Top 5 Wire Screen Suppliers (And How to Choose)

Introduction: Navigating the Global Market for wire screen

In the ever-evolving global market, sourcing high-quality wire screens poses a significant challenge for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. The right wire screen is essential for a multitude of applications, from industrial uses such as filtration and separation to architectural designs that demand both aesthetic appeal and functional durability. This guide serves as a comprehensive resource, addressing the diverse types of wire screens available, their various applications, and critical considerations for supplier vetting and cost assessment.

Navigating this complex landscape can be daunting, especially when balancing quality, compliance with local regulations, and cost-effectiveness. By leveraging this guide, buyers will gain the insights necessary to make informed purchasing decisions tailored to their specific needs. Whether you’re in Nigeria seeking robust solutions for construction or in Germany looking for innovative designs for urban spaces, this guide equips you with the knowledge to identify reputable suppliers, understand market trends, and evaluate pricing structures effectively.

Empower your sourcing strategy and streamline your procurement processes with actionable insights that ensure your wire screen investments deliver maximum value and performance.

Understanding wire screen Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Square Wire Mesh | Uniform square openings, available in various wire diameters. | Construction, architectural design, and fencing. | Pros: Versatile; Cons: May require additional coatings for corrosion resistance. |

| Rectangular Wire Mesh | Rectangular openings, customizable for specific applications. | Industrial sieving, filtration, and storage solutions. | Pros: Tailored sizes; Cons: Less common than square mesh. |

| ECO-MESH® | Three-dimensional design for plant support, lightweight. | Landscaping, garden trellises, and decorative screens. | Pros: Aesthetic appeal; Cons: Limited structural strength. |

| Wildfire Defense Mesh | High tensile strength, flame and ember resistant. | Fire safety in residential and commercial buildings. | Pros: Safety compliant; Cons: Higher cost due to specialized materials. |

| Vinyl Coated Wire Mesh | Galvanized steel with PVC coating for weather resistance. | Outdoor applications, including fencing and barriers. | Pros: Corrosion resistant; Cons: Limited color options. |

What Are the Characteristics and Uses of Square Wire Mesh?

Square wire mesh is characterized by its uniform square openings, making it a popular choice in various industries. Its adaptability allows it to be used in construction projects, architectural designs, and as fencing material. When purchasing, buyers should consider the wire diameter and coating options available, as these will affect durability and application suitability. Square wire mesh can be easily cut to size, facilitating installation across diverse projects.

How Does Rectangular Wire Mesh Differ from Other Types?

Rectangular wire mesh features openings that are rectangular rather than square, providing a customizable solution for specific applications. This type is often utilized in industrial settings for sieving and filtration purposes, as well as for storage solutions. B2B buyers should focus on the mesh size and wire gauge when selecting rectangular wire mesh, as these factors will influence the performance in their unique applications. Its tailored design makes it a versatile option, although it is less common than square mesh.

Why Choose ECO-MESH® for Landscaping Projects?

ECO-MESH® is designed with a three-dimensional structure that supports plant growth while providing aesthetic appeal. This lightweight mesh is ideal for landscaping, garden trellises, and decorative screens. For B2B buyers, the primary consideration is its structural strength, which may be limited compared to traditional wire meshes. However, its unique design offers an attractive solution for enhancing outdoor spaces.

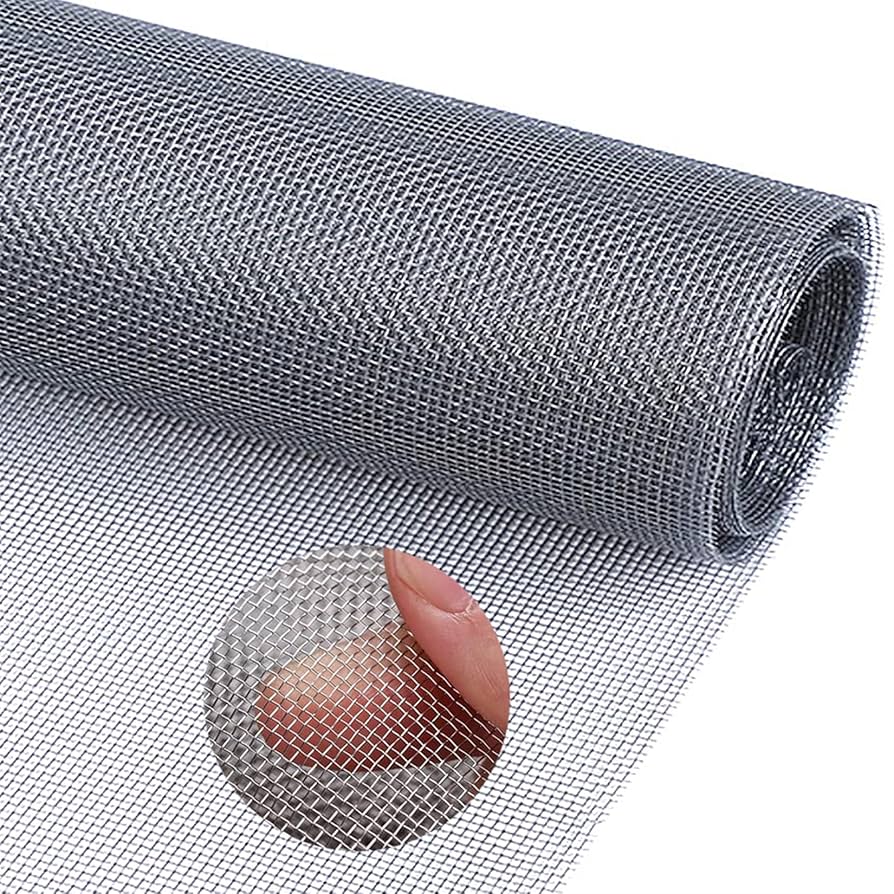

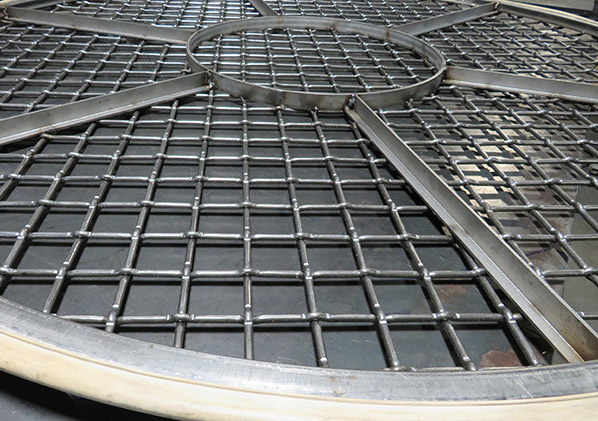

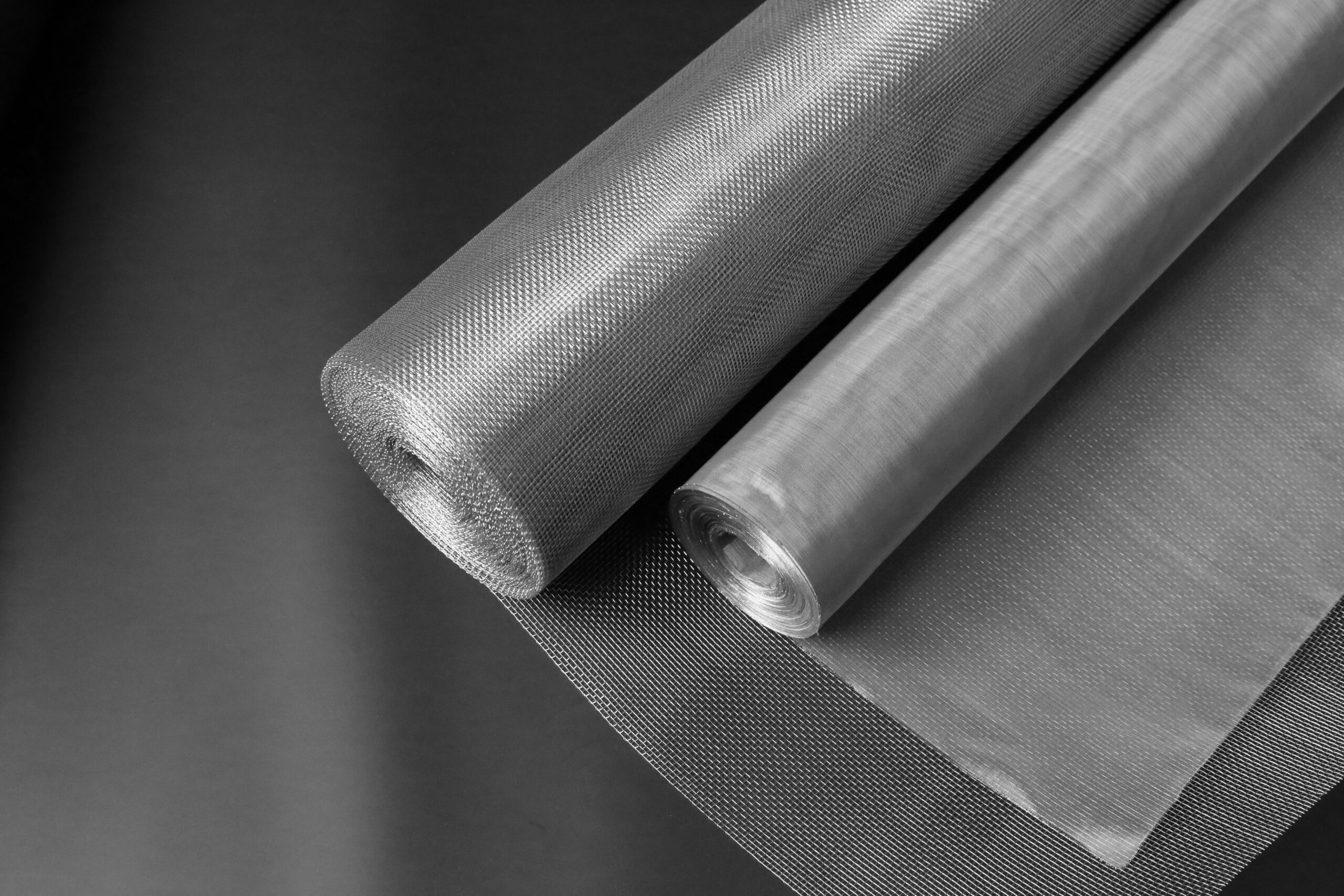

与wire screen相关的说明性图片

What Benefits Does Wildfire Defense Mesh Provide?

Wildfire Defense Mesh is engineered to resist flames and embers, making it essential for fire safety in residential and commercial buildings. Its high tensile strength ensures durability, while compliance with safety standards is crucial for B2B buyers in fire-prone areas. Although the initial investment may be higher due to specialized materials, the long-term safety benefits can justify the cost, particularly in high-risk environments.

How Does Vinyl Coated Wire Mesh Enhance Outdoor Applications?

Vinyl coated wire mesh combines galvanized steel with a PVC coating, providing excellent weather resistance and durability for outdoor applications. It is often used for fencing and barriers, making it a practical choice for various businesses. Buyers should weigh the benefits of corrosion resistance against the limited color options available. This type of wire mesh is particularly advantageous for projects requiring longevity in harsh environmental conditions.

Key Industrial Applications of wire screen

| Industry/Sector | Specific Application of wire screen | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Architecture | Railing infills and decorative partitions | Enhances aesthetic appeal while ensuring safety and durability | Material type (stainless steel, aluminum), design flexibility, local regulations |

| Agriculture & Horticulture | Plant screens and trellises | Supports plant growth and protects crops from pests | Corrosion resistance, mesh size for specific crops, ease of installation |

| Fire Safety & Prevention | Ember-resistant mesh for vents and openings | Reduces fire risk by preventing ember entry | Compliance with local fire codes, material durability, installation ease |

| Environmental Protection | Erosion control and sediment filtration systems | Enhances environmental sustainability and site stability | Mesh aperture size, material durability, environmental compliance |

| Manufacturing & Production | Filtration systems for liquids and gases | Increases efficiency in production processes | Mesh size, material compatibility, and industry standards |

How is wire screen utilized in construction and architecture?

In the construction and architecture sectors, wire screens serve as railing infills and decorative partitions. These applications not only enhance aesthetic appeal but also provide essential safety features. Buyers should consider various material types, such as stainless steel or aluminum, depending on the environment and design requirements. Local building regulations may also dictate specific standards that must be met, making it crucial for international buyers to understand regional compliance.

What role does wire screen play in agriculture and horticulture?

Wire screens are pivotal in agriculture, particularly as plant screens and trellises. They support plant growth and offer protection against pests, ensuring healthier crops. Buyers need to focus on corrosion resistance and mesh size tailored to specific crops to optimize growth conditions. Additionally, ease of installation can be a significant factor, especially for large-scale agricultural operations in regions with varying climates, such as Africa and South America.

How does wire screen contribute to fire safety and prevention?

In the realm of fire safety, wire screens are used as ember-resistant mesh for vents and openings. This application significantly reduces the risk of fire by preventing embers from entering structures, which is particularly important in fire-prone areas. Buyers should ensure compliance with local fire codes and select durable materials that can withstand extreme conditions. Installation ease is also a vital consideration, especially for large buildings or industrial facilities.

In what ways is wire screen essential for environmental protection?

Wire screens are increasingly utilized for erosion control and sediment filtration systems. These applications enhance environmental sustainability by stabilizing soil and improving water quality. For international buyers, key sourcing considerations include mesh aperture size tailored to specific environmental needs and material durability to withstand harsh conditions. Compliance with environmental regulations is also critical, especially in regions facing strict ecological standards.

How is wire screen integrated into manufacturing and production processes?

In manufacturing, wire screens are integral to filtration systems for liquids and gases. These systems increase efficiency by ensuring that only desired materials pass through, thus optimizing production processes. When sourcing wire screens for this application, buyers should focus on mesh size and material compatibility with the substances being filtered. Adherence to industry standards is crucial to ensure the effectiveness and safety of the filtration systems.

3 Common User Pain Points for ‘wire screen’ & Their Solutions

Scenario 1: Inconsistent Quality and Performance of Wire Screens

The Problem: B2B buyers often face challenges in sourcing wire screens that meet specific quality standards. This is particularly crucial in industries such as construction and manufacturing, where the durability and performance of wire mesh can significantly impact project outcomes. A buyer may receive shipments of wire screens that vary in gauge, weave density, or material quality, leading to issues in structural integrity or aesthetic appeal. Such inconsistencies can result in costly delays, rework, and even safety concerns, especially when screens are used in applications like safety barriers or filtration systems.

与wire screen相关的说明性图片

The Solution: To mitigate the risks associated with inconsistent quality, buyers should establish clear specifications before sourcing wire screens. This includes defining the required material (e.g., stainless steel, aluminum), wire gauge, mesh size, and intended application. Engage with reputable suppliers who can provide certifications and test reports to validate the quality of their products. Implementing a robust vendor management system that includes regular audits and quality checks can further ensure that the wire screens meet the specified standards consistently. Additionally, maintaining a close relationship with suppliers allows buyers to communicate any quality concerns promptly and foster a collaborative approach to problem-solving.

Scenario 2: Limited Customization Options for Specific Applications

The Problem: B2B buyers frequently encounter limitations in customization when it comes to wire screens. Many suppliers offer standard sizes and patterns, which may not fit the unique requirements of specific projects. For example, a construction company might need wire screens that fit irregular spaces or have particular aesthetic characteristics for architectural designs. This lack of customization can lead to increased costs as buyers may have to resort to purchasing standard sizes and then incur additional expenses for modifications.

The Solution: To address customization challenges, buyers should seek out suppliers that offer tailored solutions and have the capability to produce custom wire screens. Before placing an order, provide detailed specifications, including dimensions, patterns, and any specific treatments needed (such as corrosion resistance or a decorative finish). It’s beneficial to partner with manufacturers that utilize advanced technologies, such as CAD software, to visualize and prototype custom designs. Establishing a collaborative relationship with these suppliers can streamline the customization process and ensure that the final product meets both functional and aesthetic requirements effectively.

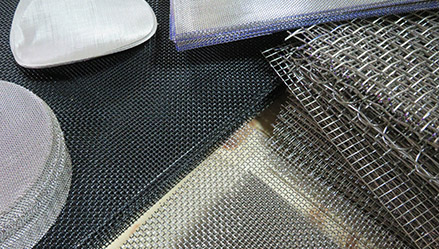

与wire screen相关的说明性图片

Scenario 3: Difficulty in Understanding Regulatory Compliance and Standards

The Problem: Navigating the complex landscape of regulatory compliance can be daunting for B2B buyers, especially when sourcing wire screens for applications in sectors like construction, food processing, or environmental protection. Different regions and industries have specific standards that wire screens must meet, which can vary significantly from one market to another. Failure to comply with these regulations can lead to legal repercussions, project delays, and reputational damage.

The Solution: To effectively manage compliance, buyers should invest time in researching the relevant standards applicable to their industry and location. This may include standards set by organizations such as ASTM, ISO, or local building codes. Collaborate with suppliers who are knowledgeable about these standards and can provide documentation to confirm that their wire screens meet necessary regulatory requirements. Additionally, consider working with compliance consultants or legal advisors who specialize in industry regulations. This proactive approach not only safeguards projects but also enhances the overall credibility and reliability of the buyer’s operations in the marketplace.

Strategic Material Selection Guide for wire screen

What Are the Key Properties of Common Wire Screen Materials?

When selecting wire screen materials for various applications, understanding their properties is crucial for ensuring optimal performance. Here, we analyze four common materials used in wire screens: stainless steel, aluminum, brass, and carbon steel. Each material offers unique properties that cater to different industrial needs.

How Does Stainless Steel Perform in Wire Screen Applications?

Stainless steel is renowned for its exceptional corrosion resistance and durability, making it ideal for harsh environments. It can withstand high temperatures and is resistant to rust, which is essential for applications exposed to moisture or chemicals. The most commonly used grades, such as 304 and 316, provide varying levels of resistance to corrosion and heat.

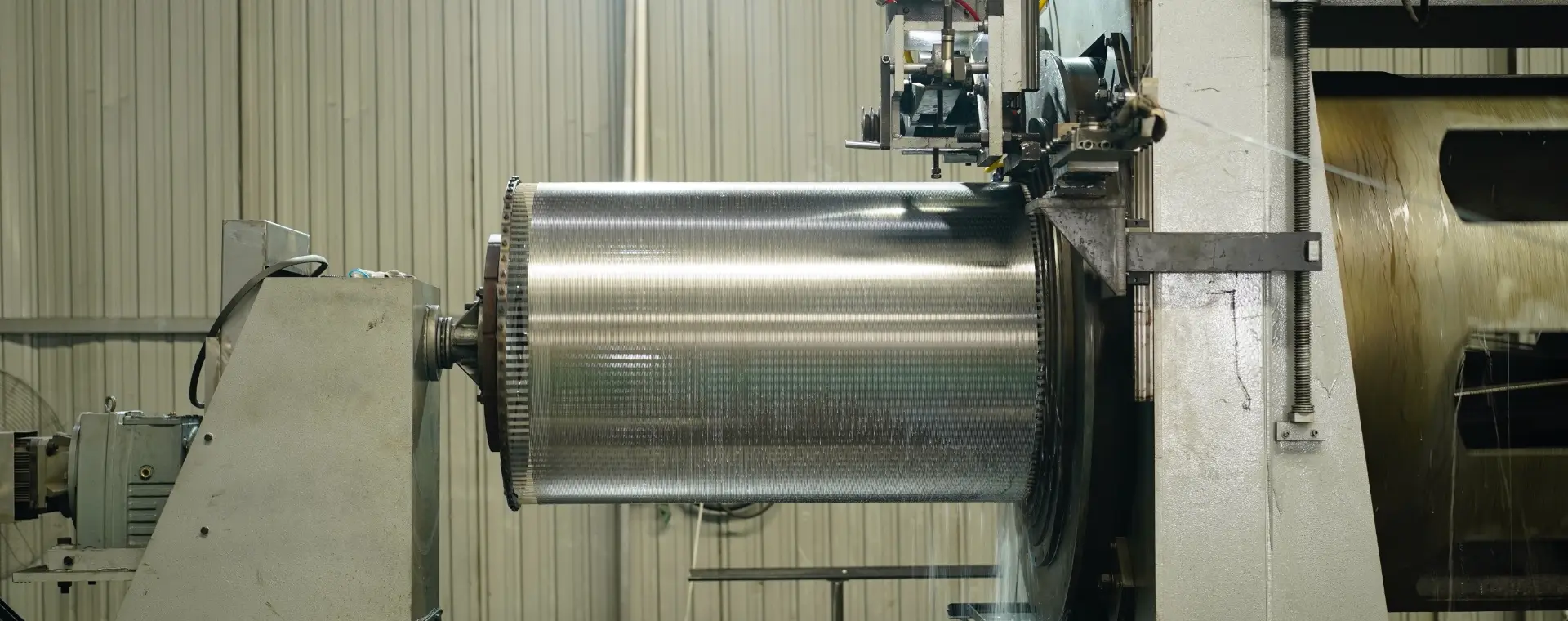

与wire screen相关的说明性图片

Pros: Stainless steel wire screens are highly durable, have a long lifespan, and require minimal maintenance. They are suitable for a wide range of applications, including filtration and architectural designs.

Cons: The primary drawback is the higher cost compared to other materials. Additionally, manufacturing processes can be more complex, requiring specialized equipment.

Impact on Application: Stainless steel wire screens are compatible with a variety of media, including liquids and gases, making them versatile for industrial filtration systems.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM and DIN, particularly when sourcing materials for critical applications in regions like Europe and the Middle East.

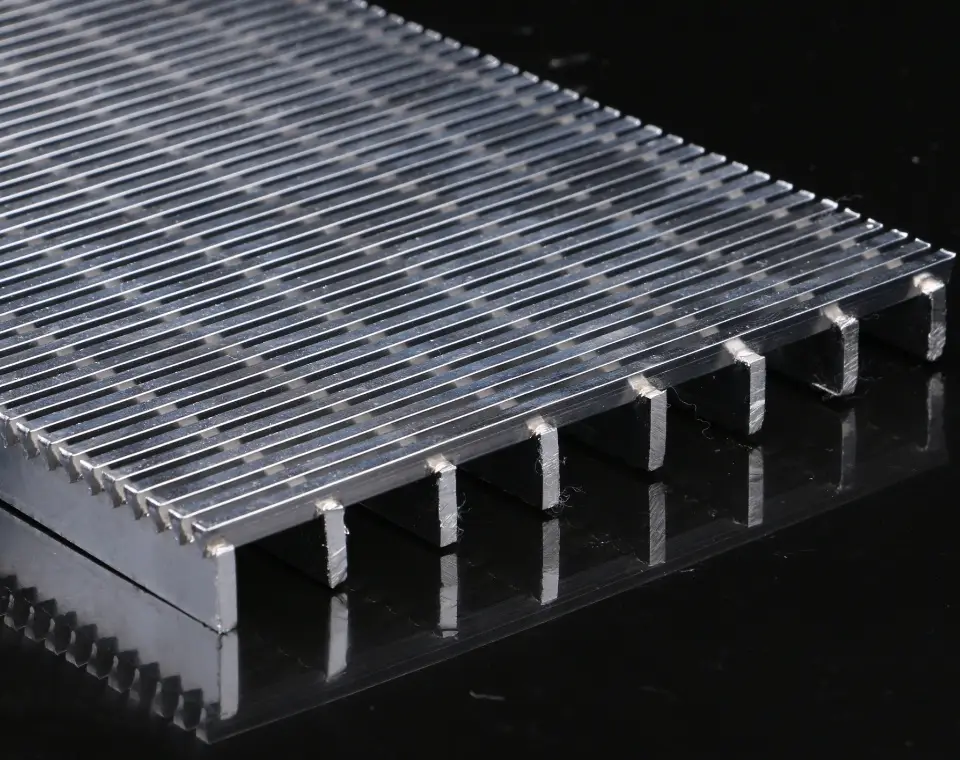

What Advantages Does Aluminum Offer for Wire Screens?

Aluminum wire screens are lightweight and easy to handle, making them an excellent choice for applications where weight is a concern. They exhibit good corrosion resistance, especially when anodized, and can be used in both indoor and outdoor settings.

与wire screen相关的说明性图片

Pros: The lightweight nature of aluminum makes it easy to transport and install. Additionally, it is generally more affordable than stainless steel.

Cons: While corrosion-resistant, aluminum is not as durable as stainless steel and can be prone to denting or bending under heavy loads. It also has a lower temperature tolerance.

Impact on Application: Aluminum wire screens are commonly used in applications such as insect screens and decorative architectural elements.

Considerations for International Buyers: Buyers in regions with high humidity or salt exposure should consider the anodizing process to enhance corrosion resistance.

Why Choose Brass for Wire Screen Applications?

Brass wire screens are known for their aesthetic appeal and resistance to corrosion, particularly in marine environments. They also have antimicrobial properties, making them suitable for applications in food processing and healthcare.

与wire screen相关的说明性图片

Pros: The unique appearance of brass can enhance the aesthetic value of products. It is also durable and has good machinability.

Cons: Brass is more expensive than aluminum and can tarnish over time, requiring regular maintenance to maintain its appearance.

Impact on Application: Brass wire screens are often used in decorative applications and environments where hygiene is critical.

Considerations for International Buyers: Buyers should verify compliance with health and safety standards, especially in food-related applications, which may vary by region.

What Role Does Carbon Steel Play in Wire Screen Manufacturing?

Carbon steel wire screens are known for their strength and affordability. They are commonly used in construction and industrial applications where high tensile strength is required.

与wire screen相关的说明性图片

Pros: Carbon steel wire screens are cost-effective and provide excellent strength and durability for various applications.

Cons: They are susceptible to rust and corrosion if not properly coated or treated, limiting their use in wet or corrosive environments.

Impact on Application: Carbon steel is ideal for applications such as fencing and construction, where strength is prioritized over corrosion resistance.

Considerations for International Buyers: Buyers should consider the need for protective coatings to enhance corrosion resistance, especially in humid climates like those found in parts of Africa and South America.

与wire screen相关的说明性图片

Summary Table of Wire Screen Materials

| Material | Typical Use Case for wire screen | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Industrial filtration, architectural design | Exceptional durability and corrosion resistance | Higher cost and complex manufacturing | High |

| Aluminum | Insect screens, decorative applications | Lightweight and cost-effective | Less durable, lower temperature tolerance | Medium |

| Brass | Decorative and hygiene-critical applications | Aesthetic appeal and antimicrobial properties | Expensive and requires maintenance | High |

| Carbon Steel | Fencing, construction applications | Cost-effective and strong | Susceptible to rust and corrosion | Low |

This guide provides a comprehensive overview of the strategic selection of wire screen materials, ensuring that international buyers can make informed decisions based on their specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for wire screen

What Are the Main Stages in the Manufacturing Process of Wire Screens?

The manufacturing process of wire screens involves several critical stages that ensure the final product meets industry standards and customer requirements.

Material Preparation

The first step in manufacturing wire screens is material preparation, which includes selecting the appropriate wire type based on the intended application. Common materials include stainless steel, aluminum, and galvanized steel, each offering unique properties such as corrosion resistance, strength, and flexibility. The wires are then cut to specific lengths and diameters, with careful consideration of the mesh size and application requirements.

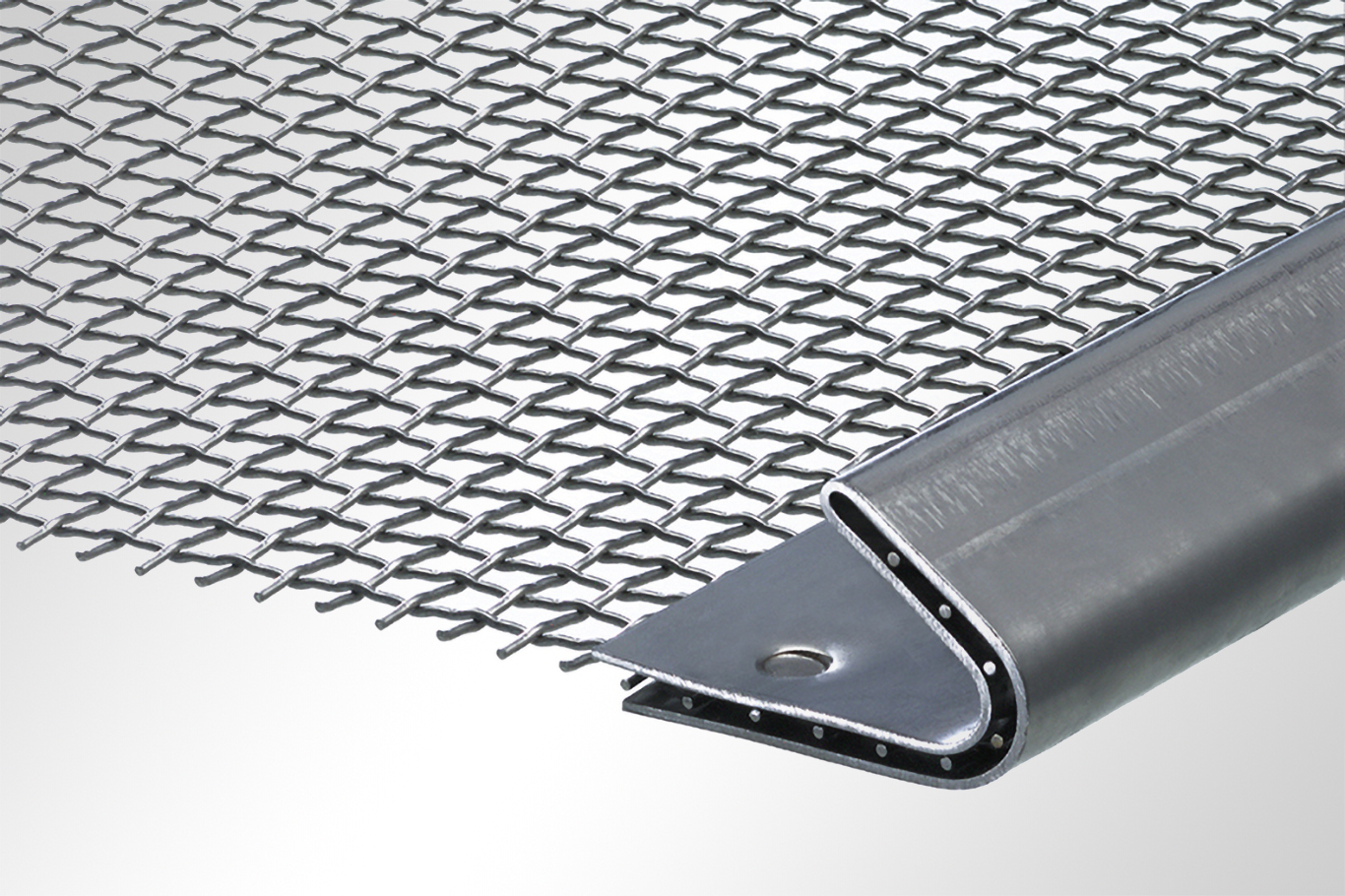

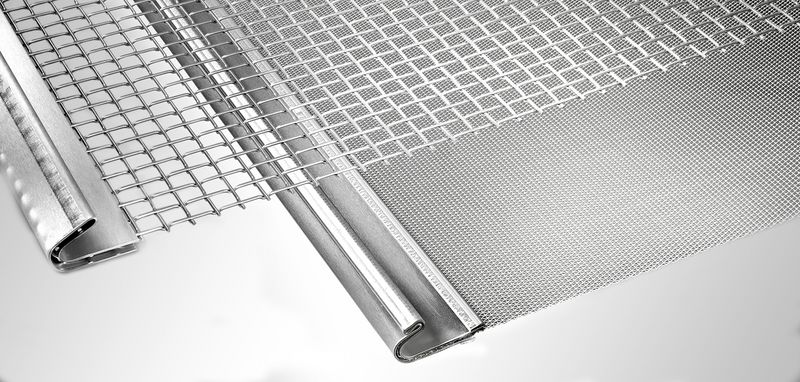

Forming Techniques

Once the materials are prepared, the next phase is forming. This can involve various techniques, including weaving, welding, or stamping. In the weaving process, wires are interlaced to create a mesh pattern, which is crucial for applications requiring filtration or ventilation. Alternatively, welding techniques may be employed for applications needing enhanced durability. Stamping is also utilized to create specific shapes or designs, particularly for decorative or architectural applications.

Assembly and Integration

After forming, the individual components are assembled. This phase may include attaching frames or borders to the mesh, which can enhance stability and ease of installation. Automated machinery often assists in this process to ensure precision and efficiency. Additionally, specialized techniques like powder coating or galvanizing may be applied during assembly to improve durability and aesthetic appeal.

Finishing Processes

The final stage of manufacturing is finishing. This can involve various treatments to enhance the wire screen’s performance, such as anti-corrosion coatings, painting, or other surface treatments. Quality control checks are typically integrated at this stage to ensure that the finished product meets specified standards before packaging and shipping.

How Is Quality Assurance Implemented in Wire Screen Manufacturing?

Quality assurance (QA) is vital in the wire screen manufacturing process to ensure that the products meet international standards and customer expectations.

What Are the Relevant International Standards for Wire Screens?

Quality assurance in wire screen manufacturing often adheres to international standards such as ISO 9001, which outlines the criteria for a quality management system. Additionally, industry-specific standards like CE marking in Europe indicate compliance with health, safety, and environmental protection standards. For specialized applications, standards set by organizations like the American Petroleum Institute (API) may also be relevant.

What Are the Key Quality Control Checkpoints?

Quality control (QC) in wire screen manufacturing generally includes several checkpoints throughout the production process:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials for compliance with specified standards. Suppliers must provide documentation of material properties and certifications.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular checks are conducted to ensure that each stage meets quality standards. This includes monitoring wire diameter, mesh size, and assembly integrity.

-

Final Quality Control (FQC): Before shipping, the finished products undergo a thorough inspection to verify that they meet all required specifications. This may include testing for strength, flexibility, and corrosion resistance.

What Common Testing Methods Are Used in Wire Screen Quality Assurance?

To ensure the quality and reliability of wire screens, various testing methods are employed:

-

Mechanical Testing: This includes tensile strength tests to determine how much force the wire can withstand before breaking, as well as flexibility tests to assess how well the wire maintains its shape.

-

Corrosion Resistance Testing: This is crucial for wire screens used in harsh environments. Tests may include salt spray tests to simulate corrosive conditions and measure how well the material holds up over time.

-

Mesh Open Area Testing: This measures the percentage of open area within the mesh, which is essential for applications requiring filtration or ventilation.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying the quality control measures of suppliers is essential to ensure product reliability and compliance with industry standards.

What Steps Can Buyers Take to Verify QC?

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality assurance practices firsthand. This can also include evaluating the supplier’s adherence to international standards.

-

Requesting Quality Reports: Suppliers should provide detailed quality reports, including test results and compliance certifications. These documents help buyers understand the quality of the products they are purchasing.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality assurance processes. These inspections can be conducted at various stages, from material preparation to final product testing.

What Are the Nuances of QC/Certifications for International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must navigate various nuances regarding quality control and certifications.

Understanding Regional Standards

Different regions may have specific standards and certifications that must be adhered to, which can complicate sourcing decisions. For example, European buyers may prioritize CE marking, while buyers in the Middle East may require compliance with local building codes. Understanding these regional requirements is essential for ensuring that the products meet all necessary regulations.

Building Relationships with Suppliers

Establishing strong relationships with suppliers can facilitate better communication regarding quality assurance practices and certifications. Buyers should engage in discussions about the supplier’s quality control measures and any challenges they may face in meeting international standards.

Conclusion

In summary, the manufacturing processes and quality assurance practices for wire screens are critical factors that B2B buyers must consider. By understanding these processes, verifying supplier capabilities, and navigating international standards, buyers can make informed decisions that ensure the quality and reliability of their wire screen products.

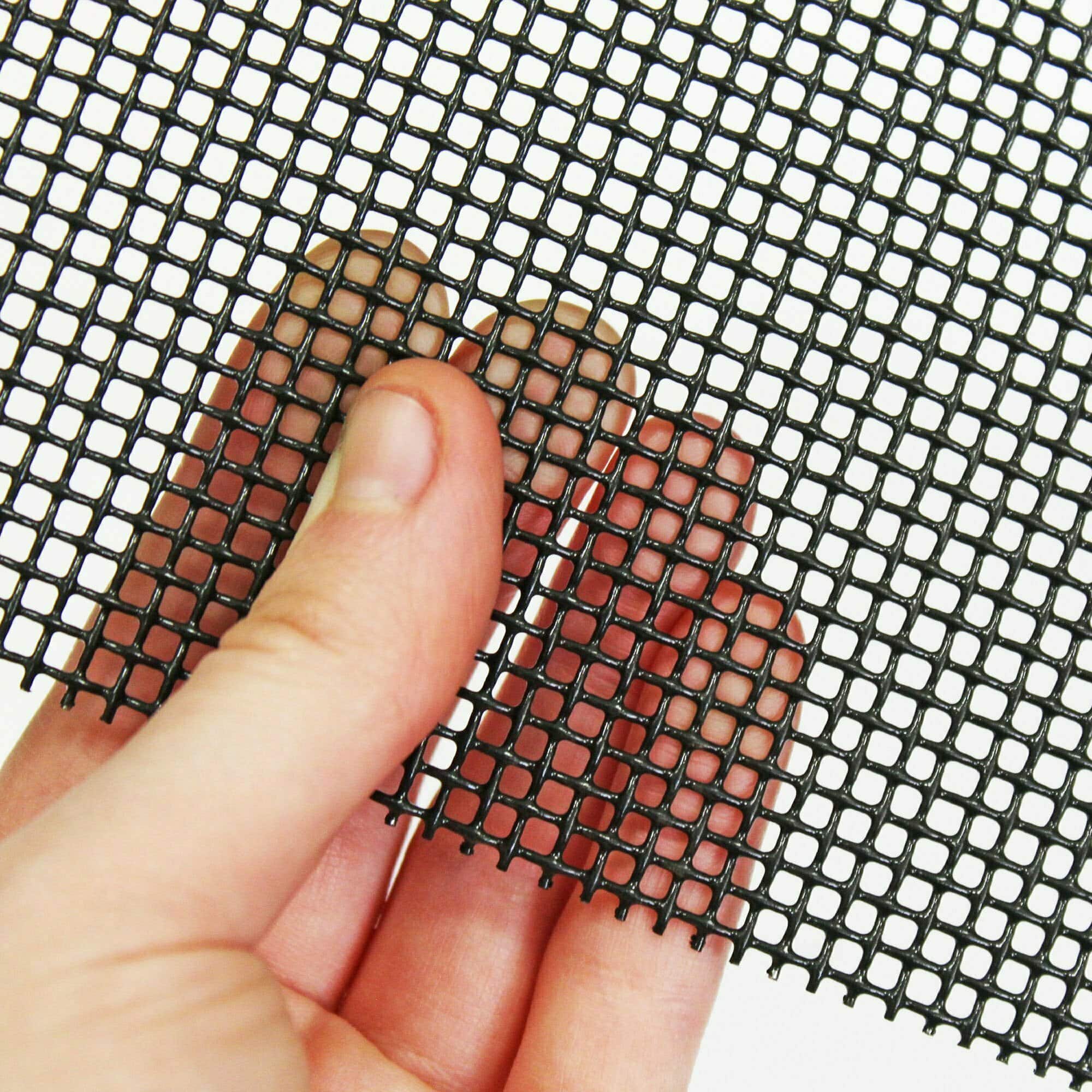

与wire screen相关的说明性图片

Practical Sourcing Guide: A Step-by-Step Checklist for ‘wire screen’

Introduction

This practical sourcing guide provides B2B buyers with a structured approach to procuring wire screens. By following this checklist, buyers can ensure they make informed decisions that align with their operational needs, budget constraints, and quality standards, ultimately leading to successful procurement outcomes.

Step 1: Define Your Technical Specifications

Before initiating your search, clearly outline the technical specifications required for your wire screen. This includes identifying the material type (e.g., stainless steel, aluminum), mesh size, wire diameter, and intended application (e.g., industrial, architectural, or safety uses). Having precise specifications helps streamline the sourcing process and ensures that you receive products that meet your operational demands.

Step 2: Research Supplier Options

Conduct thorough research to identify potential suppliers who specialize in wire screens. Utilize online directories, industry trade shows, and referrals from industry peers to compile a list. Focus on suppliers with a proven track record in your region or industry, as they are more likely to understand your specific needs and local regulations.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers that demonstrate experience with the specific type of wire screen you require, and assess their production capacity to meet your volume needs.

Step 4: Check Quality Assurance Standards

Quality assurance is vital when sourcing wire screens, as product failure can lead to significant operational issues. Ensure that suppliers adhere to international quality standards such as ISO 9001 or equivalent certifications. Additionally, inquire about their testing methods and material certifications to verify the quality and durability of their products.

与wire screen相关的说明性图片

Step 5: Request Samples for Evaluation

Before placing a large order, request samples of the wire screens you are considering. This allows you to assess the material quality, weave pattern, and overall finish firsthand. Evaluate how well the samples meet your specifications and consider conducting stress tests if applicable to ensure they can withstand your operational conditions.

Step 6: Negotiate Terms and Pricing

Once you have identified a preferred supplier, engage in negotiations to establish favorable terms. Discuss pricing, payment terms, delivery schedules, and any potential bulk purchase discounts. Ensure that all agreements are documented to avoid misunderstandings later.

Step 7: Plan for Ongoing Supplier Relationship Management

After securing your wire screen supply, establish a plan for ongoing relationship management. Regularly communicate with your supplier regarding product performance, and address any quality issues promptly. Building a strong relationship can lead to better service, pricing, and collaboration on future projects.

与wire screen相关的说明性图片

By following these steps, B2B buyers can effectively navigate the sourcing process for wire screens, ensuring they select the right products and suppliers to meet their specific business needs.

Comprehensive Cost and Pricing Analysis for wire screen Sourcing

What Are the Key Cost Components in Wire Screen Sourcing?

When sourcing wire screens, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of material significantly affects the overall cost. Options include stainless steel, aluminum, brass, and carbon steel, each with varying price points based on market demand and material properties. For instance, stainless steel generally commands a higher price due to its durability and corrosion resistance.

-

Labor: Labor costs are influenced by the complexity of the manufacturing process and the skill level required. Customizations or intricate designs necessitate skilled labor, which can increase costs.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, equipment maintenance, and indirect labor. Efficient manufacturing processes can help reduce these costs.

-

Tooling: The costs associated with manufacturing tools and molds can be significant, especially for custom wire screens. Investment in high-quality tooling can lead to better product quality and lower long-term costs.

-

Quality Control (QC): Ensuring the wire screens meet specific standards requires a robust QC process, which adds to the overall cost. Certifications (e.g., ISO) may also necessitate additional expenditures.

-

Logistics: Transportation costs vary based on distance, shipping method, and the weight of the products. Understanding Incoterms is essential for calculating these costs accurately.

-

Margin: Suppliers typically add a profit margin, which can fluctuate based on market competition and demand.

How Do Price Influencers Affect Wire Screen Costs?

Several factors can influence the pricing of wire screens, making it essential for buyers to be aware of these variables:

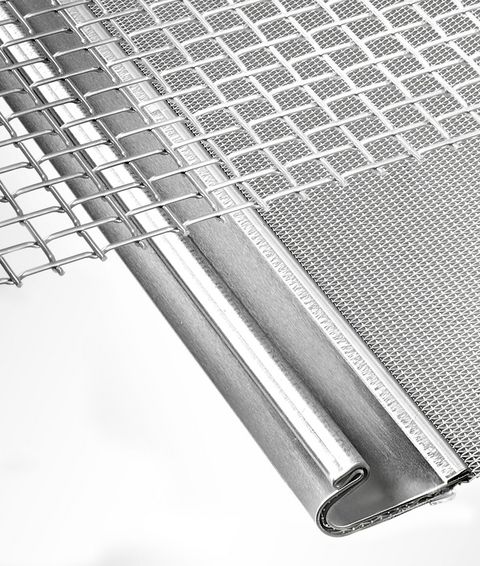

与wire screen相关的说明性图片

-

Volume/MOQ: Suppliers often offer discounts for bulk purchases. Minimum Order Quantities (MOQs) can significantly affect the price per unit, so negotiating better terms can lead to cost savings.

-

Specifications and Customization: Custom features such as specific mesh sizes, coatings, or finishes can increase costs. Clearly defining requirements upfront can help manage these expenses.

-

Materials and Quality Certifications: Higher quality materials or those with specific certifications (e.g., fire resistance) typically come at a premium. Buyers should weigh the benefits against the costs to determine the best fit for their needs.

-

Supplier Factors: Supplier reputation, production capacity, and geographic location can all impact pricing. Suppliers with a proven track record may charge more but can offer better quality and reliability.

-

Incoterms: Understanding the implications of different Incoterms (e.g., FOB, CIF) is vital as they dictate who is responsible for shipping costs and risks, affecting the overall price.

What Are the Best Buyer Tips for Cost-Efficient Wire Screen Procurement?

B2B buyers should consider the following tips to enhance cost-efficiency when sourcing wire screens:

-

Negotiation: Engaging in open discussions with suppliers can lead to better pricing, especially when placing large orders or establishing long-term partnerships. Highlighting potential future orders can incentivize suppliers to offer favorable terms.

-

Total Cost of Ownership (TCO): Buyers should evaluate not just the initial purchase price but also the long-term costs associated with installation, maintenance, and eventual replacement. A lower upfront cost may lead to higher operational expenses.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, tariffs, and import regulations that may affect pricing. Establishing relationships with local suppliers can mitigate these risks.

-

Research and Comparison: Conduct thorough research to compare prices and offerings from multiple suppliers. Leveraging online platforms can provide insights into market trends and pricing standards.

Conclusion

Sourcing wire screens requires a comprehensive understanding of the cost structure and pricing dynamics. By considering key cost components, price influencers, and employing strategic purchasing tips, international B2B buyers can navigate the complexities of wire screen procurement more effectively. Always remember that prices can vary significantly based on market conditions, and it is advisable to seek indicative pricing from multiple sources before making purchasing decisions.

Alternatives Analysis: Comparing wire screen With Other Solutions

Exploring Alternative Solutions to Wire Screens in Industrial Applications

In industrial and architectural settings, wire screens serve a range of purposes, from filtration to aesthetic enhancement. However, there are alternative solutions that may offer distinct advantages depending on specific project requirements. This analysis compares wire screens with two viable alternatives: perforated metal sheets and fiberglass mesh.

Comparison Table

| Comparison Aspect | Wire Screen | Perforated Metal Sheets | Fiberglass Mesh |

|---|---|---|---|

| Performance | High strength; versatile in various applications | Excellent airflow; customizable hole sizes | Lightweight; good for insect control |

| Cost | Moderate; varies by material | Generally higher due to manufacturing process | Low; inexpensive to produce |

| Ease of Implementation | Easy to cut and install; lightweight | Requires precision in installation; heavier | Simple installation; lightweight |

| Maintenance | Low maintenance; corrosion-resistant options available | Moderate; depends on material and finish | Low; resistant to rust and corrosion |

| Best Use Case | Architectural designs, industrial filtration | Industrial applications requiring airflow and strength | Residential and commercial insect barriers |

What Are the Pros and Cons of Perforated Metal Sheets Compared to Wire Screens?

Perforated metal sheets are an excellent alternative for applications requiring enhanced airflow while maintaining structural integrity. They can be customized to different hole sizes and patterns, making them suitable for a variety of industrial uses, including ventilation and screening. However, their cost is generally higher due to the manufacturing process, and installation can be more complex due to their weight. They also require a higher level of precision during installation, which may not be ideal for all projects.

与wire screen相关的说明性图片

How Does Fiberglass Mesh Compare to Wire Screens in Terms of Functionality?

Fiberglass mesh is a lightweight and cost-effective solution often used for insect control in residential and commercial applications. Its primary advantage lies in its resistance to rust and corrosion, making it suitable for outdoor settings. Installation is straightforward, as fiberglass mesh can be easily cut to size. However, it lacks the strength and durability of wire screens, making it less suitable for high-stress applications or environments where structural integrity is paramount.

Conclusion: How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting between wire screens and alternative solutions, B2B buyers should evaluate their specific application requirements, including performance, cost, and installation complexity. Wire screens provide versatility and strength, making them ideal for both aesthetic and industrial purposes. In contrast, perforated metal sheets excel in applications demanding airflow, while fiberglass mesh is an economical choice for insect control. By carefully considering these factors, buyers can make informed decisions that align with their project goals and operational needs.

Essential Technical Properties and Trade Terminology for wire screen

What Are the Key Technical Properties of Wire Screens That B2B Buyers Should Consider?

When selecting wire screens for industrial applications, understanding their technical properties is crucial for ensuring performance and compliance with project specifications. Here are some essential properties to consider:

1. Material Grade

Wire screens are manufactured from various materials, including stainless steel, aluminum, brass, and carbon steel. The material grade significantly impacts the screen’s durability, corrosion resistance, and overall performance. For instance, stainless steel (like grade 304 or 316) is preferred for its high resistance to rust and chemical damage, making it ideal for outdoor or corrosive environments. B2B buyers must evaluate the material grade based on the specific application and environmental conditions.

2. Wire Diameter

The wire diameter determines the strength and flexibility of the wire screen. Thicker wires (measured in gauges) can provide enhanced durability and load-bearing capacity, making them suitable for heavy-duty applications. Conversely, thinner wires may be used for applications requiring a lightweight solution. Understanding the required wire diameter is essential for ensuring that the wire screen can withstand operational demands without compromising integrity.

3. Mesh Size (Aperture)

The mesh size, or aperture, refers to the size of the openings in the wire screen. This specification is critical for applications requiring specific filtration or screening capabilities. For instance, a smaller mesh size is ideal for filtering fine particles, while a larger mesh size may be suitable for ventilation or drainage purposes. B2B buyers should assess the mesh size in relation to the intended application to ensure optimal performance.

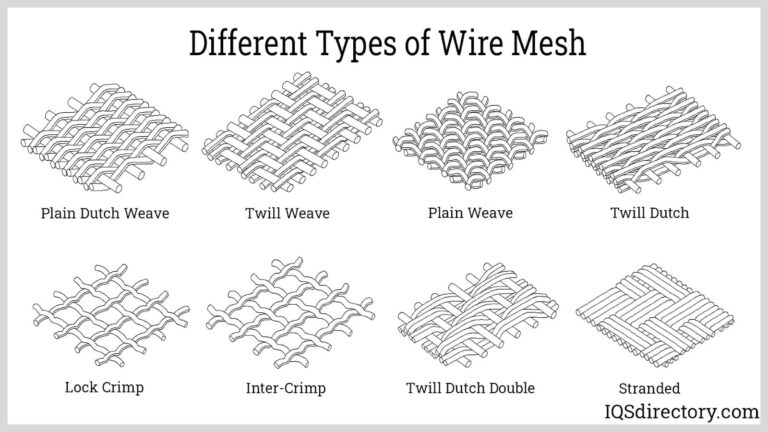

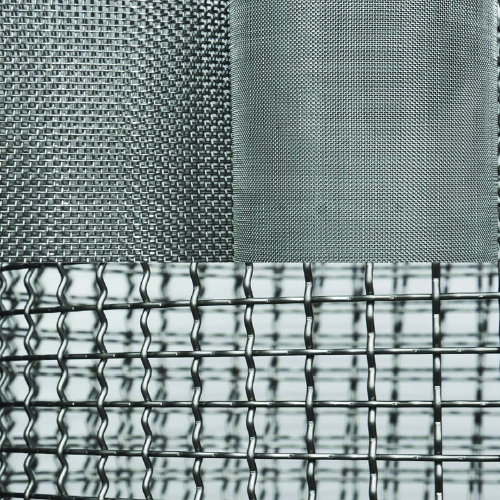

4. Weave Type

Wire screens can be woven in various patterns, such as plain weave, twill weave, or Dutch weave. Each weave type offers different characteristics in terms of strength, flexibility, and filtration capability. For example, a plain weave provides a balanced combination of strength and filtration, while a Dutch weave may offer finer filtration with increased strength. Understanding the appropriate weave type can help buyers choose the right screen for their specific needs.

5. Open Area Percentage

The open area percentage indicates the amount of free space in the screen relative to its total area. A higher open area percentage allows for greater airflow and fluid movement, making it ideal for ventilation and drainage applications. Conversely, a lower open area percentage may be necessary for filtration applications where maximum particle retention is required. B2B buyers should evaluate open area requirements based on project specifications.

与wire screen相关的说明性图片

What Are Common Trade Terms Related to Wire Screens That Buyers Should Know?

Navigating the wire screen market also involves understanding specific industry jargon. Familiarity with these terms can enhance communication and streamline purchasing processes.

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the wire screen industry, OEMs often provide customized solutions tailored to specific applications, enabling buyers to source high-quality products that meet unique requirements.

2. MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is vital for B2B buyers as it can affect inventory management and cost efficiency. Buyers should negotiate MOQs that align with their project needs and budget constraints.

3. RFQ (Request for Quotation)

An RFQ is a formal document used to solicit price quotes from suppliers. It outlines the specifications and quantities required, enabling buyers to compare offers from different vendors. Utilizing RFQs effectively can lead to better pricing and terms.

与wire screen相关的说明性图片

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs. Understanding these terms is essential for B2B buyers engaged in cross-border trade to mitigate risks and ensure compliance.

5. Lead Time

Lead time is the duration from placing an order to the delivery of the product. It is a critical factor for project planning and inventory management. B2B buyers should inquire about lead times when sourcing wire screens to ensure timely delivery and project completion.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and project specifications. This knowledge not only facilitates better purchasing outcomes but also fosters stronger supplier relationships in the global marketplace.

与wire screen相关的说明性图片

Navigating Market Dynamics and Sourcing Trends in the wire screen Sector

What Are the Key Market Dynamics and Trends in the Wire Screen Sector?

The wire screen market is experiencing significant growth driven by various global factors. One primary driver is the increasing demand for versatile applications across industries such as construction, automotive, and environmental management. Wire screens are essential for filtration, protection, and aesthetic purposes, making them invaluable in both industrial and commercial settings. For B2B buyers, particularly in Africa, South America, the Middle East, and Europe, understanding the nuances of sourcing is crucial. Emerging technologies, such as automated manufacturing processes and advanced material science, are reshaping the production landscape, leading to enhanced product quality and customization options.

Current trends indicate a shift towards lightweight and corrosion-resistant materials, with stainless steel and aluminum gaining popularity due to their durability and aesthetic appeal. Additionally, digital sourcing platforms are transforming procurement processes, allowing international buyers to access a wider array of suppliers while enabling real-time price comparisons and logistical tracking. The emphasis on local sourcing is also notable, particularly in regions like Nigeria and Germany, where reducing transportation costs and lead times is critical.

How Is Sustainability Influencing Sourcing in the Wire Screen Industry?

Sustainability has become a pivotal factor in the wire screen sector, influencing both production practices and procurement decisions. As environmental concerns grow, international buyers are increasingly prioritizing products that demonstrate minimal ecological impact. This includes sourcing from manufacturers who adhere to ethical supply chains and utilize ‘green’ materials. Certifications such as ISO 14001 (Environmental Management) and the use of recycled materials are becoming essential criteria for B2B buyers looking to align with sustainability goals.

The wire screen industry is also witnessing a push towards innovation in eco-friendly coatings and finishes that enhance durability while reducing environmental harm. For example, PVC coatings that provide weather resistance can be sourced from suppliers committed to sustainable practices. By integrating sustainability into their sourcing strategies, B2B buyers not only contribute to environmental conservation but also enhance their brand reputation and meet the growing consumer demand for responsible products.

What Is the Historical Context of Wire Screen Development?

The evolution of wire screens can be traced back to ancient civilizations that utilized woven materials for various applications, including protection and filtration. Over time, advancements in metallurgy and manufacturing processes have transformed wire screen technology, leading to the development of specialized products tailored for specific industries. The introduction of stainless steel and other corrosion-resistant materials in the mid-20th century marked a significant turning point, expanding the wire screen’s application in harsh environments.

与wire screen相关的说明性图片

Today, the wire screen sector is characterized by continuous innovation, with manufacturers exploring new materials and designs to meet the demands of a diverse market. This historical context highlights the importance of adaptability in the wire screen industry, a trait that B2B buyers should consider when evaluating suppliers and product offerings. Understanding these dynamics can aid in making informed sourcing decisions that align with both current market trends and future developments.

Frequently Asked Questions (FAQs) for B2B Buyers of wire screen

-

How do I choose the right wire screen for my application?

Selecting the appropriate wire screen depends on the specific requirements of your project, including the intended use, environmental conditions, and regulatory standards. Consider the material (e.g., stainless steel for corrosion resistance, aluminum for lightweight applications), wire diameter, mesh size, and weave type. For example, a finer mesh may be necessary for filtration applications, while a coarser mesh could be suitable for structural support. Engage with suppliers who can provide samples and technical specifications to ensure you make an informed decision. -

What are the benefits of using stainless steel wire screens?

Stainless steel wire screens offer exceptional durability, corrosion resistance, and longevity, making them ideal for demanding environments. They can withstand harsh weather conditions and resist rust, which is particularly important for outdoor applications. Additionally, stainless steel screens are easy to clean and maintain, ensuring continued performance and aesthetic appeal over time. This material is often preferred in industries such as construction, agriculture, and food processing due to its strength and hygiene properties. -

What is the typical minimum order quantity (MOQ) for wire screens?

Minimum order quantities for wire screens can vary significantly by supplier and the specific product configuration. Generally, MOQs can range from a few hundred square feet to several thousand, depending on the material and type of wire screen. It’s advisable to discuss your needs directly with suppliers, as some may be flexible with MOQs for repeat customers or larger projects. Understanding the MOQ helps in budgeting and planning your inventory effectively. -

How can I ensure the quality of wire screens from international suppliers?

To ensure quality when sourcing wire screens internationally, vet suppliers thoroughly by checking their certifications, customer reviews, and previous projects. Request samples to assess the material and craftsmanship before placing larger orders. Additionally, consider suppliers that comply with international standards such as ISO certifications. Establishing clear communication about your quality expectations and conducting inspections during production can also help mitigate risks. -

What payment terms should I expect when purchasing wire screens internationally?

Payment terms can vary widely among international suppliers but commonly include options such as advance payment, letter of credit, or payment upon delivery. It’s crucial to negotiate terms that protect your interests, especially in new relationships. Many suppliers may require a deposit upfront, particularly for custom orders. Always clarify the payment schedule, currency, and any potential fees associated with international transactions to avoid misunderstandings. -

What customization options are available for wire screens?

Many suppliers offer customization options for wire screens to meet specific project needs. Customizations may include variations in mesh size, wire gauge, coating types (such as PVC for added corrosion resistance), and dimensions tailored to your application. Discuss your requirements with potential suppliers, as they may also provide design assistance and prototypes to ensure the final product aligns with your specifications. -

How do logistics and shipping work for wire screen orders?

Logistics for wire screen orders typically involve coordination between the supplier and freight forwarders to manage shipping timelines and costs. When sourcing internationally, consider factors like shipping methods (air vs. sea), customs regulations, and delivery times. It’s advisable to work with suppliers experienced in international trade who can provide insight into the best shipping practices and help navigate any potential challenges in customs clearance. -

What are common applications for wire screens in various industries?

Wire screens are versatile and used across multiple industries, including construction, agriculture, food processing, and mining. Common applications include filtration systems, security screens, architectural elements, and insect screens. Each application may require specific mesh sizes and materials tailored to environmental conditions and regulatory compliance. Understanding your industry’s requirements can guide you in selecting the right type of wire screen for optimal performance.

Top 5 Wire Screen Manufacturers & Suppliers List

1. McNICHOLS – Wire Mesh Products

Domain: mcnichols.com

Registered: 1996 (29 years)

Introduction: This company, McNICHOLS – Wire Mesh Products, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. WireScreen – Open-Source Intelligence Platform

Domain: wirescreen.ai

Registered: 2020 (5 years)

Introduction: WireScreen is a leading software platform for open-source intelligence on Chinese corporations, providing insights into investments and relationships that influence markets, supply chains, and national security. Key features include:

– Access to comprehensive data from 50+ primary sources, including corporate filings, trade data, and regulatory disclosures, organized into a relational map of 14 mi…

3. Darby Wire Mesh – Wire Mesh and Wire Cloth Products

Domain: darbywiremesh.com

Registered: 2007 (18 years)

Introduction: Darby Wire Mesh offers a wide range of wire mesh and wire cloth products, including materials such as Aluminum, Brass, Bronze, Copper, Galvanized, Monel®, Plain Steel, T-304 Stainless Steel, T-316 Stainless Steel, and other alloys. The wire mesh is used in various applications including Fencing, Caging & Enclosures, Infill Panels, Filtration & Separation, Building & Construction, Farm, Garden & Ag…

4. McMaster – Wire Mesh Screens

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Wire Mesh Screens, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. The Western Group – Woven Wire Screens

Domain: thewesterngroup.com

Registered: 1999 (26 years)

Introduction: Woven wire screens are the most accurate method for sizing product, produced in a wide variety of sizes. Features include pre-crimped wires for accurate openings, tightly woven screens for extended wear life, and a range of tooling and local stock for timely delivery. Z-SLOT screens are available in three configurations: Standard Z-Slot (most accurate sizing), Z-Diamond (increased cleaning), and Z…

Strategic Sourcing Conclusion and Outlook for wire screen

How Can Strategic Sourcing Enhance Your Wire Screen Procurement?

In conclusion, strategic sourcing for wire screens is essential for international B2B buyers aiming to optimize their supply chains and enhance product quality. By understanding the diverse material options—ranging from stainless steel to aluminum—and their respective applications, businesses can select solutions that not only meet specific needs but also align with local regulations and environmental conditions.

The versatility of wire screens makes them suitable for various sectors, including construction, agriculture, and industrial applications. Sourcing from reputable suppliers ensures compliance with international standards, reducing risks associated with quality and safety. Furthermore, leveraging local suppliers can enhance cost-effectiveness and foster stronger partnerships within emerging markets in Africa, South America, the Middle East, and Europe.

As the market continues to evolve, it is crucial for buyers to stay informed about innovations in wire screen technology and sustainable practices. By prioritizing strategic sourcing, organizations can position themselves for future growth and resilience. We encourage you to explore your sourcing options thoroughly and engage with trusted suppliers to secure the best wire screen solutions for your business. Embrace the opportunities ahead and transform your procurement strategy today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

与wire screen相关的说明性图片

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.