Ames Reese Inc Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for ames reese inc

In an era where global supply chains are increasingly complex, sourcing high-quality powdered metal parts from AMES Reese Inc. presents both a challenge and an opportunity for international B2B buyers. Companies seeking to enhance their mechanical and hydraulic applications must navigate various considerations, from understanding the intricacies of powdered metallurgy to evaluating supplier capabilities. This guide provides a comprehensive overview of AMES Reese Inc., detailing the types of sintered components available, their diverse applications across industries, and the essential criteria for supplier vetting.

Moreover, we delve into cost considerations and logistical aspects, ensuring that buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Nigeria and Brazil—can make informed purchasing decisions. By equipping you with actionable insights and industry best practices, this guide empowers you to effectively assess your options and forge successful partnerships. Whether you are looking to enhance production efficiency or innovate your product offerings, understanding the global landscape of powdered metal parts is crucial. With AMES Reese Inc. as a focal point, you are well-positioned to leverage advanced manufacturing solutions tailored to your specific needs.

Understanding ames reese inc Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Sintered Steel Components | High dimensional precision, complex geometries | Automotive, industrial machinery | Pros: Cost-effective for mass production; high strength. Cons: Limited to specific geometries. |

| Soft-Magnetic Sintered Parts | Designed to guide or amplify magnetic fields | Electric motors, transformers | Pros: Efficient magnetic performance; lightweight. Cons: May require additional processing for certain applications. |

| Self-Lubricating Sintered Bearings | Porous structure impregnated with oil for lubrication | Automotive, machinery applications | Pros: Reduced maintenance; longer lifespan. Cons: Initial cost may be higher than standard bearings. |

| Additive Manufacturing Components | Extremely complex geometries produced via Binder Jetting | Aerospace, custom machinery | Pros: Design flexibility; rapid prototyping. Cons: Slower production rates compared to traditional methods. |

| Contract Manufacturing Services | Outsourced production services tailored to client specifications | Various industries | Pros: Reduces overhead costs; access to specialized expertise. Cons: Potential communication challenges; quality control risks. |

What Are Sintered Steel Components and Their Suitability for B2B Buyers?

Sintered steel components are characterized by their high dimensional precision and ability to form complex geometries. This makes them particularly suitable for applications in the automotive and industrial machinery sectors, where reliability and strength are paramount. When purchasing these components, B2B buyers should consider factors such as production volume, material properties, and the specific geometries required for their applications.

How Do Soft-Magnetic Sintered Parts Enhance B2B Applications?

Soft-magnetic sintered parts are specifically designed to efficiently guide or amplify magnetic fields, making them ideal for use in electric motors and transformers. Their lightweight nature and efficient magnetic performance make them a preferred choice in industries focused on energy efficiency. Buyers should evaluate their specific magnetic requirements and compatibility with existing systems when considering these components.

What Are the Benefits of Self-Lubricating Sintered Bearings for Businesses?

Self-lubricating sintered bearings feature a porous structure that is impregnated with oil, enabling them to operate without the need for external lubrication. This characteristic significantly reduces maintenance requirements and extends the lifespan of machinery. B2B buyers should weigh the initial investment against long-term savings in maintenance and downtime when considering these bearings for their operations.

Why Consider Additive Manufacturing Components in B2B Transactions?

Additive manufacturing components, produced through Binder Jetting, offer extreme design flexibility and the capability to create complex geometries. This technology is particularly beneficial for industries like aerospace and custom machinery, where unique designs are often required. Buyers should assess their production timelines and the potential need for rapid prototyping when exploring this option.

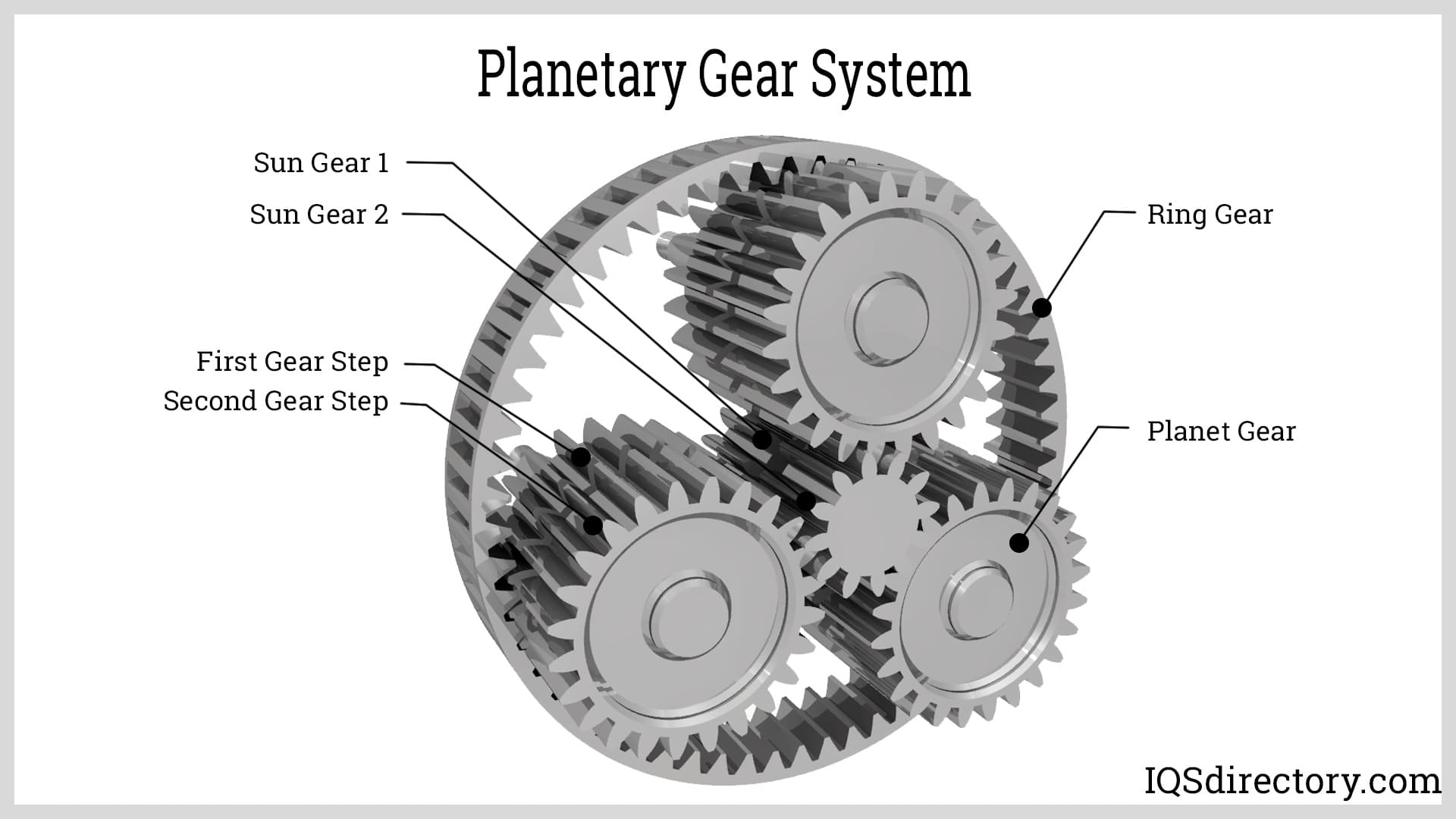

Illustrative image related to ames reese inc

How Can Contract Manufacturing Services Benefit B2B Buyers?

Contract manufacturing services allow companies to outsource production, tailoring services to specific client needs. This model can significantly reduce overhead costs and provide access to specialized expertise and technology. However, B2B buyers must consider potential communication challenges and quality control measures when engaging with contract manufacturers to ensure product consistency and reliability.

Key Industrial Applications of ames reese inc

| Industry/Sector | Specific Application of ames reese inc | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Production of structural powdered metal components | Enhanced strength and weight reduction in vehicle parts | Ensure compliance with international automotive standards and regulations. |

| Renewable Energy | Sintered soft-magnetic components for generators | Improved efficiency and reliability of energy systems | Assess the supplier’s ability to meet specific magnetic properties and tolerances. |

| Industrial Equipment | Self-lubricating sintered bearings | Reduced maintenance costs and increased operational efficiency | Evaluate the bearing’s load capacity and compatibility with machinery. |

| Aerospace | Precision sintered parts for aircraft components | Weight savings and performance enhancement | Verify adherence to aerospace industry certifications and quality standards. |

| Consumer Electronics | Additive manufacturing for complex electronic parts | Customization and rapid prototyping capabilities | Consider the supplier’s technological capabilities and production lead times. |

How Does AMES Reese Inc. Support the Automotive Industry?

In the automotive sector, AMES Reese Inc. specializes in manufacturing structural powdered metal components that enhance vehicle performance. These components are designed to be lightweight yet strong, contributing to overall fuel efficiency and safety. For international buyers, especially from regions like Africa and South America, understanding compliance with local automotive standards and regulations is crucial. Buyers should also ensure that the supplier can provide detailed specifications and certifications for the parts used in their vehicles.

What Role Does AMES Reese Inc. Play in Renewable Energy Systems?

AMES Reese Inc. produces sintered soft-magnetic components used in renewable energy generators, such as wind turbines. These components are vital for enhancing the efficiency and reliability of energy systems, which are increasingly important in global markets focused on sustainable energy solutions. Buyers in the Middle East and Europe should prioritize suppliers who can meet specific magnetic properties and tolerances essential for optimal generator performance, ensuring long-term reliability and efficiency.

How Are Self-Lubricating Bearings Beneficial in Industrial Equipment?

In the industrial sector, AMES Reese Inc. offers self-lubricating sintered bearings that significantly reduce maintenance costs and downtime for machinery. These bearings are designed to operate without the need for external lubrication, making them ideal for harsh operating conditions. B2B buyers from various regions must assess the load capacity and compatibility of these bearings with existing equipment to ensure seamless integration and optimal performance.

Illustrative image related to ames reese inc

Why Are Precision Sintered Parts Essential in Aerospace Applications?

For the aerospace industry, AMES Reese Inc. manufactures precision sintered parts that are critical for aircraft components. These parts provide significant weight savings while maintaining strength and durability, crucial for meeting stringent aerospace performance standards. Buyers in this sector should verify that potential suppliers adhere to aerospace industry certifications and quality standards, ensuring the reliability and safety of their aircraft.

How Can AMES Reese Inc. Support Customization in Consumer Electronics?

In the consumer electronics industry, AMES Reese Inc. utilizes additive manufacturing techniques to create complex electronic parts. This capability allows for customization and rapid prototyping, enabling businesses to innovate quickly and respond to market demands. International buyers must consider the technological capabilities of suppliers and inquire about production lead times to ensure timely delivery of customized components that meet their specific needs.

3 Common User Pain Points for ‘ames reese inc’ & Their Solutions

Scenario 1: Navigating Complex Specifications in Powdered Metal Parts

The Problem: B2B buyers often face challenges when trying to specify the exact requirements for powdered metal parts, particularly when dealing with complex geometries and dimensional tolerances. This can lead to misunderstandings, resulting in parts that do not meet the necessary performance standards for mechanical or hydraulic applications. Buyers may struggle to articulate their needs clearly, and manufacturers might not fully grasp the specific requirements without detailed communication. This gap can slow down the production process, increase costs, and ultimately delay project timelines.

The Solution: To effectively communicate specifications to AMES Reese, buyers should start by gathering all relevant technical data and project requirements before reaching out. Utilizing tools such as CAD models or detailed drawings can significantly enhance clarity. It’s also beneficial to engage in early-stage consultations with AMES Reese’s engineering team, leveraging their expertise in powder metallurgy. By discussing design intent and material properties with AMES, buyers can ensure that their specifications are well understood and matched to the right manufacturing processes. This proactive approach minimizes misunderstandings and streamlines production.

Scenario 2: Managing Supply Chain and Logistics Challenges

The Problem: International B2B buyers often encounter difficulties with supply chain logistics, especially when sourcing components from manufacturers like AMES Reese located in different regions. Delays in shipping, customs clearance issues, and fluctuating transportation costs can disrupt schedules and lead to increased expenses. For companies operating in fast-paced industries, these uncertainties can pose significant risks to project timelines and financial planning.

The Solution: To mitigate supply chain issues, buyers should take advantage of AMES Reese’s established logistics capabilities. It is advisable to communicate early about delivery timelines and shipping requirements, allowing for better planning and coordination. Buyers can also consider utilizing AMES Reese’s logistic centers strategically located around the world, such as in Barcelona and Hungary, to reduce transportation times and costs. Engaging with local representatives from AMES in the buyer’s region can provide insights into regional logistics and customs regulations, helping to streamline the procurement process.

Scenario 3: Ensuring Quality and Compliance in Manufacturing

The Problem: Quality assurance and compliance with industry standards can be a significant concern for B2B buyers sourcing powdered metal parts. With varying regulations across different regions, buyers may worry about whether the parts manufactured by AMES Reese comply with necessary certifications and quality standards. This is particularly critical in sectors such as automotive, where the failure of a component can have serious safety implications.

The Solution: Buyers should proactively request detailed documentation regarding AMES Reese’s quality assurance processes and compliance certifications. Establishing a robust dialogue around quality expectations at the outset can help ensure that the products meet specific industry standards. AMES Reese’s commitment to precision manufacturing and their engineering support can be leveraged to conduct thorough quality checks during production. Additionally, buyers should consider conducting audits or site visits, if feasible, to gain confidence in the manufacturing processes and quality controls in place. By fostering a transparent relationship with AMES Reese, buyers can better ensure that they receive high-quality, compliant parts tailored to their needs.

Illustrative image related to ames reese inc

Strategic Material Selection Guide for ames reese inc

What Are the Key Properties of Iron-Based Powdered Metals for AMES Reese Inc.?

Iron-based powdered metals are the cornerstone of AMES Reese Inc.’s product offerings. These materials exhibit excellent mechanical properties, including high tensile strength and good wear resistance, making them suitable for automotive and industrial applications. They can withstand elevated temperatures and pressures, which is critical for components subjected to harsh operating conditions. Additionally, iron-based materials can be alloyed with other elements to enhance specific properties, such as corrosion resistance and magnetic characteristics, thereby broadening their applicability.

How Do Sintered Steel Components Benefit B2B Buyers?

Sintered steel components are widely used in various mechanical applications due to their high dimensional accuracy and ability to be produced in complex geometries. The sintering process allows for the creation of parts that are not only durable but also lightweight. However, the manufacturing complexity can lead to higher initial costs. For international buyers, particularly in regions like Africa and South America, understanding the local market dynamics and compliance with standards such as ASTM or DIN is crucial for successful procurement.

What Are the Advantages and Limitations of Soft-Magnetic Sintered Parts?

Soft-magnetic sintered parts are essential for applications requiring effective magnetic field management, such as in electric motors and transformers. Their key advantage lies in their ability to guide and amplify magnetic fields efficiently, which is vital for energy applications. However, these components may have limitations in terms of temperature resistance, which can restrict their use in high-heat environments. Buyers from the Middle East and Europe should consider the specific media compatibility and operational conditions when selecting these materials.

How Do Self-Lubricating Sintered Bearings Enhance Performance?

Self-lubricating sintered bearings are designed to operate without the need for external lubrication, which reduces maintenance costs and downtime. These bearings are particularly beneficial in applications where traditional lubrication methods are impractical. However, their manufacturing process can be more complex and costly compared to standard bearings. For international buyers, especially in regions with varying industrial standards, it’s essential to verify that these components meet local compliance requirements and performance expectations.

Summary Table of Material Analysis

| Material | Typical Use Case for AMES Reese Inc. | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Iron-Based Powdered Metals | Automotive and industrial components | High tensile strength and wear resistance | Limited corrosion resistance | Medium |

| Sintered Steel Components | Mechanical parts with complex geometries | High dimensional accuracy | Higher manufacturing complexity | High |

| Soft-Magnetic Sintered Parts | Electric motors and transformers | Efficient magnetic field management | Limited temperature resistance | Medium |

| Self-Lubricating Sintered Bearings | Applications requiring low maintenance | Reduced maintenance costs | Higher initial manufacturing costs | High |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of various materials offered by AMES Reese Inc. Understanding these factors is crucial for making informed purchasing decisions that align with operational needs and compliance requirements in diverse international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for ames reese inc

What Are the Main Stages in AMES Reese Inc.’s Manufacturing Process?

AMES Reese Inc. employs a comprehensive manufacturing process tailored to produce high-quality powdered metal parts primarily for the automotive industry. The process is characterized by several key stages, each critical to ensuring precision and performance.

Material Preparation

The manufacturing journey begins with meticulous material preparation. AMES Reese utilizes iron-based powders, which are carefully selected based on the desired properties of the final product. The powders undergo sieving and blending to achieve uniformity in size and composition. This step is crucial as it influences the density and performance of the final sintered parts.

Illustrative image related to ames reese inc

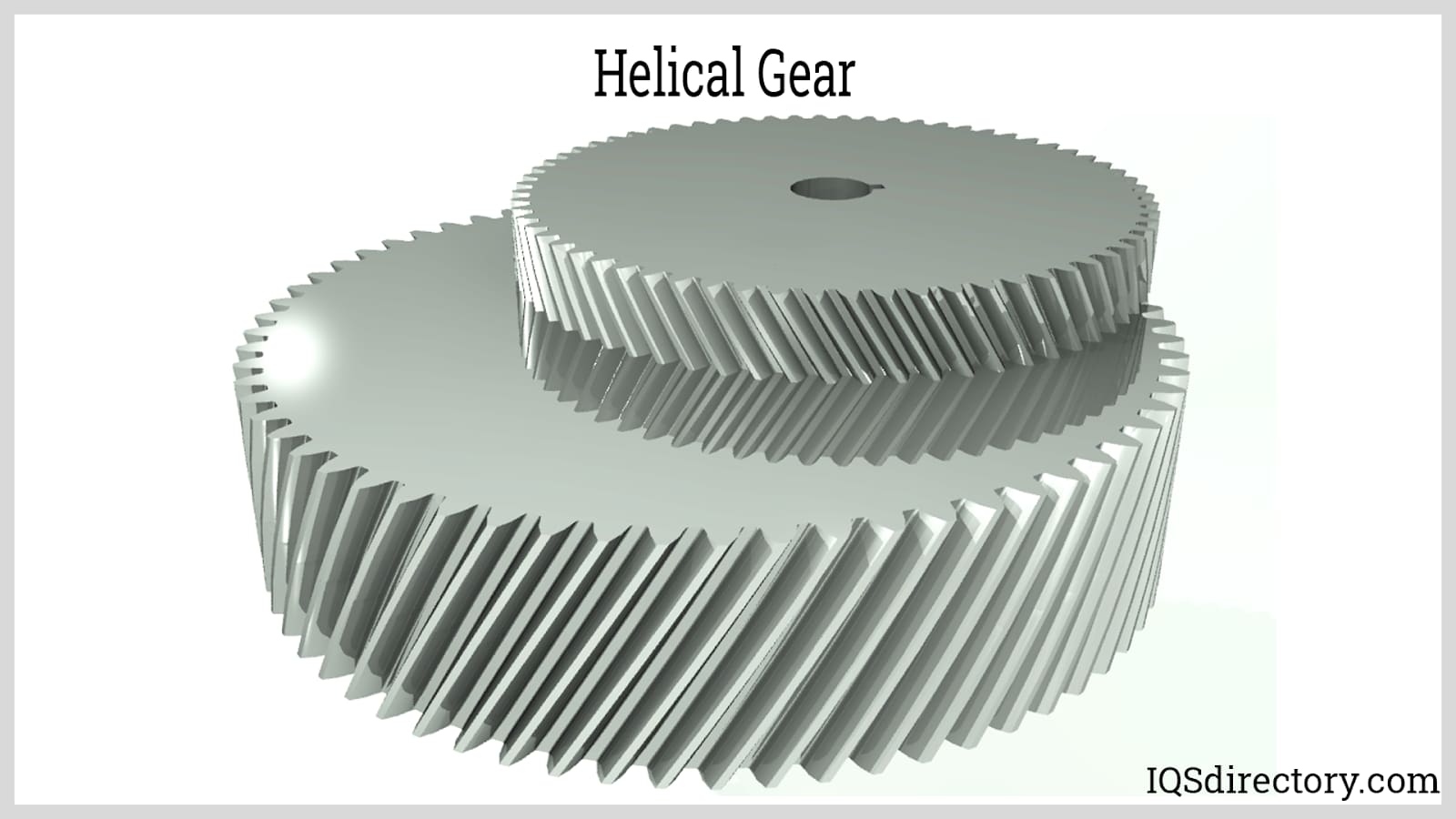

Forming Techniques

Once the materials are prepared, the next stage involves forming, where the powders are pressed into molds. AMES Reese employs advanced techniques such as cold forming and powder compaction. In cold forming, metal wire is shaped at room temperature, enhancing its mechanical properties without the need for heating. For powdered metal parts, the company uses high-pressure pressing to create dense pre-forms that are ready for sintering.

Sintering Process

The heart of AMES Reese’s manufacturing process is sintering, a method where the pre-formed parts are heated in a controlled atmosphere furnace. This process allows the particles to bond without melting, resulting in components with high dimensional accuracy and strength. The sintering conditions, including temperature and time, are meticulously controlled to meet specific material requirements.

Finishing Operations

After sintering, the parts undergo various finishing operations. These may include machining, surface treatment, and coating processes to enhance performance characteristics such as corrosion resistance and wear properties. The finishing stage is essential for achieving the precise specifications required by clients, particularly in high-performance applications.

How Does AMES Reese Inc. Ensure Quality Assurance Throughout Its Manufacturing Process?

Quality assurance (QA) is integral to AMES Reese’s operations, ensuring that every product meets international standards and customer expectations. The company adheres to stringent quality control measures throughout the manufacturing process.

What International Standards Does AMES Reese Inc. Follow?

AMES Reese Inc. is committed to maintaining high-quality standards and is ISO 9001 certified. This certification underscores the company’s dedication to quality management systems, ensuring that processes are continuously monitored and improved. Additionally, AMES Reese complies with industry-specific standards such as CE and API, which are critical for its automotive clients.

What Are the Key Quality Control Checkpoints at AMES Reese Inc.?

Quality control at AMES Reese is structured around several key checkpoints:

-

Incoming Quality Control (IQC): This initial checkpoint involves rigorous testing of raw materials to ensure they meet specified criteria before entering the production process.

-

In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor parameters such as dimensional accuracy and surface finish. This proactive approach helps identify and rectify issues early in the production cycle.

-

Final Quality Control (FQC): After the completion of manufacturing, each batch undergoes a final inspection to verify that all specifications and standards have been met. This includes functional testing, dimensional checks, and surface analysis.

What Testing Methods Are Employed for Quality Assurance?

To ensure the integrity and performance of its products, AMES Reese utilizes various testing methods throughout the manufacturing process. Common techniques include:

-

Dimensional Inspection: Utilizes tools like calipers and coordinate measuring machines (CMM) to verify that parts meet specified dimensions.

-

Mechanical Testing: Includes tensile strength and hardness testing to assess the material properties of the sintered parts.

-

Non-Destructive Testing (NDT): Techniques such as ultrasonic testing and X-ray inspections are employed to detect internal flaws without damaging the components.

How Can B2B Buyers Verify AMES Reese Inc.’s Quality Control Measures?

For B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality assurance practices is crucial. Here are actionable steps to confirm AMES Reese’s commitment to quality:

-

Supplier Audits: Buyers can request on-site audits to evaluate AMES Reese’s manufacturing and quality control processes firsthand. This transparency fosters trust and ensures adherence to standards.

-

Quality Reports and Certifications: AMES Reese provides documentation of its quality certifications and inspection reports. Buyers should review these to understand the company’s compliance with international standards.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturing processes and quality control measures in place at AMES Reese.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must navigate specific quality control nuances when sourcing from AMES Reese. Understanding regional requirements and standards is essential for seamless transactions.

-

Documentation Requirements: Different countries may have varying import regulations and documentation requirements. Buyers should ensure that AMES Reese can provide all necessary certifications and test reports to facilitate customs clearance.

-

Cultural and Regulatory Considerations: Familiarity with regional standards, such as those in the European Union or South American markets, can impact the acceptance of products. Buyers should communicate their specific needs and expectations clearly to AMES Reese.

-

Sustainability Practices: As global emphasis on sustainability increases, buyers may want to inquire about AMES Reese’s environmental practices in manufacturing. Understanding their commitment to green technology can enhance the attractiveness of the partnership.

In summary, AMES Reese Inc. combines advanced manufacturing processes with rigorous quality assurance practices to deliver high-quality powdered metal parts. For international B2B buyers, understanding these processes and verifying quality control measures is essential for establishing successful and reliable partnerships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘ames reese inc’

This practical sourcing guide is designed to assist international B2B buyers in navigating the procurement process for powdered metal parts from AMES Reese Inc. By following this checklist, buyers can ensure they make informed decisions and establish fruitful partnerships.

Step 1: Define Your Technical Specifications

Before initiating contact with AMES Reese, clearly outline your technical requirements. This includes specifying the types of components needed—such as mechanical or hydraulic parts—and any particular material characteristics, such as soft-magnetic properties. Having well-defined specifications will facilitate better communication and ensure that AMES Reese can meet your production needs effectively.

Step 2: Research AMES Reese’s Product Offerings

Familiarize yourself with the range of products offered by AMES Reese, including sintered components and self-lubricating bearings. Understanding their capabilities can help you assess whether they align with your project requirements. Additionally, review their product catalog or website to identify any innovative solutions that may benefit your operations.

Step 3: Evaluate Supplier Certifications

Ensure that AMES Reese holds relevant industry certifications that validate their manufacturing processes and quality standards. Certifications such as ISO 9001 demonstrate a commitment to quality management and continuous improvement. This verification is crucial for mitigating risks associated with supplier reliability and product quality.

Step 4: Request Samples for Evaluation

Request product samples to evaluate quality and performance before placing a larger order. Testing samples allows you to assess the precision, durability, and functionality of the parts in your specific application. Pay attention to the tolerances and finish to ensure they meet your operational standards.

Step 5: Understand Lead Times and Logistics

Inquire about production lead times and shipping logistics to better plan your project timelines. AMES Reese operates as a logistics center for the North American market, which can streamline the procurement process. Understanding these aspects will help you coordinate with your supply chain and avoid potential delays.

Step 6: Establish Communication Channels

Set up effective communication channels with your AMES Reese contact. Clear lines of communication will facilitate discussions about design iterations, production updates, and any issues that may arise. Regular updates are essential for maintaining alignment on project goals and timelines.

Step 7: Negotiate Terms and Conditions

Before finalizing any agreements, carefully negotiate terms and conditions, including pricing, payment terms, and warranties. A well-defined contract protects both parties and sets clear expectations. Ensure that all critical elements, such as delivery timelines and quality assurance processes, are included to prevent misunderstandings later.

By following this checklist, B2B buyers can effectively source from AMES Reese Inc., ensuring that they secure high-quality powdered metal parts that meet their specific needs.

Comprehensive Cost and Pricing Analysis for ames reese inc Sourcing

Understanding the cost structure and pricing strategy of AMES Reese, Inc. is essential for international B2B buyers aiming to make informed purchasing decisions. This section will break down the cost components, price influencers, and provide actionable tips for negotiations.

What Are the Key Cost Components in AMES Reese, Inc.’s Pricing Structure?

-

Materials: The primary cost driver for AMES Reese is the raw materials used in the production of powdered metal parts. Iron-based powders and alloys are typically sourced from global suppliers, and fluctuations in metal prices can significantly impact overall costs. Buyers should be aware that sourcing materials sustainably may incur additional costs but can enhance product quality and environmental compliance.

-

Labor: Labor costs at AMES Reese are influenced by the skilled workforce required for precision manufacturing. The company invests in training to ensure high-quality output, which may result in higher labor costs compared to less specialized manufacturers. Understanding the labor market in the U.S. can provide insights into potential wage fluctuations that could affect pricing.

-

Manufacturing Overhead: Overhead costs encompass utilities, maintenance, and facility expenses. AMES Reese, with its advanced manufacturing techniques, likely incurs substantial overhead to maintain quality and production efficiency. These costs are typically spread across all products, impacting pricing based on production volume.

-

Tooling: The investment in specialized tooling and machinery is significant in the powdered metallurgy industry. The initial costs can be high, but these are amortized over the production runs. Buyers should consider the tooling costs in relation to their specific needs, as custom tooling can lead to increased upfront costs.

-

Quality Control (QC): High standards of quality control are critical in ensuring product reliability, especially in sectors like automotive. QC processes add to the overall cost but are essential for maintaining certifications and meeting customer specifications.

-

Logistics: Transportation and logistics play a crucial role, particularly for international buyers. Costs can vary based on shipping methods, distances, and Incoterms. Efficient logistics management can reduce lead times and costs, making it a key factor in pricing.

-

Margin: AMES Reese, like any business, includes a profit margin in its pricing. Understanding the competitive landscape and the value proposition of AMES Reese’s products can help buyers assess whether the margin is justified.

How Do Price Influencers Affect AMES Reese’s Pricing Strategy?

Several factors can influence the pricing strategy for AMES Reese:

-

Volume/MOQ: Orders of larger volumes often result in lower per-unit costs. Buyers should inquire about minimum order quantities (MOQ) and potential discounts for bulk purchases.

-

Specifications/Customization: Customized products or specific material requirements can lead to increased costs. Buyers should clearly communicate their specifications to receive accurate quotes.

-

Quality/Certifications: Products that meet higher quality standards or specific certifications may carry a premium price. Buyers should weigh the benefits of certified products against their budget constraints.

-

Supplier Factors: The reliability and reputation of AMES Reese as a supplier can impact pricing. Established suppliers may charge more for their reliability and quality assurance.

-

Incoterms: The chosen Incoterms can significantly affect the total landed cost. Understanding the implications of terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is crucial for international transactions.

What Tips Can Enhance Cost-Efficiency for International Buyers?

-

Negotiate Effectively: Engage in discussions around pricing, especially for large orders. Understanding the cost components can empower buyers during negotiations.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the upfront cost but the overall value, including shipping, potential tariffs, and product lifespan. This approach can help identify the most cost-effective option.

-

Leverage Relationships: Building a long-term relationship with AMES Reese can lead to better pricing and terms over time. Loyalty can sometimes yield discounts or preferential treatment.

-

Stay Informed on Market Trends: Keeping abreast of global metal prices and supply chain dynamics can help buyers anticipate price changes and make timely purchasing decisions.

-

Assess the Impact of Currency Fluctuations: For buyers in Africa, South America, the Middle East, and Europe, currency exchange rates can affect purchasing power. Timing purchases to favorable exchange rates may yield cost savings.

In conclusion, understanding the complex cost structure and pricing strategy of AMES Reese, Inc. is crucial for B2B buyers. By considering these components and influencers, international buyers can make informed decisions that align with their business objectives.

Alternatives Analysis: Comparing ames reese inc With Other Solutions

When exploring options for powdered metal parts manufacturing, it is crucial to consider various alternatives to AMES Reese, Inc. This analysis will provide insights into how AMES Reese stacks up against other notable solutions in the industry. Understanding the strengths and weaknesses of each option can guide B2B buyers in making informed decisions based on their specific operational needs and market conditions.

| Comparison Aspect | Ames Reese Inc | Alternative 1: Liberty Pressed Metals, LLC | Alternative 2: Embassy Powdered Metals |

|---|---|---|---|

| Performance | High precision in sintered parts | Strong in high-volume production | Focused on custom part manufacturing |

| Cost | Competitive pricing for quality | Generally lower cost for bulk orders | Moderate pricing; premium for custom work |

| Ease of Implementation | Streamlined logistics support | Quick turnaround times in production | Customization may require longer lead times |

| Maintenance | Low maintenance; durable products | Moderate maintenance; depends on part use | Higher maintenance for complex designs |

| Best Use Case | Automotive and mechanical applications | Mass production of standard components | Custom engineering solutions for niche markets |

What are the Advantages and Disadvantages of Liberty Pressed Metals, LLC?

Liberty Pressed Metals, LLC specializes in high-volume production, making it a strong contender for businesses looking to scale operations rapidly. Their competitive pricing for bulk orders can lead to significant cost savings for large-scale manufacturers. However, their focus on mass production may limit customization options, making them less suitable for businesses needing tailored solutions.

How Does Embassy Powdered Metals Stand Out?

Embassy Powdered Metals excels in providing custom part manufacturing services. Their ability to create specialized components caters to niche markets, which is advantageous for companies with specific requirements. However, this customization can come at a premium price and potentially longer lead times, which may not align with companies needing quick, off-the-shelf solutions.

In What Situations Should B2B Buyers Choose AMES Reese, Inc.?

AMES Reese, Inc. is particularly well-suited for industries such as automotive and mechanical applications, where high precision and durability are paramount. Their competitive pricing, along with a strong focus on logistics and engineering support, provides a solid foundation for businesses aiming to integrate advanced powdered metal solutions into their products. The low maintenance of their components also makes them an attractive option for companies looking to minimize operational disruptions.

How Can B2B Buyers Choose the Right Solution?

Selecting the right powdered metal parts manufacturer involves assessing specific business needs, including production volume, budget constraints, and customization requirements. Buyers should evaluate each option’s performance metrics and how they align with their operational goals. By weighing the pros and cons of each alternative against AMES Reese, Inc., companies can make a well-informed decision that maximizes efficiency and cost-effectiveness in their manufacturing processes.

Essential Technical Properties and Trade Terminology for ames reese inc

What Are the Key Technical Properties of AMES Reese Inc. Products?

Understanding the technical specifications of AMES Reese Inc. products is crucial for B2B buyers looking to make informed decisions. Here are some critical specifications that define the quality and applicability of their powdered metal parts:

-

Material Grade

AMES Reese primarily utilizes iron-based powdered metals, which are known for their strength and durability. The choice of material grade affects the performance and longevity of components in various applications, particularly in automotive and mechanical sectors. Buyers must consider material grades to ensure compatibility with their specific operational requirements. -

Dimensional Tolerance

Precision in manufacturing is paramount. AMES Reese parts are produced with high dimensional tolerances, which means they maintain their specified measurements even under stress or wear. This is essential for ensuring that parts fit seamlessly into assemblies, reducing the risk of malfunction or failure in machinery. -

Sintering Density

The density of sintered parts affects their mechanical properties, such as strength and hardness. Higher sintering density generally leads to better performance characteristics, making this a critical specification for buyers looking for reliable and durable components. -

Geometric Complexity

AMES Reese specializes in producing parts with complex geometries. This capability allows for innovative designs that traditional manufacturing methods might not accommodate. Understanding the geometric capabilities can help buyers leverage advanced designs that improve efficiency or reduce weight in their products. -

Magnetic Properties

For applications requiring soft-magnetic components, AMES Reese provides sintered parts that can efficiently guide or amplify magnetic fields. Buyers in industries such as electronics or automotive should evaluate these properties to ensure optimal performance in magnetic applications. -

Self-lubrication Features

AMES Reese offers self-lubricating sintered bearings, which are particularly valuable in reducing maintenance needs and operational costs. These components are impregnated with oil, allowing for smoother operation without the need for additional lubricants. This can be a significant selling point for buyers looking to enhance the longevity of their machinery.

What Are Common Trade Terms Used in B2B Transactions with AMES Reese Inc.?

Familiarity with industry terminology is essential for effective communication and negotiation. Here are some key terms that B2B buyers should know when engaging with AMES Reese Inc.:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that are sold under another company’s brand. For buyers, understanding OEM relationships can help in sourcing quality components that meet specific standards and regulatory requirements. -

MOQ (Minimum Order Quantity)

MOQ defines the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for buyers to manage inventory costs effectively and ensure that they are making economically viable purchases. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific quantities of goods. For B2B buyers, crafting a clear RFQ can facilitate better responses from suppliers and lead to more competitive pricing. -

Incoterms (International Commercial Terms)

These are standardized terms used in international trade to define the responsibilities of buyers and sellers regarding the delivery of goods. Familiarity with Incoterms helps buyers understand their obligations and rights in shipping and logistics, which can mitigate risks in international transactions. -

Lead Time

This term refers to the amount of time from placing an order to receiving the goods. Buyers should inquire about lead times to effectively plan their production schedules and inventory management. -

Quality Assurance (QA)

QA refers to the systematic processes put in place to ensure that products meet specified standards before they are delivered. Understanding QA processes can help buyers assess the reliability and quality of the components they are purchasing.

By grasping these technical properties and industry terms, B2B buyers can engage more effectively with AMES Reese Inc. and make well-informed purchasing decisions that align with their operational needs.

Navigating Market Dynamics and Sourcing Trends in the ames reese inc Sector

What Are the Current Market Dynamics and Key Trends Affecting AMES Reese Inc.?

The global market for powdered metal parts is witnessing significant transformation, driven by advancements in technology and increasing demand for lightweight, high-performance components. Key trends include the adoption of automated manufacturing processes, such as additive manufacturing and binder jetting, which enable the production of complex geometries while reducing waste. International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly seeking suppliers who can offer not just cost-effectiveness but also technological innovation. The automotive industry remains a dominant sector for AMES Reese, yet there’s a growing interest in applications spanning renewable energy, consumer electronics, and medical devices.

Emerging market dynamics also indicate a shift towards localization in sourcing strategies. As geopolitical tensions and supply chain disruptions become more prevalent, businesses are reevaluating their sourcing strategies to mitigate risks. This presents an opportunity for AMES Reese to leverage its multiple manufacturing and logistic centers across the globe, particularly in North America and Europe, to better serve international buyers who prioritize agility and responsiveness in their supply chains.

Furthermore, sustainability is becoming a pivotal factor in procurement decisions. Buyers are increasingly favoring suppliers that demonstrate a commitment to sustainable practices, thereby influencing market dynamics towards greener alternatives.

How Is Sustainability Influencing Sourcing Decisions in the B2B Sector?

Sustainability is no longer an option but a necessity for B2B suppliers, especially in the powdered metal industry. AMES Reese is well-positioned to meet this demand, as it employs powder metallurgy processes that are inherently more environmentally friendly than traditional manufacturing methods. This process reduces material waste and energy consumption, making it an attractive choice for companies focused on minimizing their environmental footprint.

Moreover, the importance of ethical sourcing is gaining traction among international buyers. Companies are now more than ever scrutinizing their supply chains for ethical practices, ensuring that materials are sourced responsibly and that labor conditions meet international standards. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety are becoming crucial for suppliers aiming to establish credibility in the global market.

In addition, the integration of sustainable materials, such as recycled metals, into production processes is increasingly appealing to buyers looking to enhance their sustainability credentials. AMES Reese’s commitment to innovation in this area not only addresses buyer concerns but also aligns with the broader industry trend toward circular economy practices.

What Is the Historical Context of AMES Reese Inc. That Influences Its Current B2B Strategies?

Founded in 1951, AMES Reese has evolved significantly from its early days as a manufacturer of powdered metal components. Over the decades, the company has adapted to technological advancements and changing market demands, establishing itself as a leader in the powdered metal sector. Its extensive experience in providing high-precision components has enabled it to build strong relationships with key players in the automotive industry and beyond.

The company’s strategic expansion into global markets, with manufacturing and logistics centers across Europe, North America, and Asia, has been instrumental in its ability to serve a diverse clientele effectively. This historical context informs AMES Reese’s current B2B strategies, emphasizing innovation, sustainability, and responsiveness to market dynamics. As the company continues to leverage its rich history and expertise, it remains focused on meeting the evolving needs of international buyers, ensuring it stays at the forefront of the industry.

Frequently Asked Questions (FAQs) for B2B Buyers of ames reese inc

-

How can I ensure the quality of powdered metal parts from AMES Reese Inc.?

To ensure the quality of powdered metal parts, request detailed information about AMES Reese’s quality assurance protocols. The company employs rigorous quality control measures, including dimensional checks and material testing, to meet industry standards. Additionally, you can inquire about certifications such as ISO, which indicate adherence to international quality norms. Establishing a clear communication line with their engineering team can also help address any specific quality requirements you might have. -

What customization options are available for powdered metal parts at AMES Reese Inc.?

AMES Reese Inc. offers a variety of customization options tailored to your specific needs. This includes adjustments in size, shape, and material composition of the powdered metal parts. Their engineering team is available to collaborate with you to develop custom solutions that meet your project specifications. Discussing your requirements early in the process will facilitate a smoother customization experience, ensuring the final product aligns with your expectations. -

What are the minimum order quantities (MOQ) for AMES Reese Inc.’s products?

The minimum order quantities at AMES Reese Inc. can vary based on the type of powdered metal part you are interested in. Typically, the MOQ is designed to optimize production efficiency while accommodating client needs. For precise figures, it’s best to contact their sales team directly, as they can provide tailored information based on your specific project requirements and production capabilities. -

What payment terms does AMES Reese Inc. offer for international buyers?

AMES Reese Inc. provides flexible payment terms for international buyers, which may include options such as wire transfers, letters of credit, or payment on delivery, depending on the agreement reached. It’s essential to discuss and clarify payment terms before finalizing your order to ensure transparency and mutual understanding. This will help in establishing a smooth transaction process and financial planning for your procurement. -

How does AMES Reese Inc. handle logistics for international shipments?

Logistics at AMES Reese Inc. is managed with a focus on efficiency and reliability. They utilize established shipping partners to ensure timely delivery of products to international locations. You can discuss specific shipping methods, estimated delivery times, and tracking options with their logistics team. Additionally, ensure that customs and import duties are considered in your planning to avoid unexpected delays. -

What should I consider when vetting suppliers like AMES Reese Inc.?

When vetting suppliers, consider factors such as their industry reputation, years of experience, and the quality of their product offerings. Request references from existing clients, especially those in your region, to gauge their reliability and service levels. Additionally, assessing their certifications and adherence to international standards can provide insights into their operational integrity and quality assurance practices. -

What are the benefits of using powdered metal parts in my applications?

Powdered metal parts offer numerous advantages, including high precision, reduced waste during production, and the ability to create complex geometries that may be challenging with traditional manufacturing methods. These parts are also generally lighter, which can contribute to energy efficiency in applications like automotive or aerospace. Understanding these benefits can help you make an informed decision about integrating powdered metal components into your products. -

How can I initiate a quote request with AMES Reese Inc.?

To initiate a quote request, you can contact AMES Reese Inc. directly through their website or by phone. Provide detailed specifications of the powdered metal parts you require, including dimensions, material types, and quantities. The more information you can provide, the more accurate the quote will be. Their sales team is equipped to respond promptly and will guide you through the next steps to fulfill your order.

Top 4 Ames Reese Inc Manufacturers & Suppliers List

1. AMES – Sintered Steel Components

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, AMES – Sintered Steel Components, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. AMES Reese, Inc. – Powdered Metal Manufacturer

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: AMES Reese, Inc. is a powdered metal manufacturer specializing in short process parts and series. They produce structural sintered parts primarily for the automotive industry, as well as for hardware stores and other applications. The company also offers commercial and technical engineering support through their AMES Sintered Company.

3. Ames Reese, Inc. – Industrial Manufacturing Solutions

Domain: lancasterchamber.growthzoneapp.com

Registered: 2017 (8 years)

Introduction: This company, Ames Reese, Inc. – Industrial Manufacturing Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. AMES REESE – Company Insights

Domain: indeed.com

Registered: 1998 (27 years)

Introduction: This company, AMES REESE – Company Insights, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for ames reese inc

In the ever-evolving landscape of global manufacturing, AMES Reese Inc. stands out as a leader in powdered metal parts, particularly for the automotive industry. By leveraging advanced powder metallurgy techniques, the company produces high-precision sintered components that cater to diverse mechanical and hydraulic applications. This strategic focus on quality and innovation positions AMES Reese as a reliable partner for international buyers seeking to enhance their production capabilities.

B2B buyers from regions such as Africa, South America, the Middle East, and Europe can benefit immensely from AMES Reese’s comprehensive engineering support and logistical efficiency. The company’s extensive network, including strategic locations in the U.S. and Europe, ensures timely delivery and responsiveness to market demands. This capability not only reduces lead times but also aligns with the growing preference for sustainable manufacturing practices.

As we look to the future, the potential for collaboration between AMES Reese Inc. and international partners remains robust. Businesses are encouraged to explore how AMES Reese’s innovative solutions can drive their operational efficiency and product quality. By embracing strategic sourcing with AMES Reese, companies can navigate the complexities of global supply chains and position themselves for success in a competitive marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.