A Deep Dive into Aluminum Extrusion Press Machine Solution

Introduction: Navigating the Global Market for aluminum extrusion press machine

In the fast-evolving landscape of manufacturing, sourcing an aluminum extrusion press machine can pose significant challenges for international B2B buyers. The complexity of the global market, characterized by diverse suppliers and varying technological capabilities, can make the procurement process overwhelming. This guide aims to streamline that journey, offering insights into the types of aluminum extrusion presses available, their applications across different industries, and the intricacies of supplier vetting.

By delving into essential topics such as cost considerations, operational efficiency, and maintenance requirements, this guide empowers buyers from regions like Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Nigeria—to make informed purchasing decisions. Understanding these factors not only aids in selecting the right machinery but also enhances the overall production capabilities of businesses.

With a focus on actionable insights and comprehensive analysis, this resource is designed to help you navigate the complexities of the aluminum extrusion press machine market, ensuring that your investment aligns with your operational goals and drives long-term success. Whether you are looking for cutting-edge technology or reliable used equipment, this guide serves as your roadmap to effective sourcing in a competitive global environment.

Understanding aluminum extrusion press machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Direct Extrusion Press | Utilizes a direct method to push aluminum through a die. | Structural components, automotive parts | Pros: High efficiency, cost-effective for large runs. Cons: Limited to simpler shapes. |

| Impact Extrusion Press | Applies high-speed impact force to shape aluminum. | Small, complex parts, packaging materials | Pros: High precision, suitable for intricate designs. Cons: Higher operational costs. |

| Hydrostatic Extrusion Press | Uses fluid pressure to extrude aluminum, allowing for larger profiles. | Aerospace, heavy machinery components | Pros: Versatile, can produce large and complex shapes. Cons: Higher initial investment. |

| Hot Extrusion Press | Involves heating aluminum billets before extrusion. | Automotive, architectural profiles | Pros: Improved material properties, allows for thicker sections. Cons: Requires more energy and time. |

| Cold Extrusion Press | Extrudes aluminum at room temperature for high-strength products. | Electrical conduits, fasteners | Pros: Enhanced strength, minimal waste. Cons: Limited to specific shapes and sizes. |

What Are the Key Characteristics of Direct Extrusion Presses?

Direct extrusion presses are characterized by their straightforward process of forcing heated aluminum billets through a die to create specific shapes. These machines are particularly suitable for producing structural components and automotive parts, where efficiency and cost-effectiveness are crucial. When considering a direct extrusion press, buyers should evaluate the machine’s tonnage capacity and the types of dies available, as these factors will influence production capabilities and operational costs.

How Does an Impact Extrusion Press Stand Out?

Impact extrusion presses are distinguished by their ability to apply rapid, high-force impacts to shape aluminum into small, intricate parts. This method is ideal for creating products such as packaging materials and small components used in electronics. B2B buyers should focus on the press’s speed and precision, as these features will directly affect production efficiency and product quality. However, the higher operational costs associated with impact presses may be a consideration for businesses with tighter budgets.

What Makes Hydrostatic Extrusion Presses Unique?

Hydrostatic extrusion presses utilize fluid pressure to extrude aluminum, allowing for the production of larger and more complex profiles than traditional methods. They are widely used in aerospace and heavy machinery applications, where the demands for material integrity and design complexity are high. Buyers should assess the initial investment and ongoing maintenance costs, as hydrostatic presses can be more expensive than other types. However, their versatility often justifies the expense for manufacturers needing diverse product offerings.

What Are the Advantages of Hot Extrusion Presses?

Hot extrusion presses operate by heating aluminum billets prior to extrusion, which enhances the material properties and allows for the creation of thicker sections. This method is favored in industries such as automotive and architecture, where durability and strength are paramount. When purchasing a hot extrusion press, buyers should consider energy consumption and the time required for heating, as these factors can impact overall production efficiency. The benefits of improved material characteristics often outweigh these costs.

How Do Cold Extrusion Presses Benefit Manufacturers?

Cold extrusion presses extrude aluminum at room temperature, resulting in high-strength products with minimal waste. These presses are commonly used for manufacturing electrical conduits and fasteners. B2B buyers should look into the press’s capabilities regarding the specific shapes and sizes they intend to produce, as cold extrusion is limited to certain applications. While the process can be more efficient in terms of material usage, the range of achievable designs may not be as extensive as with other extrusion methods.

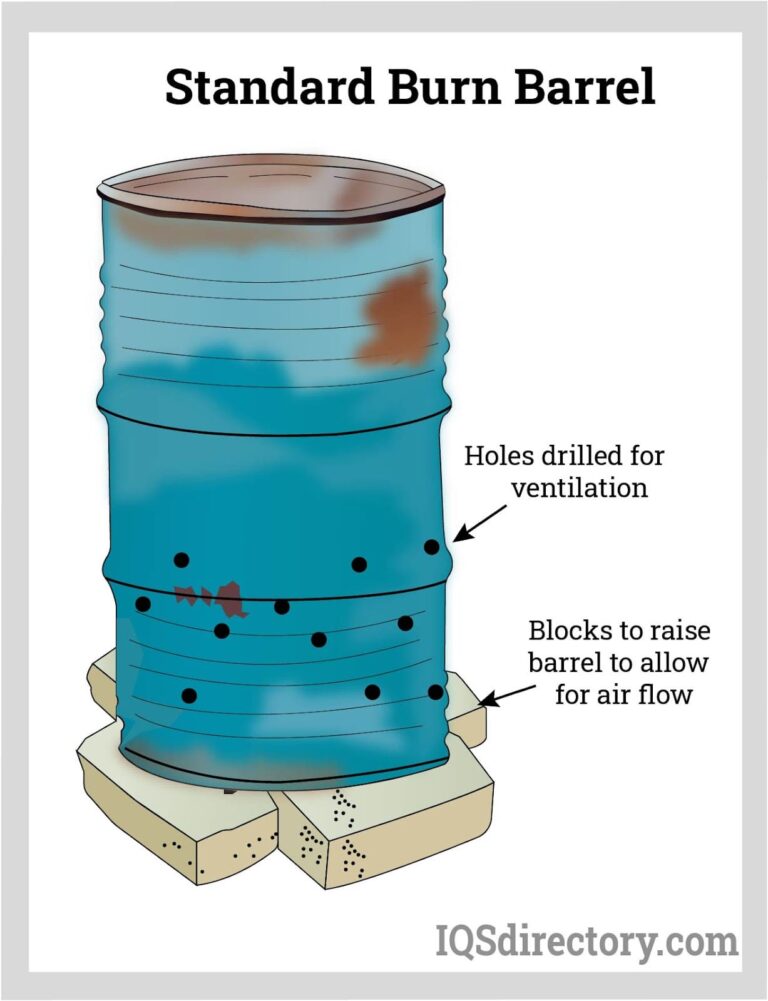

Illustrative image related to aluminum extrusion press machine

Key Industrial Applications of aluminum extrusion press machine

| Industry/Sector | Specific Application of aluminum extrusion press machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Production of lightweight structural components for vehicles | Reduces vehicle weight, enhancing fuel efficiency | Press capacity, die design, and compatibility with alloys |

| Construction | Creation of aluminum profiles for windows, doors, and facades | Provides durability and aesthetic appeal in building designs | Tonnage requirements, surface finish, and thermal properties |

| Electrical & Electronics | Manufacturing of heat sinks and enclosures for electronic devices | Improves thermal management and device longevity | Precision in extrusion dimensions and surface quality |

| Aerospace | Fabrication of aircraft components and frames | Ensures compliance with safety standards while reducing weight | Certification of equipment, material specifications, and traceability |

| Consumer Goods | Production of aluminum packaging and containers | Enhances product shelf-life and reduces environmental impact | Cost efficiency, customization options, and production speed |

How is the Aluminum Extrusion Press Machine Used in the Automotive Industry?

In the automotive sector, aluminum extrusion press machines are crucial for producing lightweight structural components such as chassis and body panels. By utilizing aluminum, manufacturers can significantly reduce vehicle weight, which improves fuel efficiency and lowers emissions. Buyers in this industry must consider the press capacity, die design, and compatibility with various aluminum alloys to meet specific automotive standards and performance requirements.

What Role Does Aluminum Extrusion Play in the Construction Industry?

Aluminum extrusion press machines are extensively used in the construction industry to create profiles for windows, doors, and facades. These extruded aluminum components provide exceptional durability and aesthetic appeal, making them ideal for modern architectural designs. For international buyers, important sourcing considerations include the required tonnage, surface finish, and thermal properties of the extrusions to ensure compliance with local building regulations and standards.

How is Aluminum Extrusion Utilized in Electrical and Electronics Manufacturing?

In the electrical and electronics sector, aluminum extrusion press machines are employed to manufacture heat sinks and enclosures for various devices. These components are essential for effective thermal management, prolonging the lifespan of electronic products. Buyers should focus on precision in extrusion dimensions and surface quality, as these factors are critical in ensuring optimal performance and reliability in electronic applications.

What is the Importance of Aluminum Extrusion in Aerospace Applications?

The aerospace industry relies on aluminum extrusion press machines to fabricate components and frames for aircraft. The lightweight nature of aluminum is vital for meeting stringent safety standards while minimizing overall aircraft weight. Buyers in this sector should prioritize sourcing equipment with proper certification, as well as ensuring that material specifications and traceability meet the high standards required for aerospace applications.

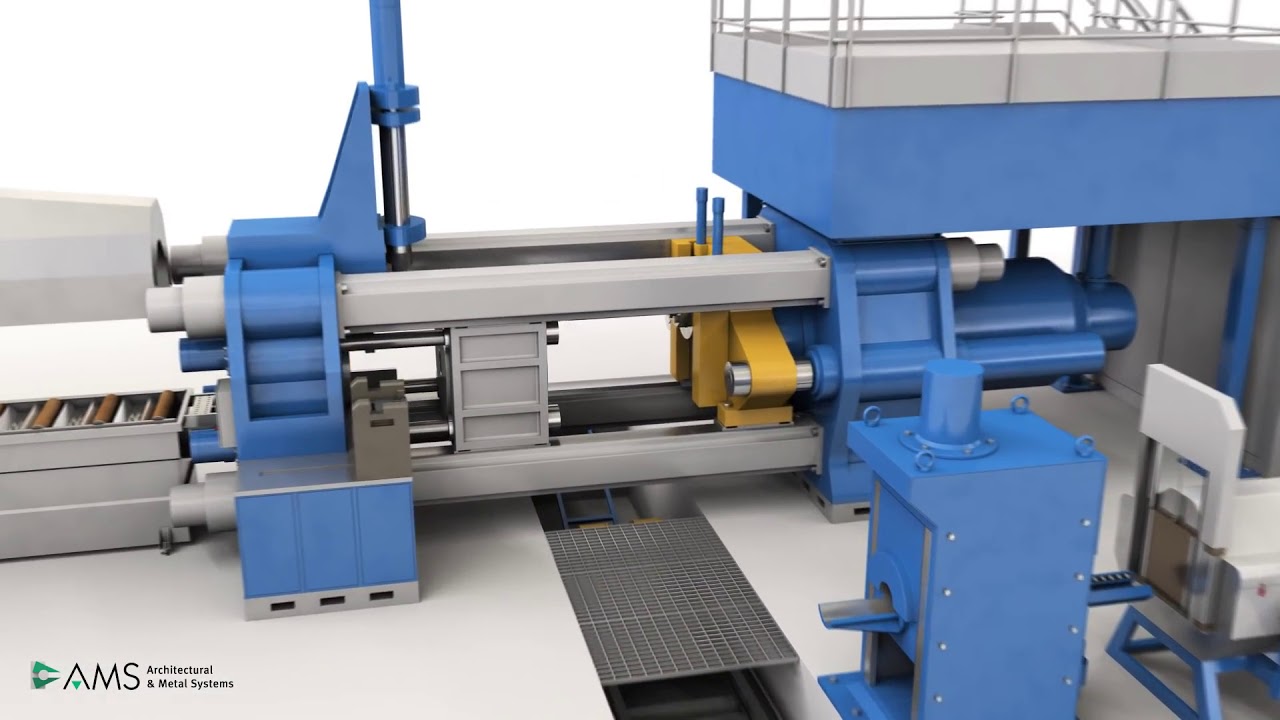

Illustrative image related to aluminum extrusion press machine

How Does Aluminum Extrusion Benefit Consumer Goods Packaging?

In the consumer goods sector, aluminum extrusion press machines are used to produce packaging and containers that enhance product shelf-life and reduce environmental impact. The lightweight and recyclable nature of aluminum make it an attractive option for manufacturers aiming for sustainability. Key considerations for sourcing include cost efficiency, customization options, and production speed, which can significantly affect the bottom line in a competitive market.

3 Common User Pain Points for ‘aluminum extrusion press machine’ & Their Solutions

Scenario 1: High Maintenance Costs and Downtime

The Problem: B2B buyers often encounter significant maintenance costs associated with aluminum extrusion press machines, particularly older models. These machines require frequent repairs and upkeep, leading to unexpected downtime that can disrupt production schedules. Buyers in regions like Africa or South America, where spare parts may not be readily available, often face extended wait times for repairs, exacerbating their operational challenges and affecting their ability to meet client demands.

The Solution: To mitigate maintenance costs and reduce downtime, buyers should prioritize sourcing newer models with advanced technology that offers improved reliability and lower maintenance requirements. When purchasing an aluminum extrusion press, consider investing in machines with predictive maintenance features, which use sensors to monitor machine performance and detect issues before they lead to failure. Additionally, establishing a partnership with local suppliers for spare parts can ensure quicker access to components, thus minimizing downtime. Regular training for operators on proper machine usage and maintenance can also prevent premature wear and tear, further reducing costs.

Scenario 2: Quality Control Issues in Extruded Products

The Problem: Many manufacturers struggle with maintaining consistent quality in their extruded aluminum products. Variability in extrusion pressure, temperature, and material quality can lead to defects such as warping, surface imperfections, and dimensional inaccuracies. This inconsistency can damage a company’s reputation and result in costly rework or scrap, especially in competitive markets across Europe and the Middle East.

The Solution: Implementing a robust quality control system is essential for maintaining product consistency. Buyers should invest in extrusion press machines equipped with advanced control systems that allow for real-time monitoring of key parameters such as temperature, pressure, and extrusion speed. Additionally, adopting a closed-loop feedback system can help automatically adjust these parameters based on real-time data, ensuring that any deviations from the desired specifications are corrected immediately. Regular training and standard operating procedures for staff on quality assurance practices can further enhance product quality, reducing the incidence of defects.

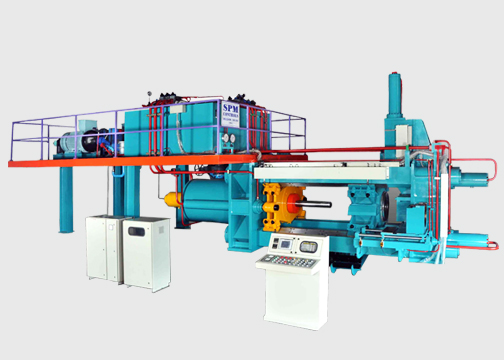

Illustrative image related to aluminum extrusion press machine

Scenario 3: Challenges in Customization and Flexibility

The Problem: As market demands evolve, manufacturers often find it challenging to adapt their aluminum extrusion processes for customized products. Buyers may be constrained by their existing extrusion press machines, which might lack the flexibility to handle varying profiles or materials. This limitation can result in missed business opportunities, especially in dynamic markets where customization is key to customer satisfaction.

The Solution: To enhance customization capabilities, buyers should look for extrusion press machines that allow for easy die changes and adjustments. Selecting machines with modular designs can facilitate quick adaptations for different profiles and materials. Additionally, investing in software that simulates the extrusion process can help in designing and testing new profiles before actual production, reducing trial and error. Collaborating closely with die manufacturers to develop specialized dies for unique applications can also ensure that the equipment remains versatile and responsive to market needs. Regularly reviewing market trends and customer feedback can guide manufacturers in anticipating changes and making necessary adjustments to their extrusion capabilities.

Strategic Material Selection Guide for aluminum extrusion press machine

What Are the Key Materials Used in Aluminum Extrusion Press Machines?

When selecting materials for aluminum extrusion press machines, it’s crucial to consider their properties, advantages, disadvantages, and how they align with specific regional requirements. The following analysis covers four common materials used in these machines: steel, aluminum alloys, brass, and composite materials.

How Does Steel Perform in Aluminum Extrusion Press Machines?

Key Properties: Steel offers high tensile strength and excellent durability, making it suitable for high-pressure applications. It can withstand elevated temperatures, typically rated for use up to 500°C, depending on the alloy.

Pros & Cons: The primary advantage of steel is its strength and longevity, which translates to a longer lifespan for machinery. However, steel is heavier and more expensive than other materials, which may increase shipping costs and installation complexity. Additionally, it has lower corrosion resistance unless treated, which can be a concern in humid or corrosive environments.

Impact on Application: Steel is compatible with various media, including hydraulic fluids and lubricants, but care must be taken to avoid corrosion from moisture or chemical exposure.

Considerations for International Buyers: Compliance with international standards such as ASTM A36 or DIN 17100 is essential. Buyers in regions like Africa and the Middle East should also consider local conditions, such as humidity and temperature, which may affect steel’s performance.

What Role Do Aluminum Alloys Play in Extrusion Press Machines?

Key Properties: Aluminum alloys are lightweight and exhibit excellent corrosion resistance, with a typical temperature rating of around 250°C. They are also highly malleable, allowing for intricate designs.

Pros & Cons: The primary advantage of aluminum alloys is their lightweight nature, which reduces operational energy costs. However, they may not withstand as much pressure as steel, making them less suitable for heavy-duty applications.

Impact on Application: Aluminum alloys are ideal for producing lightweight components, particularly in automotive and aerospace applications. Their corrosion resistance makes them suitable for environments where moisture is prevalent.

Considerations for International Buyers: Buyers should ensure that aluminum alloys meet standards such as ASTM B221 or JIS H4000. In regions like South America, where the automotive industry is growing, aluminum alloys are increasingly preferred for their lightweight properties.

How Do Brass Materials Benefit Aluminum Extrusion Press Machines?

Key Properties: Brass is known for its excellent machinability and good corrosion resistance. It can handle moderate temperatures, typically rated up to 300°C.

Pros & Cons: Brass’s main advantage is its machinability, which allows for intricate designs and components. However, it is more expensive than aluminum and steel, which can impact overall project budgets.

Impact on Application: Brass is often used in fittings and components where precision and corrosion resistance are critical. Its compatibility with various media makes it suitable for hydraulic systems.

Considerations for International Buyers: Compliance with standards such as ASTM B36 is important. Buyers in Europe may prefer brass for its aesthetic appeal in visible components, while those in Africa may consider cost-effectiveness.

What Are the Advantages of Composite Materials in Extrusion Press Machines?

Key Properties: Composite materials can be engineered for specific properties, including lightweight, high strength, and corrosion resistance. They can withstand temperatures up to 200°C.

Pros & Cons: The primary advantage of composites is their versatility and reduced weight, which can lead to lower operational costs. However, they can be more expensive and complex to manufacture, which may limit their use in some applications.

Impact on Application: Composites are often used in specialized applications where weight savings are critical, such as in aerospace components.

Considerations for International Buyers: Buyers should ensure that composite materials meet relevant international standards. In regions like the Middle East, where advanced manufacturing is growing, composites may be increasingly favored.

Summary Table of Material Selection for Aluminum Extrusion Press Machines

| Material | Typical Use Case for aluminum extrusion press machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components, frames | High strength and durability | Heavier, higher cost | High |

| Aluminum Alloys | Lightweight components, automotive parts | Lightweight, excellent corrosion resistance | Lower pressure tolerance | Medium |

| Brass | Fittings, precision components | Excellent machinability | Higher cost compared to aluminum/steel | High |

| Composite | Specialized lightweight applications | Versatile, reduced weight | More expensive, complex manufacturing | High |

This guide provides valuable insights for international B2B buyers, enabling them to make informed decisions regarding material selection for aluminum extrusion press machines based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for aluminum extrusion press machine

What Are the Key Stages in the Manufacturing Process of Aluminum Extrusion Press Machines?

The manufacturing of aluminum extrusion press machines involves several critical stages that ensure high-quality output and operational efficiency. These stages can be categorized into material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step in the manufacturing process is the careful selection and preparation of raw materials. Typically, aluminum billets of specific alloy compositions are chosen based on the intended application of the extrusion press. The billets are heated to precise temperatures to achieve optimal malleability. This heating process is crucial, as it affects the final properties of the extruded product.

-

Forming: In this stage, the heated billets are loaded into the extrusion press. The press uses hydraulic or mechanical forces to push the aluminum through a die, forming it into the desired profile. This process can involve various techniques, such as direct extrusion or indirect extrusion, each with its own advantages depending on the complexity of the profile. The forming process must be carefully controlled to minimize defects and ensure uniformity.

-

Assembly: Once the profiles are extruded, they undergo assembly, where components such as the die assembly, hydraulic systems, and control units are integrated. This stage often involves precision machining to ensure that all parts fit together seamlessly, which is critical for the performance and longevity of the extrusion press.

-

Finishing: The final stage includes surface treatments and coatings that enhance the durability and aesthetic appeal of the machine. This may involve anodizing, powder coating, or other methods to protect against corrosion and wear. Quality checks are performed to ensure that all components meet the required specifications before the machine is packaged for shipment.

What Quality Assurance Standards Are Essential for Aluminum Extrusion Press Machines?

Quality assurance (QA) is a vital aspect of manufacturing aluminum extrusion press machines. Adhering to international and industry-specific standards ensures that the machines meet safety and performance criteria.

-

International Standards: ISO 9001 is the most recognized quality management standard globally. It outlines criteria for establishing an effective quality management system (QMS). Manufacturers of aluminum extrusion presses should be ISO 9001 certified to demonstrate their commitment to quality and continuous improvement.

-

Industry-Specific Standards: Other relevant certifications may include CE marking for compliance with European safety standards, and API certifications for equipment used in the oil and gas sectors. These certifications not only enhance credibility but also facilitate market access in different regions.

-

Quality Control Checkpoints: Key checkpoints in the QA process include:

– Incoming Quality Control (IQC): Ensures that raw materials and components meet specified quality standards before production begins.

– In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to identify and rectify defects in real-time.

– Final Quality Control (FQC): A comprehensive assessment of the finished product before it is shipped. This includes functional testing and performance verification.

How Can B2B Buyers Verify Quality Control Processes?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is crucial to ensure they receive reliable and efficient machinery.

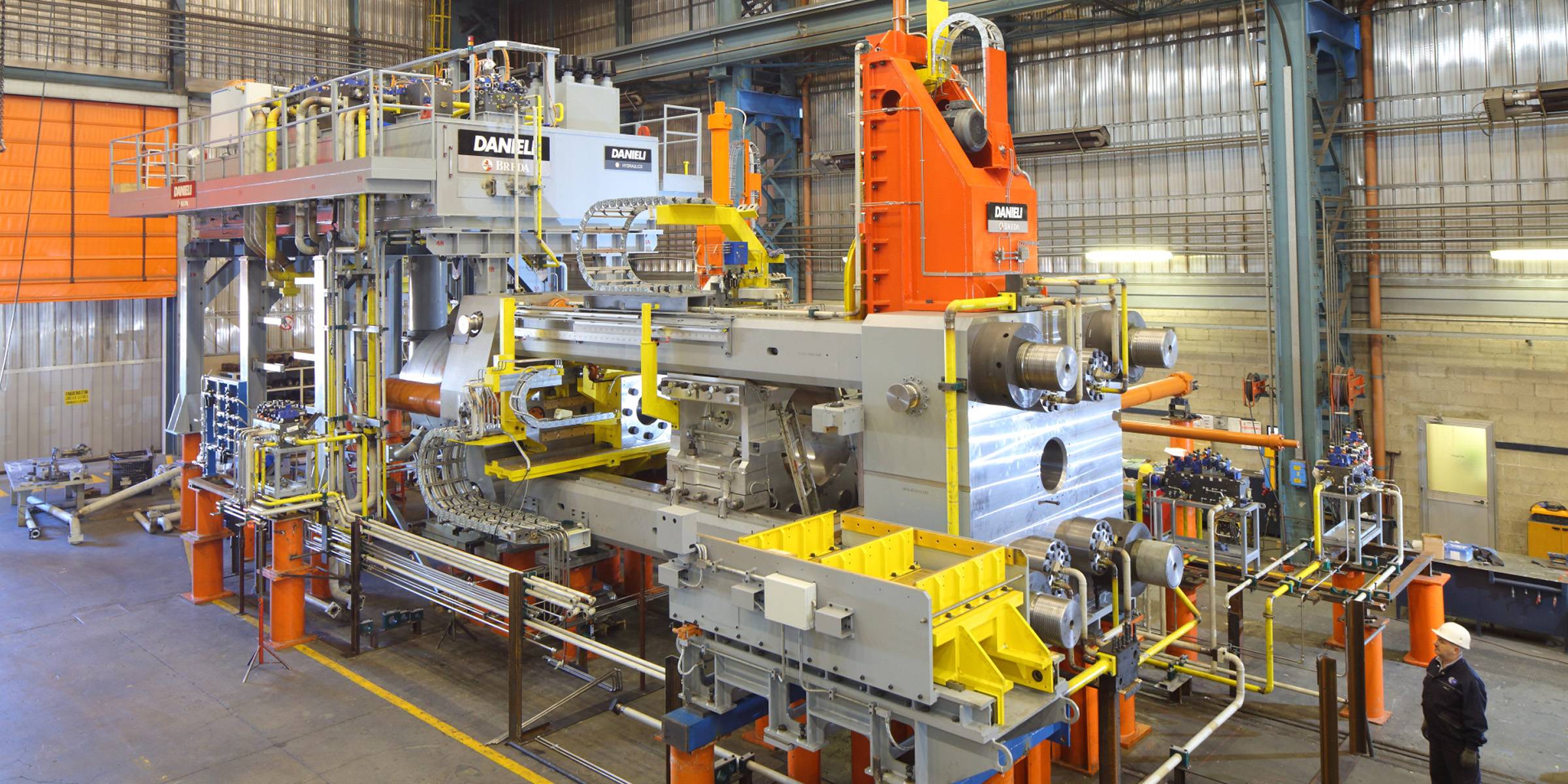

Illustrative image related to aluminum extrusion press machine

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing practices and quality control systems firsthand. This can help identify any potential gaps in compliance with international standards.

-

Quality Reports: Requesting detailed quality control reports can provide insights into the supplier’s testing methods, defect rates, and corrective actions taken in case of failures. These documents are essential for assessing the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. This is particularly important for large investments in machinery where quality assurance is paramount.

What Common Testing Methods Are Used in Quality Assurance for Aluminum Extrusion Press Machines?

The quality assurance process for aluminum extrusion press machines employs various testing methods to ensure performance and reliability. Understanding these methods can help B2B buyers make informed decisions.

-

Dimensional Inspection: This involves measuring the critical dimensions of the machine components to ensure they conform to specifications. Tools like calipers, gauges, and coordinate measuring machines (CMM) are commonly used.

-

Functional Testing: This assesses the operational capabilities of the extrusion press under normal and extreme conditions. It includes testing the hydraulic systems, controls, and overall machine performance.

-

Material Testing: Testing the properties of the materials used in the machine—such as tensile strength, hardness, and corrosion resistance—ensures that the machine can withstand operational demands and environmental factors.

-

Non-Destructive Testing (NDT): Techniques like ultrasonic testing and radiographic inspection are employed to detect internal flaws without damaging the components. This is essential for high-stakes applications where safety is a concern.

What Quality Control Nuances Should International Buyers Be Aware Of?

International buyers must navigate certain nuances in quality control and certification processes that can vary by region.

-

Regulatory Compliance: Different regions may have specific regulatory requirements that impact the manufacturing and certification of aluminum extrusion press machines. Buyers should familiarize themselves with these regulations to ensure compliance.

-

Cultural Considerations: Understanding the business culture in the supplier’s country can facilitate better communication regarding quality expectations and standards. This can help in aligning QA practices with buyer requirements.

-

Supply Chain Dynamics: Global supply chains can introduce variability in quality. Buyers should ensure that their suppliers have robust supply chain management practices in place to mitigate risks associated with material quality and consistency.

In conclusion, understanding the manufacturing processes and quality assurance protocols for aluminum extrusion press machines is essential for B2B buyers. By focusing on these key areas, buyers can ensure they select reliable suppliers who meet their quality standards and operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘aluminum extrusion press machine’

In the competitive landscape of aluminum extrusion, selecting the right press machine is critical for ensuring efficiency, quality, and cost-effectiveness in your production processes. This guide provides a structured checklist for B2B buyers to navigate the procurement process effectively.

Illustrative image related to aluminum extrusion press machine

Step 1: Define Your Technical Specifications

Before beginning your search, it’s essential to clearly outline the technical requirements of the aluminum extrusion press machine. Consider factors such as tonnage capacity, stroke length, and specific applications (e.g., profiles, tubes, or rods).

– Tonnage Capacity: Ensure the machine can handle your production volume.

– Stroke Length: Match the stroke length to the desired product dimensions.

Step 2: Research Market Trends and Innovations

Stay informed about the latest advancements in aluminum extrusion technology. Understanding current trends can help you identify features that enhance productivity, such as energy-efficient systems and automation capabilities.

– Energy Efficiency: Look for machines that minimize energy consumption without sacrificing performance.

– Automation Features: Consider machines with integrated software for monitoring and optimizing production processes.

Step 3: Evaluate Potential Suppliers

Thoroughly vet suppliers to ensure they can meet your needs and maintain quality standards. Request detailed company profiles, case studies, and references from other clients, especially those in your industry or region.

– Supplier Reputation: Investigate the supplier’s history and customer reviews to gauge reliability.

– After-Sales Support: Assess the availability of technical support, maintenance services, and warranty options.

Illustrative image related to aluminum extrusion press machine

Step 4: Request Quotes and Compare Pricing

Once you have a shortlist of potential suppliers, request formal quotations to compare pricing and terms. This step will help you understand the cost implications of different machines and configurations.

– Inclusions: Ensure quotes detail what is included (e.g., installation, training, and spare parts).

– Total Cost of Ownership: Consider not just the initial purchase price but also operational costs and potential downtime.

Step 5: Inspect Machines Before Purchase

If possible, arrange for an on-site inspection of the machines. This allows you to evaluate the condition, functionality, and compliance with your specifications firsthand.

– Testing: If feasible, request a demonstration to observe machine performance.

– Condition Assessment: Check for any signs of wear or damage that could affect operation.

Step 6: Verify Certifications and Compliance

Ensure that the machine complies with international standards and certifications relevant to your market. Compliance is crucial for safety, reliability, and regulatory acceptance.

– Quality Certifications: Look for ISO or similar quality management certifications.

– Safety Standards: Confirm compliance with safety regulations to avoid potential liabilities.

Illustrative image related to aluminum extrusion press machine

Step 7: Finalize Contract Terms

Before concluding the purchase, carefully review the contract terms. Ensure all aspects, including payment terms, delivery schedules, and service agreements, are clearly defined and acceptable.

– Negotiation Flexibility: Be prepared to negotiate terms that suit your budget and operational needs.

– Legal Review: Consider having legal counsel review the contract to safeguard your interests.

Following this checklist will help you make informed decisions when sourcing aluminum extrusion press machines, ultimately leading to enhanced production efficiency and profitability.

Comprehensive Cost and Pricing Analysis for aluminum extrusion press machine Sourcing

What are the Key Cost Components for Aluminum Extrusion Press Machines?

When sourcing aluminum extrusion press machines, understanding the cost structure is critical for informed purchasing decisions. The primary cost components include:

-

Materials: The choice of materials significantly influences the cost. High-quality steel and alloys used in machine construction can raise initial costs but enhance durability and performance. Additionally, the sourcing of aluminum billets, which are vital for extrusion, can vary in price based on market demand and geographical location.

-

Labor: Labor costs encompass both direct and indirect expenses associated with manufacturing. This includes skilled labor for assembly, welding, and quality control. It’s essential to consider the labor rates in the manufacturing country, as they can vary widely.

-

Manufacturing Overhead: This includes utilities, rent, and equipment depreciation. A well-optimized production facility can help reduce overhead costs, impacting the overall price of the machinery.

-

Tooling: Custom tooling designed for specific extrusion profiles adds to the cost. Depending on the complexity of the design, tooling can range from a minimal investment to substantial amounts, especially for bespoke solutions.

-

Quality Control (QC): Investing in rigorous quality control processes ensures the machinery meets international standards and certifications. This investment can prevent costly defects and downtime in production.

-

Logistics: Transportation costs, customs duties, and insurance are critical factors in the total cost. International shipping can be particularly complex, and understanding Incoterms is essential to avoid unexpected expenses.

-

Margin: Suppliers typically include a profit margin in their pricing. This margin can vary depending on market dynamics, competition, and the supplier’s reputation.

How Do Price Influencers Affect the Cost of Aluminum Extrusion Press Machines?

Several factors can influence the pricing of aluminum extrusion press machines:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for bulk pricing discounts. Understanding the MOQ can help buyers negotiate better rates, especially for high-volume needs.

-

Specifications and Customization: Machines with specialized features or custom specifications typically come at a premium. Buyers should clearly define their requirements to avoid paying for unnecessary features.

-

Materials and Quality Certifications: Higher-grade materials and certifications, such as ISO or CE, may increase costs but can also enhance performance and compliance with international standards.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge higher prices due to their quality assurance and service levels.

-

Incoterms: The choice of Incoterms determines the responsibilities of buyers and sellers concerning shipping, insurance, and tariffs. Understanding these terms can help buyers manage their total cost effectively.

What Buyer Tips Can Help Optimize Costs in Sourcing?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several strategies can optimize sourcing costs:

-

Negotiate Wisely: Always approach negotiations with a clear understanding of market rates and competitors’ offerings. Leverage volume commitments to negotiate better terms.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance costs, energy consumption, and potential downtime. A lower initial cost might lead to higher long-term expenses.

-

Consider Local Suppliers: Sourcing from local manufacturers can reduce logistics costs and delivery times. It can also facilitate easier communication and support.

-

Stay Informed on Market Trends: Being aware of global aluminum prices and production trends can provide leverage in negotiations and purchasing timing.

-

Request Detailed Quotations: Ensure that quotations include a breakdown of all costs. This transparency allows for better comparison and understanding of what influences the price.

Disclaimer on Indicative Prices

Prices for aluminum extrusion press machines can vary widely based on specifications, supplier, and market conditions. The figures provided in various listings may not reflect the final purchase price, which can change based on negotiation outcomes and additional costs associated with logistics and installation. Always conduct thorough due diligence and obtain multiple quotes to ensure the best purchasing decision.

Alternatives Analysis: Comparing aluminum extrusion press machine With Other Solutions

Understanding Alternatives in Aluminum Extrusion

In the realm of metalworking, particularly in the production of aluminum profiles, the aluminum extrusion press machine stands as a prominent choice. However, various alternative technologies can also achieve similar objectives, each with its unique advantages and disadvantages. This analysis will compare the aluminum extrusion press machine with two viable alternatives: the impact extrusion machine and the die casting method.

Comparison of Aluminum Extrusion Press Machine with Alternatives

| Comparison Aspect | Aluminum Extrusion Press Machine | Impact Extrusion Machine | Die Casting Method |

|---|---|---|---|

| Performance | High output for complex profiles | Excellent for small parts | High precision and surface finish |

| Cost | High initial investment | Moderate cost | Variable; can be high depending on complexity |

| Ease of Implementation | Requires significant setup and space | Easier to set up; less space needed | Complex due to mold design and setup |

| Maintenance | Regular maintenance required | Lower maintenance needs | Maintenance-intensive due to wear on molds |

| Best Use Case | Large-scale production of profiles | Small components or intricate shapes | High-volume production of detailed parts |

In-Depth Analysis of Alternatives

Impact Extrusion Machine: What Are Its Strengths and Weaknesses?

Impact extrusion machines are particularly effective for creating small, intricate components with minimal waste. They operate by forcing a metal slug into a die using a rapid impact force, allowing for high-speed production. The strengths of this method include lower material costs due to reduced scrap and the ability to produce complex geometries that might be difficult with traditional extrusion methods. However, they are less suitable for larger parts and have limitations in terms of material types, making them less versatile than aluminum extrusion presses.

Die Casting Method: Is It the Right Choice?

Die casting involves forcing molten metal into a mold under pressure, which is ideal for producing high-precision parts with excellent surface finishes. This method shines in high-volume production scenarios where speed and consistency are paramount. The primary advantage is the ability to produce complex shapes with thin walls and tight tolerances. However, the initial costs for mold creation can be significant, and the process may not be cost-effective for lower production volumes. Additionally, die casting often has limitations on the types of alloys that can be used, restricting material choice.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the appropriate manufacturing solution, B2B buyers must consider their specific production needs, including the scale of operation, type of products being manufactured, and budget constraints. While aluminum extrusion press machines are highly suitable for large-scale production of aluminum profiles, impact extrusion machines and die casting methods offer viable alternatives depending on the complexity of the parts and production volume. Conducting a thorough analysis of each technology’s strengths and weaknesses will empower buyers to make informed decisions that align with their operational goals and market demands.

Essential Technical Properties and Trade Terminology for aluminum extrusion press machine

What Are the Key Technical Properties of Aluminum Extrusion Press Machines?

When evaluating aluminum extrusion press machines, understanding their technical specifications is crucial for making informed purchasing decisions. Here are some essential properties:

Illustrative image related to aluminum extrusion press machine

-

Tonnage Capacity

Tonnage capacity refers to the maximum force the extrusion press can exert, typically measured in metric tons. For example, a 1600-ton press can handle heavy-duty applications, making it suitable for producing larger profiles or components. B2B buyers should consider their production needs; higher tonnage allows for increased productivity and the ability to work with thicker materials. -

Stroke Length

Stroke length indicates the maximum distance the ram travels during the extrusion process, usually measured in millimeters. A longer stroke length can accommodate larger dies and profiles, enhancing versatility. Buyers must assess their product range to ensure the press can meet their specific extrusion requirements. -

Material Grade

The material grade of aluminum, such as 6061 or 7075, affects the performance and characteristics of the extruded product. Different grades offer varying strength, corrosion resistance, and machinability. Understanding the required material grade helps buyers select machines capable of producing specific product qualities. -

Wall Thickness Tolerance

Tolerance specifies the allowable deviation from the desired wall thickness in the extruded profile. A tighter tolerance is crucial for applications requiring precision, such as aerospace or automotive components. Buyers should ensure the extrusion press can consistently meet these specifications to avoid costly rework or scrap. -

Production Speed (Strokes per Minute)

This metric indicates how many cycles the press can complete in one minute. Higher production speeds result in increased output, which is essential for meeting market demands. Buyers should balance speed with quality, as faster production can sometimes lead to defects if not properly managed.

Which Trade Terms Are Important in the Aluminum Extrusion Industry?

Understanding industry jargon is vital for effective communication and negotiation in the aluminum extrusion market. Here are several key terms:

-

OEM (Original Equipment Manufacturer)

An OEM produces components that are used in another company’s end product. In the context of extrusion presses, an OEM might provide parts or machines that other manufacturers use to create their products. Buyers should look for reputable OEMs to ensure quality and reliability. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units a supplier is willing to sell. This term is critical for B2B buyers as it can affect inventory levels and cash flow. Understanding the MOQ helps businesses plan their procurement strategies effectively, especially when entering new markets. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing for specific products or services. In the aluminum extrusion industry, submitting RFQs can help buyers compare prices and terms from multiple suppliers, ensuring they make cost-effective purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in shipping goods. Familiarity with terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) is essential for B2B transactions, as they clarify who is responsible for costs and risks during transport. -

Lead Time

Lead time is the time it takes from placing an order to receiving the product. This term is vital for planning production schedules and managing customer expectations. Understanding lead times helps buyers align their operations with supplier capabilities. -

Die Life

Die life refers to the duration a die can be used before it requires replacement. A longer die life means lower production costs and less downtime. Buyers should consider die life when evaluating the overall efficiency and cost-effectiveness of an extrusion press.

By grasping these technical specifications and trade terms, B2B buyers can navigate the aluminum extrusion market more effectively, ensuring they make well-informed purchasing decisions that align with their operational needs.

Navigating Market Dynamics and Sourcing Trends in the aluminum extrusion press machine Sector

What Are the Current Market Dynamics and Key Trends Influencing Aluminum Extrusion Press Machines?

The global aluminum extrusion press machine market is witnessing significant growth, driven by increasing demand across various sectors, including construction, automotive, and aerospace. Emerging economies in Africa, South America, and the Middle East are particularly active, fueled by urbanization and infrastructure development initiatives. In regions like Saudi Arabia and Nigeria, government-led investments in infrastructure are propelling the need for efficient manufacturing processes, including aluminum extrusion, which is pivotal for producing lightweight and durable materials.

Illustrative image related to aluminum extrusion press machine

Technological advancements are reshaping the industry landscape. Automation and IoT integration are becoming prominent, allowing manufacturers to enhance production efficiency and reduce operational costs. Smart extrusion presses equipped with real-time monitoring and predictive maintenance capabilities are gaining traction among B2B buyers, who are increasingly seeking machines that not only meet production needs but also offer long-term operational savings. Moreover, the trend towards customization is compelling suppliers to develop versatile machinery that can handle a variety of aluminum profiles and specifications, catering to diverse industry needs.

Furthermore, sustainability concerns are influencing sourcing trends. Buyers are increasingly favoring suppliers that adopt eco-friendly practices, such as energy-efficient machinery and sustainable sourcing of raw materials. This shift not only aligns with corporate social responsibility goals but also appeals to environmentally conscious consumers.

How Is Sustainability Shaping Ethical Sourcing in the Aluminum Extrusion Press Machine Market?

Sustainability has emerged as a cornerstone of modern manufacturing practices, particularly in the aluminum extrusion sector. The environmental impact of aluminum production, including carbon emissions and energy consumption, necessitates a shift towards more sustainable practices. B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to reducing their ecological footprint through energy-efficient processes and the use of recycled materials.

Ethical supply chains are becoming essential for businesses aiming to enhance their brand reputation and comply with regulatory requirements. Buyers should seek aluminum extrusion press machine manufacturers that hold certifications like ISO 14001 for environmental management and other ‘green’ certifications that validate their commitment to sustainability. This not only assures buyers of the quality and sustainability of their products but also positions them favorably in a market that is progressively leaning towards ethical consumption.

The use of recyclable materials in aluminum extrusion processes is another trend gaining momentum. By sourcing machines that facilitate the use of recycled aluminum, companies can significantly reduce waste and production costs while contributing to a circular economy. This not only meets customer expectations for sustainable products but also aligns with global efforts to minimize environmental impact.

Illustrative image related to aluminum extrusion press machine

What Is the Historical Context of Aluminum Extrusion Press Machines in B2B?

The aluminum extrusion press machine industry has evolved significantly since its inception in the early 20th century. Initially, extrusion processes were labor-intensive and limited in capacity. However, technological advancements have transformed the landscape, leading to the introduction of hydraulic and later, computer-controlled extrusion presses that enhanced efficiency and precision.

The 1970s and 1980s marked a significant turning point with the rise of automation, allowing for higher production rates and improved quality control. This evolution has made aluminum extrusion a vital manufacturing method for a wide array of applications, from automotive parts to architectural elements. Today, the integration of Industry 4.0 technologies is setting new benchmarks for productivity and efficiency, driving the aluminum extrusion press machine sector into a future characterized by innovation and sustainability.

In conclusion, international B2B buyers navigating the aluminum extrusion press machine market must be attuned to evolving market dynamics, prioritize sustainability in their sourcing strategies, and understand the historical context that has shaped the industry. This comprehensive approach will empower them to make informed decisions that align with both operational goals and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of aluminum extrusion press machine

-

How do I solve issues related to sourcing an aluminum extrusion press machine?

To address sourcing issues, start by clearly defining your production needs, including capacity, specifications, and budget. Research potential suppliers through industry directories and trade shows, and consider leveraging platforms that specialize in industrial machinery. Vet suppliers by checking their certifications, customer reviews, and previous projects. Establish communication to discuss your requirements and assess their responsiveness. Finally, request quotes and compare them, ensuring you understand all costs involved, including shipping and installation. -

What is the best aluminum extrusion press machine for my specific production needs?

The ideal aluminum extrusion press machine depends on your production volume, the type of aluminum products you intend to manufacture, and your budget. For high-volume production, consider a hydraulic or direct extrusion press with higher tonnage capacity. If flexibility is key, look for models that allow for easy die changes. Additionally, assess the machine’s compatibility with the specific grades of aluminum you plan to use, as this can impact the quality of your final products. -

What should I consider when vetting suppliers of aluminum extrusion press machines?

When vetting suppliers, evaluate their experience and reputation in the industry. Check for certifications like ISO and compliance with international standards. Request references from previous clients to gauge their reliability and customer service. Investigate their manufacturing capabilities, delivery timelines, and after-sales support. Additionally, consider their geographical location; a supplier closer to your operation may reduce shipping costs and lead times. -

What are the typical minimum order quantities (MOQs) for aluminum extrusion press machines?

MOQs for aluminum extrusion press machines vary widely based on the supplier and the specific machine type. While some suppliers may offer single units, others may require orders of multiple machines, especially for custom models. It’s advisable to discuss your production needs upfront with suppliers to negotiate MOQs that align with your business objectives. Consider potential bulk purchasing discounts if you anticipate future needs. -

What payment terms should I expect when purchasing an aluminum extrusion press machine?

Payment terms for purchasing aluminum extrusion press machines typically include a deposit upfront, often ranging from 20% to 50%, with the balance due upon delivery or installation. Some suppliers may offer financing options or extended payment plans for larger purchases. Always clarify payment methods accepted, such as bank transfers or letters of credit, and ensure that terms are documented in your contract to avoid disputes. -

How can I ensure quality assurance for my aluminum extrusion press machine?

To ensure quality assurance, request detailed product specifications and certifications from suppliers. Inquire about their quality control processes, including testing procedures for the machines. If possible, arrange for a factory visit to observe production practices and inspect machines before shipment. Consider hiring a third-party inspection service to assess the machine’s quality and performance before final acceptance, especially for international transactions. -

What logistics considerations should I keep in mind when importing an aluminum extrusion press machine?

Logistics considerations include understanding shipping options, customs regulations, and tariffs applicable to your region. Coordinate with your supplier to determine the best shipping method—air freight for speed or sea freight for cost-effectiveness. Ensure you have a reliable freight forwarder to handle the logistics and paperwork. Additionally, plan for installation and commissioning upon arrival, which may require skilled technicians and specific equipment. -

What customization options are available for aluminum extrusion press machines?

Customization options for aluminum extrusion press machines can include modifications to tonnage capacity, stroke length, and die designs to meet specific production requirements. Suppliers often offer tailored solutions based on your unique applications, including specialized features like enhanced cooling systems or automated controls. Discuss your requirements with potential suppliers early in the process to ensure they can accommodate your customization needs effectively.

Top 5 Aluminum Extrusion Press Machine Manufacturers & Suppliers List

1. Cowell – CWT75 Twin Screw

Domain: machinetools.com

Registered: 1995 (30 years)

Introduction: Extrusion Presses for sale listings include various models and specifications. Key details extracted are as follows: 1. COWELL CWT75 TWIN SCREW: 71 MM, Year: 2023, Location: United States. 2. FIELDING 1600 TON DIRECT EXTRUSION PRESS: 1600 Ton, Year: 1977, Location: United States. 3. FIELDING & PLATT 1600MTON ALUMINUM EXTRUSION LINE: Year: 1977, Decommissioned 2013, Location: United States. 4. HERL…

2. YUEN-SUN MACHINERY CO., LTD. – Aluminum Extrusion Machine

Domain: aluminum-extrusion-machine.com

Registered: 2010 (15 years)

Introduction: {“products”: [{“name”: “Aluminum Extrusion Machine”, “type”: “Extrusion Press Machine”, “manufacturer”: “YUEN-SUN MACHINERY CO., LTD.”, “location”: “Taiwan”, “features”: “High class manufacturing, adherence to international standards”}, {“name”: “Stretching Machine SWM-03”, “pulling_force”: “15US TON~230US TON”, “straightening_length”: “3M-50M”, “straightening_stroke”: “700mm~1200mm”, “opening_of_…

3. UBE Machinery – Extrusion Presses

Domain: ubemachinery.com

Registered: 1997 (28 years)

Introduction: UBE Machinery offers a range of extrusion presses, providing 24/7 support from facilities in Ann Arbor, Michigan, and Itasca, Illinois. The product lineup includes various types of machinery, although specific models or features of the extrusion presses are not detailed in the provided text.

4. Aluminum Extrusion Machine – DIY Builds & Small Scale Solutions

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Aluminum extrusion making machine; interest in DIY builds; potential combination with small scale foundry to melt scrap aluminum; examples of large scale aluminum recycling; price range for industrial versions: $60-$100k; inquiry about small scale metal extruders for rods or extrusion bars; challenges include high pressures and die manufacturing.

5. Macrodyne – Hydraulic Extrusion and Vertical Presses

Domain: macrodynepress.com

Registered: 1998 (27 years)

Introduction: Macrodyne manufactures hydraulic extrusion and vertical presses for hot and cold extrusion applications for a wide range of profiles in ferrous and non-ferrous materials, including several grades of steel, aluminum, copper, zirconium, and more. Key specifications include: Bed Size options of 42″ x 42″, 38″ x 36″, and 48″ x 48″; Daylight options of 152″, 7″, and 80″; Stroke options of 105″, 40″, an…

Strategic Sourcing Conclusion and Outlook for aluminum extrusion press machine

In the rapidly evolving landscape of aluminum extrusion, strategic sourcing remains crucial for international B2B buyers looking to enhance operational efficiency and product quality. By carefully evaluating suppliers and leveraging global networks, companies in Africa, South America, the Middle East, and Europe can access cutting-edge aluminum extrusion press machines that meet their unique requirements. The diversity in machinery—from high-capacity presses to specialized equipment—offers significant opportunities for customization and innovation.

Investing in advanced extrusion technology not only improves production capabilities but also supports sustainability initiatives, a growing priority across industries. As manufacturers prioritize eco-friendly practices, sourcing energy-efficient machines can lead to reduced operational costs and enhanced brand reputation.

Illustrative image related to aluminum extrusion press machine

Looking ahead, the aluminum extrusion market presents numerous growth opportunities. Buyers are encouraged to stay informed about technological advancements and market trends to make strategic decisions that align with their long-term goals. Engaging with reputable suppliers and exploring diverse options will be key to driving success in an increasingly competitive global market. Take the next step in your sourcing journey and unlock the potential of aluminum extrusion technology to elevate your business.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to aluminum extrusion press machine

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.