. It is designed to help you confidently navigate the global market for fixed wheels, optimize your procurement processes, and ultimately drive your business success.

Understanding fixed wheels Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fixed Gear Wheels | Simple gear system, direct drive, no freewheel | Urban commuting, track racing | Pros: Lightweight, low maintenance. Cons: Limited versatility, can be challenging for beginners. |

| Track Wheels | Designed for velodrome racing, aerodynamic design | Competitive cycling, training | Pros: High performance, optimized for speed. Cons: Not suitable for casual riding, typically more expensive. |

| Single Speed Wheels | One gear ratio, similar to fixed gear but with freewheel option | Urban commuting, casual cycling | Pros: Easier to ride, versatile for various terrains. Cons: Less efficient on steep inclines compared to multi-gear systems. |

| Tubeless Ready Wheels | Compatible with tubeless tires, reduces punctures | Off-road cycling, gravel riding | Pros: Improved traction, fewer flats. Cons: Requires specific tires and setup, can be more complex to install. |

| Custom Wheel Builds | Tailored specifications for unique needs | Specialized cycling, custom builds | Pros: Perfect fit for specific applications, high customization. Cons: Longer lead times, potentially higher costs. |

What are the Characteristics of Fixed Gear Wheels?

Fixed gear wheels are characterized by their direct drive system, where the pedals are directly connected to the rear wheel, eliminating the freewheel mechanism. This design results in a lightweight and low-maintenance option, making them popular for urban commuting and track racing. For B2B buyers, understanding the simplicity and reliability of fixed gear wheels is crucial, especially for businesses focused on efficient urban transport solutions or those catering to cycling enthusiasts.

How Do Track Wheels Differ from Other Types?

Track wheels are specifically engineered for high performance in velodrome settings. They feature aerodynamic designs, often with a deep rim profile, which enhances speed and stability. Businesses involved in competitive cycling or training programs should consider track wheels for their clients, as they provide an edge in competitive scenarios. However, the specialized nature of these wheels may deter casual riders, making it essential for B2B buyers to assess their target market’s needs.

What Makes Single Speed Wheels a Popular Choice?

Single speed wheels offer a simplified riding experience by providing one gear ratio, which can include a freewheel option. This makes them suitable for urban commuting and casual cycling. For B2B buyers, the versatility of single speed wheels can appeal to a broader audience, including those new to cycling. However, it’s important to note that they may not perform as efficiently on steep inclines compared to multi-gear systems, which could impact sales depending on the geographical area served.

Why Consider Tubeless Ready Wheels for Off-Road Applications?

Tubeless ready wheels are designed to work with tubeless tires, significantly reducing the risk of punctures and providing better traction on varied terrains. This feature is particularly beneficial for businesses catering to off-road cycling and gravel riding markets. However, potential buyers should be aware that these wheels require specific tires and a more complex installation process, which might necessitate additional training or resources for retailers.

What are the Advantages of Custom Wheel Builds?

Custom wheel builds allow for tailored specifications that meet unique cycling needs, making them ideal for specialized applications or high-end custom builds. B2B buyers in niche markets can leverage this option to attract clients looking for personalized solutions. While custom builds offer significant advantages in terms of performance and fit, they may come with longer lead times and higher costs, which businesses must consider when pricing their offerings.

Key Industrial Applications of fixed wheels

| Industry/Sector | Specific Application of fixed wheels | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Conveyor Systems | Enhanced material transport efficiency | Durability, load capacity, and compatibility with existing systems |

| Logistics and Warehousing | Pallet Jacks and Hand Trucks | Streamlined operations and improved mobility in tight spaces | Wheel size, material, and weight capacity for heavy loads |

| Retail and Display | Store Fixtures and Display Racks | Increased customer engagement through product visibility | Aesthetic design and stability for diverse product types |

| Construction | Equipment and Tool Carts | Improved mobility of tools and materials on-site | Resistance to wear and tear, and suitability for various terrains |

| Transportation | Fixed Gear Bicycles for Urban Delivery | Cost-effective and eco-friendly delivery solutions | Weight, aerodynamics, and customization options for specific uses |

How Are Fixed Wheels Utilized in Manufacturing Conveyor Systems?

In manufacturing, fixed wheels are integral to conveyor systems, facilitating the smooth movement of materials along assembly lines. Their robust construction ensures longevity under heavy loads, enhancing operational efficiency. Buyers in this sector should prioritize sourcing wheels that can withstand high weight capacities and harsh industrial environments. Additionally, compatibility with existing conveyor systems is crucial to minimize downtime during installation.

What Role Do Fixed Wheels Play in Logistics and Warehousing Operations?

Fixed wheels are essential for pallet jacks and hand trucks in logistics and warehousing, allowing for easy maneuverability in confined spaces. This efficiency leads to faster loading and unloading processes, ultimately improving overall productivity. International buyers should consider wheel size and material, as these factors affect the ability to handle heavy loads and navigate various surface types. Choosing the right wheels can significantly impact operational effectiveness.

Illustrative image related to fixed wheels

How Are Fixed Wheels Enhancing Retail and Display Fixtures?

In the retail sector, fixed wheels are commonly used in store fixtures and display racks, providing stability while allowing for easy repositioning. This mobility enhances customer engagement by enabling retailers to frequently update product displays. When sourcing these wheels, businesses should focus on aesthetic design and stability to ensure that displays remain visually appealing while securely holding diverse products.

In What Ways Are Fixed Wheels Beneficial in Construction Equipment?

In construction, fixed wheels are vital for tool and equipment carts, enhancing mobility across job sites. They enable workers to transport tools and materials efficiently, reducing time spent on manual labor. Buyers should look for wheels that resist wear and tear, as well as those that can perform well on various terrains. The right choice can lead to significant improvements in site productivity and worker safety.

How Do Fixed Wheels Support Urban Delivery Solutions?

Fixed gear bicycles equipped with fixed wheels are increasingly popular for urban delivery services, providing a cost-effective and eco-friendly alternative to motor vehicles. These bicycles allow for quick navigation through congested city streets, reducing delivery times. B2B buyers in this space should evaluate factors like weight, aerodynamics, and customization options to meet specific delivery needs, ensuring that their fleet remains efficient and competitive.

3 Common User Pain Points for ‘fixed wheels’ & Their Solutions

Scenario 1: Sourcing High-Quality Fixed Wheels for Diverse Applications

The Problem: B2B buyers often face challenges in sourcing fixed wheels that meet specific requirements for different applications, such as track racing, urban commuting, or cargo transport. Buyers may struggle with inconsistent quality, leading to premature wear or failure of wheels, which can impact operational efficiency and safety. Additionally, the lack of reliable suppliers who can provide detailed specifications and support can complicate the purchasing process, especially in regions where certain brands are less accessible.

The Solution: To effectively source high-quality fixed wheels, buyers should focus on establishing relationships with reputable manufacturers and distributors who specialize in fixed gear and track wheels. Start by researching suppliers with a solid track record and positive reviews in the industry. Request samples to evaluate the quality and performance of the wheels under real-world conditions. When specifying requirements, consider factors such as weight capacity, rim depth, and material composition. Engage in discussions with suppliers about customization options to ensure the wheels meet specific operational needs. Furthermore, leveraging online platforms for bulk purchasing can provide access to competitive pricing and a wider selection, enhancing the ability to find the right product for various applications.

Illustrative image related to fixed wheels

Scenario 2: Managing Maintenance and Longevity of Fixed Wheels

The Problem: Fixed wheels require regular maintenance to ensure optimal performance, but many B2B buyers may not be equipped with the knowledge or resources to manage this effectively. Issues such as spoke tension, hub lubrication, and rim wear can lead to decreased performance and increased costs if not addressed timely. In regions with diverse weather conditions, the impact of moisture and temperature fluctuations can further complicate maintenance routines, leading to premature failure of wheels.

The Solution: To enhance the longevity of fixed wheels, companies should implement a structured maintenance schedule that includes regular inspections and upkeep. Training staff on basic wheel maintenance, such as checking spoke tension and inspecting rims for damage, is crucial. Consider investing in maintenance kits that include essential tools and spare parts, which can be sourced from the same suppliers who provide the wheels. Additionally, educate the team on the signs of wear and failure to facilitate proactive maintenance, reducing downtime and operational disruptions. Establishing a partnership with a local bicycle shop or maintenance expert can also provide additional support, ensuring that any issues are addressed promptly and professionally.

Scenario 3: Overcoming Challenges with Custom Wheel Builds

The Problem: As demand for custom fixed wheels grows, B2B buyers often encounter challenges in specifying and ordering custom builds that meet unique performance or aesthetic requirements. Miscommunication regarding specifications can lead to receiving wheels that do not align with expectations, resulting in wasted resources and delays in project timelines. Furthermore, the complexity of custom orders can deter buyers who may not be familiar with the technical aspects of wheel building.

The Solution: To navigate the complexities of custom wheel builds, buyers should begin by clearly defining their specifications and desired outcomes before approaching suppliers. Creating detailed documentation that includes measurements, intended use cases, and aesthetic preferences can help prevent misunderstandings. Engage with suppliers who offer personalized consultation services, allowing for a more collaborative approach to the custom build process. This interaction can clarify any technical questions and ensure that the final product aligns with expectations. Additionally, requesting prototypes or mock-ups can be beneficial in visualizing the end product, further reducing the likelihood of discrepancies upon delivery. Investing time in this initial phase can lead to successful custom builds that enhance brand identity and performance in the long run.

Strategic Material Selection Guide for fixed wheels

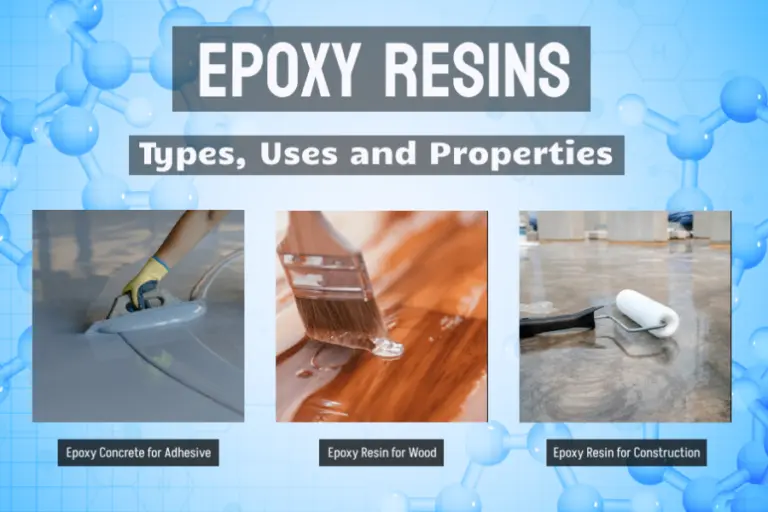

What Are the Key Materials Used in Fixed Wheels?

When selecting fixed wheels for various applications, the choice of material is crucial. Each material offers distinct properties that can influence performance, durability, and cost. Below, we analyze four common materials used in fixed wheels: aluminum, carbon fiber, steel, and plastic composites.

How Does Aluminum Benefit Fixed Wheel Performance?

Aluminum is one of the most prevalent materials for fixed wheels due to its lightweight nature and strength. It typically has a good temperature resistance and can withstand moderate pressures, making it suitable for various riding conditions. Aluminum wheels are known for their corrosion resistance, especially when anodized, which is beneficial in humid or saline environments often found in coastal regions of Africa and South America.

Pros and Cons: Aluminum wheels are durable and offer a good balance between weight and strength, making them ideal for competitive cycling. However, they can be more expensive than steel and may not provide the same level of shock absorption. Manufacturing complexity is moderate, as aluminum requires specific machining and finishing processes.

Illustrative image related to fixed wheels

Impact on Application: Aluminum wheels are particularly effective for road and track cycling, where performance and weight are critical. Buyers should ensure compliance with international standards such as ASTM for quality assurance.

What Advantages Does Carbon Fiber Offer for Fixed Wheels?

Carbon fiber is increasingly popular in high-performance fixed wheels due to its exceptional strength-to-weight ratio. It can handle high pressures and is highly resistant to temperature fluctuations, making it suitable for various climates. Additionally, carbon fiber has excellent vibration-damping properties, enhancing rider comfort.

Pros and Cons: While carbon fiber wheels are lightweight and offer superior performance, they are also the most expensive option and can be prone to damage from impacts. The manufacturing process is complex, requiring specialized equipment and expertise.

Impact on Application: Carbon fiber wheels are ideal for competitive racing and high-end applications. International buyers should be aware of compliance with standards such as ISO, particularly in markets like Germany, where quality assurance is paramount.

Illustrative image related to fixed wheels

How Does Steel Compare as a Material for Fixed Wheels?

Steel is a traditional choice for fixed wheels, known for its durability and strength. It has a high temperature and pressure rating, making it suitable for heavy-duty applications. Steel wheels are often coated to enhance corrosion resistance, which is essential in regions with high humidity or exposure to the elements.

Pros and Cons: The primary advantage of steel wheels is their robustness and lower cost compared to aluminum and carbon fiber. However, they are significantly heavier, which can affect performance in competitive settings. The manufacturing complexity is lower, making them easier to produce.

Impact on Application: Steel wheels are commonly used in urban environments and for casual riding. B2B buyers should consider the local market preferences, as steel may be favored in regions where cost is a significant factor.

What Role Do Plastic Composites Play in Fixed Wheel Design?

Plastic composites are becoming more common in fixed wheel manufacturing due to their lightweight and corrosion-resistant properties. They can withstand moderate pressures and temperatures, making them versatile for various applications.

Pros and Cons: The key advantage of plastic composites is their low cost and ease of manufacturing. However, they may not offer the same level of durability and performance as metal wheels. Their shock absorption is generally superior, but they can be less effective in high-stress situations.

Impact on Application: Plastic composite wheels are suitable for recreational cycling and casual use. Buyers should ensure that the materials meet local standards, as compliance may vary significantly across regions.

Summary of Material Selection for Fixed Wheels

| Material | Typical Use Case for fixed wheels | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Road and track cycling | Lightweight and corrosion-resistant | Higher cost than steel | Medium |

| Carbon Fiber | Competitive racing | Superior strength-to-weight ratio | Expensive and impact-prone | High |

| Steel | Urban and casual riding | Durable and cost-effective | Heavier, affecting performance | Low |

| Plastic Composites | Recreational cycling | Low cost and lightweight | Less durable under high stress | Low |

In conclusion, selecting the right material for fixed wheels involves balancing performance, cost, and application suitability. International B2B buyers should consider regional preferences and compliance with local standards to make informed purchasing decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for fixed wheels

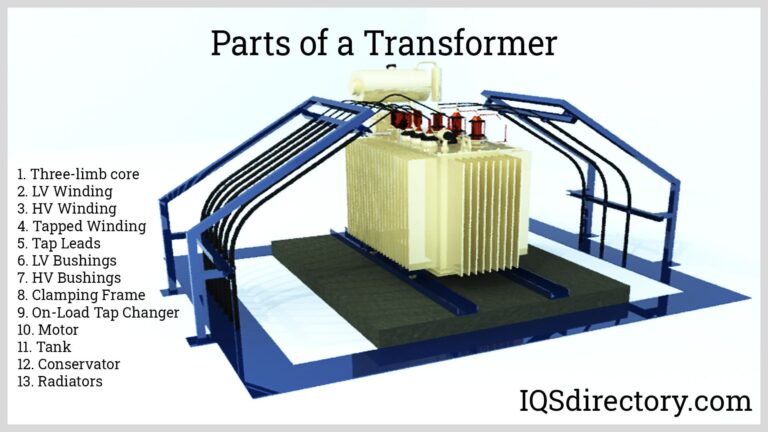

What Are the Key Stages in the Manufacturing Process of Fixed Wheels?

The manufacturing process of fixed wheels involves several critical stages that ensure the final product meets the stringent requirements of performance and durability. Each stage contributes to the overall quality and reliability of the wheels, which are crucial for various applications, from urban cycling to competitive track racing.

Material Preparation: What Materials Are Used in Fixed Wheel Manufacturing?

The first step in producing fixed wheels is selecting the appropriate materials. Common materials include aluminum alloys for their lightweight properties and steel for their strength and durability. The choice of material directly impacts the performance characteristics of the wheels, such as weight, stiffness, and resistance to wear.

Once materials are selected, they undergo preparation processes like cutting, shaping, and treatment to enhance their properties. For aluminum, anodizing is often used to improve corrosion resistance and surface hardness. Steel components may be galvanized or coated to prevent rusting, especially important for international buyers in regions with varying climates.

How Are Fixed Wheels Formed and Assembled?

What Techniques Are Employed in Wheel Forming?

The forming stage typically involves techniques such as extrusion and forging, which shape the raw materials into the desired profiles. For rims, a common approach is the extrusion of aluminum, where heated aluminum is pushed through a die to create a long, continuous shape that is then cut to size.

Illustrative image related to fixed wheels

Spokes and hubs are usually manufactured using forging or machining processes. Forged components provide greater strength and durability, essential for the high-stress environments in which fixed wheels operate. After forming, components are often subjected to heat treatment to enhance their mechanical properties.

How Is Assembly Conducted for Fixed Wheels?

The assembly stage involves bringing together the rim, spokes, and hub. This process often requires precise alignment and tensioning of the spokes to ensure the wheel is true and balanced. Manufacturers frequently use automated equipment to assist with this process, ensuring consistent quality and reducing the potential for human error.

Some manufacturers also offer custom wheel builds, allowing clients to specify particular designs or specifications. This flexibility can be a significant advantage for B2B buyers looking to meet specific market demands.

What Finishing Processes Are Applied to Ensure Quality?

Which Finishing Techniques Enhance Performance and Aesthetics?

Finishing processes are critical for both performance and aesthetic appeal. Common techniques include painting, powder coating, and polishing. Powder coating, in particular, is favored for its durability and resistance to chipping and fading, making it ideal for fixed wheels used in various environments.

Additionally, manufacturers may apply specialized treatments to reduce friction and enhance performance, such as ceramic coatings on the braking surfaces of rims. These treatments can significantly improve braking efficiency and overall performance.

How Is Quality Assurance Implemented in Fixed Wheel Manufacturing?

What International Standards Govern Fixed Wheel Quality?

Quality assurance is paramount in the manufacturing of fixed wheels, with adherence to international standards such as ISO 9001. This certification ensures that manufacturers maintain a consistent quality management system throughout their operations. Other industry-specific standards, such as CE marking for compliance with European safety regulations, are also crucial for international buyers.

What Are the Key QC Checkpoints in Fixed Wheel Production?

Quality control (QC) checkpoints are established at various stages of the manufacturing process:

- Incoming Quality Control (IQC): At this stage, raw materials are inspected for conformity with specifications, ensuring that only high-quality materials proceed to production.

- In-Process Quality Control (IPQC): Continuous monitoring occurs during manufacturing to detect any deviations from quality standards. This may involve regular checks on dimensions, material properties, and visual inspections.

- Final Quality Control (FQC): Once the wheels are fully assembled, they undergo a final inspection where critical parameters like trueness, weight, and finish are evaluated.

What Testing Methods Are Commonly Used in Fixed Wheel Quality Assurance?

Which Testing Methods Ensure Reliability and Safety?

Testing methods for fixed wheels include:

- Static and Dynamic Load Testing: These tests simulate the stresses the wheels will encounter in real-world conditions. They help assess the strength and durability of the wheels under various loads.

- Fatigue Testing: This method evaluates how the wheels perform over time under repetitive stress, ensuring they can withstand the rigors of daily use.

- Visual Inspections: Regular visual checks are conducted to identify any cosmetic defects or potential issues that could compromise performance.

How Can B2B Buyers Verify Supplier Quality Control Practices?

What Steps Should Buyers Take to Ensure Supplier Compliance?

B2B buyers should take proactive steps to verify the quality control practices of their suppliers. Here are some strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control measures firsthand. This can help establish trust and ensure compliance with international standards.

-

Requesting Quality Reports: Suppliers should provide detailed QC reports, including test results and compliance certifications. These documents can offer insights into the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can add an extra layer of assurance. These services can independently verify that products meet specified standards before shipment.

What Are the Quality Control Nuances for International Buyers?

How Do Regional Differences Impact Quality Assurance?

International buyers, particularly from diverse regions like Africa, South America, the Middle East, and Europe, must navigate various quality standards and regulations. Understanding these nuances is crucial for ensuring compliance and avoiding potential issues:

-

Regional Certifications: Different regions may have specific certifications that are recognized locally. Buyers should familiarize themselves with these to ensure products meet local regulatory requirements.

-

Cultural Considerations: The approach to quality assurance can vary by region. For instance, some cultures may place a higher emphasis on craftsmanship, while others may prioritize technological advancements in manufacturing. Understanding these differences can facilitate better supplier relationships and negotiations.

By thoroughly understanding the manufacturing processes and quality assurance practices for fixed wheels, B2B buyers can make informed decisions, ensuring they select suppliers that align with their quality expectations and market demands. This comprehensive insight not only aids in sourcing reliable products but also strengthens the overall supply chain integrity.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fixed wheels’

Introduction

This guide provides a practical checklist for B2B buyers seeking to procure fixed wheels. Fixed wheels are essential components in various applications, from bicycles to industrial casters, and understanding the sourcing process is vital for ensuring quality, reliability, and cost-effectiveness. By following these steps, buyers can navigate the market efficiently and make informed purchasing decisions.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for identifying the right fixed wheels for your needs. Consider factors such as wheel diameter, material, load capacity, and intended use. This clarity will help you communicate your requirements effectively to suppliers and ensure that the wheels meet your operational demands.

- Diameter and Width: Specify the size that fits your machinery or bike.

- Material Composition: Choose between aluminum, steel, or composite materials based on durability and weight considerations.

Step 2: Research and Identify Potential Suppliers

Conduct thorough market research to identify reputable suppliers who specialize in fixed wheels. Look for companies with a solid track record and positive reviews in your region. This step ensures you’re working with suppliers who understand local market dynamics and can meet your specific needs.

Illustrative image related to fixed wheels

- Check Industry Directories: Utilize platforms like ThomasNet or Alibaba to find verified suppliers.

- Read Customer Reviews: Pay attention to feedback from other B2B buyers to gauge reliability.

Step 3: Evaluate Supplier Capabilities

Before making a commitment, assess the capabilities of potential suppliers. This includes evaluating their production processes, quality control measures, and capacity to meet your order volume and lead times. A supplier’s ability to deliver consistently can significantly impact your operations.

- Request Case Studies: Ask for examples of similar projects they have completed.

- Visit Manufacturing Facilities: If possible, conduct site visits to observe operations firsthand.

Step 4: Verify Supplier Certifications and Compliance

Ensure that your chosen suppliers have the necessary certifications and comply with relevant industry standards. Certifications such as ISO 9001 indicate a commitment to quality management, which is critical for maintaining product consistency.

- Check Compliance with Local Regulations: Different regions may have specific requirements for materials and safety.

- Request Documentation: Ask for copies of certifications and quality assurance policies.

Step 5: Request Samples for Testing

Before placing a large order, request samples of the fixed wheels you intend to purchase. Testing samples allows you to evaluate the product’s performance, durability, and fit for your specific application. This step is essential to avoid costly mistakes later in the procurement process.

- Conduct Performance Tests: Check load capacity and durability under expected usage conditions.

- Assess Compatibility: Ensure that the wheels fit your existing equipment or designs.

Step 6: Negotiate Terms and Pricing

Once you’ve selected a supplier and tested their product, it’s time to negotiate terms and pricing. Discuss payment terms, delivery schedules, and after-sales support to ensure a mutually beneficial agreement. Clear negotiation can lead to better pricing and service conditions.

- Consider Bulk Discounts: Inquire about pricing structures for larger orders.

- Clarify Shipping and Handling: Understand all costs associated with delivery to avoid surprises.

Step 7: Establish a Long-Term Relationship

Building a long-term relationship with your supplier can lead to better service, pricing, and priority during peak demand times. Open communication and regular feedback can enhance collaboration and ensure that your needs are consistently met.

Illustrative image related to fixed wheels

- Schedule Regular Check-Ins: Maintain ongoing communication to discuss performance and any issues.

- Consider Joint Development Opportunities: Explore chances for innovation or product improvement together.

By following these steps, B2B buyers can effectively source fixed wheels that meet their operational requirements and foster successful supplier relationships.

Comprehensive Cost and Pricing Analysis for fixed wheels Sourcing

When engaging in the sourcing of fixed wheels, understanding the comprehensive cost structure and pricing nuances is essential for making informed purchasing decisions. This analysis will explore the various cost components involved, the factors that influence pricing, and provide actionable tips for buyers, particularly those in international markets such as Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Fixed Wheel Manufacturing?

The cost structure for fixed wheels encompasses several critical components:

-

Materials: The choice of materials significantly impacts the overall cost. High-quality aluminum or carbon fiber rims, stainless steel spokes, and durable hubs can increase costs but improve performance and longevity.

-

Labor: Labor costs vary by region and manufacturing complexity. Skilled labor for wheel assembly can add to expenses, especially when sourcing from countries with higher wage standards.

-

Manufacturing Overhead: This includes facility costs, equipment maintenance, and utilities. Efficient manufacturing processes can help reduce overhead, thereby lowering the final price.

-

Tooling: Initial setup costs for specialized tooling can be substantial, particularly for custom wheel designs. These costs are often amortized over larger production runs.

-

Quality Control (QC): Rigorous QC processes ensure that products meet safety and performance standards, which can add to manufacturing costs but are essential for maintaining quality assurance.

-

Logistics: Transportation and shipping costs can vary widely based on distance, shipping method, and fuel prices. For international buyers, understanding Incoterms (International Commercial Terms) is crucial to anticipate these costs.

-

Margin: Suppliers typically add a profit margin to cover operational costs and ensure profitability. This margin can vary based on market competition and demand.

What Influences the Pricing of Fixed Wheels?

Several factors influence the pricing of fixed wheels, which can affect negotiations and the overall procurement strategy:

-

Volume/MOQ (Minimum Order Quantity): Purchasing in bulk often leads to discounts. Suppliers are more willing to negotiate on price with larger orders.

-

Specifications and Customization: Unique specifications or custom designs can lead to higher costs. Standard products typically have lower prices due to established manufacturing processes.

-

Quality and Certifications: Wheels that comply with international safety standards or possess certifications (like ISO) may command higher prices, reflecting their quality and reliability.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established brands may charge more due to their market position and perceived quality.

-

Incoterms: Understanding shipping terms can significantly affect landed costs. Buyers should clarify who bears shipping, insurance, and customs costs to avoid unexpected expenses.

How Can Buyers Optimize Costs When Sourcing Fixed Wheels?

For buyers, particularly those in international markets, optimizing costs involves several strategies:

Illustrative image related to fixed wheels

-

Negotiate Effectively: Engage in open discussions with suppliers about pricing. Highlighting potential for larger orders or long-term partnerships can lead to better deals.

-

Focus on Total Cost of Ownership (TCO): Consider not just the purchase price but also long-term costs, including maintenance, durability, and potential for resale. A higher initial investment in quality wheels may yield lower TCO.

-

Be Aware of Pricing Nuances: International buyers should be mindful of currency fluctuations, import duties, and local taxes, which can affect the final cost. Building a buffer into the budget for these variables is prudent.

-

Research Market Trends: Stay informed about market trends and emerging suppliers. New entrants may offer competitive pricing to establish themselves, providing opportunities for cost savings.

Conclusion

Understanding the cost structure and pricing dynamics of fixed wheels is essential for B2B buyers to make informed decisions. By considering the various cost components, recognizing the factors that influence pricing, and employing effective sourcing strategies, buyers can optimize their procurement processes and achieve better financial outcomes. Note that prices can fluctuate based on market conditions and supplier negotiations, so it is always advisable to seek updated quotes and conduct thorough market research before finalizing any purchases.

Alternatives Analysis: Comparing fixed wheels With Other Solutions

When evaluating the best solutions for cycling needs, particularly in fixed-gear applications, it’s essential to consider various alternatives that can serve similar purposes. Fixed wheels, known for their simplicity and efficiency, can be compared against other wheel configurations such as freewheel wheels and hybrid wheels. Each alternative presents unique advantages and challenges, making it crucial for B2B buyers to assess their specific requirements before making a decision.

| Comparison Aspect | Fixed Wheels | Freewheel Wheels | Hybrid Wheels |

|---|---|---|---|

| Performance | High efficiency; direct power transfer | Allows for coasting; versatile | Balanced performance for various terrains |

| Cost | Moderate to high (e.g., $150 – $800) | Generally lower ($100 – $600) | Varies widely ($200 – $1,200) |

| Ease of Implementation | Straightforward setup; minimal parts | Easy to install; familiar to most users | May require specialized knowledge |

| Maintenance | Low; fewer moving parts | Moderate; requires regular checks | Moderate; may need more frequent servicing |

| Best Use Case | Track racing, urban commuting | Casual riding, touring | Mixed-use; gravel and road cycling |

What Are the Pros and Cons of Freewheel Wheels Compared to Fixed Wheels?

Freewheel wheels offer the advantage of allowing riders to coast, making them suitable for leisurely rides or varied terrains. They are generally more affordable, making them accessible for casual cyclists or those on a budget. However, this versatility comes at the cost of efficiency; freewheel systems introduce additional components that can add weight and complexity. For B2B buyers targeting casual or recreational markets, freewheel wheels might be the preferable choice, especially in regions where varied terrain is common.

How Do Hybrid Wheels Stack Up Against Fixed Wheels?

Hybrid wheels combine features of both fixed and freewheel systems, making them adaptable to a range of cycling conditions. They offer decent performance and comfort for diverse terrains, appealing to buyers looking for versatility in their offerings. However, the complexity of hybrid systems can lead to higher maintenance needs and costs. For businesses targeting multi-purpose cycling solutions, hybrid wheels can be a compelling option, particularly in areas with mixed cycling environments.

Conclusion: How to Choose the Right Wheel Solution for Your Needs

Selecting the right wheel solution involves understanding your target market’s specific needs and preferences. Fixed wheels excel in performance and simplicity, making them ideal for competitive and urban environments. On the other hand, freewheel and hybrid wheels provide alternatives that cater to a broader range of cycling experiences. B2B buyers should weigh the performance requirements, cost considerations, and maintenance implications of each option to determine which solution aligns best with their business objectives and customer expectations. By doing so, they can effectively position themselves in the market and meet the demands of their clientele.

Essential Technical Properties and Trade Terminology for fixed wheels

What Are the Key Technical Properties of Fixed Wheels?

Understanding the technical specifications of fixed wheels is essential for B2B buyers to make informed purchasing decisions. Here are critical properties that define the quality and performance of these wheelsets:

-

Material Grade

The material used in fixed wheels, such as aluminum, carbon fiber, or steel, significantly affects weight, durability, and performance. Aluminum wheels offer a balance of strength and lightness, making them suitable for urban riding. Carbon fiber wheels, while more expensive, provide superior stiffness and aerodynamics, ideal for competitive track cycling. Understanding material grades helps buyers select products that meet their performance requirements and budget constraints. -

Rim Depth

Rim depth impacts aerodynamics and weight. Standard depths range from 20mm to 60mm, with deeper rims providing better airflow and reduced drag at higher speeds. However, deeper rims can also be heavier and less stable in crosswinds. Buyers should consider the intended use—whether for racing or casual riding—to choose an appropriate rim depth. -

Hub Flange Distance

This measurement refers to the distance between the hub flanges, which affects the wheel’s stiffness and strength. A wider flange distance enhances lateral stiffness, providing better power transfer during acceleration and cornering. For B2B buyers, understanding this property is crucial for matching wheels to specific bike setups and rider preferences. -

Spoke Count

The number of spokes in a wheel influences its strength and weight. Common configurations range from 24 to 36 spokes, with more spokes offering greater support for heavier loads or rough terrain. Buyers should assess the rider’s weight and riding style to determine the optimal spoke count for durability without sacrificing performance. -

Tire Compatibility

Fixed wheels come with specific tire sizes and widths, typically measured in millimeters. Common sizes include 700C for road bikes and 650B for gravel or cyclocross. Ensuring tire compatibility is essential for maintaining performance, safety, and comfort, making this specification vital for B2B buyers focused on complete bike solutions.

What Are Common Trade Terms Used in the Fixed Wheel Industry?

Familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are some common terms that B2B buyers should understand:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products for other brands, often providing components that are integrated into final products. For buyers, understanding OEM relationships can reveal opportunities for bulk purchasing and customization options. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. This is crucial for buyers to understand, as it affects inventory management and pricing structures. Buyers should negotiate MOQs to align with their market demands and financial capabilities. -

RFQ (Request for Quotation)

An RFQ is a formal document requesting pricing and terms from suppliers. This process allows buyers to compare offers and ensure they receive competitive pricing. Understanding how to effectively draft and utilize RFQs can lead to better procurement outcomes. -

Incoterms (International Commercial Terms)

These are standardized trade terms used in international contracts to define responsibilities regarding shipping, insurance, and tariffs. Familiarity with Incoterms can help buyers navigate logistics, ensuring clarity about who bears the cost and risk at various stages of the shipping process. -

Lead Time

Lead time refers to the period from placing an order to its delivery. Understanding lead times is critical for inventory planning, especially in industries with fluctuating demand. Buyers should communicate their timelines clearly to suppliers to avoid stockouts or excess inventory. -

Custom Wheel Builds

This term refers to the ability to create bespoke wheelsets tailored to specific requirements, such as weight, material, and design preferences. For B2B buyers, exploring custom options can provide competitive advantages in product offerings and customer satisfaction.

By grasping these technical properties and trade terminologies, B2B buyers in various regions can make more informed decisions, leading to enhanced procurement strategies and improved business outcomes.

Navigating Market Dynamics and Sourcing Trends in the fixed wheels Sector

What Are the Key Trends Shaping the Fixed Wheels Market?

The fixed wheels sector is witnessing a transformative phase driven by several global dynamics. Increasing urbanization, particularly in regions like Africa and South America, is propelling demand for efficient, cost-effective transportation solutions. Fixed gear bikes are gaining traction in urban centers due to their simplicity, lightweight nature, and minimal maintenance requirements. Additionally, the rise of cycling as a sustainable mode of transport aligns with global initiatives to reduce carbon footprints, making fixed wheels more appealing to environmentally conscious consumers and businesses alike.

Technological advancements are also influencing sourcing trends in the fixed wheels market. Innovations in materials, such as lightweight alloys and carbon fiber, are enhancing performance and durability, attracting B2B buyers looking for high-quality products. Furthermore, the integration of e-commerce platforms and data analytics is streamlining the procurement process, allowing international buyers from regions like Europe and the Middle East to access a wider range of products and suppliers. This digital shift is crucial for optimizing supply chains and reducing lead times, which is particularly beneficial for businesses operating in competitive markets.

Additionally, customization is emerging as a vital trend. Buyers are increasingly interested in tailored solutions that meet specific performance requirements or aesthetic preferences. Suppliers offering modular wheelsets or customizable designs are likely to gain a competitive edge, catering to niche markets and diverse customer needs.

How Is Sustainability Impacting B2B Sourcing in the Fixed Wheels Sector?

Sustainability is becoming a cornerstone of procurement strategies in the fixed wheels sector. As awareness of environmental issues grows, businesses are increasingly prioritizing ethical sourcing practices and the environmental impact of their supply chains. For B2B buyers, selecting suppliers that adhere to sustainability standards is not just a trend but a necessity to align with corporate responsibility goals and consumer expectations.

The importance of using sustainable materials cannot be overstated. Buyers are encouraged to seek products that utilize recycled or eco-friendly materials in their manufacturing processes. Certifications such as ISO 14001 or eco-labels can guide buyers in identifying suppliers committed to minimizing their environmental impact. Furthermore, adopting sustainable logistics practices—such as selecting suppliers who utilize green transportation methods—can significantly enhance a company’s overall sustainability profile.

In addition to sourcing, the lifecycle of fixed wheels should be considered. B2B buyers should inquire about end-of-life options for products, including recycling programs or take-back schemes that ensure materials are reused rather than ending up in landfills. By fostering partnerships with suppliers who prioritize sustainability, businesses can enhance their brand reputation while contributing positively to the environment.

What Is the Historical Context of Fixed Wheels That Matters for B2B Buyers?

The evolution of fixed wheels can be traced back to the early days of cycling when simplicity and functionality were paramount. Originally designed for track racing, fixed gear wheels have transitioned into popular choices for urban commuting and leisure riding. This historical context is essential for B2B buyers as it highlights the durability and reliability that fixed wheels have maintained over time.

Illustrative image related to fixed wheels

As cycling culture expanded globally, especially in urbanized regions, fixed wheels gained popularity due to their low maintenance and ease of use. Today, they are not just a mode of transportation but also a lifestyle choice, appealing to a diverse demographic. Understanding this evolution can help B2B buyers appreciate the value of investing in fixed wheels that are not only functional but also part of a larger cultural movement towards sustainable living.

In conclusion, navigating the fixed wheels market requires an awareness of current trends, a commitment to sustainability, and an understanding of the historical significance of the products. By leveraging these insights, international B2B buyers can make informed decisions that align with their business goals and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of fixed wheels

-

How do I ensure the quality of fixed wheels when sourcing internationally?

To ensure quality when sourcing fixed wheels, it’s crucial to conduct thorough supplier vetting. Start by requesting samples to evaluate materials and craftsmanship. Look for certifications such as ISO or relevant quality standards that the manufacturer adheres to. Additionally, check reviews and testimonials from other international buyers. Engaging in a factory visit, if possible, can provide further insights into manufacturing processes and quality control measures. -

What is the best fixed wheel type for urban cycling?

For urban cycling, lightweight fixed gear wheels are typically the best choice due to their agility and speed. Look for wheelsets made from durable materials like aluminum or carbon fiber, which can withstand city conditions. Consider options that are tubeless-ready for better puncture resistance and lower maintenance. Brands like Wabi and Velocity offer popular urban-focused models that combine performance with style. -

How can I customize fixed wheels for my specific business needs?

Customization options for fixed wheels often include variations in rim depth, color, hub type, and spoke configuration. Most manufacturers provide the option for custom builds, allowing you to specify these details. When discussing customization, ensure you communicate your requirements clearly and inquire about lead times and pricing implications. It’s beneficial to work with suppliers who have experience in custom projects to ensure they can meet your specifications effectively. -

What are typical minimum order quantities (MOQ) for fixed wheels?

Minimum order quantities for fixed wheels vary by supplier, typically ranging from 50 to 200 units per order. However, many manufacturers may accommodate smaller orders, particularly for first-time clients or custom builds. Always confirm MOQs during the initial negotiation phase and inquire about pricing tiers that may apply to larger orders, which can provide significant cost savings. -

What payment terms should I expect when sourcing fixed wheels internationally?

Payment terms can vary widely among suppliers. Common practices include partial upfront payments (e.g., 30-50%) with the balance due upon shipment or delivery. Some suppliers may offer letters of credit or escrow services for larger transactions, adding a layer of security. Always discuss and negotiate payment terms upfront, ensuring clarity on currency, method of payment, and any potential transaction fees. -

How do I manage logistics and shipping for fixed wheels from international suppliers?

Managing logistics involves selecting reliable shipping methods and understanding customs regulations. Discuss with your supplier about their preferred shipping partners and options, which may include air freight for faster delivery or sea freight for cost-effectiveness. Ensure you are familiar with import duties and taxes in your country to avoid unexpected costs. Using a freight forwarder can simplify this process, as they will handle documentation and customs clearance. -

What are the common issues I should be aware of when importing fixed wheels?

Common issues when importing fixed wheels can include delays in shipping, customs clearance problems, and quality discrepancies upon arrival. To mitigate these, maintain open communication with your supplier throughout the shipping process and ensure all documentation is accurate and complete. Additionally, consider obtaining insurance for your shipment to protect against loss or damage during transit. -

What are the advantages of sourcing fixed wheels directly from manufacturers?

Sourcing fixed wheels directly from manufacturers offers several advantages, including lower costs, more control over customization, and direct communication regarding quality and specifications. This approach often allows for better negotiation on pricing and terms, as well as the ability to build a long-term relationship with the supplier. Additionally, direct sourcing can lead to faster response times for future orders and more reliable support for any issues that may arise.

Top 7 Fixed Wheels Manufacturers & Suppliers List

1. Caster Specialists – Rigid Casters and Fixed Wheels

Domain: casterspecialists.com

Registered: 2002 (23 years)

Introduction: Rigid Casters and Fixed Caster Wheels

– Wheel Diameter Options: 2″, 3″, 3.5″, 4″, 5″, 6″, 8″, 10″, 12″

– Capacity Categories:

– Up to 350 lbs

– 350-1250 lbs

– 1250-3000 lbs

– Over 3000 lbs

– Features:

– USA-Made

– Heavy Duty

– Ergonomic

– Kingpinless

– Maintenance-Free

– Stainless Steel

– Low Profile

– Medical

– Wheel Types:

– MAX-Efficiency Wheel Casters

– Quiet + E…

2. Wabi – Lightweight Single Speed-Fixed Gear Wheelset

Domain: wabicycles.com

Registered: 2008 (17 years)

Introduction: Fixed Gear Wheels / Track Wheels / Single Speed Wheels available from brands like Wabi, Velocity, DT Swiss, H+Son, Phil Wood, and Dia Compe. Options include: Wabi Lightweight (1720g) Single Speed-Fixed Gear Wheelset for $275.00 (sold out), Wabi Sub-15 Superlight (1475g) Single Speed-Fixed Gear Wheelset for $325.00 (in stock), Wabi All-Terrain Tubeless Ready Single Speed-Fixed Gear Wheels for $325….

3. State Bicycle Co. – ENVE AM30 Carbon Tubeless Mountain Bike Wheel Set

Domain: statebicycle.com

Registered: 2009 (16 years)

Introduction: ENVE AM30 Carbon Tubeless Mountain Bike Wheel Set (29″) – $1,400.00

Enve AG28 Carbon Tubeless Disc-Brake Wheel Set (650b) – $1,400.00

Enve AG25 Carbon Tubeless Disc-Brake Wheel Set (700c) – $1,400.00

State Bicycle Co. – GRT55 Carbon Fixed-Gear Wheelset – $899.99

DT Swiss T 1800 Classic – Track Wheel Set – $599.99

DT Swiss G 1800 SPLINE® 25 Wheel Set (650b or 700c) – $450.00

All-Road Wheel Set v2 (…

4. Velomine – Fixed Gear Wheels

Domain: velomine.com

Registered: 2009 (16 years)

Introduction: This company, Velomine – Fixed Gear Wheels, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Blickle – Fixed Castor Wheels

Domain: blickle.com

Registered: 1999 (26 years)

Introduction: Blickle offers a wide range of fixed castor wheels, featuring over 30 fixed bracket series and more than 80 different wheel series in various sizes, materials, and load capacities. Key characteristics include:

– Fixed castors consist of a rigid bracket that cannot swivel, allowing for optimal straight-line motion when combined with swivel castors.

– Load capacities up to 30,000 kg.

– Types of f…

6. California Caster – Rigid and Swivel Wheels

Domain: californiacaster.com

Registered: 1997 (28 years)

Introduction: California Caster offers a comprehensive selection of rigid and swivel wheels suitable for various business, commercial, and manufacturing needs. Rigid casters are fixed, stronger, and have higher load ratings, ideal for moving items forward and backward. Swivel casters can maneuver in tight spaces and turn corners, equipped with ball bearings for heavy loads. A combination of both types can be us…

7. Source4 Industries – Fixed Casters

Domain: source4industries.com

Registered: 1998 (27 years)

Introduction: This company, Source4 Industries – Fixed Casters, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for fixed wheels

In the evolving landscape of fixed wheels, strategic sourcing emerges as a critical component for B2B buyers aiming to optimize their procurement processes. By leveraging a diverse range of suppliers—from lightweight models to high-performance options—businesses can ensure they meet varying market demands while controlling costs. The availability of custom wheel builds and a variety of brands allows for tailored solutions, enhancing the competitive edge in local and international markets.

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should prioritize partnerships that emphasize quality, reliability, and innovation. Engaging with suppliers who understand regional needs can facilitate smoother logistics and better inventory management, ultimately leading to improved customer satisfaction.

As we look ahead, the trend towards sustainability and performance in fixed wheel manufacturing will continue to shape sourcing decisions. Businesses are encouraged to stay informed about advancements in materials and technology, as these will significantly influence product offerings. By adopting a proactive approach to sourcing, companies can position themselves to capitalize on emerging opportunities in the fixed wheel market. Now is the time to engage with reliable suppliers and explore innovative solutions that will drive growth and success in the coming years.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to fixed wheels

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.