In Line Water Chiller Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for in line water chiller

In an increasingly competitive global market, sourcing reliable in-line water chillers can pose a significant challenge for B2B buyers, particularly those operating across diverse climates and regulatory environments in regions such as Africa, South America, the Middle East, and Europe. These essential cooling systems play a crucial role in various applications, from enhancing the quality of drinking water to supporting industrial processes. However, navigating the myriad of options available—from compact under-sink models to robust industrial chillers—requires a strategic approach.

This comprehensive guide delves into the various types of in-line water chillers, their applications, and essential factors to consider when sourcing these products. It covers critical elements such as supplier vetting processes, cost considerations, and performance specifications, ensuring that international buyers are well-equipped to make informed purchasing decisions. By understanding the nuances of the market, buyers can better align their needs with the right solutions, ultimately leading to improved operational efficiency and customer satisfaction.

Whether you are a small business in South America seeking to enhance your beverage offerings or a large-scale manufacturer in Germany looking to optimize production processes, this guide serves as a valuable resource. It empowers you with the insights needed to navigate the complexities of sourcing in-line water chillers, ensuring you find the best fit for your unique requirements.

Understanding in line water chiller Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Under-Sink Water Chiller | Compact design, adjustable thermostat, easy installation | Residential kitchens, small offices | Pros: Space-saving, easy access to chilled water. Cons: Limited cooling capacity. |

| Air-Cooled Water Chiller | Uses ambient air for cooling, requires ventilation | Industrial settings, large facilities | Pros: High efficiency, lower operational costs. Cons: Dependent on ambient temperature. |

| Water-Cooled Chiller | Utilizes water for heat exchange, requires plumbing | Commercial kitchens, laboratories | Pros: Consistent cooling performance. Cons: Higher installation complexity and cost. |

| Inline Chiller for Aquariums | Specialized for aquatic environments, saltwater compatible | Aquaculture, research institutions | Pros: Precise temperature control for aquatic species. Cons: Niche application, may be costly. |

| Remote Water Chiller | Dispenses chilled water from a distance, ideal for large setups | Large commercial spaces, events | Pros: Flexibility in installation, high output capacity. Cons: Requires more space for installation. |

What are the Characteristics of Under-Sink Water Chillers?

Under-sink water chillers are designed for compact spaces, making them ideal for residential kitchens and small offices. They typically feature adjustable thermostats to control water temperature and are compatible with reverse osmosis systems. B2B buyers should consider their limited cooling capacity and the ease of installation, which allows for immediate access to chilled water, enhancing the user experience in environments where space is at a premium.

Illustrative image related to in line water chiller

How Do Air-Cooled Water Chillers Function in Industrial Settings?

Air-cooled water chillers utilize ambient air to dissipate heat, making them suitable for industrial applications and large facilities. They are recognized for their high efficiency and lower operational costs, as they do not require extensive plumbing. However, B2B buyers must account for their dependence on ambient temperature, which can impact performance. Choosing an air-cooled option is beneficial for businesses seeking reliable cooling solutions without the complexity of water lines.

What Makes Water-Cooled Chillers Ideal for Commercial Kitchens?

Water-cooled chillers are designed to provide consistent cooling performance, using water for heat exchange. They are commonly used in commercial kitchens and laboratories where precise temperature control is critical. While they offer superior performance, buyers should be aware of the higher installation complexity and costs associated with plumbing requirements. These chillers are ideal for businesses that prioritize efficiency and reliability in their cooling systems.

Why are Inline Chillers Essential for Aquaculture?

Inline chillers specifically designed for aquariums and aquaculture environments provide precise temperature control crucial for maintaining the health of aquatic species. They are often compatible with both freshwater and saltwater systems. B2B buyers in this sector should consider the niche application and potential costs involved, as these units are specialized for specific needs. The precision of temperature management can significantly impact the success of aquaculture operations.

How Do Remote Water Chillers Benefit Large Commercial Spaces?

Remote water chillers are capable of dispensing chilled water from a distance, making them ideal for large commercial spaces and events. They offer flexibility in installation and can handle high output capacities, which is essential for high-demand environments. However, businesses should consider the additional space required for installation and the potential for increased operational costs. Remote chillers are a strong choice for businesses looking to provide efficient and accessible chilled water solutions across expansive areas.

Key Industrial Applications of in line water chiller

| Industry/Sector | Specific Application of in line water chiller | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Cooling systems for beverage dispensing | Ensures consistent beverage quality and taste | Energy efficiency, capacity for high demand, and reliability |

| Aquaculture | Temperature control for fish breeding tanks | Maintains optimal water temperatures for fish health | Compatibility with existing systems, maintenance requirements |

| Pharmaceutical Manufacturing | Cooling for laboratory processes and storage | Preserves product integrity and enhances safety | Precision in temperature control, compliance with regulations |

| HVAC Systems | Chilled water supply for air conditioning systems | Improves energy efficiency and reduces operational costs | Size, cooling capacity, and integration with HVAC systems |

| Industrial Processing | Cooling for machinery and equipment in production lines | Reduces overheating risks and extends equipment life | Durability, ease of installation, and maintenance support |

How is an In-Line Water Chiller Used in the Food and Beverage Industry?

In the food and beverage sector, in-line water chillers are integral for cooling systems that dispense beverages, ensuring they are served at the ideal temperature. This application is crucial for maintaining product quality and enhancing customer satisfaction. Buyers in this industry should prioritize energy-efficient chillers with a capacity to handle high demand, as well as reliability to minimize downtime. Sourcing chillers that are compatible with existing systems and have a proven track record in similar applications can significantly benefit operations.

Why are In-Line Water Chillers Essential for Aquaculture?

Aquaculture relies heavily on maintaining optimal water temperatures in breeding tanks to promote fish health and growth. In-line water chillers are used to regulate water temperature, preventing stress on aquatic species and enhancing breeding success rates. International buyers, particularly from regions with varying climatic conditions, should consider chillers that can operate efficiently in local environments and are easy to integrate with existing systems. Regular maintenance and compatibility with specific water types are also critical factors.

Illustrative image related to in line water chiller

How Do In-Line Water Chillers Support Pharmaceutical Manufacturing?

In pharmaceutical manufacturing, in-line water chillers are vital for cooling laboratory processes and ensuring the safe storage of temperature-sensitive products. These chillers help maintain strict temperature controls that are essential for product integrity and compliance with safety regulations. Buyers should seek chillers that offer precise temperature control, robust construction, and compliance with industry standards. Additionally, sourcing from manufacturers with a strong support network can enhance operational efficiency.

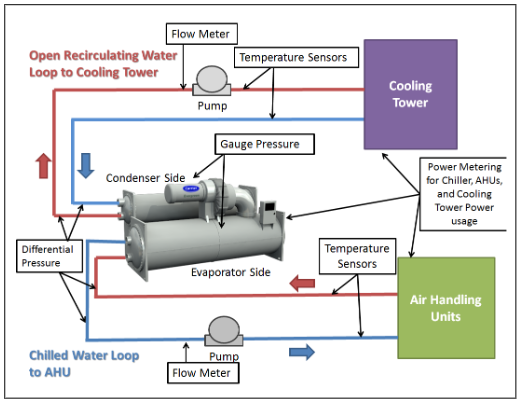

What Role Do In-Line Water Chillers Play in HVAC Systems?

In HVAC systems, in-line water chillers provide chilled water for air conditioning units, improving overall energy efficiency and reducing operational costs. These chillers facilitate effective temperature regulation, making them essential for large commercial and industrial buildings. Buyers should consider the size and cooling capacity of chillers to ensure they meet the specific demands of their HVAC systems. Additionally, ease of integration and maintenance support are crucial for long-term performance.

How are In-Line Water Chillers Used in Industrial Processing?

In industrial processing, in-line water chillers are employed to cool machinery and equipment, preventing overheating and extending the lifespan of critical components. This application is particularly important in high-demand production environments where equipment failure can lead to significant downtime. Buyers should prioritize durability and ease of installation in their sourcing decisions, along with the availability of maintenance services. Understanding the specific cooling requirements of their operations will also guide effective purchasing decisions.

3 Common User Pain Points for ‘in line water chiller’ & Their Solutions

Scenario 1: Insufficient Cooling Capacity for High Demand

The Problem: Many businesses, particularly in the food and beverage industry, require a consistent supply of chilled water to meet high customer demand. A common challenge arises when an in-line water chiller is unable to deliver the desired temperature or volume of water, especially during peak hours. This can lead to customer dissatisfaction, wasted operational time, and increased stress on staff who must manage the situation.

Illustrative image related to in line water chiller

The Solution: To ensure your in-line water chiller meets demand, it’s crucial to accurately assess your cooling needs before purchase. Start by calculating the peak water consumption rates in your facility and select a chiller with a capacity that exceeds this demand. Look for units with adjustable thermostats and efficient compressors that can handle varying loads without compromising performance. Additionally, consider investing in a chiller with built-in monitoring systems that alert you to performance issues before they affect service delivery. Regular maintenance checks will also help ensure optimal operation, allowing your chiller to perform efficiently even during high-demand periods.

Scenario 2: Complexity in Installation and Maintenance

The Problem: Installation and maintenance of in-line water chillers can be daunting, especially for businesses lacking technical expertise. Improper installation can lead to leaks, inefficiencies, and even system failures. Furthermore, complex maintenance procedures can deter staff from performing regular upkeep, resulting in decreased performance and potential downtime.

The Solution: When sourcing an in-line water chiller, prioritize models that come with user-friendly installation guides and robust customer support. Opt for systems with quick-connect fittings that simplify the setup process and minimize the need for extensive plumbing work. Additionally, consider partnering with a reliable supplier who offers installation services or technical assistance. For ongoing maintenance, develop a straightforward schedule that includes routine checks of key components like filters and compressors. Training staff on basic troubleshooting can also empower them to address minor issues promptly, reducing the risk of costly repairs.

Scenario 3: Compatibility Issues with Existing Systems

The Problem: B2B buyers often face challenges when integrating a new in-line water chiller with their existing water filtration or distribution systems. Incompatibilities can arise from differences in pressure requirements, plumbing configurations, or even electrical specifications, leading to inefficiencies or outright failures.

The Solution: To avoid compatibility issues, conduct a thorough assessment of your current systems before purchasing an in-line water chiller. Identify the specifications of your existing setup, including water pressure and electrical requirements, and match these with the chiller’s capabilities. Look for chillers that are designed for universal compatibility or those that explicitly state their adaptability to various systems. Engaging with suppliers who can provide tailored recommendations based on your setup will be invaluable. Consider scheduling a site visit with a technical expert who can evaluate your system and recommend the best chiller that integrates seamlessly with your existing infrastructure. This proactive approach will save time and resources in the long run, ensuring a smooth transition and consistent performance.

Strategic Material Selection Guide for in line water chiller

What Are the Key Materials Used in In-Line Water Chillers?

In-line water chillers are critical components in various applications, from residential settings to industrial processes. The choice of materials used in their construction significantly affects performance, durability, and compliance with international standards. Here, we analyze four common materials: stainless steel, copper, plastic (polypropylene), and aluminum.

Illustrative image related to in line water chiller

How Does Stainless Steel Benefit In-Line Water Chillers?

Stainless steel is widely regarded for its exceptional corrosion resistance, making it ideal for environments where moisture and temperature fluctuations are prevalent. Its ability to withstand high pressures and temperatures (often rated up to 150 psi) ensures reliability in cooling applications.

Pros: Stainless steel is durable, resistant to rust and staining, and can handle high-temperature applications. It is also easy to clean, which is crucial for maintaining hygiene in drinking water systems.

Cons: The primary downside is its cost, which is higher than other materials. Manufacturing complexities can also arise due to the need for specialized welding techniques.

Impact on Application: Stainless steel is compatible with a wide range of fluids, including potable water, making it suitable for both residential and commercial applications.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with standards such as EN 10088 for stainless steel grades, while those in Africa and South America may need to consider local certifications.

Why Choose Copper for In-Line Water Chillers?

Copper is another popular material, known for its excellent thermal conductivity, which allows for efficient heat exchange. It can typically handle pressures up to 100 psi and is often used in systems requiring rapid cooling.

Pros: Copper’s high thermal conductivity translates to lower energy costs and faster cooling times. It is also naturally antimicrobial, reducing the risk of bacterial growth.

Cons: However, copper is susceptible to corrosion, especially in acidic or alkaline environments. This limits its applicability in certain water types and can lead to increased maintenance costs.

Illustrative image related to in line water chiller

Impact on Application: Copper is best suited for applications where rapid cooling is essential, such as in commercial kitchens or laboratories.

Considerations for International Buyers: Compliance with ASTM B280 for copper tubing is crucial, particularly in regions like Germany, where stringent standards are enforced.

What Are the Advantages of Using Plastic (Polypropylene)?

Plastic materials, particularly polypropylene, are increasingly used in in-line water chillers due to their lightweight nature and resistance to corrosion.

Pros: Polypropylene is cost-effective and easy to manufacture, allowing for flexible designs. It also resists a wide range of chemicals, making it suitable for various applications.

Cons: While it is durable, polypropylene has lower temperature and pressure ratings compared to metals, typically around 70 psi and 140°F. This limits its use in high-demand scenarios.

Impact on Application: It is ideal for chilled water applications where the water quality is not compromised, such as in residential settings.

Considerations for International Buyers: Buyers should verify compliance with standards like ASTM D4101 for polypropylene, especially in regions with strict regulations.

How Does Aluminum Compare in In-Line Water Chillers?

Aluminum offers a balance between weight and strength, making it a viable option for in-line water chillers. Its thermal conductivity is also commendable, though not as high as copper.

Pros: Aluminum is lightweight, resistant to corrosion with proper coatings, and generally less expensive than stainless steel.

Illustrative image related to in line water chiller

Cons: It has lower pressure ratings (typically around 60 psi) and can be prone to pitting corrosion in certain water conditions.

Impact on Application: Aluminum is suitable for applications where weight is a concern, such as portable chillers, but may not be ideal for high-pressure systems.

Considerations for International Buyers: Compliance with standards like ASTM B221 for aluminum extrusions is essential, particularly for buyers in Europe and North America.

Illustrative image related to in line water chiller

Summary Table of Material Selection for In-Line Water Chillers

| Material | Typical Use Case for in line water chiller | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Residential and commercial applications | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Copper | Commercial kitchens, laboratories | High thermal conductivity | Susceptible to corrosion | Medium |

| Plastic (Polypropylene) | Residential settings | Cost-effective and lightweight | Lower temperature and pressure ratings | Low |

| Aluminum | Portable chillers | Lightweight and corrosion-resistant | Lower pressure ratings | Medium |

This material selection guide provides actionable insights for B2B buyers, enabling informed decisions that align with their specific operational needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for in line water chiller

What Are the Main Stages of Manufacturing Processes for In-Line Water Chillers?

The manufacturing of in-line water chillers involves several critical stages that ensure the final product meets the required performance, efficiency, and safety standards. Understanding these stages can provide B2B buyers with insights into product quality and reliability.

Material Preparation: What Materials Are Used in In-Line Water Chillers?

The first stage in the manufacturing process is material preparation. High-quality materials are essential for the durability and efficiency of water chillers. Common materials include stainless steel for the tank and internal components, which offer corrosion resistance and longevity. Copper is often used for tubing due to its excellent thermal conductivity, while various plastics may be employed for insulation and housing components.

Quality assurance starts at this stage, as suppliers must provide certifications proving that materials meet specific standards. Buyers should inquire about the sourcing and certification of materials to ensure compliance with international quality standards.

How Are In-Line Water Chillers Formed?

Once materials are prepared, the next step is forming. This involves cutting, bending, and shaping materials into the necessary components for the chiller. Advanced techniques such as CNC machining and laser cutting are commonly used to achieve precise dimensions, ensuring that parts fit together seamlessly during assembly.

Illustrative image related to in line water chiller

For components that require welding, like the stainless steel tank, automated welding machines may be utilized to maintain consistency and strength in joints. Buyers should be aware of the manufacturing techniques used, as precision in this stage directly affects the chiller’s performance and energy efficiency.

What Does the Assembly Process Involve for Water Chillers?

After forming, the assembly process begins. This stage typically includes the integration of various components such as the compressor, evaporator, and thermostat. Assembly is usually performed in a clean, controlled environment to minimize contamination.

Quality checks during assembly, known as In-Process Quality Control (IPQC), are crucial. These checks involve inspecting each component for defects and ensuring that assembly procedures are followed meticulously. Buyers should seek suppliers that maintain thorough documentation of assembly processes and have clear protocols for addressing any issues that arise.

How Is the Finishing Process Completed?

The final stage in the manufacturing process is finishing, which includes surface treatments, painting, and final assembly of all components. Surface treatments like powder coating or anodizing are often applied to enhance corrosion resistance and aesthetics.

Moreover, finishing includes final inspections, where the product undergoes rigorous testing for leaks, thermal performance, and overall functionality. Buyers should ensure that suppliers conduct these tests and provide detailed reports on the outcomes.

Illustrative image related to in line water chiller

What Quality Assurance Practices Are Essential for In-Line Water Chillers?

Quality assurance is paramount in the manufacturing of in-line water chillers, ensuring that products meet both regulatory and customer expectations. Several international and industry-specific standards guide these practices.

Which International Standards Should Buyers Be Aware Of?

In-line water chillers should comply with international standards such as ISO 9001, which focuses on quality management systems, and CE marking, which indicates compliance with European health, safety, and environmental protection standards. Additionally, industry-specific certifications like API (American Petroleum Institute) may apply depending on the intended use of the chiller.

B2B buyers should verify that suppliers possess these certifications and understand the implications of compliance on product reliability and safety.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control is typically structured around several checkpoints:

-

Incoming Quality Control (IQC): This involves inspecting raw materials and components upon delivery to ensure they meet specifications.

-

In-Process Quality Control (IPQC): Conducted during the manufacturing process, this includes checks at various stages to catch defects early.

-

Final Quality Control (FQC): This is the last line of defense, where finished products undergo comprehensive testing before shipping.

Buyers should inquire about the frequency and rigor of these checkpoints to gauge the overall quality assurance process.

What Common Testing Methods Are Used for Water Chillers?

Testing methods for in-line water chillers often include:

- Pressure Testing: To ensure the unit can withstand operational pressures without leaking.

- Thermal Performance Testing: To verify that the chiller meets the specified cooling capacities.

- Noise Level Testing: Important for residential applications, where quiet operation is often a requirement.

Buyers can request test reports and certifications that detail the testing methods used, ensuring transparency and reliability.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure a reliable supply chain, B2B buyers must actively verify the quality control processes of their suppliers. This can be achieved through several approaches:

What Are Effective Methods for Auditing Suppliers?

-

Supplier Audits: Conducting on-site audits allows buyers to assess manufacturing facilities, quality control practices, and compliance with standards firsthand.

-

Requesting Quality Reports: Buyers should ask suppliers for detailed quality reports, including IQC, IPQC, and FQC findings, to understand the quality landscape of the products.

-

Third-Party Inspections: Engaging third-party inspection services can provide unbiased assessments of supplier quality processes, adding an additional layer of assurance.

What Are the Nuances of Quality Control for International Buyers?

For international buyers, especially from regions like Africa, South America, the Middle East, and Europe, there are specific nuances to consider:

-

Regulatory Compliance: Different regions may have varying regulations regarding water quality and equipment safety. Understanding these can help avoid compliance issues.

-

Cultural and Language Barriers: Clear communication is essential to ensure that quality expectations are understood and met.

-

Logistical Considerations: International shipping can introduce risks that may affect product quality. Buyers should work with suppliers who have robust logistics management practices to mitigate these risks.

By understanding the manufacturing processes and quality assurance practices involved in producing in-line water chillers, B2B buyers can make informed decisions that align with their operational needs and regulatory requirements.

Illustrative image related to in line water chiller

Practical Sourcing Guide: A Step-by-Step Checklist for ‘in line water chiller’

In the competitive landscape of international B2B procurement, sourcing an in-line water chiller requires a structured approach. This guide offers a step-by-step checklist to help you navigate the complexities of selecting the right chiller for your needs. Whether you are operating in Africa, South America, the Middle East, or Europe, adhering to this checklist will ensure you make informed decisions that align with your operational requirements.

Step 1: Define Your Technical Specifications

Begin by outlining your specific technical requirements for the in-line water chiller. This includes understanding the desired cooling capacity, temperature range, and compatibility with existing systems, such as Reverse Osmosis (RO) units. Knowing these details helps in narrowing down options that meet your operational needs and ensures optimal performance.

- Cooling Capacity: Determine how much water needs to be chilled per hour.

- Temperature Range: Specify the ideal temperature you want the water to be cooled to, usually measured in degrees Fahrenheit or Celsius.

Step 2: Assess Installation Requirements

Evaluate the installation prerequisites for your selected in-line water chiller. Consider the available space, plumbing configurations, and electrical requirements. Proper installation is crucial for functionality and longevity.

- Space Constraints: Ensure there is adequate space under sinks or in cabinets for installation.

- Utility Access: Check for access to water lines and electrical outlets to avoid additional costs or complications.

Step 3: Evaluate Potential Suppliers

Before committing to a purchase, thoroughly vet potential suppliers. Request company profiles, product catalogs, and client references, especially from businesses in similar sectors or geographical locations. This process helps in assessing the reliability and reputation of suppliers.

Illustrative image related to in line water chiller

- Supplier Experience: Look for suppliers with a proven track record in providing water chillers.

- Customer Support: Inquire about post-purchase support and warranty terms.

Step 4: Verify Product Certifications

Ensure that the in-line water chiller complies with relevant industry standards and certifications, such as NSF/ANSI for drinking water safety. This verification is critical for ensuring the product’s quality and safety for end-users.

- Health and Safety Standards: Check for certifications that guarantee safe operation and drinking water quality.

- Energy Efficiency Ratings: Look for energy certifications to evaluate operational cost efficiency.

Step 5: Request Quotes and Compare Pricing

Gather quotes from multiple suppliers to compare pricing structures. Pay attention to the total cost of ownership, which includes installation, maintenance, and potential energy consumption over time.

- Breakdown of Costs: Ensure quotes detail all associated costs, including shipping and installation.

- Volume Discounts: Inquire about discounts for bulk purchases or long-term contracts.

Step 6: Review Maintenance and Support Options

Understand the maintenance requirements and support services offered by the supplier. A reliable chiller should have easily accessible parts and good customer service to assist with any operational issues.

- Maintenance Plans: Ask if the supplier offers maintenance packages or service contracts.

- Troubleshooting Support: Ensure there is adequate technical support available in your region.

Step 7: Finalize the Purchase and Monitor Performance

Once you’ve selected a supplier and product, proceed with the purchase. After installation, monitor the chiller’s performance closely to ensure it meets your specifications and operational needs.

Illustrative image related to in line water chiller

- Performance Metrics: Keep track of cooling efficiency and any operational issues that arise.

- Feedback Loop: Establish a system for providing feedback to the supplier regarding performance and support.

Following this checklist will streamline your procurement process and ensure that you invest in an in-line water chiller that meets your business needs effectively.

Comprehensive Cost and Pricing Analysis for in line water chiller Sourcing

What Are the Key Cost Components in Sourcing In-Line Water Chillers?

When evaluating the costs associated with sourcing in-line water chillers, several key components must be considered. The primary cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly impacts the cost. High-quality components such as stainless steel for tanks and durable plastics for external casings can raise initial costs but often result in longer-lasting products.

-

Labor: Labor costs vary by region and can be influenced by local wage standards and the complexity of the manufacturing process. Regions with lower labor costs may offer competitive pricing but could compromise on quality.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, equipment depreciation, and factory maintenance. Efficient manufacturing processes can help reduce overhead, leading to more competitive pricing.

-

Tooling: The cost of tooling, which includes molds and dies for production, should be factored in, especially for customized or specialized chillers. Higher tooling costs can be amortized over larger production runs, making it essential to consider minimum order quantities (MOQ).

-

Quality Control (QC): Investing in stringent QC processes ensures product reliability and compliance with international standards. While this adds to the cost, it can mitigate risks associated with product failures.

-

Logistics: Transportation costs can vary significantly based on the distance from the manufacturer to the buyer, shipping methods, and import/export tariffs. Effective logistics planning can minimize these costs.

-

Margin: Suppliers will typically include a profit margin that reflects their business strategy and market position. Understanding the typical margins in your target market can help in negotiations.

How Do Price Influencers Affect In-Line Water Chiller Costs?

Several factors can influence the pricing of in-line water chillers, making it crucial for buyers to understand these dynamics.

-

Volume/MOQ: Suppliers often provide discounts for larger orders. Understanding the MOQ is essential for negotiating better pricing and reducing per-unit costs.

-

Specifications and Customization: Custom features such as unique sizing, enhanced cooling capacity, or specific certifications can drive up costs. Buyers should balance the need for customization with budget constraints.

-

Materials and Quality Certifications: Higher quality materials and compliance with certifications (e.g., NSF, ISO) can increase costs but also enhance product value and performance. Buyers should consider the long-term benefits of investing in certified products.

-

Supplier Factors: Supplier reputation, manufacturing capabilities, and location can all influence pricing. Established suppliers may command higher prices due to their proven track record and reliability.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for international transactions. These terms define the responsibilities of buyers and sellers regarding shipping costs and risks, which can affect the total cost of ownership.

What Are Effective Buyer Tips for Negotiating In-Line Water Chiller Prices?

Navigating the sourcing process for in-line water chillers requires strategic negotiation and cost management.

-

Negotiation: Engage suppliers in discussions about pricing flexibility, especially for larger orders or long-term contracts. Building a good relationship can also lead to better terms and conditions.

-

Cost-Efficiency: Assess the total cost of ownership rather than just the purchase price. This includes installation, maintenance, and energy costs over the product’s lifespan.

-

Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should consider currency fluctuations, local taxes, and import duties. Understanding these factors can prevent unexpected costs and ensure accurate budgeting.

-

Market Research: Conduct thorough market research to benchmark pricing against competitors. Awareness of prevailing market rates can empower buyers during negotiations.

-

Supplier Diversification: Avoid reliance on a single supplier. Having multiple options can create competition, which may lead to more favorable pricing and terms.

Disclaimer on Indicative Prices

Prices for in-line water chillers can vary widely based on the aforementioned factors. The prices listed in various sources are indicative and should be verified with suppliers to account for specific requirements and current market conditions. Always request detailed quotes that reflect your unique specifications and purchasing context.

Illustrative image related to in line water chiller

Alternatives Analysis: Comparing in line water chiller With Other Solutions

Understanding Alternative Solutions to In-Line Water Chillers

In the realm of water cooling solutions, in-line water chillers are popular for their efficiency and compact design. However, there are several alternative technologies that can also achieve similar cooling objectives. This analysis compares in-line water chillers against other viable options, including under-sink water chillers and traditional cooling systems, to help B2B buyers make informed decisions based on their specific needs.

Comparison Table

| Comparison Aspect | In Line Water Chiller | Under-Sink Water Chiller | Traditional Cooling Systems |

|---|---|---|---|

| Performance | Cools water efficiently on demand | Provides instant chilled water | May cool larger volumes but is slower |

| Cost | Moderate initial investment | Generally lower cost than chillers | Higher setup and operational costs |

| Ease of Implementation | Requires plumbing and electrical setup | Easy installation under the sink | Complex installation and maintenance |

| Maintenance | Low maintenance, periodic checks required | Requires filter changes, low upkeep | High maintenance with regular service |

| Best Use Case | High-demand areas needing consistent cooling | Residential and small commercial use | Large-scale operations needing bulk cooling |

Detailed Breakdown of Alternatives

Under-Sink Water Chillers

Under-sink water chillers are compact units designed to be installed beneath sinks, providing chilled water directly from the tap. They typically feature stainless steel tanks and adjustable thermostats. One of the main advantages of under-sink chillers is their cost-effectiveness and space-saving design, making them ideal for residential and small commercial applications. However, their cooling capacity may not match that of in-line water chillers, which can be a drawback in high-demand scenarios.

Traditional Cooling Systems

Traditional cooling systems encompass a range of technologies, including central air conditioning and large chillers, often used in industrial settings. These systems can handle substantial volumes of water and provide consistent cooling over larger areas. While their performance is robust, the complexity of installation and higher operational costs can be significant downsides. Additionally, they often require extensive maintenance, making them less suitable for businesses seeking a low-maintenance solution.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting a water cooling solution, B2B buyers should consider their specific requirements, including the volume of water needed, available space, and budget constraints. In-line water chillers offer high efficiency and are best suited for environments with high demand for chilled water. In contrast, under-sink water chillers are ideal for smaller applications where cost and space are critical. Traditional cooling systems, while powerful, may not be practical for every business due to their complexity and maintenance needs. By carefully evaluating these factors, buyers can identify the most suitable solution for their operational needs, ensuring optimal performance and cost-effectiveness.

Essential Technical Properties and Trade Terminology for in line water chiller

What Are the Key Technical Properties of In-Line Water Chillers?

In-line water chillers are essential components for various applications, including industrial processes, HVAC systems, and residential setups. Understanding their technical properties can help B2B buyers make informed decisions. Here are some critical specifications to consider:

-

Cooling Capacity (BTU/hr)

The cooling capacity, measured in British Thermal Units (BTUs) per hour, indicates how much heat a chiller can remove from water in a given time. For businesses, selecting the right cooling capacity is crucial to ensure efficient operation and to meet specific cooling demands. Insufficient capacity can lead to system strain and inadequate performance, while excessive capacity may result in energy wastage. -

Material Grade

The construction material of an in-line water chiller significantly affects its durability and performance. Common materials include stainless steel, which offers resistance to corrosion and high temperatures, and plastic, which is lighter but may not be as durable. Businesses should prioritize chillers made from high-grade materials to ensure longevity and reliability, particularly in harsh environments. -

Power Consumption (Watts)

Power consumption is a critical factor that affects operational costs. It is essential to evaluate the wattage of the chiller to estimate energy expenses accurately. For international buyers, energy efficiency ratings can also inform decisions, as they indicate the chiller’s performance relative to its energy use, helping to reduce overall operational costs. -

Temperature Range

The temperature range specifies the minimum and maximum temperatures the chiller can maintain. This range is vital for applications requiring precise temperature control, such as aquaculture or food and beverage processing. Buyers should ensure the selected chiller can achieve and maintain the desired temperature range for their specific needs. -

Flow Rate (GPH or GPM)

The flow rate, measured in gallons per hour (GPH) or gallons per minute (GPM), indicates how quickly the chiller can process water. This specification is crucial for applications with high water demand, as insufficient flow rates can lead to inadequate cooling and increased operational strain. -

Refrigerant Type

The type of refrigerant used in the chiller affects both its efficiency and environmental impact. Common refrigerants include R134a and R410A, each with its own set of performance characteristics and regulatory considerations. Businesses should consider the refrigerant type in relation to local environmental regulations and potential phase-out timelines.

What Are Common Trade Terms Related to In-Line Water Chillers?

Understanding trade terminology is vital for effective communication and negotiation in the B2B space. Here are some common terms associated with in-line water chillers:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. For businesses sourcing in-line water chillers, identifying OEMs can ensure quality and compatibility with existing systems. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for B2B buyers, as it helps in budgeting and assessing whether a supplier can meet their needs without incurring excess costs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for a price quote on specific products or services. This is a crucial step in the procurement process, allowing buyers to compare prices and terms from different suppliers, ensuring they get the best deal. -

Incoterms (International Commercial Terms)

Incoterms are international trade terms that define the responsibilities of buyers and sellers in shipping goods. Familiarity with these terms helps B2B buyers understand shipping costs, risk, and liability, facilitating smoother international transactions. -

Lead Time

Lead time refers to the time taken from placing an order to its delivery. Understanding lead times is essential for planning and inventory management, especially for businesses that rely on timely deliveries to meet production schedules. -

Warranty

A warranty is a guarantee provided by the manufacturer regarding the performance and reliability of a product. Buyers should pay attention to warranty terms, as they provide insight into the manufacturer’s confidence in their product and offer protection against defects or failures.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can navigate the in-line water chiller market more effectively, ensuring they make informed purchasing decisions that align with their operational needs.

Navigating Market Dynamics and Sourcing Trends in the in line water chiller Sector

What Are the Current Market Trends Impacting the In-Line Water Chiller Sector?

The in-line water chiller market is experiencing significant growth, driven by increasing demand for efficient cooling solutions across various sectors, including food and beverage, pharmaceuticals, and aquaculture. As industries strive for higher efficiency and sustainability, the adoption of advanced cooling technologies has surged. Notably, innovations in smart technology, such as IoT-enabled chillers, are becoming commonplace, allowing for real-time monitoring and optimization of energy consumption. This trend is particularly relevant for B2B buyers in regions like Africa and South America, where energy efficiency is crucial for cost management and operational sustainability.

Emerging markets, especially in the Middle East, are witnessing a heightened interest in water chillers due to rapid urbanization and the need for reliable cooling systems in residential and commercial sectors. In Europe, particularly in Germany, the focus on regulatory compliance and energy standards is driving the demand for high-performance chillers that meet stringent efficiency criteria. International buyers must also be aware of fluctuating raw material costs and supply chain disruptions that can impact pricing and availability. A thorough understanding of these dynamics is essential for making informed sourcing decisions.

How Can Sustainability and Ethical Sourcing Influence the In-Line Water Chiller Market?

Sustainability is becoming a cornerstone of procurement strategies for B2B buyers in the in-line water chiller sector. The environmental impact of manufacturing and operating chillers is under scrutiny, with many companies seeking to minimize their carbon footprints. This shift is prompting manufacturers to explore eco-friendly refrigerants and energy-efficient designs that align with global sustainability goals. Buyers should prioritize sourcing from suppliers who demonstrate a commitment to reducing environmental impact through responsible practices.

Ethical sourcing is equally important, as businesses increasingly favor suppliers with transparent supply chains and fair labor practices. Certifications such as ISO 14001 for environmental management and ENERGY STAR for energy efficiency can serve as indicators of a manufacturer’s commitment to sustainability. By aligning their sourcing strategies with these ethical standards, B2B buyers can not only enhance their brand reputation but also contribute positively to global sustainability initiatives.

How Has the In-Line Water Chiller Sector Evolved Over Time?

The evolution of in-line water chillers dates back several decades, with early models focusing primarily on basic cooling functions. Over time, technological advancements have introduced features such as programmable thermostats, improved insulation, and energy-efficient compressors. The introduction of smart technology has further transformed the sector, enabling remote monitoring and predictive maintenance.

As industries have become more aware of the importance of water quality and temperature control, the demand for specialized chillers tailored to specific applications has grown. This trend has resulted in a diverse range of products, catering to various needs from residential setups to large-scale industrial applications. Today, the in-line water chiller market is characterized by innovation, efficiency, and a strong focus on sustainability, making it an attractive sector for international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of in line water chiller

-

How do I choose the right in-line water chiller for my business?

Selecting the right in-line water chiller involves assessing your specific cooling requirements, including the volume of water to be chilled and the desired temperature range. Consider the compatibility with existing systems, such as reverse osmosis setups, and the available space for installation. It’s crucial to evaluate the unit’s efficiency, capacity (measured in gallons per hour), and noise levels, especially in customer-facing environments. Consulting with suppliers about your specific needs can also help in making an informed decision. -

What are the key specifications to look for in an in-line water chiller?

When sourcing an in-line water chiller, prioritize specifications such as cooling capacity (GPH), energy efficiency (watts and amperage), and build quality (materials like stainless steel). Look for features like adjustable thermostats for temperature control and certifications (NSF/ANSI) ensuring safety and compliance. Additionally, consider the unit’s footprint, noise level, and maintenance requirements. Understanding these specifications will aid in selecting a chiller that meets your operational demands while ensuring reliability. -

What is the typical lead time for ordering in-line water chillers?

Lead times for in-line water chillers can vary significantly based on factors such as manufacturer location, production schedules, and order volume. Generally, you can expect a lead time ranging from 4 to 12 weeks. For customized units, this timeframe may extend further. It’s advisable to communicate with suppliers early in the procurement process to clarify timelines and ensure that your operational needs are met without delays. -

Are there minimum order quantities (MOQ) for in-line water chillers?

Many manufacturers and suppliers impose a minimum order quantity (MOQ) for in-line water chillers to ensure cost-effectiveness in production and shipping. MOQs can range from a single unit for smaller suppliers to larger quantities for manufacturers focusing on bulk sales. When sourcing, inquire about MOQs and whether they can be negotiated based on your business needs or if there are options for trial orders. -

What payment terms should I expect when purchasing in-line water chillers?

Payment terms for purchasing in-line water chillers can vary widely among suppliers. Common terms include net 30 or net 60 days, where payment is due within 30 or 60 days after the invoice date. Some suppliers may require upfront payments or deposits, especially for large orders or custom units. Always clarify payment terms before finalizing agreements to avoid misunderstandings and ensure smooth transactions. -

How can I ensure quality assurance (QA) when sourcing in-line water chillers?

To ensure quality assurance when sourcing in-line water chillers, request documentation of certifications and compliance with international standards (e.g., ISO, NSF). It’s beneficial to conduct factory audits or site visits, especially when dealing with new suppliers. Additionally, inquire about warranty terms and after-sales support, as these are indicators of the manufacturer’s commitment to quality. Engaging with other businesses that have sourced from the supplier can also provide valuable insights into product reliability. -

What logistics considerations should I keep in mind when importing in-line water chillers?

Logistics considerations for importing in-line water chillers include evaluating shipping methods (air vs. sea), customs regulations, and potential tariffs specific to your region. Ensure that the supplier provides accurate shipping documentation to facilitate customs clearance. Additionally, consider working with a freight forwarder who can navigate complex logistics and help mitigate potential delays. Understanding lead times and planning for storage upon arrival are also critical to managing inventory effectively. -

Can in-line water chillers be customized to fit specific business needs?

Yes, many manufacturers offer customization options for in-line water chillers to meet specific business requirements. Customizations may include modifications to capacity, temperature settings, and design features. When discussing customization with suppliers, be clear about your operational needs, intended use, and any unique specifications. This collaboration can lead to a more tailored solution that enhances performance and efficiency in your business operations.

Top 3 In Line Water Chiller Manufacturers & Suppliers List

1. InSinkErator – CWT100 Water Chiller

Domain: insinkerator.com

Registered: 1995 (30 years)

Introduction: {“product_name”: “CWT100 Water Chiller”, “description”: “Serve perfectly chilled drinking water instantly with the CWT100 Water Chiller from InSinkErator. Designed to fit under your kitchen sink and ready to dispense water cooled from the stainless steel tank as cool as 40°F.”, “SKU”: “45512-ISE”, “features”: {“compact_size”: “10.3” x 8.7″ x 14.6″”, “adjustable_thermostat”: “Yes”, “stainless_steel…

2. Advanced Water Products Inc – Brio USCOLD100 Inline Water Chiller

Domain: advancedwaterproductsinc.com

Registered: 2020 (5 years)

Introduction: Inline Water Chillers – Brio USCOLD100 Premiere Series Under Sink Cooler

– Premium Stainless-Steel Quality

– Supplies cooled water on demand from a countertop tap

– Compatible with Reverse Osmosis and other drinking water systems

– Dispenses 11.5 litres per hour

– High-efficiency compressor with low cycle rate for long lifespan

– Convection cooling with hermetically sealed compressor and automatic…

3. Oasis – Oasis Coolers 1.0 GPH Remote Drinking Water Chiller

Domain: oasiscoolers.com

Registered: 2000 (25 years)

Introduction: {“Product Name”: “Oasis Coolers 1.0 GPH Remote Drinking Water Chiller”, “SKU”: “R1P 503802”, “Price”: “$1,159.50”, “Water Delivery Rate”: “1.0 GPH”, “Cooling Specifications”: “Cools water from 80°F inlet to 50°F at 90°F ambient”, “Evaporator”: “Copper evaporator tube on stainless steel water storage tank”, “Insulation”: “Encapsulated insulation”, “Material”: “Total water system shall be stainless …

Strategic Sourcing Conclusion and Outlook for in line water chiller

In conclusion, the strategic sourcing of in-line water chillers offers significant advantages for businesses aiming to enhance their operations across various sectors, including food service, hospitality, and manufacturing. Key takeaways include the importance of investing in energy-efficient models that align with sustainability goals and the necessity of ensuring compatibility with existing systems, such as reverse osmosis water filtration.

By prioritizing quality and performance, buyers can secure reliable solutions that not only meet their immediate cooling needs but also contribute to long-term cost savings through reduced energy consumption and maintenance costs. As global markets continue to expand, particularly in regions such as Africa, South America, the Middle East, and Europe, the demand for effective water management solutions will only grow.

International B2B buyers are encouraged to leverage the insights from this guide to make informed decisions that will enhance their operational efficiency and customer satisfaction. As you move forward, consider engaging with reputable suppliers who can provide tailored solutions to meet your unique business requirements. The right strategic sourcing approach will position your company for success in an increasingly competitive landscape.

Illustrative image related to in line water chiller

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.