Choosing Your A/C Electric Supply: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for a/c electric supply

As international B2B buyers increasingly seek reliable sources for A/C electric supply, navigating the complexities of this global market presents both challenges and opportunities. From sourcing high-quality components to ensuring compliance with regional regulations, the task can often feel daunting, especially for businesses operating in diverse locales such as Nigeria, Germany, and Brazil. This guide aims to simplify the process of acquiring A/C electric supply by providing insights into various types of products, their applications, and essential supplier vetting strategies.

In this comprehensive resource, you will find detailed information on the different categories of A/C electric supplies, including distribution equipment, motor controls, and LED lighting solutions. We delve into critical factors influencing purchasing decisions, such as cost analysis, inventory management, and logistical considerations. Moreover, we highlight key aspects to consider when evaluating suppliers, ensuring that you choose partners who not only meet your quality standards but also align with your operational needs.

By leveraging the insights provided in this guide, B2B buyers from Africa, South America, the Middle East, and Europe will be empowered to make informed decisions that enhance efficiency and profitability. Whether you are a seasoned procurement professional or new to the industry, this resource will equip you with the knowledge necessary to navigate the A/C electric supply landscape confidently.

Understanding a/c electric supply Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Single-Phase Supply | Common in residential areas; uses two wires (live and neutral) for power. | Small businesses, residential HVAC systems | Pros: Lower installation cost, easier to manage. Cons: Limited power capacity, not suitable for larger installations. |

| Three-Phase Supply | Utilizes three wires to deliver power; offers a more balanced load. | Industrial facilities, large commercial buildings | Pros: Higher efficiency, better load distribution. Cons: More complex installation, requires specialized equipment. |

| Direct Current (DC) | Provides constant voltage; commonly used in battery systems. | Telecommunications, data centers | Pros: Stable power supply, less energy loss. Cons: Limited range, requires conversion for AC systems. |

| Alternating Current (AC) | Fluctuating voltage; widely used for general power distribution. | General commercial applications, HVAC systems | Pros: Versatile, easily transformed to different voltages. Cons: More susceptible to power loss over long distances. |

| Renewable Energy Supply | Generated from sustainable sources like solar or wind; can be AC or DC. | Eco-friendly businesses, off-grid applications | Pros: Reduces carbon footprint, potential long-term savings. Cons: High initial investment, dependency on environmental conditions. |

What Are the Key Characteristics of Single-Phase Supply?

Single-phase supply is the most common type of electric power system for residential and light commercial applications. It operates using two wires: one live and one neutral, making it simpler and more cost-effective to install. This type of supply is ideal for smaller HVAC systems and basic electrical needs. However, its limited power capacity makes it unsuitable for larger installations, which may require a three-phase supply for efficiency and reliability.

How Does Three-Phase Supply Differ from Other Types?

Three-phase supply delivers power through three conductors, providing a more balanced load and higher efficiency. This system is essential for industrial facilities and large commercial buildings that demand significant power for machinery and HVAC systems. The complexity of installation and the need for specialized equipment can be a barrier for some buyers, but the advantages of reduced energy costs and improved performance often outweigh these drawbacks.

In What Scenarios is Direct Current (DC) Most Beneficial?

Direct current (DC) is characterized by a constant voltage level, making it ideal for applications requiring stable power, such as telecommunications and data centers. While DC systems are efficient and experience less energy loss, their limited range and the need for conversion to AC for broader applications can be disadvantages. Buyers should consider their specific power requirements and the compatibility of their existing systems when opting for DC supply.

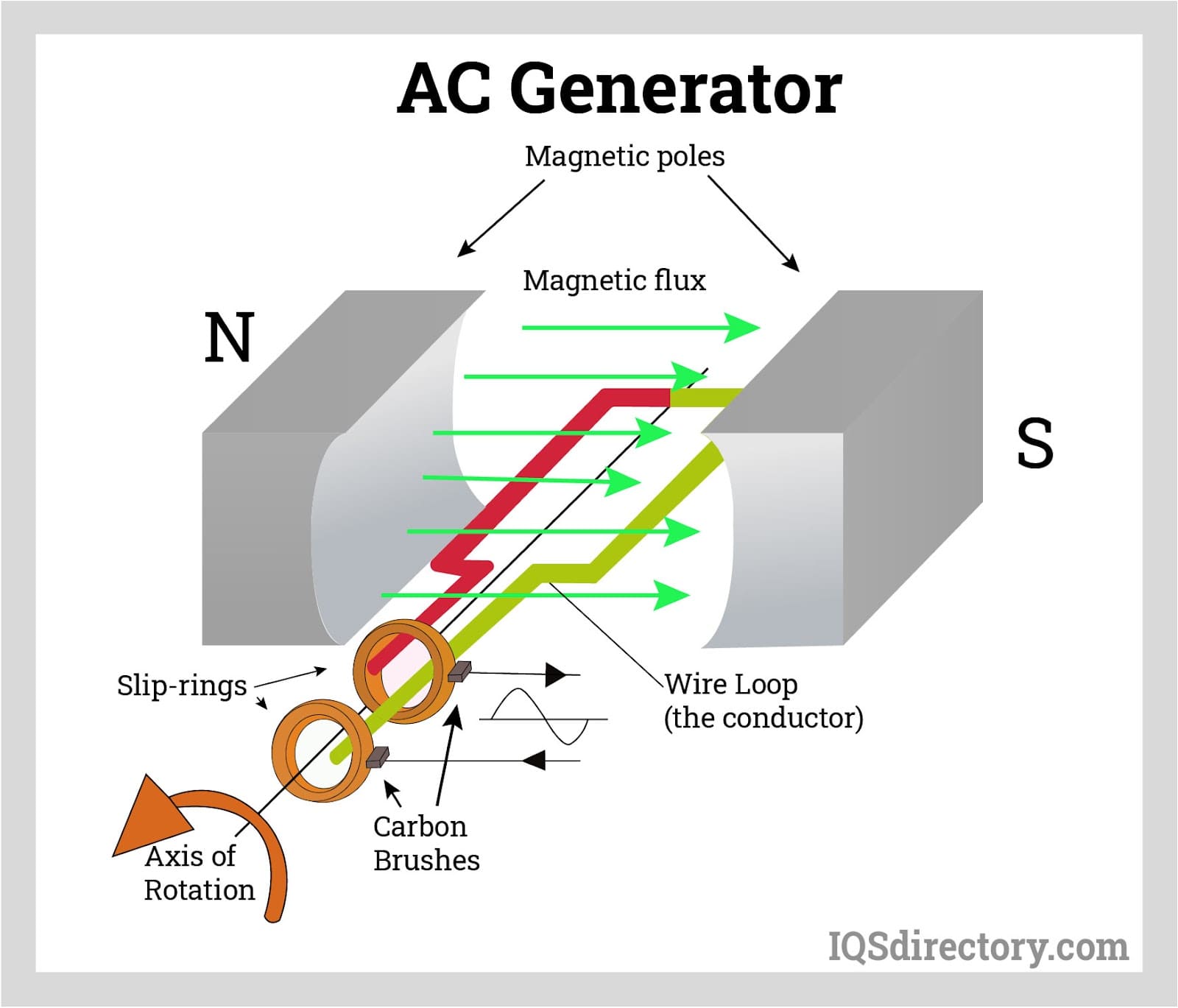

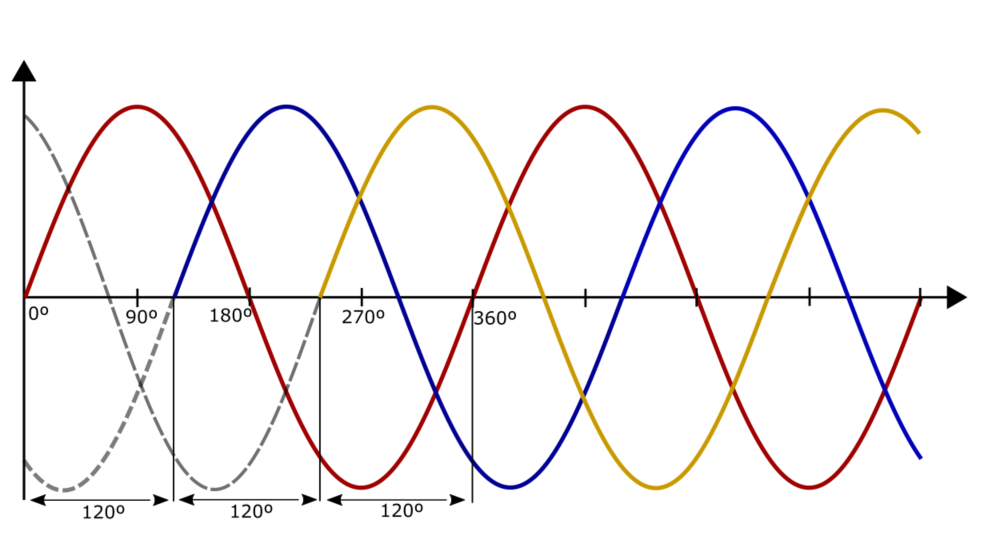

Why is Alternating Current (AC) the Most Widely Used?

Alternating current (AC) is the standard for most electrical power distribution due to its versatility and ability to be easily transformed to different voltages. This type of supply is suitable for a wide range of commercial applications and HVAC systems. However, AC systems can suffer from power loss over long distances, which is a consideration for businesses operating across expansive areas. Understanding the specific energy needs and infrastructure of a business is crucial when choosing AC supply.

What Are the Advantages of Renewable Energy Supply?

Renewable energy supply is generated from sustainable sources like solar and wind, and it can be either AC or DC. This type of supply is gaining popularity among eco-conscious businesses and those looking for off-grid solutions. While the initial investment may be high, the long-term savings and environmental benefits can be significant. Buyers should evaluate their energy usage patterns and potential incentives available for renewable energy systems to determine feasibility.

Key Industrial Applications of a/c electric supply

| Industry/Sector | Specific Application of a/c electric supply | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Powering machinery and equipment | Ensures operational efficiency and reduces downtime | Reliability of supply, compatibility with existing systems, and local support services |

| Construction | Temporary power supply for tools and lighting | Enhances safety and productivity on construction sites | Compliance with local regulations, availability of rental options, and rapid delivery capabilities |

| Telecommunications | Powering network infrastructure | Supports uninterrupted service and data transmission | Scalability, energy efficiency, and technical support for installation |

| Agriculture | Electrification of irrigation systems | Increases crop yield and optimizes water usage | Durability in harsh environments, energy consumption efficiency, and local availability of parts |

| Hospitality and Retail | Lighting and climate control systems | Improves customer experience and energy efficiency | Aesthetic compatibility, energy ratings, and after-sales service support |

How is a/c electric supply utilized in manufacturing, and what are the benefits?

In the manufacturing sector, a/c electric supply is crucial for powering machinery and equipment that drive production processes. This ensures operational efficiency and minimizes downtime, critical factors in meeting production targets. For international buyers, especially in regions like Africa and South America, sourcing reliable electric supply systems that are compatible with existing machinery is essential. Additionally, the availability of local support services can greatly reduce lead times for maintenance and repairs, enhancing overall productivity.

What role does a/c electric supply play in construction projects?

Construction sites often require temporary power for tools and lighting, which is where a/c electric supply comes into play. By providing reliable electricity, it enhances safety and productivity on-site, allowing workers to operate tools and equipment efficiently. Buyers should consider compliance with local regulations regarding power use and the availability of rental options for temporary installations. Rapid delivery capabilities are also critical to ensure that projects remain on schedule.

How does a/c electric supply support telecommunications infrastructure?

In the telecommunications industry, a/c electric supply is vital for powering network infrastructure, including servers and transmission equipment. This support is essential for ensuring uninterrupted service and data transmission, which are critical for customer satisfaction. When sourcing electric supply solutions, businesses should focus on scalability to accommodate future growth, energy efficiency to reduce operational costs, and technical support for installation and maintenance, especially in regions with varying levels of infrastructure.

Why is a/c electric supply important in agriculture?

Agriculture relies heavily on a/c electric supply for the electrification of irrigation systems. This technology significantly increases crop yield and optimizes water usage, making it indispensable for modern farming practices. Buyers need to consider the durability of electric supply systems in harsh environmental conditions and their energy consumption efficiency to ensure sustainability. Additionally, local availability of parts is crucial for quick repairs and maintenance, particularly in remote agricultural areas.

How does a/c electric supply enhance hospitality and retail environments?

In the hospitality and retail sectors, a/c electric supply is fundamental for powering lighting and climate control systems, which directly impact customer experience. A well-lit and comfortable environment encourages customer spending and loyalty. When sourcing electric supply solutions, businesses should look for aesthetic compatibility with their branding, energy ratings for cost savings, and robust after-sales service support to address any potential issues promptly.

3 Common User Pain Points for ‘a/c electric supply’ & Their Solutions

Scenario 1: Challenges with Timely Deliveries of A/C Electric Supply

The Problem: For B2B buyers, particularly in regions where the climate demands efficient air conditioning systems, timely delivery of electric supply components can be a critical issue. Delays in receiving necessary parts can halt project timelines, resulting in financial losses and strained relationships with clients. Many suppliers may not offer flexible delivery options, leaving buyers in a lurch when they require urgent supplies to meet installation deadlines.

The Solution: To mitigate this pain point, buyers should prioritize suppliers that offer flexible delivery options, such as same-day or evening deliveries. When sourcing A/C electric supply, inquire specifically about their logistics capabilities and delivery guarantees. Establish relationships with suppliers that have a strong inventory management system, ensuring that they can fulfill orders quickly. Utilizing technology, such as automated ordering systems that allow for real-time inventory checks, can also enhance the efficiency of the procurement process. Finally, consider implementing a vendor management system to streamline communications and track delivery schedules more effectively.

Scenario 2: Difficulty in Sourcing Specialized A/C Electric Components

The Problem: In a competitive market, B2B buyers often face difficulties sourcing specialized A/C electric components that meet specific project requirements. This can be particularly true for businesses operating in niche markets or those requiring unique specifications, such as energy-efficient systems or environmentally-friendly technologies. The challenge intensifies when suppliers lack the necessary product knowledge or inventory depth to support such specialized needs.

The Solution: To address this issue, buyers should conduct thorough research to identify suppliers with a robust catalog of specialized products and a proven track record in their respective fields. Engaging with suppliers that are members of professional networks or purchasing groups, like IMARK, can provide access to a wider range of products and competitive pricing. Additionally, establishing a clear communication channel with suppliers regarding specific project requirements can facilitate better support. Organizing regular meetings or consultations with suppliers to discuss upcoming projects can also ensure they are prepared to meet your needs efficiently.

Scenario 3: Navigating Compliance and Regulatory Challenges in A/C Electric Supply

The Problem: Compliance with local regulations and standards can be a significant pain point for B2B buyers sourcing A/C electric supplies. Different regions, such as Europe, Africa, and South America, have varied regulatory frameworks regarding energy efficiency and safety standards. Navigating these regulations can be overwhelming and may result in costly fines or project delays if components do not meet the required specifications.

The Solution: To effectively navigate compliance challenges, buyers should invest time in understanding the regulatory landscape of the regions they operate in. This includes familiarizing themselves with both local and international standards. Partnering with suppliers who have expertise in regulatory compliance can be invaluable; they can offer insights into which products meet specific standards and help buyers avoid potential pitfalls. Additionally, consider utilizing third-party compliance services to conduct audits and ensure that all supplied materials adhere to local regulations. Implementing a compliance checklist during the procurement process can also streamline the evaluation of potential suppliers and their offerings.

Strategic Material Selection Guide for a/c electric supply

What Are the Key Materials for A/C Electric Supply and Their Properties?

When selecting materials for A/C electric supply, it is crucial to consider their properties, benefits, and limitations. Here, we analyze four common materials: copper, aluminum, PVC, and stainless steel, focusing on their relevance to B2B buyers in diverse international markets.

How Does Copper Perform in A/C Electric Supply Applications?

Copper is widely regarded as the gold standard for electrical wiring due to its excellent electrical conductivity and thermal properties. It can handle high temperatures and pressures, making it suitable for various A/C applications. Copper’s resistance to corrosion enhances its longevity, particularly in humid environments.

Pros: Copper is highly durable and has a long lifespan, which reduces the need for frequent replacements. It is also relatively easy to work with, allowing for efficient manufacturing processes.

Cons: The primary drawback of copper is its cost, which can be significantly higher than alternatives like aluminum. Additionally, while it is resistant to corrosion, it can still be affected by certain environmental factors, necessitating protective coatings in some applications.

Impact on Application: Copper is compatible with various media, including refrigerants and oils, making it a versatile choice for A/C systems.

Illustrative image related to a/c electric supply

International Considerations: Buyers from regions such as Africa and South America should ensure compliance with local electrical standards, which may reference ASTM or IEC standards. In Europe, adherence to DIN standards is crucial.

What Role Does Aluminum Play in A/C Electric Supply?

Aluminum is another popular choice for A/C electric supply, particularly in applications where weight is a concern. It offers good conductivity, though not as high as copper, and is resistant to corrosion due to its natural oxide layer.

Pros: Aluminum is lightweight, making it easier to handle and install. It is also more cost-effective than copper, which can be advantageous for large-scale projects.

Cons: While aluminum is durable, it is less robust than copper and may require larger diameters to achieve the same conductivity. This can complicate design and installation processes.

Impact on Application: Aluminum is generally compatible with various refrigerants but may require specific connectors to ensure optimal performance.

Illustrative image related to a/c electric supply

International Considerations: Buyers should be aware of the specific standards applicable in their regions, including JIS in Japan and ASTM in the U.S., to ensure compliance with local regulations.

How Does PVC Contribute to A/C Electric Supply Systems?

Polyvinyl chloride (PVC) is widely used for insulation and protective casing in A/C electric supply applications. It offers excellent electrical insulation properties and is resistant to moisture and chemicals.

Pros: PVC is lightweight and cost-effective, making it a popular choice for insulation. Its resistance to corrosion and chemicals enhances its suitability in various environments.

Cons: While PVC is durable, it may not withstand high temperatures as effectively as metals, limiting its use in certain high-heat applications. Additionally, it can be less environmentally friendly due to its production process.

Impact on Application: PVC is ideal for protecting wiring from environmental hazards, ensuring safety and longevity in A/C systems.

International Considerations: Compliance with international standards such as RoHS and REACH is essential for PVC products, especially in Europe.

What Advantages Does Stainless Steel Offer in A/C Electric Supply?

Stainless steel is often used in A/C applications that require high strength and corrosion resistance, particularly in outdoor or harsh environments. Its durability makes it an excellent choice for components exposed to the elements.

Pros: Stainless steel is highly resistant to corrosion and can withstand extreme temperatures, making it suitable for various applications. Its strength ensures long-term reliability.

Cons: The primary disadvantage is its cost, which is generally higher than aluminum and PVC. Additionally, stainless steel can be heavier, complicating installation.

Impact on Application: Stainless steel is compatible with various refrigerants and is often used in piping and structural components of A/C systems.

International Considerations: Buyers should verify compliance with relevant standards such as ASTM and ISO, particularly in Europe and the Middle East.

Summary Table of Material Selection for A/C Electric Supply

| Material | Typical Use Case for A/C Electric Supply | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Electrical wiring and components | Excellent conductivity and durability | High cost and potential corrosion issues | High |

| Aluminum | Conductors and structural components | Lightweight and cost-effective | Lower conductivity and strength than copper | Medium |

| PVC | Insulation and protective casings | Moisture and chemical resistance | Limited high-temperature performance | Low |

| Stainless Steel | Piping and structural components | High strength and corrosion resistance | Higher cost and heavier weight | High |

This guide serves as a strategic resource for international B2B buyers, providing insights into material selection for A/C electric supply, tailored to meet the diverse needs of markets across Africa, South America, the Middle East, and Europe.

In-depth Look: Manufacturing Processes and Quality Assurance for a/c electric supply

What Are the Key Stages in the Manufacturing Process of A/C Electric Supply?

The manufacturing process for A/C electric supply components involves several critical stages, each designed to ensure that the final products meet stringent quality and performance standards. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation

The first step in manufacturing A/C electric supply components is material preparation. This involves sourcing high-quality raw materials, such as copper for wiring and various plastics or metals for housing and connectors. Suppliers often implement stringent incoming quality control (IQC) measures, ensuring that materials meet specifications before they enter the production line. Buyers should inquire about the sourcing of raw materials and the standards adhered to during this phase.

How Are A/C Electric Supply Components Formed?

Once materials are prepared, the forming stage begins. This stage may involve techniques such as stamping, extrusion, and molding, depending on the component being manufactured. For instance, copper wires are often drawn to the required gauge, while plastic housings may undergo injection molding.

Advanced manufacturing technologies, such as computer numerical control (CNC) machining, are also employed for precision components. Understanding the forming techniques used can help B2B buyers assess the precision and durability of the products they are considering.

What Is Involved in the Assembly Process?

The assembly phase is critical as it combines various components to create the final product. This could involve soldering wires to connectors, assembling circuit boards, or integrating electronic components into housings. Manufacturers often use automated assembly lines to enhance efficiency and consistency.

Quality assurance during assembly is vital. Businesses should look for suppliers that implement in-process quality control (IPQC) measures, such as visual inspections and automated testing, to catch defects early in the production cycle.

How Is Finishing Performed on A/C Electric Supply Products?

The finishing stage includes surface treatments, such as plating or painting, to enhance durability and aesthetics. Finishing processes also often involve additional quality checks to ensure that the final product meets international standards. B2B buyers should consider asking suppliers about their finishing processes and any associated certifications.

What International Quality Assurance Standards Are Relevant for A/C Electric Supply?

Quality assurance in the manufacturing of A/C electric supply components is governed by several international standards that ensure products are safe, reliable, and efficient. Two of the most recognized standards are ISO 9001 and CE certification.

ISO 9001 Certification

ISO 9001 is a quality management standard that organizations can use to demonstrate their ability to consistently provide products that meet customer and regulatory requirements. For B2B buyers, choosing suppliers with ISO 9001 certification can be a strong indicator of a commitment to quality management practices.

CE Marking and Other Industry Standards

In Europe, CE marking indicates that products comply with applicable safety, health, and environmental protection standards. For specific components, additional certifications such as API (American Petroleum Institute) may also be relevant, particularly for products used in oil and gas applications. Buyers should verify that suppliers possess the necessary certifications relevant to their market.

What Are the Common Quality Control Checkpoints in A/C Electric Supply Manufacturing?

Quality control (QC) checkpoints are essential throughout the manufacturing process to ensure product reliability and compliance with standards. Common QC checkpoints include:

- Incoming Quality Control (IQC): Inspecting raw materials upon arrival.

- In-Process Quality Control (IPQC): Monitoring and inspecting products during various manufacturing stages.

- Final Quality Control (FQC): Comprehensive testing of the final product before it is shipped.

Each of these checkpoints plays a crucial role in maintaining the integrity of the production process. B2B buyers should inquire about the specific QC measures implemented by suppliers to ensure comprehensive oversight.

What Testing Methods Are Commonly Used for A/C Electric Supply Products?

Testing methods for A/C electric supply components vary depending on the type of product but often include:

- Electrical Testing: Verifying that products meet voltage and current specifications.

- Environmental Testing: Assessing performance under various temperature and humidity conditions.

- Safety Testing: Ensuring compliance with safety standards to prevent hazards such as electric shock or fire.

B2B buyers should request information on the testing methods employed by their suppliers and whether third-party testing is utilized for additional credibility.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control practices is essential for B2B buyers, especially in international markets. Here are several effective strategies:

- Supplier Audits: Conducting on-site audits allows buyers to review the manufacturing processes and QC practices directly.

- Requesting Quality Reports: Suppliers should provide detailed reports on their quality control measures, testing results, and certifications.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control systems.

What QC and Certification Nuances Should International Buyers Consider?

International B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control and certification:

- Regional Standards: Different regions may have varying standards and regulations that suppliers must comply with. Understanding these can help buyers make informed decisions.

- Cultural Differences: Communication styles and business practices may differ across regions, which can impact supplier relationships and quality assurance processes.

- Logistical Considerations: Shipping products internationally can introduce additional quality risks. Buyers should discuss how suppliers manage these risks, including packaging and handling procedures.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make more informed decisions when sourcing A/C electric supply components. This knowledge will empower them to select reliable suppliers who meet their quality and performance expectations, ultimately contributing to successful business operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘a/c electric supply’

To successfully procure A/C electric supply, it’s essential to follow a structured approach. This guide provides a step-by-step checklist to help B2B buyers navigate the complexities of sourcing electrical supplies effectively.

Step 1: Define Your Technical Specifications

Begin by outlining the specific requirements for your A/C electric supply. This includes determining the type of electrical components, voltage ratings, and any particular features necessary for your project. Clear specifications help streamline the sourcing process, ensuring that you only engage suppliers who can meet your needs.

- Considerations:

- Identify the expected load and power requirements.

- List any compliance standards relevant to your industry or region.

Step 2: Conduct Market Research

Once your specifications are defined, research the market to identify potential suppliers. This involves exploring various distributors and manufacturers who specialize in A/C electric supply. Understanding market trends and pricing will empower you to make informed decisions.

Illustrative image related to a/c electric supply

- Resources to Utilize:

- Industry reports and trade publications.

- Online marketplaces and supplier directories.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, thorough evaluation is critical. Assess their company profile, product offerings, and customer feedback. Request case studies or references from other businesses, particularly those in your industry or geographic region.

- Key Factors to Review:

- Supplier experience and reputation in the market.

- Availability of customer support and after-sales service.

Step 4: Verify Supplier Certifications

Ensure that your chosen suppliers hold the necessary certifications and licenses. This is crucial for compliance with local and international regulations. Valid certifications indicate that the supplier adheres to quality and safety standards.

- What to Look For:

- ISO certifications or other relevant industry standards.

- Local regulatory compliance certifications.

Step 5: Assess Delivery and Logistics Capabilities

Understanding a supplier’s delivery options can significantly impact your project’s timeline. Investigate their logistics capabilities, including shipping times, flexibility for urgent orders, and return policies.

- Considerations:

- Availability of same-day or next-day delivery services.

- Policies regarding damaged or incorrect orders.

Step 6: Negotiate Pricing and Terms

Once you’ve selected a supplier, engage in negotiations to secure the best possible pricing and terms. Discuss bulk purchasing discounts, payment terms, and warranty conditions. Effective negotiation can lead to significant cost savings.

Illustrative image related to a/c electric supply

- Negotiation Tips:

- Be prepared with competitor pricing for leverage.

- Clarify all terms in writing to avoid misunderstandings.

Step 7: Establish a Long-Term Relationship

After successful procurement, focus on building a long-term relationship with your supplier. Open communication and regular feedback can lead to improved service and better pricing in the future.

- Ways to Foster Relationships:

- Schedule regular check-ins to discuss performance and needs.

- Attend industry events together for networking and collaboration opportunities.

By following these steps, B2B buyers can effectively source A/C electric supply that meets their specific needs while ensuring compliance and quality. This structured approach not only simplifies the procurement process but also fosters relationships with reliable suppliers.

Comprehensive Cost and Pricing Analysis for a/c electric supply Sourcing

What Are the Key Cost Components in A/C Electric Supply Sourcing?

When sourcing A/C electric supply, understanding the cost structure is essential for effective budgeting and pricing strategy. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Illustrative image related to a/c electric supply

-

Materials: The cost of raw materials is a significant portion of the total expenses. Prices can fluctuate based on market demand and supply chain stability, particularly for metals and electronic components.

-

Labor: Labor costs vary by region and can be influenced by local wage standards, skill levels, and labor availability. In developing regions, labor may be more affordable, but quality and expertise should be carefully evaluated.

-

Manufacturing Overhead: This encompasses costs associated with utilities, factory maintenance, and administrative expenses. Efficient production processes can help minimize overhead costs, impacting overall pricing.

-

Tooling: The initial investment in tooling for custom parts can be substantial. Buyers should consider whether standard parts suffice or if custom tooling is necessary for their specific requirements.

-

Quality Control (QC): Ensuring compliance with international standards and certifications can incur additional costs. Effective QC processes are crucial for maintaining product reliability and safety, especially in markets with stringent regulations.

-

Logistics: Shipping costs, including freight and insurance, can vary significantly based on the distance and mode of transportation. Efficient logistics management is crucial for minimizing costs and ensuring timely delivery.

-

Margin: Suppliers typically include a profit margin that reflects their operational risk and market position. Understanding the margins applied by different suppliers can aid in negotiation and sourcing decisions.

How Do Price Influencers Affect A/C Electric Supply Costs?

Several factors influence pricing in the A/C electric supply sector, particularly for international B2B buyers.

-

Volume and Minimum Order Quantity (MOQ): Larger order volumes often lead to discounts, as suppliers are incentivized to reduce per-unit costs. Establishing a strong relationship with suppliers may provide leverage for better pricing on smaller orders as well.

-

Specifications and Customization: Customized products typically incur higher costs due to additional design and production requirements. Buyers should weigh the benefits of customization against the potential for increased expenses.

-

Material Quality and Certifications: Higher-quality materials and internationally recognized certifications can elevate costs but may be necessary for compliance and reliability in certain markets. Buyers should assess the Total Cost of Ownership (TCO) when considering quality.

-

Supplier Factors: The reputation, location, and financial stability of the supplier can influence pricing. Established suppliers with a robust supply chain may offer more competitive rates compared to newer entrants.

-

Incoterms: Understanding the chosen Incoterms (International Commercial Terms) can significantly affect overall costs. Terms like FOB (Free on Board) and CIF (Cost, Insurance, and Freight) dictate who bears shipping costs and risks, impacting the final price.

What Negotiation Strategies Can B2B Buyers Use for Cost-Efficiency?

For international buyers from Africa, South America, the Middle East, and Europe, effective negotiation strategies can yield significant savings.

-

Research and Benchmarking: Conduct thorough market research to understand typical pricing structures and competitor offerings. This knowledge empowers buyers during negotiations.

-

Establish Long-Term Relationships: Building rapport with suppliers can lead to better pricing, preferential treatment, and more flexible payment terms. Suppliers are often more willing to negotiate with repeat customers.

-

Leverage TCO Insights: Emphasizing the Total Cost of Ownership—factoring in installation, maintenance, and operational costs—can help justify the need for better pricing or quality assurances.

-

Utilize Group Purchasing: Consider joining purchasing groups or cooperatives to increase order volumes collectively, thus enhancing bargaining power.

-

Be Open to Alternative Solutions: If a supplier cannot meet pricing expectations, explore alternative products or suppliers that may offer better value without compromising quality.

Conclusion: Understanding Pricing Nuances for International B2B Buyers

Navigating the complexities of pricing in A/C electric supply sourcing requires awareness of various cost components and influencers. By employing strategic negotiation techniques and understanding the implications of different purchasing decisions, B2B buyers can optimize their sourcing strategies, ensuring they achieve the best possible outcomes in a competitive market. Always remember that prices can vary widely due to regional factors, so it’s prudent to seek multiple quotes and be flexible in your sourcing approach.

Alternatives Analysis: Comparing a/c electric supply With Other Solutions

When evaluating solutions for electrical supply, particularly in the context of air conditioning (A/C) systems, it’s essential to consider various alternatives. These alternatives may offer different performance metrics, cost structures, and maintenance requirements, catering to diverse needs across industries. Below, we present a comparison of A/C electric supply against two viable alternatives: solar power systems and generator-based power solutions.

Illustrative image related to a/c electric supply

| Comparison Aspect | A/C Electric Supply | Solar Power Systems | Generator-Based Power Solutions |

|---|---|---|---|

| Performance | High reliability and efficiency in delivering consistent power for A/C units. | Performance can vary based on sunlight availability, typically providing moderate to high efficiency. | High performance with immediate power generation, suitable for emergencies. |

| Cost | Generally lower upfront costs with ongoing electricity expenses. | Higher initial investment but lower long-term operational costs; potential government incentives available. | Moderate to high initial costs; fuel costs and maintenance can add to long-term expenses. |

| Ease of Implementation | Straightforward installation and integration with existing electrical systems. | Requires careful planning and installation of solar panels and inverters; may need space for installation. | Installation can be quick but requires fuel supply management and safety considerations. |

| Maintenance | Minimal maintenance required; regular inspections recommended. | Low maintenance; periodic cleaning of panels and inverter checks needed. | Higher maintenance needs; regular servicing and fuel management required. |

| Best Use Case | Ideal for urban environments with stable electricity supply and high demand for A/C. | Best for regions with abundant sunlight and a focus on sustainability; suitable for remote areas. | Ideal for backup power in emergency situations or in locations with unreliable grid access. |

What Are the Pros and Cons of Solar Power Systems Compared to A/C Electric Supply?

Solar power systems harness energy from the sun, making them a sustainable alternative. Their primary advantage lies in their low operational costs after installation, as they rely on a free energy source. Additionally, many governments offer incentives for solar installations, which can offset initial costs. However, solar systems may struggle to provide consistent power in regions with limited sunlight, making them less reliable than traditional electric supply for A/C needs.

How Do Generator-Based Power Solutions Compare to A/C Electric Supply?

Generator-based power solutions offer immediate and reliable electricity, making them valuable for emergency situations or areas with unstable grid access. Their ease of use in providing on-demand power is a significant advantage. However, the drawbacks include the ongoing fuel costs and higher maintenance requirements, which can lead to increased operational expenses over time. Additionally, generators can produce noise and emissions, which may not align with sustainability goals.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting the appropriate electrical supply solution, B2B buyers should assess their specific requirements, including the reliability of local power sources, budget constraints, and sustainability goals. For businesses in urban settings with reliable electric supply, A/C electric supply may be the most straightforward option. Conversely, companies in remote areas or those seeking to reduce their carbon footprint may benefit from solar power systems. Lastly, businesses needing backup power solutions should consider generators as a viable alternative. Each solution has its unique benefits and challenges, and understanding these can lead to informed decision-making that aligns with operational objectives.

Essential Technical Properties and Trade Terminology for a/c electric supply

What Are the Essential Technical Properties for A/C Electric Supply?

Understanding the technical specifications of A/C electric supply components is crucial for B2B buyers, particularly when ensuring compatibility and reliability in electrical systems. Here are several critical specifications to consider:

-

Material Grade

The material grade of electrical components, such as copper or aluminum for wiring, significantly impacts conductivity and durability. For example, copper wiring is preferred for its superior conductivity and resistance to corrosion. B2B buyers should verify material grades to ensure they meet industry standards for their specific applications, preventing costly failures or inefficiencies. -

Voltage Rating

The voltage rating indicates the maximum voltage a component can handle safely. Common ratings include 120V, 240V, and 480V. Understanding voltage ratings is vital for ensuring components are suitable for the intended electrical load, which can vary significantly across different regions and applications. -

Current Rating (Amperage)

This specification indicates the maximum current a component can carry without overheating. Current ratings are expressed in amperes (A) and are critical for selecting circuit breakers, wiring, and other electrical devices. Properly matching current ratings to application requirements prevents overheating and enhances safety. -

Tolerance Levels

Tolerance refers to the permissible limits of variation in a component’s dimensions and performance. For instance, resistors may have a tolerance of ±5%, indicating how much the actual resistance may deviate from the stated value. Tolerances are crucial for ensuring that components perform consistently within desired specifications, particularly in sensitive applications. -

IP Rating (Ingress Protection)

The IP rating classifies the degree of protection against solid objects and liquids. For example, an IP65 rating indicates complete protection from dust and water jets. Buyers must consider the IP rating to ensure components are suitable for environmental conditions, especially in outdoor or harsh industrial settings.

What Are Common Trade Terms in A/C Electric Supply?

Familiarity with industry jargon is essential for effective communication and negotiation in the A/C electric supply sector. Here are some common trade terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the A/C electric supply industry, OEM components are often preferred for their guaranteed compatibility and reliability with existing systems, ensuring quality and performance. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. Understanding MOQs is crucial for B2B buyers, as it impacts inventory management and cash flow. Buyers should negotiate MOQs to align with their purchasing strategies and avoid overstocking. -

RFQ (Request for Quotation)

An RFQ is a document that solicits price quotes from suppliers for specific products or services. Issuing an RFQ allows buyers to compare prices, terms, and delivery options, facilitating informed purchasing decisions. This process is essential for budgeting and ensuring competitive pricing. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) clarify who bears the costs and risks at various stages of shipping. Understanding Incoterms is crucial for managing logistics and ensuring compliance with international trade regulations. -

Lead Time

Lead time refers to the time taken from placing an order to its delivery. In the A/C electric supply sector, lead times can vary based on stock availability, production schedules, and shipping logistics. Buyers should account for lead times in project planning to avoid delays in implementation.

By grasping these essential properties and trade terms, B2B buyers can make more informed decisions when sourcing A/C electric supply components, ultimately enhancing project outcomes and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the a/c electric supply Sector

What Are the Current Market Dynamics in the A/C Electric Supply Sector?

The global A/C electric supply sector is witnessing significant transformation driven by technological advancements, regulatory changes, and evolving customer demands. Increased urbanization and infrastructural development, particularly in Africa and South America, are propelling the demand for reliable electrical supplies. Additionally, the Middle East’s booming construction industry is contributing to the rising need for energy-efficient solutions. In Europe, particularly Germany, stringent energy regulations are pushing companies towards sustainable and efficient electrical products.

Emerging trends in B2B technology, such as the adoption of e-procurement platforms and digital marketplaces, are streamlining sourcing processes. International buyers are increasingly leveraging these platforms to compare prices, access a broader range of products, and facilitate smoother transactions. The integration of IoT (Internet of Things) within electrical systems is also gaining traction, enabling real-time monitoring and management of energy consumption, which is crucial for businesses aiming to optimize operational efficiency.

Moreover, the current market dynamics are influenced by fluctuating raw material prices and supply chain disruptions, necessitating buyers to develop agile sourcing strategies. Understanding local market conditions and fostering relationships with reliable suppliers can enhance competitiveness, especially in regions with diverse regulatory environments.

How Is Sustainability Shaping Sourcing Trends in the A/C Electric Supply Sector?

Sustainability has become a focal point in the A/C electric supply sector, driven by increasing environmental awareness among consumers and regulatory bodies. The environmental impact of traditional electrical supplies, including their carbon footprint and resource depletion, has led to a growing emphasis on sustainable sourcing practices. International B2B buyers are now prioritizing suppliers who demonstrate a commitment to sustainability through transparent supply chains and eco-friendly product offerings.

The importance of ethical sourcing cannot be overstated. Companies are increasingly scrutinizing their supply chains to ensure compliance with environmental standards and labor practices. This shift is not only beneficial for the planet but also enhances brand reputation and customer loyalty. Buyers are encouraged to seek suppliers with certifications such as ISO 14001 (Environmental Management) and those who provide ‘green’ materials, such as recyclable wiring or energy-efficient LED lighting.

Illustrative image related to a/c electric supply

Furthermore, the adoption of renewable energy sources in product manufacturing is gaining momentum. Suppliers who invest in sustainable technologies not only reduce environmental impact but also capitalize on the growing market demand for eco-conscious products. For B2B buyers, aligning with such suppliers can lead to long-term cost savings and improved operational efficiency.

What Is the Historical Context of the A/C Electric Supply Sector?

The A/C electric supply sector has evolved significantly since its inception, with roots tracing back to the industrial revolution when electric power began to be harnessed for various applications. In the mid-20th century, the proliferation of electrical appliances and the expansion of urban infrastructure marked a pivotal shift towards mass production and distribution of electrical supplies.

As the demand for electrical systems grew, so did the need for specialized suppliers. Companies began to emerge that focused on providing a wide array of electrical components, catering to both commercial and residential needs. The introduction of regulations and standards over the decades has shaped the industry, ensuring safety and reliability in electrical systems.

In recent years, the sector has seen a shift towards digitalization and sustainability, reflecting global trends in technology and environmental responsibility. This evolution presents a unique landscape for B2B buyers, who must navigate a complex market while seeking reliable, efficient, and sustainable sourcing solutions. As the sector continues to adapt, understanding its historical context can provide valuable insights for future procurement strategies.

Illustrative image related to a/c electric supply

Frequently Asked Questions (FAQs) for B2B Buyers of a/c electric supply

-

How do I choose the right a/c electric supply supplier for my business needs?

Selecting the right supplier involves evaluating their product range, reliability, and service capabilities. Look for suppliers with a proven track record in your industry and strong customer testimonials. Additionally, consider their inventory levels, as a supplier with extensive stock can reduce lead times. Ensure they offer competitive pricing and flexible delivery options that suit your project timelines. Finally, assess their customer service responsiveness to guarantee support when you need it. -

What factors should I consider when negotiating payment terms with a/c electric supply suppliers?

When negotiating payment terms, consider the supplier’s credit policies and your own cash flow requirements. Common terms include net 30, net 60, or even letter of credit for larger orders. Explore discounts for early payments or bulk purchases, which can enhance your profitability. Additionally, ensure you understand any potential fees for late payments or currency exchange if dealing internationally. Clear communication about payment expectations can foster a strong supplier relationship. -

What is the minimum order quantity (MOQ) for a/c electric supplies?

Minimum order quantities can vary significantly among suppliers. Some may have no MOQ, while others might require larger orders to ensure cost-effectiveness. It’s crucial to discuss MOQs upfront to align with your inventory management and project demands. If your needs are smaller, inquire about flexibility in order sizes or potential for future orders that could meet MOQ requirements. Understanding MOQs helps avoid excess inventory costs and ensures you receive what you need. -

How can I ensure the quality of a/c electric supplies I am sourcing?

To ensure quality, request certifications and compliance documentation for the products you intend to purchase. Inquire about the supplier’s quality assurance processes, including testing and inspection protocols. Building relationships with suppliers who prioritize quality control can provide peace of mind. Additionally, consider third-party audits or certifications relevant to your industry, and if possible, request samples before placing larger orders to verify product standards. -

What are the logistics considerations when importing a/c electric supplies?

Logistics play a critical role in the timely delivery of your supplies. Evaluate shipping options based on cost, transit time, and reliability. Understand customs regulations in your country to avoid unexpected delays and fees. Collaborate with suppliers who have experience in international shipping and can provide necessary documentation. Additionally, consider warehousing solutions if you require storage before distribution, which can streamline your supply chain management. -

How do I vet international suppliers for a/c electric supplies?

Vetting suppliers involves researching their business history, customer feedback, and industry reputation. Request references from previous clients and verify their credibility through online reviews or industry associations. Conduct background checks to assess financial stability and operational capacity. Additionally, consider visiting their facilities if feasible, or arrange for third-party audits. Establishing trust in your supplier is essential for ensuring a reliable supply chain. -

What customization options are available for a/c electric supply products?

Many suppliers offer customization options to meet specific project requirements. This can include tailored sizes, colors, or functionalities of electrical components. Discuss your needs with potential suppliers early in the negotiation process to gauge their flexibility and capabilities. Customization can enhance your project’s efficiency and effectiveness, but be mindful of potential impacts on lead times and costs. Ensure that any agreements are documented to avoid misunderstandings. -

What are the common challenges faced when sourcing a/c electric supplies internationally?

Common challenges include navigating complex customs regulations, varying quality standards, and potential language barriers. Supply chain disruptions can also occur due to geopolitical issues or logistics delays. To mitigate these risks, establish strong communication with your supplier and stay informed about international trade policies. Developing contingency plans, such as alternative suppliers or shipping routes, can help maintain operational continuity and minimize the impact of unforeseen challenges.

Top 5 A/C Electric Supply Manufacturers & Suppliers List

1. EngProducts – Temporary Power Solutions

Domain: engproducts.com

Registered: 1998 (27 years)

Introduction: Temporary Power, Prefabricated Whips, Lighting, Ground Bonding, Splice Kits / Heat Shrink Tubing, Product Accessories

2. A-C Electric – Key Services

Domain: a-celectric.com

Registered: 1996 (29 years)

Introduction: A-C Electric Company offers the following key services: 1. Design-Build: Comprehensive management from initial planning to installation and final build-out for a streamlined electrical construction process. 2. Electrical Construction: High-quality installations for power distribution, lighting, and complex infrastructure systems, backed by decades of experience. 3. Service & Maintenance: Predictiv…

3. AC Electric – Electrical Supplies & Equipment

Domain: ac-elect.com

Registered: 2001 (24 years)

Introduction: Products: Ballasts, Batteries, Boxes & Covers, Busway, Cable Trays & Support Systems, Ceiling Fans, Conduit, Data/Com, Cable Management, Distribution & Control Equipment, Electrician Supplies, Fans & Ventilation, Fasteners, Fittings & Connectors, Fuses, Grounding, Heaters & Baseboard, Interior Lighting, Lamps/Light Bulbs, Landscape Lighting, Lighting, Low Voltage Cable, Motor Controls, Outdoor Lig…

4. AC Pro – Electrical Parts

Domain: store.acpro.com

Registered: 2000 (25 years)

Introduction: Parts – Electrical includes a variety of components such as Electrical Fan Coil Accessories, Filter-Driers, Heating Parts, Metering Devices, Mini Split Accessories, Motors & Accessories, Package Unit Parts, PTAC Accessories, Security Cages, Smart Home Devices, Smoke Detectors & Accessories, Thermostats & Accessories, and Ventilation Whole House Fan Zoning.

5. AC Wholesale Electrical/Lighting Supply – Key Electrical Supplies

Domain: thebluebook.com

Registered: 1995 (30 years)

Introduction: AC Wholesale Electrical/Lighting Supply specializes in a wide range of electrical and lighting supplies for residential, commercial, and industrial applications. Key product categories include: 1. Electrical Supplies: – Wiring devices – Electrical panels – Industrial motor controls – Bulbs – Cable – Conduit – Breakers – Fans – Heaters – Panel boards – Switchboards – Tools – Transformers – Wire 2. …

Strategic Sourcing Conclusion and Outlook for a/c electric supply

In the evolving landscape of A/C electric supply, strategic sourcing has become a vital component for international B2B buyers. By understanding the nuances of supply chain dynamics, businesses can ensure timely access to high-quality materials while optimizing costs. Key takeaways include the importance of building strong relationships with reliable suppliers, leveraging technology for efficient procurement processes, and staying informed about market trends that impact pricing and availability.

Investing in strategic sourcing not only enhances operational efficiency but also positions companies to respond adeptly to fluctuating demand and supply challenges. This proactive approach is particularly beneficial for buyers in diverse regions such as Africa, South America, the Middle East, and Europe. For instance, by tapping into local suppliers and understanding regional market conditions, businesses can mitigate risks associated with international shipping and tariffs.

As we look to the future, it is crucial for B2B buyers to prioritize strategic sourcing as a pathway to resilience and growth. Engaging with suppliers who offer comprehensive support services—such as flexible delivery options and extensive inventories—can further bolster your competitive edge. Start today by assessing your current sourcing strategies and exploring new partnerships that align with your business goals. The future of A/C electric supply is bright, and with the right strategies in place, you can ensure your business thrives in this dynamic environment.

Illustrative image related to a/c electric supply

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.