Is Your Pipeline Expansion Joints Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for pipeline expansion joints

In today’s global marketplace, sourcing pipeline expansion joints can present significant challenges for B2B buyers, especially those operating in diverse regions like Africa, South America, the Middle East, and Europe. The complexity arises not only from varying industrial standards and environmental conditions but also from the need to ensure reliability and efficiency in pipeline systems. This comprehensive guide aims to demystify the world of pipeline expansion joints by exploring the various types available, their specific applications, and the critical factors to consider when evaluating potential suppliers.

From metal and rubber expansion joints to specialized designs for seismic and thermal applications, this guide covers the full spectrum of products available in the market. Additionally, it provides actionable insights on supplier vetting, cost considerations, and compliance with international standards, empowering buyers to make informed purchasing decisions. By equipping stakeholders with the knowledge needed to navigate the intricacies of procurement, this guide serves as a valuable resource for optimizing supply chain strategies and enhancing operational efficiency.

Understanding the nuances of pipeline expansion joints is essential for ensuring the integrity and longevity of infrastructure. With the right information at hand, international buyers can confidently source high-quality solutions that meet their specific needs, ultimately driving project success and sustainability.

Understanding pipeline expansion joints Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Metal Bellows Expansion Joints | Stainless steel construction, allows significant movement | HVAC systems, industrial piping | Pros: Durable, high-temperature resistance. Cons: Higher initial cost compared to rubber joints. |

| Rubber Expansion Joints | Flexible rubber material, absorbs vibrations and noise | Water treatment, chemical processing | Pros: Cost-effective, excellent vibration dampening. Cons: Limited temperature and pressure tolerance. |

| Externally Pressurized Expansion Joints | Designed for high movement applications, robust structure | Oil and gas pipelines, seismic applications | Pros: Greater movement capability, suitable for extreme conditions. Cons: Complex installation requirements. |

| Fabric Expansion Joints | Lightweight, customizable shapes, suitable for various media | Ducting systems, low-pressure applications | Pros: Versatile, easy to install. Cons: Not suitable for high-pressure environments. |

| Seismic Expansion Joints | Specifically designed for seismic activity, flexible design | Infrastructure in seismic zones | Pros: Protects systems during earthquakes, high flexibility. Cons: May require specialized installation. |

What are Metal Bellows Expansion Joints and When Should They Be Used?

Metal bellows expansion joints are primarily constructed from stainless steel, offering exceptional durability and the ability to handle significant movement. They are ideal for high-temperature and high-pressure applications, making them suitable for HVAC systems and industrial piping. When considering a purchase, buyers should weigh the initial investment against the long-term benefits of durability and reliability, especially in demanding environments.

How Do Rubber Expansion Joints Compare in Flexibility and Cost?

Rubber expansion joints are made from flexible rubber materials that effectively absorb vibrations and noise, making them a popular choice in water treatment and chemical processing industries. They are generally more cost-effective than metal options but come with limitations in temperature and pressure tolerance. Buyers should consider the specific application requirements, especially if the system operates under extreme conditions, where metal joints might be more appropriate.

What Are the Advantages of Externally Pressurized Expansion Joints?

Externally pressurized expansion joints are designed to accommodate high movement and are robustly constructed to withstand extreme conditions, making them ideal for oil and gas pipelines and seismic applications. They provide greater movement capability than standard joints, but their installation can be complex and may require specialized knowledge. Buyers should assess their project needs and the expertise of their installation teams when considering these joints.

In What Scenarios are Fabric Expansion Joints Most Effective?

Fabric expansion joints are lightweight and can be customized to fit various shapes and sizes, making them suitable for ducting systems and low-pressure applications. They offer versatility and ease of installation, but they are not recommended for high-pressure environments. B2B buyers should evaluate the specific requirements of their systems, especially if they need a lightweight solution that can be adapted to different configurations.

Why Are Seismic Expansion Joints Crucial for Infrastructure in Seismic Zones?

Seismic expansion joints are specifically engineered to protect piping systems from the stresses caused by seismic activity. Their flexible design allows for significant movement, making them essential for infrastructure located in earthquake-prone areas. While they offer substantial protection, they may require specialized installation techniques. Buyers must consider local seismic codes and the expertise required for proper installation when selecting these joints.

Key Industrial Applications of pipeline expansion joints

| Industry/Sector | Specific Application of pipeline expansion joints | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Integration in upstream and downstream pipeline systems | Enhances flexibility and reduces stress on pipes, ensuring longevity | Compliance with industry standards, pressure ratings, and material compatibility |

| Water & Wastewater | Used in municipal water treatment plants | Prevents damage from thermal expansion and contraction, reducing maintenance costs | Resistance to corrosion, size specifications, and adaptability to various media |

| Power Generation | Implementation in steam and cooling systems | Improves efficiency and safety by accommodating thermal movements | Temperature tolerance, pressure ratings, and custom design options |

| Chemical Processing | Application in chemical transport pipelines | Minimizes leaks and failures, ensuring safety and compliance | Chemical resistance, temperature and pressure ratings, and customization capabilities |

| HVAC Systems | Installation in heating and cooling systems | Provides system flexibility, reducing wear and tear on components | Compatibility with existing systems, material selection, and performance under varying conditions |

How Are Pipeline Expansion Joints Used in the Oil & Gas Industry?

In the oil and gas sector, pipeline expansion joints are crucial for managing the dynamic stresses that occur in both upstream and downstream operations. These joints accommodate thermal expansion, vibration, and misalignment, which are common due to temperature fluctuations and pressure changes. For international buyers, particularly in regions like the Middle East and South America, sourcing expansion joints that meet specific industry standards and are designed to withstand high pressures and corrosive environments is essential. Ensuring compliance with regulations, such as API and ASME, is vital for operational safety and efficiency.

What Role Do Pipeline Expansion Joints Play in Water & Wastewater Management?

In municipal water treatment facilities, pipeline expansion joints are employed to handle the thermal expansion and contraction of pipelines, which is critical for maintaining structural integrity. These joints help prevent leaks and failures that can result from temperature variations, thus reducing maintenance costs and downtime. Buyers from Africa and Europe should prioritize sourcing materials that are resistant to corrosion and designed for specific pressure ratings, ensuring longevity in harsh environments. Additionally, understanding local regulations regarding wastewater management can influence purchasing decisions.

Why Are Pipeline Expansion Joints Important in Power Generation?

In power generation, particularly in steam and cooling systems, pipeline expansion joints are essential for accommodating thermal movements. They help maintain system efficiency and safety by allowing for the expansion and contraction of pipes without causing damage. For buyers in regions like Saudi Arabia, where temperatures can vary significantly, sourcing joints that can withstand extreme conditions and are tailored to specific operational requirements is critical. Considerations such as temperature tolerance and pressure ratings can significantly impact performance and reliability.

How Do Pipeline Expansion Joints Benefit the Chemical Processing Industry?

In chemical processing, pipeline expansion joints play a vital role in safely transporting various chemicals. They help minimize leaks and failures by accommodating the thermal and mechanical stresses that occur during operation. For international buyers, particularly in South America, it’s important to ensure that the sourced joints are chemically resistant and meet specific pressure and temperature requirements. Customization options can also be a key factor in meeting the unique demands of different chemical applications, enhancing safety and compliance with industry standards.

What Advantages Do Pipeline Expansion Joints Offer in HVAC Systems?

In HVAC systems, pipeline expansion joints are crucial for maintaining system flexibility and reducing wear on components. They effectively manage thermal expansion and contraction, which is essential for optimal performance in heating and cooling applications. Buyers in Europe and Africa should focus on sourcing joints that are compatible with existing systems and can withstand varying operational conditions. Material selection is also important, as it impacts durability and performance, ensuring that the HVAC system operates efficiently and reliably over time.

Illustrative image related to pipeline expansion joints

3 Common User Pain Points for ‘pipeline expansion joints’ & Their Solutions

Scenario 1: Challenges with Thermal Expansion in Pipeline Systems

The Problem: In regions with extreme temperature variations, such as parts of Africa and the Middle East, pipeline systems are particularly susceptible to thermal expansion and contraction. B2B buyers often face challenges in selecting the right expansion joints that can accommodate significant movement without compromising system integrity. Failure to address these thermal fluctuations can lead to leaks, ruptures, and costly downtime, affecting production schedules and operational efficiency.

The Solution: To effectively manage thermal expansion, it is essential to choose expansion joints designed for high flexibility and movement. Opt for metal bellows expansion joints, such as the Metragator series, which can handle large amounts of displacement and are built to withstand high temperatures. When specifying these joints, consider both the maximum expected temperature and the thermal movement in your calculations. It’s advisable to pre-compress the joints during installation to allow for the expected contraction, which ensures optimal performance. Regular maintenance checks should also be scheduled to monitor the condition of the joints, ensuring they remain effective throughout their operational life.

Scenario 2: The Risk of Pressure Surges and Equipment Damage

The Problem: Pressure surges, often caused by sudden changes in flow rate or valve operations, can be detrimental to pipeline systems. In industries like oil and gas, where pipelines operate under high pressure, B2B buyers must be vigilant about the potential for damage. Without properly specified expansion joints, these surges can lead to catastrophic failures, causing not only equipment damage but also safety hazards and costly downtime.

The Solution: To mitigate the risks associated with pressure surges, buyers should select expansion joints that are specifically rated for high-pressure applications. For example, the Metragator series includes options with enhanced pressure ratings, capable of handling pressures up to 300 PSI. It is crucial to consult with manufacturers to ensure that the selected joints meet the specific pressure requirements of your system. Additionally, using double braided flexible connectors can provide extra tensile strength and pressure tolerance. Implementing pressure relief valves in conjunction with expansion joints can also help manage sudden pressure changes, safeguarding the entire pipeline system.

Scenario 3: Difficulty in Sizing and Specifying Expansion Joints

The Problem: Sizing and specifying the correct expansion joints can often be a complicated and confusing process for B2B buyers, particularly in large-scale projects involving multiple pipeline segments. Miscalculations can lead to the installation of joints that are either too small or too large, resulting in operational inefficiencies and increased maintenance costs. This challenge is exacerbated when dealing with custom installations or when the project requirements are not clearly defined.

Illustrative image related to pipeline expansion joints

The Solution: To ensure accurate sizing and specification of expansion joints, it is essential to collaborate closely with manufacturers and utilize their design services. Engaging in a detailed discussion about your specific application, including temperature ranges, movement requirements, and pressure conditions, will help in identifying the right joint. Using software tools and 3D modeling can aid in visualizing how the expansion joints will fit within the pipeline system. Additionally, consider using standardized models for common applications to simplify the selection process. Documenting the installation parameters and maintenance schedules can also provide a reference for future projects, reducing the likelihood of errors in subsequent installations.

By proactively addressing these common pain points, B2B buyers can enhance the reliability and efficiency of their pipeline systems, ultimately leading to improved operational performance and cost savings.

Strategic Material Selection Guide for pipeline expansion joints

What are the Key Properties of Common Materials Used in Pipeline Expansion Joints?

When selecting materials for pipeline expansion joints, it is essential to consider their key properties, as these directly influence performance in various applications. Here are three common materials used in the manufacturing of pipeline expansion joints:

1. Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance, high-temperature endurance (up to 1,200°F), and strong mechanical properties. It can withstand high pressures, making it suitable for demanding environments.

Illustrative image related to pipeline expansion joints

Pros & Cons: The durability of stainless steel ensures a long service life, reducing the need for frequent replacements. However, it is more expensive than other materials, which can impact budget considerations for projects. Manufacturing complexity can also be higher due to the need for specialized welding techniques.

Impact on Application: Stainless steel is compatible with a wide range of media, including corrosive substances like acids and alkalis. Its strength makes it ideal for high-pressure applications, commonly found in oil and gas pipelines.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial. Buyers in regions like Europe and the Middle East often prefer stainless steel for its reliability, while ensuring that it meets local regulations for pressure and temperature ratings.

2. Rubber

Key Properties: Rubber expansion joints are flexible and can accommodate significant movement. They typically operate effectively at lower temperatures (up to 250°F) and pressures (around 150 PSI).

Pros & Cons: The primary advantage of rubber is its cost-effectiveness and ease of installation. However, its susceptibility to degradation from UV exposure and certain chemicals limits its application in harsh environments. Additionally, rubber joints may require more frequent replacement than metal counterparts.

Impact on Application: Rubber is suitable for water, wastewater, and some chemical applications, but it may not perform well with oils or high-temperature media.

Considerations for International Buyers: In regions like Africa and South America, where budget constraints are common, rubber joints may be favored. However, buyers must ensure that the rubber material complies with local standards to avoid premature failure.

3. PTFE (Polytetrafluoroethylene)

Key Properties: PTFE is renowned for its exceptional chemical resistance and ability to operate at temperatures up to 500°F. It also has low friction properties, which can reduce wear on connected components.

Pros & Cons: The main advantage of PTFE is its versatility in handling aggressive chemicals, making it ideal for the chemical processing industry. However, it can be more expensive than rubber and may have limitations in high-pressure applications.

Impact on Application: PTFE is particularly suitable for applications involving corrosive chemicals, such as acids and solvents, which are common in industrial settings.

Considerations for International Buyers: Buyers in the Middle East and Europe often require PTFE expansion joints for chemical applications, ensuring compliance with relevant standards like ASTM F-2934. Understanding local regulations regarding chemical handling is vital for effective procurement.

Summary Table of Material Selection for Pipeline Expansion Joints

| Material | Typical Use Case for pipeline expansion joints | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | High-pressure oil and gas pipelines | Excellent corrosion resistance and durability | Higher cost and manufacturing complexity | High |

| Rubber | Water and wastewater applications | Cost-effective and easy to install | Susceptible to UV degradation and chemical attack | Low |

| PTFE | Chemical processing applications | Exceptional chemical resistance | Higher cost and limited high-pressure capability | Medium |

This strategic material selection guide provides B2B buyers with actionable insights into the properties, advantages, and limitations of common materials used in pipeline expansion joints, enabling informed decision-making tailored to specific applications and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for pipeline expansion joints

The manufacturing processes and quality assurance mechanisms for pipeline expansion joints are critical to ensuring reliability and performance in various applications. For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, understanding these processes can significantly influence procurement decisions. This section will explore the main stages of manufacturing, key techniques, and relevant quality control measures, providing actionable insights for international buyers.

Illustrative image related to pipeline expansion joints

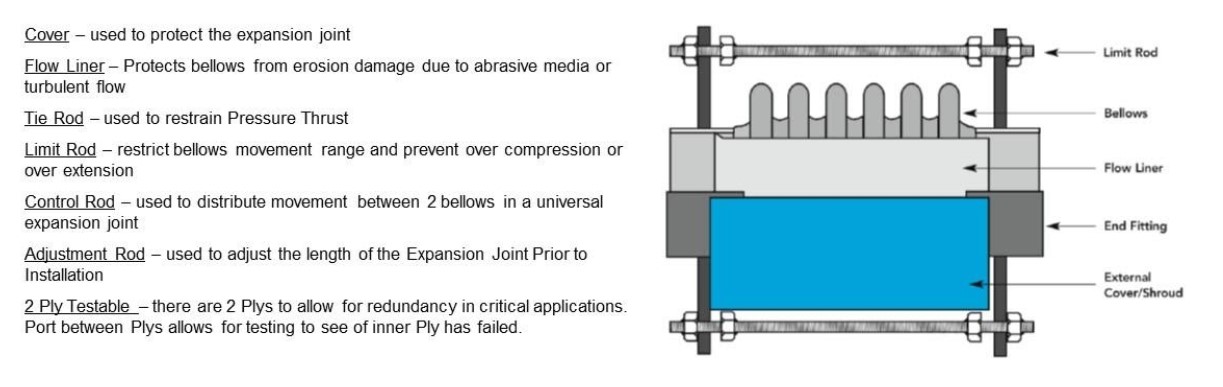

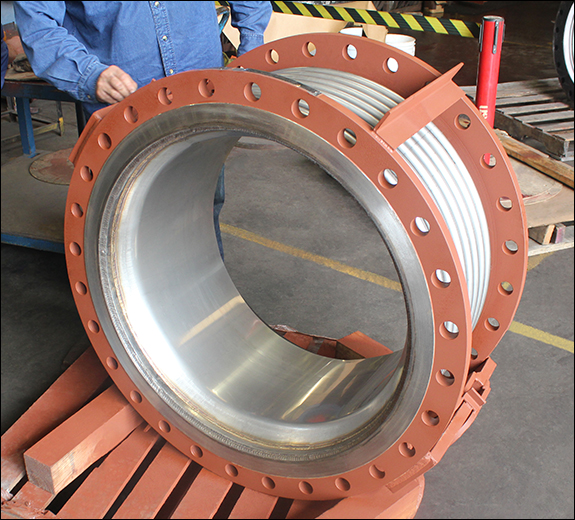

What are the Main Stages of Manufacturing Pipeline Expansion Joints?

The manufacturing of pipeline expansion joints typically involves several key stages: material preparation, forming, assembly, and finishing. Each stage plays a vital role in ensuring the final product meets industry standards and customer specifications.

How is Material Prepared for Expansion Joints?

The first step in the manufacturing process is material preparation. High-quality raw materials, often stainless steel or other alloys, are selected based on the specific requirements of the application, such as temperature and pressure conditions. Materials are then subjected to various tests to ensure they meet the necessary mechanical and chemical properties. This might include tensile strength tests and corrosion resistance assessments.

What Forming Techniques are Used in the Production of Expansion Joints?

Once the materials are prepared, they undergo forming processes to create the required shapes. Common techniques include:

- Hydroforming: This method utilizes high-pressure fluid to shape metal into desired geometries, ensuring uniform thickness and strength.

- Welding: Various welding techniques (such as TIG or MIG welding) are employed to join components, particularly for bellows and flanges, ensuring leak-proof integrity.

- Bending and Rolling: These techniques are often used for creating curves or specific angles in the joints, allowing for flexible designs that accommodate thermal expansion and contraction.

The choice of forming technique depends on the specific design and operational requirements of the expansion joint.

How is the Assembly of Pipeline Expansion Joints Conducted?

After forming, the next stage is assembly. This involves the integration of various components such as bellows, flanges, and fittings. Precision is critical during this phase to ensure all parts fit correctly and function as intended. Often, assembly is done in a controlled environment to prevent contamination and ensure the integrity of the components.

What Finishing Processes are Applied to Pipeline Expansion Joints?

Finishing processes enhance the durability and performance of the expansion joints. Common finishing techniques include:

- Surface Treatment: This may involve polishing, coating, or galvanizing to protect against corrosion and wear.

- Heat Treatment: This process is used to relieve stresses and improve the mechanical properties of the joints, ensuring they can withstand operational demands.

- Quality Inspections: Conducted at various stages of the finishing process to ensure compliance with specifications and industry standards.

What Quality Assurance Standards Are Relevant for Expansion Joints?

Quality assurance is paramount in the manufacturing of pipeline expansion joints. Adhering to international standards not only ensures product quality but also builds trust with buyers. Key standards include:

Illustrative image related to pipeline expansion joints

- ISO 9001: This standard outlines requirements for a quality management system, ensuring that manufacturers consistently provide products that meet customer and regulatory requirements.

- CE Marking: Particularly relevant in Europe, this certification indicates that products comply with EU safety, health, and environmental protection standards.

- API Standards: For applications in the oil and gas sector, adherence to American Petroleum Institute (API) standards is crucial for ensuring safety and reliability.

How is Quality Control Implemented During Manufacturing?

Quality control (QC) involves multiple checkpoints throughout the manufacturing process. These can be categorized into three main phases:

What is Incoming Quality Control (IQC)?

Incoming Quality Control (IQC) occurs at the beginning of the manufacturing process, where raw materials are inspected for quality and compliance with specifications. This step is essential to prevent defects from entering the production line.

How is In-Process Quality Control (IPQC) Conducted?

In-Process Quality Control (IPQC) focuses on monitoring the manufacturing process itself. This involves regular inspections and tests during each stage of production, from material preparation to assembly. Techniques may include:

- Dimensional checks to ensure components meet specified tolerances.

- Non-destructive testing (NDT) methods, such as ultrasonic or radiographic testing, to detect internal flaws in welded joints.

What is Final Quality Control (FQC)?

Final Quality Control (FQC) is the last stage before products are shipped. This involves comprehensive testing and inspection to confirm that the expansion joints meet all specifications and standards. Common tests include pressure testing, leak testing, and functional assessments.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control practices is crucial. Here are actionable steps to ensure that suppliers maintain high standards:

Illustrative image related to pipeline expansion joints

- Supplier Audits: Conduct on-site audits to assess the supplier’s manufacturing processes, quality control measures, and adherence to standards.

- Request Quality Reports: Suppliers should provide documentation of quality tests, certifications, and compliance with relevant standards.

- Third-Party Inspections: Engage third-party organizations to conduct independent inspections and tests on products before shipment, ensuring unbiased verification of quality.

What QC and Certification Nuances Should International Buyers Consider?

When sourcing from international suppliers, particularly in regions like Africa, South America, the Middle East, and Europe, buyers should be aware of specific nuances:

- Regulatory Compliance: Different regions may have unique regulatory requirements. Ensure that suppliers are compliant with local standards and can provide relevant certifications.

- Cultural Differences: Understand that manufacturing practices and quality expectations may vary by region. Building strong communication channels can help bridge these gaps.

- Logistical Challenges: Consider the implications of logistics on quality assurance, including potential risks during transportation that may affect product integrity.

By comprehensively understanding the manufacturing processes and quality assurance mechanisms for pipeline expansion joints, B2B buyers can make informed decisions, ensuring they select reliable suppliers capable of delivering high-quality products suited to their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pipeline expansion joints’

In the complex world of pipeline systems, selecting the right expansion joints is critical for ensuring operational efficiency and longevity. This guide provides a step-by-step checklist tailored for international B2B buyers, especially those operating in Africa, South America, the Middle East, and Europe. By following these actionable steps, buyers can make informed decisions that align with their technical and operational needs.

Step 1: Define Your Technical Specifications

Begin by outlining the specific requirements for your pipeline expansion joints. Consider factors such as the diameter, pressure rating, temperature range, and the type of media being transported. Each application may have unique demands; for example, high-temperature applications may require special materials to withstand thermal stress.

- Key Considerations:

- Material compatibility (e.g., stainless steel vs. rubber)

- Movement capabilities (axial, lateral, angular)

Step 2: Research Compliance Standards

Ensure that the expansion joints meet relevant industry standards and regulations. Different regions may have specific requirements, such as ASTM or ISO certifications. Compliance with these standards not only assures quality but also enhances safety and reliability.

- Important Standards:

- ASTM F-1120 or ASTM F-2934 for metal joints

- Regional compliance for specific applications (HVAC, marine, etc.)

Step 3: Evaluate Potential Suppliers

Before committing, thoroughly vet potential suppliers to ensure they have a proven track record. Request detailed company profiles, product catalogs, and references from similar industries or regions. A reliable supplier will have a robust portfolio demonstrating their expertise and experience.

- What to Look For:

- Case studies showcasing successful installations

- Customer testimonials and feedback

Step 4: Request Samples and Specifications

Once you have shortlisted suppliers, request product samples and detailed technical specifications. Evaluating samples allows you to assess the quality and suitability of the materials for your application. Look for comprehensive technical data sheets that detail performance metrics.

Illustrative image related to pipeline expansion joints

- Key Documents:

- Technical data sheets (TDS)

- Installation and maintenance guidelines

Step 5: Assess Pricing and Lead Times

Obtain detailed quotations from your selected suppliers, ensuring that all costs are transparent. Compare pricing not only on the products but also on shipping and handling. Additionally, inquire about lead times, as timely delivery is crucial for project schedules.

- Considerations:

- Bulk pricing options

- Shipping costs and delivery timelines

Step 6: Check After-Sales Support and Warranty Terms

Evaluate the after-sales support offered by suppliers, including warranty terms and customer service availability. A strong warranty and responsive support can save you significant costs in the long run, especially if issues arise post-installation.

- Support Aspects:

- Length and coverage of warranty

- Availability of technical support and training

Step 7: Finalize Contracts and Confirm Orders

Once you have selected a supplier that meets all your criteria, finalize the contract. Ensure that all agreed terms, including specifications, pricing, and delivery schedules, are documented. Clear communication at this stage minimizes potential disputes and sets the foundation for a successful partnership.

Illustrative image related to pipeline expansion joints

By following this structured checklist, B2B buyers can confidently navigate the procurement process for pipeline expansion joints, ensuring they select the most suitable solutions for their operational needs.

Comprehensive Cost and Pricing Analysis for pipeline expansion joints Sourcing

What Are the Key Cost Components in Pipeline Expansion Joints Sourcing?

When sourcing pipeline expansion joints, several cost components must be taken into account. The primary cost factors include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margin.

-

Materials: The choice of materials directly impacts the cost. Options range from standard stainless steel to specialized alloys designed for high temperatures or corrosive environments. Custom specifications may further increase material costs.

-

Labor: Labor costs are influenced by the complexity of the manufacturing process. Skilled labor is essential for high-quality production, particularly for custom or specialized joints that require precise fabrication.

-

Manufacturing Overhead: This includes indirect costs such as utilities, equipment maintenance, and facility costs. Efficient manufacturing processes can help reduce overhead, contributing to overall cost savings.

-

Tooling: Initial tooling costs can be significant, especially for custom designs. However, once the tooling is established, the cost per unit can decrease substantially with higher production volumes.

-

Quality Control: Ensuring that expansion joints meet industry standards and certifications (like ASTM) necessitates rigorous QC processes. This includes testing for pressure ratings and durability, which can add to overall costs.

-

Logistics: Shipping costs vary based on the distance, mode of transport, and the volume of the order. International buyers must consider customs duties and tariffs, which can significantly affect the final price.

-

Margin: Suppliers typically include a margin to cover their operational costs and profit. This can vary based on market competition and the supplier’s positioning.

How Do Price Influencers Affect Pipeline Expansion Joints?

Several factors can influence pricing, particularly for international B2B buyers:

-

Volume/MOQ: Purchasing larger quantities often results in lower per-unit costs due to economies of scale. Buyers should assess their needs to negotiate better terms.

-

Specifications and Customization: Custom designs or specialized materials can lead to higher costs. Buyers should clearly define their specifications to avoid unexpected expenses during production.

-

Materials: The type and quality of materials used will greatly impact pricing. Higher-grade materials offer better performance but come at a premium.

-

Quality and Certifications: Compliance with international standards can affect costs. Buyers should consider the long-term benefits of investing in certified products that ensure reliability and safety.

-

Supplier Factors: The supplier’s reputation, reliability, and location can influence pricing. Established suppliers may offer better warranties and support, justifying higher costs.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can all affect the total cost.

What Are Effective Buyer Tips for Cost-Efficiency in Sourcing?

To maximize cost-efficiency when sourcing pipeline expansion joints, consider the following strategies:

-

Negotiation: Engage suppliers in discussions to explore volume discounts, flexible payment terms, or bundled services that can reduce costs.

-

Total Cost of Ownership (TCO): Evaluate the TCO rather than just the initial purchase price. This includes maintenance, durability, and replacement costs, which can significantly affect long-term expenses.

-

Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe must account for currency fluctuations, import duties, and local market conditions. Building relationships with local suppliers can mitigate risks and enhance purchasing power.

-

Market Research: Conduct thorough market research to understand current pricing trends and benchmark against competitors. This knowledge can empower buyers during negotiations.

-

Supplier Diversification: Avoid reliance on a single supplier. Engaging multiple suppliers can foster competitive pricing and reduce risks associated with supply chain disruptions.

In conclusion, understanding the cost structure and pricing dynamics of pipeline expansion joints is essential for making informed purchasing decisions. By focusing on these factors, buyers can enhance their sourcing strategies and achieve better financial outcomes.

Alternatives Analysis: Comparing pipeline expansion joints With Other Solutions

Understanding Alternatives to Pipeline Expansion Joints

In the realm of industrial piping systems, pipeline expansion joints are crucial for accommodating thermal expansion and contraction, thereby preventing damage to pipes and ensuring system integrity. However, various alternatives exist that can also fulfill similar roles. Exploring these alternatives allows B2B buyers to make informed decisions tailored to their specific operational requirements and budget constraints.

Comparison Table

| Comparison Aspect | Pipeline Expansion Joints | Rubber Expansion Joints | Bellows Expansion Joints |

|---|---|---|---|

| Performance | High flexibility for thermal movement; withstands pressure variations | Good for moderate movements; limited pressure handling | Excellent for high-pressure applications; accommodates substantial movements |

| Cost | Moderate to high, depending on material and customization | Lower initial cost; less durable over time | Higher initial investment but long-term reliability |

| Ease of Implementation | Requires precise installation; may need additional supports | Easier to install; can be integrated into various systems | More complex installation; often requires custom engineering |

| Maintenance | Low maintenance; periodic inspections recommended | Moderate maintenance; susceptible to wear | Low maintenance; robust design reduces failure risk |

| Best Use Case | Ideal for high-pressure systems and extreme temperature variations | Suitable for HVAC and low-pressure applications | Perfect for high-pressure and high-temperature environments |

Pros and Cons of Each Alternative

Rubber Expansion Joints

Rubber expansion joints are a popular alternative due to their lower cost and ease of installation. They are particularly effective in HVAC systems and other applications where moderate movements and lower pressure are involved. However, their durability is limited compared to metal options, as they can degrade over time due to environmental factors like UV exposure and temperature fluctuations. While they are an economical choice, buyers should consider their longevity and potential replacement costs.

Bellows Expansion Joints

Bellows expansion joints are engineered for high-pressure applications and are designed to accommodate significant thermal movements. Their robust construction makes them suitable for challenging environments, including chemical processing and power generation. While they tend to have a higher upfront cost, their durability and reliability often result in lower maintenance costs over time. The complexity of their installation may require specialized knowledge, which could lead to increased labor costs. However, for businesses that prioritize long-term operational efficiency, bellows joints can be an excellent investment.

Conclusion: How to Choose the Right Solution

Selecting the appropriate expansion joint solution involves assessing your specific operational needs, including pressure requirements, environmental conditions, and budget constraints. Pipeline expansion joints are ideal for high-pressure and extreme temperature applications, while rubber joints offer a cost-effective solution for moderate requirements. Bellows joints, although more expensive, provide unmatched durability in demanding environments. By carefully evaluating these factors, B2B buyers can make informed decisions that enhance the efficiency and reliability of their piping systems.

Essential Technical Properties and Trade Terminology for pipeline expansion joints

What Are the Key Technical Properties of Pipeline Expansion Joints?

Understanding the technical properties of pipeline expansion joints is crucial for making informed procurement decisions. Here are several critical specifications to consider:

1. Material Grade

Pipeline expansion joints are typically made from various materials, including stainless steel, carbon steel, and rubber. The material grade affects the joint’s durability, resistance to corrosion, and ability to withstand high temperatures and pressures. For example, stainless steel joints are favored in corrosive environments, while rubber joints are often used in low-pressure applications. Choosing the right material can significantly impact the longevity and reliability of the piping system.

2. Pressure Rating

The pressure rating of an expansion joint indicates the maximum pressure it can safely handle. Common ratings include 150 PSI, 300 PSI, and higher for specialized applications. This specification is vital for ensuring that the joint can withstand the operational pressures of the pipeline without failure, which is critical for safety and operational efficiency.

3. Movement Capability

This specification describes the amount of axial, lateral, and angular movement the expansion joint can accommodate. Different designs, such as bellows or gimbals, offer varying movement capabilities. Understanding these limits is essential for selecting the right joint for applications involving thermal expansion or seismic activity, ensuring the integrity of the entire pipeline system.

4. Tolerance

Tolerance refers to the acceptable deviation from the specified dimensions of the expansion joint. It is crucial for ensuring a proper fit within the piping system, which minimizes stress and potential leaks. Maintaining tight tolerances is especially important in high-precision industries like oil and gas, where even minor discrepancies can lead to significant operational issues.

Illustrative image related to pipeline expansion joints

5. Temperature Range

The operational temperature range indicates the minimum and maximum temperatures the expansion joint can endure. This property is critical in applications where temperature fluctuations are significant, such as in steam or hot water systems. Selecting a joint with an appropriate temperature range ensures optimal performance and prevents premature failure.

6. End Connections

End connections, such as flanged, grooved, or welded ends, determine how the expansion joint integrates into the existing pipeline. The choice of end connection affects installation ease and compatibility with other system components. Understanding the available options helps in making a seamless connection within the piping system.

What Are Common Trade Terms Associated with Pipeline Expansion Joints?

Navigating the procurement of pipeline expansion joints involves understanding industry terminology. Here are some key terms:

1. OEM (Original Equipment Manufacturer)

An OEM refers to the company that produces the original product or component that is incorporated into a larger system. In the context of expansion joints, knowing the OEM can help in assessing quality and reliability, which is crucial for long-term partnerships.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is important for B2B buyers as it affects inventory management and cost efficiency. Understanding MOQ helps in budgeting and planning for larger projects.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for a quote on specific products or services. It typically includes detailed specifications, quantities, and delivery requirements. Crafting a precise RFQ can lead to better pricing and terms, making it a vital part of the procurement process.

4. Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in the shipping process. They clarify who is responsible for shipping costs, insurance, and risks during transit. Familiarity with Incoterms is essential for avoiding misunderstandings and ensuring smooth international transactions.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. This metric is crucial for project planning, as longer lead times can delay project timelines and increase costs. Understanding lead time can help buyers manage expectations and logistics effectively.

6. Certification Standards

Certification standards, such as ASTM or ISO, indicate that a product meets specific quality and safety requirements. Knowing these standards can help buyers ensure they are sourcing reliable products that comply with industry regulations, which is vital for maintaining operational safety and integrity.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions regarding pipeline expansion joints, ultimately leading to better project outcomes and enhanced operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the pipeline expansion joints Sector

What Are the Current Market Dynamics for Pipeline Expansion Joints?

The pipeline expansion joints market is experiencing significant growth driven by various global factors. Increased infrastructure development, particularly in emerging markets in Africa, South America, the Middle East, and Europe, is a key driver. These regions are investing heavily in energy and water infrastructure to support economic growth and urbanization. Additionally, the oil and gas industry continues to demand high-performance expansion joints that can withstand extreme conditions, further propelling market expansion.

Emerging technologies are transforming sourcing strategies in this sector. Digital platforms and e-commerce solutions are gaining traction among B2B buyers, facilitating easier access to product specifications, pricing, and supplier comparisons. Moreover, the trend towards customization is becoming more pronounced, as buyers seek tailored solutions that meet specific operational requirements. This shift is prompting suppliers to invest in advanced manufacturing techniques, including 3D printing, to produce bespoke expansion joints more efficiently.

International buyers are also navigating complex regulatory environments that vary by region. Compliance with standards such as ASTM and ISO is critical, especially in Europe and North America, where regulations are stringent. Suppliers that can demonstrate adherence to these standards and provide certifications are likely to gain a competitive advantage.

Illustrative image related to pipeline expansion joints

How Is Sustainability Influencing Sourcing Trends in Pipeline Expansion Joints?

Sustainability is becoming a cornerstone of procurement strategies in the pipeline expansion joints sector. Environmental concerns are prompting businesses to evaluate the lifecycle impact of their products and supply chains. Buyers are increasingly prioritizing suppliers who adopt sustainable practices and materials, such as recyclable metals and eco-friendly manufacturing processes.

The importance of ethical sourcing cannot be overstated. With rising global awareness of ethical labor practices, B2B buyers are scrutinizing their suppliers’ supply chains to ensure compliance with labor standards and environmental regulations. This scrutiny extends to certifications that signal a commitment to sustainability, such as ISO 14001 for environmental management and various green building certifications.

Moreover, the demand for ‘green’ materials is on the rise. Pipeline expansion joints made from recyclable materials or those that minimize resource consumption during production are gaining traction among environmentally-conscious buyers. Suppliers who can offer such materials not only enhance their market appeal but also align with the growing trend toward corporate social responsibility.

What Is the Historical Context of Pipeline Expansion Joints in the B2B Sector?

The evolution of pipeline expansion joints can be traced back to the early 20th century, driven by the need for reliable and flexible piping solutions in industrial applications. Initially, these joints were primarily made from rubber and simple metal configurations, designed to accommodate thermal expansion and contraction in piping systems.

As industries evolved and the demand for more robust solutions grew, the materials and designs of expansion joints advanced significantly. The introduction of high-performance metals and sophisticated engineering techniques in the late 20th century allowed for the development of metal bellows expansion joints, which offered enhanced durability and flexibility.

Today, the pipeline expansion joints market reflects a blend of historical innovation and modern technological advancements, catering to the increasingly complex requirements of global industries. Buyers now benefit from a vast array of options designed to meet stringent performance standards while also addressing sustainability and ethical sourcing concerns.

Frequently Asked Questions (FAQs) for B2B Buyers of pipeline expansion joints

-

How do I solve issues with thermal expansion in pipeline systems?

To address thermal expansion, it’s crucial to choose the right type of expansion joint that can accommodate the expected movements. Metal bellows expansion joints are often recommended for their ability to handle significant thermal movements. Additionally, ensure that the joint is pre-compressed at the factory to allow for proper extension when the pipe contracts. Consulting with a supplier about the specific thermal conditions and movements in your application will help in selecting the most suitable joint. -

What is the best type of expansion joint for high-pressure applications?

For high-pressure applications, double-braided flexible connectors or metal bellows expansion joints designed for elevated pressures are ideal. These products can handle higher stress levels due to their reinforced construction. It’s essential to discuss your specific pressure requirements with suppliers to ensure compliance with safety standards and to determine if custom solutions are necessary. -

How can I ensure the quality of expansion joints sourced internationally?

To ensure quality, consider suppliers with established certifications such as ISO 9001 or those that comply with relevant ASTM standards. Request product samples or detailed submittals before finalizing orders. Additionally, conducting factory audits or third-party inspections can verify the manufacturing processes and quality control measures in place, particularly for suppliers in regions with varying regulatory standards. -

What customization options are available for expansion joints?

Many suppliers offer customization options, including specific sizes, materials, pressure ratings, and configurations tailored to your project needs. Customization can also extend to features like built-in control rods or specific end fittings. It’s advisable to communicate your requirements early in the procurement process to ensure that the supplier can meet your specifications without delays. -

What are the minimum order quantities (MOQ) for expansion joints?

Minimum order quantities can vary significantly between suppliers and depend on the type of expansion joints required. Some manufacturers may have an MOQ as low as 10 units, while others may require larger orders for custom products. Always clarify the MOQ with potential suppliers, especially if you are looking to source specific or customized products. -

What payment terms should I expect when sourcing expansion joints internationally?

Payment terms typically range from 30% upfront and 70% upon delivery to net 30 or net 60 days post-delivery. Factors influencing these terms include the supplier’s policies, your relationship with them, and the size of the order. For larger international transactions, consider using letters of credit or escrow services to mitigate risks and ensure secure payment processes. -

How do logistics and shipping impact the procurement of expansion joints?

Logistics and shipping can significantly affect lead times and costs. Factors such as the distance from the supplier, shipping method (air vs. sea), and import regulations in your country play crucial roles. It’s essential to work with suppliers who have experience in international shipping and can provide detailed information on delivery timelines and customs clearance processes. -

What factors should I consider when vetting potential suppliers for expansion joints?

When vetting suppliers, consider their industry experience, customer reviews, and certifications. Ask for references and case studies of similar projects. Additionally, assess their production capacity, lead times, and after-sales support. Establishing a clear communication channel and understanding their responsiveness can also indicate the level of service you can expect throughout the procurement process.

Top 5 Pipeline Expansion Joints Manufacturers & Suppliers List

1. Garlock – Expansion Joints

Domain: garlock.com

Registered: 1995 (30 years)

Introduction: This company, Garlock – Expansion Joints, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Proco Products – Expansion Joints

Domain: procoproducts.com

Registered: 1998 (27 years)

Introduction: Proco Products is a leading manufacturer of expansion joints for piping and ducting systems, offering a variety of designs in rubber, stainless steel, and polytetrafluoroethylene (PTFE). Their expansion joints are designed to protect equipment against thermal expansion, vibration, and ground movement, ensuring safe and reliable operations while minimizing maintenance downtime. Key features include…

3. EBAA Iron, Inc. – FLEX-TEND® Expansion Joints

Domain: ebaa.com

Registered: 1996 (29 years)

Introduction: EBAA Iron, Inc. offers a range of flexible expansion joints and mechanical joint restraints for pipelines. Key products include: 1. FLEX-TEND® Force Balanced Flexible Expansion Joints (3″ to 48″ sizes), 2. FLEX-TEND® Flexible Expansion Joints (2″ to 48″ sizes), 3. FLEX-TEND® DWV Flexible Expansion Joints (3″ to 8″ sizes), 4. EX-TEND® Force Balanced Expansion and Contraction Joints (4″ to 24″ sizes…

4. Hayward Pipe – Expansion Joints

Domain: haywardpipe.com

Registered: 2005 (20 years)

Introduction: Expansion Joints are components made typically of stainless steel or other corrosion-resistant materials for flexibility and compatibility with different media. They feature an outer braid for added strength and protection, end fittings made from stainless steel, carbon steel, or other compatible materials, and some designs may include an optional liner to reduce turbulence and improve flow. The p…

5. PDBlowers – Pipe Expansion Joints

Domain: pdblowers.com

Registered: 1998 (27 years)

Introduction: Pipe Expansion Joints isolate the blower or vacuum pump from other system components to allow for thermal expansion and misalignment of the piping. Common flanged rubber expansion joints feature single or double arched bellows made of molded elastomers, specifically EPDM elastomer for standard models. Functions include reducing flange loading, allowing thermal expansion, vibration isolation, reduc…

Strategic Sourcing Conclusion and Outlook for pipeline expansion joints

In the evolving landscape of pipeline expansion joints, strategic sourcing plays a crucial role in ensuring reliability and efficiency in various applications across industries. By understanding the diverse offerings—from metal and rubber expansion joints to specialized options tailored for specific environments—international B2B buyers can make informed decisions that enhance operational performance and reduce downtime.

Investing in high-quality expansion joints that meet rigorous standards, such as ASTM F-1120 and ASTM F-2934, ensures compliance with safety regulations while optimizing system functionality. Furthermore, addressing factors like thermal expansion, pressure ratings, and installation environments can lead to significant long-term cost savings and improved system resilience.

As industries in Africa, South America, the Middle East, and Europe seek to expand their infrastructure, the demand for reliable pipeline solutions will continue to rise. Now is the time for buyers to leverage strategic sourcing to secure partnerships with reputable suppliers, ensuring they have access to the latest innovations and best practices in pipeline expansion technology. Embrace this opportunity to enhance your supply chain and drive your projects toward success.

Illustrative image related to pipeline expansion joints

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.