How to Source Box Channel Steel Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for box channel steel

Navigating the complexities of sourcing box channel steel can be a daunting challenge for international B2B buyers, particularly as the demand for reliable and durable structural materials continues to rise across diverse markets. With industries ranging from construction to manufacturing increasingly reliant on high-quality steel channels, understanding the nuances of this product is essential for making informed purchasing decisions. This comprehensive guide delves into the various types of box channel steel, exploring their applications in different sectors, and providing critical insights into supplier vetting processes and cost considerations.

Throughout this guide, readers will discover a wealth of information tailored to meet the specific needs of buyers from regions such as Africa, South America, the Middle East, and Europe, including key markets like Brazil and Vietnam. By highlighting industry standards, material specifications, and the competitive landscape of suppliers, this resource empowers B2B buyers to navigate the global market with confidence. Whether you are sourcing for large-scale construction projects or specialized manufacturing needs, this guide aims to equip you with the knowledge necessary to select the right box channel steel for your unique requirements. Engage with this essential resource to enhance your procurement strategy and foster successful partnerships in the international steel market.

Understanding box channel steel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Steel Box Channel | Rectangular shape, high strength, and durability | Structural supports, frames, and enclosures | Pros: High load-bearing capacity; Cons: Heavier than alternatives. |

| Aluminum Box Channel | Lightweight, corrosion-resistant, non-magnetic | Aerospace, automotive, and marine applications | Pros: Lightweight; Cons: Lower strength compared to steel. |

| Stainless Steel Box Channel | Corrosion-resistant, aesthetic finish, and strength | Food processing, chemical handling, and architecture | Pros: Excellent corrosion resistance; Cons: Higher cost. |

| Galvanized Box Channel | Coated for corrosion resistance, available in various thicknesses | Construction, outdoor structures, and fencing | Pros: Cost-effective corrosion protection; Cons: Limited aesthetic options. |

| Custom Box Channel | Tailored dimensions and finishes to specific requirements | Specialized applications in various industries | Pros: Meets unique specifications; Cons: Longer lead times. |

What Are the Characteristics of Steel Box Channels?

Steel box channels are characterized by their rectangular profile, which provides significant structural strength. They are commonly used in construction and engineering projects where high load-bearing capabilities are essential. Buyers should consider factors such as the required dimensions, thickness, and the specific steel grade (e.g., A36) to ensure suitability for their projects.

How Do Aluminum Box Channels Differ in Usage?

Aluminum box channels are known for their lightweight nature and resistance to corrosion, making them ideal for industries like aerospace and automotive where weight reduction is critical. These channels are also non-magnetic, which is beneficial in certain electrical applications. When purchasing, buyers should evaluate the trade-offs between weight and strength, as aluminum channels generally have lower load capacities compared to their steel counterparts.

Why Choose Stainless Steel Box Channels?

Stainless steel box channels offer both strength and aesthetic appeal, making them suitable for applications in food processing and architecture. Their resistance to corrosion is particularly valuable in environments where exposure to moisture and chemicals is a concern. Buyers should weigh the higher cost against the long-term durability and maintenance savings that stainless steel provides.

What Advantages Do Galvanized Box Channels Offer?

Galvanized box channels are treated with a zinc coating to enhance their corrosion resistance, making them a cost-effective choice for outdoor applications and construction projects. They come in various thicknesses, which allows for flexibility in design. However, buyers should consider that while they are effective in preventing rust, they may not offer the same aesthetic appeal as uncoated metals.

How to Approach Custom Box Channel Purchases?

Custom box channels provide the advantage of tailored dimensions and finishes to meet specific project requirements. This flexibility is crucial for specialized applications across various industries. However, buyers should be prepared for potentially longer lead times and higher costs associated with custom manufacturing. It’s essential to clearly communicate specifications and expectations to suppliers to ensure the final product meets the intended application needs.

Key Industrial Applications of box channel steel

| Industry/Sector | Specific Application of box channel steel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Structural frames for buildings and bridges | Provides strong, lightweight support while reducing overall costs | Ensure compliance with local building codes and standards |

| Automotive Manufacturing | Chassis and frame components | Enhances vehicle strength and safety while optimizing weight | Consider corrosion resistance and weight specifications |

| Renewable Energy | Support structures for solar panels and wind turbines | Increases durability and stability of energy systems | Look for sustainable sourcing and certifications for materials |

| Rail and Transportation | Support beams for rail systems | Improves safety and reliability of transport infrastructure | Evaluate load-bearing capacities and compatibility with existing systems |

| Marine and Offshore | Structural components for ships and platforms | Offers high strength-to-weight ratio essential for marine applications | Assess resistance to corrosion and environmental factors |

How is box channel steel used in construction, and what problems does it solve?

In the construction sector, box channel steel is primarily utilized for structural frames in buildings and bridges. Its design allows for lightweight yet robust support, significantly reducing material costs without compromising safety. International buyers should consider sourcing box channel steel that complies with local building codes and standards, ensuring that it meets the specific load-bearing requirements of different projects. Additionally, understanding regional variations in steel grades can help optimize project outcomes.

What role does box channel steel play in automotive manufacturing?

In automotive manufacturing, box channel steel is essential for creating chassis and frame components. Its strength-to-weight ratio is crucial for enhancing vehicle safety while also contributing to fuel efficiency. Buyers from emerging markets like Brazil and Vietnam should prioritize sourcing materials that meet stringent safety and performance standards, while also considering the environmental impact of their production processes. Ensuring that suppliers can provide corrosion-resistant options can further enhance the longevity of automotive applications.

How does box channel steel contribute to renewable energy projects?

Box channel steel serves a vital role in renewable energy applications, particularly in the construction of support structures for solar panels and wind turbines. Its durability and stability help ensure the long-term performance of energy systems, which is increasingly important as the global demand for sustainable energy solutions grows. International buyers should seek suppliers that offer environmentally friendly sourcing options and certifications, as these can enhance the credibility and marketability of renewable energy projects.

In what ways is box channel steel utilized in rail and transportation?

In the rail and transportation sector, box channel steel is used to manufacture support beams and structural components, which are critical for the safety and reliability of transportation infrastructure. This application demands high load-bearing capacities and compatibility with existing systems, particularly in regions with extensive rail networks. Buyers should conduct thorough evaluations of potential suppliers to ensure their products meet the rigorous demands of the rail industry, including compliance with international safety standards.

How is box channel steel applied in marine and offshore industries?

Box channel steel is extensively used in marine and offshore industries for constructing structural components of ships and platforms. Its high strength-to-weight ratio is essential for ensuring the structural integrity of vessels operating in challenging environments. Buyers in this sector must prioritize sourcing options that offer enhanced corrosion resistance and durability to withstand harsh marine conditions. Additionally, understanding the specific environmental factors at play in different regions can aid in selecting the right specifications for box channel steel.

3 Common User Pain Points for ‘box channel steel’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality Box Channel Steel

The Problem:

B2B buyers often struggle with sourcing high-quality box channel steel, especially when dealing with international suppliers. This challenge is exacerbated by varying quality standards across regions, leading to concerns about the structural integrity and longevity of the material. Buyers may face situations where the steel received does not meet the specified dimensions or quality certifications, resulting in project delays and increased costs due to rework or replacements.

The Solution:

To ensure that box channel steel meets the required specifications, buyers should conduct thorough research on potential suppliers. Start by verifying certifications such as ISO 9001 or ASTM standards that guarantee quality. It’s beneficial to request material test reports before placing large orders. Additionally, establishing a relationship with a reliable local supplier can mitigate risks associated with international shipping and quality discrepancies. Engaging in small trial orders can also help assess a supplier’s reliability before committing to larger quantities.

Scenario 2: Complications with Custom Specifications

The Problem:

Many projects require custom dimensions or finishes for box channel steel, which can lead to complications in both communication and production. Buyers often find that specifying custom requirements can be met with resistance from suppliers, who may not have the flexibility or capacity to fulfill such requests. This can result in delays and increased costs, as well as potential mismatches in product expectations and final delivery.

The Solution:

To effectively navigate custom orders, B2B buyers should provide detailed specifications and drawings when communicating with suppliers. Using CAD software to create precise designs can help convey requirements clearly. Additionally, buyers should inquire about the supplier’s capabilities upfront to ensure they can accommodate custom orders. It may also be advantageous to work with suppliers who specialize in custom fabrication, as they are more likely to have the necessary tools and expertise to meet unique specifications without compromising on quality or timeline.

Scenario 3: Uncertainty in Pricing Structures

The Problem:

B2B buyers frequently encounter confusion regarding pricing structures for box channel steel. Fluctuations in raw material costs, shipping fees, and additional charges for customization can lead to unpredictable expenses. This unpredictability can strain budgets and hinder project planning, making it difficult for buyers to secure accurate quotes and manage financial expectations effectively.

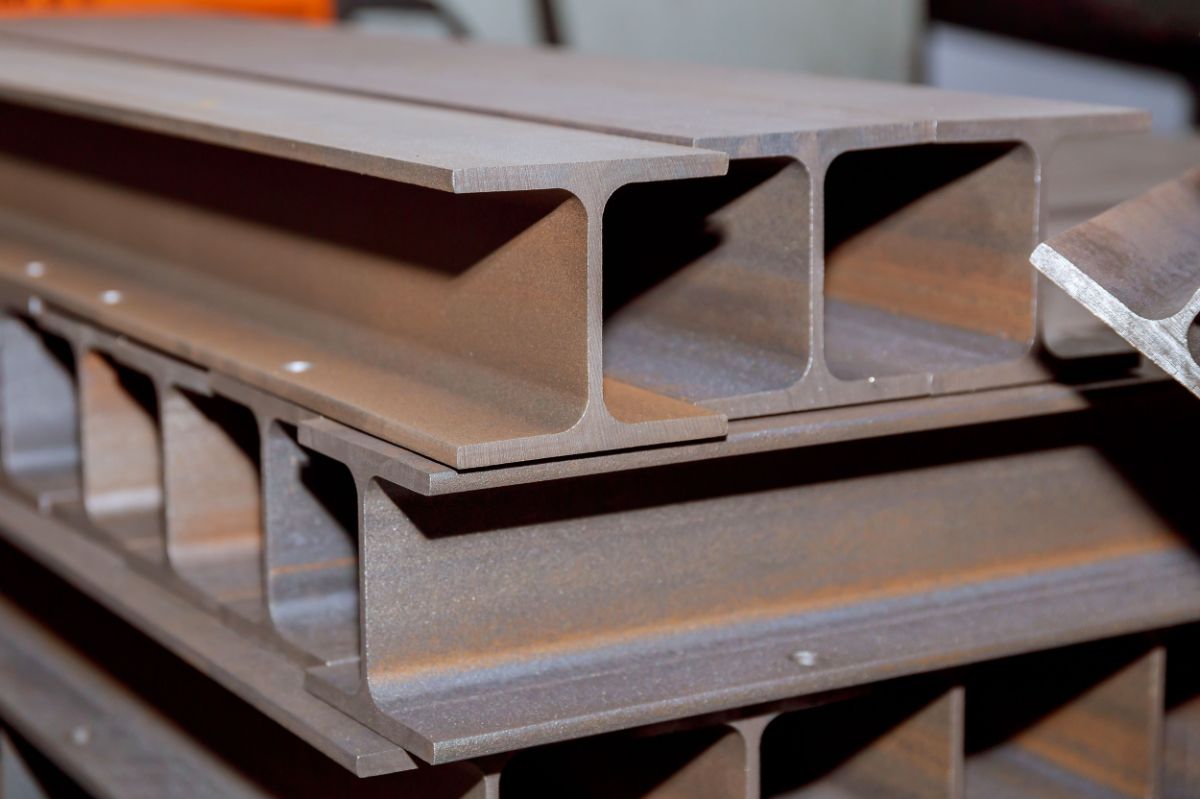

Illustrative image related to box channel steel

The Solution:

To tackle pricing uncertainty, buyers should seek to establish long-term contracts with suppliers to lock in prices for extended periods. This can provide a buffer against sudden market fluctuations. Additionally, it’s essential to request a comprehensive breakdown of pricing from suppliers, including any potential extra costs for customization or delivery. Engaging with multiple suppliers to compare quotes can also provide leverage in negotiations and help identify competitive pricing. Finally, keeping abreast of market trends and forming alliances with industry groups can offer insights into pricing forecasts, allowing buyers to plan more effectively.

By addressing these common pain points with actionable solutions, B2B buyers can enhance their procurement process for box channel steel, leading to more successful project outcomes and stronger supplier relationships.

Strategic Material Selection Guide for box channel steel

What are the Key Properties of Common Materials Used for Box Channel Steel?

When selecting materials for box channel steel, understanding the properties of different options is critical for ensuring optimal performance in various applications. Here, we analyze four common materials: carbon steel, stainless steel, aluminum, and galvanized steel. Each material has unique properties, advantages, and limitations that can significantly impact their suitability for specific applications.

How Does Carbon Steel Perform in Box Channel Applications?

Carbon steel, particularly A36 grade, is widely used in box channel applications due to its strength and versatility. It exhibits excellent mechanical properties, with a yield strength of approximately 250 MPa, making it suitable for structural applications. However, carbon steel has limited corrosion resistance, which can be a drawback in humid or corrosive environments.

Pros: High strength, cost-effective, widely available, and easy to fabricate.

Cons: Prone to rusting if not protected, requiring additional coatings or treatments for outdoor applications.

Impact on Application: Best suited for structural support in dry environments or where additional protective measures are employed.

Considerations for Buyers: Compliance with ASTM standards is crucial, especially in regions like Europe and the Middle East, where quality assurance is paramount.

What Advantages Does Stainless Steel Offer for Box Channels?

Stainless steel, particularly grades 304 and 316, is known for its exceptional corrosion resistance and durability. It maintains structural integrity even in extreme temperatures and aggressive environments, making it ideal for applications in the food processing, marine, and chemical industries.

Pros: Excellent corrosion resistance, high strength-to-weight ratio, and aesthetic appeal.

Cons: Higher cost compared to carbon steel and can be more challenging to machine and weld.

Impact on Application: Suitable for environments exposed to moisture and chemicals, ensuring longevity and reduced maintenance costs.

Considerations for Buyers: Buyers should be aware of compliance with international standards such as ASTM and EN, especially in regions like Africa and South America where import regulations may vary.

How Does Aluminum Compare as a Material for Box Channel Steel?

Aluminum box channels are lightweight and resistant to corrosion, making them an attractive option for applications requiring reduced weight without sacrificing strength. Aluminum alloys, such as 6061 and 6063, offer good machinability and weldability.

Illustrative image related to box channel steel

Pros: Lightweight, excellent corrosion resistance, and good thermal conductivity.

Cons: Lower strength compared to steel and can be more expensive depending on the alloy.

Impact on Application: Ideal for lightweight structures, automotive applications, and environments where weight savings are critical.

Considerations for Buyers: Compliance with JIS standards is important for buyers in Asia, including Vietnam, while European buyers may prefer EN standards.

What Role Does Galvanized Steel Play in Box Channel Applications?

Galvanized steel is carbon steel that has been coated with zinc to enhance corrosion resistance. This material is commonly used in outdoor applications where exposure to moisture is a concern. The galvanization process provides a protective barrier that significantly extends the lifespan of the steel.

Pros: Cost-effective, good corrosion resistance, and readily available.

Cons: The coating can be damaged during fabrication, which may require re-coating.

Impact on Application: Suitable for outdoor structures, such as fencing and support systems, where exposure to the elements is a factor.

Considerations for Buyers: Buyers should ensure compliance with local standards and consider the environmental impact of galvanization processes in their region.

Summary Table of Material Properties for Box Channel Steel

| Material | Typical Use Case for box channel steel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Structural applications in dry areas | High strength and cost-effective | Prone to rust without protection | Low |

| Stainless Steel | Marine and chemical applications | Exceptional corrosion resistance | Higher cost and fabrication difficulty | High |

| Aluminum | Lightweight structures and automotive | Lightweight and corrosion-resistant | Lower strength than steel | Medium |

| Galvanized Steel | Outdoor structures and fencing | Good corrosion resistance | Coating can be damaged | Low |

This guide provides a comprehensive overview of the various materials used in box channel steel, helping B2B buyers make informed decisions based on their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for box channel steel

What Are the Key Stages in the Manufacturing Process of Box Channel Steel?

The manufacturing of box channel steel involves several critical stages, ensuring that the final product meets the required specifications for strength, durability, and functionality. Here’s a breakdown of the main stages involved:

Material Preparation: What Raw Materials Are Used?

The process begins with sourcing high-quality raw materials, typically hot-rolled steel, which is known for its strength and workability. Other materials like stainless steel or aluminum may also be used, depending on the specific application. The steel is often sourced in bulk and inspected for impurities, ensuring compliance with international standards such as ISO 9001.

The raw material is then cut into manageable lengths, which allows for efficient handling during the subsequent manufacturing stages. This initial preparation is crucial, as any defects in the raw material can propagate through to the final product, affecting quality.

How is Box Channel Steel Formed?

The forming stage is where the raw materials are transformed into box channel shapes. This is typically accomplished through various techniques:

-

Roll Forming: This method involves feeding the flat steel strips through a series of rollers that gradually shape the steel into a box channel profile. This technique is favored for its efficiency and ability to produce long lengths with consistent cross-sections.

-

Welding: For box channels that require seams, the edges of the formed steel are welded together. This can be done using different welding techniques, including MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding, depending on the material and desired strength.

-

Punching and Notching: During the forming process, holes may be punched or notches cut into the box channel for applications like mounting or assembly. Precision in this stage is critical to ensure that the final product meets design specifications.

What Finishing Processes Are Commonly Used?

After forming, the box channel undergoes finishing processes that enhance its appearance and protect it from corrosion:

-

Surface Treatment: Depending on the intended use, various surface treatments may be applied. Common methods include galvanization (coating with zinc to prevent rust), powder coating, or painting. These treatments not only improve aesthetics but also extend the lifespan of the steel.

-

Cutting and Trimming: The channels are then cut to the specified lengths, with precision cutting techniques employed to ensure clean edges and accurate dimensions.

-

Inspection and Quality Control: Before the final product is packaged, it undergoes rigorous quality checks to ensure it meets all specifications.

What Quality Assurance Practices Are Essential for Box Channel Steel?

Quality assurance (QA) is a critical component of the manufacturing process, especially in the international market where standards can vary widely. Here are the key practices that should be in place:

Which International Standards Should Buyers Be Aware Of?

To ensure that box channel steel meets industry requirements, suppliers often adhere to several international standards:

-

ISO 9001: This standard outlines criteria for a quality management system. Compliance indicates that the manufacturer has processes in place to consistently provide products that meet customer and regulatory requirements.

-

CE Marking: For products sold within the European Union, CE marking signifies compliance with EU health, safety, and environmental protection standards.

-

API Standards: For box channels used in the oil and gas industry, compliance with American Petroleum Institute (API) standards is crucial.

Understanding these standards helps buyers ensure that they are sourcing from reputable manufacturers who prioritize quality.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is typically integrated into the manufacturing process through several checkpoints:

-

Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specifications. This includes checking for material composition, dimensions, and surface quality.

-

In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor processes such as forming and welding. This ensures that any deviations are caught early, minimizing waste and defects.

-

Final Quality Control (FQC): Once production is complete, the final product undergoes comprehensive testing and inspection. This may include dimensional checks, surface quality assessments, and strength tests to verify that the box channel meets the required standards.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality is essential to mitigate risks associated with sourcing. Here are actionable steps buyers can take:

Illustrative image related to box channel steel

What Documentation Should Buyers Request?

-

Quality Control Reports: Request detailed reports from the supplier that outline their QC procedures, results from testing, and certifications. This documentation should verify adherence to the relevant standards.

-

Third-Party Inspections: Consider engaging third-party inspection services. These independent auditors can conduct on-site evaluations of the manufacturing process and product quality.

-

Supplier Audits: Conducting audits of potential suppliers can provide insights into their manufacturing processes, quality systems, and overall operational capabilities. This proactive approach helps establish trust and ensures compliance with international standards.

What Testing Methods Are Commonly Used?

Common testing methods for box channel steel include:

-

Tensile Testing: Measures the strength and ductility of the steel, ensuring it can withstand operational stresses.

-

Ultrasonic Testing: Detects internal flaws within the steel that could compromise its integrity.

-

Visual Inspections: Simple yet effective, visual inspections can identify surface defects, such as cracks or corrosion.

Conclusion: Why Is It Important for B2B Buyers to Understand These Processes?

Understanding the manufacturing processes and quality assurance measures for box channel steel is critical for B2B buyers looking to source reliable and high-quality products. By being informed about the stages of production, relevant standards, and quality control practices, buyers can make educated decisions, minimize risks, and ensure that the materials they procure meet their specific requirements. This knowledge not only fosters stronger supplier relationships but also enhances the overall success of their projects in a competitive international marketplace.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘box channel steel’

To successfully procure box channel steel, it is essential for B2B buyers to follow a structured approach. This checklist serves as a practical guide to help you navigate the complexities of sourcing box channel steel, ensuring that you make informed decisions that meet your project’s requirements.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical specifications for box channel steel. Consider factors such as dimensions, weight capacity, material grade (e.g., A36, stainless steel), and finish options (e.g., galvanized, painted). This step is vital to ensure that the products you procure align with your project’s structural and aesthetic requirements.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify potential suppliers that specialize in box channel steel. Utilize online platforms, industry directories, and trade shows to compile a list of candidates. Focus on suppliers with a proven track record and positive customer feedback, as this can significantly impact the quality of your procurement.

Step 3: Evaluate Supplier Certifications and Compliance

Verify that potential suppliers possess relevant certifications and comply with international standards (e.g., ISO, ASTM). Certifications can indicate a supplier’s commitment to quality and safety. Additionally, check for compliance with regional regulations, especially if you are sourcing from a different country.

Step 4: Request Samples and Conduct Quality Assessments

Before placing a bulk order, request samples of the box channel steel. This allows you to assess the material’s quality, dimensions, and finish firsthand. Conduct thorough quality assessments to ensure that the samples meet your specifications and standards, as this can prevent costly issues later on.

Step 5: Discuss Pricing and Payment Terms

Engage in discussions regarding pricing and payment terms with your shortlisted suppliers. Be transparent about your budget and inquire about bulk pricing options or discounts for larger orders. Understanding payment terms is crucial, as this will affect your cash flow and project timelines.

Step 6: Review Lead Times and Logistics

Inquire about lead times for production and delivery, as these can vary significantly among suppliers. Understanding the logistics involved in shipping, especially for international orders, will help you plan your project timeline effectively. Confirm that the supplier can meet your deadlines to avoid delays in project execution.

Step 7: Establish a Communication Plan

Once you have selected a supplier, establish a clear communication plan. Designate points of contact for both parties and outline preferred communication channels. Regular updates on order status, shipping details, and any potential issues will foster a productive relationship and ensure transparency throughout the procurement process.

By following this step-by-step checklist, B2B buyers can streamline their sourcing process for box channel steel, ensuring they make informed decisions that align with their project requirements and timelines.

Comprehensive Cost and Pricing Analysis for box channel steel Sourcing

When sourcing box channel steel, understanding the comprehensive cost structure and pricing dynamics is essential for B2B buyers, especially in diverse markets like Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Box Channel Steel Pricing?

The cost of box channel steel is influenced by several critical components:

-

Materials: The primary cost driver, the choice of material (steel, aluminum, stainless steel) significantly impacts pricing. Steel is generally more affordable than aluminum but may require additional treatment processes like galvanization, which can add to costs.

-

Labor: This encompasses the workforce required for production, including skilled labor for machining and assembly. Labor costs vary by region, with lower costs in developing countries, which can be advantageous for buyers.

-

Manufacturing Overhead: This includes fixed and variable costs associated with running a manufacturing facility, such as utilities, equipment maintenance, and administrative expenses. Efficient production processes can help lower these costs.

-

Tooling: Initial tooling costs for custom or specialized box channel designs can be significant. Buyers should consider whether the supplier has the necessary tooling capabilities to meet their specifications without incurring excessive costs.

-

Quality Control (QC): Investments in QC ensure that products meet required specifications and certifications. Suppliers that implement rigorous QC processes may charge higher prices, but this can lead to fewer defects and higher reliability.

-

Logistics: Transportation costs, including shipping and handling, can vary widely based on distance, shipping method, and Incoterms. Buyers should factor these costs into their total expenditure.

-

Margin: Suppliers will include a margin in their pricing to ensure profitability. This margin can vary based on market competition and the supplier’s positioning.

What Influences Box Channel Steel Prices?

Several factors can influence the pricing of box channel steel:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes typically lead to better pricing. Suppliers may offer discounts for large orders or long-term contracts, which can significantly reduce unit costs.

-

Specifications and Customization: Custom specifications, such as unique dimensions or finishes, can increase costs. Buyers should balance the need for customization with budget constraints.

-

Material Quality and Certifications: Higher-quality materials or products that meet specific industry certifications (like ISO or ASTM) often command higher prices. Buyers should assess the long-term value of investing in certified products.

-

Supplier Factors: Supplier reputation, reliability, and geographic location play a role in pricing. Established suppliers with a track record of quality may charge more but can also provide assurance of product performance.

-

Incoterms: The agreed-upon Incoterms can significantly impact total costs. Buyers should clarify responsibilities for shipping, insurance, and customs duties to avoid unexpected expenses.

How Can Buyers Optimize Costs in Box Channel Steel Sourcing?

-

Negotiation Strategies: Engage suppliers in discussions about pricing, especially for larger orders. Leverage relationships and market knowledge to negotiate better terms.

-

Focus on Total Cost of Ownership (TCO): Rather than simply comparing initial prices, consider the TCO, which includes maintenance, operational efficiency, and potential resale value. Lower upfront costs may lead to higher long-term expenses.

-

Consider Regional Variations: Pricing can vary based on geographic location and market conditions. Buyers in regions like Africa and South America may find different pricing dynamics than those in Europe, so it’s crucial to research local suppliers.

-

Be Aware of Pricing Nuances: Understand that international shipping, tariffs, and local taxes can affect final pricing. It’s advisable to work with logistics experts to navigate these complexities.

Conclusion

Sourcing box channel steel requires a keen understanding of cost structures and pricing dynamics. By considering the various cost components, price influencers, and strategies for cost optimization, B2B buyers can make informed decisions that align with their operational needs and budget constraints. Prices can vary widely, so it’s essential to obtain quotes from multiple suppliers and conduct thorough market research to ensure competitive pricing.

Alternatives Analysis: Comparing box channel steel With Other Solutions

Introduction to Alternatives in Structural Solutions

In the competitive landscape of industrial construction and manufacturing, selecting the right structural materials is crucial for optimizing performance and cost-effectiveness. Box channel steel is a popular choice due to its strength and versatility; however, other alternatives may offer comparable or even superior benefits depending on specific project requirements. This analysis compares box channel steel with two viable alternatives: aluminum channels and cold-formed steel sections.

Comparison Table

| Comparison Aspect | Box Channel Steel | Aluminum Channels | Cold-Formed Steel Sections |

|---|---|---|---|

| Performance | High strength, excellent load-bearing capacity | Moderate strength, lightweight | High strength, versatile shapes |

| Cost | Generally more affordable, fluctuates with steel prices | Higher initial cost, lower long-term maintenance | Competitive pricing, cost-effective for large projects |

| Ease of Implementation | Requires welding and heavy equipment | Easier to handle, can be joined with fasteners | Requires specialized equipment for forming |

| Maintenance | Low maintenance, corrosion can be a concern | Resistant to corrosion, minimal upkeep | Moderate maintenance, can rust without protection |

| Best Use Case | Structural frames, support systems | Lightweight applications, architectural features | Wall studs, trusses, and framing applications |

Pros and Cons of Alternatives

Aluminum Channels

Aluminum channels are increasingly favored in applications where weight reduction is critical. They offer a significant advantage in terms of corrosion resistance, making them ideal for environments with high humidity or exposure to harsh chemicals. The lightweight nature of aluminum allows for easier handling and installation, potentially reducing labor costs. However, aluminum has lower tensile strength compared to box channel steel, which may limit its use in heavy-load applications. Additionally, the initial cost can be higher, which might not be ideal for budget-sensitive projects.

Cold-Formed Steel Sections

Cold-formed steel sections provide a strong alternative to box channel steel, particularly in framing applications. These sections are manufactured by forming steel sheets into desired shapes, which allows for a variety of profiles suitable for different structural needs. Cold-formed steel is known for its high strength-to-weight ratio, making it an efficient choice for projects requiring strong yet lightweight materials. The initial investment is often competitive with box channel steel, and they can be produced in large quantities, driving down costs for bulk projects. However, like box channel steel, they are susceptible to corrosion if not properly treated, necessitating protective coatings or galvanization.

Conclusion: How to Choose the Right Solution

When selecting between box channel steel and its alternatives, B2B buyers should carefully evaluate their specific project requirements, including load-bearing needs, environmental conditions, and budget constraints. Box channel steel is a robust choice for heavy-duty applications, while aluminum channels excel in lightweight and corrosion-resistant scenarios. Cold-formed steel sections offer a versatile and cost-effective solution for framing and structural needs. By considering performance, cost, ease of implementation, and maintenance, buyers can make informed decisions that align with their operational goals and project specifications.

Essential Technical Properties and Trade Terminology for box channel steel

What Are the Key Technical Properties of Box Channel Steel?

When sourcing box channel steel, understanding its technical specifications is crucial for ensuring that it meets the requirements of your project. Here are some of the critical properties to consider:

-

Material Grade: The most commonly used material grade for box channel steel is A36, which offers excellent weldability and machinability. Understanding material grades helps buyers ensure compatibility with specific applications and structural integrity.

-

Thickness: Box channels typically come in various thicknesses, ranging from 0.003 inches to 0.150 inches or more. The thickness affects the strength and load-bearing capacity of the channel. Buyers must select the appropriate thickness to meet load requirements while considering cost-effectiveness.

-

Length Tolerance: Length tolerances refer to the allowable deviation from specified lengths. Standard tolerances might range from ±1/16 inch to ±1/8 inch. Accurate tolerances are essential for ensuring that the box channel fits correctly into the intended application, minimizing the need for further adjustments.

-

Weight Per Unit Length: This specification indicates the weight of the box channel per foot or meter. Understanding the weight is vital for logistics planning and structural calculations, as it impacts the overall load on structures.

-

Finish Type: Box channels can have various finishes, including galvanized, pre-painted, or plain. The finish affects corrosion resistance and aesthetic appeal. Buyers should consider the environmental conditions of the application area when selecting a finish.

What Common Trade Terms Should Buyers Know When Purchasing Box Channel Steel?

Navigating the procurement process can be simplified by understanding key industry jargon. Here are some essential terms:

-

OEM (Original Equipment Manufacturer): This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reliable sources for high-quality box channel steel.

-

MOQ (Minimum Order Quantity): This is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is vital for budgeting and planning inventory levels, especially for businesses looking to maintain stock without overcommitting financially.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers asking for pricing and terms for specific quantities of products. This process is crucial for comparing costs and services among different suppliers, helping businesses make informed purchasing decisions.

-

Incoterms (International Commercial Terms): These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping responsibilities, risk transfer, and cost allocation, which are critical for smooth logistics.

-

Lead Time: This term indicates the amount of time it takes from placing an order to receiving the product. Understanding lead times is essential for project planning and ensuring that materials arrive when needed to avoid project delays.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions regarding their purchases of box channel steel, ensuring that they meet both project specifications and budgetary constraints.

Illustrative image related to box channel steel

Navigating Market Dynamics and Sourcing Trends in the box channel steel Sector

What Are the Current Market Dynamics and Key Trends in the Box Channel Steel Sector?

The box channel steel market is experiencing significant growth driven by various global factors. Key drivers include the rising demand for construction materials in developing regions, particularly in Africa and South America, where urbanization and infrastructure projects are accelerating. In Europe and the Middle East, the focus is shifting towards high-strength and lightweight materials, which are essential for modern construction and manufacturing processes. The increasing adoption of advanced manufacturing technologies, such as automation and digital supply chain solutions, is enhancing efficiency and responsiveness in sourcing strategies.

Emerging trends include a preference for customized solutions, as buyers seek specific dimensions and finishes tailored to their unique applications. The rise of e-commerce platforms is also reshaping the way B2B buyers source box channel steel, facilitating easier access to suppliers and competitive pricing. Moreover, the integration of data analytics in procurement processes is allowing companies to make informed decisions based on market trends, inventory levels, and pricing forecasts. Overall, the market dynamics are characterized by a blend of traditional sourcing methods and innovative approaches, catering to a diverse range of customer needs.

How Is Sustainability Impacting the Box Channel Steel Sector?

Sustainability is becoming a critical consideration in the box channel steel sector, driven by growing environmental awareness among consumers and regulatory pressures. The production of steel has a substantial carbon footprint, making it essential for buyers to seek suppliers committed to reducing environmental impact. Ethical sourcing practices are increasingly valued, with companies prioritizing suppliers who demonstrate transparency and responsibility in their supply chains. This trend is particularly pronounced in markets such as Europe and North America, where consumers demand sustainable practices from manufacturers.

Incorporating ‘green’ certifications and materials is essential for B2B buyers looking to align with sustainability goals. Certifications such as ISO 14001 and LEED can enhance the credibility of suppliers and products. Buyers are encouraged to engage with suppliers who utilize recycled steel or innovative production methods that minimize waste and emissions. By prioritizing sustainability, companies not only fulfill regulatory requirements but also position themselves favorably in a competitive market, appealing to environmentally-conscious customers.

What Is the Historical Context of Box Channel Steel?

The evolution of box channel steel can be traced back to the industrial revolution, where the need for sturdy yet lightweight materials in construction and manufacturing became paramount. Initially, the production of steel channels was labor-intensive and lacked the precision required for modern applications. However, advancements in metallurgy and manufacturing techniques, such as roll forming and laser cutting, have significantly enhanced the quality and versatility of box channels. Today, box channel steel is widely used in various applications, including structural frameworks, automotive components, and equipment supports, reflecting its enduring importance in the industrial landscape.

By understanding the historical context, international B2B buyers can appreciate the advancements in material technology and manufacturing processes that have shaped the current box channel steel market, guiding them in making informed purchasing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of box channel steel

-

How do I determine the right size and thickness of box channel steel for my project?

To select the appropriate size and thickness of box channel steel, assess the specific requirements of your project, including load-bearing capacity, structural integrity, and environmental conditions. Consult engineering specifications and industry standards relevant to your application. It’s also advisable to collaborate with your supplier, who can provide expert guidance on the best dimensions and material properties based on your intended use. Consider factors such as the weight of materials to be supported, potential corrosion, and local building codes. -

What is the best type of box channel steel for construction in humid climates?

For construction in humid climates, galvanized or stainless steel box channels are ideal due to their superior corrosion resistance. Galvanized steel is coated with zinc, providing a protective barrier against moisture. Stainless steel, particularly grades like 304 or 316, offers enhanced durability and is suitable for marine environments. When selecting materials, consider the specific environmental challenges your project may face, including salt exposure or temperature fluctuations, and consult with your supplier for the best options. -

What customization options are available for box channel steel?

Box channel steel can be customized in various ways to meet specific project needs. Common customization options include cutting to length, varying thickness, and applying different finishes such as galvanization or powder coating. Some suppliers also offer bending or welding services to create unique shapes or configurations. Always discuss your requirements with the supplier to ensure that they can accommodate your customization requests and provide samples if necessary. -

What is the minimum order quantity (MOQ) for box channel steel?

The minimum order quantity for box channel steel varies by supplier and can depend on factors such as material type, thickness, and processing requirements. Generally, MOQs can range from a few hundred kilograms to several tons. It’s advisable to inquire directly with potential suppliers to understand their specific policies and negotiate terms that suit your purchasing needs. Some suppliers may offer flexibility for smaller orders, especially for established business relationships. -

How do I vet suppliers of box channel steel for international trade?

Vetting suppliers for international trade involves several key steps. Start by checking their credentials, including certifications, industry experience, and customer reviews. Request references from previous clients and assess their production capabilities through factory visits or virtual tours. Ensure that the supplier complies with international quality standards, such as ISO certifications. Additionally, consider their logistics capabilities, including shipping times and customs clearance processes, to ensure smooth transactions. -

What payment terms should I expect when purchasing box channel steel internationally?

Payment terms for international purchases of box channel steel can vary widely based on the supplier and the buyer’s negotiation. Common payment methods include letters of credit, advance payments, or payment upon delivery. It’s essential to clarify the terms upfront, including any deposits required and the timeline for payments. Consider using secure payment methods to mitigate risks, and ensure that all financial agreements are documented to avoid disputes. -

What quality assurance measures should I look for when sourcing box channel steel?

When sourcing box channel steel, ensure that the supplier implements strict quality assurance measures. Look for suppliers who conduct regular inspections and testing of materials to verify compliance with industry standards. Certifications like ISO 9001 can indicate robust quality management practices. Additionally, request documentation such as mill test reports that outline the chemical composition and mechanical properties of the steel, ensuring that it meets your specifications. -

How can I ensure timely delivery of box channel steel for my projects?

To ensure timely delivery of box channel steel, communicate your project timelines clearly with the supplier. Discuss lead times for production and shipping, and factor in potential delays due to customs or logistics. It’s beneficial to establish a reliable relationship with your supplier, as this can facilitate better prioritization of your orders. Additionally, consider placing orders well in advance of your project deadlines to accommodate any unforeseen delays. Regular follow-ups and updates can also help keep the delivery on track.

Top 6 Box Channel Steel Manufacturers & Suppliers List

1. MetalsDepot® – A36 Steel Channel

Domain: metalsdepot.com

Registered: 1999 (26 years)

Introduction: MetalsDepot® – Buy Steel Channel Online! A36 Structural Steel Channel is a hot rolled, mild steel structural C shape with inside radius corners. Ideal for structural applications, general fabrication, manufacturing, and repairs. Commonly used in industrial maintenance, agricultural implements, transportation equipment, truck beds, trailers, etc. C-shape or U-shape configuration provides added stre…

2. McMaster – Box Channels & Steel Tubes

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Box Channels & Steel Tubes, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Johnson Roll Forming – C-Channels and Metal Channels

Domain: johnsonrollforming.com

Registered: 2004 (21 years)

Introduction: C-Channels, Box Channels, Steel C Channel, Aluminum C Channel, Stainless C Channel; Types of Metals: Steel, Stainless, Aluminum, Brass, Bronze, Copper Alloys, Galvanized, Martinsite, Titanium, High Strength Domex, Cor-Ten; Channel Finishes: Plain, Pre-Painted, Pre-Plated, Pre-Anodized, Pre-Galvanized, Bonderized, Chem-Treat, Electro Chromate, Galvanneal, Galvan Aluminized, Terne Plated, Black Oxid…

4. Steel Supply, L.P. – 20′ Galvanized Steel Channel

Domain: steelsupplylp.com

Registered: 2005 (20 years)

Introduction: This company, Steel Supply, L.P. – 20′ Galvanized Steel Channel, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Metal Supermarkets – Structural Channel

Domain: metalsupermarkets.com

Registered: 1996 (29 years)

Introduction: Channel is a structural metal available in Aluminum, Mild Steel, and Stainless Steel. It is commonly used in building and construction, shipbuilding, automotive industries, and general fabrication. The channel has a C- or U-shape, suitable for structural applications where loads are focused vertically or horizontally. Measurements for the channel can be taken by the width of the channels, height o…

6. One Touch Exim – Stainless Steel Box Channels

Domain: onetouchexim.com

Registered: 2023 (2 years)

Introduction: Stainless Steel Box Channels are made from hot-rolled steel with box-shaped cross-sections that have four sides perpendicular to each other, increasing strength and rigidity. They are ideal for applications with high loads or stresses, such as supports or braces in bridges, towers, and buildings. Available in a range of sizes (20 X 20 to 100 X 100) and thicknesses (3 mm to 25 mm), they can be cust…

Strategic Sourcing Conclusion and Outlook for box channel steel

What Are the Key Takeaways for B2B Buyers in Box Channel Steel Sourcing?

In today’s competitive market, strategic sourcing of box channel steel is crucial for ensuring quality, cost-effectiveness, and timely delivery. Buyers must focus on establishing relationships with reliable suppliers who can provide a variety of materials, including steel, aluminum, and stainless options. Understanding the specifications, such as thickness and finish, allows for better alignment with project requirements. Additionally, leveraging local suppliers can mitigate lead times and enhance supply chain resilience, particularly for international buyers in Africa, South America, the Middle East, and Europe.

How Can Buyers Prepare for Future Trends in Box Channel Steel?

As the demand for box channel steel continues to grow, especially in construction and manufacturing sectors, staying ahead of market trends is essential. Adopting a proactive sourcing strategy will not only help in securing favorable pricing but also in navigating fluctuations in availability and quality. Collaborating with suppliers that offer innovative solutions and sustainable practices can yield long-term benefits.

What Should International B2B Buyers Do Next?

Now is the time for international B2B buyers to assess their sourcing strategies and align them with evolving market demands. By fostering strong partnerships and prioritizing strategic sourcing, you can enhance operational efficiency and drive project success. Engage with suppliers who understand local market nuances and can provide customized solutions tailored to your needs. The future of your sourcing strategy begins today—take action and secure your competitive edge in the box channel steel market.

Illustrative image related to box channel steel

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.