The Definitive Guide to Ohio Magnetics Inc: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for ohio magnetics inc

In today’s dynamic global market, sourcing high-quality industrial lifting magnets and magnetic separation equipment can be a daunting challenge for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, including countries such as Nigeria and Saudi Arabia. Ohio Magnetics Inc., a leader in the manufacturing of these essential tools, offers a diverse range of products designed to meet the specific needs of industries such as steel, scrap processing, recycling, and mining. This guide serves as a comprehensive resource for international buyers looking to navigate the complexities of sourcing from Ohio Magnetics.

Throughout this guide, we will delve into the various types of lifting magnets and separation equipment available, their applications in different industrial settings, and the importance of thorough supplier vetting to ensure quality and reliability. Additionally, we will provide insights into cost considerations and best practices for integrating these solutions into your operations. By equipping buyers with the knowledge they need to make informed purchasing decisions, this guide empowers businesses to enhance productivity and efficiency in their respective markets. With Ohio Magnetics’ century-long expertise, you can trust that you’re investing in solutions that not only meet but exceed industry standards, paving the way for sustainable growth in your operations.

Understanding ohio magnetics inc Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Lifting Magnets | Available in circular, bipolar, and rectangular designs; tailored power supplies. | Steel handling, scrap processing, recycling. | Pros: Versatile for various loads; high efficiency. Cons: Requires proper maintenance for optimal performance. |

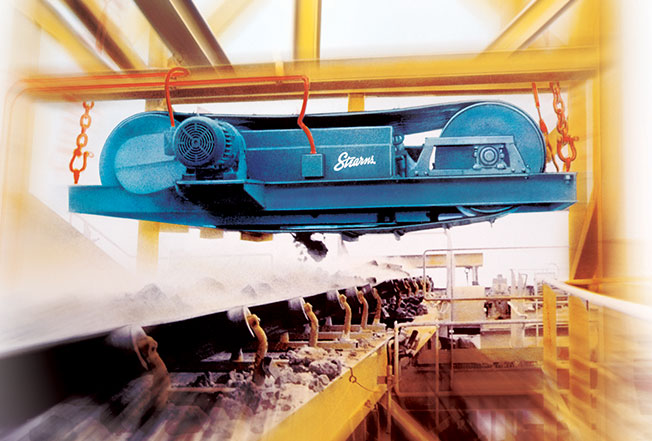

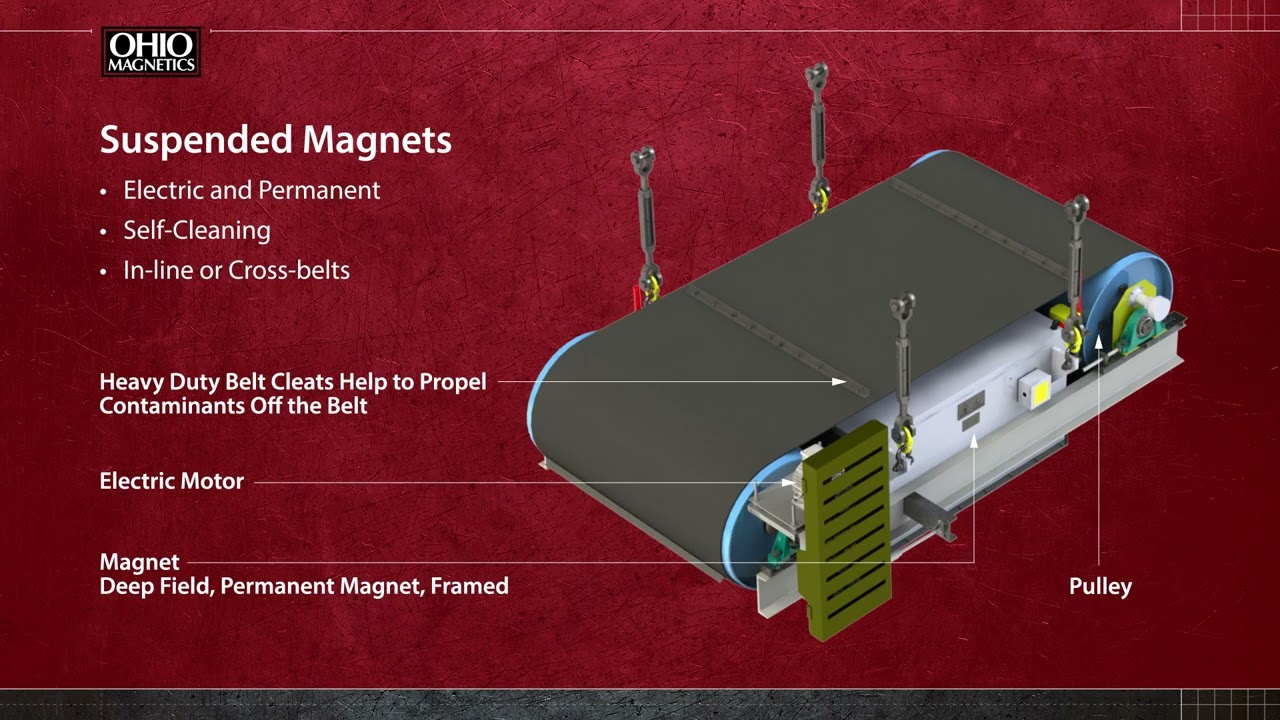

| Magnetic Separation Equipment | Includes suspended magnets, drums, and pulleys; designed for heavy-duty applications. | Mining, recycling, and waste management. | Pros: Enhances material recovery; reduces contamination. Cons: Initial investment can be high. |

| Magnet Controls | Advanced controllers, power supplies, and safety equipment; compatible with various magnets. | Industrial automation, safety systems. | Pros: Improves operational efficiency; enhances safety. Cons: Complexity may require specialized training. |

| Parts & Service | Comprehensive inspection and remanufacturing programs; tailored support solutions. | Maintenance for lifting and separation equipment. | Pros: Extends equipment lifespan; reduces downtime. Cons: Ongoing service costs can add up. |

| Custom Solutions | Tailored magnet designs and systems; specific to client needs and applications. | Specialized industrial applications. | Pros: Meets unique operational challenges; maximizes effectiveness. Cons: Longer lead times and potential higher costs. |

What Are the Key Features of Lifting Magnets and Their Applications?

Lifting magnets are designed for handling steel and scrap materials effectively. They come in various shapes—circular, bipolar, and rectangular—allowing for versatility in applications ranging from steel mills to recycling facilities. When purchasing lifting magnets, B2B buyers should consider the load capacity, power supply compatibility, and maintenance requirements. These magnets significantly enhance operational efficiency but require regular inspections to ensure reliability.

How Do Magnetic Separation Equipment Enhance B2B Operations?

Magnetic separation equipment, including suspended magnets, drums, and pulleys, is essential for industries such as mining and waste management. These systems are designed to extract ferrous materials from non-ferrous waste, improving material recovery rates and reducing contamination. Buyers should evaluate the equipment’s capacity, durability, and adaptability to their specific processes. While the initial investment may be substantial, the long-term benefits in efficiency and productivity can justify the cost.

What Are the Advantages of Magnet Controls in Industrial Applications?

Magnet controls play a crucial role in managing the operation of lifting magnets and separation equipment. They include advanced controllers and power supplies that enhance safety and efficiency in industrial settings. B2B buyers should consider the compatibility of these controls with existing systems, as well as their ease of use and reliability. While they add complexity to operations, the benefits in terms of improved safety and operational efficiency can be significant.

Why Is Parts & Service Essential for Maintaining Magnet Equipment?

Parts and service offerings from Ohio Magnetics ensure that lifting and separation equipment remains operational and efficient. Their comprehensive inspection and remanufacturing programs help extend the lifespan of equipment, reducing the risk of unexpected downtime. Buyers should factor in the cost of ongoing service and maintenance when budgeting for their magnet systems. Investing in quality service can lead to significant savings and enhanced productivity over time.

How Can Custom Solutions Address Unique B2B Needs?

Custom magnet solutions are designed to meet the specific requirements of individual businesses, addressing unique operational challenges. These tailored systems can optimize performance in specialized applications, making them invaluable for companies with unique needs. Buyers should assess the time and cost implications of custom solutions, as they may involve longer lead times and higher upfront costs. However, the potential for enhanced efficiency and effectiveness often outweighs these considerations.

Key Industrial Applications of ohio magnetics inc

| Industry/Sector | Specific Application of Ohio Magnetics Inc | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Steel Manufacturing | Lifting Magnets for Steel Handling | Enhances efficiency in moving heavy steel components | Consider load capacity, magnet type, and safety features |

| Scrap Processing | Magnetic Separation Systems for Recycling | Increases recycling rates and reduces waste | Evaluate system compatibility with existing operations |

| Mining | Magnet Controls for Material Handling | Improves operational safety and minimizes downtime | Look for robust power supplies and reliable controls |

| Rail Industry | Scrap Handling Magnets for Rail Maintenance | Streamlines maintenance processes and reduces costs | Assess magnet durability and ease of installation |

| Construction | Auxiliary Magnets for Lifting Equipment | Enhances lifting capabilities and reduces labor costs | Ensure compliance with safety standards and load specs |

How Are Lifting Magnets Used in Steel Manufacturing?

In the steel manufacturing sector, Ohio Magnetics’ lifting magnets are crucial for handling heavy steel components efficiently. These magnets enable quick and safe movement of materials, reducing manual labor and the risk of injury. B2B buyers in this industry should consider the load capacity and type of lifting magnets required, ensuring they meet safety standards and operational needs. International buyers, particularly from regions like Europe and the Middle East, may also prioritize compliance with local regulations regarding equipment safety and performance.

What Role Do Magnetic Separation Systems Play in Scrap Processing?

Magnetic separation systems from Ohio Magnetics are vital in the scrap processing industry, where they facilitate the efficient recycling of metals. These systems help separate ferrous materials from non-ferrous ones, thus maximizing recovery rates and minimizing waste. For B2B buyers, it is essential to evaluate the compatibility of these systems with their existing operations and consider the specific requirements for installation and maintenance. Buyers from Africa and South America should also assess the availability of technical support and service options in their regions.

How Do Magnet Controls Enhance Safety in Mining Operations?

In the mining industry, Ohio Magnetics’ magnet controls are essential for ensuring the safe handling of materials. These controls improve operational efficiency by allowing precise management of magnetic equipment, thereby minimizing downtime and enhancing safety protocols. Buyers should focus on the robustness of power supplies and the reliability of control systems to withstand harsh mining environments. For international buyers, particularly in regions like Saudi Arabia, understanding local operational conditions and sourcing durable equipment is critical for successful implementation.

Why Are Scrap Handling Magnets Important for the Rail Industry?

Scrap handling magnets are integral to the rail industry, particularly for maintenance and recycling operations. Ohio Magnetics provides solutions that streamline the removal of scrap materials from rail yards, thus enhancing operational efficiency and reducing maintenance costs. When sourcing these magnets, buyers should assess their durability and ease of installation, especially in regions with challenging environmental conditions. International buyers from Europe may also need to consider compliance with local safety standards and regulations related to rail operations.

How Do Auxiliary Magnets Improve Construction Operations?

In the construction sector, auxiliary magnets from Ohio Magnetics significantly enhance lifting capabilities for heavy equipment and materials. These magnets provide a reliable means of moving large items, thereby reducing labor costs and improving site safety. B2B buyers should ensure that the magnets comply with industry safety standards and possess the required load specifications. International buyers, particularly from Africa and South America, should also evaluate the availability of local support and service options to facilitate ongoing maintenance and operational efficiency.

3 Common User Pain Points for ‘ohio magnetics inc’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Lifting Magnet for Specific Applications

The Problem: B2B buyers often face challenges when it comes to selecting the appropriate lifting magnet for their unique operational needs. For instance, a steel mill in Nigeria may require a heavy-duty lifting magnet that can handle large steel billets, while a recycling facility in Brazil might need specialized scrap handling magnets that can manage a variety of materials. The risk of choosing the wrong magnet can lead to operational inefficiencies, safety hazards, and financial losses due to equipment malfunctions or the inability to lift required loads.

The Solution: To effectively source the right lifting magnet from Ohio Magnetics, buyers should start by conducting a thorough analysis of their specific operational requirements, including load types, weight capacities, and environmental conditions. Ohio Magnetics offers a range of products, such as the LoadStar Series and the Vers-A-Lift, which can be tailored to meet these needs. Buyers should engage with Ohio Magnetics’ sales team to request detailed product specifications and recommendations based on their application. Additionally, leveraging Ohio Magnetics’ expertise in custom solutions can ensure that the selected magnet is optimized for performance, thereby enhancing safety and efficiency in operations.

Scenario 2: Inadequate Knowledge of Magnet Maintenance and Safety Protocols

The Problem: Many B2B buyers are unfamiliar with the maintenance and safety protocols associated with lifting magnets and magnetic separation equipment. This lack of knowledge can lead to improper usage, resulting in equipment failures or accidents in the workplace. For instance, a mining company in Saudi Arabia may not have established a routine inspection schedule for their magnets, which could result in performance degradation or even catastrophic failures during critical operations.

The Solution: To mitigate these risks, buyers should take advantage of Ohio Magnetics’ comprehensive parts and service offerings, including inspection and maintenance programs. It is crucial for companies to develop a robust maintenance schedule that includes regular inspections and servicing as recommended by Ohio Magnetics. Buyers can also request training sessions for their staff on proper magnet operation and safety practices, ensuring that all personnel are well-versed in handling equipment safely. By prioritizing maintenance and training, companies can extend the lifespan of their magnets and significantly reduce the risk of accidents.

Scenario 3: Challenges in Integrating Magnet Controls with Existing Systems

The Problem: Integrating new magnet controls with existing operational systems can be a complex task for B2B buyers, particularly for industries that rely heavily on automation. For example, a manufacturing facility in Europe might struggle to incorporate Ohio Magnetics’ advanced magnet controllers and power supplies into its current setup, leading to operational delays and increased costs. This challenge can stem from compatibility issues or a lack of understanding of how to effectively integrate new technology into established processes.

The Solution: To address these integration challenges, buyers should work closely with Ohio Magnetics’ technical support team during the planning phase of their projects. It is essential to provide comprehensive details about existing systems and operational workflows to facilitate a smooth integration process. Ohio Magnetics can offer tailored solutions and guidance on configuring their magnet controllers and power supplies to ensure compatibility. Additionally, buyers should consider investing in comprehensive training for their technical teams on the new equipment, which can enhance overall operational efficiency and minimize downtime during the transition phase. By proactively addressing integration issues, companies can streamline their operations and capitalize on the advanced features of Ohio Magnetics’ products.

Strategic Material Selection Guide for ohio magnetics inc

What Are the Key Materials Used in Ohio Magnetics Inc Products?

Ohio Magnetics Inc specializes in manufacturing high-performance lifting magnets and magnetic separation equipment. The selection of materials in their products is crucial for ensuring optimal performance, durability, and safety. Here, we analyze four common materials used in their offerings, focusing on their properties, pros and cons, and implications for international B2B buyers.

How Does Steel Perform as a Core Material?

Steel is a primary material used in lifting magnets and magnetic separation equipment due to its excellent magnetic properties and strength.

Key Properties: Steel offers high tensile strength and durability, withstanding significant weight and pressure. It typically has a temperature rating up to 300°C, making it suitable for various industrial applications.

Pros & Cons: The advantages of steel include its robustness and relatively low cost. However, it is susceptible to corrosion, which can limit its lifespan if not properly treated. Additionally, manufacturing complexity can arise when fabricating specialized shapes or sizes.

Impact on Application: Steel’s compatibility with ferromagnetic materials makes it ideal for lifting heavy steel objects in scrap processing and steel mills.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure compliance with local standards such as ASTM or DIN for steel quality. Corrosion-resistant coatings may be necessary in humid environments.

What Role Does Aluminum Play in Magnet Manufacturing?

Aluminum is increasingly used in certain components of magnetic systems, particularly in applications requiring lightweight materials.

Key Properties: Aluminum is lightweight and has a good strength-to-weight ratio. It exhibits excellent corrosion resistance, especially when anodized.

Pros & Cons: The primary advantage of aluminum is its reduced weight, which can enhance the efficiency of lifting operations. However, it is generally more expensive than steel and may not provide the same magnetic strength, limiting its use in heavy-duty applications.

Impact on Application: Aluminum is suitable for applications where weight reduction is critical, such as in portable lifting systems or for use in environments where corrosion is a significant concern.

Considerations for International Buyers: Buyers should verify the availability of aluminum grades that meet international standards, ensuring they are suitable for their specific applications.

Why Is Copper Important in Magnet Controls?

Copper is a key material in the electrical components of magnet systems, especially in wiring and connections.

Key Properties: Copper has excellent electrical conductivity and thermal properties, essential for efficient magnet control systems. It also has good resistance to corrosion.

Pros & Cons: The main advantage of copper is its superior conductivity, which enhances the performance of magnet controls. However, it is more expensive than alternatives like aluminum and can be heavy, which may not be ideal for all applications.

Illustrative image related to ohio magnetics inc

Impact on Application: Copper is critical for ensuring reliable power supply and control in lifting magnets, directly affecting operational efficiency.

Considerations for International Buyers: Buyers should consider copper quality standards and ensure compliance with electrical safety regulations in their respective countries.

How Does Plastic Contribute to Magnet Systems?

Plastics are often used in auxiliary components and housings within magnet systems.

Key Properties: Plastics are lightweight, resistant to corrosion, and can be molded into complex shapes. They typically have a lower temperature resistance compared to metals.

Pros & Cons: The advantages of plastic include its versatility and cost-effectiveness. However, plastics may not withstand high temperatures or heavy loads, limiting their application scope.

Impact on Application: Plastics are ideal for non-load-bearing components, such as housings for controls or protective covers, where weight and corrosion resistance are important.

Considerations for International Buyers: Buyers should ensure that the plastics used meet relevant safety and environmental regulations, especially in regions with stringent compliance standards.

Summary Table of Material Selection for Ohio Magnetics Inc

| Material | Typical Use Case for Ohio Magnetics Inc | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Lifting magnets, magnetic separation | High strength and durability | Susceptible to corrosion | Low |

| Aluminum | Lightweight lifting systems | Reduced weight | Higher cost and lower magnetic strength | Medium |

| Copper | Magnet control systems | Excellent electrical conductivity | High cost and weight | High |

| Plastic | Auxiliary components and housings | Lightweight and corrosion-resistant | Limited temperature and load capacity | Low |

This strategic material selection guide provides a comprehensive overview for international B2B buyers, helping them make informed decisions when sourcing products from Ohio Magnetics Inc.

In-depth Look: Manufacturing Processes and Quality Assurance for ohio magnetics inc

What are the Main Stages of Manufacturing at Ohio Magnetics Inc.?

Ohio Magnetics Inc. follows a rigorous manufacturing process tailored to produce high-quality lifting magnets and magnetic separation equipment. The key stages in their manufacturing process include material preparation, forming, assembly, and finishing.

-

Material Preparation: The manufacturing journey begins with the selection of high-grade materials. Ohio Magnetics sources steel and other components that meet stringent specifications. The materials undergo initial inspections to ensure they are free from defects and suitable for the intended application.

-

Forming: During the forming stage, raw materials are shaped into components through various techniques such as machining, welding, and stamping. For lifting magnets, specific designs like bipolar and rectangular magnets are formed using advanced machinery, ensuring precision and uniformity.

-

Assembly: Following the forming process, components are meticulously assembled. This includes integrating magnet coils, power supplies, and control systems into the final product. Skilled technicians oversee this stage to ensure that every component is correctly positioned and securely fastened.

-

Finishing: The final stage involves applying protective coatings, surface treatments, and rigorous cleaning processes to enhance durability and performance. This ensures that the products can withstand harsh industrial environments, which is critical for clients in industries such as steel processing and recycling.

What Quality Control Measures Are Implemented at Ohio Magnetics Inc.?

Quality assurance is a cornerstone of Ohio Magnetics’ operations. The company adheres to international standards, such as ISO 9001, ensuring that their products consistently meet customer expectations and regulatory requirements.

Illustrative image related to ohio magnetics inc

-

Relevant International Standards: Ohio Magnetics is committed to maintaining ISO 9001 certification, which signifies their dedication to quality management systems. This certification involves regular audits and updates to processes to improve efficiency and product quality continually.

-

Industry-Specific Standards: In addition to ISO, Ohio Magnetics also complies with other industry-specific standards, such as CE marking for products sold within the European Union and API standards for equipment used in the oil and gas sector. These certifications further validate the reliability and safety of their products.

-

Quality Control Checkpoints: Quality control at Ohio Magnetics encompasses several critical checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This initial inspection phase checks all incoming materials against predefined specifications to prevent defective components from entering production.

– In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to monitor the quality of processes and outputs. This ensures that any deviations are identified and corrected promptly.

– Final Quality Control (FQC): Before products are shipped, a comprehensive final inspection is performed to ensure they meet all quality standards. This includes performance testing and compliance checks.

How Are Common Testing Methods Utilized in Quality Assurance?

Ohio Magnetics employs various testing methods to validate the performance and safety of their products. These testing methods include:

-

Magnetic Testing: This assesses the strength and uniformity of the magnetic field produced by lifting magnets. It ensures that the products will perform effectively in operational environments.

-

Load Testing: Magnets are subjected to load tests to verify their capacity to handle specified weights safely. This testing is critical for applications in steel handling and recycling where safety is paramount.

-

Electrical Testing: For products that integrate electronic controls, rigorous electrical testing is performed to ensure safety and functionality. This includes verifying power supply outputs and controller performance.

-

Environmental Testing: Products are tested under various environmental conditions to assess their durability and resistance to factors such as temperature fluctuations, humidity, and corrosion.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers, particularly those from international markets such as Africa, South America, the Middle East, and Europe, should take proactive steps to verify the quality control processes of suppliers like Ohio Magnetics. Here are actionable strategies:

-

Conducting Audits: Buyers can arrange for on-site audits of the manufacturing facilities. This allows them to observe quality control processes in action and verify compliance with international standards.

-

Requesting Quality Reports: Suppliers should be willing to provide documentation of their quality control measures, including inspection reports, test results, and certifications. This transparency builds trust and confidence in the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control processes and product quality. These inspections can be particularly beneficial for buyers unfamiliar with local suppliers.

-

Reviewing Certifications: Buyers should verify that suppliers hold relevant certifications, such as ISO 9001, CE, or API, which can serve as indicators of a supplier’s adherence to quality standards.

What Are the Quality Control and Certification Nuances for International Buyers?

For international B2B buyers, understanding the nuances of quality control and certification is crucial. Here are key considerations:

-

Regional Standards Compliance: Different regions may have unique regulations and standards. Buyers from Africa or South America should ensure that suppliers can meet local compliance requirements in addition to international standards.

-

Shipping and Customs Regulations: Quality certifications may also impact shipping and customs processes. Buyers should be aware of any specific documentation needed to avoid delays or issues during importation.

-

Cultural Considerations: Establishing relationships with suppliers from different cultural backgrounds may require understanding local business practices and negotiation styles. Building rapport can enhance collaboration and communication.

-

Ongoing Monitoring: After establishing a supplier relationship, ongoing monitoring of quality control processes is essential. Regular communication and feedback can help address any emerging issues and maintain product quality over time.

Conclusion

Ohio Magnetics Inc. employs a comprehensive manufacturing process and quality assurance framework designed to meet the demands of diverse industries. By understanding these processes and implementing effective verification strategies, B2B buyers can make informed decisions, ensuring they partner with reliable suppliers that meet international quality standards. This is particularly crucial for international buyers who must navigate varying regulations and expectations across different markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘ohio magnetics inc’

Introduction

This sourcing guide serves as a comprehensive checklist for international B2B buyers seeking to procure products from Ohio Magnetics, Inc., a leading manufacturer of lifting magnets and magnetic separation equipment. The following steps will help you navigate the procurement process efficiently, ensuring that you acquire high-quality products that meet your specific needs.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the lifting magnets or separation equipment you need. This includes understanding load capacities, dimensions, and operational environments. Having detailed specifications will facilitate better communication with Ohio Magnetics and ensure that the products you order are fit for purpose.

- Consider application requirements: Identify the specific industry needs, such as steel processing or recycling, to tailor your specifications accordingly.

- Assess environmental factors: Take into account any environmental conditions that might affect performance, such as temperature or humidity.

Step 2: Research Product Offerings

Familiarize yourself with Ohio Magnetics’ range of products, including lifting magnets, magnetic separation equipment, and auxiliary components. Understanding the product lineup will help you determine which solutions best meet your requirements.

- Explore specialized options: Look for custom solutions if your application has unique needs, such as heavy-duty or bipolar magnets.

- Review product brochures: Access detailed product literature from Ohio Magnetics to get insights into capabilities and features.

Step 3: Evaluate Supplier Certifications

It is essential to verify that Ohio Magnetics meets industry standards and holds relevant certifications. This step ensures that you are partnering with a reputable manufacturer known for quality and compliance.

- Check ISO certifications: Confirm that the company adheres to quality management standards, which can significantly impact product reliability.

- Review safety certifications: Ensure that the products comply with safety regulations applicable to your industry.

Step 4: Request Quotations and Terms

Reach out to Ohio Magnetics for detailed quotations based on your specifications. This process should also include inquiries about payment terms, delivery timelines, and warranty policies.

Illustrative image related to ohio magnetics inc

- Compare pricing: Evaluate quotations from Ohio Magnetics against market standards to ensure competitiveness.

- Understand payment options: Clarify payment terms to avoid any cash flow issues during procurement.

Step 5: Assess After-Sales Support and Services

Inquire about the support and services offered post-purchase, including installation, maintenance, and warranty services. Strong after-sales support can significantly enhance the longevity and performance of your equipment.

- Understand service contracts: Look for options that provide ongoing maintenance and inspection services.

- Evaluate responsiveness: Gauge the supplier’s customer service responsiveness to ensure timely support when needed.

Step 6: Check Customer References and Reviews

Before finalizing your decision, seek references from other businesses that have purchased from Ohio Magnetics. This feedback can provide valuable insights into product performance and supplier reliability.

- Connect with industry peers: Reach out to companies within your industry for their experiences and recommendations.

- Review online testimonials: Look for feedback on independent platforms to gain an unbiased perspective.

Step 7: Finalize and Place Your Order

Once you are satisfied with all aspects of your supplier evaluation, finalize your order with Ohio Magnetics. Ensure all terms are clearly documented to prevent misunderstandings.

Illustrative image related to ohio magnetics inc

- Confirm order details: Double-check specifications, quantities, and delivery dates before placing the order.

- Maintain communication: Keep an open line of communication with the supplier to facilitate a smooth procurement process.

Following this step-by-step checklist will help you make informed decisions when sourcing products from Ohio Magnetics, ensuring that you receive high-quality equipment tailored to your operational needs.

Comprehensive Cost and Pricing Analysis for ohio magnetics inc Sourcing

What Are the Key Cost Components in Sourcing from Ohio Magnetics Inc?

When sourcing from Ohio Magnetics Inc., understanding the cost structure is crucial for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control, logistics, and profit margin.

-

Materials: The type and quality of materials significantly influence the overall cost. Ohio Magnetics specializes in high-quality magnets, which may come at a premium but ensure durability and efficiency in applications such as steel handling and scrap processing.

-

Labor: Labor costs in the U.S. manufacturing sector can be higher than in some other regions. However, Ohio Magnetics employs skilled labor to ensure precision in magnet manufacturing, which can be a worthwhile investment for buyers seeking reliability.

-

Manufacturing Overhead: This includes expenses related to facilities, utilities, and equipment maintenance. Ohio Magnetics has a long-standing reputation and operational efficiency, which helps mitigate excessive overhead costs, making them competitive in the market.

-

Tooling: Custom tooling can be necessary for specialized magnet designs, affecting initial costs. Buyers should be prepared for these potential upfront expenses, especially if they require unique specifications.

-

Quality Control (QC): Quality assurance processes are integral to Ohio Magnetics’ operations. Investing in QC ensures that products meet international standards, which can save buyers from future costs related to product failures.

-

Logistics: Shipping and handling costs vary based on the destination, weight, and dimensions of the magnets. International buyers must account for these variables when budgeting for purchases.

-

Margin: Profit margins are typically influenced by the complexity of the product and market demand. Ohio Magnetics maintains a balance between quality and pricing, reflecting their commitment to customer satisfaction.

How Do Pricing Influencers Affect Your Purchase Decision?

Several factors influence the pricing structure at Ohio Magnetics, and understanding these can empower buyers to make informed decisions.

-

Volume and Minimum Order Quantity (MOQ): Larger orders often result in reduced per-unit costs due to economies of scale. Buyers should consider negotiating favorable terms if they plan to make bulk purchases.

-

Specifications and Customization: Customized products may incur additional costs. Clear communication of specifications can help avoid misunderstandings that lead to delays or increased costs.

-

Materials and Quality Certifications: Premium materials and certifications (e.g., ISO standards) can elevate pricing but also enhance product reliability. Buyers should weigh the long-term benefits of investing in higher-quality products.

-

Supplier Factors: The reputation and reliability of Ohio Magnetics can justify higher prices. Buyers should evaluate the supplier’s history and service level as part of their procurement strategy.

-

Incoterms: Understanding Incoterms is vital for international transactions. These terms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, influencing the total landed cost.

What Negotiation Tips Can Help Secure Cost-Efficiency?

International B2B buyers should employ strategic negotiation techniques to optimize their sourcing from Ohio Magnetics:

-

Research and Benchmarking: Conduct market research to understand competitive pricing. Knowledge of industry standards can provide leverage during negotiations.

-

Total Cost of Ownership (TCO): Evaluate not only the purchase price but also long-term operational costs, including maintenance and energy efficiency. This broader perspective can reveal the true value of the investment.

-

Flexibility in Terms: Be open to discussing payment terms, delivery schedules, and other conditions that could lead to cost savings. Flexibility can lead to more favorable pricing arrangements.

-

Build Relationships: Establishing a long-term relationship with the supplier can lead to better pricing and terms in future transactions. Trust can often translate into financial advantages.

-

Cultural Sensitivity: When negotiating with suppliers in different regions, understanding cultural nuances can facilitate smoother discussions and foster goodwill.

Conclusion: What Should Buyers Keep in Mind?

While sourcing from Ohio Magnetics Inc., buyers should remain mindful of the various cost components and pricing influencers that affect their purchase decisions. By leveraging negotiation strategies and understanding the total cost of ownership, international buyers from regions such as Africa, South America, the Middle East, and Europe can secure optimal value in their procurement processes. Always consult with Ohio Magnetics directly for the most accurate pricing information and to discuss specific needs, as prices can vary widely based on individual requirements and market conditions.

Alternatives Analysis: Comparing ohio magnetics inc With Other Solutions

Understanding Alternatives for Ohio Magnetics Inc Solutions

In the competitive landscape of industrial lifting magnets and magnetic separation equipment, it is crucial for B2B buyers to explore various alternatives to Ohio Magnetics Inc. This analysis will provide insights into how Ohio Magnetics compares with other viable solutions, focusing on performance, cost, ease of implementation, maintenance, and best use cases. Such comparisons can help international buyers from regions like Africa, South America, the Middle East, and Europe make informed decisions that align with their operational needs.

Comparison Table

| Comparison Aspect | Ohio Magnetics Inc | Magswitch Technology | Walker Magnetics |

|---|---|---|---|

| Performance | High-efficiency lifting and separation; custom solutions available | Innovative magnetic technology; versatile applications | Reliable magnetic solutions; strong performance in heavy-duty applications |

| Cost | Moderate initial investment; competitive pricing for custom solutions | Higher cost due to advanced technology; long-term savings through efficiency | Mid-range pricing; good value for standard applications |

| Ease of Implementation | Requires specialized installation; comprehensive support available | User-friendly with quick setup; training provided | Straightforward installation; existing infrastructure may suffice |

| Maintenance | Regular inspections recommended; robust support services | Minimal maintenance; durable design | Routine checks needed; service support available |

| Best Use Case | Steel handling, recycling, and mining industries | Diverse applications across industries; ideal for complex setups | Heavy-duty industrial applications; effective in steel mills |

Detailed Breakdown of Alternatives

Magswitch Technology

Magswitch Technology is known for its innovative approach to magnetic solutions, utilizing advanced magnetic technology that allows for versatile applications across various industries. One significant advantage is its ease of use; the systems are designed for quick setup and require minimal maintenance. However, the initial investment can be higher than traditional options like Ohio Magnetics, which may deter budget-conscious buyers. For businesses that value efficiency and advanced features, Magswitch can offer long-term savings through improved operational performance.

Walker Magnetics

Walker Magnetics offers a robust range of magnetic solutions that are reliable and particularly well-suited for heavy-duty applications in environments like steel mills. The company’s products are competitively priced, making them an attractive option for businesses looking for good value in standard applications. While the installation process is relatively straightforward, some routine maintenance is required to ensure optimal performance. Walker Magnetics is an excellent choice for companies needing dependable and effective magnetic solutions without the complexity of advanced technology.

Conclusion: How to Choose the Right Solution

When considering alternatives to Ohio Magnetics Inc, B2B buyers must evaluate their specific operational needs and budget constraints. Factors such as performance requirements, cost implications, ease of implementation, and maintenance capabilities should guide the decision-making process. For those in heavy industries or recycling sectors, the choice might lean towards Ohio Magnetics for its specialized solutions. Conversely, companies that prioritize innovative technology or straightforward installations may find Magswitch or Walker Magnetics to be more aligned with their objectives. Ultimately, the right solution will depend on a careful assessment of each option against the unique demands of the buyer’s operational context.

Essential Technical Properties and Trade Terminology for ohio magnetics inc

What Are the Key Technical Properties of Ohio Magnetics’ Products?

When considering the purchase of lifting magnets and magnetic separation equipment from Ohio Magnetics, understanding the critical technical specifications is essential for making informed decisions. Here are some vital properties to consider:

-

Material Grade

The material used in manufacturing lifting magnets is crucial for performance and durability. Typically, high-grade steel is used for the magnet housing, which offers strength and resistance to wear and corrosion. For B2B buyers, selecting products made from superior materials ensures longevity and reduces the frequency of replacements. -

Magnetic Pull Force

This specification indicates the maximum weight a magnet can lift under optimal conditions. It is vital for determining whether a specific magnet can handle the requirements of your operations, especially in industries like steel processing and scrap handling. Understanding pull force helps buyers select the right magnet for their lifting needs, enhancing safety and efficiency. -

Duty Cycle

The duty cycle refers to the ratio of time a magnet can be energized versus the time it must be deactivated to avoid overheating. For applications requiring continuous operation, knowing the duty cycle is essential. It directly impacts productivity and equipment longevity, making it a key consideration for B2B purchasers. -

Voltage and Power Supply Requirements

Different magnets require specific voltages and power supplies for optimal operation. Ohio Magnetics provides a range of power supplies including DC rectifiers and hydraulic-driven generators. Understanding these requirements ensures that buyers can integrate the magnets into their existing systems without unexpected costs or compatibility issues. -

Safety Features

Safety disconnect switches and emergency power supplies are integral to the operation of lifting magnets. These features prevent accidents and ensure operational safety, which is a priority for businesses in heavy industries. B2B buyers should prioritize products that include comprehensive safety measures to protect their workforce and equipment.

What Are Common Trade Terminology and Jargon Related to Ohio Magnetics?

Understanding industry-specific terminology is vital for effective communication and negotiation in B2B transactions. Here are some common terms that buyers should be familiar with:

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. For buyers, understanding the OEM status of Ohio Magnetics ensures that they are purchasing high-quality, original products rather than generic substitutes. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers manage their budgets and inventory levels effectively, ensuring they can meet operational needs without overcommitting resources. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers. It outlines the specifics of what the buyer needs and helps in comparing different offers. Familiarity with RFQs streamlines the procurement process and aids in securing favorable terms. -

Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs, which is crucial for B2B buyers involved in cross-border purchases. -

Lead Time

Lead time refers to the amount of time from the initiation of an order until the product is delivered. Understanding lead time helps businesses plan their operations and inventory management effectively, ensuring they have the necessary equipment when needed.

By grasping these technical properties and trade terminologies, international B2B buyers can navigate their purchasing decisions with confidence, ensuring they select the right products for their operational needs while fostering strong supplier relationships.

Navigating Market Dynamics and Sourcing Trends in the ohio magnetics inc Sector

What Are the Key Market Dynamics Affecting Ohio Magnetics Inc.?

The global market for industrial lifting magnets and magnetic separation equipment is witnessing significant growth, driven by increasing demand across sectors such as steel manufacturing, recycling, and mining. Key trends indicate a shift towards automation and advanced technologies, including smart magnet controls and energy-efficient solutions. International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly looking for suppliers who can provide innovative and customized solutions to meet specific operational needs. This demand is partly fueled by the rising need for efficiency in scrap processing and steel handling, where maximizing uptime and minimizing operational costs are crucial.

Additionally, as industries seek to optimize their supply chains, there is a growing emphasis on sourcing from established manufacturers with proven track records, like Ohio Magnetics Inc. The company’s extensive experience since its founding in 1917 positions it well within this competitive landscape. With a focus on quality and reliability, Ohio Magnetics is also adapting to emerging trends such as remote monitoring and predictive maintenance, enabling clients to enhance their operational efficiencies further.

How Does Sustainability Impact the Sourcing of Magnetic Equipment?

Sustainability has become a pivotal concern for international B2B buyers, particularly as environmental regulations tighten globally. Companies are increasingly prioritizing ethical sourcing and the environmental impact of their suppliers. For Ohio Magnetics Inc., this presents both a challenge and an opportunity. By adopting ‘green’ practices, such as using recycled materials in manufacturing processes and ensuring energy-efficient operations, the company can appeal to environmentally conscious buyers.

The importance of ethical supply chains cannot be overstated. Buyers are more inclined to partner with manufacturers who prioritize sustainability, as this not only enhances their corporate responsibility profile but also mitigates risks associated with environmental compliance. Certifications such as ISO 14001 for environmental management systems and adherence to sustainable practices can significantly influence purchasing decisions. By integrating these principles into their operations, Ohio Magnetics can position itself as a leader in sustainable manufacturing, attracting international clients seeking responsible sourcing options.

What Is the Historical Context of Ohio Magnetics Inc. for B2B Buyers?

Founded in 1917, Ohio Magnetics Inc. has a rich history in the manufacturing of lifting magnets and magnetic separation equipment. As one of the oldest companies in this sector in the United States, it has built a reputation for quality and innovation over more than a century. The company has evolved its product offerings to include advanced magnet controls and a comprehensive range of support services, including inspection and remanufacturing programs.

This historical context is significant for B2B buyers, as it reflects Ohio Magnetics’ commitment to long-term partnerships and customer satisfaction. Their extensive experience not only assures reliability but also provides clients with the confidence that they are sourcing from a trusted leader in the industry. As buyers navigate the complexities of the global market, Ohio Magnetics’ legacy serves as a testament to its capability and stability in meeting diverse industrial needs.

Illustrative image related to ohio magnetics inc

Frequently Asked Questions (FAQs) for B2B Buyers of ohio magnetics inc

1. How do I solve issues related to magnet performance and reliability?

To address performance and reliability issues with magnets, first ensure that they are regularly inspected and maintained according to the manufacturer’s guidelines. Ohio Magnetics offers comprehensive inspection and remanufacturing services to enhance the longevity and efficiency of their lifting and separation magnets. If problems persist, consult with their technical support team, who can provide expert advice on troubleshooting and optimization tailored to your specific application.

2. What is the best lifting magnet for handling scrap metal?

The optimal lifting magnet for scrap metal handling is often a bipolar or rectangular lifting magnet, designed for high-efficiency operation in scrap yards. Ohio Magnetics offers a variety of models such as the LoadStar Series and AWX Series, which are engineered for heavy-duty applications. When selecting a magnet, consider factors such as the weight of the materials being lifted, the environment in which it will operate, and compatibility with your existing equipment.

3. How can I customize a magnet solution for my specific needs?

Ohio Magnetics provides customization options for their lifting and separation magnets to meet specific operational requirements. To initiate a custom solution, contact their sales team with details about your application, including load specifications, environmental conditions, and any unique challenges. Their engineering team will work closely with you to design a magnet that meets your exact specifications, ensuring optimal performance.

4. What are the minimum order quantities (MOQs) for Ohio Magnetics products?

Minimum order quantities (MOQs) for Ohio Magnetics products can vary based on the specific product line and customization requirements. Generally, standard products may have lower MOQs, while custom solutions may require higher minimums. It’s advisable to discuss your needs directly with the sales team to understand the specific MOQs applicable to your order.

5. What payment terms does Ohio Magnetics offer for international buyers?

Ohio Magnetics typically offers flexible payment terms, which may include options such as advance payments, letters of credit, or net payment terms depending on the order size and buyer’s creditworthiness. International buyers should engage with the sales department to discuss preferred payment methods and negotiate terms that suit their financial processes and cash flow considerations.

Illustrative image related to ohio magnetics inc

6. How does Ohio Magnetics ensure quality assurance in their products?

Ohio Magnetics adheres to stringent quality assurance protocols throughout the manufacturing process. This includes rigorous inspection and testing of all products before shipment to ensure they meet industry standards and customer specifications. Clients can expect detailed documentation of quality checks and, if necessary, can request specific certifications related to their order.

7. What logistics options are available for international shipping?

Ohio Magnetics collaborates with various logistics partners to facilitate international shipping. Options typically include air freight for faster delivery or sea freight for cost-effective bulk shipping. The shipping method can be tailored based on the urgency of the order and the destination. Buyers are encouraged to discuss their logistics preferences with the sales team to ensure a smooth delivery process.

8. How can I verify the credibility of Ohio Magnetics as a supplier?

To verify the credibility of Ohio Magnetics as a supplier, consider reviewing their history and reputation within the industry, which spans over a century. Additionally, check for customer testimonials, case studies, and certifications that demonstrate their commitment to quality and service. Engaging directly with their sales or customer service teams can also provide insights into their operational practices and reliability.

Top 4 Ohio Magnetics Inc Manufacturers & Suppliers List

1. Ohio Magnetics – Lifting & Magnetic Separation Equipment

Domain: ohiomagnetics.com

Registered: 2002 (23 years)

Introduction: Lifting Magnets: Custom Steel Handling Magnets, Scrap Handling Magnets; Magnetic Separation Equipment: Stearns Suspended Magnets, Stearns Magnetic Drums, Stearns Magnetic Pulleys, Stearns Magnetic Sweepers; Magnet Controls: Magnet Controllers, DC Power Rectifiers, Emergency Power Supplies, Auxiliary Equipment; Parts & Service: Inspection, Remanufacture/Rebuild Programs for Lifting and Separation M…

2. Ohio Magnetics – Lifting Magnet Systems

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Ohio Magnetics – Lifting Magnet Systems, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Spectech Industries – Lifting Magnet Systems

Domain: spectechind.com

Registered: 2002 (23 years)

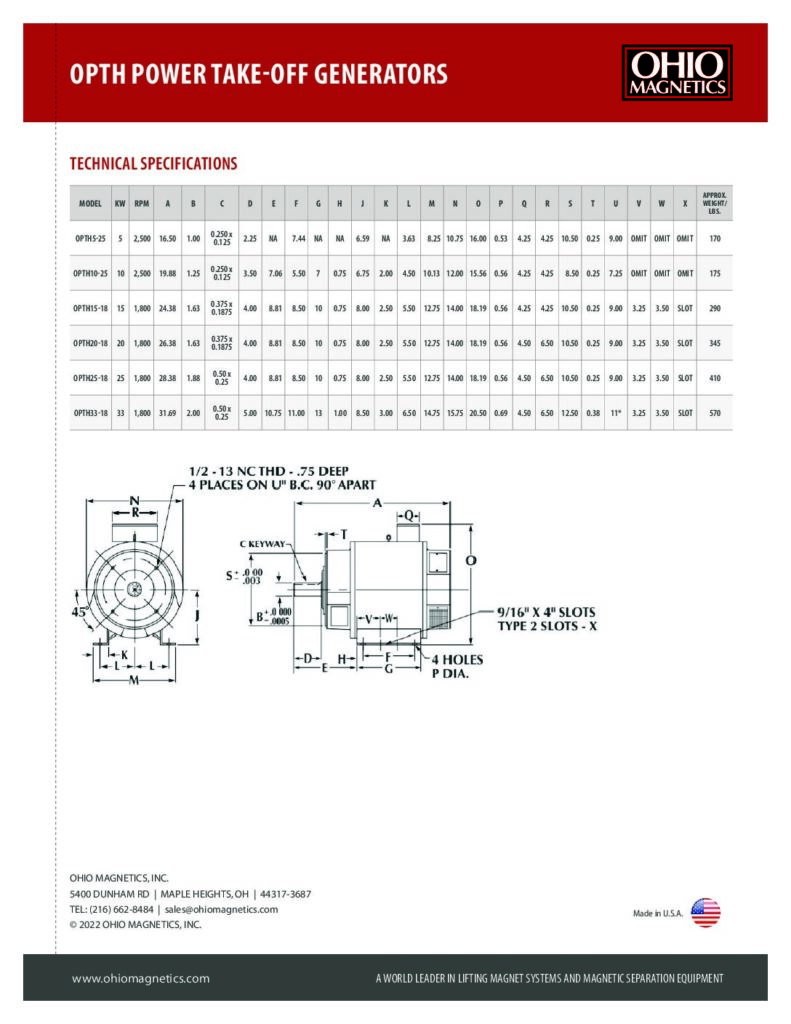

Introduction: Ohio Magnetics Lifting Magnet Systems include a wide range of products such as standard and specialized circular, bipolar, and rectangular lifting magnets. They also offer power supplies including rectifiers, power takeoff, hydraulic-driven generators, and magnet controls. Key product families include: Scrap Handling and Auxiliary Magnets, Vers-A-Lift, Pow-R-Lite, LoadStar Series, LS-X Series, AWX…

4. Ohio Magnetics – Lifting Magnet Systems

Domain: bloomberg.com

Registered: 1993 (32 years)

Introduction: Ohio Magnetics, Inc. manufactures lifting magnet systems and magnetic separation equipment. The company offers scrap handling, auxiliary equipment, steel mill type magnets, controllers, separation systems, pulleys, drums, and other related products. Ohio Magnetics serves the processing and mining operation industries in the United States.

Strategic Sourcing Conclusion and Outlook for ohio magnetics inc

In conclusion, Ohio Magnetics Inc. stands out as a pivotal player in the industrial machinery sector, specializing in lifting and separation magnet systems. With over a century of experience, their commitment to quality and innovation ensures they meet the diverse needs of clients in steel, scrap processing, recycling, and mining industries. For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, strategic sourcing from Ohio Magnetics can facilitate enhanced operational efficiency and productivity through reliable, U.S.-made products.

The importance of strategic sourcing cannot be overstated; it enables companies to optimize their supply chain, reduce costs, and improve quality through informed purchasing decisions. Ohio Magnetics’ extensive range of lifting magnets and separation equipment, along with their exceptional customer service and support programs, positions them as a valuable partner for businesses seeking to enhance their operational capabilities.

As we look to the future, Ohio Magnetics is poised to expand its global footprint, offering innovative solutions tailored to the evolving needs of international markets. We encourage B2B buyers to engage with Ohio Magnetics to explore how their products can drive efficiency and success in your operations. Connect today to discover the transformative potential of strategic sourcing with Ohio Magnetics.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.