Top 3 Ps3 Warranty Seal Suppliers (And How to Choose)

Introduction: Navigating the Global Market for ps3 warranty seal

In the fast-evolving landscape of gaming technology, sourcing a reliable PS3 warranty seal poses unique challenges for international B2B buyers. With the increasing demand for PlayStation 3 consoles, especially in regions like Africa, South America, the Middle East, and Europe, understanding the intricacies of warranty seals is crucial for ensuring product integrity and customer satisfaction. This comprehensive guide delves into the various types of PS3 warranty seals, their applications, and the critical factors to consider when vetting suppliers.

Buyers will gain insights into the specific locations of these seals on the console and the implications of seal integrity for warranty claims. Additionally, the guide will cover cost considerations, enabling businesses to make informed purchasing decisions that align with their operational budgets. By equipping B2B buyers with the knowledge to navigate the complexities of sourcing PS3 warranty seals, this resource aims to empower companies to maintain high standards of service and reliability in their product offerings.

Ultimately, whether you are a distributor in Nigeria looking to secure quality components or a retailer in Saudi Arabia aiming to enhance customer trust, this guide provides the actionable insights needed to thrive in the competitive gaming market.

Understanding ps3 warranty seal Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Warranty Seal | Basic adhesive seal, often with brand logo | General repair and resale markets | Pros: Easy to identify; Cons: Limited protection against tampering. |

| Tamper-Evident Seal | Features unique patterns that reveal tampering | High-value product protection | Pros: Enhanced security; Cons: Higher cost. |

| Holographic Seal | Multi-dimensional design with holographic effects | Luxury and premium product lines | Pros: Difficult to replicate; Cons: More expensive to produce. |

| Serialized Warranty Seal | Each seal has a unique serial number | Tracking and inventory management | Pros: Facilitates product verification; Cons: Can be cumbersome to manage. |

| Custom Branded Seal | Tailored designs for specific brands or models | Brand differentiation and loyalty | Pros: Strengthens brand identity; Cons: Higher initial investment. |

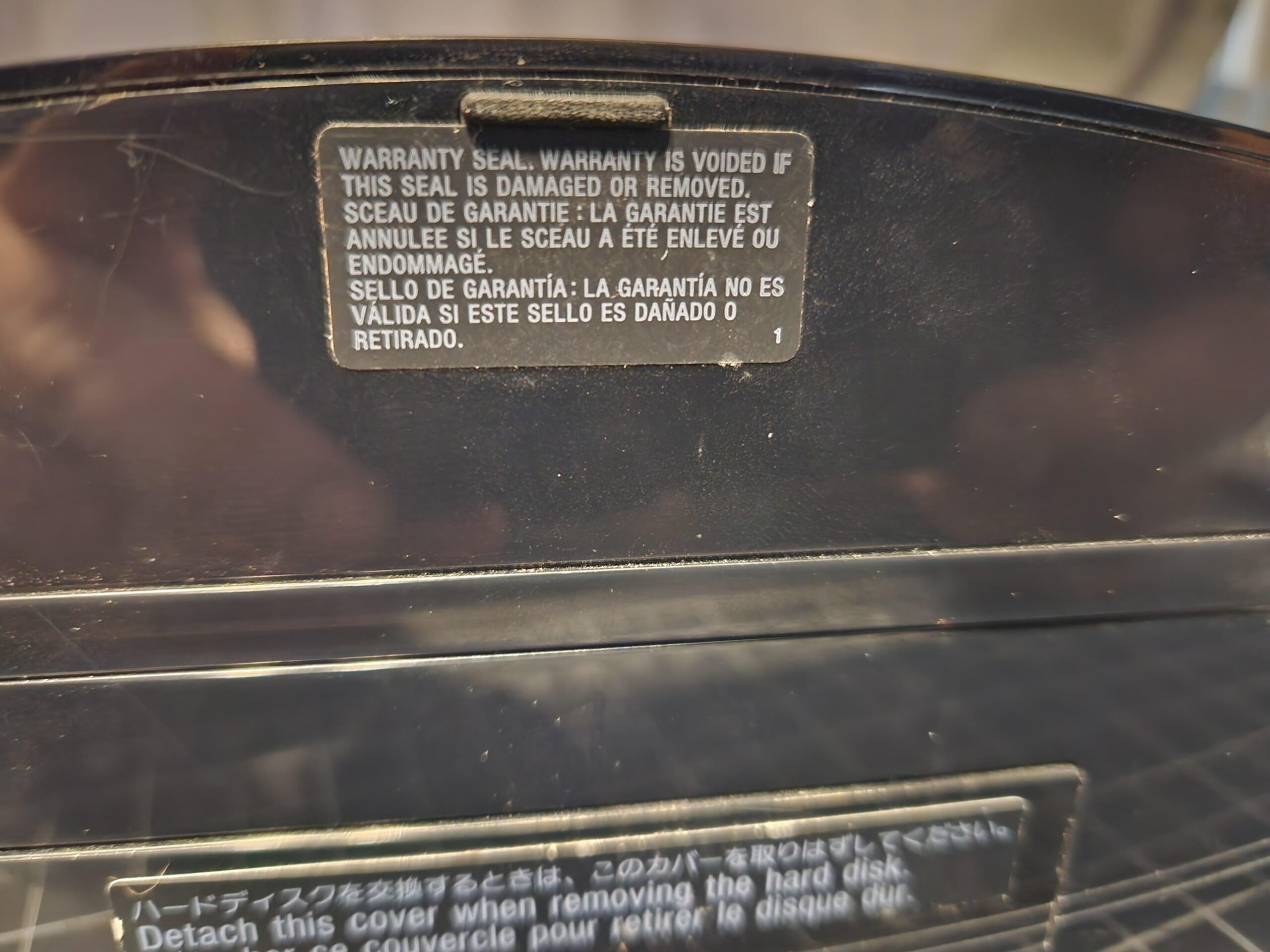

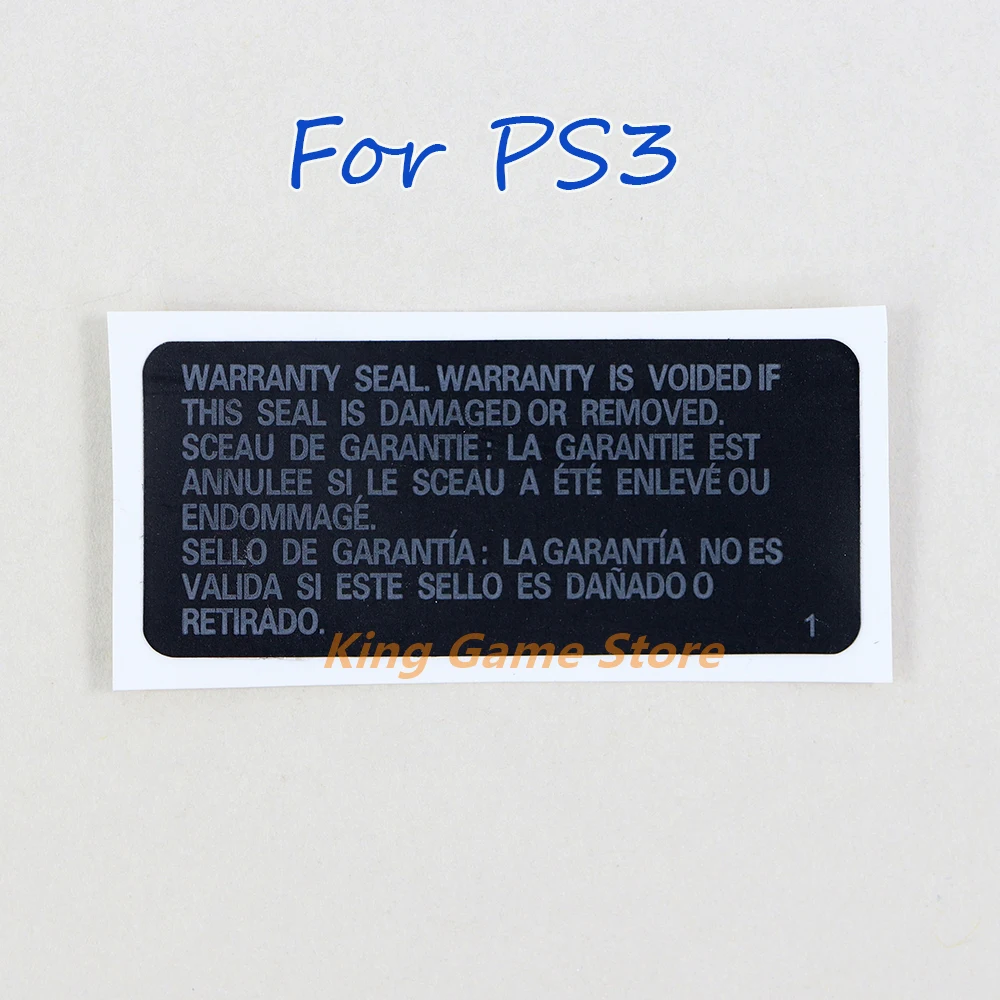

What Are the Characteristics of Standard Warranty Seals?

Standard warranty seals are the most common type found on PS3 consoles. They typically feature a basic adhesive design that may include the manufacturer’s logo. These seals are primarily used in general repair and resale markets, making them suitable for businesses that deal with refurbished or second-hand consoles. While they are easy to identify, the downside is that they offer limited protection against tampering, which may raise concerns for buyers prioritizing security.

How Do Tamper-Evident Seals Enhance Product Security?

Tamper-evident seals are designed with unique patterns that visibly change if tampered with. This type of seal is crucial for high-value product protection, as it provides a clear indication of unauthorized access. B2B buyers focusing on security will find this seal beneficial, especially for products that require a higher level of integrity. However, the enhanced security features come at a higher cost, which may affect the overall pricing strategy for businesses.

Why Are Holographic Seals Considered Premium Options?

Holographic seals are characterized by their multi-dimensional designs that create a holographic effect. These seals are often used for luxury and premium product lines, making them appealing to businesses that want to convey exclusivity. The difficulty in replicating these seals adds a layer of security, but it also results in a higher production cost. B2B buyers should weigh the benefits of brand prestige against the increased investment required for these seals.

What Are the Benefits of Serialized Warranty Seals?

Serialized warranty seals come with a unique serial number that allows for easy tracking and inventory management. This feature is particularly beneficial for businesses that need to verify product authenticity or maintain detailed records. While these seals facilitate product verification, they can be cumbersome to manage, especially for larger operations. B2B buyers must consider their capacity for inventory tracking when opting for this type of seal.

How Do Custom Branded Seals Foster Brand Loyalty?

Custom branded seals are designed specifically for certain brands or models, providing a unique identity that strengthens brand loyalty. These seals can enhance a company’s image and differentiate its products in a competitive market. However, the initial investment for custom designs can be higher, making it essential for businesses to evaluate their budget and marketing strategy. The long-term benefits of brand recognition often outweigh the upfront costs, making this a worthwhile consideration for B2B buyers.

Key Industrial Applications of ps3 warranty seal

| Industry/Sector | Specific Application of ps3 warranty seal | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Electronics Manufacturing | Quality Control in Assembly | Ensures product integrity and reduces returns | Verify seal authenticity and compliance with local standards |

| Retail & Distribution | Warranty Management for Consumer Electronics | Enhances customer trust and satisfaction | Source seals that meet international warranty requirements |

| Repair Services | Verification of Warranty Status during Repairs | Streamlines service processes and customer assurance | Ensure seals are tamper-proof and easy to verify |

| E-commerce | Fraud Prevention in Online Sales | Protects against counterfeit products | Select seals that are trackable and provide security features |

| Logistics & Supply Chain | Tracking and Authenticating Products in Transit | Minimizes losses due to theft and counterfeiting | Partner with reliable suppliers for consistent quality |

How is the PS3 Warranty Seal Used in Electronics Manufacturing?

In the electronics manufacturing sector, the PS3 warranty seal plays a pivotal role in quality control during assembly. It is applied to ensure that each unit is intact and has not been tampered with before reaching the consumer. For international buyers, particularly from regions like Africa and South America, sourcing authentic warranty seals that comply with local manufacturing standards is crucial. This prevents issues related to product returns and enhances the overall quality assurance process.

What Role Does the PS3 Warranty Seal Play in Retail & Distribution?

Retailers rely on the PS3 warranty seal for effective warranty management of consumer electronics. By ensuring that the seal remains unbroken, businesses can enhance customer trust and satisfaction, leading to improved sales and brand loyalty. For B2B buyers in the Middle East and Europe, it is essential to select warranty seals that align with international warranty protocols to avoid complications in customer service and returns.

How Does the PS3 Warranty Seal Assist Repair Services?

Repair service providers utilize the PS3 warranty seal to verify warranty status during repairs. This application helps streamline service processes and assures customers that their products are being handled with care. For B2B buyers, especially in regions with a growing electronics repair market, sourcing tamper-proof seals that are easy to authenticate is vital for maintaining credibility and ensuring smooth operations.

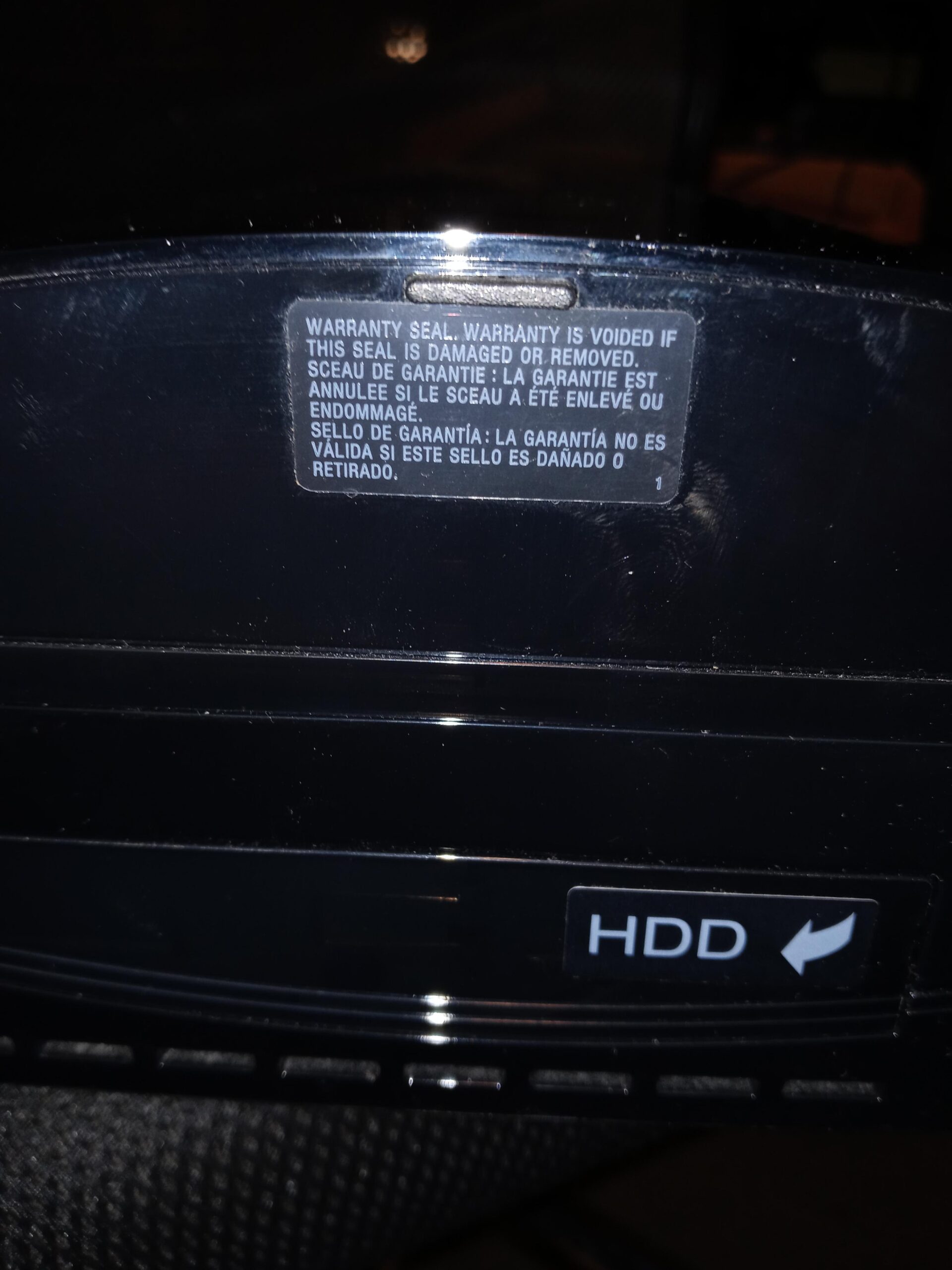

Illustrative image related to ps3 warranty seal

In What Ways Does the PS3 Warranty Seal Contribute to E-commerce?

In the e-commerce sector, the PS3 warranty seal is essential for fraud prevention. It helps protect against counterfeit products, ensuring that customers receive genuine items. For international B2B buyers, particularly those operating in diverse markets like Nigeria and Saudi Arabia, selecting seals that incorporate trackable features and robust security measures is crucial to safeguard their brand reputation and build customer confidence.

How Does the PS3 Warranty Seal Enhance Logistics & Supply Chain Management?

The PS3 warranty seal serves a significant function in logistics and supply chain management by tracking and authenticating products during transit. This application minimizes losses due to theft and counterfeiting, which is especially important for B2B buyers operating in regions with higher risks of such issues. Partnering with reliable suppliers for consistent quality and authenticity of the seals is essential for ensuring product integrity throughout the supply chain.

3 Common User Pain Points for ‘ps3 warranty seal’ & Their Solutions

Scenario 1: Difficulty in Identifying Authenticity of PS3 Warranty Seals

The Problem: B2B buyers, especially those sourcing PS3 consoles for resale or refurbishment, often face challenges in verifying the authenticity of warranty seals. Counterfeit or damaged seals can lead to complications with warranties, impacting resale value and customer trust. This issue is particularly acute for international buyers in regions like Africa and South America, where access to original parts may be limited, and counterfeit products are prevalent.

The Solution: To mitigate this risk, buyers should establish relationships with reputable suppliers who provide certified warranty seals. Conduct thorough due diligence by checking supplier credentials and requesting proof of authenticity for the seals. Additionally, implementing a verification system that includes checking the seal’s unique identifiers or serial numbers against manufacturer databases can help ensure the legitimacy of the product. Regular training on identifying authentic seals can also empower staff to recognize potential counterfeits.

Scenario 2: Challenges in Warranty Claims Due to Seal Damage

The Problem: B2B buyers may encounter situations where warranty claims are denied due to damaged or tampered warranty seals. This often occurs during the repair process or when products are disassembled for inspection. For businesses operating in competitive markets, such losses can significantly affect profit margins and customer satisfaction, especially in regions like the Middle East and Europe, where consumer protection laws are stringent.

The Solution: To address this issue, companies should implement strict protocols for handling products with warranty seals. This includes training technicians on the importance of preserving seals during repairs and using specialized tools that minimize damage when accessing internal components. Additionally, businesses can establish a communication channel with manufacturers to clarify warranty terms and conditions, ensuring that any necessary disassembly is covered under the warranty guidelines. Maintaining detailed records of all service actions can also support claims in case of disputes.

Scenario 3: Misunderstanding Warranty Seal Regulations Across Regions

The Problem: International B2B buyers often grapple with varying regulations and practices regarding warranty seals across different markets. This complexity can lead to misunderstandings about warranty coverage and responsibilities, particularly for companies operating in diverse regions like Nigeria and Saudi Arabia. Misalignment with local regulations can result in legal issues or financial penalties.

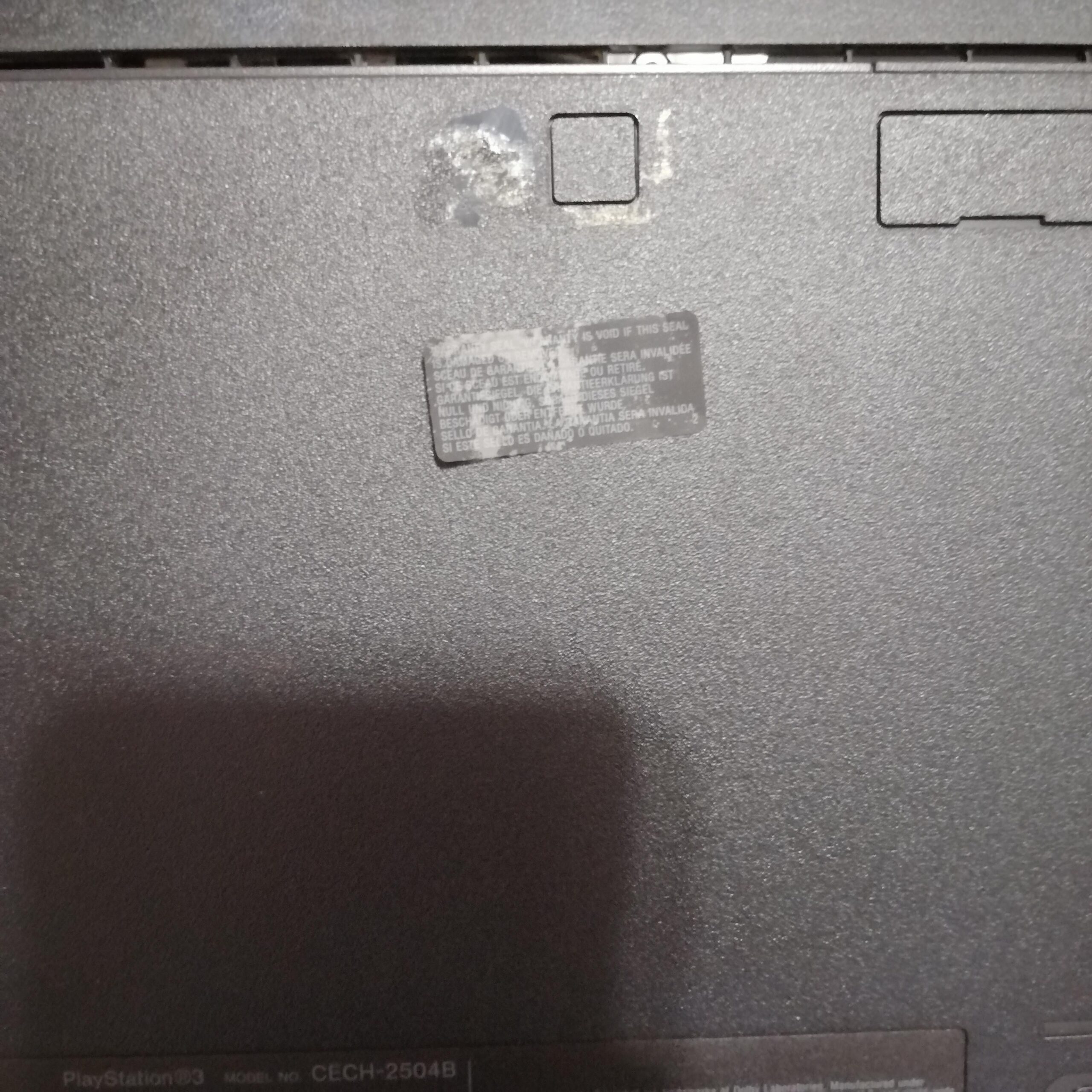

Illustrative image related to ps3 warranty seal

The Solution: To navigate these regulatory challenges, it is crucial for businesses to engage local legal experts who understand the nuances of warranty regulations in each target market. Establishing a compliance framework that aligns with local laws while maintaining consistency with manufacturer guidelines will help ensure all warranty seals are handled appropriately. Additionally, creating a comprehensive training program for staff on regional warranty policies can enhance understanding and compliance, reducing the risk of costly mistakes. Regular audits and updates to the compliance framework will ensure ongoing adherence to changing regulations.

Strategic Material Selection Guide for ps3 warranty seal

When selecting materials for the PS3 warranty seal, it is crucial to consider the specific requirements of the application, including durability, environmental resistance, and compliance with international standards. Below is an analysis of four common materials used for warranty seals, tailored to the needs of B2B buyers in diverse markets such as Africa, South America, the Middle East, and Europe.

What are the Key Properties of Polyvinyl Chloride (PVC) for PS3 Warranty Seals?

Polyvinyl Chloride (PVC) is a widely used thermoplastic known for its excellent chemical resistance and durability. It can withstand moderate temperatures and is resistant to moisture, making it suitable for electronic applications. PVC is also relatively lightweight, which can reduce shipping costs.

Pros: PVC is cost-effective and easy to manufacture, allowing for high-volume production. Its flexibility enables it to conform to various shapes, which is beneficial for sealing applications.

Cons: While PVC is durable, it has limitations in high-temperature environments and can become brittle over time, especially when exposed to UV light. Additionally, it may not be suitable for applications requiring extreme flexibility.

Impact on Application: PVC is compatible with a range of media, including water and oils, but may not perform well with solvents or high-temperature conditions.

Considerations for International Buyers: Buyers should ensure compliance with local regulations regarding PVC use, especially in regions with strict environmental laws. Standards such as ASTM D1784 for PVC materials may be relevant.

How Does Polyethylene (PE) Perform as a Material for Warranty Seals?

Polyethylene (PE) is another common material for warranty seals, known for its excellent moisture barrier properties and chemical resistance. It is available in various densities, allowing for customization based on strength and flexibility requirements.

Pros: PE is lightweight, cost-effective, and exhibits good impact resistance. Its flexibility allows for easy application and sealing.

Cons: PE has a lower temperature resistance compared to other materials, which may limit its use in high-heat environments. It also has a lower tensile strength than some alternatives.

Impact on Application: PE is compatible with various substances, including water and many chemicals, but may not be suitable for high-polarity solvents.

Considerations for International Buyers: Buyers should be aware of the different grades of PE and their respective applications. Compliance with international standards such as ISO 1183 for plastics may be necessary.

What are the Advantages of Using Polypropylene (PP) for PS3 Warranty Seals?

Polypropylene (PP) is a versatile thermoplastic that offers excellent chemical resistance and a higher melting point than both PVC and PE. This makes it suitable for applications that may experience elevated temperatures.

Pros: PP is lightweight, durable, and resistant to moisture and chemicals. It is also less likely to become brittle over time, which enhances its longevity in sealing applications.

Cons: While PP has many advantages, it can be more expensive than PVC and PE, potentially impacting overall project budgets. Additionally, its manufacturing process can be more complex.

Impact on Application: PP is compatible with a wide range of media, including oils and solvents, making it a robust choice for warranty seals.

Considerations for International Buyers: Buyers should consider compliance with standards such as ASTM D4101 for polypropylene. Additionally, understanding the local market’s preferences for material types can guide purchasing decisions.

Why Consider Silicone for PS3 Warranty Seals?

Silicone is a high-performance elastomer known for its exceptional temperature resistance and flexibility. It can withstand extreme temperatures, making it ideal for applications where thermal stability is critical.

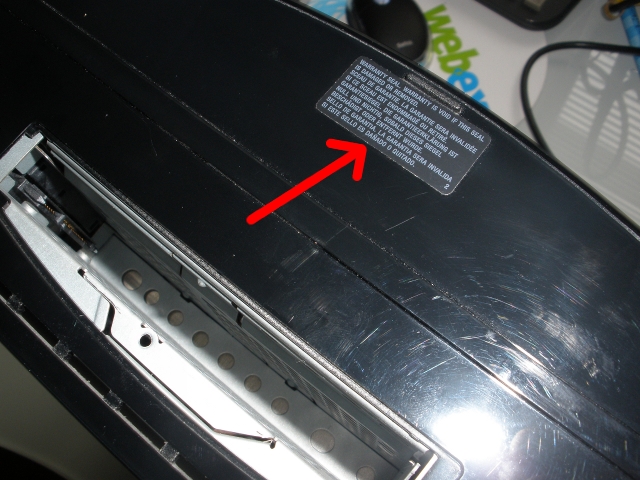

Illustrative image related to ps3 warranty seal

Pros: Silicone provides excellent sealing capabilities, is resistant to UV light, and has a long service life. Its flexibility allows for easy application and adaptation to various shapes.

Cons: Silicone is generally more expensive than other materials, which may be a concern for budget-conscious buyers. Additionally, its manufacturing process can be more complex.

Impact on Application: Silicone is compatible with a wide range of substances, including oils and solvents, making it suitable for diverse applications.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM D2000 for rubber materials. The higher cost may be justified in applications requiring superior performance.

| Material | Typical Use Case for ps3 warranty seal | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | General sealing applications | Cost-effective and flexible | Limited high-temperature resistance | Low |

| Polyethylene | Moisture barrier seals | Lightweight and impact-resistant | Lower temperature resistance | Low |

| Polypropylene | Chemical-resistant seals | High melting point and durability | More expensive than PVC/PE | Medium |

| Silicone | High-performance sealing | Exceptional temperature resistance | Higher cost and complexity | High |

This material selection guide provides actionable insights for B2B buyers, enabling them to make informed decisions based on their specific needs and compliance requirements in diverse markets.

In-depth Look: Manufacturing Processes and Quality Assurance for ps3 warranty seal

What Are the Main Stages of the Manufacturing Process for PS3 Warranty Seals?

The manufacturing process for PS3 warranty seals encompasses several critical stages that ensure the product meets quality and performance standards. The key stages include material preparation, forming, assembly, and finishing.

Material Preparation: Sourcing and Quality Control

The initial step involves sourcing raw materials that comply with industry standards. Common materials for warranty seals include high-quality adhesives and polymer films that exhibit durability and resistance to environmental factors. Suppliers should provide certificates of conformity to verify that materials meet international standards, such as ISO 9001. It’s advisable for B2B buyers to inquire about the supplier’s sourcing practices, ensuring that materials are sourced ethically and sustainably.

Forming: Precision and Technology

In the forming stage, raw materials are shaped into the desired form of the warranty seal. This process often utilizes advanced techniques such as die-cutting or laser cutting, which ensures precision and consistency in dimensions. The use of automated machinery can enhance the efficiency of this stage, minimizing human error. Buyers should look for suppliers who invest in modern technology and maintain a rigorous maintenance schedule for their equipment, which can directly impact the quality of the final product.

Assembly: Quality Control Measures

Once the seals are formed, they proceed to the assembly stage. This involves integrating additional features, such as tamper-evident designs that enhance security. Key aspects of this stage include proper alignment and adhesion of components. B2B buyers should ensure that their suppliers implement strict assembly protocols and use trained personnel to mitigate errors. Quality checks during this phase are crucial, as any defects can compromise the integrity of the warranty seal.

Finishing: Ensuring Durability and Aesthetics

The finishing stage adds the final touches to the warranty seals, which may include surface treatments for enhanced durability or printing for branding purposes. This stage also involves applying protective coatings to enhance resistance against wear and environmental conditions. Buyers should inquire about the types of finishes offered and their longevity, as this can affect the performance of the seal over time.

Illustrative image related to ps3 warranty seal

What Quality Assurance Practices Are Essential for PS3 Warranty Seals?

Quality assurance is paramount in the production of PS3 warranty seals to ensure they function as intended and comply with international standards.

Which International Standards Should B2B Buyers Consider?

When assessing potential suppliers, B2B buyers should prioritize those who adhere to internationally recognized standards such as ISO 9001, which focuses on quality management systems. Additionally, certifications like CE (Conformité Européenne) and API (American Petroleum Institute) can indicate compliance with specific industry requirements. Buyers in regions like Africa and South America may also need to consider local regulations that could influence product standards.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are critical at various stages of the manufacturing process.

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials upon arrival. Suppliers should have robust procedures to evaluate materials before production begins.

-

In-Process Quality Control (IPQC): During production, real-time monitoring is essential. This phase includes regular inspections to ensure adherence to specifications and standards.

-

Final Quality Control (FQC): Before products are shipped, a thorough inspection is performed to identify defects or deviations. This stage often includes functional testing to verify that the warranty seals perform their intended function.

B2B buyers should insist on detailed reporting from suppliers regarding their quality control processes, including documentation of inspections and testing results.

How Can B2B Buyers Verify Supplier Quality Assurance?

To ensure that suppliers maintain high-quality standards, B2B buyers can employ several verification methods.

What Types of Audits Should Buyers Conduct?

Conducting supplier audits is a critical step in verifying quality assurance practices. These audits can be either announced or unannounced and should assess various aspects, including manufacturing processes, quality control measures, and compliance with industry standards. Buyers should consider engaging third-party inspection agencies that specialize in auditing manufacturing facilities to provide an unbiased evaluation.

How Important Are Reports and Certifications?

Requesting certifications and quality assurance reports is vital for establishing trust in a supplier’s capabilities. Buyers should review documents that verify adherence to international standards and any industry-specific certifications. These documents should include details on the methodologies used during testing and the outcomes of previous audits.

What Are the Common Testing Methods for Warranty Seals?

Different testing methods are employed to ensure the quality and effectiveness of PS3 warranty seals.

What Testing Techniques Are Most Relevant?

-

Adhesion Testing: This method assesses the bond strength of the adhesive used in the warranty seal, ensuring it can withstand environmental stressors.

-

Durability Testing: Warranty seals should undergo tests that simulate long-term exposure to various conditions, such as temperature fluctuations, humidity, and UV exposure.

-

Tamper-Evidence Testing: This ensures that the seal cannot be removed or altered without visible damage, maintaining the integrity of the warranty.

B2B buyers should inquire about the specific testing methodologies employed by suppliers and the frequency of these tests to ensure ongoing compliance with quality standards.

Illustrative image related to ps3 warranty seal

What Nuances Should International B2B Buyers Consider?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, several nuances can impact the quality assurance process.

How Do Regional Regulations Affect Quality Standards?

Each region may have its own set of regulations that influence quality standards. Buyers should familiarize themselves with local compliance requirements, especially in countries like Nigeria and Saudi Arabia, where regulations may differ significantly from European standards. Engaging with local experts or consultants can provide valuable insights into these requirements.

What Role Do Cultural Differences Play in Quality Assurance?

Cultural differences may impact communication and expectations regarding quality assurance. B2B buyers should ensure that their suppliers understand their quality requirements and are willing to adapt their processes to meet these expectations. Building strong relationships with suppliers can facilitate better communication and understanding of quality standards.

By understanding the manufacturing processes and quality assurance measures for PS3 warranty seals, B2B buyers can make informed decisions that ensure product integrity and compliance with international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘ps3 warranty seal’

This sourcing guide aims to assist B2B buyers in effectively procuring PS3 warranty seals, essential for ensuring product integrity and compliance in the gaming console market. By following this checklist, you can streamline your sourcing process and secure high-quality seals that meet your business needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is critical before initiating your search for PS3 warranty seals. This includes understanding the dimensions, adhesive quality, and durability requirements that align with your product needs. A well-defined specification will help you communicate effectively with suppliers and ensure the seals are suitable for your intended applications.

Step 2: Identify Reliable Suppliers

Finding trustworthy suppliers is paramount to the procurement process. Research potential suppliers through industry directories, trade shows, and online platforms. Look for suppliers with a proven track record in providing warranty seals and verify their business credentials to ensure reliability.

Step 3: Evaluate Supplier Certifications and Compliance

Before making a purchase, it’s essential to verify that suppliers hold relevant certifications, such as ISO or equivalent quality standards. This ensures that the warranty seals meet international quality and safety benchmarks. Check for compliance with local regulations in your target markets, especially if you are sourcing from different regions.

Step 4: Request Samples for Quality Assessment

Once you have shortlisted potential suppliers, request samples of the PS3 warranty seals. This allows you to assess the quality, adhesive strength, and overall durability of the seals firsthand. Evaluate the samples against your defined specifications to ensure they meet your expectations before placing a bulk order.

Step 5: Negotiate Pricing and Terms

Engage in negotiations with your chosen supplier to establish favorable pricing and terms. Discuss bulk order discounts, payment terms, and lead times. Having a clear understanding of these factors can significantly impact your overall procurement costs and cash flow.

Step 6: Review Shipping and Delivery Options

Consider the shipping methods and delivery timelines offered by your supplier. This is especially important if you are sourcing internationally, as delays can affect your production schedules. Ensure that the shipping options align with your operational needs and budget.

Step 7: Establish a Quality Assurance Process

After securing your order, implement a quality assurance process to monitor the incoming warranty seals. This can include visual inspections and tests to confirm that the seals meet your specifications. Establishing this process will help mitigate risks associated with product returns and warranty claims down the line.

By following this practical sourcing guide, B2B buyers can ensure they procure high-quality PS3 warranty seals that enhance product reliability and customer satisfaction. Each step is designed to minimize risks and streamline the procurement process, ultimately leading to better business outcomes.

Comprehensive Cost and Pricing Analysis for ps3 warranty seal Sourcing

What Are the Key Cost Components for PS3 Warranty Seal Sourcing?

When analyzing the cost structure for sourcing PS3 warranty seals, several components must be considered. The primary cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Illustrative image related to ps3 warranty seal

-

Materials: The type of adhesive and plastic used in warranty seals can significantly affect costs. High-quality materials that offer durability and resistance to tampering may be more expensive but essential for maintaining product integrity. Buyers should inquire about the sourcing of materials, as local suppliers may offer cost advantages due to lower shipping costs.

-

Labor: Labor costs vary based on the region of production. Countries with lower labor costs might provide a more competitive pricing structure; however, it’s crucial to balance this with the quality of workmanship. Skilled labor can lead to better quality control, reducing defects and returns.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities and facility maintenance. Understanding the overhead rates of potential suppliers can provide insights into the overall pricing structure.

-

Tooling: Initial tooling costs for custom designs can be significant. Buyers should evaluate the need for bespoke seals versus standardized options, as this will impact upfront investment and lead times.

-

Quality Control (QC): Implementing stringent QC processes is essential, especially for warranty seals, as they serve as a deterrent against tampering. The cost of QC should be factored into the overall pricing, as it directly affects the reliability and reputation of the product.

-

Logistics: Shipping costs can fluctuate based on the chosen Incoterms and the distance from the supplier to the buyer’s location. For international buyers, understanding these logistics costs is crucial to avoid unexpected expenses.

-

Margin: Suppliers typically include a profit margin in their pricing. The margin can vary based on market demand, competition, and the supplier’s operational costs.

What Factors Influence Pricing for PS3 Warranty Seals?

Several factors can influence the pricing of PS3 warranty seals beyond the basic cost components.

-

Volume/MOQ: Bulk purchasing often leads to lower per-unit costs. Suppliers may have minimum order quantities (MOQ) that buyers should be aware of, as meeting or exceeding these thresholds can yield significant savings.

-

Specifications and Customization: Custom-designed seals may incur higher costs due to the complexity of production. Buyers should weigh the benefits of customization against the potential for cost savings with standard options.

-

Quality and Certifications: Warranty seals that meet international quality standards or certifications may command higher prices. However, investing in quality can reduce the Total Cost of Ownership (TCO) by minimizing returns and enhancing customer satisfaction.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers with a proven track record may charge a premium, but they often provide better service and quality assurance.

-

Incoterms: Understanding the implications of different Incoterms can help buyers manage costs effectively. Terms that place more responsibility on the buyer can lead to lower initial prices but potentially higher logistics costs.

What Are Effective Buyer Tips for Negotiating PS3 Warranty Seal Prices?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, negotiation strategies can lead to more favorable pricing.

-

Research and Compare: Conduct thorough research on multiple suppliers to compare pricing and services. Leverage competitive offers to negotiate better terms.

-

Focus on Total Cost of Ownership: Consider not just the upfront cost but also long-term implications. A higher initial investment in quality seals may reduce replacement and warranty claims costs.

-

Engage in Long-term Partnerships: Establishing ongoing relationships with suppliers can result in better pricing over time. Loyal customers may receive discounts or priority treatment on orders.

-

Be Transparent About Needs: Clear communication regarding volume needs and product specifications can help suppliers provide more accurate quotes and avoid unforeseen costs.

-

Utilize Local Resources: Engage local intermediaries or sourcing agents who understand the regional market dynamics. This can enhance negotiation power and facilitate smoother transactions.

By understanding the cost structure, pricing influencers, and effective negotiation strategies, B2B buyers can make informed decisions when sourcing PS3 warranty seals, ensuring both quality and cost-efficiency.

Alternatives Analysis: Comparing ps3 warranty seal With Other Solutions

Exploring Alternatives to the PS3 Warranty Seal

When considering the PS3 warranty seal, it’s essential for B2B buyers to evaluate alternative solutions that can serve similar purposes in protecting electronic devices. These alternatives may offer different benefits, such as cost savings, ease of use, or enhanced security features. Below, we compare the PS3 warranty seal against two viable alternatives: tamper-evident tape and electronic warranty tracking systems.

Illustrative image related to ps3 warranty seal

| Comparison Aspect | Ps3 Warranty Seal | Tamper-Evident Tape | Electronic Warranty Tracking System |

|---|---|---|---|

| Performance | High | Moderate | High |

| Cost | Moderate | Low | High |

| Ease of Implementation | Moderate | Easy | Moderate |

| Maintenance | Low | Low | High |

| Best Use Case | Warranty assurance | General tamper-proofing | Comprehensive warranty management |

What are the Advantages and Disadvantages of Tamper-Evident Tape?

Tamper-evident tape serves as a cost-effective alternative to the PS3 warranty seal. It is designed to show clear signs of tampering when removed, thereby ensuring that any unauthorized access is immediately evident. This solution is particularly advantageous for companies looking for a budget-friendly option without sacrificing security. The ease of application makes it accessible for businesses with limited technical expertise. However, while it can effectively deter tampering, it does not provide the same level of assurance as a warranty seal, especially for high-value electronics like gaming consoles.

How Does an Electronic Warranty Tracking System Compare?

Electronic warranty tracking systems offer a modern approach to warranty management by leveraging technology to track and manage warranties digitally. This method allows for comprehensive monitoring of warranty claims, service histories, and product registrations. It excels in performance, especially for businesses with high volumes of electronics, as it minimizes paperwork and provides real-time updates. However, the initial investment in software and ongoing maintenance costs can be substantial, making it less appealing for smaller businesses. Despite these costs, the long-term benefits of streamlined processes and enhanced tracking capabilities often outweigh the upfront expenses.

Conclusion: Which Solution Should B2B Buyers Choose?

When selecting the right solution for warranty assurance, B2B buyers must assess their specific needs, budget, and operational capabilities. The PS3 warranty seal is an excellent choice for high-value items requiring strict tamper evidence, while tamper-evident tape offers a more economical option for general use. For companies looking to embrace digital transformation, an electronic warranty tracking system could provide significant long-term benefits, albeit with higher initial costs. Ultimately, understanding the nuances of each alternative will empower businesses to make informed decisions that align with their strategic goals.

Essential Technical Properties and Trade Terminology for ps3 warranty seal

What Are the Key Technical Properties of a PS3 Warranty Seal?

Understanding the essential technical properties of a PS3 warranty seal is crucial for international B2B buyers. These properties ensure that the seal effectively protects the integrity of the console and safeguards manufacturers’ warranties.

-

Material Composition

The PS3 warranty seal is typically made from high-grade vinyl or polyester. These materials are resistant to tearing and environmental factors, ensuring durability. For B2B buyers, selecting a warranty seal made from premium materials is vital, as it reflects the product’s quality and longevity, ultimately impacting customer satisfaction. -

Adhesive Strength

The adhesive used in the warranty seal is crucial for its effectiveness. A strong adhesive ensures that the seal remains intact during shipping and handling, preventing unauthorized access to the device. In B2B transactions, understanding adhesive strength can aid in evaluating the seal’s reliability and the potential for warranty claims, thus protecting the buyer’s investment. -

Tamper Evidence

A critical feature of the PS3 warranty seal is its tamper-evident design. This means that once the seal is broken, it cannot be resealed without visible evidence of tampering. For businesses, this property is essential as it helps in maintaining the warranty’s integrity, deterring fraud, and ensuring that customers receive genuine products. -

Temperature Resistance

The warranty seal must withstand a range of temperatures, especially considering that gaming consoles can be used in various environments. A seal that can endure extreme heat or cold without compromising its adhesive properties is essential for maintaining warranty conditions. B2B buyers should prioritize temperature resistance to avoid potential issues in diverse climatic regions. -

Size and Shape Specifications

Each warranty seal has specific dimensions and shapes tailored to fit the PS3 console. These specifications ensure that the seal covers critical access points without obstructing functionality. For B2B buyers, understanding these dimensions is crucial for compliance with packaging and shipping regulations, as well as for ensuring that the seal effectively protects the product.

What Are the Common Trade Terminologies Related to PS3 Warranty Seals?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions involving PS3 warranty seals. Here are some key terms to know:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of PS3 warranty seals, an OEM may supply the seals directly to console manufacturers. Understanding OEM relationships can help buyers identify reliable sources and ensure product authenticity. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ for PS3 warranty seals is crucial for budgeting and inventory management. This term often influences purchasing decisions, particularly for smaller businesses. -

RFQ (Request for Quotation)

An RFQ is a document sent by a buyer to potential suppliers requesting pricing and terms for specific goods or services. When sourcing PS3 warranty seals, an RFQ can help buyers compare offers and negotiate better deals, ensuring they get the best value for their investment. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in the shipping process. Familiarity with these terms is essential for B2B transactions involving PS3 warranty seals, as they clarify who is responsible for shipping costs, insurance, and risk during transport. -

Lead Time

Lead time refers to the amount of time it takes from placing an order until it is fulfilled. Understanding lead times for PS3 warranty seals is critical for businesses planning their inventory and ensuring timely delivery to customers. -

Certification Standards

Certification standards are guidelines that products must meet to ensure quality and safety. For warranty seals, certification may pertain to material safety or tamper-evidence features. B2B buyers should ensure that the seals they purchase meet relevant certification standards to maintain quality assurance and compliance.

By familiarizing themselves with these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing PS3 warranty seals, ensuring they protect their investments and maintain customer trust.

Navigating Market Dynamics and Sourcing Trends in the ps3 warranty seal Sector

What Are the Current Trends Driving the PS3 Warranty Seal Market?

The PS3 warranty seal market is witnessing several dynamic shifts influenced by global sourcing trends and evolving consumer expectations. One of the primary drivers is the increasing demand for gaming consoles in emerging markets such as Africa and South America, where the gaming culture is rapidly expanding. In these regions, local distributors and retailers are seeking reliable warranty seals to ensure product authenticity and customer satisfaction, creating a robust market for B2B suppliers.

Technological advancements are also reshaping sourcing strategies. Businesses are increasingly adopting digital platforms for procurement, enabling them to source materials and components more efficiently. This trend is especially prominent in the Middle East and Europe, where B2B buyers are leveraging data analytics to optimize their supply chains and predict market needs. Furthermore, the rise of e-commerce is prompting suppliers to diversify their offerings, including customizable warranty seals that cater to specific market requirements.

Another significant trend is the emphasis on quality assurance and compliance. With rising concerns over counterfeit products, B2B buyers are prioritizing suppliers who can demonstrate the reliability and integrity of their warranty seals. This shift is prompting manufacturers to invest in advanced technologies for seal production, such as tamper-proof materials and holographic designs that enhance security and traceability.

How Does Sustainability Impact Sourcing in the PS3 Warranty Seal Sector?

Sustainability is becoming increasingly important in the PS3 warranty seal market, influencing sourcing decisions across international supply chains. As businesses face growing pressure to adopt environmentally friendly practices, there is a heightened focus on the environmental impact of materials used in warranty seals. Buyers are now actively seeking suppliers who utilize sustainable materials, such as recycled plastics or biodegradable options, which align with their corporate social responsibility goals.

The importance of ethical sourcing cannot be overstated. B2B buyers are increasingly scrutinizing the supply chain to ensure that their products are sourced from manufacturers who adhere to ethical labor practices. This focus on ethical supply chains not only enhances brand reputation but also fosters trust among consumers, particularly in regions where ethical considerations are paramount, such as Europe.

Moreover, obtaining green certifications for warranty seals can provide a competitive edge in the marketplace. Certifications such as ISO 14001 or FSC (Forest Stewardship Council) can validate a supplier’s commitment to sustainability and responsible sourcing, making them more attractive to environmentally-conscious buyers. As the demand for sustainable products continues to rise, suppliers who prioritize eco-friendly materials and practices will likely find themselves at a significant advantage.

What is the Historical Context of the PS3 Warranty Seal Market?

The PS3 warranty seal market has evolved significantly since the console’s launch in 2006. Initially, warranty seals were primarily designed to deter tampering and ensure product integrity. As gaming technology advanced, so did the complexity and security of these seals. The introduction of digital rights management (DRM) and online gaming further highlighted the importance of authenticity, leading manufacturers to innovate warranty seals with enhanced security features.

Over the years, as gaming became a global phenomenon, the demand for PS3 warranty seals expanded beyond traditional markets. This evolution has pushed suppliers to adapt to varying regional requirements, ensuring that their products meet the expectations of diverse consumer bases across Africa, South America, the Middle East, and Europe. Today, the focus is not only on functionality but also on sustainability and ethical sourcing, reflecting broader societal shifts toward responsible consumption.

In summary, understanding the market dynamics, sustainability trends, and historical context of the PS3 warranty seal sector is essential for B2B buyers seeking to navigate this complex landscape effectively. By aligning with innovative suppliers who prioritize quality, sustainability, and ethical practices, businesses can position themselves for success in a competitive market.

Frequently Asked Questions (FAQs) for B2B Buyers of ps3 warranty seal

-

1. How do I ensure the authenticity of PS3 warranty seals when sourcing from international suppliers?

To verify the authenticity of PS3 warranty seals, conduct thorough due diligence on potential suppliers. Request samples to inspect quality and adherence to specifications. Use trusted platforms or trade organizations to vet suppliers and ensure they have a history of reliable transactions. Additionally, seek references from other businesses that have sourced similar products. Establishing a clear communication line and documenting agreements can also help mitigate risks associated with counterfeit products. -

2. What is the best way to negotiate payment terms for PS3 warranty seals?

When negotiating payment terms, consider factors such as the total order value, your relationship with the supplier, and market conditions. Aim for terms that balance cash flow and supplier security, such as a partial upfront payment with the balance upon delivery. For international transactions, consider using letters of credit or escrow services to protect both parties. Always document payment agreements clearly and ensure they are understood by both sides to avoid misunderstandings. -

3. What is the minimum order quantity (MOQ) for PS3 warranty seals from suppliers?

Minimum order quantities (MOQs) can vary widely based on the supplier, production capabilities, and regional factors. Typically, MOQs for PS3 warranty seals may range from 500 to 10,000 units. Before placing an order, inquire about the supplier’s flexibility in MOQs, especially if you are testing the market or entering a new region. Some suppliers may offer lower MOQs for first-time buyers or bulk orders, so it’s worth negotiating based on your specific needs. -

4. How can I customize PS3 warranty seals for my brand?

Customization options for PS3 warranty seals often include branding elements such as logos, colors, and specific designs. When sourcing, communicate your branding needs clearly to the supplier and inquire about available customization services. Some manufacturers may offer a design service, while others may require you to provide your own artwork. Be sure to discuss lead times for custom orders, as these can extend delivery times depending on the complexity of the design. -

5. What quality assurance measures should I expect from suppliers of PS3 warranty seals?

Quality assurance measures can vary by supplier, but reputable manufacturers should have established processes for testing and inspecting warranty seals. Inquire about their quality control protocols, including materials used, production methods, and any certifications they hold. Request documentation of quality checks, such as ISO certifications or third-party testing results. Establishing a quality assurance agreement in your contract can further ensure that products meet your standards before shipment. -

6. How do I handle logistics and shipping for PS3 warranty seals internationally?

Handling logistics for international shipments of PS3 warranty seals involves understanding customs regulations, shipping options, and potential tariffs. Work with a freight forwarder who specializes in international trade to streamline the process. Discuss shipping methods (air, sea, or land) based on your timeline and budget. Ensure that all necessary documentation, such as commercial invoices and packing lists, is prepared to avoid delays at customs. Tracking shipments can also help manage expectations and address issues proactively. -

7. What are the common challenges faced when sourcing PS3 warranty seals internationally?

Common challenges include navigating different regulatory environments, potential language barriers, and cultural differences in business practices. Additionally, fluctuating exchange rates can impact costs. It’s crucial to conduct market research to understand regional demands and compliance requirements. Establishing clear communication and building strong relationships with suppliers can help mitigate these challenges. Consider working with local partners who understand the market dynamics in regions like Africa, South America, and the Middle East. -

8. How do I ensure timely delivery of PS3 warranty seals from international suppliers?

To ensure timely delivery, set clear deadlines with suppliers and establish a production timeline during negotiations. Regularly communicate with your supplier to monitor progress and address any potential delays. It’s advisable to include buffer time in your scheduling to accommodate unforeseen circumstances such as customs delays or production issues. Utilizing reliable logistics partners and tracking shipments can further enhance your ability to meet delivery timelines.

Top 3 Ps3 Warranty Seal Manufacturers & Suppliers List

1. PS3 – Backwards Compatible Gaming Console

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Backwards compatible PS3, warranty seal intact, loud while playing games, opened for cleaning and thermal paste replacement, surprisingly clean inside, running better after maintenance, used for streaming PS1, PS2, and PS3 games.

2. Unbranded – PS3 Warranty Sticker

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Ps3 Warranty Sticker, Compatible Model: Sony PlayStation 3, Type: Casing/Housing, Brand: Unbranded, Condition: New (277 items), Used (4,729 items), Price Range: Under $4.00 to Over $8.00, Buying Format: Auction (32), Buy It Now (5,033), Accepts Offers (2,960), Shipping: Arrives in 2-4 days, Free Shipping, Local Pickup available.

3. PS3 – Warranty Dispute

Domain: avforums.com

Registered: 2000 (25 years)

Introduction: This company, PS3 – Warranty Dispute, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for ps3 warranty seal

In the competitive landscape of gaming accessories, the strategic sourcing of PS3 warranty seals presents significant opportunities for international B2B buyers. Understanding the critical role of these seals in ensuring product authenticity and compliance can enhance brand trust and customer loyalty. Buyers must focus on sourcing high-quality, reliable seals that meet industry standards, as these components directly impact warranty claims and customer satisfaction.

A proactive approach to sourcing can yield long-term benefits, including reduced costs and improved supply chain efficiency. Buyers should consider establishing strong relationships with manufacturers who prioritize quality control and offer transparent sourcing practices. This not only mitigates risks associated with counterfeit products but also aligns with the growing demand for integrity in the supply chain.

As markets in Africa, South America, the Middle East, and Europe continue to expand, the importance of strategic sourcing cannot be overstated. Companies that invest in quality sourcing today will position themselves as leaders in their markets tomorrow. We encourage B2B buyers to explore innovative sourcing strategies and collaborate with trusted suppliers to secure a competitive edge in the gaming accessory industry. Embrace the future of sourcing with confidence and commitment to excellence.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.