How to Source Automatic Canopy Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for automatic canopy

In today’s competitive landscape, sourcing automatic canopies presents a unique challenge for B2B buyers navigating fluctuating market demands and diverse regional preferences. Whether you are enhancing outdoor spaces in bustling urban centers or providing shade solutions in sun-soaked climates, understanding the nuances of automatic canopies is essential for making informed purchasing decisions. This guide offers a comprehensive exploration of the various types of automatic canopies, their applications, and how to effectively vet suppliers to ensure quality and reliability.

For international buyers from regions such as Africa, South America, the Middle East, and Europe—including countries like Nigeria and Vietnam—this resource is tailored to address specific market conditions and operational needs. We delve into critical factors such as cost considerations, material options, and technological advancements, empowering you to navigate the complexities of the global market with confidence. By equipping yourself with actionable insights and a clear framework for evaluating potential suppliers, you can optimize your procurement strategy and secure the best solutions for your business. Let this guide be your roadmap to harnessing the benefits of automatic canopies, transforming outdoor spaces while meeting the demands of your clientele.

Understanding automatic canopy Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Retractable Awnings | Motorized, remote-controlled operation; various fabric options; customizable sizes | Restaurants, hotels, residential properties | Pros: Easy operation, customizable, energy-efficient. Cons: Initial cost can be high; requires electrical installation. |

| Fixed Canopies | Permanent structures; sturdy materials; can be designed for specific aesthetics | Commercial buildings, outdoor events | Pros: Durable, low maintenance. Cons: Less flexibility; cannot be retracted. |

| Semi-Cassette Awnings | Combines features of retractable and fixed canopies; protective hood for fabric | Cafés, outdoor lounges | Pros: Protects fabric, aesthetically pleasing. Cons: More expensive than standard retractables. |

| Freestanding Canopies | Independent structures; portable options available; often used in outdoor events | Trade shows, festivals, outdoor markets | Pros: Versatile placement, easy setup. Cons: Less stable in high winds; may require additional anchoring. |

| Side Awnings | Vertical drop design; often used in conjunction with other canopies; provides wind protection | Patios, balconies, outdoor dining areas | Pros: Adds privacy, blocks wind. Cons: Limited coverage area; may obstruct views. |

What Are the Key Characteristics of Retractable Awnings?

Retractable awnings are a popular choice for B2B applications due to their motorized functionality and ease of use. They can be operated with a remote control, allowing businesses to quickly adjust shade coverage as needed. These awnings come in various fabric options, providing flexibility in design and aesthetics. They are particularly suitable for restaurants and hotels seeking to enhance outdoor dining areas while improving energy efficiency by reducing indoor cooling costs.

How Do Fixed Canopies Serve Commercial Needs?

Fixed canopies offer a permanent solution for businesses requiring robust shelter from the elements. Constructed from durable materials, these canopies withstand harsh weather conditions, making them ideal for commercial buildings and outdoor events. Their low maintenance needs and long lifespan can offset the initial investment, making them a practical choice for B2B buyers looking for reliable outdoor coverage.

What Are the Benefits of Semi-Cassette Awnings?

Semi-cassette awnings blend the advantages of both retractable and fixed canopies, featuring a protective hood that shields the fabric when not in use. This design not only extends the lifespan of the awning but also enhances the overall aesthetic appeal. Businesses such as cafés and outdoor lounges can benefit from this type of canopy, as it provides a stylish solution for outdoor spaces while ensuring fabric longevity.

Why Choose Freestanding Canopies for Events?

Freestanding canopies are versatile structures that can be placed independently, making them ideal for outdoor events like trade shows and festivals. Their portability allows for easy setup and relocation, catering to businesses that require temporary solutions. However, buyers should consider the need for additional anchoring in windy conditions, as stability can be a concern.

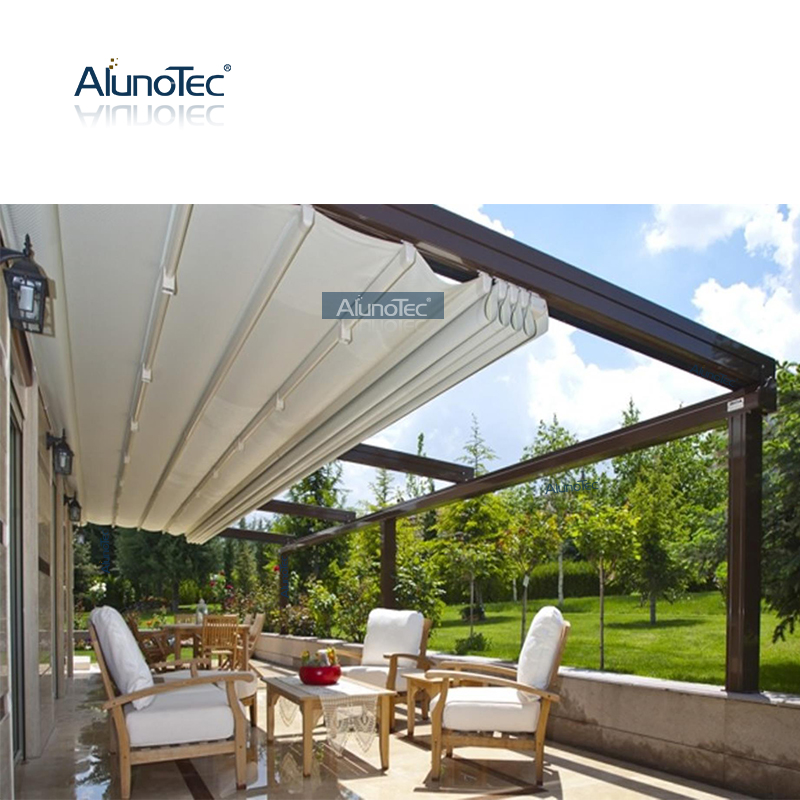

Illustrative image related to automatic canopy

How Do Side Awnings Enhance Outdoor Spaces?

Side awnings are designed to drop vertically, often complementing other canopy types to provide additional shade and protection from wind. They are particularly effective in outdoor dining areas and patios, where privacy and comfort are essential. While they enhance the usability of outdoor spaces, buyers should be mindful of their limited coverage area and potential obstruction of views.

Key Industrial Applications of automatic canopy

| Industry/Sector | Specific Application of automatic canopy | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Outdoor dining areas for restaurants and cafes | Enhances customer experience by providing shade and comfort, increasing seating capacity. | Durability against weather, ease of operation, aesthetic appeal, and warranty support. |

| Retail | Entrance protection for shopping malls and stores | Attracts customers with a welcoming ambiance while protecting merchandise from weather elements. | Size specifications, customization options, and installation support. |

| Transportation | Canopies for bus stops and train stations | Provides shelter for passengers, improving public transport experience and safety. | Compliance with local regulations, durability, and maintenance requirements. |

| Event Management | Temporary canopies for outdoor events and festivals | Offers flexibility for event setups, protecting attendees from sun and rain, enhancing event appeal. | Portability, ease of installation, and weather resistance. |

| Agriculture | Shade structures for livestock and crops | Improves crop yield and livestock health by reducing heat stress, leading to higher productivity. | Material quality, UV resistance, and local climate adaptability. |

How is Automatic Canopy Utilized in the Hospitality Industry?

In the hospitality sector, automatic canopies are essential for creating inviting outdoor dining spaces. Restaurants and cafes can quickly deploy these canopies to offer shade or shelter from rain, enhancing the dining experience and extending service areas. This not only increases seating capacity but also attracts customers seeking comfortable outdoor environments. International buyers must prioritize durability against harsh weather conditions, ease of operation, and aesthetic appeal to meet diverse customer expectations.

What Role Does Automatic Canopy Play in Retail Environments?

For retail businesses, automatic canopies serve as attractive entrance features that enhance customer engagement. They provide shelter for shoppers and protect merchandise from adverse weather, creating a welcoming atmosphere. This is particularly important in regions with variable climates, where businesses can leverage these canopies to maintain a consistent shopping experience. Sourcing decisions should focus on size specifications, customization options, and installation support to ensure a seamless integration with existing store designs.

How Can Automatic Canopy Improve Transportation Hubs?

In transportation sectors, such as bus stops and train stations, automatic canopies are critical for passenger comfort and safety. They protect commuters from sun and rain, enhancing the overall public transport experience. This application is vital in densely populated urban areas, where weather conditions can significantly affect ridership. When sourcing, businesses must consider compliance with local regulations, durability, and maintenance requirements to ensure long-term functionality.

Why Are Automatic Canopies Important for Event Management?

Event management companies utilize automatic canopies for outdoor events and festivals, providing flexible and temporary shelter solutions. These canopies can be quickly set up and taken down, offering protection for attendees from unpredictable weather. This adaptability enhances the overall appeal of events, making them more enjoyable and accessible. Buyers should look for canopies that are portable, easy to install, and resistant to various weather conditions to ensure successful event execution.

How Does Automatic Canopy Benefit the Agriculture Sector?

In agriculture, automatic canopies are used to create shade structures for crops and livestock. These canopies help mitigate heat stress, improving the health and productivity of both plants and animals. This application is particularly valuable in regions with extreme temperatures, where shade can lead to significant increases in yield and livestock welfare. Buyers should prioritize high-quality materials, UV resistance, and adaptability to local climate conditions to maximize agricultural benefits.

Illustrative image related to automatic canopy

3 Common User Pain Points for ‘automatic canopy’ & Their Solutions

Scenario 1: Limited Operational Control in Adverse Weather

The Problem: B2B buyers in outdoor hospitality, such as hotels and restaurants, often face the challenge of managing outdoor spaces during unpredictable weather conditions. Manual canopies can be labor-intensive, requiring staff to frequently adjust or retract them, leading to operational inefficiencies and potential safety hazards. For instance, a sudden rainstorm can leave outdoor dining areas exposed, negatively impacting guest experiences and resulting in lost revenue.

The Solution: Investing in a high-quality automatic canopy system equipped with smart sensors can significantly mitigate this issue. These advanced systems can automatically retract or extend based on real-time weather data, such as rain or wind speed. When sourcing an automatic canopy, look for options with integrated weather sensors that will trigger the canopy’s movement without manual intervention. Additionally, consider models with a remote control feature for manual override in case of sudden weather changes. This not only ensures a seamless guest experience but also optimizes labor efficiency, allowing staff to focus on service rather than constant adjustments.

Scenario 2: Durability Concerns in Harsh Environments

The Problem: Many B2B buyers operate in regions with extreme weather conditions, such as high UV exposure or heavy rainfall. This can lead to premature wear and tear on canopies, causing them to fade, tear, or degrade quickly. For instance, outdoor cafes in sunny climates may find their fabric canopies fading and becoming less effective at blocking harmful UV rays, which poses a risk to customer health and increases replacement costs.

The Solution: When selecting an automatic canopy, prioritize materials specifically designed for durability and weather resistance. Look for canopies made from high-quality, UV-resistant fabrics that have been independently tested for their durability against harsh environmental factors. Additionally, consider models that come with a robust warranty that covers material defects and degradation over time. Some manufacturers offer optional aluminum hoods that protect the canopy fabric when not in use, extending its lifespan. By choosing the right materials and protective features, B2B buyers can reduce replacement frequency and ensure long-term value.

Scenario 3: Complexity in Installation and Maintenance

The Problem: B2B buyers may encounter difficulties related to the installation and ongoing maintenance of automatic canopies. Complex installation processes can lead to increased labor costs and downtime, particularly if the product is not user-friendly. Furthermore, if maintenance is complicated or if parts are not readily available, it can lead to prolonged periods without the use of the canopy, impacting outdoor business operations.

Illustrative image related to automatic canopy

The Solution: To streamline the installation and maintenance process, look for automatic canopies that come with clear, comprehensive installation guides and offer professional installation services. Choose models that are designed for easy setup, ideally with minimal tools required. Additionally, consider purchasing canopies from reputable suppliers that provide ongoing support and have a readily available inventory of spare parts. Establishing a relationship with a supplier that offers maintenance kits and cleaning solutions can also help prolong the lifespan of the canopy and keep it in optimal working condition. By selecting products that emphasize ease of installation and maintenance, B2B buyers can minimize operational disruptions and maximize their outdoor space’s usability.

Strategic Material Selection Guide for automatic canopy

What Are the Key Materials for Automatic Canopy Construction?

When selecting materials for automatic canopies, several factors come into play, including durability, cost, and environmental resistance. The following analysis explores four common materials used in the construction of automatic canopies, focusing on their properties, advantages, disadvantages, and considerations for international buyers.

How Do Acrylic Fabrics Perform in Automatic Canopies?

Acrylic fabrics are widely used for automatic canopies due to their excellent weather resistance and UV protection. These materials can withstand high temperatures and are resistant to mold and mildew, making them suitable for various climates, particularly in regions with high humidity, such as parts of Africa and South America.

Pros: Acrylic fabrics are durable, lightweight, and available in a wide range of colors and patterns. They can block up to 98% of harmful UV rays, providing excellent sun protection. Additionally, they are relatively easy to clean and maintain.

Cons: While acrylic fabrics are durable, they can be more expensive than other fabric options. They may also require special coatings to enhance water resistance, which can complicate manufacturing.

Illustrative image related to automatic canopy

Impact on Application: Acrylic fabrics are ideal for outdoor applications where UV protection is critical. They are compatible with various framing materials, including aluminum and steel.

Considerations for International Buyers: Buyers should ensure that the acrylic fabrics meet local standards for UV resistance and weather durability. Compliance with ASTM standards is often preferred in regions like Europe.

What Are the Advantages of Using Aluminum in Automatic Canopy Structures?

Aluminum is a popular choice for the frame of automatic canopies due to its lightweight and corrosion-resistant properties. It can withstand various environmental conditions, making it suitable for outdoor applications in diverse climates.

Pros: Aluminum is highly durable and requires minimal maintenance. It is also recyclable, making it an environmentally friendly option. The material can be easily fabricated into various shapes and sizes, allowing for customization.

Illustrative image related to automatic canopy

Cons: Although aluminum is lightweight, it can be less robust than steel, making it unsuitable for extremely high-stress applications. Additionally, the initial cost can be higher compared to other metals.

Impact on Application: Aluminum frames are ideal for automatic canopies that require frequent retraction and extension, as they can handle the mechanical stresses involved.

Considerations for International Buyers: Buyers should verify that aluminum components comply with local corrosion resistance standards, especially in coastal areas where saltwater exposure is a concern.

How Does Steel Compare as a Material for Automatic Canopy Structures?

Steel is another common material used for the structural components of automatic canopies. It offers high strength and durability, making it suitable for large installations.

Pros: Steel can support heavy loads and is highly resistant to deformation. It is also cost-effective compared to aluminum, especially for large-scale projects.

Cons: Steel is prone to corrosion if not properly treated, requiring regular maintenance and protective coatings. It is also heavier, which can complicate installation.

Illustrative image related to automatic canopy

Impact on Application: Steel frames are ideal for large commercial canopies or structures requiring significant load-bearing capacity.

Considerations for International Buyers: Compliance with local standards for structural integrity and corrosion resistance is crucial. Buyers should look for certifications that align with regional safety standards.

What Role Does PVC Play in Automatic Canopy Applications?

Polyvinyl chloride (PVC) is commonly used in the manufacturing of canopy fabrics due to its flexibility and water resistance. It is often employed in commercial settings where cost-effectiveness is a priority.

Pros: PVC is highly durable, resistant to water, and easy to clean. It is also available in various colors and thicknesses, making it versatile for different applications.

Cons: PVC can be less environmentally friendly compared to other materials, as it is not biodegradable. It may also not provide the same level of UV protection as acrylic fabrics.

Impact on Application: PVC is suitable for temporary or semi-permanent installations where cost is a significant factor. It works well in environments where water resistance is crucial.

Considerations for International Buyers: Buyers should ensure that PVC materials comply with local environmental regulations and standards for safety.

Summary Table of Material Selection for Automatic Canopies

| Material | Typical Use Case for automatic canopy | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Acrylic Fabric | Residential and commercial awnings | Excellent UV protection | Higher cost than other fabrics | High |

| Aluminum | Frames for retractable canopies | Lightweight and corrosion-resistant | Less robust than steel | Medium |

| Steel | Large commercial canopies | High strength and load capacity | Prone to corrosion without treatment | Medium |

| PVC | Temporary or budget canopies | Cost-effective and water-resistant | Less environmentally friendly | Low |

This guide provides a comprehensive overview of materials for automatic canopies, offering valuable insights for international B2B buyers in diverse markets.

In-depth Look: Manufacturing Processes and Quality Assurance for automatic canopy

What Are the Key Stages in the Manufacturing Process of Automatic Canopies?

The manufacturing process for automatic canopies encompasses several critical stages that ensure the final product meets both functional and aesthetic standards.

Material Preparation: What Materials Are Used and How Are They Prepared?

The first stage involves sourcing high-quality materials, which typically include aluminum for frames, weather-resistant fabrics for the canopy, and electrical components for motorization. The aluminum is often treated with a powder coating to enhance durability and resistance to corrosion, which is crucial for outdoor applications. Fabrics, such as acrylic or polyester, are selected based on their UV resistance, water repellency, and ease of maintenance. During this stage, materials are inspected for defects and inconsistencies before moving on to the forming process.

Forming: How Are Components Shaped and Prepared for Assembly?

Once the materials are ready, the forming stage begins. This includes processes like cutting, bending, and molding aluminum into the desired shapes for frames and support structures. Advanced techniques such as CNC machining may be employed to ensure precision in the dimensions of the components. For fabric canopies, cutting machines are utilized to create the required shapes, often incorporating patterns and designs as specified by customer orders. This stage is crucial as it sets the foundation for the product’s structural integrity and overall appearance.

Assembly: What Techniques Are Used to Assemble Automatic Canopies?

The assembly process involves bringing together all the prepared components. Skilled labor is essential here, as workers must ensure that all parts fit together seamlessly. Automated assembly lines may be used for certain processes, such as attaching motors to the frames. This stage often includes the installation of electronic components like remote controls and sensors. Quality checks are integrated into the assembly process to ensure that each unit operates correctly and meets safety standards.

Finishing: What Are the Final Touches Applied Before Shipping?

After assembly, the canopies undergo a finishing process that may include additional coatings for weatherproofing and aesthetic enhancements. This could involve the application of protective sealants or paints to ensure longevity. The final inspection is performed to check for any cosmetic imperfections and to ensure that the product meets the specified quality standards before it is packaged for shipment.

How is Quality Assurance Managed in Automatic Canopy Manufacturing?

Quality assurance (QA) is an integral part of the manufacturing process, particularly for B2B buyers who need reliable products.

Which International Standards Should B2B Buyers Be Aware Of?

Manufacturers of automatic canopies often adhere to international standards such as ISO 9001, which outlines criteria for a quality management system. Compliance with these standards ensures that products are consistently produced to meet customer requirements and regulatory demands. Additionally, certifications like CE (Conformité Européenne) signify that products meet EU safety, health, and environmental protection standards, which can be particularly relevant for buyers in Europe.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves several checkpoints throughout the manufacturing process, including:

- Incoming Quality Control (IQC): This occurs at the material preparation stage, where raw materials are inspected for quality and compliance with specifications.

- In-Process Quality Control (IPQC): Conducted during the assembly phase, this involves monitoring processes to ensure components are being assembled correctly.

- Final Quality Control (FQC): Before products are shipped, they undergo a final inspection to ensure they meet all functional and aesthetic requirements.

What Common Testing Methods Are Used to Ensure Quality?

Testing methods may include load testing to ensure structural integrity, UV exposure tests for fabric durability, and electrical tests for motor functions. These assessments help identify any weaknesses in the product that could lead to failures in the field.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, especially those in diverse regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential.

What Audits and Reports Should Be Requested?

Buyers should request copies of quality management system audits, product inspection reports, and certifications that demonstrate compliance with international standards. Regular audits of suppliers can also provide insights into their operational practices and commitment to quality.

How Can Third-Party Inspections Enhance Confidence in Supplier QC?

Engaging third-party inspection agencies can provide an unbiased evaluation of the supplier’s production processes and product quality. These inspections can cover everything from raw material sourcing to finished product assessments, giving buyers additional assurance of quality.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must navigate various regulations and standards that may differ by region. For example, a product certified for the European market may not automatically meet the requirements for markets in Africa or South America. Understanding these nuances is crucial for ensuring compliance and minimizing risks associated with importation.

Illustrative image related to automatic canopy

How Can Buyers Stay Informed About Changing Standards?

Staying updated on changing industry standards and regulations can be achieved through participation in industry associations, attending trade shows, and subscribing to relevant publications. These resources can provide valuable insights into emerging trends and best practices in quality assurance.

In conclusion, understanding the manufacturing processes and quality assurance practices associated with automatic canopies equips B2B buyers with the knowledge necessary to make informed purchasing decisions. By focusing on quality control at every stage—from material preparation to final inspection—buyers can ensure they partner with manufacturers that prioritize excellence and reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘automatic canopy’

Introduction

Procuring an automatic canopy can enhance outdoor spaces for various business applications, from restaurants to event venues. This guide aims to provide a practical checklist for B2B buyers looking to source high-quality automatic canopies. Following these steps will ensure a well-informed purchasing decision that meets both operational needs and budget constraints.

Step 1: Define Your Technical Specifications

Clearly outlining your technical specifications is vital for ensuring the canopy meets your needs. Consider factors such as size, material, and operational features. For example, determine the dimensions required for your space and the type of fabric that will offer the best protection against weather elements.

Illustrative image related to automatic canopy

- Material Choices: Look for options like water-resistant or 100% waterproof fabrics, which are essential in regions with heavy rainfall.

- Operational Mechanism: Decide between remote-controlled or manual options, keeping in mind ease of use for your staff.

Step 2: Research Supplier Credentials

Before engaging with suppliers, research their credentials to ensure reliability and quality. Look for certifications such as ISO or specific industry standards that indicate a commitment to quality.

- Company History: Investigate how long they have been in the industry and their experience with automatic canopies.

- Client Testimonials: Seek feedback from previous clients, especially those in similar markets or regions, to gauge their satisfaction.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website; a comprehensive evaluation can reveal a supplier’s reliability and quality of service.

- Sample Products: Request samples or visit installations to assess the quality and functionality of the canopies firsthand.

- After-Sales Support: Inquire about warranty terms and the availability of maintenance services to ensure long-term satisfaction.

Step 4: Compare Pricing Models

When sourcing automatic canopies, comparing pricing models from various suppliers is essential. Look beyond the initial costs; consider total cost of ownership, including installation, maintenance, and potential repairs.

Illustrative image related to automatic canopy

- Hidden Costs: Be aware of any additional fees that might not be included in the initial quote, such as shipping or installation charges.

- Financing Options: Some suppliers may offer financing plans, which can ease the upfront financial burden.

Step 5: Assess Customization Options

Customization can significantly enhance the functionality and aesthetics of your canopy. Discuss available customization options with suppliers, such as color choices, branding opportunities, and additional features like integrated lighting or side panels.

- Adaptability: Ensure the canopy can be tailored to fit your specific business environment and branding requirements.

- Future Needs: Consider whether the design allows for potential expansions or modifications in the future.

Step 6: Review Installation Requirements

Understanding the installation requirements is crucial for a smooth setup process. Verify whether the supplier provides installation services or if you will need to hire external contractors.

- DIY vs. Professional Installation: If opting for DIY, ensure the supplier provides comprehensive installation instructions and support.

- Site Assessment: Confirm if a site visit is necessary to evaluate structural considerations and mounting options.

Step 7: Finalize Your Purchase

Once you’ve completed the previous steps, it’s time to finalize your purchase. Ensure all terms are documented, including delivery timelines, payment terms, and warranty details.

- Contract Review: Carefully read through the contract to ensure all aspects of your agreement are clear and satisfactory.

- Post-Purchase Follow-Up: Plan for a follow-up with the supplier post-installation to address any issues or questions regarding the product.

By following this checklist, B2B buyers can confidently navigate the procurement process for automatic canopies, ensuring they select a product that meets their business needs effectively.

Comprehensive Cost and Pricing Analysis for automatic canopy Sourcing

What Are the Key Cost Components in Automatic Canopy Manufacturing?

When sourcing automatic canopies, understanding the cost structure is paramount for B2B buyers. Key cost components include:

Illustrative image related to automatic canopy

-

Materials: The choice of fabric (e.g., water-resistant acrylic or laminated materials), frame materials (aluminum or steel), and additional components (like motors and sensors) significantly impact costs. Premium materials may offer better durability and aesthetics but will increase the overall price.

-

Labor: Labor costs vary by region and supplier. In regions with higher labor costs, such as Europe, you may encounter higher pricing. Conversely, sourcing from countries with lower labor costs could present cost advantages but may also affect quality and service levels.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can reduce overhead, which can be passed on to the buyer in the form of lower prices.

-

Tooling: Initial setup costs for manufacturing tools and molds can be significant, especially for custom designs. For small orders, these costs may be amortized over fewer units, increasing per-unit costs.

-

Quality Control (QC): Investing in quality assurance processes ensures that the canopies meet specified standards. While this can add to costs, it is crucial for maintaining product integrity and customer satisfaction.

-

Logistics: Shipping costs can fluctuate based on distance, weight, and mode of transport. Import duties and tariffs must also be considered, especially for international transactions.

-

Margin: Suppliers typically add a margin to cover their operational costs and profit. This can vary widely based on the supplier’s market position and the competitive landscape.

How Do Price Influencers Affect Automatic Canopy Sourcing?

Several factors influence the pricing of automatic canopies, particularly for international buyers:

-

Volume/MOQ: Bulk purchases often lead to reduced per-unit prices. Suppliers may offer tiered pricing based on the minimum order quantity (MOQ), making it essential to negotiate these terms upfront.

-

Specifications and Customization: Custom designs or specific fabric choices can increase costs. Buyers should assess whether these features are essential to their needs or if standard options would suffice.

-

Material Quality and Certifications: Higher quality materials and certifications (such as UV resistance or fire retardant standards) can justify higher prices. Buyers should evaluate whether the additional cost aligns with their operational requirements.

-

Supplier Factors: The reputation and reliability of the supplier can significantly influence pricing. Established suppliers with a proven track record may charge more but offer better warranties and support.

-

Incoterms: Understanding Incoterms is crucial when determining who bears the cost and risk at various stages of transport. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can impact overall cost calculations.

What Buyer Tips Can Enhance Cost-Efficiency in Automatic Canopy Procurement?

To maximize value and minimize costs when sourcing automatic canopies, consider the following strategies:

-

Negotiation: Engage in negotiations to secure better pricing, especially when ordering in bulk. Be prepared to discuss payment terms, delivery schedules, and potential discounts.

-

Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider long-term costs, including maintenance, durability, and energy efficiency. A higher upfront cost may result in lower maintenance expenses and longer product life.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import tariffs, and local taxes that may affect the final cost. Partnering with local representatives or using local suppliers can sometimes mitigate these issues.

-

Quality Assurance: Invest in a supplier with a solid QC process to avoid costly returns or replacements later. Ensuring that products meet your specifications from the start can save significant time and resources.

In conclusion, a comprehensive understanding of cost structures, price influencers, and strategic buying approaches will empower international B2B buyers to make informed decisions in the automatic canopy market. These insights are essential for optimizing procurement strategies and achieving favorable outcomes.

Alternatives Analysis: Comparing automatic canopy With Other Solutions

Exploring Alternatives to Automatic Canopy Solutions

In the quest for effective outdoor shading and shelter solutions, automatic canopies stand out due to their convenience and modern technology. However, there are several viable alternatives that B2B buyers should consider based on their specific needs, budgets, and operational contexts. This section analyzes automatic canopies in relation to other shading solutions, providing a clear comparison to help businesses make informed decisions.

| Comparison Aspect | Automatic Canopy | Retractable Awning | Fixed Canopy |

|---|---|---|---|

| Performance | High durability; blocks 98% UV rays | Varies by fabric; typically good | Excellent for permanent shade |

| Cost | Mid to high-range investment | Low to mid-range | Moderate to high initial cost |

| Ease of Implementation | Requires professional installation | DIY-friendly options available | Permanent installation required |

| Maintenance | Low; periodic cleaning needed | Moderate; fabric replacement needed | Low; minimal upkeep |

| Best Use Case | Versatile for patios and decks | Ideal for residential use | Best for commercial spaces |

What are the Advantages and Disadvantages of Retractable Awnings?

Retractable awnings are a popular alternative to automatic canopies, offering a balance between affordability and functionality. These awnings can be manually operated or motorized, allowing users to adjust them based on weather conditions. They are particularly effective for residential settings, such as patios or balconies, where versatility is desired. However, their performance can vary significantly based on the quality of the fabric used and the mechanics involved. While they are generally less expensive than automatic canopies, they may require more maintenance, especially if the fabric becomes worn from sun exposure.

How Do Fixed Canopies Compare to Automatic Canopies?

Fixed canopies offer a more permanent solution for shade and protection, making them ideal for commercial applications such as cafes, restaurants, and outdoor venues. These structures are usually constructed from durable materials and can withstand harsh weather conditions. The primary advantage of fixed canopies is their excellent performance in terms of UV protection and durability. However, the initial installation cost can be higher than that of retractable options, and they lack the flexibility of being retracted or removed. Maintenance is minimal, but any repairs can be more complicated due to their fixed nature.

Conclusion: How to Choose the Right Shading Solution for Your Needs?

When selecting a shading solution, B2B buyers must assess their specific requirements, including budget constraints, installation capabilities, and desired flexibility. Automatic canopies offer advanced technology and ease of use, making them suitable for those seeking modern solutions. Retractable awnings provide a budget-friendly option for residential use, while fixed canopies excel in commercial settings needing consistent coverage. Ultimately, understanding the unique advantages and limitations of each option will empower buyers to make the best choice tailored to their operational demands.

Essential Technical Properties and Trade Terminology for automatic canopy

What Are the Key Technical Properties of Automatic Canopies?

When considering automatic canopies, understanding their technical properties is crucial for ensuring quality, functionality, and durability. Here are several essential specifications that B2B buyers should be aware of:

-

Material Grade: The quality of materials used in the construction of canopies directly affects their performance and longevity. Common materials include high-grade aluminum for frames, which offers strength without excessive weight, and weather-resistant fabrics like acrylic or PVC. Selecting the right material can enhance the canopy’s resistance to UV rays, moisture, and wear, making it vital for outdoor applications in varying climates.

-

Tolerance: Tolerance refers to the allowable deviation in dimensions and performance specifications during manufacturing. This is critical in ensuring that components fit together properly and function as intended. For instance, if a canopy is designed to extend a specific distance, maintaining tight tolerances ensures that it operates smoothly and safely, preventing issues such as jamming or structural failure.

-

Wind Resistance Rating: This specification indicates the maximum wind speed that the canopy can withstand without damage. It is especially important for buyers in regions prone to high winds or storms. A robust wind resistance rating ensures safety and longevity, reducing the need for frequent repairs or replacements, thus offering a more cost-effective solution over time.

-

Projection and Width Options: Understanding the available dimensions for canopies is essential for ensuring they fit the intended space. Projection refers to how far the canopy extends out from the building, while width is the total span of the canopy. These specifications help buyers select the right product for their specific requirements, whether for residential patios or commercial outdoor spaces.

-

Warranty and Support: A comprehensive warranty reflects the manufacturer’s confidence in their product’s durability and performance. Buyers should look for warranties that cover materials and craftsmanship, often ranging from 5 to 10 years. This assurance is crucial in B2B transactions, as it can significantly impact the total cost of ownership and maintenance.

-

Installation Requirements: Understanding installation needs—including mounting height, surface compatibility, and electrical requirements for motorized models—is vital for successful implementation. Clear guidelines on installation help streamline the process, whether through professional services or DIY methods, and can influence purchasing decisions based on the buyer’s capabilities.

What Are Common Trade Terms Associated with Automatic Canopies?

Familiarity with trade terminology can significantly enhance negotiations and procurement processes in the automatic canopy market. Here are several key terms:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce components or products that are used in another company’s end product. In the context of automatic canopies, OEMs may provide specific parts like motors or fabrics that meet particular standards. Understanding OEM relationships can help buyers ensure they are sourcing quality components.

-

MOQ (Minimum Order Quantity): MOQ is the smallest number of units that a supplier is willing to sell. This term is vital for B2B buyers as it can affect inventory management and cash flow. Knowing the MOQ helps businesses plan purchases effectively, especially when entering new markets or launching products.

-

RFQ (Request for Quotation): An RFQ is a standard business process to invite suppliers to bid on specific products or services. It is essential for buyers seeking competitive pricing and detailed information on product specifications. Crafting an effective RFQ can help streamline procurement and ensure that suppliers meet specific requirements.

-

Incoterms (International Commercial Terms): These are standardized terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is crucial for international transactions, as it clarifies who is responsible for costs and risks at various stages of the shipping process, enhancing negotiation strategies.

-

Lead Time: This term refers to the amount of time it takes from placing an order to receiving the goods. Understanding lead times is essential for effective project management and scheduling, especially in industries where timely installation is critical.

-

Customization Options: This term refers to the range of modifications available for products, such as color, size, or additional features. Knowing the customization options allows buyers to tailor products to their specific needs, enhancing customer satisfaction and market competitiveness.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational requirements and market strategies.

Navigating Market Dynamics and Sourcing Trends in the automatic canopy Sector

What are the Key Market Dynamics and Trends in the Automatic Canopy Sector?

The automatic canopy sector is experiencing a transformative phase, driven by several global factors. One of the primary drivers is the increasing demand for outdoor living spaces, particularly in urban settings. Buyers from Africa, South America, the Middle East, and Europe are increasingly seeking solutions that enhance outdoor experiences while providing protection against harsh weather conditions. Additionally, advancements in technology, such as remote control functionalities and smart home integrations, are becoming standard features, appealing to tech-savvy consumers.

Emerging trends also indicate a rising preference for customizable and aesthetically pleasing designs, allowing buyers to align products with their brand identities or personal tastes. The integration of energy-efficient materials and designs is another significant trend, as businesses look to reduce operational costs and promote sustainability. In markets like Nigeria and Vietnam, where climate conditions can be extreme, the demand for durable and weather-resistant solutions is particularly pronounced.

Furthermore, the competitive landscape is shifting, with manufacturers increasingly adopting direct-to-consumer models and enhancing online presence to cater to international B2B buyers. This shift allows for greater accessibility to a variety of products and fosters transparency in sourcing, which is becoming increasingly important in today’s market.

How is Sustainability Impacting the Sourcing of Automatic Canopies?

Sustainability is a crucial consideration for B2B buyers in the automatic canopy sector. The environmental impact of manufacturing processes and materials used in canopies has led to a significant shift towards ethical sourcing. Buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainable practices, such as using recycled or eco-friendly materials. Certifications like GreenGuard or OEKO-TEX can serve as indicators of a manufacturer’s commitment to sustainability, ensuring that products are free from harmful substances and produced in environmentally responsible ways.

Illustrative image related to automatic canopy

Moreover, consumers are becoming more educated about the impact of their purchases, leading to a demand for products that contribute positively to their environments. This trend is particularly strong in regions like Europe, where regulatory pressures around sustainability are more pronounced. For international buyers, aligning with suppliers who share a commitment to ethical sourcing not only enhances brand reputation but also meets the growing expectations of eco-conscious consumers.

In addition, implementing sustainable practices can also lead to cost savings over time, through energy-efficient designs and materials that require less maintenance. Buyers should seek partnerships with manufacturers who can provide a clear narrative about their sustainability efforts and the environmental benefits of their products.

What is the Historical Context of the Automatic Canopy Industry?

The automatic canopy industry has evolved significantly over the past few decades. Initially, canopies were primarily manual, requiring considerable effort for deployment and retraction. However, with advancements in technology, the introduction of motorized systems and remote controls has revolutionized the market. This evolution has made automatic canopies more accessible and user-friendly, enhancing their appeal to both residential and commercial buyers.

Historically, the industry was dominated by traditional materials such as canvas and metal. However, innovation has led to the development of advanced fabrics that offer better durability, weather resistance, and UV protection. As outdoor living became a trend in the late 20th century, the demand for stylish and functional canopies surged, paving the way for a diverse range of products tailored to various markets and climates. Today, the focus is on integrating technology and sustainability, ensuring that automatic canopies meet the needs of modern consumers while addressing environmental concerns.

Illustrative image related to automatic canopy

Frequently Asked Questions (FAQs) for B2B Buyers of automatic canopy

-

How do I solve issues with automatic canopy installation?

To address installation challenges with automatic canopies, ensure you select a reputable supplier who offers comprehensive installation guides and support. Many manufacturers provide professional installation services or detailed DIY instructions. Verify that your installation site meets the minimum mounting requirements and is compatible with the chosen awning model. Additionally, consider reaching out to local installers with experience in similar projects, as they can provide insights and practical assistance tailored to your specific environment. -

What is the best material for a durable automatic canopy?

The best materials for a durable automatic canopy include water-resistant woven acrylic and laminated fabrics, which offer excellent UV protection and weather resistance. For high-wind areas, canopies with aluminum frames and stainless steel components are recommended due to their strength and corrosion resistance. Evaluate your local climate conditions to choose materials that can withstand specific weather challenges, ensuring long-lasting performance and reduced maintenance costs. -

How can I vet suppliers for automatic canopies?

To effectively vet suppliers, conduct thorough research on their reputation and industry experience. Look for certifications, customer reviews, and case studies showcasing successful projects. Additionally, request samples of their materials to assess quality firsthand. Engage in direct communication to gauge their responsiveness and willingness to address your specific needs. It’s also beneficial to check their compliance with international standards to ensure product reliability and safety. -

What is the typical minimum order quantity (MOQ) for automatic canopies?

The minimum order quantity (MOQ) for automatic canopies can vary significantly based on the supplier and the complexity of the product. Generally, MOQs can range from a few units for standard products to larger quantities for custom solutions. When negotiating with suppliers, clarify your project scope and budget to see if they can accommodate smaller orders or offer flexible terms for bulk purchases. -

What payment terms should I expect when sourcing automatic canopies?

Payment terms for automatic canopies typically involve a deposit upfront, with the balance due upon delivery or installation. Common practices include 30% to 50% deposit with the order and the remainder before shipment. However, terms can vary based on supplier policies and your business relationship. It’s advisable to negotiate terms that align with your cash flow and project timelines while ensuring clarity to avoid misunderstandings. -

How do I ensure quality assurance (QA) for my automatic canopy order?

Quality assurance can be ensured by establishing clear specifications and standards with your supplier before production. Request samples and conduct pre-production inspections to verify that materials and craftsmanship meet your requirements. Additionally, consider implementing third-party inspections during manufacturing and before shipping. Establishing a clear communication channel with your supplier for ongoing updates can help address any issues promptly. -

What logistics considerations should I keep in mind when importing automatic canopies?

When importing automatic canopies, consider shipping methods, customs regulations, and potential tariffs that could affect costs. Work with a reliable freight forwarder who understands international shipping processes and can manage documentation. Additionally, assess lead times for production and shipping to ensure timely delivery. It’s also essential to plan for warehousing and distribution within your region to facilitate smooth operations post-delivery. -

Can automatic canopies be customized to fit specific business needs?

Yes, many suppliers offer customization options for automatic canopies, including size, color, and fabric choices. Businesses can also request specific features such as integrated lighting or smart technology for enhanced functionality. When discussing customization, provide detailed specifications and any relevant design preferences to ensure the final product aligns with your branding and operational needs. Collaborating closely with the supplier during the design phase can yield optimal results.

Top 5 Automatic Canopy Manufacturers & Suppliers List

1. SunSetter – Motorized Awning

Domain: sunsetter.com

Registered: 1996 (29 years)

Introduction: Product: SunSetter Motorized Awning

Features:

– Instant transformation of deck/patio into a relaxing space

– Protects from sun, UV rays, and light rain

– One-touch remote control operation with built-in Somfy® motor

– Blocks 98% of harmful UVA and UVB rays

– Can be up to 20° cooler under the awning

– Available in water-resistant SunSetter Woven Acrylic or 100% waterproof Laminated fabric

– Optiona…

2. Mastertent – Automatic Awnings

Domain: mastertent.com

Registered: 1997 (28 years)

Introduction: This company, Mastertent – Automatic Awnings, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Somfy – Motorized Awnings

Domain: somfysystems.com

Registered: 1997 (28 years)

Introduction: Motorized Awnings powered by Somfy offer convenience, efficiency, and luxury for outdoor spaces. Key features include:

– Automated adjustments based on weather conditions using sun and wind sensors.

– Self-protecting design that retracts fully into a sealed cassette to prevent water penetration.

– Smart home compatibility allowing control via smartphone, voice commands, or remote.

– Energy eff…

4. Marygrove – Automated Awnings

Domain: marygrove.com

Registered: 1998 (27 years)

Introduction: Automated Awnings are motorized retractable awnings that can be controlled remotely via smartphone or tablet. They are designed for outdoor spaces such as patios and decks, providing shade and protection from the elements. Key features include:

– Convenience of remote control operation, with manual override in case of power outages.

– Available in multiple sizes larger than manual options.

– Ener…

5. Graber by SunSetter – Motorized Awnings

Domain: motorizedawnings.com

Registered: 2004 (21 years)

Introduction: Brand: Graber by SunSetter

Fabric: 100% Sunbrella Acrylic

Motor: 110 Volt, UL Listed (File No. E60495), Brand: Somfy

Power Cord: 18′ (24′ available)

Widths Available: 8′ to 20′ (actual fabric width is 5″ narrower)

Colors: 16 stylish Sunbrella colors

Valance: Straight Valance for an upscale look

Installation: Can be installed into wood, brick, stucco, aluminum, and vinyl siding (must be structural)…

Strategic Sourcing Conclusion and Outlook for automatic canopy

In the evolving landscape of automatic canopies, strategic sourcing emerges as a crucial factor for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. By understanding market dynamics, quality standards, and supplier capabilities, businesses can enhance their purchasing strategies, ensuring they secure high-quality products that meet both aesthetic and functional needs.

Investing in automatic canopies not only elevates outdoor spaces but also offers significant advantages in energy efficiency and protection against the elements. Buyers are encouraged to consider factors such as durability, warranty options, and innovative features like remote control and integrated lighting, which add value to their investment.

As you navigate the sourcing process, leverage this knowledge to identify reliable suppliers who can provide tailored solutions that align with your business objectives. The future of automatic canopies is bright, with advancements in technology and design poised to redefine outdoor experiences. Embrace this opportunity to enhance your offerings and meet the growing demand for versatile, high-quality outdoor solutions. Engage with suppliers today to explore how automatic canopies can transform your business landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to automatic canopy

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.