Top 4 Plastic Christmas Hat Suppliers (And How to Choose)

Introduction: Navigating the Global Market for plastic christmas hat

In the competitive landscape of holiday decorations, sourcing high-quality plastic Christmas hats poses a unique challenge for international B2B buyers. With diverse consumer preferences and varying seasonal demands, understanding the market dynamics is essential for successful procurement. This comprehensive guide delves into the intricacies of the plastic Christmas hat market, exploring various types, applications, and innovative designs that cater to different cultural celebrations across regions. Whether you are a retailer in Brazil looking to stock festive merchandise or a distributor in Germany aiming to enhance your product offerings, our insights will equip you to make informed purchasing decisions.

Navigating supplier vetting processes, assessing cost structures, and understanding logistical considerations are crucial for maximizing profitability and ensuring product quality. This guide not only highlights the best practices for sourcing plastic Christmas hats but also emphasizes the importance of aligning your inventory with local market trends and consumer preferences in Africa, South America, the Middle East, and Europe. By leveraging the information provided, B2B buyers can enhance their competitive edge and effectively meet the festive needs of their clientele. Join us as we explore the vibrant world of plastic Christmas hats, and empower your business to thrive in this seasonal market.

Understanding plastic christmas hat Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Santa Hat | Traditional conical shape, red with white trim | Retail, Event Planning, Costumes | Pros: Iconic design, widely recognized. Cons: Limited to holiday use. |

| Mini Santa Hat | Smaller version, often used as a novelty item | Promotions, Gifts, Party Favors | Pros: Cost-effective, fun accessory. Cons: Less visibility than larger hats. |

| Outdoor Santa Hat | Made from durable, weather-resistant materials | Outdoor Decorations, Event Displays | Pros: Weatherproof, suitable for outdoor use. Cons: Higher cost due to materials. |

| Plush Santa Hat | Soft, plush texture with faux fur accents | Costume Retailers, Holiday Events | Pros: Comfortable, appealing texture. Cons: May require special care. |

| Custom Branded Hats | Personalized with logos or messages | Corporate Events, Brand Promotions | Pros: Enhances brand visibility, unique. Cons: Longer lead times for production. |

What are the Characteristics of the Classic Santa Hat?

The Classic Santa Hat is a quintessential holiday accessory characterized by its traditional conical shape, vibrant red color, and fluffy white trim. This type is ideal for retailers and event planners looking to create a festive atmosphere during the holiday season. When purchasing, consider factors such as bulk pricing and seasonal demand, as these hats are highly sought after during Christmas.

How Do Mini Santa Hats Serve B2B Needs?

Mini Santa Hats are compact versions of the classic design, often used for promotional events, party favors, or as gifts. Their smaller size allows for cost-effective shipping and storage, making them a popular choice for businesses looking to distribute holiday-themed items without significant investment. Buyers should evaluate the potential for customization and branding opportunities to maximize their impact.

What Makes Outdoor Santa Hats a Practical Choice?

Outdoor Santa Hats are crafted from durable, weather-resistant materials, making them suitable for outdoor decorations and event displays. Their robust construction ensures longevity, even in adverse weather conditions, which is essential for businesses that host outdoor holiday events. When considering these hats, businesses should assess the balance between quality and cost, as higher-quality materials may lead to increased expenditure.

Why Choose Plush Santa Hats for Holiday Events?

Plush Santa Hats offer a luxurious feel with their soft texture and faux fur accents, appealing to both children and adults alike. These hats are particularly suitable for costume retailers and holiday events where comfort and aesthetics are paramount. Buyers should consider the maintenance and care required for plush materials, as they may not be as durable as other types.

How Can Custom Branded Hats Enhance Corporate Events?

Custom Branded Hats allow businesses to personalize their holiday offerings with logos or messages, enhancing brand visibility during corporate events and promotions. This type of hat is an excellent way to engage customers and employees alike while fostering a festive spirit. However, buyers should be mindful of the longer lead times associated with custom orders, ensuring they plan ahead for seasonal events.

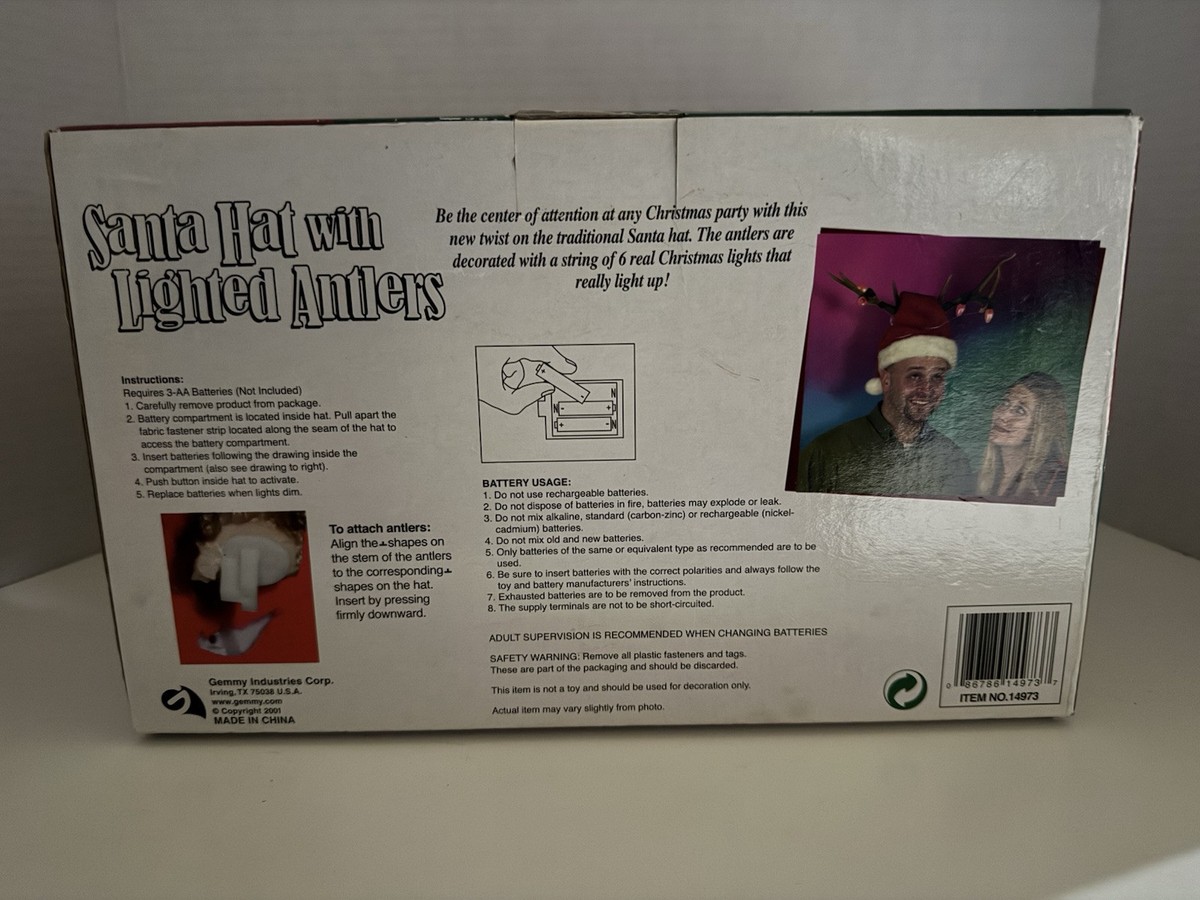

Illustrative image related to plastic christmas hat

Key Industrial Applications of plastic christmas hat

| Industry/Sector | Specific Application of plastic christmas hat | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail and E-commerce | Seasonal merchandise displays and promotions | Enhances visual merchandising, attracting customer attention | Sourcing durable, vibrant designs that align with brand identity |

| Event Management | Costumes for holiday-themed events and parties | Provides a fun and festive atmosphere, increasing engagement | Ensuring sizes and styles cater to diverse audiences |

| Hospitality and Tourism | Guest experience enhancement during festive seasons | Improves customer satisfaction and brand loyalty | Prioritizing quality and comfort for extended wear |

| Educational Institutions | Holiday-themed events and celebrations | Fosters community spirit and engagement among students | Sourcing bulk quantities at competitive prices |

| Corporate Gifting | Employee gifts or promotional giveaways | Strengthens employee morale and brand representation | Customization options for branding and messaging |

How is the Plastic Christmas Hat Used in Retail and E-commerce?

In the retail and e-commerce sectors, plastic Christmas hats serve as essential tools for seasonal merchandise displays and promotions. Retailers leverage these hats to create visually appealing setups that draw in customers, especially during the holiday season. The vibrant colors and festive designs can enhance the shopping experience, ultimately leading to increased foot traffic and sales. B2B buyers in this sector should consider sourcing hats that are durable and align with their brand identity to maintain a cohesive marketing strategy.

What Role Does the Plastic Christmas Hat Play in Event Management?

Event management companies utilize plastic Christmas hats as part of costumes for holiday-themed events and parties. These hats contribute to a festive atmosphere, helping to engage attendees and enhance the overall experience. By incorporating fun accessories, event managers can create memorable events that resonate with participants. Buyers in this sector must ensure that the hats come in various sizes and styles to accommodate diverse audiences, enhancing inclusivity and enjoyment.

How Can Hospitality and Tourism Benefit from Plastic Christmas Hats?

In the hospitality and tourism industry, plastic Christmas hats are used to enhance guest experiences during festive seasons. Hotels and resorts often provide these hats to guests during holiday events, fostering a sense of community and celebration. This small touch can significantly improve customer satisfaction and encourage repeat visits. When sourcing hats, businesses should prioritize quality and comfort, as guests may wear them for extended periods during events.

Why Are Plastic Christmas Hats Important for Educational Institutions?

Educational institutions frequently use plastic Christmas hats during holiday-themed events and celebrations to foster community spirit among students. These hats can be part of school plays, parties, or festive gatherings, creating a joyful environment that promotes engagement and participation. For B2B buyers in this sector, sourcing hats in bulk at competitive prices is crucial to accommodate large groups while managing budgets effectively.

How Do Plastic Christmas Hats Enhance Corporate Gifting Strategies?

In the realm of corporate gifting, plastic Christmas hats can serve as unique employee gifts or promotional giveaways. By incorporating these festive items into their gifting strategies, companies can strengthen employee morale and enhance brand representation during the holiday season. Customization options for branding and messaging are vital for businesses looking to create a lasting impression. Buyers should consider the quality and design of the hats to ensure they reflect the company’s values and image.

3 Common User Pain Points for ‘plastic christmas hat’ & Their Solutions

Scenario 1: Sourcing Quality Plastic Christmas Hats for Diverse Markets

The Problem: B2B buyers, especially those targeting international markets in regions like Africa and South America, often struggle to source high-quality plastic Christmas hats that meet local preferences and standards. Factors such as material durability, design appeal, and cultural significance can vary significantly between regions. This variability makes it challenging for buyers to find products that resonate with their target demographics, resulting in unsold inventory and lost revenue.

The Solution: To effectively source plastic Christmas hats, buyers should conduct thorough market research to understand regional preferences and trends. Engaging with local distributors and suppliers can provide insights into popular designs and material preferences. Additionally, requesting samples before bulk purchasing is crucial to assess quality and alignment with market expectations. Leveraging online platforms that connect suppliers from different regions can also facilitate a more comprehensive view of available options, ensuring that the products not only meet quality standards but also appeal to local aesthetics.

Illustrative image related to plastic christmas hat

Scenario 2: Managing Inventory and Seasonal Demand Fluctuations

The Problem: Another common pain point for B2B buyers is managing inventory levels of plastic Christmas hats, particularly given the seasonal nature of the product. Misjudging demand can lead to overstock situations, tying up capital and increasing storage costs, or understocking, resulting in missed sales opportunities during peak seasons. This challenge is exacerbated in regions where holiday celebrations may vary in timing and scale.

The Solution: Implementing a robust inventory management system can help buyers forecast demand more accurately. This can involve analyzing historical sales data, current market trends, and even incorporating predictive analytics tools that factor in local economic conditions and consumer behavior patterns. Collaborating with logistics partners to ensure timely restocking and considering flexible supply agreements can also mitigate risks associated with demand fluctuations. Moreover, establishing clear communication channels with suppliers can allow for quick adjustments in orders based on real-time sales data.

Scenario 3: Ensuring Compliance with Safety and Environmental Standards

The Problem: B2B buyers face the challenge of ensuring that plastic Christmas hats comply with various safety and environmental regulations, which can differ significantly across regions like Europe and the Middle East. Non-compliance can lead to costly fines, product recalls, and damage to brand reputation, making it critical for buyers to navigate these regulations effectively.

The Solution: To ensure compliance, buyers should familiarize themselves with the specific regulations governing plastic products in their target markets. This may include restrictions on harmful materials, labeling requirements, and recycling mandates. Working with suppliers who have a proven track record of compliance can streamline this process, as they will typically provide necessary certifications and documentation. Additionally, investing in compliance management tools can help buyers monitor regulatory changes and maintain records efficiently. Regular training and updates for procurement teams on compliance best practices can further safeguard against potential issues, ensuring that the products sold not only meet customer expectations but also adhere to legal standards.

Strategic Material Selection Guide for plastic christmas hat

What Are the Key Materials Used in Plastic Christmas Hats?

When selecting materials for plastic Christmas hats, it is essential to consider various factors that impact performance, cost, and suitability for different markets. Below is an analysis of four common materials used in the production of plastic Christmas hats, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Polyethylene (PE) Perform in Plastic Christmas Hats?

Polyethylene (PE) is a widely used thermoplastic known for its versatility and cost-effectiveness. It offers excellent chemical resistance and is suitable for various environmental conditions, making it a popular choice for outdoor decorations.

Illustrative image related to plastic christmas hat

Key Properties: PE has a temperature resistance ranging from -50°C to 80°C, ensuring it remains stable in diverse climates. It is lightweight and has good impact resistance.

Pros & Cons: The advantages of PE include its low cost and ease of manufacturing, which allows for high-volume production. However, it may not be as durable as other materials, potentially leading to wear and tear over time, especially in harsh weather conditions.

Impact on Application: PE is compatible with various media, including dyes and coatings, which can enhance the visual appeal of the hats. However, its lower durability might be a concern for long-term use.

Illustrative image related to plastic christmas hat

Considerations for International Buyers: Compliance with international standards such as ASTM and EN is crucial. Buyers from Europe and South America may prefer materials that meet these standards for safety and quality assurance.

What Are the Advantages of Using Polypropylene (PP) for Christmas Hats?

Polypropylene (PP) is another popular thermoplastic that offers a balance of strength and flexibility. It is often used in applications requiring durability while remaining lightweight.

Key Properties: PP exhibits a temperature resistance of up to 100°C and is known for its excellent fatigue resistance, making it suitable for repeated use.

Pros & Cons: The key advantage of PP is its higher durability compared to PE, making it ideal for reusable Christmas hats. However, it can be more expensive to produce, impacting overall cost.

Impact on Application: PP’s compatibility with various printing techniques allows for vibrant designs. Its strength makes it suitable for decorative elements that may experience stress during use.

Illustrative image related to plastic christmas hat

Considerations for International Buyers: Buyers should be aware of the varying regulations regarding plastic materials in different regions. In Europe, for example, there is a strong emphasis on sustainability, which may influence purchasing decisions.

How Does Polyester Contribute to the Quality of Christmas Hats?

Polyester is a synthetic fabric often blended with other materials to enhance the aesthetic and functional properties of Christmas hats. It is known for its softness and vibrant color retention.

Key Properties: Polyester has excellent UV resistance and can withstand temperatures up to 150°C, making it suitable for both indoor and outdoor use.

Pros & Cons: The primary advantage of polyester is its durability and resistance to fading, which keeps the hats looking fresh for longer. However, it can be more expensive than other materials and may require specific manufacturing processes.

Impact on Application: Polyester’s softness makes it comfortable to wear, appealing to consumers looking for quality. Its ability to hold color well enhances the festive appearance of the hats.

Considerations for International Buyers: Buyers in the Middle East and Africa may prioritize materials that offer UV protection due to higher sun exposure. Compliance with local textile regulations is also essential.

What Role Does PVC Play in the Production of Christmas Hats?

Polyvinyl Chloride (PVC) is a versatile plastic that can be rigid or flexible, depending on its formulation. It is often used in decorations for its durability and weather resistance.

Key Properties: PVC can withstand temperatures from -15°C to 60°C and is resistant to moisture and chemicals.

Pros & Cons: The main advantage of PVC is its excellent weather resistance, making it suitable for outdoor decorations. However, it can be heavier and less breathable than other materials, which may affect comfort.

Impact on Application: PVC’s durability makes it ideal for hats that need to withstand outdoor elements. However, its weight might deter consumers looking for lightweight options.

Illustrative image related to plastic christmas hat

Considerations for International Buyers: Buyers should consider the environmental impact of PVC, as some regions have restrictions on its use due to health concerns. Understanding local regulations regarding plastic use is essential for compliance.

Summary of Material Selection for Plastic Christmas Hats

| Material | Typical Use Case for plastic christmas hat | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene | Basic outdoor decorations | Low cost and lightweight | Less durable, prone to wear | Low |

| Polypropylene | Reusable hats for festive events | High durability and flexibility | Higher production cost | Medium |

| Polyester | Comfortable, vibrant holiday hats | Excellent color retention | More expensive, specific manufacturing | Medium |

| PVC | Weather-resistant outdoor decorations | Excellent durability | Heavier and less breathable | Medium |

This guide provides a comprehensive overview of material options for plastic Christmas hats, helping international B2B buyers make informed decisions that align with their market needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for plastic christmas hat

What Are the Key Manufacturing Stages for Plastic Christmas Hats?

The manufacturing of plastic Christmas hats involves several critical stages that ensure the final product meets quality standards while being cost-effective. Each stage is designed to optimize the efficiency of production while maintaining high-quality output.

Material Preparation: What Materials Are Used?

The primary materials for plastic Christmas hats typically include various grades of polyester or polyethylene. These materials are chosen for their durability, light weight, and ability to retain color and shape. The manufacturing process begins with sourcing high-quality raw materials, which are then tested for consistency and compliance with relevant international standards. Suppliers must ensure that materials are free from harmful substances, particularly for markets in Europe where regulations are stringent.

How Are Plastic Christmas Hats Formed?

The forming stage is crucial for creating the shape of the hats. Common techniques include:

-

Injection Molding: This method is prevalent for producing high-volume, uniform hats. The raw material is heated until it becomes a liquid, then injected into a mold that shapes the hat. This process allows for intricate designs and ensures consistency across batches.

-

Thermoforming: For lighter hats, thermoforming is often used. Sheets of plastic are heated until pliable and then shaped over a mold. This technique is more flexible for small production runs but may not offer the same durability as injection molding.

What Happens During the Assembly Stage?

Once the hats are formed, they undergo assembly, where additional elements such as faux fur trims, pom-poms, or decorative elements are attached. This step often requires manual labor or semi-automated processes, depending on the complexity of the design. Quality control checkpoints are established at this stage to ensure that all components are correctly attached and that the overall appearance meets design specifications.

How Is the Finishing Process Conducted?

The finishing stage involves several processes to enhance the aesthetic and functional qualities of the hats. This may include dyeing, printing, or adding embellishments. Final inspection for visual defects occurs here, ensuring that the hats are vibrant and free from flaws. Proper packaging is also critical to prevent damage during shipping, particularly for international orders.

What Quality Assurance Measures Are Implemented?

Quality assurance is an integral part of the manufacturing process for plastic Christmas hats. It ensures that products are safe, reliable, and meet customer expectations.

Which International Standards Should Buyers Be Aware Of?

Manufacturers often adhere to international quality standards such as ISO 9001, which focuses on quality management systems. For products sold in Europe, CE marking is essential, indicating compliance with safety and health requirements. These standards are critical for B2B buyers, as they provide a framework for quality assurance that can be trusted across different markets.

What Are the Common Quality Control Checkpoints?

Quality control is typically divided into several checkpoints:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specified criteria before production begins.

-

In-Process Quality Control (IPQC): Ongoing checks during the manufacturing process help identify defects early. This includes monitoring machine performance and inspecting components at various stages of production.

-

Final Quality Control (FQC): This final inspection occurs before packaging and shipping. It involves a thorough examination of the finished product against established quality standards.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to verify a supplier’s quality control processes:

-

Audits: Conducting supplier audits can provide insight into their manufacturing practices, compliance with international standards, and quality control measures.

-

Reports: Requesting detailed quality control reports can help buyers understand the quality assurance processes in place and any historical performance data.

-

Third-party Inspections: Utilizing third-party inspection services can provide an unbiased evaluation of the manufacturing process and the final product.

What Are the Specific Quality Control Considerations for International Buyers?

When sourcing plastic Christmas hats from different regions, international buyers must be aware of specific quality control nuances. For instance, regulations may vary significantly between Africa, South America, the Middle East, and Europe. Understanding local compliance requirements is essential for avoiding legal issues and ensuring product acceptance in the target market.

How Do Cultural Preferences Impact Quality Standards?

Cultural preferences may also influence quality standards. For instance, buyers in Europe may prioritize eco-friendly materials and sustainable manufacturing practices, while markets in Africa or South America might focus more on cost-effectiveness and durability. Suppliers should be prepared to adapt their quality assurance processes to meet these varying expectations.

Conclusion: Ensuring Quality in Plastic Christmas Hat Manufacturing

A comprehensive understanding of the manufacturing processes and quality assurance measures for plastic Christmas hats is vital for B2B buyers. By being informed about material preparation, forming techniques, assembly, and finishing processes, as well as international standards and quality control checkpoints, buyers can make educated decisions when sourcing products. Furthermore, verifying supplier quality through audits and third-party inspections will ensure that the hats meet the required standards for safety, durability, and aesthetic appeal in diverse global markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘plastic christmas hat’

In the competitive landscape of holiday merchandise, procuring high-quality plastic Christmas hats requires a structured approach. This guide offers a practical checklist to help B2B buyers navigate the sourcing process effectively, ensuring you make informed decisions that align with your business needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your product requirements. This includes the size, material (e.g., durable plastic or polyester), color options, and design elements like faux fur trim or pom-poms. Precise specifications help streamline the sourcing process and ensure that suppliers can meet your expectations.

- Size Variations: Consider offering different sizes to cater to various demographics, especially if targeting family-oriented markets.

- Material Quality: Ensure that the plastic used is non-toxic and suitable for extended use, as customers may expect durability.

Step 2: Conduct Market Research

Understanding the current market trends for plastic Christmas hats is crucial. Research competitors, pricing strategies, and popular styles to inform your purchasing decisions.

- Trend Analysis: Identify what styles are trending in different regions, such as Africa or Europe, to tailor your offerings.

- Pricing Insights: Analyze price points to ensure your sourcing aligns with market expectations while maintaining profitability.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they can deliver quality products on time. Request company profiles, case studies, and references from similar businesses.

- Supplier Reputation: Look for suppliers with a strong reputation in the industry. Check reviews and testimonials from previous clients.

- Production Capacity: Ensure the supplier can handle your order volume and timelines, especially during peak holiday seasons.

Step 4: Request Samples

Before finalizing any orders, request samples of the plastic Christmas hats. This step allows you to assess the quality, comfort, and aesthetic appeal of the product.

- Quality Assessment: Examine the stitching, material feel, and overall durability. This is crucial for customer satisfaction.

- Fit Testing: If possible, have team members of different demographics try the hats to ensure a comfortable fit across various sizes.

Step 5: Verify Compliance and Certifications

Ensure that the supplier adheres to industry standards and regulations. This includes safety certifications, especially for products intended for children.

- Safety Standards: Check for compliance with local and international safety regulations to avoid potential liabilities.

- Sustainability Certifications: If your brand emphasizes eco-friendliness, verify that the supplier uses sustainable materials and practices.

Step 6: Negotiate Terms and Pricing

Once you’ve selected a supplier, engage in negotiations to secure the best terms. Discuss pricing, payment terms, lead times, and minimum order quantities.

- Volume Discounts: Explore discounts for larger orders, which can significantly impact your bottom line.

- Payment Flexibility: Consider negotiating payment terms that allow for better cash flow management, especially during the holiday season.

Step 7: Establish a Logistics Plan

Plan the logistics of how the products will be delivered to your location. This includes shipping methods, costs, and timelines.

Illustrative image related to plastic christmas hat

- Shipping Options: Evaluate different shipping methods to balance cost and speed. Consider air freight for urgent orders.

- Inventory Management: Develop a strategy for managing stock levels to avoid shortages during peak sales periods.

By following this structured checklist, B2B buyers can effectively source plastic Christmas hats that meet their quality standards and market demands, ultimately leading to a successful holiday sales season.

Comprehensive Cost and Pricing Analysis for plastic christmas hat Sourcing

What Are the Key Cost Components in Sourcing Plastic Christmas Hats?

When sourcing plastic Christmas hats for B2B purposes, understanding the cost structure is crucial for effective budgeting and pricing strategies. The primary cost components include:

-

Materials: The choice of materials significantly affects the overall cost. Commonly used materials like polyester and PVC can vary in price based on quality and supplier. High-quality, durable fabrics are essential for ensuring the hats withstand wear and tear, particularly in festive environments.

-

Labor: Labor costs can fluctuate based on the region where the hats are produced. Countries with lower labor costs might offer more competitive pricing, but this can also lead to variability in quality.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, equipment maintenance, and factory management salaries. Efficient production processes can reduce overhead costs.

-

Tooling: If custom designs or unique shapes are required, tooling costs can increase significantly. This includes the expenses associated with creating molds and other necessary production tools.

-

Quality Control (QC): Implementing stringent QC measures is essential to ensure that the hats meet specified standards. This can add to the overall cost but is necessary to avoid returns and maintain customer satisfaction.

-

Logistics: Transportation and handling fees should be factored into the total cost. International shipping can be particularly costly and is influenced by the chosen Incoterms.

-

Margin: Suppliers typically add a profit margin to cover their risks and ensure business viability. Understanding the expected margin can help buyers negotiate better terms.

How Do Price Influencers Affect Sourcing Decisions for Plastic Christmas Hats?

Several factors influence the pricing of plastic Christmas hats, impacting the overall cost structure for international buyers:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should consider their demand forecasts to negotiate favorable pricing based on volume.

-

Specifications and Customization: Custom designs, colors, and features can increase costs. Standard options tend to be less expensive, so buyers should evaluate whether customization is necessary for their market.

-

Materials and Quality Certifications: Higher-quality materials and certifications (like safety standards) can drive up costs. However, these factors also enhance the product’s marketability and can justify a higher selling price.

-

Supplier Factors: The reliability, reputation, and geographical location of suppliers can affect pricing. Suppliers with a strong track record may charge a premium, but this can lead to better quality and service.

-

Incoterms: Understanding the terms of trade (like FOB or CIF) is crucial as they dictate responsibility for shipping costs and risks. This knowledge can help buyers make informed decisions about total landed costs.

What Tips Can Help Buyers Optimize Costs for Plastic Christmas Hats?

When sourcing plastic Christmas hats, particularly for international markets like Africa, South America, the Middle East, and Europe, consider the following tips:

-

Negotiate Effectively: Build strong relationships with suppliers and be prepared to negotiate prices based on your order size and payment terms. Leverage market research to support your negotiations.

-

Focus on Cost-Efficiency: Analyze total costs, including shipping and duties, not just the unit price. A seemingly lower price may not be the best option if logistics costs are high.

-

Understand Pricing Nuances: Be aware of seasonal demand fluctuations which can impact prices. Placing orders well in advance of the holiday season can help lock in lower rates.

-

Evaluate Total Cost of Ownership (TCO): Consider factors like durability and potential returns when selecting products. A higher initial cost may be justified by longer-lasting products that reduce replacement frequency.

Disclaimer on Indicative Prices

Prices for plastic Christmas hats can vary widely based on the factors discussed. Buyers are encouraged to conduct thorough market research and obtain multiple quotes to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing plastic christmas hat With Other Solutions

In the competitive landscape of holiday accessories, particularly for festive occasions, the demand for Christmas hats is ever-present. As international B2B buyers evaluate their options, understanding the alternatives to plastic Christmas hats is essential for making informed purchasing decisions. This analysis compares plastic Christmas hats with two viable alternatives: felt Christmas hats and fabric (cotton/polyester blend) Christmas hats.

Comparison Table

| Comparison Aspect | Plastic Christmas Hat | Felt Christmas Hat | Fabric (Cotton/Polyester) Christmas Hat |

|---|---|---|---|

| Performance | Durable and water-resistant, suitable for outdoor use | Less durable, may not withstand wet conditions | Comfortable, breathable, and retains shape |

| Cost | Generally low-cost | Moderate cost | Higher cost due to material quality |

| Ease of Implementation | Easy to mass-produce and distribute | Moderate; requires more careful handling | Moderate; requires sewing or stitching for production |

| Maintenance | Low maintenance; easy to clean | Requires careful cleaning; may lose shape | Moderate maintenance; machine washable but may require ironing |

| Best Use Case | Outdoor events, bulk sales for parties | Indoor gatherings, costume parties | Gifts, upscale events, or themed parties |

Pros and Cons of Alternatives

Felt Christmas Hats

Felt Christmas hats are a popular alternative that offers a softer and more traditional look. They are typically less durable than plastic options, which means they may not be suitable for outdoor events where exposure to the elements is a concern. However, felt hats are lightweight and can provide a cozy feel, making them ideal for indoor gatherings or costume parties. The moderate cost makes them accessible for bulk purchases, though they may require more careful handling to maintain their shape.

Fabric (Cotton/Polyester) Christmas Hats

Fabric hats made from a blend of cotton and polyester provide a premium alternative to plastic options. These hats are known for their comfort and breathability, making them a great choice for extended wear. They tend to retain their shape better than felt hats and can often be machine washed, which adds to their practicality. However, they are generally more expensive due to the quality of materials and may involve a more complex production process, including sewing. This makes them less ideal for mass-market applications but perfect for gifting or upscale holiday events.

Conclusion

When choosing the right Christmas hat solution, B2B buyers should consider their specific needs, including the intended use case, budget constraints, and desired quality. Plastic Christmas hats offer durability and cost-effectiveness for large-scale events, while felt and fabric alternatives provide unique benefits that may appeal to niche markets or specific occasions. By evaluating the performance, cost, and maintenance of each option, businesses can strategically select the product that aligns best with their objectives and customer preferences.

Illustrative image related to plastic christmas hat

Essential Technical Properties and Trade Terminology for plastic christmas hat

What Are the Key Technical Properties of Plastic Christmas Hats?

Understanding the critical specifications of plastic Christmas hats is essential for B2B buyers aiming to select high-quality products that meet their market needs. Here are some key technical properties to consider:

-

Material Grade

Plastic Christmas hats are typically made from polyester or polyethylene, with variations in thickness and durability. High-grade polyester offers better resilience against wear and tear, making it suitable for both indoor and outdoor use. For buyers, selecting the right material grade ensures that the product can withstand various environmental conditions while maintaining its festive appeal. -

Circumference and Size Variability

The size of a Christmas hat, often measured by its circumference, is critical for ensuring a good fit. Standard sizes may range from 44 inches for decorative purposes to larger sizes for costume use. Offering a variety of sizes can cater to different customer demographics, enhancing marketability and customer satisfaction. -

Weight Tolerance

The weight of the plastic used in the hats can significantly affect shipping costs and handling. A lighter hat may be more cost-effective for bulk shipments, while heavier materials may provide a perception of quality. Buyers should consider weight tolerance to optimize logistics and pricing strategies. -

Color Fastness

The ability of the fabric to retain its color after exposure to sunlight and washing is vital. Hats that fade quickly may lead to customer dissatisfaction and returns. Understanding color fastness ratings will help buyers select products that maintain their vibrant appearance throughout the holiday season. -

Fire Retardancy

Safety is a paramount concern, especially for products used in festive decorations. Fire retardant materials reduce the risk of fire hazards, making them suitable for commercial use. Buyers should prioritize hats that meet safety standards to ensure compliance and protect their brand reputation.

What Are Common Trade Terms in the Plastic Christmas Hat Industry?

Familiarity with industry jargon can streamline communications and negotiations for B2B buyers. Here are several common trade terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products that are sold under another company’s brand. For buyers, partnering with an OEM can provide custom designs and materials while allowing them to focus on branding and marketing. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers to plan their inventory and budget effectively, ensuring they don’t overcommit resources. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing information for specific products. This process enables buyers to compare costs and terms across multiple suppliers, aiding in informed decision-making. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risk management, and delivery responsibilities, which are essential for smooth international trade. -

Lead Time

Lead time refers to the time required to manufacture and deliver products after an order is placed. Buyers should be aware of lead times to align their inventory needs with seasonal demand, ensuring they have products available when customers are shopping for holiday items. -

Durability Rating

This rating assesses how well a product can withstand physical stress and environmental conditions. For plastic Christmas hats, durability is essential for maintaining appearance and functionality, especially in outdoor settings. Buyers should look for products with high durability ratings to reduce the risk of returns and enhance customer satisfaction.

By understanding these technical properties and trade terms, B2B buyers can make more informed purchasing decisions, ensuring they choose high-quality plastic Christmas hats that meet their operational needs and customer expectations.

Navigating Market Dynamics and Sourcing Trends in the plastic christmas hat Sector

What Are the Current Market Dynamics and Key Trends in the Plastic Christmas Hat Sector?

The global market for plastic Christmas hats is experiencing notable growth, driven by factors such as increased consumer spending during the holiday season and a rising trend in festive-themed events. In regions like Africa, South America, the Middle East, and Europe, international B2B buyers are leveraging the increasing demand for affordable and visually appealing holiday decorations. The emergence of e-commerce platforms has further facilitated access to a diverse range of products, allowing buyers to source plastic Christmas hats from various suppliers worldwide.

Technological advancements in manufacturing processes are also reshaping the landscape. Innovations such as digital printing and improved material technologies are enabling manufacturers to produce customized designs quickly, meeting the specific preferences of local markets. For instance, European buyers may prioritize traditional designs, while South American markets might favor vibrant, colorful options. Additionally, the rise of social media marketing has made it easier for companies to showcase their products, enhancing visibility and attracting a broader customer base.

Another trend is the shift towards bulk purchasing, as retailers and event organizers aim to meet the growing demand for festive items at competitive prices. This is particularly relevant in regions with expanding middle-class populations, where holiday celebrations are becoming increasingly elaborate. Consequently, B2B buyers are encouraged to explore partnerships with suppliers who can offer not only quality products but also flexibility in order sizes and delivery schedules.

How Is Sustainability and Ethical Sourcing Impacting the Plastic Christmas Hat Market?

Sustainability is becoming a pivotal concern in the plastic Christmas hat sector, as consumers and businesses alike are increasingly prioritizing eco-friendly products. The environmental impact of plastic waste is prompting buyers to seek alternatives that minimize their carbon footprint. As a result, suppliers are beginning to explore sustainable materials such as recycled plastics and biodegradable options for manufacturing Christmas hats.

Ethical sourcing practices are also gaining traction, with B2B buyers recognizing the importance of transparent supply chains. Ensuring that products are sourced responsibly can enhance brand reputation and consumer trust. Certifications such as ISO 14001 for environmental management and Fair Trade can serve as benchmarks for suppliers aiming to demonstrate their commitment to sustainability. Buyers are encouraged to inquire about these certifications when sourcing plastic Christmas hats, ensuring that they align with their corporate social responsibility goals.

Furthermore, the integration of sustainability into marketing strategies can create a competitive advantage. Brands that communicate their commitment to eco-friendly practices are more likely to resonate with consumers, especially in markets where environmentally conscious purchasing is on the rise. This trend is particularly pronounced in Europe, where regulations surrounding plastic use are becoming more stringent, driving demand for sustainable alternatives.

What Is the Evolution of the Plastic Christmas Hat Market?

The evolution of the plastic Christmas hat market can be traced back to the mid-20th century when holiday celebrations began to incorporate more playful and diverse elements. Originally, Christmas hats were made from fabric or paper, but the introduction of plastic materials provided a more durable and versatile option. This shift allowed for mass production, making festive hats widely accessible to consumers at various price points.

As consumer preferences evolved, manufacturers began to innovate with designs and materials, leading to the development of hats that are not only functional but also decorative. The use of colorful embellishments and themed designs has become commonplace, catering to a broad audience. Today, plastic Christmas hats are not just a seasonal accessory; they have transformed into a staple for holiday parties, corporate events, and festive gatherings worldwide.

The market continues to adapt to changing consumer demands and technological advancements, ensuring that plastic Christmas hats remain relevant and appealing in the ever-evolving landscape of holiday celebrations. As B2B buyers navigate this dynamic market, understanding these historical shifts can provide valuable insights for making informed sourcing decisions.

Illustrative image related to plastic christmas hat

Frequently Asked Questions (FAQs) for B2B Buyers of plastic christmas hat

-

1. How do I ensure the quality of plastic Christmas hats from suppliers?

To ensure the quality of plastic Christmas hats, start by vetting suppliers through their certifications and production standards. Request samples to assess material quality, durability, and design. It’s advisable to inquire about their quality assurance processes, including inspections and testing methods. Additionally, consider using third-party inspection services to verify product quality before shipment, particularly if you’re sourcing from overseas manufacturers. Establishing clear quality expectations in your purchase agreement can also safeguard against potential discrepancies. -

2. What is the best way to negotiate pricing for bulk orders of plastic Christmas hats?

When negotiating pricing for bulk orders, research market prices to establish a baseline. Leverage your order volume to negotiate discounts, especially if you can commit to future orders. Discuss payment terms, such as deposits and net payment schedules, to find mutually beneficial arrangements. It can also be helpful to build a relationship with the supplier, as long-term partnerships may lead to better pricing and flexibility. Don’t hesitate to ask about seasonal promotions or discounts for early orders. -

3. What are the typical minimum order quantities (MOQs) for plastic Christmas hats?

Minimum order quantities (MOQs) for plastic Christmas hats can vary significantly among suppliers. Generally, MOQs can range from 100 to several thousand units, depending on the supplier’s production capabilities and your specific requirements. When sourcing, it’s essential to communicate your needs clearly and explore potential flexibility on MOQs, especially if you’re willing to pay a premium for smaller quantities or if you can combine orders of different products to meet the MOQ. -

4. How can I customize plastic Christmas hats for my brand?

Customization options for plastic Christmas hats typically include color, design, and branding elements such as logos or slogans. Discuss your specific requirements with potential suppliers and ask for their customization capabilities. Many manufacturers can provide digital mock-ups before production begins. Ensure you understand the cost implications of customization, including setup fees and minimum order requirements for custom designs. A well-defined design brief will help streamline the process and ensure your branding is accurately represented. -

5. What payment terms should I expect when sourcing plastic Christmas hats internationally?

Payment terms can vary widely based on the supplier’s location, reputation, and your relationship with them. Common terms include a deposit (often 30-50%) upfront with the balance due upon shipment or delivery. Some suppliers may offer letters of credit or escrow services for larger orders to mitigate risk. It’s advisable to clarify payment methods accepted (e.g., bank transfer, PayPal, etc.) and consider using secure payment platforms that provide buyer protection, especially when dealing with new suppliers. -

6. What logistics considerations should I keep in mind for shipping plastic Christmas hats?

When arranging logistics for shipping plastic Christmas hats, consider factors such as shipping methods (air vs. sea), delivery times, and customs regulations. Determine the best shipping option based on your timeline and budget. It’s crucial to understand the import duties and taxes applicable in your country, as these can impact the total cost. Collaborating with a logistics partner familiar with international shipping can streamline the process and help you navigate any potential challenges. -

7. How do I handle potential disputes with suppliers of plastic Christmas hats?

To handle disputes effectively, ensure that you have a clear contract outlining terms of sale, quality expectations, and dispute resolution procedures. Maintain open communication with your supplier throughout the process to address any issues promptly. If a dispute arises, document all correspondence and evidence related to the issue. Mediation or arbitration can be effective methods for resolving disputes without escalating to legal action. Engaging a legal professional familiar with international trade can provide additional support if necessary. -

8. What certifications should I look for when sourcing plastic Christmas hats?

When sourcing plastic Christmas hats, look for certifications that ensure the products meet safety and environmental standards. Common certifications include ISO 9001 for quality management, CE marking for compliance with European standards, and ASTM or CPSIA for safety in children’s products. Additionally, inquire about the materials used, particularly if the hats will be used in regions with strict regulations on plastic products. Certifications can help assure you of the product’s quality and compliance with local regulations.

Top 4 Plastic Christmas Hat Manufacturers & Suppliers List

1. Etsy – Plastic Santa Hats

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: This company, Etsy – Plastic Santa Hats, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. eBay – Plastic Christmas Decorations

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: This company, eBay – Plastic Christmas Decorations, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Oriental Trading – Bulk Santa Hats & Christmas Hats

Domain: orientaltrading.com

Registered: 1998 (27 years)

Introduction: Bulk Santa Hats & Christmas Hats, Category: Hats, Caps & Bandanas, Active Filters: Christmas, Items: 107, Price Range: $2.01 – $50.00, Material: Cotton, Fabric, Felt, Foam, Polyester, Color Options: Assorted Colors, Black, Blue, Brown, Gold, Green, Red, White, Occasion: Christmas, Holidays: Christmas, Brand: Oriental Trading, Popular Items: 22″ Fabulous Felt Santa Hats with Pom-Pom Tassel – 12 Pc….

4. Windy City Novelties – Christmas Hats & Headbands

Domain: windycitynovelties.com

Registered: 2001 (24 years)

Introduction: This company, Windy City Novelties – Christmas Hats & Headbands, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for plastic christmas hat

In today’s competitive landscape, strategic sourcing of plastic Christmas hats can significantly enhance your business’s holiday offerings. By leveraging high-quality materials and sustainable practices, suppliers can provide products that not only meet consumer demand but also align with increasing environmental concerns. As buyers from Africa, South America, the Middle East, and Europe seek unique and festive merchandise, the versatility and durability of plastic Christmas hats make them an appealing choice for various markets.

Understanding regional preferences and seasonal trends is crucial for optimizing inventory and maximizing sales. Collaborating with suppliers who offer diverse designs and customization options can further differentiate your product line, ensuring you cater to local tastes while maintaining cost-effectiveness.

Looking ahead, the demand for festive products is expected to rise as consumers increasingly embrace holiday celebrations. Engaging in strategic partnerships with reliable manufacturers and distributors will position your business to capitalize on this growth. Now is the time to explore sourcing opportunities that will not only enhance your product offerings but also drive customer satisfaction and loyalty. Embrace the spirit of the season and take action to secure your competitive edge in the plastic Christmas hat market.

Illustrative image related to plastic christmas hat

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.