The Definitive Guide to Harmonic Gear Reducer: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for harmonic gear reducer

In today’s competitive landscape, sourcing a reliable harmonic gear reducer can pose significant challenges for international B2B buyers. With applications spanning robotics, aerospace, and automation, the need for precision and reliability is paramount. This guide offers a comprehensive overview of harmonic gear reducers, detailing various types, their specific applications, and the critical factors to consider when vetting suppliers. By understanding the intricacies of design specifications and performance metrics, businesses can make informed purchasing decisions that not only meet their operational needs but also optimize cost efficiency.

Navigating the global market requires a strategic approach, especially for buyers in diverse regions like Africa, South America, the Middle East, and Europe, including countries such as Nigeria and Vietnam. This guide empowers decision-makers by addressing key considerations such as supplier credibility, pricing structures, and technological advancements in harmonic drive systems. Additionally, it will explore how to leverage industry trends and innovations to enhance operational capabilities.

By arming yourself with the knowledge contained in this guide, you will be better positioned to select a harmonic gear reducer that aligns with your business objectives, ensuring both performance excellence and long-term reliability.

Understanding harmonic gear reducer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Harmonic Drive Gear Units | Zero backlash, compact design, high torque density | Robotics, aerospace, medical devices | Pros: High precision, lightweight; Cons: Higher initial cost. |

| Miniature Harmonic Reducers | Small form factor, suitable for tight spaces | Semiconductor manufacturing, automation | Pros: Space-saving, efficient; Cons: Limited torque capacity. |

| Hollow Shaft Gear Reducers | Integrated hollow shaft for cable management | CNC machines, industrial automation | Pros: Simplified design, easy installation; Cons: May require custom solutions. |

| Servo Mount Gearheads | Direct compatibility with servo motors | Robotics, CNC, and automation systems | Pros: Easy integration, high performance; Cons: Potential compatibility issues with non-standard motors. |

| Phase Adjusters | Designed for precise phase adjustments | Printing, textile, and packaging machines | Pros: High reduction ratios, precise control; Cons: May need specialized knowledge for setup. |

What are the Characteristics of Harmonic Drive Gear Units?

Harmonic Drive Gear Units are renowned for their zero backlash, compact design, and ability to handle high torque densities. These features make them ideal for applications in robotics, aerospace, and medical devices, where precision is critical. When considering a purchase, buyers should evaluate the initial investment against the long-term benefits of reliability and performance, as these units often come with a higher upfront cost.

Why Choose Miniature Harmonic Reducers for Your Applications?

Miniature Harmonic Reducers are specifically designed for applications where space is at a premium. Their small form factor allows for efficient integration into semiconductor manufacturing and automation systems. Buyers should consider the torque capacity of these reducers, as their compact size may limit their application in high-torque environments. However, their efficiency and space-saving capabilities make them a strong choice for many modern applications.

How Do Hollow Shaft Gear Reducers Simplify Installation?

Hollow Shaft Gear Reducers feature an integrated hollow shaft that allows for the passage of cables and pipes, streamlining installation in CNC machines and industrial automation setups. This design reduces the complexity of machinery layouts, making it easier for engineers to implement. Buyers should assess the specific requirements of their projects to determine if the advantages of simplified installation outweigh potential custom solutions needed for unique applications.

What Are the Benefits of Servo Mount Gearheads?

Servo Mount Gearheads offer direct compatibility with servo motors, enhancing performance in robotics and CNC applications. Their ease of integration is a significant advantage, allowing for faster assembly and testing. However, buyers must ensure compatibility with their existing systems, as non-standard motors may pose integration challenges. This consideration is crucial for minimizing downtime and maximizing efficiency.

How Do Phase Adjusters Enhance Precision in Operations?

Phase Adjusters are specialized harmonic gear reducers designed for precise phase adjustments, particularly in printing, textile, and packaging machinery. Their high reduction ratios enable accurate control over movement, which is essential in applications requiring exact positioning. Buyers should weigh the need for specialized knowledge and potential training against the benefits of improved operational precision when considering these components.

Key Industrial Applications of harmonic gear reducer

| Industry/Sector | Specific Application of harmonic gear reducer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Robotics | Precision motion control in robotic arms and automated systems | Enhanced accuracy and repeatability in tasks, reducing downtime | Compatibility with existing systems, torque requirements, and backlash specifications. |

| Aerospace | Actuation systems in aircraft control surfaces | Improved reliability and weight savings, crucial for safety | Compliance with aviation standards, weight constraints, and environmental resistance. |

| Medical Equipment | Drive mechanisms in surgical robots and imaging devices | High precision and safety in critical medical applications | Regulatory compliance, sterilization capabilities, and size constraints. |

| Industrial Automation | Automation in assembly lines and conveyor systems | Increased efficiency and reduced operational costs | Customization options, durability under heavy loads, and maintenance requirements. |

| Renewable Energy | Tracking systems for solar panels and wind turbines | Maximized energy output and system longevity | Environmental resilience, integration with existing technologies, and efficiency ratings. |

How Is Harmonic Gear Reducer Used in Robotics?

In the robotics sector, harmonic gear reducers are integral to precision motion control in robotic arms and automated systems. They enable smooth, accurate movements necessary for tasks like assembly, welding, and painting. These reducers solve the challenge of backlash, ensuring that robots can perform repetitive tasks without positional errors, enhancing productivity. International buyers should consider the compatibility of these reducers with their existing robotics systems, focusing on torque requirements and backlash specifications to ensure optimal performance.

What Role Does Harmonic Gear Reducer Play in Aerospace?

In aerospace applications, harmonic gear reducers are utilized in actuation systems for aircraft control surfaces, such as flaps and rudders. Their compact design and lightweight characteristics contribute to overall aircraft efficiency and performance. The reliability of these gear reducers is critical, given the safety implications in aviation. Buyers from regions like the Middle East and Europe must ensure that the products meet stringent aviation standards and can withstand various environmental conditions, including temperature fluctuations and pressure changes.

How Are Harmonic Gear Reducers Applied in Medical Equipment?

In the medical equipment industry, harmonic gear reducers are essential for the drive mechanisms in surgical robots and imaging devices. They provide the high precision required for delicate procedures, ensuring patient safety and successful outcomes. The challenge for buyers in this sector is to source gear reducers that comply with medical regulations and can be easily sterilized, while also fitting within the compact constraints of medical devices. Attention to detail in specifications is paramount to ensure reliability in critical applications.

What Benefits Do Harmonic Gear Reducers Offer in Industrial Automation?

Harmonic gear reducers are widely used in industrial automation for automation processes in assembly lines and conveyor systems. They contribute to enhanced efficiency by allowing for smoother and more controlled movements of machinery, which can lead to reduced operational costs and minimized downtime. For international buyers, especially in Africa and South America, it is vital to consider customization options that suit specific operational needs, as well as durability to withstand heavy loads and rigorous use.

How Do Harmonic Gear Reducers Enhance Renewable Energy Systems?

In the renewable energy sector, harmonic gear reducers are employed in tracking systems for solar panels and wind turbines. These systems require precise movements to maximize energy capture, and harmonic gear reducers provide the necessary accuracy and efficiency. The challenge for buyers is to ensure that the gear reducers are resilient to environmental factors such as wind and moisture while integrating seamlessly with existing technologies. Evaluating efficiency ratings and durability is essential for long-term performance in renewable energy applications.

3 Common User Pain Points for ‘harmonic gear reducer’ & Their Solutions

Scenario 1: Difficulty in Achieving Precision in Motion Control Applications

The Problem: Many B2B buyers in sectors such as robotics, aerospace, and automation often face challenges in achieving the required precision in motion control applications. For instance, a manufacturer may be working on a robotic arm that requires exact positioning to perform intricate tasks. However, traditional gear systems can introduce backlash, leading to errors in position and timing. This not only compromises the integrity of the application but can also result in costly downtime and rework, impacting overall productivity and profitability.

The Solution: To overcome precision issues, buyers should consider sourcing harmonic gear reducers known for their zero-backlash design. When specifying these reducers, focus on key parameters such as gear ratio, torque capacity, and load ratings. It is crucial to engage with suppliers who offer detailed technical support and can assist in selecting the right gear for specific applications. Additionally, implementing a system of regular maintenance and monitoring can help ensure that the gear reducer operates at optimal performance levels, thus maintaining the precision needed for demanding tasks.

Scenario 2: Integration Challenges with Existing Systems

The Problem: Another common pain point arises when B2B buyers attempt to integrate harmonic gear reducers into existing machinery or systems. Compatibility issues can emerge, especially in industries where legacy equipment is prevalent. For example, a manufacturer might have a well-established assembly line that requires an upgrade for improved efficiency. However, the new harmonic gear reducer may not fit seamlessly with older components, leading to delays and increased costs associated with modifications or replacements.

The Solution: To mitigate integration challenges, it is advisable to conduct a thorough compatibility assessment before procurement. Buyers should collaborate with manufacturers who provide comprehensive product specifications and integration guidelines. Utilizing a modular approach can also facilitate easier upgrades. Consider engaging in a pilot program or prototype testing phase to evaluate the performance of the harmonic gear reducer within the existing system. This proactive approach allows for adjustments before full-scale implementation, minimizing operational disruptions.

Scenario 3: High Costs of Maintenance and Replacement

The Problem: B2B buyers often experience high maintenance costs and frequent replacements of gear systems, which can strain operational budgets. For instance, in heavy-duty applications such as construction equipment, the wear and tear on conventional gear systems can lead to unexpected failures, resulting in downtime and significant repair expenses. Companies may find themselves caught in a cycle of continual replacements that affect their bottom line.

The Solution: To address these concerns, investing in high-quality harmonic gear reducers can provide long-term savings. These reducers are engineered for durability and often require less frequent maintenance compared to traditional gear systems. Buyers should prioritize sourcing from reputable manufacturers known for their robust designs and warranty programs. Implementing a preventive maintenance schedule that includes regular inspections and lubrication can also extend the life of the gear reducer. Additionally, educating the maintenance team on proper operational practices will help in maximizing the performance and lifespan of the equipment, ultimately leading to reduced costs over time.

Strategic Material Selection Guide for harmonic gear reducer

When selecting materials for harmonic gear reducers, it is essential to consider various factors such as mechanical properties, cost, and suitability for specific applications. Here, we analyze four common materials used in the manufacturing of harmonic gear reducers: aluminum, steel, plastic, and titanium. Each material has its unique properties and implications for performance, manufacturing, and international compliance.

What Are the Key Properties of Aluminum for Harmonic Gear Reducers?

Aluminum is a lightweight metal known for its excellent corrosion resistance and good strength-to-weight ratio. It typically performs well at moderate temperatures and pressures, making it suitable for various applications. In harmonic gear reducers, aluminum can help reduce overall weight, which is particularly beneficial in robotics and aerospace applications.

Pros: Aluminum is relatively inexpensive and easy to machine, allowing for complex shapes and designs. Its low density also contributes to energy efficiency in applications where weight is a critical factor.

Cons: While aluminum has good corrosion resistance, it may not perform well in high-temperature environments or under heavy loads compared to steel. Its lower tensile strength can limit its use in high-torque applications.

Impact on Application: Aluminum is compatible with various media, but care should be taken when exposed to strong acids or alkalis.

Considerations for International Buyers: Compliance with standards such as ASTM and EN for aluminum alloys is crucial. Buyers in regions like Africa and South America may prefer aluminum for its cost-effectiveness and availability.

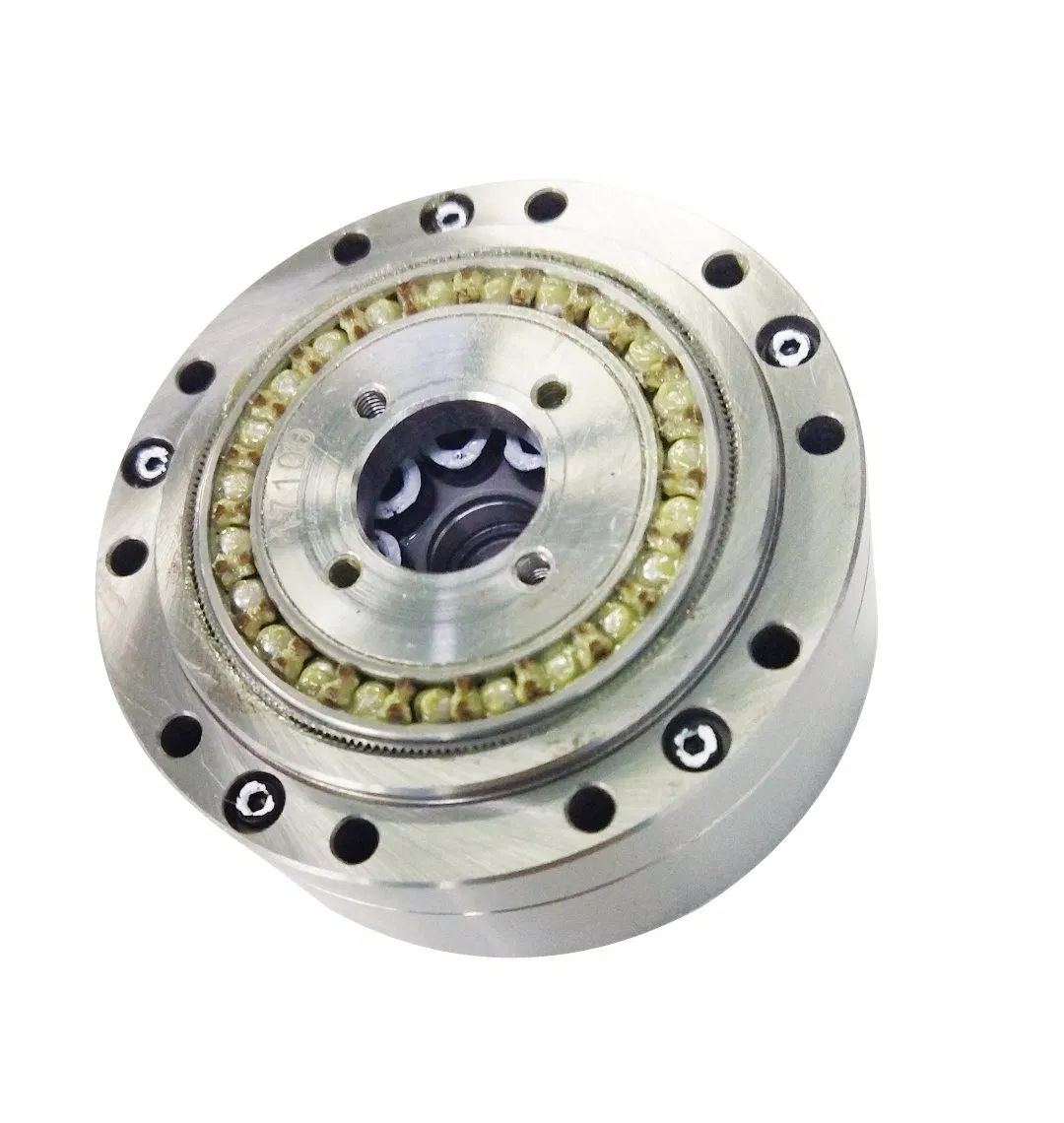

Illustrative image related to harmonic gear reducer

How Does Steel Perform in Harmonic Gear Reducers?

Steel, particularly alloy steel, is a common choice for harmonic gear reducers due to its high strength, durability, and wear resistance. It can withstand high temperatures and pressures, making it suitable for demanding applications.

Pros: Steel offers superior mechanical properties, including high tensile strength and toughness, making it ideal for high-load applications. It also has good machinability and can be heat-treated to enhance performance.

Cons: The primary drawback of steel is its susceptibility to corrosion, which necessitates protective coatings or treatments. It is also heavier than aluminum, which can be a disadvantage in weight-sensitive applications.

Impact on Application: Steel is compatible with a wide range of media and is often preferred in industrial applications where robustness is critical.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as DIN and JIS for steel grades. In regions like the Middle East, where high temperatures are common, selecting the right steel grade is vital.

What Are the Advantages of Using Plastic in Harmonic Gear Reducers?

Plastics, particularly engineering plastics like nylon and acetal, are increasingly used in harmonic gear reducers due to their lightweight and corrosion-resistant properties. They perform well in applications where noise reduction and low friction are essential.

Pros: Plastics are lightweight, which can significantly reduce the overall weight of the gear reducer. They also offer excellent chemical resistance and can be molded into complex shapes, facilitating design flexibility.

Cons: The main limitation of plastics is their lower mechanical strength compared to metals, which can restrict their use in high-load applications. They may also have a limited temperature range, which can affect performance in extreme conditions.

Illustrative image related to harmonic gear reducer

Impact on Application: Plastics can be suitable for applications involving non-corrosive media but should be avoided in high-temperature or high-pressure environments.

Considerations for International Buyers: Compliance with international standards for plastics, such as ASTM for specific grades, is essential. In regions like Europe, buyers may favor plastics for lightweight applications in automotive and consumer products.

How Does Titanium Compare for Harmonic Gear Reducers?

Titanium is a high-performance material known for its exceptional strength-to-weight ratio and corrosion resistance. It is often used in specialized applications requiring high durability and low weight.

Illustrative image related to harmonic gear reducer

Pros: Titanium’s high strength allows for thinner components, reducing weight without sacrificing performance. It also exhibits excellent corrosion resistance, making it suitable for harsh environments.

Cons: The primary drawback of titanium is its high cost and complex manufacturing processes, which can limit its use in standard applications.

Impact on Application: Titanium is ideal for high-performance applications in aerospace and medical devices, where reliability and weight are critical.

Considerations for International Buyers: Buyers should be aware of compliance with international standards for titanium alloys. In regions like Africa, where cost may be a concern, titanium may be less favored unless specific performance criteria justify the expense.

Summary of Material Selection for Harmonic Gear Reducers

| Material | Typical Use Case for harmonic gear reducer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight robotics and aerospace | Excellent strength-to-weight ratio | Lower tensile strength than steel | Medium |

| Steel | Industrial applications with high loads | Superior mechanical properties | Susceptible to corrosion | Low |

| Plastic | Low-load applications requiring noise reduction | Lightweight and corrosion-resistant | Limited mechanical strength | Low |

| Titanium | Aerospace and medical devices | Exceptional strength and corrosion resistance | High cost and complex manufacturing | High |

This guide provides a comprehensive overview of material options for harmonic gear reducers, enabling international B2B buyers to make informed decisions based on their specific application needs and regional considerations.

Illustrative image related to harmonic gear reducer

In-depth Look: Manufacturing Processes and Quality Assurance for harmonic gear reducer

What Are the Key Stages in the Manufacturing Process of Harmonic Gear Reducers?

The manufacturing process of harmonic gear reducers involves several critical stages that ensure the final product meets the high precision and performance standards required in various applications. These stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Harmonic Gear Reducers?

Material selection is fundamental to the manufacturing process. Typically, high-strength alloys such as stainless steel or specialized carbon steels are used due to their durability and resistance to wear. The first step involves sourcing these materials from reputable suppliers, ensuring they meet international standards such as ASTM or equivalent.

Once sourced, the materials undergo rigorous testing for quality and consistency. This includes chemical composition analysis and tensile strength tests to confirm they will withstand the operational demands of the gear reducer. After verification, materials are cut and shaped into required sizes using advanced machining techniques, including CNC milling and turning, which provide the precision necessary for the subsequent forming processes.

What Techniques Are Used in Forming Harmonic Gear Reducers?

The forming stage is critical in shaping the components of the harmonic gear reducer. This typically involves processes such as gear hobbing, shaping, and grinding.

-

Hobbing: This is often the primary method for creating the gear teeth. It involves using a specialized cutting tool known as a hob, which shapes the teeth of the gear in a single pass, ensuring high accuracy and efficiency.

-

Shaping: In this stage, flat surfaces or internal gears are formed. This is crucial for achieving the precise contact surfaces needed for zero backlash operation, a key feature of harmonic gear reducers.

-

Grinding: After initial shaping, grinding is performed to achieve the final dimensions and surface finish. This process removes any imperfections and ensures tight tolerances, which are vital for the gear’s performance and longevity.

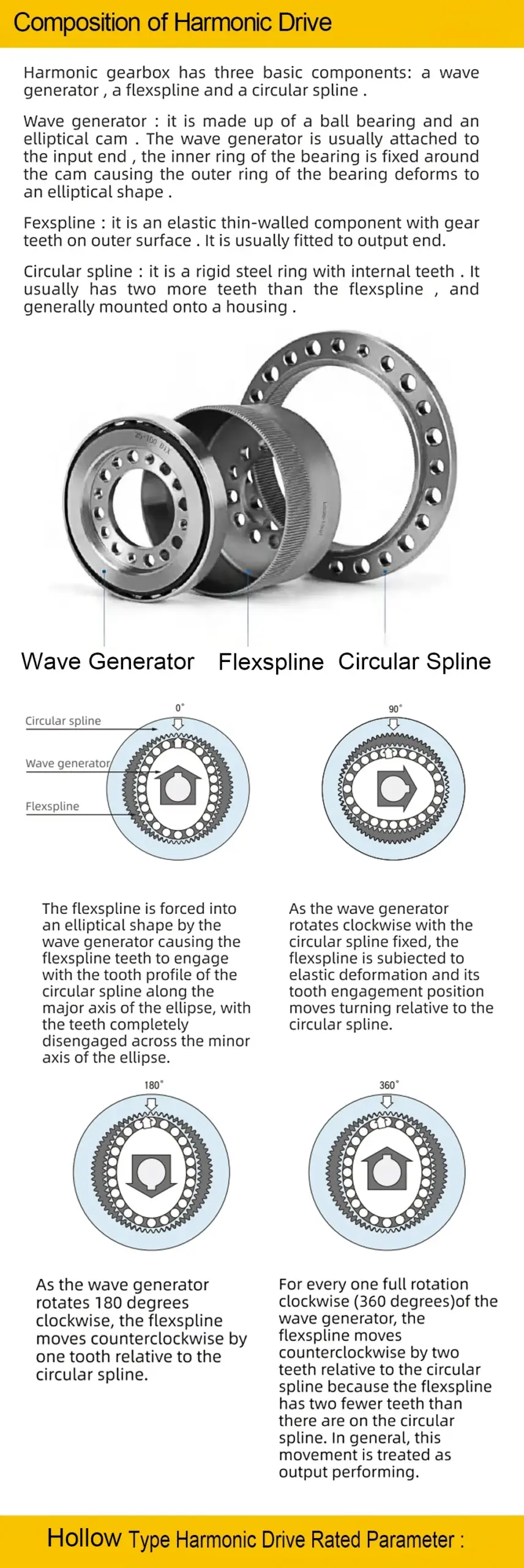

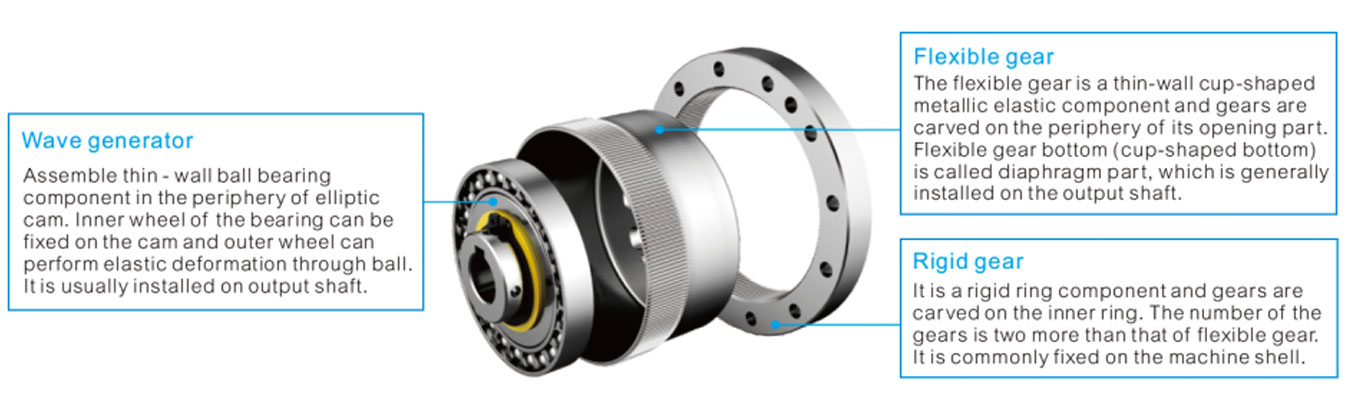

How Are Harmonic Gear Reducers Assembled?

The assembly process is where the individual components come together to form the harmonic gear reducer. This stage is highly sensitive and requires skilled labor to ensure that all components fit perfectly.

During assembly, components such as the wave generator, flexspline, and circular spline are integrated. The assembly process often includes the application of special lubricants, like HarmonicGrease®, which are specifically designed to enhance performance and longevity. Each assembly step is meticulously documented to maintain traceability.

Additionally, assembly is often conducted in cleanroom environments to minimize contamination risks. This is particularly important in industries such as robotics or aerospace, where even minute particles can compromise performance.

What Quality Assurance Standards Are Important for Harmonic Gear Reducers?

Quality assurance (QA) is paramount in the manufacturing of harmonic gear reducers. B2B buyers should look for suppliers who adhere to internationally recognized standards, such as ISO 9001, which outlines a framework for effective quality management systems.

Which International Standards Should B2B Buyers Consider?

In addition to ISO 9001, there are several industry-specific certifications that may be relevant, including:

- CE Certification: This indicates compliance with European safety standards, essential for buyers in Europe.

- API Standards: For applications in oil and gas, suppliers may need to comply with American Petroleum Institute standards.

These certifications assure buyers that the products are manufactured under strict quality controls and are suitable for their intended applications.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) involves systematic monitoring throughout the manufacturing process to identify and rectify defects. Key checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified requirements.

- In-Process Quality Control (IPQC): Throughout the manufacturing stages, periodic checks are conducted to ensure each process is performed correctly and to specification.

- Final Quality Control (FQC): Once the gear reducers are fully assembled, they undergo comprehensive testing, including functional tests, dimensional checks, and performance evaluations.

What Common Testing Methods Are Used for Harmonic Gear Reducers?

Testing is a critical aspect of quality assurance. Common testing methods include:

- Load Testing: Evaluating the gear reducer’s performance under simulated operational loads to ensure it can handle the expected torque and speed.

- Backlash Measurement: Ensuring that the gear reducer maintains its zero backlash specification, which is crucial for precision applications.

- Vibration Analysis: Detecting any irregularities that may indicate potential failures.

These testing methods provide insights into the reliability and longevity of the gear reducer, ensuring it meets buyer specifications.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers can take several steps to verify the quality control practices of their suppliers:

- Audits: Conducting on-site audits of the supplier’s manufacturing facility can provide firsthand insights into their processes and adherence to quality standards.

- Quality Reports: Requesting detailed quality control reports can help buyers understand the supplier’s testing methods, frequency of checks, and any issues encountered during production.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices.

What Are the Nuances of Quality Control for International B2B Buyers?

For international buyers, particularly from Africa, South America, the Middle East, and Europe, understanding local compliance and certification nuances is essential. Buyers should ensure that suppliers can navigate the regulatory landscape of their respective regions, which may involve additional certifications or testing protocols.

Additionally, language barriers and time zone differences can complicate communication regarding quality concerns. Establishing clear lines of communication and expectations upfront can mitigate these challenges.

By understanding the manufacturing processes and quality assurance measures for harmonic gear reducers, B2B buyers can make informed decisions when selecting suppliers, ensuring they receive high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘harmonic gear reducer’

This guide provides a structured approach for B2B buyers aiming to procure harmonic gear reducers. By following these steps, you can ensure that your sourcing process is efficient, aligns with your technical requirements, and results in a reliable partnership with a manufacturer or supplier.

Step 1: Define Your Technical Specifications

Before beginning your search, clearly outline the technical requirements for the harmonic gear reducer you need. This includes parameters such as torque capacity, gear ratio, size, weight, and compatibility with existing systems. A well-defined specification helps you communicate effectively with suppliers and ensures that the products meet your precise application needs.

Step 2: Research Potential Suppliers

Start by identifying potential suppliers and manufacturers of harmonic gear reducers. Look for companies with a strong reputation in the industry, particularly those that specialize in high-precision gear systems. Utilize resources such as industry trade shows, online directories, and professional networks to gather a list of candidates.

Step 3: Evaluate Supplier Certifications

It’s essential to verify the certifications and quality standards of potential suppliers. Look for ISO certifications or other relevant quality assurance measures that indicate adherence to international standards. This step is crucial as it assures you of the reliability and performance consistency of the products you plan to procure.

Step 4: Request Detailed Product Information

Once you have shortlisted suppliers, request detailed product catalogs and technical data sheets for the harmonic gear reducers. This should include specifications, performance data, and any customization options available. Assessing this information helps you understand how well their offerings align with your requirements.

Illustrative image related to harmonic gear reducer

Step 5: Assess Lead Times and Availability

Inquire about the lead times for production and delivery of the harmonic gear reducers. Understanding the timelines is critical for planning your project and ensuring that you can meet your operational deadlines. Additionally, check the supplier’s inventory levels to ensure they can fulfill your order promptly.

Step 6: Review Pricing and Payment Terms

Discuss pricing structures and payment terms with your selected suppliers. Be sure to compare quotes from multiple vendors to understand the market rate and ensure you are getting a fair deal. Consider total cost implications, including shipping, tariffs, and potential discounts for bulk orders.

Step 7: Establish Communication Channels

Finally, establish clear communication channels with your chosen supplier. Regular communication is vital for addressing any issues that may arise during the procurement process. Make sure there is a designated contact person who can provide timely updates and support throughout the transaction.

By following this checklist, you will enhance your sourcing strategy for harmonic gear reducers, ensuring that you select the right partner and product for your business needs.

Comprehensive Cost and Pricing Analysis for harmonic gear reducer Sourcing

What are the Key Cost Components in Sourcing Harmonic Gear Reducers?

When sourcing harmonic gear reducers, understanding the cost structure is crucial for effective budgeting and supplier negotiations. The primary cost components include:

Illustrative image related to harmonic gear reducer

-

Materials: The choice of materials significantly impacts the overall cost. High-quality alloys and specialized composites can enhance performance but at a higher price point. The demand for durability and precision often leads to the selection of premium materials, contributing substantially to the final price.

-

Labor: Labor costs vary depending on the manufacturing location and the complexity of the gear reducers. Regions with higher labor costs may drive up the price, while manufacturers in lower-cost regions may offer more competitive pricing.

-

Manufacturing Overhead: This includes expenses associated with the production facility, utilities, and equipment maintenance. Efficient manufacturing processes can lower overhead costs, which can then be reflected in the pricing of the gear reducers.

-

Tooling: Custom tooling for specific designs or features can add to upfront costs. Buyers should consider the impact of these tooling costs on the overall pricing, especially for low-volume orders.

-

Quality Control (QC): Implementing robust QC measures ensures that the gear reducers meet required specifications and performance standards. However, enhanced QC protocols can increase production costs.

-

Logistics: Shipping and handling costs are critical, particularly for international buyers. Factors such as shipping distance, packaging requirements, and customs duties can significantly influence the total cost.

-

Margin: Suppliers typically add a margin to cover their operational costs and ensure profitability. Understanding the margin expectations can aid in negotiation and overall cost management.

How Do Price Influencers Affect the Sourcing of Harmonic Gear Reducers?

Several factors can influence the pricing of harmonic gear reducers, making it essential for buyers to be aware of these nuances:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to better pricing per unit due to economies of scale. Buyers should evaluate their needs and consider consolidating orders to negotiate lower prices.

-

Specifications and Customization: Custom gear reducers tailored to specific applications typically incur higher costs. Buyers should clearly define their requirements to balance performance with budget constraints.

-

Materials: As mentioned earlier, material selection can greatly affect pricing. Buyers should weigh the benefits of premium materials against the additional costs they bring.

-

Quality and Certifications: Gear reducers with industry-standard certifications or superior quality assurance processes may come at a premium. However, investing in certified products can reduce long-term operational risks.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers with proven track records might charge more, but they can also offer better support and reliability.

-

Incoterms: Understanding shipping terms (Incoterms) is essential for calculating the total landed cost. The choice between FOB (Free on Board), CIF (Cost, Insurance, and Freight), and other terms can significantly affect pricing.

What Tips Can Help Buyers Optimize Costs in Their Sourcing Strategy?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, here are some strategic tips to optimize costs:

-

Negotiate Wisely: Leverage volume commitments and long-term partnerships to negotiate better pricing. Building a strong relationship with suppliers can lead to favorable terms.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also maintenance, operational efficiency, and potential downtime costs. This holistic view can reveal the most cost-effective options.

-

Understand Pricing Nuances: Be aware that prices may vary by region due to local economic conditions, tariffs, and currency fluctuations. Buyers should conduct thorough market research to make informed decisions.

-

Consider Local Suppliers: Sourcing from local manufacturers can reduce logistics costs and lead times. This is especially relevant for buyers in emerging markets where importing may incur significant tariffs.

-

Stay Informed on Market Trends: Keeping abreast of industry developments, material availability, and technological advancements can provide leverage in negotiations and sourcing decisions.

Disclaimer

Prices for harmonic gear reducers can vary widely based on the above factors and market conditions. It is advisable to request quotes from multiple suppliers and conduct thorough comparisons to ensure the best value.

Alternatives Analysis: Comparing harmonic gear reducer With Other Solutions

Understanding Alternative Solutions to Harmonic Gear Reducers

In the landscape of motion control and precision engineering, harmonic gear reducers are a popular choice due to their unique advantages, such as high precision and compact design. However, there are several alternative solutions available that cater to various applications. Evaluating these alternatives is crucial for B2B buyers seeking to optimize their machinery or systems for specific performance requirements, cost constraints, and operational efficiencies.

Illustrative image related to harmonic gear reducer

Comparison Table

| Comparison Aspect | Harmonic Gear Reducer | Planetary Gearbox | Worm Gear Drive |

|---|---|---|---|

| Performance | High torque density, zero backlash | Good efficiency, moderate backlash | Moderate efficiency, high reduction ratios |

| Cost | Higher initial investment | Moderate cost | Generally lower cost |

| Ease of Implementation | Requires precise alignment | Easier to install, modular options available | Simple design, easy to integrate |

| Maintenance | Low maintenance, durable | Moderate maintenance needs | Regular lubrication needed |

| Best Use Case | Robotics, aerospace, medical devices | Automotive, industrial applications | Low-speed, high-torque applications |

Pros and Cons of Alternative Solutions

Planetary Gearbox

Planetary gearboxes are known for their compact design and high efficiency. They typically consist of a central sun gear, planet gears, and an outer ring gear, allowing for multiple gear ratios within a small footprint. This design results in good torque distribution and the ability to handle high loads. However, they may experience some backlash, which can affect precision in applications where this is critical. Planetary gearboxes are often more affordable and easier to install than harmonic gear reducers, making them a suitable choice for automotive and general industrial applications.

Worm Gear Drive

Worm gear drives are characterized by their unique design, which allows for high torque transmission at low speeds. They provide a high reduction ratio in a compact form, making them ideal for applications that require substantial mechanical advantage with limited space. One significant advantage is their self-locking feature, which prevents back-driving, adding a level of safety in certain applications. However, worm gears typically have lower efficiency compared to harmonic gear reducers and require regular lubrication to maintain performance, which can lead to higher maintenance costs over time. They are best suited for low-speed applications in industrial settings.

Choosing the Right Solution for Your Needs

When selecting a gear solution, B2B buyers should carefully assess their specific application requirements. Harmonic gear reducers excel in high-precision environments such as robotics and aerospace, where performance and compactness are paramount. In contrast, planetary gearboxes offer a balance of efficiency and cost, making them suitable for broader industrial applications. Worm gear drives can be a cost-effective solution for low-speed, high-torque needs but may not deliver the precision required in more demanding environments.

Ultimately, the choice between these alternatives should be guided by a comprehensive understanding of the operational demands, budget constraints, and maintenance capabilities of the organization. By evaluating these factors, buyers can ensure they select the most appropriate gear solution for their unique applications.

Essential Technical Properties and Trade Terminology for harmonic gear reducer

When considering the procurement of harmonic gear reducers, understanding their essential technical properties and trade terminology is crucial for making informed purchasing decisions. Below, we explore the key specifications and terminology that will benefit international B2B buyers.

Illustrative image related to harmonic gear reducer

What Are the Critical Technical Specifications of Harmonic Gear Reducers?

-

Material Grade

Harmonic gear reducers are typically constructed from high-strength materials such as aluminum alloy or stainless steel. The choice of material impacts durability, weight, and corrosion resistance. For applications in harsh environments, such as those found in the oil and gas or marine industries, opting for corrosion-resistant materials can prolong the lifespan of the gear reducer and minimize maintenance costs. -

Backlash

Backlash refers to the slight play or movement between the gears when they change direction. For harmonic gear reducers, achieving zero or minimal backlash is vital for high-precision applications like robotics and aerospace. This characteristic ensures accurate positioning and repeatability, which are essential for operational efficiency and quality control. -

Torque Capacity

Torque capacity defines the maximum torque that the gear reducer can handle without failure. It is a critical specification for applications requiring high power transmission, such as industrial automation. Understanding torque capacity helps buyers select a harmonic gear reducer that meets the operational demands of their machinery, ensuring reliability and performance. -

Reduction Ratio

The reduction ratio indicates how much the input speed is reduced at the output. Common ratios range from 50:1 to over 100:1. This specification is crucial for determining the speed and torque output of the gear reducer. Buyers should align the reduction ratio with their specific application needs to ensure optimal performance. -

Tolerance

Tolerance refers to the allowable variation in dimensions and performance characteristics of the gear reducer. Higher precision tolerances are essential for applications requiring exact positioning, such as CNC machinery. Specifying the right tolerance ensures compatibility with other components and minimizes the risk of mechanical failure. -

Operating Temperature Range

The operating temperature range indicates the conditions under which the gear reducer can function effectively. It is essential for applications in extreme environments, such as mining or manufacturing, where temperature fluctuations can impact performance. Buyers should consider the operating temperature to ensure the longevity and reliability of the reducer.

What Are Common Trade Terms in the Harmonic Gear Reducer Industry?

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of harmonic gear reducers, buyers often engage with OEMs to source high-quality components that meet their specific design requirements. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of an item that a supplier is willing to sell. Understanding the MOQ is crucial for buyers, as it can affect inventory management and overall project costs. It is important to negotiate MOQs that align with production needs without resulting in excess inventory. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting a price quote for specific products or services. For buyers of harmonic gear reducers, issuing an RFQ enables them to gather competitive pricing and terms, facilitating informed decision-making. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, delivery responsibilities, and risk management, which are critical for smooth cross-border procurement. -

Lead Time

Lead time is the duration between placing an order and receiving the product. Understanding lead times for harmonic gear reducers is vital for project planning and ensuring that operations remain on schedule, particularly for time-sensitive projects. -

Warranty Period

The warranty period defines the length of time during which the manufacturer guarantees the performance of the gear reducer. Knowing the warranty terms helps buyers assess the reliability and support they can expect post-purchase, providing peace of mind and financial protection against defects.

Understanding these technical properties and trade terms empowers B2B buyers to make strategic decisions when sourcing harmonic gear reducers, ensuring they select the right products for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the harmonic gear reducer Sector

What Are the Key Market Dynamics and Trends Influencing the Harmonic Gear Reducer Sector?

The harmonic gear reducer market is experiencing significant growth driven by the rising demand for precision motion control in various industries, including robotics, aerospace, and automation. Key trends include the increasing integration of harmonic drives in compact and lightweight applications, particularly in robotics and medical devices. The shift towards automation across sectors in Africa, South America, the Middle East, and Europe is propelling the demand for high-performance gear reducers that offer zero backlash and high torque density.

Additionally, advancements in manufacturing technologies, such as additive manufacturing and smart manufacturing, are enabling companies to produce more efficient and tailored harmonic gear reducers. International B2B buyers should be aware of the growing importance of digital platforms for sourcing components. E-commerce and digital marketplaces are becoming vital in connecting manufacturers with buyers, facilitating quick access to product specifications, pricing, and lead times. Furthermore, the trend towards modularity allows for easier customization, enabling businesses to adapt to changing market demands swiftly.

How Are Sustainability and Ethical Sourcing Shaping the Harmonic Gear Reducer Industry?

Sustainability has become a pivotal concern in the harmonic gear reducer sector, with increasing pressure on manufacturers to adopt environmentally friendly practices. The environmental impact of manufacturing processes, including energy consumption and waste generation, is under scrutiny. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainability through the use of eco-friendly materials and practices.

Ethical sourcing is equally important, with businesses seeking transparent supply chains that ensure fair labor practices and responsible sourcing of raw materials. Certifications such as ISO 14001 for environmental management and materials with recognized ‘green’ certifications can enhance a supplier’s credibility. Buyers from regions like Africa and South America are particularly attuned to ethical considerations, as these markets increasingly demand accountability in sourcing practices. By partnering with manufacturers who prioritize sustainability, companies can not only reduce their environmental footprint but also enhance their brand reputation and customer loyalty.

What Is the Historical Context of the Harmonic Gear Reducer Market?

The harmonic gear reducer, originally developed in the 1950s, has evolved significantly over the decades. Initially utilized in niche applications, advancements in materials and manufacturing processes have broadened their application across various industries. The introduction of digital technologies and enhanced design capabilities has further propelled their adoption, especially in automation and robotics. Today, harmonic gear reducers are celebrated for their efficiency, compact design, and precision, making them an essential component in high-tech machinery and systems. This evolution highlights the importance of continuous innovation in meeting the demands of modern manufacturing and automation.

In summary, understanding the dynamic market landscape, prioritizing sustainability, and recognizing the historical context of harmonic gear reducers will empower international B2B buyers to make informed sourcing decisions that align with their operational goals and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of harmonic gear reducer

-

How do I select the right harmonic gear reducer for my application?

Selecting the appropriate harmonic gear reducer involves understanding your application’s torque, speed, and precision requirements. First, assess the load characteristics, including dynamic and static loads, to determine the necessary torque. Next, consider the gear ratio that best matches your desired output speed and input motor specifications. Finally, evaluate the form factor and space constraints of your design to ensure compatibility. Collaborating with suppliers who offer customization options can also help tailor a solution that fits your unique needs. -

What are the advantages of using harmonic gear reducers over traditional gear systems?

Harmonic gear reducers offer several advantages, including zero backlash, high torque density, and compact design. Their unique strain wave gearing mechanism allows for precise motion control, making them ideal for applications requiring high accuracy, such as robotics and aerospace. Additionally, they typically feature lightweight constructions and can handle high reduction ratios, which can save space and reduce weight in your overall design. These benefits make them a preferred choice for high-performance applications. -

What is the typical lead time for ordering harmonic gear reducers?

Lead times for harmonic gear reducers can vary significantly based on factors such as customization, order size, and supplier location. Generally, standard products may be available within 2-4 weeks, while customized solutions could take 6-12 weeks or longer. It’s essential to communicate your timeline and requirements with your supplier upfront to ensure they can meet your delivery expectations. Planning for potential delays in shipping and customs, especially for international orders, is also advisable. -

What are the minimum order quantities (MOQ) for harmonic gear reducers?

Minimum order quantities for harmonic gear reducers vary by manufacturer and product line. Some suppliers may have an MOQ of one unit for standard products, while others may require larger quantities for customized solutions. When sourcing from international suppliers, consider negotiating MOQs based on your project’s scale and budget. It’s beneficial to establish a good relationship with your supplier, as this can lead to flexibility in future orders. -

How can I ensure quality when sourcing harmonic gear reducers internationally?

To ensure quality when sourcing harmonic gear reducers internationally, conduct thorough supplier vetting. Look for manufacturers with ISO certifications and positive industry reputations. Request samples to evaluate performance and durability before placing a large order. Additionally, consider visiting the supplier’s facility, if feasible, to assess their manufacturing processes. Establishing clear quality assurance protocols and specifications in your contract can also help mitigate risks associated with international sourcing. -

What payment terms should I expect when sourcing harmonic gear reducers?

Payment terms for harmonic gear reducers can vary widely depending on the supplier and your negotiation leverage. Common terms include a deposit upon order placement (typically 30-50%) with the balance due before shipment. Some suppliers may offer letter of credit or payment upon delivery for established customers. It’s essential to clarify payment methods, currency, and any potential fees associated with international transactions early in negotiations to avoid misunderstandings. -

What logistics considerations should I keep in mind when importing harmonic gear reducers?

When importing harmonic gear reducers, consider logistics factors such as shipping methods, customs regulations, and potential tariffs. Choose a reliable freight forwarder familiar with international shipping to manage logistics efficiently. Ensure that all necessary documentation, including invoices, packing lists, and customs declarations, is accurately prepared to avoid delays at customs. Additionally, factor in shipping times and costs when planning your project timeline and budget. -

Can harmonic gear reducers be customized for specific applications?

Yes, many manufacturers offer customization options for harmonic gear reducers to meet specific application requirements. Customization can include alterations in gear ratios, sizes, and mounting configurations. Some suppliers may also provide tailored solutions for unique operational conditions, such as extreme temperatures or environmental exposure. Engaging with your supplier early in the design process can help you explore available customization options and ensure the final product aligns with your application needs.

Top 5 Harmonic Gear Reducer Manufacturers & Suppliers List

1. Harmonic Drive – High Precision Motion Control Solutions

Domain: harmonicdrive.net

Registered: 2002 (23 years)

Introduction: Harmonic Drive offers a variety of high precision motion control products including: 1. Rotary Actuators – Designed for high precision applications with performance matched gearing, motors, and encoders. 2. Integrated Actuators – Mini actuators with integrated servo drives utilizing CANopen® communication. 3. Gear Units – Zero backlash strain wave gears with precision output bearings, available in…

2. PG Fun – Harmonic Drive Reducer with Nema 17 Stepper Motor

Domain: pgfuntransmission.com

Registered: 2023 (2 years)

Introduction: [{‘name’: ‘Harmonic Drive Reducer with Nema 17 (42mm) Stepper Motor, 1.2 A 1.8 NM Ratio 30:1 Rotary Gear Reducer’, ‘price’: ‘$145.00’, ‘specifications’: {‘motor_type’: ‘Nema 17’, ‘current’: ‘1.2 A’, ‘torque’: ‘1.8 NM’, ‘reduction_ratio’: ’30:1′}}, {‘name’: ‘Harmonic Drive Reducer with Nema 17 (42mm) Stepper Motor, 1.4 A 2.1 NM Ratio 30:1 Rotary Gear Reducer’, ‘price’: ‘$149.00’, ‘specifications’: …

3. Sumitomo – Strain Wave Gearbox

Domain: us.sumitomodrive.com

Registered: 2003 (22 years)

Introduction: Strain Wave Gearbox/Harmonic Gearboxes are specialized gear systems that utilize elasticity and harmonic distortion for high precision power transmission. Key features include:

– High reduction ratios (up to 1:320 in a single stage)

– Compact design with excellent torque density

– Near-zero backlash for precise control

– Torsional stiffness approximately twice that of competitors

– Torque nominal:…

4. Harmonic Drive Systems – Precision Reducers & Actuators

Domain: hds.co.jp

Introduction: Harmonic Drive Systems offers a range of products including: 1. Reducers for precision control 2. High-performance Gear Heads for Servo Motors 3. Rotary Actuators 4. Linear Actuators 5. Motors 6. Optical Galvano Scanners 7. Sensor Systems 8. Servo Drivers. Recent product releases include the AC Servo Driver HA-900A Series, which enhances the performance of HarmonicDrive® Actuators, and the CSF-min…

5. Cone Drive – Harmonic Gearing Solutions

Domain: conedrive.com

Registered: 1997 (28 years)

Introduction: Harmonic Gearing Solutions by Cone Drive provide ultra-compact, high-precision motion control with zero backlash and exceptional torque density. They are customizable and made in the USA for robotics, automation, and space-constrained applications. The product series includes: 1. Cup Series (CBC, CBCF-, CBC-L, CBG, CBGF-) – Designed for compact, high-torque applications with integrated cross-rolle…

Strategic Sourcing Conclusion and Outlook for harmonic gear reducer

In the competitive landscape of precision engineering, strategic sourcing of harmonic gear reducers emerges as a vital component for enhancing operational efficiency and product reliability. By focusing on suppliers that prioritize innovation, quality, and technical support, international B2B buyers can significantly improve their product offerings. The advantages of zero backlash, compact design, and high torque density offered by harmonic gear reducers translate into improved performance across various applications, from robotics to aerospace.

Investing in long-term partnerships with reputable manufacturers not only ensures access to cutting-edge technology but also fosters collaboration for customized solutions tailored to specific needs. As global markets evolve, particularly in regions such as Africa, South America, the Middle East, and Europe, the demand for high-performance motion control solutions will continue to rise.

International buyers are encouraged to explore strategic sourcing opportunities that align with their operational goals. By prioritizing quality and reliability in their supply chain, companies can position themselves for sustainable growth in an increasingly dynamic marketplace. As we look to the future, embracing innovation and forging strong supplier relationships will be key to unlocking new potential in the harmonic gear reducer sector.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.