Unlocking Value: A Strategic Analysis of the Air Veyor Market

Introduction: Navigating the Global Market for air veyor

In an increasingly interconnected world, sourcing efficient pneumatic conveying systems like air veyors poses a significant challenge for international B2B buyers. Whether you are in Africa, South America, the Middle East, or Europe, navigating the myriad options available can be daunting. This guide aims to demystify the complexities of air veyors, covering essential aspects such as types of systems, their applications across various industries, supplier vetting processes, and cost considerations.

Air veyors are pivotal for industries that require the safe and efficient transport of lightweight materials, such as plastics, paper, and electronics. With options like Positive Pressure Conveyors and Vacuum Pressure Conveyors, it’s crucial to understand which system best meets your specific operational needs. This comprehensive guide will empower you to make informed purchasing decisions by providing actionable insights and best practices tailored to your region’s unique market dynamics.

By delving into the technical specifications, operational efficiencies, and integration capabilities of air veyors, you will be better equipped to select the right solutions that enhance productivity and reduce costs. Whether you are optimizing an existing production line or seeking to innovate your material handling processes, this guide serves as an invaluable resource for achieving your business goals in a global marketplace.

Understanding air veyor Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Positive Pressure Conveyor | Utilizes high-pressure ambient air; efficient for blowing parts | Plastics manufacturing, packaging | Pros: Reliable in low air supply; customizable. Cons: May require more energy; less effective for heavy parts. |

| Vacuum Pressure Conveyor | Creates negative pressure to pull parts; requires compressed air | Electronics, pharmaceuticals, light metal | Pros: Efficient for long distances; minimizes part damage. Cons: Dependent on compressed air availability. |

| Airveyor with Sequencing | Integrates with multiple machines; efficient material flow | Trim removal, die-cutting applications | Pros: Streamlined operations; supports heavy loads. Cons: Initial setup complexity; may need specialized maintenance. |

| Lightweight Air Conveyors | Designed for gentle transport of lightweight parts | Packaging, electronics, and pharmaceuticals | Pros: Reduces part damage; minimal maintenance. Cons: Limited to lighter materials; may require custom configurations. |

| High-Efficiency Airveyor | Uses advanced blower design for optimal energy consumption | General manufacturing, recycling | Pros: Cost-effective; energy-efficient. Cons: Higher upfront investment; requires careful sizing for specific applications. |

What are the Characteristics of Positive Pressure Conveyors?

Positive Pressure Conveyors (PPC) leverage high-pressure air to propel parts through the system. They are particularly suited for environments where compressed air is not consistently available. This type of conveyor is ideal for transporting small plastic components in manufacturing settings, especially in cellular production lines where distance is limited to approximately 30 feet. B2B buyers should consider energy consumption and part weight when selecting PPC systems, as these factors will influence overall efficiency and operational costs.

How Do Vacuum Pressure Conveyors Function?

Vacuum Pressure Conveyors (VPC) utilize a line vacuum to create negative pressure, effectively pulling parts through the system. This design is beneficial for longer transport distances and is commonly used in sectors like electronics and pharmaceuticals, where part integrity is crucial. When purchasing VPC systems, companies should assess the availability of compressed air and the specific requirements of their materials, as these will impact the system’s performance and reliability.

What Advantages Do Airveyors with Sequencing Offer?

Airveyors equipped with sequencing capabilities are designed to optimize material flow between multiple machines. They are particularly effective in applications like trim removal and die-cutting, where efficient transport of scrap materials is necessary. Buyers should evaluate the complexity of setup and the potential need for specialized maintenance when considering this option, as these factors can influence long-term operational efficiency.

Why Choose Lightweight Air Conveyors?

Lightweight air conveyors are specifically engineered for the gentle transport of fragile parts, making them a popular choice in packaging and electronics industries. Their design minimizes contact, reducing the risk of part damage during transit. B2B buyers should consider the materials being transported, as these systems are typically limited to lighter components. Custom configurations may also be necessary to meet specific production requirements.

What Makes High-Efficiency Airveyors Stand Out?

High-Efficiency Airveyors utilize advanced blower designs to maximize energy efficiency while maintaining effective material transport capabilities. These systems are versatile and can be applied across various manufacturing and recycling processes. When considering a high-efficiency airveyor, B2B buyers should analyze the initial investment against long-term energy savings and operational costs to ensure a balanced decision that aligns with their business objectives.

Key Industrial Applications of air veyor

| Industry/Sector | Specific Application of air veyor | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Plastics Manufacturing | Transporting plastic parts from injection molding | Enhances production efficiency and reduces manual handling | Compatibility with part shape/size; testing for optimal setup |

| Electronics Assembly | Moving lightweight electronic components | Minimizes damage and maintains consistent flow | Air pressure control; integration with automation systems |

| Packaging | Conveying packaging materials like cardboard | Supports high-speed production and reduces downtime | Custom lengths; ability to handle various material types |

| Pharmaceuticals | Transporting pharmaceutical products | Ensures cleanliness and minimizes contamination risk | Compliance with industry standards; material compatibility |

| Metal Fabrication | Handling light metal scraps during processing | Improves safety and operational efficiency | Weight capacity; system durability under heavy use |

How is ‘air veyor’ used in the plastics manufacturing sector?

In the plastics manufacturing industry, air veyors are essential for transporting small plastic parts efficiently from injection molding machines to packaging or assembly areas. These systems minimize manual handling, thereby reducing labor costs and enhancing production speed. Buyers should ensure that the air veyor system is compatible with the specific shapes and sizes of the plastic parts being conveyed. Testing with actual parts is often necessary to optimize the air flow and system configuration for effective operation.

What role does ‘air veyor’ play in electronics assembly?

Air veyors are increasingly used in electronics assembly for the gentle transport of lightweight components, such as circuit boards and connectors. The controlled airflow minimizes physical contact, thus reducing the risk of damage to sensitive electronic parts. For international buyers, especially in regions like Africa and South America, it is crucial to consider air pressure controls and the system’s ability to integrate seamlessly with existing automation technologies to maintain consistent production flow.

How does ‘air veyor’ enhance packaging processes?

In the packaging industry, air veyors are utilized to efficiently move materials like cardboard and plastic containers along production lines. Their ability to support high-speed operations while minimizing downtime is a significant advantage for businesses aiming to scale production. Buyers must focus on sourcing air veyors that can be customized in length and layout to fit their specific production line requirements, ensuring they can handle various packaging materials effectively.

Why is ‘air veyor’ important in pharmaceuticals?

Air veyors are critical in the pharmaceutical sector for transporting products while ensuring compliance with strict cleanliness and contamination prevention standards. These systems help maintain the integrity of sensitive products, which is vital for regulatory compliance. International buyers should prioritize sourcing air veyors that meet industry-specific standards and are made from materials compatible with pharmaceutical products to avoid contamination.

How is ‘air veyor’ utilized in metal fabrication?

In metal fabrication, air veyors are employed to handle light metal scraps efficiently during the manufacturing process. This application improves workplace safety by reducing the need for manual scrap handling and enhances operational efficiency by automating the transport of materials. When sourcing air veyors for this purpose, businesses should consider the system’s weight capacity and durability to withstand the rigors of heavy use in a metalworking environment.

3 Common User Pain Points for ‘air veyor’ & Their Solutions

Scenario 1: Inconsistent Material Flow Leading to Production Delays

The Problem: A manufacturer in the plastics industry struggles with inconsistent material flow when using traditional conveying systems. This disruption often results in production delays, leading to increased operational costs and missed deadlines. The buyer is particularly concerned about how the fluctuating flow of small plastic parts affects the efficiency of their automated filling systems. Without a reliable solution, the company faces the risk of accumulating inventory and dissatisfied customers.

The Solution: To address this challenge, B2B buyers should consider implementing a Positive Pressure Conveyor (PPC) system. This airveyor technology utilizes high-pressure ambient air to propel materials, ensuring a consistent flow of parts regardless of fluctuations in material volume. When sourcing an airveyor, it’s essential to evaluate the system’s specifications based on part weight, shape, and the total distance of the run. Collaborating with suppliers to conduct tests with actual parts can provide critical insights into the required power and airflow specifications. Additionally, integrating throttle throat control gates can help in fine-tuning air flow, further stabilizing the material movement. Regular maintenance checks will also be crucial to ensure the system operates at peak performance, thereby minimizing downtime and enhancing production reliability.

Scenario 2: Risk of Part Damage During Transport

The Problem: In industries such as electronics and pharmaceuticals, the risk of damaging lightweight parts during transport is a significant concern. A company faces frequent complaints about defective components due to mishandling while being conveyed. The buyer understands that maintaining product integrity is paramount for customer satisfaction and compliance with industry standards. However, the existing conveyor systems often lead to scratches and other forms of damage that could tarnish their reputation.

The Solution: For this scenario, investing in a high-quality air conveyor designed for gentle handling can make a considerable difference. Air conveyors utilize controlled airflow to transport parts with minimal contact, significantly reducing the risk of damage. When selecting an airveyor, buyers should look for customizable options that allow for variable air pressure controls tailored to the specific types of parts being moved. Additionally, integrating sensors and automated controls can enhance the system’s efficiency, ensuring that parts are conveyed smoothly along the production line. Conducting a thorough evaluation of the materials and design of the airveyor will be crucial in preventing damage, thus ensuring high-quality output and maintaining brand integrity.

Scenario 3: Limited Space for Conveyor Installation

The Problem: A B2B buyer in the packaging sector is faced with a space constraint in their facility, making it challenging to install traditional conveyor systems. The buyer is aware that a lack of efficient material handling can lead to bottlenecks in the production process. As production demands increase, the existing space limitations pose a risk of not meeting operational goals. The buyer needs a solution that maximizes space while still ensuring effective material transport.

The Solution: Airveyors can be an ideal solution for facilities with limited space, as they are designed to be compact and can fit beneath or within existing machinery without the need for extensive modifications. When sourcing airveyors, it’s essential to consult with manufacturers about the specific spatial constraints and the types of materials being conveyed. Opting for a system that can accommodate custom layouts and can be integrated with existing equipment will maximize efficiency. Additionally, exploring options such as the use of aluminum construction can offer lightweight yet durable solutions that do not compromise on performance. By choosing a system that optimally utilizes available space, buyers can streamline their operations, improve workflow, and ultimately enhance productivity without the need for costly renovations.

Strategic Material Selection Guide for air veyor

What Are the Key Materials Used in Airveyor Systems?

When selecting materials for airveyor systems, it’s essential to consider properties that directly impact performance, durability, and compatibility with specific applications. Below, we analyze four common materials used in airveyor construction: aluminum, stainless steel, carbon steel, and plastic composites.

How Does Aluminum Perform in Airveyor Applications?

Aluminum is a popular choice for airveyor systems due to its lightweight nature and excellent corrosion resistance. It typically has a temperature rating of up to 150°C and can withstand moderate pressures, making it suitable for various environments.

Pros: Aluminum is durable and lightweight, which simplifies installation and reduces energy consumption during operation. Additionally, it is relatively cost-effective compared to other metals, making it an attractive option for many manufacturers.

Cons: While aluminum is resistant to corrosion, it can be less durable than steel in high-impact applications. It may also not be suitable for environments with extreme temperatures or aggressive chemicals.

Impact on Application: Aluminum is particularly effective for transporting lightweight materials such as plastics and paper products. Its compatibility with non-corrosive media makes it a preferred choice in industries like packaging and electronics.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial. Buyers from regions like Africa and South America should ensure that suppliers can provide certifications for aluminum quality and performance.

What Are the Benefits of Stainless Steel in Airveyor Systems?

Stainless steel is renowned for its exceptional strength and corrosion resistance, making it ideal for airveyor systems that handle abrasive or corrosive materials. It can typically operate at temperatures up to 300°C and withstand high pressures.

Pros: The durability of stainless steel ensures a long lifespan, reducing the need for frequent replacements. Its resistance to rust and staining makes it suitable for food and pharmaceutical applications, where hygiene is paramount.

Cons: The primary drawback is its higher cost compared to aluminum and carbon steel. Additionally, stainless steel can be more challenging to fabricate, which may increase manufacturing complexity.

Impact on Application: Stainless steel is particularly beneficial in industries that require stringent hygiene standards, such as food processing and pharmaceuticals. Its ability to handle a wide range of media, including corrosive substances, makes it versatile.

Considerations for International Buyers: Buyers should be aware of the specific grades of stainless steel that meet local regulations, especially in the food and pharmaceutical sectors. Compliance with standards like JIS is essential for ensuring product safety.

Why Choose Carbon Steel for Airveyor Systems?

Carbon steel is a robust and cost-effective material often used in airveyor systems for heavy-duty applications. It can handle high pressures and temperatures, typically rated up to 200°C.

Pros: The primary advantage of carbon steel is its strength and affordability, making it suitable for applications that require heavy lifting and durability. It can be easily welded and fabricated, allowing for customizable designs.

Cons: Carbon steel is susceptible to corrosion, which can limit its use in humid or corrosive environments unless coated or treated. Maintenance is also required to prevent rusting.

Impact on Application: Carbon steel is ideal for transporting heavier materials in manufacturing settings, such as metal parts and scrap. Its strength allows for efficient handling of bulk materials.

Considerations for International Buyers: Buyers should consider the availability of protective coatings to enhance corrosion resistance. Compliance with local standards such as ASTM is also necessary for ensuring quality.

What Role Do Plastic Composites Play in Airveyor Systems?

Plastic composites are increasingly being used in airveyor systems, particularly for lightweight applications. They can operate at temperatures up to 80°C and are generally resistant to chemicals.

Pros: Plastic composites are lightweight, reducing energy consumption and installation costs. They also offer excellent corrosion resistance and can be manufactured in various shapes and sizes.

Cons: The primary limitation is their lower strength compared to metals, making them unsuitable for heavy-duty applications. Additionally, they may have a shorter lifespan under high-stress conditions.

Impact on Application: Plastic composites are ideal for transporting lightweight and non-abrasive materials, such as packaging components and electronic parts. Their versatility allows for innovative designs in airveyor systems.

Considerations for International Buyers: Buyers must ensure that the plastic composites meet local regulations for safety and environmental impact. Compliance with standards like DIN is crucial for quality assurance.

Summary Table of Material Selection for Airveyor Systems

| Material | Typical Use Case for air veyor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight materials (plastics, paper) | Lightweight and corrosion-resistant | Less durable under high impact | Medium |

| Stainless Steel | Food and pharmaceutical applications | High strength and corrosion resistance | Higher cost and fabrication complexity | High |

| Carbon Steel | Heavy-duty manufacturing applications | Strong and cost-effective | Susceptible to corrosion | Low |

| Plastic Composites | Lightweight and non-abrasive materials | Lightweight and versatile | Lower strength and shorter lifespan | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for air veyor

What Are the Main Stages in the Manufacturing Process of Air Veyors?

The manufacturing process of air veyors is essential for ensuring the performance and reliability of these systems in various applications. The process can be divided into several key stages: material preparation, forming, assembly, and finishing.

-

Material Preparation: The initial stage involves selecting high-quality materials such as aluminum or heavy-duty steel. These materials are often pre-treated to enhance their durability and resistance to wear and corrosion. Suppliers may conduct tests to verify the material properties, ensuring they meet the specified requirements for strength and weight.

-

Forming: In this stage, the prepared materials are shaped using various techniques such as cutting, bending, and welding. Advanced technologies, including CNC machining and laser cutting, may be employed to achieve precise dimensions and complex geometries. The forming process is critical in ensuring that air flow paths are optimized for efficient conveying.

-

Assembly: Once the components are formed, they are brought together in the assembly stage. This involves integrating the blower systems, air ducts, and control mechanisms. Employing automated assembly lines can enhance efficiency and consistency. Operators must ensure that all parts fit together correctly, with special attention given to sealing and airflow connections to prevent leaks.

-

Finishing: The finishing stage includes surface treatments, such as painting or powder coating, to protect against environmental factors. This stage may also involve the installation of safety features, like intake grates and control gates. Quality checks during this stage ensure that the final product meets aesthetic and functional standards.

How Is Quality Assurance Implemented in Air Veyor Manufacturing?

Quality assurance (QA) is paramount in the manufacturing of air veyors, particularly for international B2B buyers who require high standards of reliability and safety. Key elements of QA include adherence to international standards, establishment of quality checkpoints, and implementation of testing protocols.

-

International Standards Compliance: Manufacturers should comply with relevant international standards such as ISO 9001 for quality management systems. This certification ensures that the manufacturing processes are well-documented and consistently applied. Additionally, compliance with industry-specific standards such as CE marking for products sold in Europe and API standards for industrial equipment may be required.

-

Quality Checkpoints: Quality control checkpoints are integrated throughout the manufacturing process. Incoming Quality Control (IQC) assesses raw materials upon arrival, ensuring they meet specifications. In-Process Quality Control (IPQC) monitors the manufacturing stages, identifying any deviations from the process standards. Final Quality Control (FQC) occurs before shipment, confirming that the finished product meets all quality criteria.

-

Common Testing Methods: Testing methods used in the quality assurance process include dimensional inspections, functional testing, and performance evaluations. These tests may involve assessing the air flow efficiency, checking for leaks, and ensuring that the components withstand specified pressure ratings. Advanced non-destructive testing methods may also be employed to ensure the integrity of welded joints and material integrity.

What Steps Can B2B Buyers Take to Verify Supplier Quality Control?

B2B buyers must ensure that their suppliers maintain rigorous quality control standards. Here are actionable steps buyers can take to verify supplier QC:

-

Conduct Supplier Audits: Regular audits of suppliers’ manufacturing facilities can provide insights into their quality control practices. During these audits, buyers should assess compliance with international standards, observe manufacturing processes, and review documentation related to quality assurance.

-

Request Quality Reports: Suppliers should be willing to share quality reports, including results from IQC, IPQC, and FQC stages. These reports should detail the testing methods used, results obtained, and any corrective actions taken in response to identified issues.

-

Engage Third-Party Inspection Services: Employing third-party inspection services can enhance trust in the quality of the products being sourced. These independent organizations can conduct detailed inspections and provide unbiased assessments of the manufacturing processes and final products.

What Are the Quality Control Nuances for International B2B Buyers?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is crucial:

-

Cultural and Regulatory Differences: Different regions may have varying expectations regarding quality standards and compliance. Buyers should familiarize themselves with local regulations and standards that may impact product quality and safety.

-

Supply Chain Transparency: Transparency in the supply chain is vital. Buyers should insist on clear documentation of the sourcing of materials, manufacturing practices, and quality control measures. This transparency fosters trust and helps mitigate risks associated with product quality.

-

Adaptability to Local Conditions: Manufacturers should demonstrate their ability to adapt their products to local conditions. For instance, air veyors must function efficiently in diverse environments, which may require different materials or design considerations based on regional climate and operational practices.

Conclusion

Understanding the manufacturing processes and quality assurance measures for air veyors is essential for B2B buyers aiming to procure reliable equipment. By focusing on material preparation, forming, assembly, and finishing, alongside stringent quality control practices, buyers can ensure they are sourcing high-quality products that meet their operational needs. Implementing thorough verification steps further ensures that suppliers adhere to the necessary standards, fostering successful international partnerships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘air veyor’

This guide serves as a comprehensive checklist for B2B buyers looking to procure airveyors. Airveyors are specialized pneumatic conveying systems that facilitate the efficient movement of lightweight materials in various industries, including manufacturing, packaging, and pharmaceuticals. Understanding the key steps in the sourcing process will ensure that you select the right system for your operational needs.

Step 1: Define Your Technical Specifications

Clearly outline your operational requirements before starting your search. Consider factors such as the type of materials to be conveyed, the required distance, and the layout of your facility. Understanding these specifications will help in selecting the right airveyor model and ensure compatibility with your existing systems.

- Material Type: Identify if you need to transport plastics, metals, or other materials.

- Distance and Layout: Measure the distance and layout for the airveyor installation, as this influences system design.

Step 2: Determine System Type

Select between positive pressure and vacuum pressure airveyors based on your operational needs. Positive pressure systems are ideal for environments where compressed air availability is inconsistent, while vacuum pressure systems are effective in applications requiring precise material handling.

- Positive Pressure Systems: Best for blowing materials over shorter distances.

- Vacuum Pressure Systems: Suitable for pulling materials through longer runs.

Step 3: Evaluate Potential Suppliers

Conduct thorough evaluations of potential suppliers to ensure reliability and quality. Request company profiles, case studies, and references from similar industries or regions to understand their capabilities and reputation.

- Supplier Reputation: Look for established suppliers with a proven track record.

- Customer Testimonials: Seek feedback from other businesses that have used their products.

Step 4: Request Proposals and Quotes

After identifying potential suppliers, request detailed proposals and quotes. Ensure that the proposals include specifications, pricing, lead times, and warranty information to facilitate comparison.

- Detailed Specifications: Ensure all technical aspects are clearly outlined in the proposals.

- Transparent Pricing: Look for clear breakdowns of costs, including installation and maintenance.

Step 5: Assess Compliance and Safety Standards

Verify that the airveyor systems meet relevant industry standards and regulations, such as NFPA, OSHA, or EPA compliance. This step is critical to ensure safety and legal compliance in your operations.

- Documentation: Request certification documents from suppliers to confirm compliance.

- Safety Features: Inquire about safety features included in the airveyor design.

Step 6: Consider Integration with Existing Systems

Evaluate how the airveyor will integrate with your current production systems. Compatibility is essential for maintaining workflow efficiency and minimizing downtime during installation.

- Automation Compatibility: Check if the airveyor can seamlessly integrate with your existing automation systems.

- Space Constraints: Consider the physical space available for installation and operation.

Step 7: Plan for Installation and Training

Once you’ve selected a supplier and system, plan for installation and training. Proper installation and staff training are vital for maximizing the efficiency and longevity of the airveyor.

- Installation Support: Ensure the supplier provides installation assistance or guidelines.

- Training Programs: Look for suppliers that offer training for your team on system operation and maintenance.

By following this checklist, you can make informed decisions when sourcing airveyors that align with your operational needs and business goals.

Comprehensive Cost and Pricing Analysis for air veyor Sourcing

What Are the Key Cost Components Involved in Sourcing Airveyors?

When sourcing airveyors, understanding the cost structure is essential for making informed purchasing decisions. The main cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margin.

Illustrative image related to air veyor

-

Materials: Airveyors are typically constructed from aluminum or heavy steel, impacting the material cost significantly. The choice of materials affects durability and performance, which can influence long-term operational costs.

-

Labor: Labor costs encompass both the workforce involved in manufacturing and installation. Regions with higher labor costs may see increased pricing, which is critical for international buyers to consider when sourcing from different geographical locations.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and indirect labor. Efficient manufacturing processes can help minimize overhead costs, which can be a negotiation point with suppliers.

-

Tooling: Custom tooling for specific airveyor configurations can add to initial costs. Buyers should evaluate whether the tooling costs can be amortized over a larger production run to enhance cost efficiency.

-

Quality Control (QC): Ensuring that airveyors meet industry standards and certifications incurs additional QC costs. Buyers should prioritize suppliers with robust QC practices to avoid future operational issues.

-

Logistics: Shipping and handling costs vary significantly depending on the distance and the chosen Incoterms. International buyers should be aware of potential tariffs, duties, and transportation fees that can add to the overall cost.

-

Margin: Supplier margins can vary based on market demand and competition. Understanding the supplier’s pricing strategy can help buyers gauge whether they are receiving a fair price.

How Do Price Influencers Affect Airveyor Sourcing?

Several factors can influence the pricing of airveyors, which buyers should consider when sourcing.

-

Volume/MOQ: Minimum Order Quantities (MOQ) can significantly impact pricing. Bulk purchases typically yield discounts, making it beneficial for businesses with larger production needs.

-

Specifications/Customization: Custom-designed airveyors tailored to specific operational needs can increase costs. Buyers must weigh the benefits of customization against their budget constraints.

-

Materials: The choice of materials not only affects initial costs but also influences the total cost of ownership (TCO) through durability and maintenance requirements.

-

Quality/Certifications: Airveyors that meet specific industry standards often come at a premium. Buyers should ensure that the additional costs are justified by the expected performance and compliance benefits.

-

Supplier Factors: Supplier reliability, reputation, and geographical location can influence price. Building strong relationships with suppliers can lead to better pricing and support.

-

Incoterms: Understanding the implications of various Incoterms is critical for international buyers. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) can significantly impact the final landed cost.

What Tips Can Help Buyers Optimize Their Airveyor Procurement Costs?

To enhance cost efficiency when sourcing airveyors, international B2B buyers should consider the following strategies:

-

Negotiation: Engage in open discussions with suppliers to negotiate pricing and terms. Leverage bulk purchasing or long-term contracts for better rates.

-

Total Cost of Ownership (TCO): Look beyond the initial price. Assess maintenance, operational efficiency, and potential downtime costs to evaluate the true value of the airveyor.

-

Supplier Diversification: Consider multiple suppliers to compare pricing and service levels. This can create competitive tension and lead to better offers.

-

Local Sourcing: When possible, sourcing from local suppliers can reduce shipping costs and lead times, especially for international buyers from regions like Africa or South America.

-

Research and Due Diligence: Conduct thorough research on potential suppliers, including their production capabilities, quality assurance processes, and customer reviews. This can help avoid costly mistakes in the sourcing process.

Conclusion

Understanding the comprehensive cost structure and pricing influencers for airveyors is crucial for B2B buyers. By considering these factors and employing strategic sourcing practices, businesses can optimize their procurement process, ultimately leading to improved operational efficiency and cost savings. While prices may vary, staying informed and adaptable can help navigate the complexities of international sourcing, particularly in diverse markets such as Africa, South America, and Europe.

Alternatives Analysis: Comparing air veyor With Other Solutions

When evaluating air veyor systems, it’s essential to consider alternative solutions that may better suit specific operational requirements. The right choice can significantly impact efficiency, cost, and maintenance. Below, we compare air veyors with two viable alternatives: traditional belt conveyors and pneumatic vacuum conveyors, focusing on key performance aspects.

| Comparison Aspect | Air Veyor | Traditional Belt Conveyor | Pneumatic Vacuum Conveyor |

|---|---|---|---|

| Performance | Efficient for lightweight parts; minimal contact reduces damage | High capacity for various weights; effective for bulk materials | Excellent for delicate parts; customizable air pressure for different materials |

| Cost | Moderate initial investment; low operational costs | Lower initial cost but higher maintenance costs due to wear and tear | Higher initial cost; energy-efficient in long runs |

| Ease of Implementation | Requires specific installation setup; flexible design | Straightforward installation; requires more space | Can be complex to set up; needs compressed air supply |

| Maintenance | Low maintenance; long lifespan with minimal wear | Regular maintenance required; belt replacements needed | Moderate maintenance; dependent on air compressor efficiency |

| Best Use Case | Ideal for lightweight, fragile items; compact spaces | Suitable for heavy, bulk materials in large spaces | Best for delicate items in industries like food and pharmaceuticals |

What Are the Pros and Cons of Traditional Belt Conveyors Compared to Air Veyors?

Traditional belt conveyors are well-established in many industries for transporting bulk materials. They offer high capacity and are suitable for various product weights. However, they require more maintenance due to wear on belts and motors, leading to higher long-term costs. Their straightforward installation process makes them appealing, but they often require more floor space, which can be a limitation in compact manufacturing setups.

How Do Pneumatic Vacuum Conveyors Stack Up Against Air Veyors?

Pneumatic vacuum conveyors utilize air pressure to move materials, which is advantageous for delicate components that require gentle handling. They can be highly effective in environments where contamination must be minimized, such as pharmaceuticals or food processing. However, they typically come with a higher initial investment and may require a reliable compressed air source, which can complicate installation. While they are energy-efficient for long-distance transport, the need for regular maintenance of the air compressor adds to operational costs.

How Can B2B Buyers Choose the Right Conveying Solution?

When selecting the right conveying system, B2B buyers should assess their specific operational needs. Consider factors such as the type of materials being transported, space constraints, and the required speed of operation. For lightweight and fragile items, air veyors may be the best choice due to their gentle handling and low maintenance. If handling bulk materials in a spacious environment, traditional belt conveyors could be more cost-effective. Conversely, for applications requiring minimal contamination, pneumatic vacuum conveyors could provide the best solution despite their higher upfront costs. Ultimately, aligning the choice with production goals, space limitations, and budget will guide buyers to the most effective conveying solution.

Essential Technical Properties and Trade Terminology for air veyor

What Are the Key Technical Properties of Air Veyors?

When considering air veyors for your manufacturing processes, understanding their essential technical properties is crucial for ensuring optimal performance and efficiency. Here are some critical specifications to keep in mind:

1. Material Grade

Air veyors are typically constructed from high-quality materials such as aluminum or stainless steel. The choice of material impacts the durability and resistance to corrosion, especially in environments where moisture or chemicals are present. For B2B buyers, selecting the right material ensures longevity and reliability, reducing maintenance costs over time.

2. Pressure Ratings

Air veyors operate under specific pressure conditions, with common ratings around 40-80 PSIG. This rating determines the effectiveness of the air conveyance system in transporting materials. Understanding pressure ratings is essential for buyers to match the air veyor’s capabilities with their production needs, ensuring efficient operation without the risk of system failure.

3. Diameter of Tubing

The tubing diameter in air veyors can vary significantly, affecting the volume and type of materials that can be transported. Common diameters range from 1.5 inches to 6 inches, depending on the size and shape of the parts being moved. Choosing the appropriate diameter is crucial for achieving optimal airflow and minimizing blockages, which can lead to production delays.

Illustrative image related to air veyor

4. Motor Power

Air veyors come with different motor power options, typically ranging from 1/3 HP to 5 HP. The motor’s power directly influences the system’s ability to move materials quickly and efficiently. Buyers must consider their production volume and material weight when selecting motor power to ensure that the air veyor can handle the required workload without strain.

5. System Configuration

Air veyors can be configured in various layouts, including horizontal, vertical, and diagonal runs. This flexibility allows for integration into existing manufacturing processes without significant redesign. For B2B buyers, understanding the potential configurations can help in optimizing space and workflow in production lines.

6. Maintenance Requirements

Air veyors are designed for low maintenance, but certain features, such as self-cleaning mechanisms and easy access points for servicing, can significantly reduce downtime. Buyers should assess maintenance requirements to ensure that the air veyor fits their operational capabilities and minimizes interruptions in production.

What Are Common Trade Terms Related to Air Veyors?

Navigating the purchasing process for air veyors involves familiarizing yourself with specific industry jargon and trade terms that can impact negotiations and agreements. Here are some essential terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to the company that manufactures products that are sold under another company’s brand name. In the context of air veyors, understanding OEM relationships can help buyers ensure they are sourcing high-quality parts and components that meet industry standards.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. Knowing the MOQ is essential for buyers to assess whether they can meet production needs without incurring excess inventory costs.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers. This is a critical step in B2B transactions, allowing buyers to compare options and make informed purchasing decisions based on detailed proposals.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international shipping. Understanding these terms is vital for B2B buyers engaged in global trade, as they dictate shipping costs, risks, and insurance responsibilities.

5. Lead Time

Lead time refers to the time taken from placing an order to delivery. For B2B buyers, understanding lead times is crucial for planning production schedules and ensuring that materials arrive in a timely manner to meet demand.

6. Warranty

A warranty is a guarantee provided by the manufacturer regarding the performance and reliability of the air veyor. Buyers should carefully review warranty terms to protect their investment and ensure they have recourse in case of product defects or failures.

By understanding these technical properties and trade terms, international B2B buyers can make more informed decisions when selecting air veyors that best meet their operational needs.

Navigating Market Dynamics and Sourcing Trends in the air veyor Sector

What are the Current Market Dynamics and Key Trends in the Air Veyor Sector?

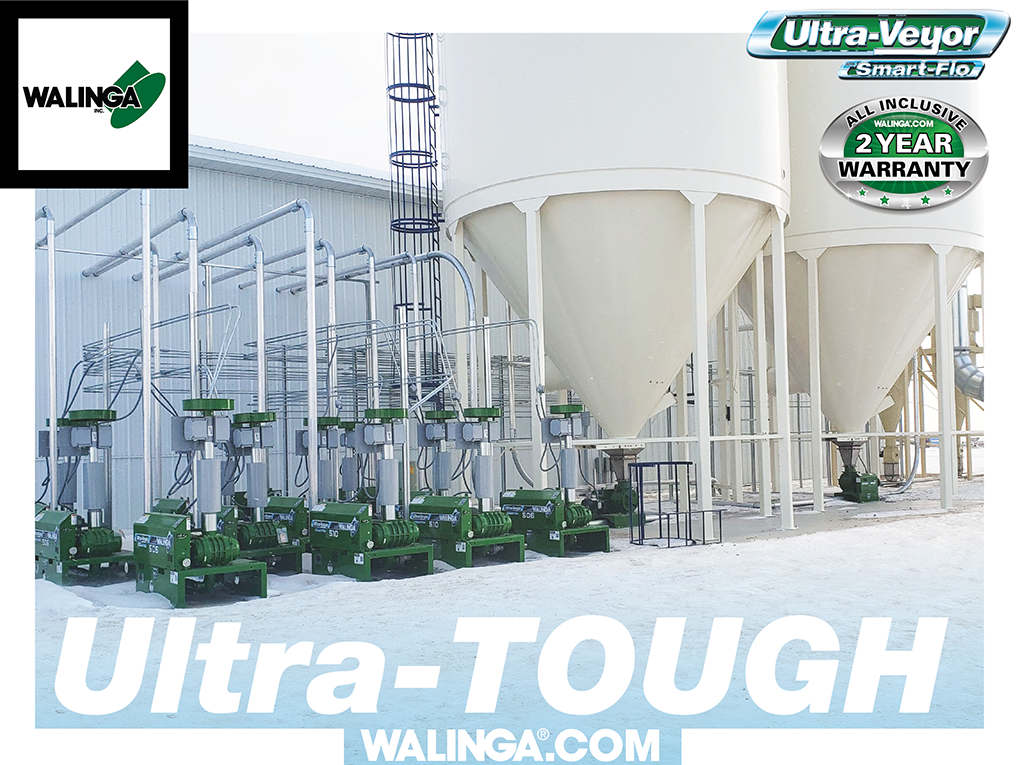

The global air veyor market is experiencing significant growth, driven by increasing demand for efficient material handling solutions across various industries, including plastics, electronics, and pharmaceuticals. One of the foremost trends is the integration of automation technologies in air veyor systems, facilitating improved efficiency and reduced labor costs. As industries move towards more automated production lines, air veyors that can seamlessly integrate with existing systems are becoming essential.

Illustrative image related to air veyor

Moreover, the shift towards lightweight materials in manufacturing is influencing the design and functionality of air veyors. These systems are now engineered to handle diverse materials such as light metals, cardboard, and plastics, adapting to the specific needs of different sectors. In regions like Africa and South America, where manufacturing is on the rise, the demand for customized air veyor solutions that accommodate local production needs is increasing. Buyers are particularly interested in systems that can be tailored to their operational requirements, emphasizing the importance of flexibility in sourcing strategies.

Sourcing trends are also evolving, with international buyers seeking suppliers that offer both competitive pricing and high-quality materials. The importance of reliable supply chains cannot be overstated, especially in regions where logistical challenges may arise. Buyers are encouraged to evaluate suppliers based on their ability to deliver consistent quality and timely service, which can significantly impact overall operational efficiency.

How is Sustainability Influencing Sourcing Decisions in the Air Veyor Industry?

Sustainability is becoming a crucial factor in the sourcing of air veyor systems, as companies face increasing pressure to reduce their environmental impact. Many manufacturers are now prioritizing the use of eco-friendly materials and energy-efficient technologies in their air veyor solutions. For instance, systems that utilize recyclable components or consume less energy during operation are gaining traction among B2B buyers.

Moreover, ethical sourcing practices are essential in today’s market. Companies are expected to provide transparency in their supply chains, ensuring that materials are sourced responsibly and ethically. This includes compliance with environmental regulations and adherence to certifications that promote sustainable practices. Buyers are encouraged to seek out suppliers that have obtained ‘green’ certifications, as these can serve as a testament to a manufacturer’s commitment to sustainability.

Investing in sustainable air veyor systems can also lead to cost savings in the long run. Energy-efficient models can reduce operational costs, while the use of sustainable materials may lead to fewer regulatory hurdles and a better public image. For international buyers, especially in emerging markets, aligning sourcing strategies with sustainability goals can enhance competitiveness and appeal to environmentally conscious consumers.

What is the Historical Context of Air Veyor Development?

The air veyor technology has evolved significantly since its inception, initially developed to address the limitations of traditional conveyor systems. Early models focused primarily on moving bulk materials, but advancements in design and technology have broadened their application. Innovations have led to the development of more sophisticated air veyors capable of handling a variety of lightweight parts with minimal contact, thereby reducing the risk of damage and enhancing operational efficiency.

Over the years, the introduction of automation and control systems has transformed air veyors into integral components of modern manufacturing lines. This evolution reflects the growing need for flexibility and efficiency in production processes, particularly in fast-paced industries. Today, air veyors are recognized not only for their functionality but also for their role in supporting sustainable manufacturing practices, making them a vital consideration for B2B buyers seeking to optimize their operations.

In conclusion, the air veyor market is poised for continued growth, driven by technological advancements and a heightened focus on sustainability. For international B2B buyers, understanding these dynamics is crucial for making informed sourcing decisions that align with both operational needs and environmental responsibilities.

Frequently Asked Questions (FAQs) for B2B Buyers of air veyor

-

How do I choose the right airveyor system for my production needs?

Choosing the right airveyor system involves evaluating several factors including the type of materials being conveyed, the distance of the run, and the specific layout of your production line. Assess whether a Positive Pressure Conveyor (PPC) or a Vacuum Pressure Conveyor (VPC) better suits your operation. For lightweight parts, air conveyors may minimize damage and enhance efficiency. Additionally, consult with suppliers for testing your materials and obtaining a custom quote based on your unique requirements. -

What is the best airveyor model for transporting lightweight plastic parts?

For lightweight plastic parts, a Positive Pressure Conveyor (PPC) is often the best choice due to its ability to effectively blow parts along the conveyor system without damaging them. Models like PPC01 or PPC02 are ideal for shorter runs and can be customized based on part size and weight. Always consider the specific air pressure requirements and test your materials with the supplier to ensure optimal performance. -

What customization options are available for airveyor systems?

Most airveyor manufacturers offer extensive customization options, including length, layout, and air pressure controls tailored to specific part types. You can also integrate sensors and automation controls to enhance efficiency. When requesting a quote, provide detailed specifications about your production environment and the materials being handled to ensure the solution fits seamlessly into your operations. -

What are the minimum order quantities (MOQ) for airveyor systems?

Minimum order quantities vary by supplier and can depend on the complexity and customization of the airveyor systems. Generally, larger suppliers may have flexible MOQs, especially for international buyers looking to place bulk orders. It’s advisable to discuss your needs directly with suppliers to negotiate terms that suit your business requirements, particularly if you are entering a new market. -

What payment terms should I expect when sourcing airveyor systems internationally?

Payment terms can vary widely between suppliers, but common practices include a deposit upfront with the balance due upon delivery or installation. Some suppliers might offer letter of credit options or payment upon inspection. It’s crucial to clarify payment terms in advance, especially for international transactions, to avoid any misunderstandings that could affect delivery timelines. -

How can I ensure quality assurance when purchasing airveyor systems?

To ensure quality assurance, request documentation of compliance with international standards such as ISO certifications. Additionally, inquire about the supplier’s quality control processes and whether they conduct pre-shipment inspections. Establishing a strong communication channel with the supplier can also help in addressing any concerns promptly and ensuring that the equipment meets your specific quality standards. -

What logistics considerations should I keep in mind when importing airveyor systems?

Logistics considerations include understanding the shipping methods, potential customs duties, and the time frame for delivery. Work with suppliers who have experience in international shipping to streamline the process. It’s also beneficial to have a reliable logistics partner to manage customs clearance and ensure that your equipment arrives in good condition and on time. -

What after-sales support can I expect from airveyor suppliers?

After-sales support varies among suppliers but typically includes installation assistance, operational training, and ongoing maintenance services. Some suppliers offer warranties and service agreements that cover parts and labor for a specified period. Be sure to discuss these options during the purchasing process to ensure you have access to necessary support as your system is integrated into your operations.

Top 5 Air Veyor Manufacturers & Suppliers List

1. MAC Automation – Airveyor Systems

Domain: macautomation.com

Registered: 1999 (26 years)

Introduction: Airveyor Systems by MAC Automation Concepts offers two types of air conveyance systems for transporting small plastic parts: Positive Pressure Conveyor (PPC) and Vacuum Pressure Conveyor (VPC).

Positive Pressure Conveyor (PPC):

– Uses high pressure ambient air to ‘blow’ parts.

– Recommended when compressed air is not consistently available.

– Models:

– PPC01: 1/3 HP, 115/230 1 phase, 4″ or…

2. Authorized Dealer – Redneck Blinds, Bull Creek Blinds, Sportsman Condo

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Authorized Dealer – Redneck Blinds, Bull Creek Blinds, Sportsman Condo, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Hoosier Feeder – Air Conveyors

Domain: hoosierfeeder.com

Registered: 2012 (13 years)

Introduction: Air Conveyors – Efficient High-Speed Transport for Lightweight Parts. Uses controlled airflow to gently and quickly move lightweight parts along production lines. Designed to minimize contact and reduce part damage, supporting smooth, consistent flow and low maintenance. Commonly used in packaging, electronics, and pharmaceuticals. Integrates easily with automation systems to improve efficiency. B…

4. Air Conveying Corp – Airveyor

Domain: accfilter.com

Registered: 2009 (16 years)

Introduction: The Airveyor from Air Conveying Corp is designed for efficient air conveying, equipped with a 3 h.p. or 5 h.p. Pressure Blower, which is more efficient than the 10 or 15 h.p. motors used by competitors. Its design includes an air in-feed, cavity, and conveying surface that saves on equipment costs and electricity. The Airveyor features a strong top that allows operators to walk on it for setup, cl…

5. Innoveyance – Airveyor Conveyor System

Domain: innoveyance.com

Registered: 2019 (6 years)

Introduction: The Airveyor by Innoveyance is a unique conveyor system designed for handling materials such as cardboard, paper, file, laminates, and light metal. It can be integrated beneath or within die cutters, printer slotters, and other converting equipment. Key features include:

– Support for machine setup or maintenance

– Ability to change the direction of material movement without complex mechanisms

…

Strategic Sourcing Conclusion and Outlook for air veyor

In conclusion, the strategic sourcing of airveyor systems presents a significant opportunity for businesses across diverse sectors, particularly in the plastics, packaging, and electronics industries. By understanding the unique advantages of both Positive Pressure Conveyors and Vacuum Pressure Conveyors, international B2B buyers can make informed decisions that optimize production efficiency and reduce operational costs. Key considerations include system customization, integration with existing automation, and the importance of testing with actual materials to ensure compatibility and performance.

As global markets continue to evolve, the demand for efficient, low-maintenance conveying solutions will only increase. Strategic sourcing not only enhances supply chain resilience but also aligns with sustainability goals by reducing waste and energy consumption.

For businesses in regions such as Africa, South America, the Middle East, and Europe, investing in advanced airveyor technology can be a game-changer. We encourage buyers to explore partnerships with reputable suppliers to leverage these innovative solutions, ensuring they remain competitive in an increasingly dynamic landscape. Engage with industry experts today to discover how airveyor systems can transform your operations and drive growth.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.