Soft Nylon Brush For Cleaning Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for soft nylon brush for cleaning

In today’s competitive market, sourcing high-quality soft nylon brushes for cleaning presents a significant challenge for international B2B buyers. These brushes, known for their versatility and gentle cleaning capabilities, are essential for maintaining cleanliness in various sectors, from automotive to hospitality. However, selecting the right supplier and understanding the diverse applications and types available can be daunting, especially for businesses operating across different regions such as Africa, South America, the Middle East, and Europe, including countries like Germany and Nigeria.

This comprehensive guide aims to equip B2B buyers with the knowledge necessary to make informed purchasing decisions regarding soft nylon brushes. We will delve into the various types of brushes available, their specific applications, and the essential factors to consider when vetting suppliers. Additionally, we will provide insights into pricing structures, ensuring that buyers understand the market landscape and can negotiate effectively.

By addressing the complexities of sourcing soft nylon brushes, this guide empowers businesses to streamline their procurement processes. Armed with expert insights and actionable strategies, international buyers will be better positioned to select the right products that meet their unique cleaning requirements, ultimately enhancing operational efficiency and ensuring customer satisfaction.

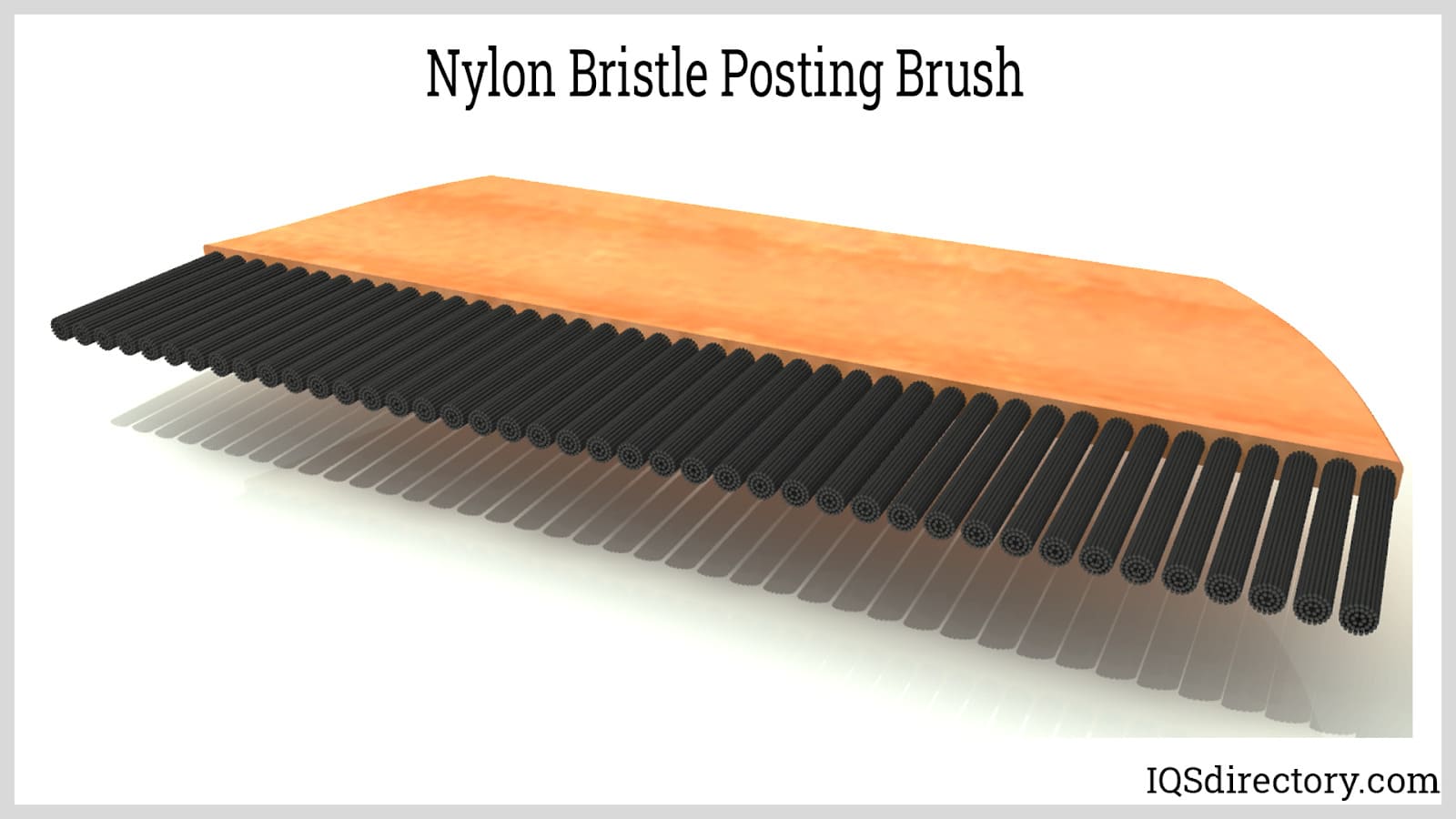

Understanding soft nylon brush for cleaning Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Utility Soft Nylon Brush | Versatile design, medium bristle stiffness, ergonomic handle | General cleaning, maintenance tasks | Pros: Cost-effective, adaptable; Cons: May not reach tight spaces. |

| Tile and Grout Brush | Angled bristles, narrow head for precision | Tile and grout cleaning in commercial spaces | Pros: Excellent for tough stains; Cons: Limited to specific applications. |

| Long Handle Scrub Brush | Extended reach, soft bristles for gentle scrubbing | High ceilings, large surfaces | Pros: Reduces strain, effective on large areas; Cons: Bulky, may be unwieldy. |

| Bore Cleaning Brush | Soft bristles designed for delicate cleaning | Firearm maintenance, precision cleaning | Pros: Gentle on surfaces, effective for fine cleaning; Cons: Limited to specific industries. |

| Specialty Brush Set | Variety of shapes and sizes, often includes multiple brushes | Diverse cleaning tasks across industries | Pros: Comprehensive solution; Cons: Higher initial investment. |

What are the Characteristics of Utility Soft Nylon Brushes?

Utility soft nylon brushes are designed for versatility, making them suitable for various cleaning tasks across multiple industries. Their medium bristle stiffness allows for effective cleaning without damaging surfaces. These brushes are often ergonomically designed, providing comfort during prolonged use. B2B buyers should consider their adaptability for different applications, from general maintenance to specific cleaning tasks. Price points are generally favorable, making them an economical choice for businesses needing reliable cleaning tools.

How Do Tile and Grout Brushes Stand Out?

Tile and grout brushes feature angled bristles and narrow heads, specifically designed for precision cleaning in tight spaces. This makes them ideal for commercial cleaning applications, especially where stubborn stains and grime accumulate. Their design enables users to tackle challenging areas effectively, such as corners and crevices. When purchasing, B2B buyers should evaluate the brush’s durability and effectiveness in their specific cleaning environments, ensuring it meets the demands of high-traffic areas.

Why Consider Long Handle Scrub Brushes?

Long handle scrub brushes are equipped with extended reach capabilities, allowing users to clean high ceilings and large surfaces without the need for ladders or stools. The soft bristles provide a gentle scrubbing action, making them suitable for various surfaces. B2B buyers should assess the balance between reach and maneuverability, as the bulkiness can be a drawback in tighter spaces. These brushes are especially advantageous for maintenance teams in facilities management, where efficiency and safety are paramount.

What Makes Bore Cleaning Brushes Unique?

Bore cleaning brushes are specifically designed for firearm maintenance, featuring soft bristles that provide a delicate cleaning option for sensitive surfaces. These brushes are essential for precision cleaning, allowing users to scrub without risking damage to the bore. B2B buyers in the firearms industry should prioritize brushes that offer the right balance of softness and cleaning power. Additionally, considering compatibility with various bore sizes is crucial for effective cleaning solutions.

How Can Specialty Brush Sets Enhance Cleaning Efficiency?

Specialty brush sets include a variety of brushes tailored for different cleaning tasks, often featuring multiple shapes and sizes. This diversity allows businesses to handle various cleaning challenges with a single purchase. While the initial investment may be higher, the long-term benefits in efficiency and effectiveness can outweigh the cost. B2B buyers should evaluate the specific needs of their operations to determine if a specialty set aligns with their cleaning strategies, ensuring they have the right tools for every task.

Key Industrial Applications of soft nylon brush for cleaning

| Industry/Sector | Specific Application of soft nylon brush for cleaning | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food & Beverage | Cleaning production equipment and surfaces | Ensures hygiene compliance and reduces contamination risks | Material safety certifications, bristle stiffness options |

| Automotive Manufacturing | Cleaning precision components and machinery | Maintains quality control and operational efficiency | Durability of bristles, compatibility with cleaning agents |

| Electronics Assembly | Cleaning circuit boards and sensitive components | Prevents damage and improves product reliability | Softness of bristles, resistance to static electricity |

| Hospitality Services | Cleaning hotel rooms and common areas | Enhances customer satisfaction through cleanliness | Ergonomics of handle design, ease of use |

| Healthcare Facilities | Cleaning medical equipment and surfaces | Ensures patient safety and compliance with health standards | Compliance with healthcare regulations, bristle softness |

How is a Soft Nylon Brush Used in the Food & Beverage Industry?

In the food and beverage industry, soft nylon brushes are essential for cleaning production equipment, countertops, and storage areas. They effectively remove residues without scratching sensitive surfaces, ensuring compliance with hygiene standards. Buyers in this sector must prioritize brushes with food-safe materials and certifications, as well as bristle stiffness tailored to various cleaning tasks. Sourcing from reliable manufacturers who understand local regulations, especially in regions like Africa and South America, is crucial to maintaining safety standards.

What Role Does a Soft Nylon Brush Play in Automotive Manufacturing?

Automotive manufacturers utilize soft nylon brushes to clean precision components and machinery parts, ensuring that any contaminants are removed without causing damage. This process is vital for maintaining quality control and optimizing operational efficiency. Buyers should consider the durability of the bristles, compatibility with various cleaning agents, and the brush’s ability to withstand harsh environments. Selecting suppliers with a proven track record in the automotive sector, particularly in Europe, can enhance procurement efficiency.

How are Soft Nylon Brushes Used in Electronics Assembly?

In electronics assembly, soft nylon brushes are used to clean delicate circuit boards and components, where traditional cleaning methods might cause damage. These brushes help prevent dust accumulation and ensure the reliability of electronic devices. Buyers should focus on sourcing brushes that offer the right bristle softness to avoid static electricity issues and damage to sensitive parts. International buyers, especially from the Middle East, must ensure compliance with specific industry standards to avoid costly rework.

Why are Soft Nylon Brushes Important in Hospitality Services?

In the hospitality sector, soft nylon brushes are employed for cleaning hotel rooms, bathrooms, and common areas. Their gentle yet effective cleaning capabilities enhance customer satisfaction by ensuring a high standard of cleanliness. When sourcing these brushes, businesses should consider ergonomic designs for ease of use and longevity, as well as the ability to withstand frequent washing. Suppliers that offer customizable options can provide significant advantages in meeting varying cleaning needs across different regions, such as Nigeria.

How Does the Healthcare Sector Benefit from Soft Nylon Brushes?

Healthcare facilities rely on soft nylon brushes for cleaning medical equipment, ensuring that all surfaces are free from contaminants and compliant with health regulations. The brushes must be made from materials that meet stringent safety standards, and their bristles should be soft enough to avoid damaging sensitive equipment. Buyers should prioritize sourcing from manufacturers who understand healthcare compliance, particularly in regions with strict regulations, to ensure patient safety and operational efficiency.

3 Common User Pain Points for ‘soft nylon brush for cleaning’ & Their Solutions

Scenario 1: Struggling with Durability of Cleaning Brushes

The Problem: B2B buyers often face the challenge of sourcing cleaning tools that can withstand rigorous use in various environments, such as industrial or commercial settings. Soft nylon brushes, while effective for delicate surfaces, may wear down quickly when used on tougher materials or for prolonged periods. This leads to frequent replacements, increased costs, and downtime during cleaning operations, all of which can negatively impact operational efficiency.

The Solution: To address durability concerns, buyers should focus on sourcing high-quality soft nylon brushes specifically designed for industrial applications. Look for brushes that feature reinforced bristles and ergonomic handles to enhance longevity and ease of use. Furthermore, consider brushes with varying bristle stiffness to accommodate different cleaning tasks. For instance, while a soft nylon brush is ideal for cleaning sensitive surfaces, a medium-stiff variant can be used for more abrasive tasks. Establishing a relationship with reliable manufacturers or distributors that offer warranties or satisfaction guarantees can also provide peace of mind and reduce the risk of frequent replacements.

Scenario 2: Inefficiency in Cleaning Processes

The Problem: In many B2B cleaning operations, the choice of tools directly affects efficiency. Buyers may find that soft nylon brushes do not effectively remove dirt or grime, especially in hard-to-reach areas or on textured surfaces. This inefficiency can lead to longer cleaning times and unsatisfactory results, ultimately affecting customer satisfaction and operational budgets.

The Solution: To enhance cleaning effectiveness, buyers should consider integrating soft nylon brushes with specialized designs tailored for specific tasks. For example, brushes with angled bristles can more effectively reach corners and crevices, allowing for a more thorough cleaning experience. Additionally, investing in multi-pack options that include brushes of varying sizes and shapes can provide versatility for different applications. Training staff on proper cleaning techniques and brush usage can further optimize results, ensuring that brushes are employed in a manner that maximizes their effectiveness and lifespan.

Scenario 3: Difficulty in Maintaining Cleanliness Standards

The Problem: Many B2B buyers are under pressure to meet strict cleanliness and hygiene standards, particularly in industries such as food service, healthcare, or manufacturing. The challenge arises when soft nylon brushes are not adequately maintained or cleaned after use, leading to cross-contamination or reduced cleaning effectiveness over time. This can result in compliance issues and potential financial penalties.

The Solution: To maintain high cleanliness standards, it is essential to implement a rigorous cleaning and maintenance routine for all soft nylon brushes. Buyers should source brushes that are easy to clean and can withstand regular sanitization processes. For instance, opting for brushes that are dishwasher-safe or designed with antimicrobial properties can enhance hygiene and prevent bacterial growth. Establishing a regular inspection and replacement schedule can also ensure that brushes remain effective and compliant with industry standards. Additionally, providing staff with training on proper brush care and cleaning techniques can further bolster hygiene efforts and ensure adherence to cleanliness protocols.

Illustrative image related to soft nylon brush for cleaning

Strategic Material Selection Guide for soft nylon brush for cleaning

What Are the Key Properties of Soft Nylon Brushes for Cleaning?

When selecting materials for soft nylon brushes used in cleaning applications, several options are commonly considered. Each material has unique properties that impact performance, durability, and suitability for various cleaning tasks. Below are analyses of four prevalent materials used in soft nylon brushes for cleaning.

1. Nylon

Key Properties: Nylon is a synthetic polymer known for its strength, flexibility, and resistance to abrasion. It can withstand temperatures up to 120°C (248°F) without losing its structural integrity. Nylon brushes are also resistant to many chemicals, making them suitable for a variety of cleaning agents.

Pros & Cons: The durability of nylon contributes to its long lifespan, reducing the need for frequent replacements. However, nylon can be more expensive than natural fibers, which may affect cost-sensitive buyers. Manufacturing nylon brushes can be complex due to the need for specific molding techniques.

Impact on Application: Nylon brushes are compatible with a wide range of cleaning media, including solvents and detergents. Their flexibility allows them to reach into crevices and corners effectively.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is essential. Buyers in regions like Europe often prefer products that meet stringent quality and safety regulations. Additionally, the availability of nylon brushes in local markets can vary, impacting procurement decisions.

2. Polypropylene

Key Properties: Polypropylene is another synthetic material that offers excellent chemical resistance and durability. It has a lower temperature threshold than nylon, typically around 100°C (212°F).

Pros & Cons: Polypropylene brushes are generally less expensive than nylon, making them an attractive option for bulk purchases. However, they may not be as durable or flexible as nylon, which can limit their effectiveness in certain cleaning tasks.

Impact on Application: These brushes work well with water-based cleaning solutions but may not perform as effectively with harsher chemicals. Their stiffness can be advantageous for scrubbing tough surfaces but may not be suitable for delicate tasks.

Considerations for International Buyers: Polypropylene brushes are widely accepted in various markets, including Africa and South America, where cost-effectiveness is often prioritized. Buyers should verify the material’s compliance with local regulations to ensure safety and performance.

Illustrative image related to soft nylon brush for cleaning

3. Polyester

Key Properties: Polyester fibers are known for their strength and resistance to shrinking and stretching. They can endure temperatures up to 130°C (266°F) and are resistant to many chemicals and UV light.

Pros & Cons: Polyester brushes offer a good balance between cost and performance. They are durable and maintain their shape well, but they may not be as effective as nylon in terms of flexibility and softness.

Impact on Application: Polyester brushes are suitable for various cleaning applications, especially in environments where UV exposure is a concern. However, their effectiveness may diminish when used with certain abrasive cleaners.

Considerations for International Buyers: In regions like the Middle East, where UV exposure is significant, polyester brushes can be an ideal choice. Buyers should consider local preferences for durability and performance, ensuring compliance with relevant standards.

4. Natural Fibers (e.g., Tampico)

Key Properties: Natural fibers like Tampico are derived from the agave plant and offer a soft touch while being biodegradable. They are less resistant to chemicals compared to synthetic options but are effective for gentle cleaning tasks.

Pros & Cons: The eco-friendliness of natural fibers appeals to environmentally conscious buyers. However, their durability is generally lower than synthetic brushes, leading to more frequent replacements.

Impact on Application: Natural fiber brushes are ideal for delicate surfaces and applications where a softer touch is needed. They may not perform well with harsh chemicals, limiting their versatility.

Illustrative image related to soft nylon brush for cleaning

Considerations for International Buyers: In markets with a growing emphasis on sustainability, such as Germany, natural fiber brushes may be preferred. Buyers should assess the availability and compliance of these products with local environmental regulations.

Summary Table of Material Selection

| Material | Typical Use Case for soft nylon brush for cleaning | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nylon | General-purpose cleaning, automotive, and industrial applications | High durability and flexibility | Higher cost compared to natural fibers | High |

| Polypropylene | Scrubbing surfaces, especially with water-based cleaners | Cost-effective | Less durable and flexible than nylon | Medium |

| Polyester | Cleaning in UV-exposed environments | Good balance of cost and performance | Less effective in flexibility than nylon | Medium |

| Natural Fibers | Gentle cleaning of delicate surfaces | Eco-friendly and biodegradable | Lower durability and chemical resistance | Low |

This guide provides a comprehensive overview for international B2B buyers, enabling them to make informed decisions based on material properties, application suitability, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for soft nylon brush for cleaning

What Are the Key Stages in the Manufacturing Process of Soft Nylon Brushes for Cleaning?

The manufacturing of soft nylon brushes for cleaning involves several key stages, each crucial for ensuring the final product meets quality and performance standards. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation: What Raw Materials Are Used?

The process begins with the selection of high-quality nylon fibers, which are known for their durability and softness. Depending on the intended use, manufacturers may choose different grades of nylon. Once selected, these fibers undergo various treatments, such as washing and dyeing, to enhance their performance characteristics, including resistance to chemicals and wear.

How Are Soft Nylon Brushes Formed?

The forming stage involves several techniques, including extrusion and tufting. In extrusion, nylon filaments are shaped into bristle strands, which are then cut to the desired length. Tufting is the process where these strands are inserted into a brush base, which can be made from plastic, wood, or other materials. This stage is critical as it determines the density and arrangement of the bristles, affecting the brush’s cleaning efficiency.

What Does the Assembly Process Entail?

During assembly, the tufted bristles are securely fixed into the brush handle or base. This may involve adhesive bonding or mechanical fastening, depending on the design of the brush. The assembly process must ensure that the bristles are firmly attached to prevent shedding during use, which is vital for maintaining product integrity and customer satisfaction.

What Finishing Techniques Are Commonly Used?

The final stage is finishing, where the brushes undergo quality checks, surface treatments, and packaging. Finishing may include additional cleaning to remove any residue from manufacturing, applying protective coatings, and ensuring that the brushes meet specific aesthetic standards. Packaging is tailored for both retail and bulk distribution, considering international shipping requirements.

What Quality Control Standards Should B2B Buyers Be Aware Of?

Quality assurance is paramount in the production of soft nylon brushes, especially for international B2B buyers. Adhering to international standards, such as ISO 9001, ensures that manufacturers maintain consistent quality management systems. This certification indicates that the supplier has implemented processes to monitor and improve quality continuously.

Illustrative image related to soft nylon brush for cleaning

Which Industry-Specific Certifications Are Relevant?

In addition to general quality standards, there are industry-specific certifications like CE marking for products sold in Europe, which signifies compliance with health, safety, and environmental protection standards. For specific applications, such as cleaning brushes used in food processing or healthcare, certifications from organizations like the American National Standards Institute (ANSI) or the American Petroleum Institute (API) may also be necessary.

How Are Quality Control Checkpoints Implemented?

Quality control (QC) checkpoints are integrated at various stages of the manufacturing process, including:

- Incoming Quality Control (IQC): This involves inspecting raw materials and components upon arrival to ensure they meet predefined specifications.

- In-Process Quality Control (IPQC): During manufacturing, QC personnel conduct regular inspections to monitor processes and product characteristics, ensuring that any deviations are corrected promptly.

- Final Quality Control (FQC): The final inspection occurs before packaging, where finished products are tested for functionality, durability, and compliance with quality standards.

What Common Testing Methods Are Used for Soft Nylon Brushes?

Common testing methods for soft nylon brushes include tensile strength tests, bristle retention tests, and chemical resistance evaluations. These tests help ensure that the brushes can withstand the stresses of cleaning applications without degrading or losing bristles. Additionally, manufacturers may conduct customer satisfaction surveys or performance trials to gather feedback for continuous improvement.

Illustrative image related to soft nylon brush for cleaning

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers can take several steps to verify the quality control processes of potential suppliers:

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control measures, and overall operational capabilities of the supplier.

- Quality Reports: Requesting detailed quality assurance reports can provide insights into the supplier’s performance, including defect rates and compliance with international standards.

- Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of the supplier’s quality control practices and product quality.

What Are the QC/CERT Nuances for International B2B Buyers?

When dealing with international suppliers, particularly from regions like Africa, South America, the Middle East, and Europe, buyers must be aware of the nuances in quality certification and compliance. Different regions may have varying regulations and standards, which can impact shipping, import duties, and product acceptance.

For example, products shipped to the European Union must comply with CE marking, while those destined for North America may need to meet ANSI or ASTM standards. Understanding these requirements is crucial for avoiding delays and ensuring compliance upon arrival.

Conclusion: Ensuring Quality in Soft Nylon Brush Manufacturing

In conclusion, the manufacturing processes and quality assurance practices for soft nylon brushes are complex yet critical for delivering high-quality products to B2B buyers. By understanding the manufacturing stages, quality control standards, and verification processes, international buyers can make informed decisions when selecting suppliers. This not only enhances product reliability but also fosters long-term business relationships built on trust and quality assurance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘soft nylon brush for cleaning’

Introduction

Sourcing a soft nylon brush for cleaning requires a systematic approach to ensure quality, functionality, and cost-effectiveness. This guide provides B2B buyers with a practical checklist to facilitate informed decisions when procuring these cleaning tools, tailored for diverse market needs across Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Clearly outline the specifications required for the soft nylon brush, including bristle stiffness, size, and intended application. This step is vital to ensure the product meets the specific cleaning needs of your industry, whether for delicate surfaces or heavy-duty tasks.

– Bristle stiffness: Soft bristles are ideal for sensitive surfaces, while firmer options may be necessary for tougher cleaning jobs.

– Size and shape: Consider the dimensions and design that will provide the best access to hard-to-reach areas.

Illustrative image related to soft nylon brush for cleaning

Step 2: Identify Key Suppliers

Research and compile a list of potential suppliers who specialize in cleaning tools, particularly soft nylon brushes. Evaluating multiple suppliers increases the chances of finding quality products at competitive prices.

– Industry reputation: Look for suppliers with a proven track record in the cleaning tools market.

– Geographic considerations: Choose suppliers that can efficiently service your region, considering shipping times and costs.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. This ensures that the supplier is reliable and capable of meeting your needs.

– Quality assurance: Inquire about quality control measures and certifications that the supplier adheres to.

– Customer feedback: Seek testimonials or reviews from existing customers to gauge satisfaction levels.

Step 4: Request Samples

Once you have shortlisted suppliers, request samples of their soft nylon brushes. Testing samples allows you to assess the quality, performance, and suitability for your specific cleaning tasks before making a bulk purchase.

– Functionality testing: Evaluate how the brush performs on the surfaces you intend to clean.

– Durability check: Consider the longevity of the bristles and handle under typical usage conditions.

Step 5: Compare Pricing and Terms

Analyze the pricing structures and payment terms offered by different suppliers. Understanding the total cost of ownership—including shipping and potential tariffs—will help you make a financially sound decision.

– Bulk discounts: Inquire about pricing tiers for larger orders, which could significantly reduce costs.

– Payment flexibility: Look for suppliers who offer favorable payment terms that align with your cash flow.

Step 6: Negotiate Contract Terms

Once you’ve selected a preferred supplier, negotiate the contract terms to ensure clarity on pricing, delivery schedules, and warranties. Establishing clear terms protects your interests and fosters a positive supplier relationship.

– Delivery timelines: Confirm lead times for orders to ensure they align with your operational needs.

– Warranties: Understand the warranty conditions for the brushes to safeguard against defects.

Step 7: Establish a Feedback Loop

After purchasing, implement a feedback mechanism to evaluate the performance of the soft nylon brushes in your cleaning operations. Continuous improvement is essential for maintaining quality standards and supplier relationships.

– Performance reviews: Regularly assess how well the brushes meet your cleaning requirements.

– Supplier communication: Maintain open lines of communication with your supplier to address any issues promptly.

By following this checklist, B2B buyers can confidently source high-quality soft nylon brushes that meet their cleaning needs while ensuring cost-effectiveness and supplier reliability.

Comprehensive Cost and Pricing Analysis for soft nylon brush for cleaning Sourcing

Analyzing the cost structure and pricing of soft nylon brushes for cleaning involves a comprehensive look at various components that contribute to the final price. Understanding these components can help international B2B buyers make informed purchasing decisions.

What are the Key Cost Components for Soft Nylon Brushes?

-

Materials: The primary cost driver in manufacturing soft nylon brushes is the bristle material, typically nylon or polypropylene. The choice of material impacts not only the cost but also the brush’s durability and cleaning effectiveness. High-quality nylon can increase costs due to its superior performance and longevity.

-

Labor: Labor costs vary significantly based on geographical location. In regions with lower labor costs, such as parts of Africa and South America, production costs can be reduced. However, in developed markets like Germany, labor costs are higher, which can reflect in the product pricing.

-

Manufacturing Overhead: This includes expenses related to factory maintenance, utilities, and administrative costs. Efficient manufacturing processes can help minimize overhead, impacting overall pricing.

-

Tooling: The initial setup for brush manufacturing requires significant investment in tooling and machinery. Suppliers often spread these costs over large production runs, meaning that the per-unit cost decreases with higher order volumes.

-

Quality Control (QC): Ensuring that each brush meets specific standards incurs additional costs. Rigorous QC processes are essential for maintaining product integrity, especially for international buyers who may require certifications or compliance with local regulations.

-

Logistics: Shipping costs can vary greatly depending on the destination and the chosen Incoterms. International shipping can add significant overhead, especially with customs duties and taxes. Buyers should consider these factors when evaluating total costs.

-

Margin: Suppliers typically include a profit margin that can vary based on market conditions, competition, and perceived value. Understanding the margin expectations can aid in negotiations.

What Influences Pricing for Soft Nylon Brushes?

-

Volume and Minimum Order Quantity (MOQ): Purchasing in larger quantities often leads to lower prices per unit. Suppliers may offer tiered pricing, incentivizing bulk orders.

-

Specifications and Customization: Custom designs or specific material requirements can increase costs. Buyers should evaluate whether customization is necessary or if standard options suffice to optimize costs.

-

Quality and Certifications: Brushes that meet international standards or possess specific certifications (e.g., ISO, FDA) may command higher prices due to the assurance of quality and compliance.

-

Supplier Factors: The supplier’s reputation, reliability, and production capabilities also affect pricing. Established suppliers with proven track records may charge a premium.

-

Incoterms: The terms agreed upon in the purchase contract (e.g., FOB, CIF) significantly impact the total landed cost. Buyers should clearly understand their responsibilities regarding shipping and duties.

What Are Effective Buyer Tips for Sourcing Soft Nylon Brushes?

-

Negotiation: Engage in discussions about pricing and terms. Suppliers may be open to negotiation, especially for larger orders. Establishing a good rapport can lead to better pricing and terms.

-

Cost-Efficiency: Focus on the total cost of ownership rather than just the purchase price. Consider factors like durability, performance, and maintenance costs to assess long-term value.

-

Understanding Pricing Nuances: International buyers should be aware of local market conditions, currency fluctuations, and trade agreements that may impact pricing. For instance, buyers in Europe may face different tariffs compared to those in Africa or South America.

-

Supplier Research: Investigate multiple suppliers to compare pricing, quality, and service. Utilize online platforms and trade shows to connect with potential partners and gather insights.

-

Request for Quotes (RFQs): Always obtain multiple quotes to ensure competitive pricing. This will also give insight into the market rate and help identify any anomalies in pricing.

Conclusion

Understanding the cost structure and pricing dynamics of soft nylon brushes for cleaning is crucial for international B2B buyers. By being aware of the key cost components, pricing influencers, and effective sourcing strategies, buyers can make informed decisions that align with their operational needs and budget constraints. Always consider the total cost of ownership to achieve the best value in your purchasing strategy.

Alternatives Analysis: Comparing soft nylon brush for cleaning With Other Solutions

Introduction: Exploring Alternatives to Soft Nylon Brushes for Cleaning

In the quest for effective cleaning solutions, soft nylon brushes have emerged as a popular choice due to their versatility and gentle bristle structure. However, various alternatives exist that may offer distinct advantages depending on the cleaning context and requirements. This section provides a comparative analysis of soft nylon brushes against alternative cleaning solutions, enabling B2B buyers to make informed decisions that align with their operational needs.

| Comparison Aspect | Soft Nylon Brush For Cleaning | Electric Rotary Scrubber | Microfiber Cloth |

|---|---|---|---|

| Performance | Effective for delicate surfaces and tight spaces | High efficiency for large areas and tough stains | Excellent at trapping dust and dirt, but may require more effort on tough stains |

| Cost | $3 – $50 per unit | $30 – $150 per unit | $5 – $20 per unit |

| Ease of Implementation | Simple to use, no setup required | Requires initial charging and maintenance | Easy to use, no setup needed |

| Maintenance | Washable and reusable | Requires battery maintenance and occasional part replacements | Machine washable, but may wear out over time |

| Best Use Case | Ideal for cleaning grout, tiles, and delicate surfaces | Best for large areas like floors and bathrooms | Perfect for dusting and light cleaning tasks |

Detailed Breakdown of Alternatives

Electric Rotary Scrubber

Electric rotary scrubbers provide a powerful cleaning solution, utilizing rotating brushes or pads to tackle tough stains and grime effectively. The primary advantage of this method is the efficiency with which it can cover large areas, reducing labor time significantly. However, it is generally more expensive and requires charging, which may limit its use in areas without access to power. Additionally, while effective on tough surfaces, it may not be suitable for delicate materials, where a soft nylon brush would excel.

Microfiber Cloth

Microfiber cloths are highly effective for dusting and light cleaning tasks, known for their ability to trap dirt, dust, and allergens due to their fine fibers. They are inexpensive, reusable, and machine washable, making them an eco-friendly option. However, they may require more physical effort to clean tough stains compared to the mechanical action provided by brushes or scrubbers. Their best use case is in environments where maintaining cleanliness without scratching surfaces is crucial, such as in offices or homes.

Conclusion: Choosing the Right Cleaning Solution

When selecting a cleaning solution, B2B buyers should consider their specific cleaning needs, including the type of surfaces involved, the scale of cleaning tasks, and budget constraints. Soft nylon brushes offer a gentle yet effective cleaning option for delicate surfaces, while electric rotary scrubbers provide speed and power for larger cleaning jobs. Meanwhile, microfiber cloths are excellent for everyday cleaning and dusting. By evaluating these alternatives in light of their unique operational requirements, businesses can optimize their cleaning processes, enhance efficiency, and ultimately improve overall cleanliness in their facilities.

Essential Technical Properties and Trade Terminology for soft nylon brush for cleaning

Understanding the technical properties and trade terminology associated with soft nylon brushes for cleaning is crucial for B2B buyers, especially when making informed purchasing decisions. This section highlights essential specifications and jargon that facilitate effective communication and negotiation within the industry.

What are the Key Technical Properties of Soft Nylon Brushes for Cleaning?

-

Material Composition

Soft nylon brushes are primarily made from nylon, a synthetic polymer known for its durability and flexibility. The quality of nylon can vary, impacting the brush’s performance. High-grade nylon offers better abrasion resistance and longevity, making it suitable for various cleaning applications, from household chores to industrial uses. -

Bristle Stiffness

The stiffness of the bristles is a critical specification that influences the brush’s cleaning efficacy. Soft bristles are designed to clean delicate surfaces without scratching, making them ideal for sensitive materials like glass or painted surfaces. Understanding the bristle stiffness helps buyers select brushes tailored to specific cleaning tasks. -

Bristle Length and Density

The length and density of the bristles affect the brush’s ability to reach tight spaces and its overall cleaning effectiveness. Longer bristles can access deeper crevices, while a denser arrangement provides more scrubbing power. Buyers should consider these factors to ensure they choose the right brush for their cleaning needs. -

Handle Design and Ergonomics

The design of the brush handle is important for user comfort and efficiency. Ergonomic handles reduce hand fatigue during prolonged use, which is crucial in professional settings. Features like non-slip grips enhance control, ensuring effective cleaning without compromising safety. -

Chemical Resistance

Many cleaning applications involve the use of chemicals. A brush’s resistance to various cleaning agents can prolong its lifespan and maintain performance. Buyers should verify that the nylon used can withstand the specific chemicals encountered in their cleaning processes. -

Washability and Reusability

Brushes that can be washed and reused reduce waste and overall cleaning costs. It’s essential to check if the brushes are designed for easy cleaning and if they maintain their integrity after multiple uses. This property is especially valuable for businesses focused on sustainability.

What Are Common Trade Terms Related to Soft Nylon Brushes for Cleaning?

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for buyers who seek to source high-quality brushes that meet specific performance standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Knowing the MOQ helps buyers plan their inventory and budget effectively, particularly for bulk purchasing. This term often affects pricing and negotiations. -

RFQ (Request for Quotation)

An RFQ is a document sent by buyers to suppliers requesting pricing and terms for specific products. Crafting a clear RFQ ensures that suppliers provide accurate quotes, facilitating smoother procurement processes. -

Incoterms (International Commercial Terms)

These are a set of predefined international rules that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risk management, and delivery obligations. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is vital for inventory management and ensuring that cleaning operations are not disrupted. -

Certification Standards

Many buyers seek brushes that meet specific certification standards (e.g., ISO, ASTM) to ensure quality and safety. Knowledge of relevant certifications helps buyers assess product reliability and compliance with industry regulations.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make more informed decisions, ensuring they select the right soft nylon brushes for their cleaning applications.

Navigating Market Dynamics and Sourcing Trends in the soft nylon brush for cleaning Sector

Market Overview & Key Trends in the Soft Nylon Brush for Cleaning Sector

The global market for soft nylon brushes used in cleaning applications has been steadily evolving, driven by increasing awareness of hygiene and sanitation, especially in the wake of the COVID-19 pandemic. B2B buyers in regions like Africa, South America, the Middle East, and Europe are witnessing a shift towards high-quality, durable cleaning tools that enhance efficiency and effectiveness in various industries, including hospitality, healthcare, and food services.

Emerging technology trends are reshaping the sourcing landscape. Automation and digital platforms are becoming prevalent, enabling buyers to streamline procurement processes and improve supply chain visibility. Additionally, the rise of e-commerce has facilitated easier access to international suppliers, allowing businesses to compare products, prices, and reviews more effectively. This trend is particularly beneficial for buyers in developing markets, where traditional supply chains may be less established.

Furthermore, customization is gaining traction as companies seek brushes tailored to specific cleaning tasks. This includes variations in bristle stiffness, handle design, and size to cater to different surfaces and cleaning requirements. As buyers increasingly prioritize performance and functionality, manufacturers are responding with innovative designs and materials that meet these demands.

Illustrative image related to soft nylon brush for cleaning

Sustainability & Ethical Sourcing in B2B Cleaning Products

Sustainability is a critical consideration for B2B buyers in the soft nylon brush market. The environmental impact of manufacturing processes and materials used in cleaning tools is under scrutiny, prompting companies to seek ethically sourced products. The demand for eco-friendly brushes made from recycled or biodegradable materials is rising, reflecting a broader trend towards sustainability in procurement practices.

Buyers should look for suppliers that prioritize ethical sourcing and can provide certifications for their products. Certifications such as ISO 14001 for environmental management or Oeko-Tex for textile safety can assure buyers of a commitment to reducing environmental footprints. Additionally, manufacturers focusing on minimizing waste and energy consumption in production processes are becoming increasingly attractive to conscientious buyers.

Incorporating sustainability into the supply chain not only enhances brand reputation but also aligns with the growing consumer preference for environmentally friendly products. As a result, B2B buyers are encouraged to engage with suppliers who share their values regarding sustainability and ethical practices, fostering long-term partnerships that benefit both parties.

Brief Evolution/History of Soft Nylon Brushes in the Cleaning Sector

The evolution of soft nylon brushes dates back several decades, with advancements in material technology leading to the development of synthetic bristles that offer superior durability and cleaning efficiency compared to traditional natural fibers. Initially used primarily in domestic settings, these brushes have gained traction in various commercial applications, including industrial cleaning and specialized tasks in sectors like automotive and healthcare.

As the importance of hygiene and cleanliness has grown, particularly in response to global health crises, the demand for effective cleaning tools has surged. Innovations in brush design, including ergonomic handles and specialized bristle configurations, have further enhanced their effectiveness, making them indispensable tools in modern cleaning protocols across diverse industries. Today, soft nylon brushes are recognized for their versatility, making them a preferred choice for B2B buyers seeking reliable cleaning solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of soft nylon brush for cleaning

-

How do I choose the right soft nylon brush for cleaning?

Choosing the right soft nylon brush depends on the specific cleaning task and the surfaces involved. Consider factors such as bristle stiffness, brush size, and ergonomic design. For delicate surfaces like automotive interiors or electronic devices, opt for softer bristles to prevent scratches. If the brush is intended for grout or tile cleaning, a slightly firmer bristle may be more effective. Additionally, assess whether a long handle is necessary for reaching difficult areas. Always consult product specifications and supplier recommendations for best results. -

What is the best use case for soft nylon brushes?

Soft nylon brushes are ideal for cleaning delicate surfaces where scratching or damage is a concern. They excel in applications such as automotive cleaning, electronics maintenance, and gentle scrubbing of painted or finished surfaces. These brushes can also be used in food processing environments due to their non-abrasive nature. Furthermore, they are effective for removing dust, dirt, and grime from intricate components, making them a versatile tool in various industries, including hospitality, manufacturing, and healthcare. -

What should I consider when vetting suppliers for soft nylon brushes?

When vetting suppliers for soft nylon brushes, consider their manufacturing capabilities, quality assurance processes, and experience in the industry. Request samples to evaluate product quality and performance. Verify certifications such as ISO or other relevant standards that ensure compliance with international safety and quality norms. Additionally, check for customer reviews and testimonials to gauge reliability. Establishing clear communication about lead times, production capacity, and after-sales support is also critical to a successful partnership. -

What are the typical minimum order quantities (MOQs) for soft nylon brushes?

Minimum order quantities (MOQs) for soft nylon brushes can vary significantly based on the supplier and the specific product. Generally, MOQs may range from 100 to 1,000 units, depending on factors like customization, material, and manufacturing processes. For larger orders, suppliers may offer discounts or more favorable terms. Always clarify MOQs with potential suppliers and consider negotiating if your purchasing needs fall below their standard requirements, especially if you’re testing a new product line. -

What payment terms are common for international B2B transactions?

Common payment terms for international B2B transactions include options like letter of credit (LC), wire transfer, and open account terms. A letter of credit provides security for both parties, ensuring that payment is made only upon fulfillment of contract terms. Wire transfers are often used for upfront payments or deposits, while open account terms allow for payment after delivery, which can improve cash flow for buyers. Always discuss and agree upon payment terms in advance to avoid misunderstandings and ensure a smooth transaction. -

How can I ensure quality assurance for soft nylon brushes?

To ensure quality assurance for soft nylon brushes, implement a robust quality control process. This includes establishing clear specifications and standards with your supplier, requesting pre-production samples, and conducting inspections during production and before shipment. Consider third-party quality inspection services for an unbiased evaluation. Additionally, include quality assurance clauses in your purchase agreements to hold suppliers accountable for meeting agreed-upon standards, thereby reducing the risk of receiving defective products. -

What logistics considerations should I keep in mind when importing soft nylon brushes?

Logistics considerations when importing soft nylon brushes include shipping methods, customs regulations, and lead times. Determine whether air or sea freight is more suitable based on urgency and cost. Familiarize yourself with import duties and taxes that may apply in your country to avoid unexpected expenses. Work with reliable freight forwarders who can navigate customs processes efficiently. Additionally, plan for potential delays and communicate timelines clearly with your supplier to align expectations. -

Can I customize soft nylon brushes to meet specific needs?

Yes, many manufacturers offer customization options for soft nylon brushes to meet specific needs. Customization can include variations in bristle stiffness, brush shape, handle design, and even branding options such as logo printing. Discuss your requirements with potential suppliers and inquire about their capabilities for producing custom products. Keep in mind that customization may affect lead times and MOQs, so plan accordingly to ensure timely delivery while meeting your unique specifications.

Top 5 Soft Nylon Brush For Cleaning Manufacturers & Suppliers List

1. Biokleen – Ultra Soft Brush

Domain: biokleen.com

Registered: 1998 (27 years)

Introduction: Wash Brush – Ultra Soft Brush – Nylon Brush

Price: $9.95

Description: A soft grip 10″ ultra soft brush for boats, RVs, cars, trucks, and more. Features nylon brush with lightly crimped flagged-tip green bristles. Sturdy and durable, resistant to rot, mildew, chemicals, alkalis, most solvents, and heat. Comes with a deluxe, custom soft grip handle for easy, fatigue-free cleaning and washing. Safe f…

2. Powr-Flite – 18 Soft Nylon Scrub Brush

Domain: powr-flite.com

Registered: 2000 (25 years)

Introduction: {“name”:”18″ Soft Nylon Scrub Brush, for 20″ Machines”,”model”:”SN218M”,”price”:”$378.39″,”weight”:”8 lb”,”brush_type”:”Soft Nylon Hard Floor Brush”,”brush_width”:”18″”,”recommended_use”:[“Marble”,”Terrazzo”,”Highly polished floors”,”Textured floors”,”Resilient floors such as rubber and Luxury Vinyl Tile (LVT)”,”Epoxy or non-slip floors”,”Finished hardwood”],”features”:[“Gentle cleaning”,”Good abr…

3. Restorer Tools – Nylon Brush Attachment 80 Grit

Domain: restorertools.com

Registered: 2020 (5 years)

Introduction: Nylon Brush Attachment 80 Grit – Designed for cleaning with the Restorer tool. Price: $55.00. Features include: lightweight for one-handed use, gentle on reclaimed wood while removing dirt and grime, suitable for live edge slabs, quick restoration of surfaces, versatile for wood and metal, easy assembly, vacuum connector for dust elimination, and effective in removing paint and rust without warpin…

4. Iosso – Nylon Bore Brush

Domain: snipershide.com

Registered: 2000 (25 years)

Introduction: Manufacturer: Iosso

Product Type: Nylon Bore Brush

Intended Use: Soft bristles for scrubbing bore with Iosso or Chameleon bore paste

User Feedback: Some users found Iosso brushes stiffer than expected; alternative suggestions include using a brush one caliber down wrapped in a patch.

5. Cimex – White Nylon Brushes (3 Pack)

Domain: cimex.us

Registered: 2016 (9 years)

Introduction: {‘name’: ‘White Nylon Brushes (3 Pack)’, ‘price_range’: ‘$196.01 – $407.77’, ‘description’: ‘Pack of 3 economical white nylon brushes. These scrub brushes are safe for use on most surfaces. Available in both soft and stiff bristles. Soft bristles are gentle enough to use with Cimex Carpet Machines in encapsulation carpet cleaning. Stiff bristles offer more aggressive cleaning on hard floors with C…

Strategic Sourcing Conclusion and Outlook for soft nylon brush for cleaning

In conclusion, strategic sourcing of soft nylon brushes for cleaning presents a significant opportunity for B2B buyers across diverse markets, including Africa, South America, the Middle East, and Europe. Understanding the unique cleaning requirements of various industries is crucial, as the versatility and durability of soft nylon brushes make them ideal for applications ranging from household cleaning to industrial maintenance. Buyers should prioritize suppliers that offer quality assurance, competitive pricing, and the ability to meet specific regional needs.

By fostering strong supplier relationships and leveraging data-driven insights, businesses can enhance their procurement strategies, ensuring a consistent supply of high-quality cleaning tools. Additionally, staying informed about market trends and innovations in cleaning technology will enable companies to remain competitive and responsive to customer demands.

Illustrative image related to soft nylon brush for cleaning

As international B2B buyers navigate this evolving landscape, it is imperative to take proactive steps towards sourcing the right products. Engage with reliable suppliers, explore new partnerships, and invest in product quality to optimize your cleaning operations. Embrace this opportunity to elevate your procurement strategies and ensure your business remains at the forefront of the cleaning industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to soft nylon brush for cleaning

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.