Choosing Your 3 16 Bungee Cord: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for 3 16 bungee cord

The global market for 3/16 bungee cord presents unique challenges for B2B buyers, particularly when it comes to sourcing reliable and high-quality products. With applications ranging from securing cargo to creating custom elastic solutions, understanding the intricacies of this versatile material is essential for businesses operating in diverse sectors. This guide aims to equip international B2B buyers—especially those from Africa, South America, the Middle East, and Europe (including key markets like Brazil and Saudi Arabia)—with the insights needed to make informed purchasing decisions.

Throughout this comprehensive resource, we will delve into various types of 3/16 bungee cords, highlighting their specific applications and benefits. We will also address critical aspects such as supplier vetting processes, cost considerations, and best practices for ensuring product quality and compliance with international standards. By providing actionable insights and expert recommendations, this guide empowers buyers to navigate the complexities of the global bungee cord market confidently.

Understanding these nuances not only helps in selecting the right products but also fosters long-term partnerships with reliable suppliers. As you explore the following sections, you will gain valuable knowledge to enhance your procurement strategies, ultimately driving business success in a competitive marketplace.

Understanding 3 16 bungee cord Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard 3/16″ Bungee Cord | Made with rubber core and polyethylene jacket; 200 lbs breaking strength | Cargo securing, outdoor equipment, general use | Pros: Cost-effective, versatile. Cons: Limited UV resistance. |

| Marine Grade Dacron Polyester | UV and moisture resistant, abrasion-resistant 1000 Denier cover | Marine applications, outdoor recreation | Pros: Durable, long-lasting. Cons: Higher cost than standard cords. |

| High-Performance Shock Cord | Enhanced elasticity and strength; consistent 100% stretch | Industrial applications, heavy lifting | Pros: Superior performance, reliable. Cons: May require specialized handling. |

| Heavy-Duty 3/16″ Bungee Cord | Reinforced construction for higher load capacity | Construction, transportation, logistics | Pros: Excellent for heavy loads. Cons: Bulkier than standard options. |

| Color-Coded Bungee Cord | Available in various colors for easy identification | Retail, inventory management | Pros: Improves organization. Cons: Limited strength options. |

What are the Key Characteristics of Standard 3/16″ Bungee Cord?

Standard 3/16″ bungee cord features a rubber core encased in a polyethylene jacket, providing a breaking strength of 200 lbs. This type is widely used for general applications such as securing cargo, outdoor equipment, and travel needs. When purchasing, consider the cord’s elasticity and stretch, which typically reaches 120% of its original length. Its affordability makes it attractive for businesses, but it may lack UV and weather resistance, leading to wear over time.

How Does Marine Grade Dacron Polyester Differ from Standard Bungee Cords?

Marine grade Dacron polyester shock cords are designed for durability in harsh environments, featuring a thick 1000 Denier cover that resists UV rays and moisture. This makes them ideal for marine applications and outdoor recreational activities. B2B buyers should consider the longevity and strength of this cord, as it offers superior performance compared to standard cords. While the initial investment is higher, the long-term savings from reduced replacement frequency can justify the cost.

Illustrative image related to 3 16 bungee cord

What Makes High-Performance Shock Cord Suitable for Industrial Use?

High-performance shock cords are engineered for exceptional elasticity and strength, often maintaining a consistent 100% stretch. This makes them ideal for industrial applications where reliability is crucial, such as heavy lifting and secure load management. When sourcing these cords, businesses should focus on their tensile strength and elongation properties. While they provide enhanced performance, they may require specialized handling and installation techniques, adding to overall costs.

Why Choose Heavy-Duty 3/16″ Bungee Cord for Construction and Logistics?

Heavy-duty 3/16″ bungee cords feature reinforced construction, making them suitable for high-load applications in construction and logistics. With a higher load capacity than standard cords, they ensure safety and reliability under demanding conditions. Buyers should evaluate the specific load requirements and consider the bulkiness of these cords, which may affect storage and transportation. The investment in heavy-duty options can significantly reduce the risk of failure in critical applications.

How Can Color-Coded Bungee Cords Enhance Inventory Management?

Color-coded bungee cords come in various colors, allowing for easy identification and organization in retail and inventory management settings. This feature can streamline operations and improve efficiency when managing multiple cord types or sizes. While they offer organizational benefits, buyers should ensure that the strength and performance specifications meet their operational needs, as color-coding may limit strength options compared to standard cords.

Key Industrial Applications of 3 16 bungee cord

| Industry/Sector | Specific Application of 3/16 Bungee Cord | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Transportation | Securing cargo in trucks and trailers | Ensures safe transport, reducing damage and loss of goods | Look for high tensile strength and UV resistance to withstand conditions. |

| Marine and Boating | Lashing down equipment on boats and kayaks | Prevents equipment loss overboard, enhancing safety and efficiency | Marine-grade options are essential for durability against saltwater. |

| Outdoor Recreation | Creating custom cargo nets for outdoor gear | Provides versatile storage solutions for camping and hiking gear | Consider elasticity and resistance to weather for longevity. |

| Construction | Temporary securing of materials on job sites | Improves safety and organization, reducing risk of accidents | Ensure compliance with safety standards and adequate load capacity. |

| Retail and Logistics | Bundling products for shipping and storage | Streamlines logistics, saving time and reducing shipping costs | Evaluate bulk purchasing options for cost-effectiveness. |

How is 3/16 Bungee Cord Used in Transportation?

In the transportation industry, 3/16 bungee cord is primarily used for securing cargo in trucks and trailers. Its high tensile strength of 200 lbs makes it ideal for keeping loads stable during transit, thus minimizing the risk of damage or loss. Businesses should consider sourcing bungee cords that are UV-resistant to endure harsh outdoor conditions while maintaining elasticity. International buyers, especially from regions like Africa and South America, must ensure that the cords meet local transport regulations and safety standards.

Illustrative image related to 3 16 bungee cord

What are the Applications of 3/16 Bungee Cord in Marine and Boating?

In the marine sector, 3/16 bungee cord is essential for lashing down equipment on boats and kayaks. This application is critical for preventing gear from being lost overboard, which enhances safety during water activities. Marine-grade bungee cords are particularly advantageous as they resist saltwater and UV exposure. Buyers from the Middle East and Europe should prioritize suppliers that offer durable, marine-specific options to ensure longevity and reliability in marine environments.

How is 3/16 Bungee Cord Utilized in Outdoor Recreation?

Outdoor recreation businesses frequently use 3/16 bungee cord for creating custom cargo nets to hold camping and hiking gear securely. The elasticity of the cord allows for versatile adjustments, accommodating various gear sizes and shapes. When sourcing for this application, it is vital to select cords that can withstand environmental factors such as moisture and temperature variations. International buyers should look for suppliers who can provide detailed specifications and performance testing to ensure product reliability.

What Role Does 3/16 Bungee Cord Play in Construction?

In construction, 3/16 bungee cord serves as a temporary solution for securing materials on job sites. This application enhances safety by keeping tools and materials organized, thereby reducing the risk of accidents. Buyers should ensure that the cords comply with safety standards and possess adequate load capacity to handle construction demands. Sourcing from reputable manufacturers who provide detailed testing and certifications is crucial for international buyers, particularly in regions with stringent safety regulations.

How is 3/16 Bungee Cord Beneficial in Retail and Logistics?

In the retail and logistics sector, 3/16 bungee cord is used for bundling products for shipping and storage. This application streamlines logistics processes, saving time and reducing shipping costs by ensuring that items remain securely packaged during transit. When sourcing, businesses should consider bulk purchasing options that offer cost savings without compromising on quality. International buyers should also assess the availability of various lengths and elasticity to meet specific logistical needs effectively.

Illustrative image related to 3 16 bungee cord

3 Common User Pain Points for ‘3 16 bungee cord’ & Their Solutions

Scenario 1: Inconsistent Quality and Durability of 3/16 Bungee Cords

The Problem: B2B buyers often face challenges with the quality and durability of 3/16 bungee cords. Inconsistent manufacturing processes can lead to products that don’t meet the specified breaking strength or elongation parameters. This inconsistency can result in product failures during critical applications, such as securing cargo in transportation or during outdoor events, leading to costly damages and dissatisfied customers.

The Solution: To mitigate quality issues, buyers should prioritize sourcing from reputable suppliers with verified quality control practices. Request certifications or test reports demonstrating the bungee cord’s breaking strength and elongation capabilities. Additionally, consider suppliers that provide samples for testing before committing to larger orders. This hands-on assessment allows buyers to ensure that the product meets their specifications and can withstand the intended applications. Regularly engaging with suppliers and providing feedback can also foster improvements in product quality.

Scenario 2: Difficulty in Selecting the Right Specifications for 3/16 Bungee Cord

The Problem: B2B buyers frequently struggle with selecting the right specifications for their 3/16 bungee cords, especially when dealing with various applications across industries. Confusion regarding breaking strength, working load limits, and material types can lead to overestimating or underestimating the requirements for specific projects, ultimately affecting safety and performance.

The Solution: To simplify the selection process, buyers should develop a clear understanding of their application needs. Create a checklist that includes the load requirements, environmental conditions (like exposure to UV light or moisture), and the specific use case for the bungee cord. Utilize resources from manufacturers that detail the properties of their products, such as elongation percentages and material composition. Consulting with technical experts from the supplier can also provide tailored recommendations based on industry standards and best practices. Lastly, consider investing in training for procurement teams to enhance their understanding of product specifications.

Illustrative image related to 3 16 bungee cord

Scenario 3: Limited Availability of Length and Configuration Options for 3/16 Bungee Cord

The Problem: Many B2B buyers encounter challenges with the availability of specific lengths and configurations of 3/16 bungee cords, which can hinder project timelines. For instance, buyers may require continuous lengths for large-scale applications, but suppliers often offer only pre-cut sections or spooled options with breaks. This limitation can result in waste, increased costs, and project delays.

The Solution: To overcome this challenge, buyers should communicate their specific needs to suppliers upfront. Inquire about custom options for lengths and configurations, and explore suppliers who offer the flexibility of creating continuous runs or larger spools without breaks. Establishing a strong relationship with the supplier can facilitate better negotiation for bulk orders, potentially leading to tailored solutions. Additionally, consider collaborating with suppliers who have robust inventory systems, ensuring that they can accommodate varied order sizes and configurations promptly. This proactive approach can help ensure that the right materials are available when needed, thereby streamlining project execution and reducing waste.

Strategic Material Selection Guide for 3 16 bungee cord

What Are the Common Materials Used in 3/16 Bungee Cord and Their Key Properties?

When selecting materials for 3/16 bungee cords, it is essential to consider various factors such as performance, durability, and cost. The most common materials used in the construction of these cords include rubber, polyester, nylon, and polypropylene. Each material offers distinct properties that can influence the suitability of the bungee cord for specific applications.

How Does Rubber Impact the Performance of 3/16 Bungee Cord?

Rubber is the core material for most bungee cords, providing excellent elasticity and stretch. The typical elongation for rubber in these cords is around 120%, allowing for significant stretch without losing its original shape. Rubber also has good temperature resistance, maintaining its properties in a range of temperatures, though it can degrade under prolonged UV exposure.

Pros: The key advantages of rubber include high elasticity, excellent tensile strength, and affordability. It is suitable for various applications, from securing cargo in vehicles to outdoor recreational uses.

Illustrative image related to 3 16 bungee cord

Cons: However, rubber can be susceptible to wear and tear when exposed to harsh environmental conditions, particularly UV radiation and extreme temperatures, leading to degradation over time.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure that the rubber used meets local standards for durability and UV resistance, as these factors can significantly impact the cord’s longevity.

What Role Does Polyester Play in 3/16 Bungee Cord Construction?

Polyester, especially in marine-grade formulations, is often used as a protective outer layer for bungee cords. Its properties include high resistance to UV rays, moisture, and abrasion, making it ideal for outdoor and marine applications.

Pros: The primary advantage of polyester is its durability in harsh environments. It resists fading and degradation from sunlight, making it a preferred choice for outdoor applications.

Cons: The downside is that polyester can be more expensive than other materials and may require more complex manufacturing processes.

Illustrative image related to 3 16 bungee cord

Considerations for International Buyers: Buyers in Europe and South America should look for polyester cords that comply with ASTM or DIN standards for strength and durability, ensuring they meet the rigorous demands of outdoor applications.

How Does Nylon Compare as a Material for 3/16 Bungee Cord?

Nylon is another common material used in bungee cords, known for its strength and flexibility. It has a higher tensile strength compared to rubber and polyester, making it suitable for heavy-duty applications.

Pros: Nylon cords are incredibly strong and can handle significant loads, making them ideal for industrial applications.

Cons: However, nylon is less resistant to UV light and moisture than polyester, which can lead to degradation over time if used outdoors.

Considerations for International Buyers: For buyers in regions with high humidity or UV exposure, such as Brazil and Saudi Arabia, it is crucial to evaluate the specific nylon formulation and its resistance to environmental factors.

Illustrative image related to 3 16 bungee cord

What About Polypropylene as a Material for 3/16 Bungee Cord?

Polypropylene is often used as a budget-friendly alternative for bungee cords. It is lightweight and offers moderate elasticity, making it suitable for less demanding applications.

Pros: The main advantage of polypropylene is its low cost and lightweight nature, making it easy to handle and transport.

Cons: However, polypropylene has lower tensile strength and is less durable than rubber or polyester, which may limit its applications.

Illustrative image related to 3 16 bungee cord

Considerations for International Buyers: Buyers should assess the specific use case and environmental conditions, as polypropylene may not perform well in extreme temperatures or UV exposure, particularly in regions like the Middle East.

Summary Table of Material Selection for 3/16 Bungee Cord

| Material | Typical Use Case for 3/16 Bungee Cord | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Rubber | General cargo securing | High elasticity and affordability | Susceptible to UV degradation | Low |

| Polyester | Marine and outdoor applications | Excellent UV and moisture resistance | Higher cost and complex manufacturing | Medium |

| Nylon | Heavy-duty industrial applications | Superior tensile strength | Poor UV and moisture resistance | Medium |

| Polypropylene | Budget-friendly applications | Lightweight and low cost | Lower tensile strength and durability | Low |

This strategic material selection guide provides a comprehensive overview of the common materials used in 3/16 bungee cords, highlighting their properties, advantages, and limitations while considering the specific needs of international B2B buyers.

In-depth Look: Manufacturing Processes and Quality Assurance for 3 16 bungee cord

What Are the Main Stages of Manufacturing 3/16 Bungee Cord?

The manufacturing process of 3/16 bungee cord involves several critical stages: material preparation, forming, assembly, and finishing.

-

Material Preparation: The primary materials for 3/16 bungee cord include high-quality rubber and a durable outer jacket made from polyethylene or Dacron polyester. The rubber is typically extruded to form continuous strands that provide elasticity. The polyethylene jacket is also extruded and must be carefully selected to ensure it can withstand environmental factors such as UV exposure and moisture.

-

Forming: During this stage, the rubber core is combined with the outer jacket. This is often done through a process called co-extrusion, where both materials are simultaneously fed into a mold. The temperature and pressure must be precisely controlled to ensure a strong bond between the rubber core and the outer jacket, as this affects the cord’s overall strength and durability.

-

Assembly: After forming, the bungee cord is cut to specified lengths. This is a crucial step, as the length can impact the cord’s elasticity and functional applications. Manufacturers may also integrate additional features, such as hooks or loops, depending on the intended use of the bungee cord.

-

Finishing: The final stage involves inspecting the cord for any defects and packaging it for distribution. Manufacturers often apply protective coatings to enhance resistance against abrasion and environmental damage.

Which Key Techniques Are Used in the Production of 3/16 Bungee Cord?

Advanced manufacturing techniques are employed to ensure the quality and performance of 3/16 bungee cord. Key techniques include:

-

Co-Extrusion: This method allows for the simultaneous production of the rubber core and outer jacket, ensuring that they are perfectly bonded and that the final product maintains its elasticity and strength.

-

Quality Control Testing: Manufacturers often conduct stress testing on samples of the bungee cord to evaluate its breaking strength, elongation, and performance under various environmental conditions. This testing ensures that the cord meets industry standards before it is packaged and shipped.

-

Automated Production Lines: Automation enhances precision and efficiency in the manufacturing process, minimizing human error and ensuring consistent quality across large batches.

How Is Quality Assurance Implemented in 3/16 Bungee Cord Manufacturing?

Quality assurance (QA) is paramount in the production of 3/16 bungee cords, particularly for B2B buyers who require reliability and safety in their products.

Illustrative image related to 3 16 bungee cord

-

International Standards: Many manufacturers adhere to international quality standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with ISO 9001 can enhance a manufacturer’s credibility and ensure that their processes consistently meet customer and regulatory requirements.

-

Industry-Specific Certifications: Depending on the application, bungee cords may also need to comply with specific certifications such as CE marking for products sold in Europe or API standards for industrial applications. These certifications indicate that the product meets stringent safety and performance criteria.

-

Quality Control Checkpoints: Quality control is integrated throughout the manufacturing process:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specifications.

– In-Process Quality Control (IPQC): Regular checks during the manufacturing process help identify any deviations from quality standards early.

– Final Quality Control (FQC): The finished product undergoes a final inspection and testing to verify its performance characteristics before shipment.

What Common Testing Methods Are Used to Ensure Bungee Cord Quality?

Several testing methods are employed to ensure the quality of 3/16 bungee cords:

-

Breaking Strength Tests: These tests measure the maximum load the cord can handle before breaking. This is critical for understanding the cord’s performance in real-world applications.

-

Elongation Tests: These tests assess how much the cord can stretch before reaching its breaking point, providing insight into its elasticity.

-

Environmental Testing: Cords may undergo exposure to extreme temperatures, UV light, and moisture to evaluate their durability and resistance to wear over time.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential to ensure they receive high-quality products.

-

Supplier Audits: Conducting on-site audits of potential suppliers can provide insights into their manufacturing processes, quality control measures, and overall operational standards. This is particularly important for international buyers who may not have direct access to suppliers.

-

Requesting Quality Reports: Buyers should ask for documentation that outlines the results of quality tests and certifications. This includes details on any third-party testing that has been conducted.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes and the products being manufactured. This is especially useful for bulk orders or long-term contracts.

What Are the Quality Control Nuances for International B2B Buyers?

When dealing with international suppliers, B2B buyers must consider several nuances in quality control:

-

Cultural and Regulatory Differences: Different regions may have varying standards for quality and safety. Understanding these differences can help buyers set realistic expectations and requirements for their suppliers.

-

Language Barriers: Communication can be a challenge. Buyers should ensure that they have clear, documented specifications and requirements that can be easily understood by the supplier.

-

Logistics and Transportation: The conditions under which products are transported can impact their quality. Buyers should discuss how products will be packaged and shipped to prevent damage during transit.

By understanding the manufacturing processes and quality assurance measures in place for 3/16 bungee cords, B2B buyers can make informed decisions and foster successful partnerships with suppliers worldwide.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘3 16 bungee cord’

In the competitive landscape of B2B procurement, sourcing the right 3/16 bungee cord is essential for ensuring product reliability and operational efficiency. This guide provides a systematic checklist to help international buyers navigate the sourcing process effectively.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of a successful procurement process. Consider factors such as the cord’s breaking strength, elasticity, and material composition. For 3/16 bungee cords, look for cords with a minimum breaking strength of 200 lbs, typically made from a combination of rubber and polyethylene for durability.

Illustrative image related to 3 16 bungee cord

Step 2: Identify Your Application Needs

Understanding the specific applications for which you need the bungee cord is crucial. Whether it’s for securing cargo, outdoor activities, or industrial uses, each application may demand different performance characteristics. Assess whether you need additional features, such as UV resistance for outdoor use or marine-grade materials for exposure to moisture.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s essential to conduct a thorough evaluation. Request detailed company profiles, including their experience in the industry, certifications, and customer testimonials. Focus on suppliers who have a strong track record in your specific market region, as they will better understand local regulations and demands.

- Consider supplier location: Proximity can influence shipping times and costs.

- Check for certifications: Ensure they meet international standards, which can provide quality assurance.

Step 4: Request Samples

Before making a bulk purchase, request samples of the 3/16 bungee cord to test its performance. This step allows you to verify the quality, elasticity, and durability of the product. Pay attention to how the cord performs under load, and whether it meets your defined specifications.

Illustrative image related to 3 16 bungee cord

Step 5: Negotiate Terms and Pricing

Once you have selected a supplier, engage in negotiations to secure favorable terms. Discuss bulk pricing, payment terms, and delivery schedules. Be sure to also clarify return policies and warranties, as these can impact your overall cost and risk.

- Consider long-term agreements: If you’re satisfied with the supplier, negotiating a long-term contract may yield better pricing.

Step 6: Confirm Compliance with Regulations

Ensure that the bungee cord complies with all relevant safety and quality regulations in your target markets. This is especially important for industries like construction and transport, where adherence to standards can influence liability and safety. Request documentation that verifies compliance with regional and international standards.

Step 7: Plan for Logistics and Distribution

Finally, develop a logistics plan that outlines how the bungee cord will be stored, handled, and distributed. Consider factors such as inventory management, warehousing conditions, and transportation methods. Efficient logistics planning can reduce costs and improve delivery timelines, ultimately enhancing your business operations.

By following these steps, B2B buyers can make informed decisions when sourcing 3/16 bungee cords, ensuring they select products that meet their operational needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for 3 16 bungee cord Sourcing

What Are the Key Cost Components for Sourcing 3/16 Bungee Cord?

When sourcing 3/16 bungee cord, understanding the cost structure is essential for international B2B buyers. The primary cost components include:

Illustrative image related to 3 16 bungee cord

-

Materials: The core of bungee cords typically consists of rubber, while the outer layer may be made from polyethylene or Dacron polyester. The quality of these materials significantly impacts pricing; higher-quality, UV-resistant materials will command a premium.

-

Labor: Manufacturing labor costs vary by region. For instance, suppliers in regions with lower labor costs can offer more competitive pricing. However, labor quality should not be compromised, as skilled labor is essential for producing high-quality bungee cords.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can reduce overhead, allowing suppliers to pass savings on to buyers.

-

Tooling: Initial tooling costs for specific designs or customizations can be significant. Buyers should discuss tooling costs upfront, especially if they require unique specifications or custom lengths.

-

Quality Control (QC): Implementing rigorous QC processes ensures the cords meet safety and performance standards. Suppliers with comprehensive QC protocols may charge higher prices but offer better reliability.

-

Logistics: Shipping costs can vary based on the destination and the chosen Incoterms. For international buyers, understanding logistics pricing is crucial, as freight charges can significantly impact the total cost.

-

Margin: Suppliers typically build a profit margin into their pricing. This margin can fluctuate based on market demand, supplier competition, and the buyer’s negotiation skills.

How Do Price Influencers Affect Bungee Cord Pricing?

Several factors influence the pricing of 3/16 bungee cords:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for bulk pricing discounts. Buyers should assess their needs to determine the optimal order size that balances cost savings with inventory management.

-

Specifications and Customization: Custom lengths, colors, or material blends can lead to increased costs. Buyers should clearly define their requirements to avoid unexpected price hikes.

-

Material Quality and Certifications: Higher quality materials with certifications (such as ISO or safety certifications) may come at a premium. Buyers should weigh the benefits of higher-quality products against their budget constraints.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their proven track record, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Understanding the terms of shipping (e.g., FOB, CIF) can help buyers anticipate additional costs. Incoterms dictate who bears the shipping and insurance costs, which can affect overall pricing.

What Are the Best Buyer Tips for Cost-Efficiency?

To maximize cost-efficiency when sourcing 3/16 bungee cords, consider these strategies:

-

Negotiate: Engage in negotiations with suppliers to explore discounts or better terms. Understanding the supplier’s cost structure can provide leverage during discussions.

-

Evaluate Total Cost of Ownership (TCO): Look beyond initial pricing; consider factors such as shipping, potential tariffs, and the lifespan of the bungee cord. A higher-quality product may reduce long-term costs due to fewer replacements.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and economic conditions in the supplier’s country, as these can affect pricing. Additionally, consider local market demand and how it might impact supply and pricing strategies.

-

Conduct Market Research: Understanding regional pricing trends can help buyers make informed decisions. For instance, prices may vary significantly between suppliers in Africa, South America, the Middle East, and Europe.

Disclaimer

The prices mentioned in various sources are indicative and may vary based on market conditions, supplier negotiations, and specific order requirements. Always consult with multiple suppliers to ensure competitive pricing and quality.

Alternatives Analysis: Comparing 3 16 bungee cord With Other Solutions

Understanding the Alternatives to 3/16 Bungee Cord

When considering solutions for securing or bundling items, the 3/16 bungee cord stands out for its flexibility and strength. However, various alternative options may better suit specific requirements based on performance, cost, and application. This analysis will compare the 3/16 bungee cord with other viable solutions, helping international B2B buyers make informed decisions.

| Comparison Aspect | 3/16 Bungee Cord | Heavy-Duty Ratchet Straps | Elastic Tie-Down Straps |

|---|---|---|---|

| Performance | Breaking strength: 200 lbs; stretches up to 120% | High tensile strength; can secure heavy loads | Moderate stretch; suitable for light to medium loads |

| Cost | Approximately $0.16 per foot | Ranges from $10 to $50 per pair | Typically $5 to $20 per strap |

| Ease of Implementation | Easy to cut and customize; requires minimal tools | Requires proper strapping technique | Simple to use but less adjustable |

| Maintenance | Low maintenance; inspect for wear | Moderate; check for fraying or damage | Low; replace if damaged |

| Best Use Case | Outdoor activities, securing luggage | Heavy machinery, automotive transport | General light-duty securing tasks |

What Are the Benefits and Drawbacks of Heavy-Duty Ratchet Straps?

Heavy-duty ratchet straps provide a robust alternative to bungee cords, particularly for securing heavy loads. Their design allows for precise tension adjustments, making them ideal for transporting machinery and equipment. However, they require a bit more expertise to use effectively, as improper strapping can lead to accidents. While they are generally more expensive than bungee cords, their durability and strength often justify the investment in high-stakes environments.

How Do Elastic Tie-Down Straps Compare?

Elastic tie-down straps offer a more user-friendly approach for securing items without the need for tools or specialized techniques. They are typically less expensive than both bungee cords and ratchet straps, making them an attractive option for light to medium-duty applications. However, their elasticity may not provide the same level of security as bungee cords or ratchet straps, particularly for heavier items. This makes them suitable for everyday tasks, such as securing luggage or cargo in personal vehicles.

Illustrative image related to 3 16 bungee cord

Conclusion: How Should B2B Buyers Choose the Right Solution?

Selecting the right securing solution hinges on understanding the specific needs of your operation. If flexibility and ease of use are paramount, the 3/16 bungee cord is an excellent choice. For heavy-duty applications where safety and security are critical, heavy-duty ratchet straps might be the best fit. Meanwhile, elastic tie-down straps can serve well in light-duty scenarios where cost-effectiveness is essential. By evaluating the performance, cost, ease of implementation, maintenance, and best use cases, B2B buyers can make informed decisions that align with their operational requirements.

Essential Technical Properties and Trade Terminology for 3 16 bungee cord

What Are the Key Technical Properties of 3/16 Bungee Cord?

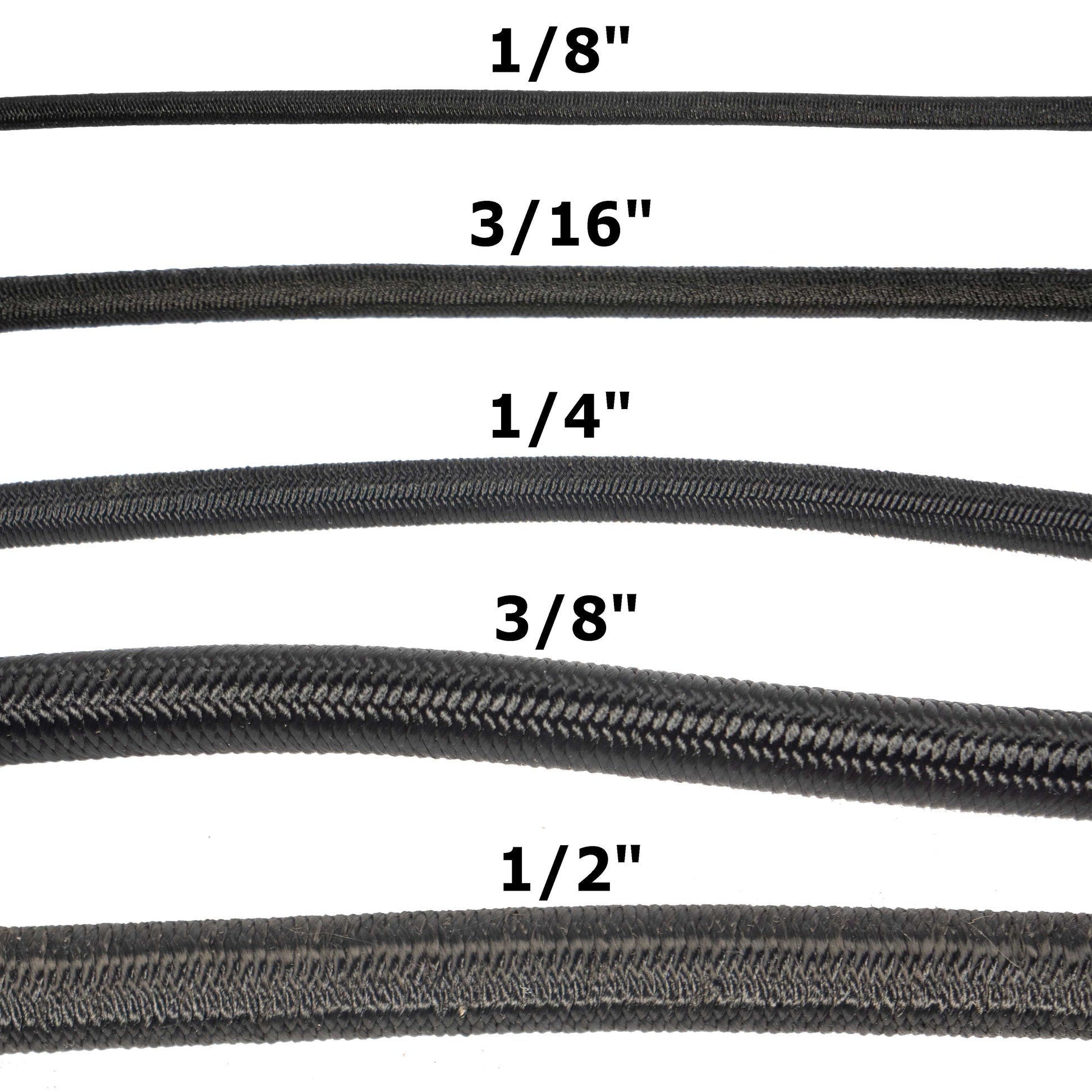

When selecting a 3/16 bungee cord for industrial applications, understanding its technical properties is crucial for ensuring performance, safety, and reliability. Here are some essential specifications to consider:

-

Material Composition

The 3/16 bungee cord typically consists of a core made from high-quality latex rubber, surrounded by a durable outer layer of polyethylene or Dacron polyester. The rubber core provides elasticity, while the outer layer enhances abrasion resistance and UV stability. This combination is vital for applications exposed to harsh environments, ensuring longevity and consistent performance. -

Breaking Strength

The breaking strength of a 3/16 bungee cord is generally around 200 lbs. This specification indicates the maximum load the cord can withstand before failure. Understanding breaking strength is essential for B2B buyers to match the cord’s capacity with their application needs, ensuring safety and operational efficiency. -

Working Load Limit (WLL)

The working load limit is typically set at 16-40 lbs for a 3/16 bungee cord. This metric represents the safe load that can be applied during regular use, factoring in safety margins. For international buyers, adhering to WLL is crucial to prevent accidents and product failures, particularly in commercial transport and outdoor settings. -

Elongation

The 3/16 bungee cord has an elongation of approximately 120% +/- 15%. This property defines how much the cord can stretch under load, which is important for applications requiring flexibility, such as securing cargo. Buyers should consider this when designing systems that rely on shock absorption and tension. -

Diameter

With a diameter of 3/16 inches, this bungee cord strikes a balance between strength and flexibility. Diameter is a critical specification as it affects compatibility with hooks, clips, and other hardware. Ensuring the right diameter can enhance the efficiency of fastening systems in various applications.

Which Trade Terms Should B2B Buyers Understand Regarding 3/16 Bungee Cord?

Navigating the procurement process for 3/16 bungee cords involves familiarity with industry jargon. Here are some key terms that buyers should know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reliable suppliers for bungee cords that meet specific quality and performance standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest amount of product that a supplier is willing to sell. For international buyers, being aware of MOQs helps in budgeting and inventory planning, ensuring they meet supplier requirements while optimizing costs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other details for specified products. B2B buyers should use RFQs to gather competitive pricing and terms for 3/16 bungee cords, enabling informed decision-making. -

Incoterms (International Commercial Terms)

These are standardized terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms can help buyers understand shipping responsibilities, risk management, and cost allocation, especially when importing bungee cords from global suppliers. -

Lead Time

Lead time refers to the time taken from placing an order to its delivery. Knowing the lead time is essential for B2B buyers to align their inventory management and project timelines, ensuring they have the necessary materials when needed.

Understanding these technical properties and trade terms enables B2B buyers to make informed decisions when sourcing 3/16 bungee cords, ultimately enhancing operational efficiency and safety in their respective industries.

Navigating Market Dynamics and Sourcing Trends in the 3 16 bungee cord Sector

What Are the Key Market Dynamics Driving the 3/16 Bungee Cord Sector?

The global market for 3/16 bungee cords is witnessing significant growth, driven primarily by an increase in outdoor recreational activities, industrial applications, and transportation needs. Key regions, including Africa, South America, the Middle East, and Europe, are observing heightened demand for versatile and durable elastic cords. In particular, countries like Brazil and Saudi Arabia are expanding their logistics and outdoor sectors, which further fuels the need for reliable bungee cords.

Emerging trends in B2B sourcing highlight the integration of technology, such as e-commerce platforms, which simplify procurement processes for international buyers. Buyers can now access a wide variety of products, read reviews, and compare prices in real time, leading to more informed purchasing decisions. Moreover, the rise of digital supply chain management tools is helping businesses streamline operations, enhance visibility, and reduce lead times.

Additionally, the increasing emphasis on safety and quality assurance is shaping buyer preferences. Bungee cords with higher breaking strengths and better elongation properties are becoming the standard, as businesses prioritize performance and reliability. As manufacturers continue to innovate and improve product specifications, international buyers are encouraged to seek out suppliers who adhere to stringent quality standards, thereby ensuring that their sourcing decisions align with industry best practices.

How Is Sustainability Influencing B2B Sourcing of 3/16 Bungee Cords?

Sustainability is rapidly becoming a focal point in the sourcing of 3/16 bungee cords, as businesses recognize the environmental impact of their supply chains. The production of bungee cords typically involves synthetic materials, which can contribute to pollution and resource depletion. Consequently, buyers are increasingly seeking out manufacturers that utilize sustainable practices and materials, such as recycled fibers or bio-based elastomers.

Ethical sourcing is equally critical, as companies aim to enhance their corporate social responsibility (CSR) profiles. Suppliers who demonstrate transparency in their supply chains and adhere to fair labor practices are more attractive to international buyers. Certifications such as Global Organic Textile Standard (GOTS) or OEKO-TEX can serve as indicators of a supplier’s commitment to sustainability and ethical production methods.

Incorporating ‘green’ certifications not only helps businesses meet regulatory requirements but also resonates with environmentally conscious consumers. By prioritizing sustainable sourcing, B2B buyers can enhance their brand reputation, appeal to a broader customer base, and contribute positively to global sustainability efforts.

What Is the Historical Context of Bungee Cord Development for B2B Buyers?

The evolution of bungee cords can be traced back to the late 1940s, initially developed for military applications. Over the decades, their versatility has seen them adopted in a wide range of sectors, from outdoor recreation to industrial logistics. The introduction of synthetic materials in the 1960s, such as rubber and polyethylene, significantly improved their durability and elasticity, leading to their widespread use in various applications.

Illustrative image related to 3 16 bungee cord

In the 1980s and 1990s, the consumer market began to embrace bungee cords for everyday uses, such as securing cargo and outdoor equipment. As the demand grew, manufacturers began to innovate further, leading to the development of specialized versions like the 3/16 bungee cord, which balances strength and flexibility for various tasks. Today, international B2B buyers benefit from an extensive selection of high-performance bungee cords tailored to meet the diverse needs of modern industries, further solidifying their importance in global supply chains.

Frequently Asked Questions (FAQs) for B2B Buyers of 3 16 bungee cord

-

How do I choose the right type of 3/16 bungee cord for my application?

When selecting a 3/16 bungee cord, consider the specific requirements of your application, such as load capacity, elasticity, and environmental exposure. Look for cords with a breaking strength of at least 200 lbs, which is suitable for most commercial uses. Additionally, materials like Dacron polyester offer enhanced durability against UV and moisture, making them ideal for outdoor applications. Always ensure that the cord’s elongation characteristics meet your needs, particularly if stretch and flexibility are critical for securing items. -

What is the best use case for 3/16 bungee cord in industrial settings?

The 3/16 bungee cord is highly versatile and can be used in various industrial applications, including securing loads during transportation, creating cargo nets, and even in manufacturing processes where flexibility is necessary. Its robust breaking strength allows it to handle significant weight, making it perfect for packaging, logistics, and outdoor activities. Ensure that you assess the specific requirements of your operation to determine whether a shock cord or a standard bungee is more suitable. -

What are the key factors to consider when vetting suppliers for 3/16 bungee cords?

When vetting suppliers, prioritize their track record, product quality, and compliance with international standards. Request samples to evaluate the cord’s strength and elasticity, and review certifications that ensure the product meets safety regulations. Additionally, assess the supplier’s ability to provide consistent supply, responsiveness to inquiries, and customer service. Feedback from previous buyers can provide valuable insights into reliability and product performance. -

What are the minimum order quantities (MOQ) for 3/16 bungee cords?

Minimum order quantities can vary significantly among suppliers. Some may offer flexible MOQ options starting from small quantities for trial orders, while others may require larger commitments, often in the range of 500 to 1,000 meters. It’s crucial to communicate your specific needs with potential suppliers, as some may be willing to negotiate MOQs, especially for first-time buyers or bulk orders. -

What payment terms should I expect when sourcing 3/16 bungee cords internationally?

Payment terms can vary by supplier and region, but common practices include upfront payments, partial payments (50% upfront and 50% upon delivery), or payment upon receipt. Ensure that you clarify these terms before finalizing your order. Additionally, consider using secure payment methods like letters of credit or escrow services to mitigate risk, especially in international transactions. -

How can I ensure quality assurance for 3/16 bungee cords?

Implementing a robust quality assurance process is vital. Request detailed product specifications and testing reports from suppliers to verify compliance with your quality standards. Consider conducting periodic inspections or audits at the supplier’s facility, or use third-party inspection services to evaluate the product’s quality before shipment. Establishing clear communication regarding quality expectations will help minimize potential issues. -

What logistics considerations should I keep in mind when importing 3/16 bungee cords?

When importing, consider shipping costs, delivery timelines, and customs regulations specific to your region. Work closely with your supplier to determine the best shipping method—air or sea—based on urgency and budget. Additionally, ensure that all documentation, such as invoices and certificates of origin, is in order to facilitate smooth customs clearance. It’s wise to partner with a reliable freight forwarder to navigate these logistics effectively. -

Can 3/16 bungee cords be customized for specific applications?

Yes, many suppliers offer customization options for 3/16 bungee cords, including length, color, and material composition. Customization can enhance the suitability of the cord for particular applications, such as branding or specific environmental conditions. When requesting customization, provide detailed specifications and inquire about lead times and any additional costs associated with tailored products.

Top 7 3 16 Bungee Cord Manufacturers & Suppliers List

1. Paracord Planet – High Quality Shock Cord

Domain: paracordplanet.com

Registered: 2011 (14 years)

Introduction: 3/16″ High Quality Shock Cord, available in multiple colors, priced from $7.99 to $29.99, with free standard shipping on orders over $8.99 (US only). Uses include bungee straps and cargo nets, suitable for securing luggage in vehicles or holding items in suitcases.

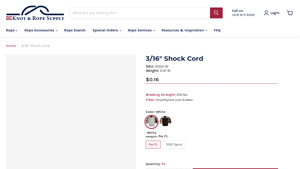

2. Knot and Rope – Polyethylene Over Rubber Rope

Domain: knotandrope.com

Registered: 2003 (22 years)

Introduction: {“SKU”: “2502-W”, “Weight”: “0.01 lb”, “Original Price”: “$0.16 – $155.00”, “Current Price”: “$0.16”, “Breaking Strength”: “200 lbs.”, “Fiber Composition”: “Polyethylene over Rubber”, “Elongation”: “120% +/- 15%”, “Diameter Options”: [{“Size”: “1/8”, “Breaking Strength”: “100 lbs.”, “Working Load Limit”: “8-20 lbs.”}, {“Size”: “5/32”, “Breaking Strength”: “150 lbs.”, “Working Load Limit”: “12-30 l…

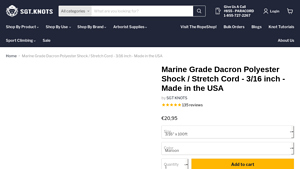

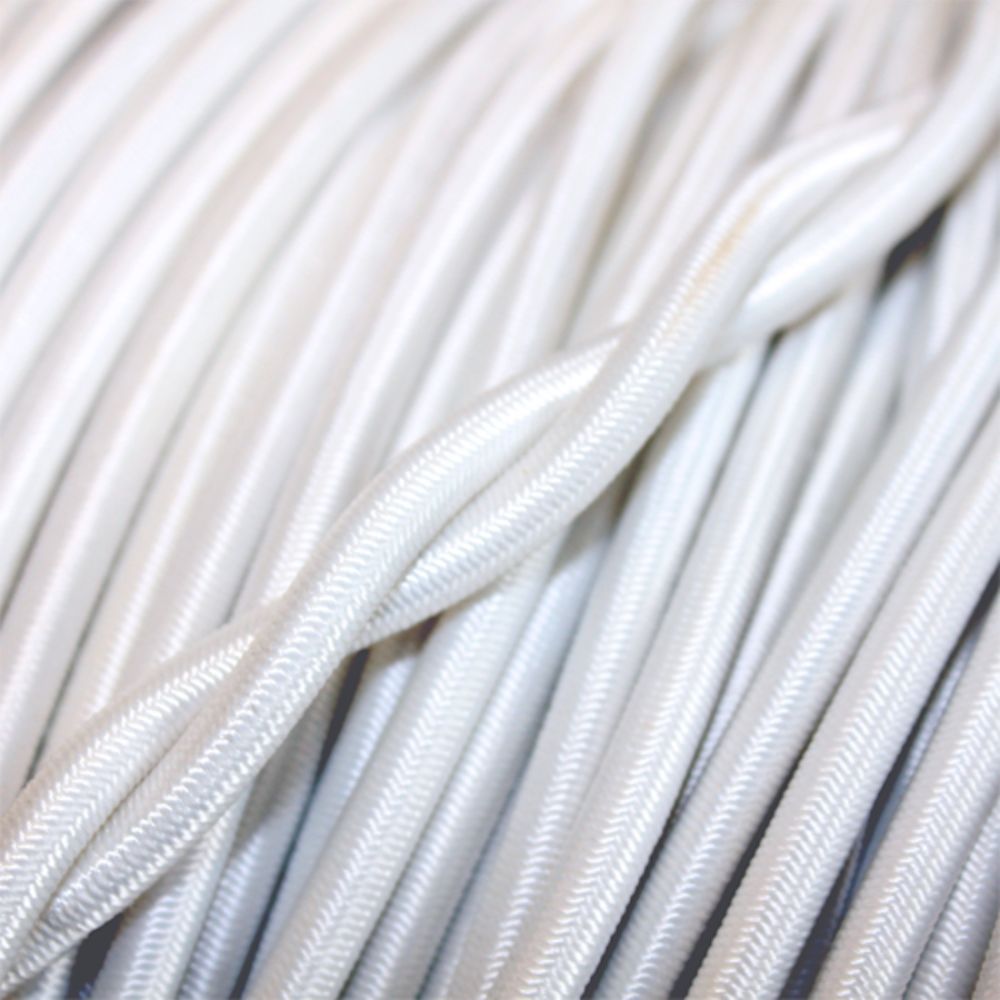

3. SGT KNOTS – Marine Grade Dacron Polyester Shock Cord

Domain: sgtknots.com

Registered: 2010 (15 years)

Introduction: {“product_name”: “Marine Grade Dacron Polyester Shock / Stretch Cord”, “brand”: “SGT KNOTS”, “diameter”: “3/16 inch”, “made_in”: “USA”, “available_lengths”: [“10ft”, “25ft”, “50ft”, “100ft”], “colors”: [“Black”, “Brown”, “Emerald Green”, “Kelly Green”, “Maroon”, “Neon Green”, “Neon Orange”, “Neon Yellow”, “OD Green”, “Pink”, “Purple”, “Red”, “Royal Blue”, “Silver”, “Tan”, “White”, “Woodland Camo”]…

4. Quality Nylon Rope – 3/16 Polypropylene Black Bungee Cord

Domain: qualitynylonrope.com

Registered: 2009 (16 years)

Introduction: {“name”: “3/16\” Polypropylene Black Bungee Cord”, “SKU”: “B316BungieCordPP”, “price_range”: “$24.00 – $115.00”, “length_options”: [“100 ft Bulk”, “250 ft Spool”, “500 ft Spool”, “1000 ft Spool”], “diameter”: “3/16\””, “color”: “Black”, “weight”: “1 lbs”, “material”: “Polypropylene”, “features”: [“UV-treated polypropylene jacket”, “ribbed design for better gripping and knotting”, “approximate 100%…

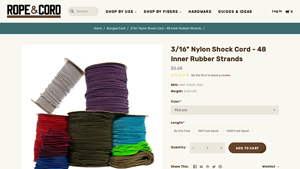

5. Rope and Cord – 3/16 Nylon Shock Cord

Domain: ropeandcord.com

Registered: 2017 (8 years)

Introduction: {‘name’: ‘3/16″ Nylon Shock Cord – 48 Inner Rubber Strands’, ‘price’: ‘$0.68’, ‘SKU’: ‘PAR-316SC-RAC’, ‘weight’: ‘0.02 LBS’, ‘diameter’: ‘3/16″ (4.76mm)’, ‘elongation’: ‘100%’, ‘core_strands’: ’48 Strands’, ‘composition’: ‘Nylon’, ‘construction’: ‘Nylon Jacket w/ Rubber Core’, ‘made_in_usa’: ‘Yes’, ‘rot_resistant’: ‘Yes’, ‘ultraviolet_light_resistant’: ‘Yes’, ‘absorbs_water’: ‘Yes’, ‘floats’: ‘Not…

6. Tarps Now – Elastic Shock Cord 3/16” x 1000’ Spool

Domain: tarpsnow.com

Registered: 2010 (15 years)

Introduction: {“Product Name”: “Elastic Shock Cord – 3/16” x 1000’ Spool”, “SKU”: “TA-UC-SC1875”, “Price”: “$99.99”, “Discount”: “$69.99”, “Material”: “100% Polyester (sleeve) / 100% Synthetic Rubber”, “Diameter”: “3/16″ (0.1875″)”, “Roll Length”: “1000 Feet”, “Minimum Break Strength”: “200 lbs”, “Approx Density /100 ft”: “1.2 lbs”, “Color”: “White (with Black tracer)”, “Finish”: “UV Resistant”, “Availability”:…

7. The Paracord Store – Tan 3/16 Shock Cord/Bungee Cord

Domain: theparacordstore.com

Registered: 2009 (16 years)

Introduction: {“name”: “Tan 3/16″ Shock Cord/Bungee Cord”, “length_options”: [“1 ft”, “10 ft”, “25 ft”, “50 ft”, “100 ft”], “prices”: {“1 ft”: “$0.99”, “10 ft”: “$6.99”, “25 ft”: “$11.75”, “50 ft”: “$19.00”, “100 ft”: “$30.00”}, “sku”: “S316-TAN-1”, “color”: “Tan”, “material”: “Braided Nylon Outer Sheath with Rubber Core”, “features”: [“100% Elongation +/- 10%”, “Approx. Diameter: 3/16″ (4.75mm)”, “Mildew and R…

Strategic Sourcing Conclusion and Outlook for 3 16 bungee cord

As international B2B buyers consider the procurement of 3/16 bungee cords, the importance of strategic sourcing cannot be overstated. This versatile elastic cord, with a breaking strength of 200 lbs and applications ranging from securing cargo to crafting, presents an opportunity for businesses to enhance their operational efficiency. By focusing on quality materials, such as polyethylene and rubber, buyers can ensure durability and performance across various environments, particularly in outdoor and industrial settings.

Additionally, understanding the specifics of bungee cord specifications—such as elongation rates and working load limits—enables informed decision-making that can mitigate risks associated with product failure. Sourcing from reputable suppliers who prioritize quality and customer service will not only ensure reliable supply chains but also foster long-term partnerships.

Illustrative image related to 3 16 bungee cord

Looking ahead, businesses in regions like Africa, South America, the Middle East, and Europe should leverage the growing demand for durable and adaptable materials. Embracing strategic sourcing practices now will position them favorably in a competitive market. Engage with trusted suppliers to explore innovative uses for 3/16 bungee cords and stay ahead of industry trends. Your proactive approach can lead to enhanced product offerings and customer satisfaction.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.