Top 6 Vacuum Generator Suppliers (And How to Choose)

Introduction: Navigating the Global Market for vacuum generator

In the dynamic landscape of industrial automation, sourcing the right vacuum generator can present a significant challenge for B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. These versatile devices are essential for a range of applications, from packaging and material handling to precise clamping and lifting tasks. However, understanding the nuances of different types, applications, and supplier reliability is crucial for making informed purchasing decisions.

This comprehensive guide is designed to navigate you through the global market for vacuum generators, offering insights into various models, their specific applications, and the factors that influence pricing. We will delve into the technical specifications that matter, such as flow rates and vacuum levels, as well as the importance of selecting the right accessories and maintenance practices to ensure optimal performance. Additionally, we will provide actionable tips for vetting suppliers, helping you identify trustworthy partners who can meet your operational needs.

By empowering international B2B buyers with in-depth knowledge, this guide aims to simplify the procurement process and enhance your ability to select the most suitable vacuum generator for your business. Whether you are looking to improve efficiency in your manufacturing process or enhance packaging operations, understanding these key elements will drive your purchasing strategy and foster long-term success in your industry.

Understanding vacuum generator Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Adjustable E-Vac® | Compressed air-powered, adjustable vacuum and flow rates | Pick and place, vacuum packaging, mold evacuation | Pros: Cost-effective, maintenance-free, compact. Cons: Requires clean, dry air supply. |

| Venturi Vacuum Generators | Uses compressed air to create a vacuum via Venturi effect | Packaging, material handling, robotics | Pros: Simple design, low cost. Cons: Less efficient for high vacuum applications. |

| Electric Vacuum Generators | Operates on electric power, providing continuous vacuum | Medical equipment, semiconductor manufacturing | Pros: Consistent performance, suitable for delicate items. Cons: Higher energy costs. |

| Pneumatic Vacuum Generators | Powered by compressed air, ideal for automated systems | Assembly lines, automotive production | Pros: Fast operation, good for high-speed applications. Cons: Air supply dependency. |

| Oil-Sealed Vacuum Pumps | Uses oil to create a vacuum seal, ideal for high vacuum levels | Laboratory processes, scientific research | Pros: Achieves high vacuum levels. Cons: Requires maintenance, risk of oil contamination. |

What are the Characteristics of Adjustable E-Vac® Vacuum Generators?

The Adjustable E-Vac® vacuum generator is characterized by its ability to modify vacuum and flow rates to meet specific application needs. This flexibility makes it suitable for a wide range of tasks, including pick and place operations and vacuum packaging. B2B buyers should consider the device’s maintenance-free design and compact size, which can save space in production environments. However, it is essential to ensure a clean and dry compressed air supply for optimal performance.

How Do Venturi Vacuum Generators Operate?

Venturi vacuum generators leverage the Venturi effect, where compressed air creates a vacuum by passing through a constricted area. This type is often utilized in packaging and robotics, providing a simple and cost-effective solution. Buyers should note that while Venturi generators are economical, they may not be suitable for applications requiring high vacuum levels. Their straightforward design makes them an appealing choice for many businesses looking to integrate vacuum systems into their operations.

What are the Benefits of Electric Vacuum Generators?

Electric vacuum generators offer a continuous and reliable vacuum source powered by electricity. They are particularly beneficial in industries such as medical equipment manufacturing and semiconductor production, where precision and consistency are crucial. While they provide stable performance, buyers must consider the potential for higher energy costs and the necessity of power supply infrastructure, which may not be available in all regions.

Why Choose Pneumatic Vacuum Generators for Automation?

Pneumatic vacuum generators are powered by compressed air, making them ideal for automated systems in assembly lines and automotive production. Their fast operation allows for efficient handling of materials, which can enhance productivity. However, businesses must ensure a consistent air supply to avoid operational disruptions. The balance of speed and efficiency makes pneumatic generators a popular choice for high-volume manufacturing settings.

What Makes Oil-Sealed Vacuum Pumps Unique?

Oil-sealed vacuum pumps are designed to achieve high vacuum levels by using oil to create a seal within the pump. They are commonly used in laboratory processes and scientific research, where maintaining a precise vacuum is critical. While they can achieve superior vacuum levels, buyers should be aware of the maintenance requirements and the potential risk of oil contamination in sensitive applications. This trade-off between performance and upkeep is a key consideration for B2B buyers in specialized fields.

Key Industrial Applications of vacuum generator

| Industry/Sector | Specific Application of Vacuum Generator | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Packaging and Food Processing | Vacuum packaging of perishable goods | Extends shelf life, reduces spoilage, and enhances product appeal | Ensure compatibility with food safety regulations and material standards. |

| Automotive Manufacturing | Clamping and holding components during assembly | Increases efficiency in production lines and ensures precision | Look for vacuum generators with adjustable flow rates to accommodate various part sizes. |

| Electronics | Surface mounting of circuit boards | Reduces defects in assembly and improves handling of delicate components | Consider vacuum generators that can handle small, intricate parts without damage. |

| Woodworking | Vacuum pressing of veneers and laminates | Enhances adhesion quality and reduces waste of materials | Seek models that can provide consistent vacuum levels for uniform pressure application. |

| Pharmaceutical | Leak testing of vials and containers | Ensures product integrity and compliance with regulations | Focus on generators that can maintain high vacuum levels and are easy to integrate into existing systems. |

How is a Vacuum Generator Used in the Packaging and Food Processing Industry?

In the packaging and food processing sector, vacuum generators are crucial for vacuum packaging, which preserves food by removing air and sealing it in airtight containers. This process significantly extends the shelf life of perishable goods, thereby reducing spoilage and enhancing product appeal. Buyers in this industry need to ensure that the vacuum generators comply with food safety regulations, including materials that do not contaminate food products.

What Role Does a Vacuum Generator Play in Automotive Manufacturing?

In automotive manufacturing, vacuum generators are employed for clamping and holding components during assembly. This application is vital for maintaining precision and efficiency on production lines, allowing for quick adjustments and minimizing downtime. When sourcing vacuum generators for automotive applications, it is essential to select models with adjustable flow rates to accommodate various part sizes and shapes, ensuring optimal performance across different assembly tasks.

How is a Vacuum Generator Beneficial for Electronics Manufacturing?

Vacuum generators are extensively used in the electronics industry for surface mounting of circuit boards. They facilitate the handling of delicate components, reducing defects during assembly by providing a secure grip without damaging the parts. International buyers should prioritize vacuum generators that can handle small, intricate components and maintain consistent vacuum levels to ensure reliability in their manufacturing processes.

What Advantages Does a Vacuum Generator Provide in Woodworking?

In woodworking, vacuum generators are utilized for vacuum pressing of veneers and laminates, which enhances the quality of adhesion and minimizes material waste. This application is especially valuable for businesses looking to improve production efficiency and product quality. When sourcing vacuum generators for woodworking, it is important to choose models that can maintain consistent vacuum levels to ensure uniform pressure across the entire surface area being pressed.

How Do Vacuum Generators Ensure Product Integrity in the Pharmaceutical Sector?

In the pharmaceutical industry, vacuum generators are essential for leak testing vials and containers to ensure product integrity. This process is critical for compliance with stringent regulations and quality assurance standards. Buyers should focus on vacuum generators that can maintain high vacuum levels and are easy to integrate into existing testing systems, ensuring that they meet the specific demands of pharmaceutical applications.

3 Common User Pain Points for ‘vacuum generator’ & Their Solutions

Scenario 1: Inconsistent Vacuum Levels Affecting Production Efficiency

The Problem: Many B2B buyers encounter issues with inconsistent vacuum levels when using vacuum generators, which can severely disrupt production processes. For example, a packaging facility might experience fluctuating vacuum pressure when lifting various materials, leading to missed cycles and, ultimately, production delays. These inconsistencies not only affect throughput but can also result in damaged products if items are dropped or not securely held during transport. Buyers may feel frustrated, as these problems translate to increased operational costs and lost revenue.

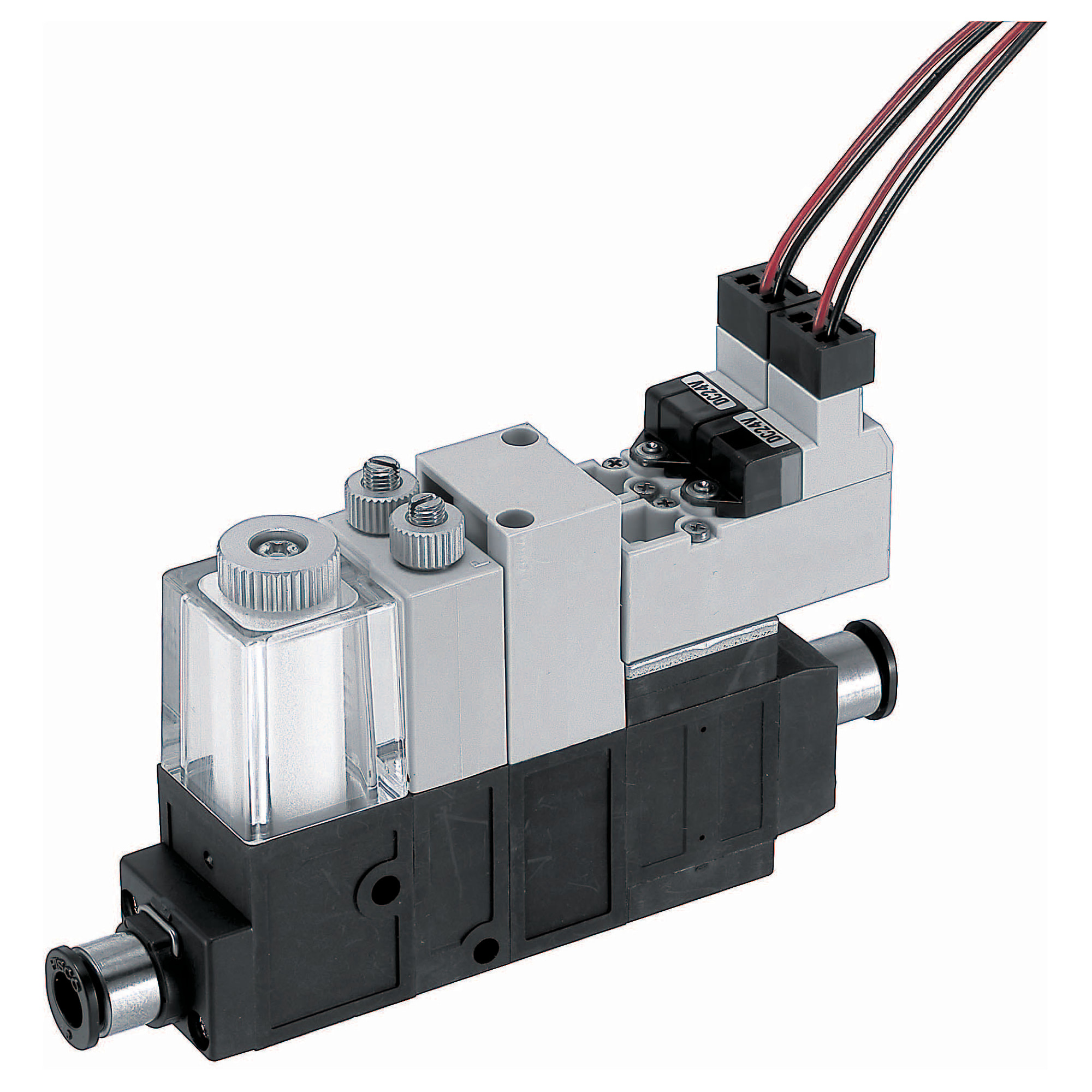

Illustrative image related to vacuum generator

The Solution: To address this issue, it is essential to invest in adjustable vacuum generators like the EXAIR Adjustable E-Vac®. These generators allow users to fine-tune vacuum levels according to the specific materials being handled. When selecting a vacuum generator, prioritize models that offer variable vacuum and flow rates. This capability ensures that the generator can adapt to different material porosities and weights, maintaining a consistent vacuum level. Additionally, incorporating vacuum check valves can help retain vacuum levels even during air supply fluctuations, thus preventing production interruptions. Regular monitoring and adjusting of the vacuum settings can optimize performance and reduce the risk of inconsistencies.

Scenario 2: High Compressed Air Consumption Increasing Operational Costs

The Problem: B2B buyers often face the challenge of high compressed air consumption associated with vacuum generators, leading to inflated operational costs. In industries like food packaging or automotive assembly, where compressed air is a primary energy source, inefficiencies in air usage can significantly impact the bottom line. Buyers may struggle to find a balance between maintaining adequate vacuum levels and controlling costs, making it a pressing concern.

The Solution: To mitigate high compressed air consumption, choose vacuum generators designed for efficiency, such as those with adjustable air consumption features. For instance, the Adjustable E-Vac® allows users to minimize air usage by tuning the vacuum level to suit specific applications. Buyers should also consider implementing automatic drain filter separators to keep the compressed air clean and dry, enhancing the generator’s efficiency. Regular maintenance of the entire compressed air system, including air filters and regulators, can prevent leaks and ensure optimal performance. By investing in energy-efficient vacuum technology and maintaining the air supply system, companies can significantly reduce their compressed air costs.

Scenario 3: Difficulty in Handling Diverse Materials and Product Types

The Problem: B2B buyers frequently encounter challenges when handling a diverse range of materials and product types, particularly in industries such as manufacturing and logistics. For instance, a manufacturer may need to switch between handling lightweight cardboard boxes and heavy metal components, each requiring different vacuum strengths and techniques. This variability can lead to inefficiencies, as using the same vacuum generator settings for all materials often results in suboptimal performance and potential damage to products.

The Solution: The ideal approach is to utilize a versatile vacuum generator that allows for easy adjustments to both vacuum strength and flow rates. The EXAIR Adjustable E-Vac® is particularly suited for this scenario, as it can be quickly tuned to meet the requirements of different materials. When purchasing, consider opting for a vacuum generator kit that includes various vacuum cups and fittings, enabling easy customization for different applications. Furthermore, training staff on how to adjust settings and select appropriate vacuum attachments for varying materials can enhance operational flexibility. This adaptability not only increases productivity but also minimizes the risk of product damage, ensuring a smoother workflow across diverse applications.

Strategic Material Selection Guide for vacuum generator

What Are the Key Materials Used in Vacuum Generators?

When selecting materials for vacuum generators, it is crucial to consider their properties, advantages, and limitations, especially for B2B applications across diverse regions such as Africa, South America, the Middle East, and Europe. The following materials are commonly used in vacuum generators:

Aluminum: A Lightweight and Corrosion-Resistant Option

Key Properties: Aluminum is known for its excellent strength-to-weight ratio, good corrosion resistance, and thermal conductivity. It typically operates effectively in a temperature range from -40°C to 80°C and can withstand moderate pressure levels.

Pros & Cons: Aluminum is lightweight, making it easy to handle and install. Its corrosion resistance is particularly beneficial in humid environments, which is common in regions like South America and Southeast Asia. However, aluminum can be more expensive than some alternatives and may not be suitable for high-temperature applications beyond its rated limits.

Impact on Application: Aluminum is ideal for applications requiring lightweight components, such as portable vacuum systems used in robotic tooling or packaging. Its compatibility with various media makes it a versatile choice.

Considerations for International Buyers: Buyers should ensure that the aluminum used meets international standards such as ASTM or DIN. Additionally, they should consider local corrosion factors, especially in coastal areas, which may influence the choice of aluminum alloy.

Stainless Steel: Durability and High-Temperature Resistance

Key Properties: Stainless steel is renowned for its high strength, durability, and resistance to corrosion and oxidation. It can endure high temperatures (up to 800°C) and pressures, making it suitable for demanding applications.

Illustrative image related to vacuum generator

Pros & Cons: The primary advantage of stainless steel is its longevity and ability to maintain performance in harsh environments. However, it is heavier and more expensive than aluminum, which can increase shipping costs and installation complexity.

Impact on Application: Stainless steel is particularly effective in applications involving harsh chemicals or high temperatures, such as vacuum filling or leak testing in industrial settings. Its robust nature ensures reliability in critical operations.

Considerations for International Buyers: Compliance with international standards (e.g., ASTM A240 for stainless steel) is essential. Buyers should also consider the local availability of specific grades of stainless steel, as this can impact lead times and costs.

Plastic Composites: Cost-Effective and Lightweight Solutions

Key Properties: Plastic composites, such as polycarbonate or nylon, are lightweight, corrosion-resistant, and can be molded into complex shapes. They typically operate effectively in temperatures up to 100°C.

Illustrative image related to vacuum generator

Pros & Cons: The primary advantage of plastic composites is their low cost and ease of manufacturing, allowing for rapid prototyping and production. However, they may not withstand high pressures or extreme temperatures as effectively as metals, which limits their application scope.

Impact on Application: Plastic composites are suitable for low-pressure vacuum applications, such as packaging and handling lightweight materials. Their chemical resistance makes them ideal for use in environments where corrosive substances are present.

Considerations for International Buyers: Buyers should verify that the plastics used comply with relevant standards (e.g., JIS for Japan or EN standards in Europe). Additionally, local climate conditions may affect the longevity and performance of plastic materials.

Rubber: Essential for Sealing Applications

Key Properties: Rubber materials, particularly silicone and nitrile, offer excellent elasticity, chemical resistance, and temperature flexibility, typically operating effectively between -40°C and 120°C.

Illustrative image related to vacuum generator

Pros & Cons: Rubber is essential for seals and gaskets in vacuum generators, providing effective airtight solutions. However, its lifespan can be shorter than metals or composites, particularly in high-temperature or high-stress environments.

Impact on Application: Rubber components are crucial in applications requiring airtight seals, such as vacuum packaging and clamping systems. Their flexibility allows for effective operation across various surfaces.

Considerations for International Buyers: Buyers should consider the specific rubber compounds used, ensuring they meet relevant standards for chemical resistance and temperature ratings. Local sourcing may also affect availability and cost.

Summary Table of Material Selection for Vacuum Generators

| Material | Typical Use Case for Vacuum Generator | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Robotic tooling, lightweight systems | Lightweight and corrosion-resistant | Higher cost than some alternatives | Medium |

| Stainless Steel | High-temperature industrial applications | Durable and high-pressure resistant | Heavier and more expensive | High |

| Plastic Composites | Packaging, lightweight handling | Cost-effective and easy to mold | Limited pressure and temperature resistance | Low |

| Rubber | Seals and gaskets | Excellent elasticity and sealing | Shorter lifespan in extreme conditions | Low |

This strategic material selection guide provides insights into the properties and implications of various materials used in vacuum generators, helping international B2B buyers make informed decisions tailored to their specific applications and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for vacuum generator

What are the Main Stages of Manufacturing Vacuum Generators?

The manufacturing process for vacuum generators involves several critical stages, each ensuring that the end product meets the necessary performance and quality standards. Here’s a breakdown of the typical stages:

Material Preparation

The first step in manufacturing vacuum generators is the selection and preparation of materials. Common materials include high-grade aluminum, which is favored for its lightweight and durable properties. The materials undergo rigorous inspection to ensure they meet specifications. This often involves testing for hardness, tensile strength, and corrosion resistance, ensuring they can withstand operational stresses.

Illustrative image related to vacuum generator

Forming Techniques

Once materials are prepared, they undergo various forming techniques, which may include machining, casting, or extruding.

- Machining is frequently used for precision components, where CNC (Computer Numerical Control) machines create intricate parts with high accuracy. This is essential for components like the venturi units, which must maintain precise dimensions to function effectively.

- Casting may be employed for larger components, allowing for complex shapes while minimizing waste.

- Extruding is useful for producing parts like tubing, ensuring consistent cross-sections that can be easily integrated into the vacuum system.

These forming techniques help ensure that all components are manufactured to exact specifications, which is crucial for maintaining consistent performance across different models.

Assembly Process

The assembly stage combines various components into a fully functional vacuum generator. This process typically follows a systematic approach, ensuring that each part is correctly installed and tested.

- Sub-assembly may occur where groups of components are first assembled before being integrated into the main unit. This can include assembling the vacuum cups, fittings, and tubing.

- Final assembly involves integrating all parts, including the vacuum generator body, into a cohesive unit. Quality checks at this stage often include visual inspections and functional tests to ensure that all components interact smoothly.

Finishing Touches

The finishing stage involves surface treatments that enhance durability and performance. Common techniques include anodizing or powder coating, which not only improve corrosion resistance but also provide a visually appealing finish.

Additionally, labeling and packaging are essential components of this stage, ensuring that products are correctly identified and protected during shipping. This also includes providing detailed documentation regarding the product specifications and certifications, which is particularly important for international buyers.

How is Quality Assurance Managed in Vacuum Generator Manufacturing?

Quality assurance (QA) is integral to the manufacturing process, ensuring that vacuum generators meet both international standards and customer expectations. Here are key aspects of the QA process:

What International Standards Apply to Vacuum Generators?

B2B buyers should be aware of various international standards that govern the quality of vacuum generators.

- ISO 9001 is the most recognized quality management standard, focusing on consistent quality and continuous improvement. Certification to this standard indicates that the manufacturer has established a quality management system that meets international benchmarks.

- CE Marking is crucial for products sold in Europe, indicating compliance with health, safety, and environmental protection standards. This is particularly relevant for vacuum generators intended for various applications across different sectors.

- API Standards may apply if the vacuum generators are used in petroleum and natural gas industries, ensuring that products meet the stringent requirements of these sectors.

What are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are strategically integrated throughout the manufacturing process to catch defects early and ensure that products meet specifications.

- Incoming Quality Control (IQC) involves inspecting raw materials before they enter the production line. This step is critical to prevent defective materials from causing issues in later stages.

- In-Process Quality Control (IPQC) monitors the manufacturing process, ensuring that each component meets quality standards during production. This can include real-time checks of dimensions and tolerances.

- Final Quality Control (FQC) occurs once the product is fully assembled. This stage includes rigorous testing of functionality, performance, and safety, often involving pressure tests to ensure the vacuum generator performs as expected under operational conditions.

What Common Testing Methods are Used for Vacuum Generators?

Testing is a vital component of quality assurance in vacuum generator manufacturing. Several methods are commonly employed:

- Performance Testing assesses the vacuum generator’s ability to create and maintain the desired vacuum levels under various conditions. This may involve simulating real-world applications to ensure reliability.

- Durability Testing evaluates how well the vacuum generator withstands prolonged use, often involving accelerated life tests.

- Leak Testing is critical, especially for vacuum applications. Manufacturers may use helium leak detection or pressure decay methods to ensure that all seals and joints are airtight.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is crucial to mitigate risks associated with product quality. Here are effective strategies:

Conduct Supplier Audits

Regular audits of suppliers can provide insight into their manufacturing and quality assurance processes. During an audit, buyers can assess compliance with international standards, evaluate production capabilities, and ensure that the supplier maintains necessary certifications.

Request Quality Reports

Buyers should request detailed quality reports, including data from IQC, IPQC, and FQC processes. These reports can provide transparency regarding the supplier’s performance and adherence to quality standards.

Utilize Third-Party Inspections

Engaging third-party inspection services can provide an unbiased evaluation of the manufacturing process and product quality. These inspections typically include checks for compliance with industry standards and verification of test results.

What are the Quality Control Nuances for International Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

- Regulatory Compliance: Different regions may have unique regulations affecting product specifications, packaging, and labeling. Understanding these requirements is crucial for smooth import processes.

- Cultural Considerations: Establishing a solid relationship with suppliers can enhance communication regarding quality expectations. Cultural differences can affect negotiation styles and perceptions of quality, so being culturally aware can facilitate better partnerships.

- Logistics and Supply Chain: Quality control can be impacted by logistics, particularly in regions with varying infrastructure quality. Ensuring that suppliers have reliable logistics processes can help maintain product integrity during transit.

In conclusion, understanding the manufacturing processes and quality assurance mechanisms for vacuum generators is essential for B2B buyers. By focusing on the critical stages of production, relevant quality standards, testing methods, and verification strategies, buyers can make informed decisions that align with their operational needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘vacuum generator’

Introduction

This practical sourcing guide is designed to assist B2B buyers in navigating the procurement process for vacuum generators. With a focus on efficiency and effectiveness, this checklist will help you identify the right specifications, evaluate potential suppliers, and ensure that your procurement aligns with your operational needs.

Step 1: Define Your Technical Specifications

Clearly outline your technical requirements before initiating the sourcing process. Understanding the specific application for the vacuum generator—whether for pick and place, vacuum packaging, or mold evacuation—will guide your choices. Consider factors such as vacuum levels, flow rates, and the types of materials you will be handling.

- Key Specifications to Consider:

- Maximum vacuum level (e.g., 25″ Hg)

- Flow rate requirements (e.g., SCFM)

- Compatibility with existing systems (e.g., pneumatic or electric)

Step 2: Assess Application Compatibility

Evaluate how the vacuum generator will integrate into your current operations. Different applications may require specific features such as adjustable vacuum levels or maintenance-free designs. Understanding these needs ensures that you select a generator that can handle your unique production demands without interruption.

- Considerations for Compatibility:

- Compatibility with existing machinery

- Required accessories (e.g., vacuum cups, fittings)

- Environmental factors (e.g., dust, moisture)

Step 3: Evaluate Potential Suppliers

Before making a purchase, conduct thorough due diligence on potential suppliers. This step is crucial for ensuring reliability and quality. Request detailed company profiles, client references, and case studies that demonstrate their experience in your industry.

- What to Look For:

- Certifications and industry standards compliance (e.g., ISO)

- Customer reviews and feedback

- After-sales support and warranty policies

Step 4: Analyze Total Cost of Ownership

Evaluate not just the upfront costs, but the total cost of ownership over the lifecycle of the vacuum generator. This includes maintenance, energy consumption, and any additional components required for operation. A lower initial price might lead to higher long-term costs if not carefully analyzed.

- Cost Factors to Consider:

- Energy efficiency ratings

- Expected lifespan and maintenance needs

- Availability of replacement parts

Step 5: Verify Quality and Performance Metrics

Ensure that the vacuum generator meets your quality standards and performance expectations. Review performance metrics such as noise levels, efficiency ratings, and operational reliability. Testing or obtaining a demo unit can provide valuable insights into its performance in real-world applications.

- Performance Metrics to Assess:

- Sound level in dBA

- Air consumption at specific pressures

- Maximum achievable vacuum under load conditions

Step 6: Review Supply Chain Logistics

Understand the logistics involved in procuring the vacuum generator, including lead times, shipping costs, and delivery schedules. An efficient supply chain can significantly impact your operational timelines and minimize disruptions.

- Logistical Considerations:

- Shipping times from the supplier’s location

- Import/export regulations in your region

- Availability of local distributors or support services

Step 7: Plan for After-Sales Support and Training

Consider the after-sales support and training offered by the supplier. Effective training can help your team utilize the vacuum generator efficiently, while robust support can assist in resolving any operational issues that arise post-purchase.

- Support Elements to Investigate:

- Availability of training sessions or materials

- Access to technical support and troubleshooting resources

- Warranty coverage and service agreements

By following these steps, B2B buyers can make informed decisions when sourcing vacuum generators, ensuring that they meet operational needs and provide long-term value.

Comprehensive Cost and Pricing Analysis for vacuum generator Sourcing

What are the Key Cost Components in Vacuum Generator Manufacturing?

Understanding the cost structure behind vacuum generators is crucial for B2B buyers to negotiate effectively. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the supplier’s margin.

-

Materials: The choice of materials significantly affects the cost. Common materials for vacuum generators include aluminum for housing and various plastics for components like suction cups. The quality of materials directly impacts durability and performance, making it a critical factor in pricing.

-

Labor: Labor costs vary by region. In areas with higher wages, such as parts of Europe, manufacturing costs will be greater. Conversely, sourcing from regions with lower labor costs, like parts of South America or Asia, may offer savings, but could also involve trade-offs in quality and service.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and administrative expenses. Efficient manufacturing processes can help minimize overhead, which is often passed on to buyers.

-

Tooling: Custom tooling can be a significant upfront investment, especially for specialized vacuum generators. Buyers should consider whether the tooling costs can be amortized over large production runs, which can lower the per-unit cost.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability but adds to the overall cost. Certifications such as ISO can increase costs but also enhance product credibility.

-

Logistics: Shipping costs can vary widely based on the location of the supplier and the buyer. Incoterms play a vital role in determining who bears the logistics costs, which can significantly impact the final price.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure profitability. Understanding the typical margins in the industry can help buyers gauge whether they are receiving a fair price.

How Do Price Influencers Affect Vacuum Generator Costs?

Several factors influence the final pricing of vacuum generators:

-

Volume/MOQ: Bulk purchasing often leads to reduced pricing per unit. Buyers should negotiate Minimum Order Quantities (MOQ) to maximize savings.

-

Specifications/Customization: Customized solutions generally incur higher costs due to additional engineering and tooling. Buyers should assess whether the benefits of customization justify the extra expense.

-

Material Quality/Certifications: Higher-quality materials and certifications may lead to increased costs but can enhance the product’s reliability and lifespan, ultimately contributing to lower total ownership costs.

-

Supplier Factors: The reputation, reliability, and financial stability of a supplier can impact pricing. Established suppliers may offer better support and warranty terms, which can be worth the higher price.

-

Incoterms: Understanding the implications of Incoterms is essential for international buyers. They dictate shipping responsibilities, which can greatly affect the total landed cost.

What Are Effective Buyer Tips for Negotiating Vacuum Generator Prices?

To optimize purchasing decisions, consider the following strategies:

-

Negotiate Pricing and Terms: Engage suppliers in discussions about pricing, payment terms, and volume discounts. A strong negotiating position can lead to significant savings.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the purchase price but the total cost over the product’s lifecycle, including maintenance, energy consumption, and potential downtime.

-

Research Market Prices: Having a benchmark for the prices of similar products can empower buyers during negotiations. Utilize resources like industry reports and supplier catalogs.

-

Consider Local Suppliers: Depending on the region, local suppliers may offer more favorable terms due to reduced shipping costs and shorter lead times, which can enhance overall cost efficiency.

-

Be Aware of International Pricing Nuances: Different regions may have varying cost structures due to tariffs, taxes, and local economic conditions. Buyers should be prepared for price fluctuations based on these factors.

Disclaimer

The prices mentioned in this analysis are indicative and subject to change based on market conditions and supplier negotiations. Always confirm current pricing with suppliers before making procurement decisions.

Alternatives Analysis: Comparing vacuum generator With Other Solutions

Introduction: Understanding Alternatives to Vacuum Generators

In the industrial and manufacturing sectors, vacuum generators play a crucial role in material handling and automation processes. However, businesses often seek alternatives that might better suit their specific operational needs, budget constraints, or performance requirements. Understanding these alternatives is essential for B2B buyers to make informed decisions. Below, we compare vacuum generators with two viable alternatives: electric vacuum pumps and mechanical vacuum lifts.

Comparison Table

| Comparison Aspect | Vacuum Generator | Electric Vacuum Pump | Mechanical Vacuum Lift |

|---|---|---|---|

| Performance | Adjustable vacuum levels; high efficiency; suitable for various applications | Consistent vacuum levels; high performance; limited adjustment | Excellent for heavy loads; reliable lifting capacity |

| Cost | Low initial cost; ongoing air costs | Moderate initial investment; low operational costs | Higher initial investment; low maintenance costs |

| Ease of Implementation | Simple setup; requires compressed air | Requires electrical installation; moderate complexity | Requires installation; can be complex depending on application |

| Maintenance | Low maintenance; no moving parts | Moderate maintenance; wear on electrical components | Low maintenance; mechanical reliability |

| Best Use Case | Versatile applications in light to medium tasks | Precision tasks requiring consistent vacuum levels | Heavy lifting applications in industrial settings |

Detailed Breakdown of Alternatives

Electric Vacuum Pumps

Electric vacuum pumps are designed to generate a consistent vacuum without the need for compressed air. They are particularly effective in applications requiring precise vacuum levels, such as in packaging and medical devices. The primary advantage of electric pumps is their ability to maintain a steady vacuum, making them ideal for tasks that demand reliability. However, they come with a moderate initial cost and require electrical connections, which can complicate installation in some environments. Additionally, while they offer low operational costs, they may require more maintenance over time due to wear on electrical components.

Mechanical Vacuum Lifts

Mechanical vacuum lifts utilize a combination of vacuum technology and mechanical systems to lift heavy loads. These systems are particularly advantageous in settings where heavy materials need to be moved, such as in warehouses or manufacturing facilities. The key benefits include their ability to handle substantial weights with ease and their reliability in lifting applications. Although the initial investment is higher than that of vacuum generators, mechanical lifts typically incur low maintenance costs. However, their complexity in installation may deter some businesses, especially in environments with space constraints.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the right solution for material handling, B2B buyers should carefully assess their specific operational requirements, budget, and the types of tasks they need to accomplish. Vacuum generators offer versatility and low initial costs, making them suitable for a range of applications. On the other hand, electric vacuum pumps provide precision and consistency, while mechanical vacuum lifts excel in heavy-duty scenarios. By evaluating these factors, businesses can make an informed choice that aligns with their operational goals and enhances productivity.

Illustrative image related to vacuum generator

Essential Technical Properties and Trade Terminology for vacuum generator

What Are the Key Technical Properties of a Vacuum Generator?

When selecting a vacuum generator, understanding its technical specifications is crucial for ensuring it meets application requirements. Here are some essential properties to consider:

1. Vacuum Level

The vacuum level indicates the maximum suction capability of the generator, typically measured in inches of mercury (Hg) or kilopascals (kPa). A higher vacuum level is necessary for applications involving solid, non-porous materials, while lower levels suffice for porous items. Understanding the required vacuum level helps buyers select a generator that maximizes efficiency while minimizing air consumption.

2. Flow Rate

Flow rate, expressed in Standard Cubic Feet per Minute (SCFM) or Liters per Minute (LPM), measures the volume of air the generator can move. This specification is vital for applications requiring quick pick-and-place operations or rapid cycle times. Buyers should match the flow rate to their operational needs to ensure optimal performance without wasting energy.

3. Material Construction

The material grade of a vacuum generator influences its durability and resistance to environmental factors. Common materials include aluminum and plastic, each offering different benefits. For instance, aluminum is lightweight and robust, while plastic may be more cost-effective. Knowing the material helps buyers assess the generator’s suitability for their specific conditions, such as exposure to moisture or corrosive substances.

4. Noise Level

Noise level, measured in decibels (dBA), is an important consideration for workplace environments. Generators with lower noise levels contribute to a better working atmosphere and comply with occupational safety regulations. Buyers should evaluate noise levels to ensure they do not exceed permissible limits in their facilities.

5. Maintenance Requirements

Many modern vacuum generators are designed to be maintenance-free, featuring no moving parts. This property is critical for reducing downtime and operational costs. Buyers should inquire about maintenance needs, as lower maintenance requirements can lead to significant savings over the product’s lifecycle.

6. Operating Pressure

Operating pressure refers to the air pressure required to achieve optimal performance, typically measured in pounds per square inch (PSI). Understanding the required operating pressure is vital for compatibility with existing compressed air systems. This ensures that the generator operates efficiently and effectively, maximizing productivity.

What Are Common Trade Terms Used in the Vacuum Generator Industry?

Familiarity with industry jargon helps streamline communication and negotiation processes in B2B transactions. Here are some commonly used terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is essential for buyers seeking customized solutions or components that integrate seamlessly with existing systems.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. It is crucial for budget planning and inventory management, especially for international buyers. Knowing the MOQ can help buyers determine whether a supplier can meet their needs while staying within budget constraints.

3. RFQ (Request for Quotation)

An RFQ is a formal request for pricing and terms from suppliers. This document outlines the specifications and quantities of products desired. It is an essential step in the procurement process, allowing buyers to gather competitive offers and make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules defining the responsibilities of sellers and buyers in the shipping process. Familiarity with these terms is vital for understanding costs, risks, and obligations related to shipping and delivery, especially in cross-border transactions.

5. Lead Time

Lead time refers to the period between placing an order and receiving the product. This term is important for project planning and inventory management. Buyers should inquire about lead times to ensure that they can meet production schedules without delays.

6. Compatibility

In the context of vacuum generators, compatibility refers to how well a generator integrates with existing systems or components. Understanding compatibility is critical for ensuring that investments in new equipment do not lead to additional costs or operational disruptions.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when selecting vacuum generators, ensuring they choose solutions that align with their operational goals and budgetary constraints.

Navigating Market Dynamics and Sourcing Trends in the vacuum generator Sector

What Are the Current Trends Shaping the Vacuum Generator Market?

The vacuum generator market is experiencing significant growth, driven by advancements in automation, increasing demand for energy-efficient solutions, and a growing focus on industrial safety. Key trends include the integration of IoT technology, allowing for real-time monitoring and optimization of vacuum systems. This trend is particularly relevant for international buyers in regions like Africa and South America, where industries are rapidly modernizing. Additionally, the shift towards compact and portable vacuum generators is gaining traction, making it easier for businesses to integrate these solutions into existing workflows.

Emerging markets are seeing a surge in demand for versatile vacuum generators, with adjustable models being favored for their ability to cater to various applications. For instance, the Adjustable E-Vac® series allows users to tune vacuum and flow levels, thus minimizing compressed air usage and enhancing efficiency. This adaptability is critical for industries like packaging, automotive, and electronics, which require precise handling of diverse materials.

Furthermore, sustainability is becoming a core consideration in procurement decisions. International B2B buyers are increasingly seeking suppliers who prioritize eco-friendly practices, from manufacturing processes to the materials used in vacuum generators. As a result, companies that can demonstrate a commitment to sustainability will have a competitive advantage in the global marketplace.

How Can Sustainability and Ethical Sourcing Impact the Vacuum Generator Sector?

Sustainability and ethical sourcing are integral to the vacuum generator sector, particularly as global awareness of environmental impacts grows. The production of vacuum generators often involves materials that can be harmful to the environment if not sourced responsibly. Therefore, international buyers are prioritizing suppliers who adhere to sustainable practices and can provide certifications that reflect their commitment to reducing their ecological footprint.

For instance, vacuum generators made from recyclable materials or those that utilize energy-efficient technologies are increasingly preferred. Companies that incorporate ‘green’ certifications, such as ISO 14001 for environmental management, are likely to attract conscientious buyers. These certifications not only serve as a mark of quality but also indicate that the supplier is committed to minimizing waste and pollution throughout their supply chain.

Moreover, the ethical sourcing of materials contributes to building a transparent supply chain, which is crucial for maintaining trust with stakeholders. Buyers from regions like Europe and the Middle East are particularly sensitive to ethical considerations, making it essential for suppliers to ensure that their materials are sourced from responsible providers. This focus on sustainability and ethical practices not only enhances brand reputation but also aligns with the growing consumer demand for environmentally friendly products.

What Is the Historical Context of Vacuum Generators in B2B Applications?

The evolution of vacuum generators can be traced back to the industrial revolution, where the need for efficient material handling led to the development of various pneumatic technologies. Initially, vacuum systems were large and cumbersome, limiting their applications primarily to heavy industries. However, advancements in engineering and materials science have transformed vacuum generators into compact, versatile devices suitable for a wide range of applications.

Illustrative image related to vacuum generator

By the late 20th century, the introduction of compressed air-powered vacuum generators marked a significant milestone, making these systems more accessible and cost-effective for various industries. The advent of automation in manufacturing further propelled the adoption of vacuum generators, as businesses sought to improve efficiency and reduce labor costs.

Today, vacuum generators are pivotal in sectors such as packaging, automotive, and electronics, with a focus on customization and efficiency. As technology continues to advance, the future of vacuum generators looks promising, with innovations aimed at enhancing performance while minimizing environmental impact. This historical context is crucial for B2B buyers to understand the trajectory of vacuum generator technology and its implications for their operational strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of vacuum generator

-

How do I solve performance issues with my vacuum generator?

To address performance issues with your vacuum generator, start by checking the compressed air supply for cleanliness and dryness, as contaminants can hinder operation. Verify that the vacuum level and flow rates are correctly set for your specific application; adjustments can be made easily with models like the Adjustable E-Vac. Additionally, inspect all connections and hoses for leaks or blockages, as these can significantly affect performance. Regular maintenance and timely replacement of worn components will also help ensure optimal functionality. -

What is the best vacuum generator for handling fragile items?

For handling fragile items, the Adjustable E-Vac vacuum generator is an excellent choice due to its ability to finely tune vacuum levels and flow rates. Its design minimizes the risk of damaging delicate materials while providing sufficient lifting power. Consider using suitable vacuum cups designed specifically for fragile items, as they can enhance grip without applying excessive force. Always test the setup with your specific materials to determine the best configuration for your applications. -

What customization options are available for vacuum generators?

Most manufacturers offer customization options for vacuum generators, including adjustable flow rates, specialized suction cups, and tailored fittings. You can specify the size, type of materials, and other features based on your unique operational needs. It’s advisable to communicate directly with suppliers about your requirements, as they may also provide custom kits that include various accessories to enhance system compatibility. Ensure to discuss any specific application challenges you face to receive targeted solutions. -

What are the typical minimum order quantities (MOQs) for vacuum generators?

Minimum order quantities (MOQs) for vacuum generators can vary widely depending on the manufacturer and the specific model. Generally, MOQs may range from a single unit for standard models to larger quantities for custom or specialized units. When sourcing from international suppliers, inquire about MOQs during the negotiation phase, as some may offer flexibility based on your business needs or potential for future orders. -

How can I vet suppliers of vacuum generators effectively?

To vet suppliers of vacuum generators, consider their industry reputation, years of experience, and customer reviews. Request references from previous clients and check for certifications that demonstrate compliance with international standards. Conducting a factory visit or virtual audit can also provide insights into their production capabilities and quality control processes. Lastly, assess their customer service responsiveness, as a reliable supplier should be available to address your concerns and provide support post-purchase. -

What payment terms should I expect when sourcing vacuum generators internationally?

Payment terms can vary based on the supplier and the countries involved in the transaction. Typically, you may encounter terms like advance payment, letters of credit, or payment upon delivery. Some suppliers may offer favorable terms for bulk orders or established clients. It’s essential to clarify payment methods (e.g., bank transfer, PayPal) and any associated fees. Make sure to negotiate terms that align with your cash flow management and risk tolerance. -

What quality assurance (QA) measures should I look for in vacuum generators?

When evaluating vacuum generators, look for suppliers that implement stringent quality assurance measures, including thorough testing for performance and durability. Certifications such as ISO 9001 can indicate adherence to international quality standards. Request documentation of testing results, and inquire about warranties and return policies, as these can provide additional assurance of product reliability. A reputable supplier will be transparent about their QA processes and willing to address any concerns you may have. -

What logistical considerations should I keep in mind when importing vacuum generators?

When importing vacuum generators, consider shipping costs, lead times, and customs regulations in your country. Choose a reliable logistics partner to manage shipping and ensure compliance with local import laws. Additionally, assess the potential need for insurance during transit to protect against loss or damage. Understanding the total landed cost, including duties and taxes, will help you make informed purchasing decisions and maintain budget control throughout the procurement process.

Top 6 Vacuum Generator Manufacturers & Suppliers List

1. Exair – Adjustable E-Vac® Vacuum Generator

2. Emicorp – Vacuum Generators for Plastics Applications

Domain: emicorp.com

Registered: 2003 (22 years)

Introduction: Vacuum Generators for End of Arm Tooling, focused on plastics applications. Key products include: 1. Schmalz SBP Lightweight Vacuum Generators (various models: SBP-07-G01-SDA, SBP-10-G02-SDA, SBP-15-G02-SDA) 2. PIAB COAX PiInline Micro Vacuum Generator (PIVG-MICRO-SI6) 3. PIAB COAX PiInline Mini Vacuum Generator (PIVG-MINI-SI6) 4. PIAB COAX PiInline Midi Vacuum Generator (PIVG-MINI-SI8) 5. Parker …

3. Festo – Vacuum Generators

Domain: festo.com

Registered: 1997 (28 years)

Introduction: Festo vacuum generators have a single-stage design and operate according to the Venturi principle, generating vacuum from compressed air. They feature a compact design, making them suitable for direct integration into systems. Unlike electrical vacuum generators, they are independent of power supply and utilize a compressed air connection. Festo offers three core models: the lightweight OVEL, the …

4. SMC USA – Vacuum Generators

Domain: smcusa.com

Registered: 1995 (30 years)

Introduction: This company, SMC USA – Vacuum Generators, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Tameson – Vacuum Generators

Domain: tameson.com

Registered: 2015 (10 years)

Introduction: Vacuum generators are devices used to create a low-pressure environment for various industrial and scientific applications such as vacuum packing, distillation, filtration, and drying. They are essential for processes where air removal is crucial for maintaining product integrity or enhancing process efficiency. There are two types of vacuum generators: pneumatic vacuum generators (venturi vacuum …

6. Fibreglast – High Efficiency Vacuum Generator

Domain: fibreglast.com

Registered: 1995 (30 years)

Introduction: High Efficiency Vacuum Generator, in stock, ships same day, certified & traceable products, order by 2:30pm ET for same-day shipping.

Strategic Sourcing Conclusion and Outlook for vacuum generator

Why is Strategic Sourcing Essential for Vacuum Generators?

In the competitive landscape of vacuum generator procurement, strategic sourcing emerges as a crucial component for optimizing operational efficiency and cost-effectiveness. By identifying reliable suppliers, buyers can secure high-quality products, such as EXAIR’s Adjustable E-Vac® vacuum generators, which offer adaptability and low maintenance costs. Understanding the specifications and applications of various models enables businesses to tailor their choices to specific operational needs, ensuring maximum productivity.

What Benefits Can International Buyers Expect from Investing in Vacuum Generators?

For international B2B buyers from regions like Africa, South America, the Middle East, and Europe, investing in efficient vacuum generators can lead to significant improvements in manufacturing processes. These products enhance automation capabilities, reduce labor costs, and improve safety standards by eliminating electrical hazards. Additionally, the versatility of vacuum generators supports a wide range of applications—from packaging to robotics—making them invaluable across industries.

How Can You Move Forward in Your Sourcing Strategy?

As the demand for innovative manufacturing solutions grows, now is the time to refine your sourcing strategy. Embrace the opportunity to explore diverse suppliers and cutting-edge technologies that can elevate your operations. Investing in quality vacuum generators today will not only streamline your processes but also position your business for future success. Take proactive steps to engage with suppliers and evaluate the best options tailored to your specific needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.