Hinge Pipe: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for hinge pipe

In the ever-evolving global marketplace, sourcing hinge pipe solutions presents a distinct challenge for international B2B buyers, especially those operating in regions like Africa, South America, the Middle East, and Europe. The need for reliable and versatile hinge pipes—critical components in various applications such as construction, manufacturing, and furniture design—demands a comprehensive understanding of the product landscape. This guide will delve into the different types of hinge pipes available, their specific applications, and strategies for effective supplier vetting.

Navigating the complexities of hinge pipe procurement can be daunting. With the increasing demand for quality and durability, making informed purchasing decisions is crucial. This guide empowers B2B buyers by providing actionable insights into pricing structures, material specifications, and key factors that influence cost. Furthermore, we will explore innovative solutions and best practices for integrating hinge pipes into diverse operational frameworks.

By the end of this guide, you will be equipped with the knowledge to confidently select the right hinge pipe solutions tailored to your unique business needs, ensuring optimal functionality and cost-effectiveness. Whether you are in Germany looking for advanced manufacturing options or in Vietnam seeking durable construction materials, this resource is designed to facilitate strategic decision-making in the global hinge pipe market.

Understanding hinge pipe Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Tee Hinge Joint Set Steel | Allows 360-degree rotation; includes nuts and bolts. | Movable doors, foldable shelves. | Pros: Versatile, easy assembly. Cons: Requires installation effort. |

| Heavy Duty Galvanized Hinge Pipe | Robust construction; ideal for outdoor use. | Docks, gates, heavy machinery. | Pros: Durable, rust-resistant. Cons: Heavier, may be costlier. |

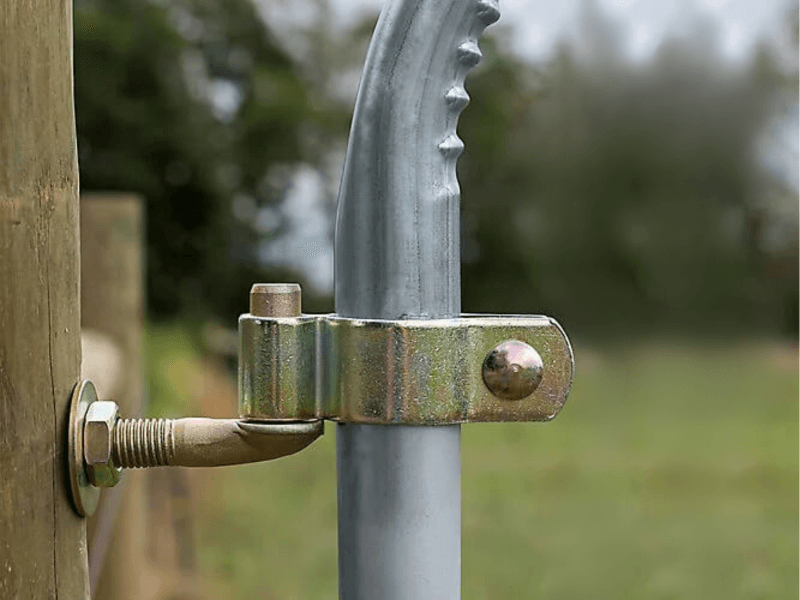

| Adjustable Clamp-on Gate Hinge | Easy installation without welding; adjustable design. | Gates, fences, temporary structures. | Pros: Quick setup, flexible. Cons: Limited weight capacity. |

| Swivel Hinge Pipe | Allows for rotation in multiple directions; often used in adjustable setups. | Machinery, mobile structures. | Pros: High mobility, adaptable. Cons: Complexity in installation. |

| Pivot Hinge Pipe | Designed for pivoting motion; typically used in gates. | Doors, gates, movable barriers. | Pros: Space-efficient, smooth operation. Cons: May require precise alignment. |

What are the Characteristics of Tee Hinge Joint Set Steel?

The Tee Hinge Joint Set Steel is characterized by its ability to rotate 360 degrees, making it a flexible solution for various applications. This type is particularly useful for creating movable doors and foldable shelves, which are common in warehouses and production facilities. B2B buyers should consider its ease of assembly, as it comes with all necessary components. However, the requirement for installation may be a drawback for businesses seeking immediate solutions.

Why Choose Heavy Duty Galvanized Hinge Pipe?

Heavy Duty Galvanized Hinge Pipes are built for strength and longevity, making them ideal for outdoor applications such as docks and gates. Their rust-resistant properties ensure that they withstand harsh weather conditions, which is crucial for projects in regions with extreme climates. Buyers should note the higher weight of these pipes, which might impact shipping costs. However, their durability often justifies the investment.

What Makes Adjustable Clamp-on Gate Hinges a Practical Choice?

Adjustable Clamp-on Gate Hinges are designed for easy, no-weld installation, making them an attractive option for temporary or semi-permanent structures. Their adjustable nature allows for quick modifications, accommodating various gate sizes and weights. While they offer flexibility and speed in setup, buyers should be aware of their limited weight capacity, which may restrict use in more demanding applications.

How Do Swivel Hinge Pipes Enhance Mobility?

Swivel Hinge Pipes are designed to allow rotation in multiple directions, making them suitable for machinery and mobile structures. This feature enhances the adaptability of setups, particularly in dynamic environments where flexibility is essential. B2B buyers should weigh the advantages of high mobility against the potential complexity in installation, as these systems may require more precise engineering.

What Benefits Do Pivot Hinge Pipes Provide?

Pivot Hinge Pipes are specifically engineered for pivoting motion, commonly used in doors and gates. Their design allows for efficient space utilization, making them ideal for environments where space is limited. Buyers should consider the need for precise alignment during installation, as any misalignment can affect functionality. However, their smooth operational capabilities often outweigh this concern, making them a reliable choice for various applications.

Key Industrial Applications of hinge pipe

| Industry/Sector | Specific Application of hinge pipe | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Movable structures and scaffolding | Enhanced flexibility and easy assembly on-site | Durability, load capacity, and compliance with local regulations |

| Agriculture | Gates and fencing solutions | Improved accessibility and security for livestock | Corrosion resistance and compatibility with existing systems |

| Manufacturing | Adjustable shelving and conveyor systems | Increased efficiency and adaptability in production lines | Customization options and ease of installation |

| Marine and Outdoor | Dock and boat lift systems | Safety and reliability for watercraft storage solutions | Weather resistance and material quality for longevity |

| Transportation | Vehicle loading ramps and access points | Streamlined operations and enhanced safety for loading | Weight capacity and material strength to withstand heavy loads |

How Are Hinge Pipes Used in Construction Projects?

In the construction sector, hinge pipes are pivotal for creating movable structures and scaffolding systems. They facilitate quick assembly and disassembly, making them ideal for temporary installations. This flexibility allows construction teams to adapt to changing site conditions efficiently. International buyers must prioritize sourcing hinge pipes that meet rigorous durability standards and are compliant with local building regulations to ensure safety and reliability.

What Role Do Hinge Pipes Play in Agriculture?

In agriculture, hinge pipes are commonly utilized for gates and fencing solutions, providing secure and accessible enclosures for livestock and crops. Their ability to pivot allows for easy entry and exit, enhancing operational efficiency on farms. Buyers, particularly in regions with diverse climates, should consider corrosion-resistant materials to ensure longevity and reduce maintenance costs, especially in humid or saline environments.

Why Are Hinge Pipes Important in Manufacturing Facilities?

Manufacturing facilities leverage hinge pipes in adjustable shelving and conveyor systems, allowing for dynamic configurations that optimize workflow. The adaptability of hinge pipes facilitates seamless transitions between different production processes, enhancing overall efficiency. Buyers should seek customizable solutions that fit their specific operational needs and verify that the materials used can withstand the rigors of a busy manufacturing environment.

How Are Hinge Pipes Used in Marine Applications?

In marine and outdoor settings, hinge pipes are essential for constructing dock systems and boat lifts. They provide a reliable means to secure watercraft while allowing for easy access and storage. Buyers must focus on sourcing weather-resistant materials that can endure harsh marine conditions, ensuring safety and durability over time. It’s crucial to consider the weight capacity of the hinge pipes to accommodate various types of boats and equipment.

What Benefits Do Hinge Pipes Offer in Transportation?

In the transportation sector, hinge pipes are integral to creating vehicle loading ramps and access points. Their design allows for secure and safe loading and unloading of goods, enhancing operational efficiency. When sourcing hinge pipes for this application, businesses should prioritize strength and weight capacity to ensure they can handle heavy loads without compromising safety. Additionally, compatibility with existing loading equipment is a key consideration for seamless integration.

3 Common User Pain Points for ‘hinge pipe’ & Their Solutions

Scenario 1: Difficulty in Sourcing Reliable Hinge Pipe Suppliers

The Problem: International B2B buyers often struggle to find trustworthy suppliers for hinge pipes that meet their specific requirements. This challenge is exacerbated by language barriers, varying quality standards, and regional differences in manufacturing capabilities. Buyers may face delays in production timelines due to unreliable suppliers, leading to project holdups and increased costs. Additionally, the lack of standardized specifications can result in confusion about product quality and compatibility with existing systems.

The Solution: To effectively source hinge pipes, buyers should establish a clear set of specifications that includes material types, dimensions, load capacities, and any necessary certifications. Engaging in thorough market research can help identify reputable suppliers, particularly those with a proven track record in the target regions (e.g., Europe or Africa). Utilizing platforms that facilitate supplier verification, such as trade associations or industry fairs, can also enhance trust. Furthermore, establishing a direct line of communication with potential suppliers can clarify any doubts regarding product quality and delivery timelines, ensuring that the buyer’s needs are fully understood and met.

Illustrative image related to hinge pipe

Scenario 2: Challenges with Installation and Assembly of Hinge Pipe Systems

The Problem: Many buyers encounter difficulties during the installation and assembly of hinge pipe systems, often due to the complexity of the parts and the assembly process. Incomplete or unclear installation instructions can lead to errors that compromise the integrity of the structure, resulting in safety hazards and additional costs for rework. This is particularly relevant for industries that rely on quick setups, such as construction or event management.

The Solution: To mitigate installation challenges, buyers should prioritize purchasing hinge pipe systems that come with comprehensive assembly instructions, including visual aids or video tutorials. Engaging with suppliers who offer pre-assembly services can also significantly reduce the complexity of on-site installations. Additionally, investing in training for staff on proper installation techniques can enhance overall efficiency. Buyers should consider creating a checklist of necessary tools and components prior to installation to ensure all parts are available, thus minimizing delays. Lastly, establishing a feedback loop with the supplier can help address any recurring issues and improve future installations.

Scenario 3: Ensuring Durability and Longevity of Hinge Pipe Systems

The Problem: Buyers often worry about the durability and lifespan of hinge pipe systems, especially in harsh environments like construction sites or outdoor installations. Environmental factors such as moisture, temperature fluctuations, and physical stress can lead to premature wear or failure, resulting in costly repairs and potential safety risks. This concern is particularly prevalent among buyers in regions with extreme weather conditions, such as the Middle East or South America.

The Solution: To enhance the durability of hinge pipe systems, buyers should focus on sourcing high-quality materials that are resistant to environmental stresses. This includes galvanized steel or other corrosion-resistant options that can withstand moisture and temperature extremes. Consulting with suppliers about the environmental conditions the hinge pipes will face can lead to better material recommendations. Furthermore, buyers should consider implementing regular maintenance schedules that include inspections for wear and tear, ensuring any issues are addressed promptly. Investing in protective coatings or treatments can also extend the life of the hinge pipes, providing an additional layer of defense against environmental factors.

Strategic Material Selection Guide for hinge pipe

What Are the Key Properties of Different Materials Used in Hinge Pipe Manufacturing?

When selecting materials for hinge pipes, it is crucial to consider their properties that directly affect performance, such as temperature and pressure ratings, as well as corrosion resistance. The most common materials used in hinge pipe manufacturing include steel, stainless steel, aluminum, and plastic. Each material offers unique benefits and drawbacks that can influence the final product’s suitability for specific applications.

How Does Steel Perform as a Material for Hinge Pipes?

Steel is a popular choice for hinge pipes due to its high strength and durability. It typically has a temperature resistance of up to 400°F (204°C) and can withstand significant pressure, making it suitable for heavy-duty applications. However, steel is prone to corrosion if not properly treated, which can limit its lifespan in harsh environments.

Pros: Steel is relatively low-cost and easy to manufacture, making it accessible for various applications. Its strength allows for use in structural components that require robust support.

Illustrative image related to hinge pipe

Cons: The main limitation is its susceptibility to rust, particularly in humid or corrosive environments. Buyers must consider additional treatments, such as galvanization or powder coating, to enhance corrosion resistance.

For international buyers, compliance with standards like ASTM A36 for structural steel can be critical, especially in regions with strict regulatory environments.

What Advantages Does Stainless Steel Offer for Hinge Pipes?

Stainless steel is another widely used material for hinge pipes, known for its excellent corrosion resistance and aesthetic appeal. It can operate effectively in temperatures ranging from -320°F to 1500°F (-196°C to 815°C), making it suitable for a variety of applications, including food processing and marine environments.

Pros: The primary advantage of stainless steel is its resistance to rust and staining, which extends the lifespan of hinge pipes significantly. It also requires minimal maintenance and is often preferred for its hygienic properties.

Cons: The main drawback is the higher cost compared to regular steel, which may deter budget-conscious buyers. Additionally, the manufacturing process can be more complex, requiring specialized equipment.

International buyers should be aware of standards such as ASTM A304 or A316 for stainless steel, as these can influence procurement decisions based on quality assurance.

Why Choose Aluminum for Hinge Pipes?

Aluminum is a lightweight alternative that offers good corrosion resistance and is often used in applications where weight is a critical factor, such as in aerospace or automotive industries. It can withstand temperatures up to 400°F (204°C) and is suitable for moderate pressure applications.

Pros: The lightweight nature of aluminum makes it easier to handle and install, reducing labor costs. It also has a natural resistance to corrosion, which can be beneficial in outdoor applications.

Cons: Aluminum is generally less strong than steel and can be more expensive to produce. It may not be suitable for heavy-duty applications where high strength is required.

For B2B buyers, understanding the specific grades of aluminum, such as 6061 or 6063, is essential, especially in regions like Europe, where compliance with EN standards may be necessary.

Illustrative image related to hinge pipe

What Role Does Plastic Play in Hinge Pipe Applications?

Plastic, particularly high-density polyethylene (HDPE) and polyvinyl chloride (PVC), is used for hinge pipes in applications requiring chemical resistance and lightweight properties. These materials can typically handle temperatures up to 180°F (82°C) and are often used in plumbing and irrigation systems.

Pros: The primary advantage of plastic is its resistance to corrosion and chemicals, making it ideal for environments where metal would degrade. It is also lightweight and easy to install.

Cons: Plastic hinge pipes can be less durable than metal options and may not withstand high-pressure applications. They can also be affected by UV exposure, leading to degradation over time.

International buyers should consider compliance with standards such as ASTM D1784 for PVC and ASTM D3350 for HDPE, especially in regions with stringent environmental regulations.

Summary Table of Material Selection for Hinge Pipes

| Material | Typical Use Case for hinge pipe | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural applications | High strength and low cost | Prone to corrosion | Low |

| Stainless Steel | Food processing, marine uses | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Aluminum | Aerospace, automotive | Lightweight and corrosion-resistant | Less strength than steel | Medium |

| Plastic | Plumbing, irrigation | Chemical resistance and lightweight | Less durable and UV sensitivity | Low |

In-depth Look: Manufacturing Processes and Quality Assurance for hinge pipe

What Are the Main Stages in the Manufacturing Process of Hinge Pipe?

The manufacturing of hinge pipes involves several critical stages, each designed to ensure that the final product meets the necessary specifications for performance and durability. Here’s a breakdown of the typical stages involved in hinge pipe production:

Material Preparation: What Materials Are Used for Hinge Pipes?

The first step in the manufacturing process is the selection and preparation of raw materials. Common materials for hinge pipes include steel, stainless steel, and sometimes aluminum, depending on the intended application. Steel is often galvanized to prevent rust and corrosion, enhancing the longevity of the hinge pipe in outdoor or moist environments. The material is sourced from certified suppliers to ensure consistency in quality.

Once sourced, the material undergoes rigorous inspection to confirm that it meets specified standards. This includes checking for surface defects, thickness, and chemical composition. Only materials that pass these inspections proceed to the next stage.

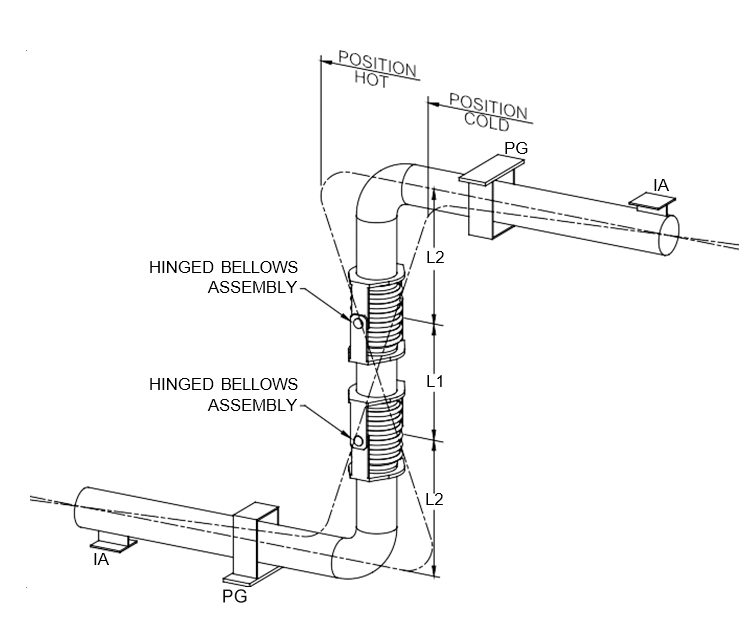

How Is Hinge Pipe Formed During the Manufacturing Process?

The forming stage is where the raw materials are shaped into the desired hinge pipe specifications. This process typically involves techniques such as:

- Stamping and Cutting: Large sheets of metal are stamped into specific shapes using high-pressure machinery. This is a cost-effective method for producing large quantities of hinge pipes with consistent dimensions.

- Bending: Pipes are bent into the required angles for functionality. This may involve CNC machines for precision.

- Welding: For certain designs, components may be welded together to form a complete hinge assembly. This requires skilled welders to ensure structural integrity and strength.

Quality control measures are integrated at this stage, with inspections conducted after each forming process to ensure adherence to design specifications.

Illustrative image related to hinge pipe

What Are the Assembly and Finishing Processes for Hinge Pipes?

After forming, the next step is assembly. This involves the joining of various components, including the hinge brackets, pins, and any additional hardware. Each assembly is tested for movement and functionality to ensure that it operates smoothly.

Finishing processes, such as powder coating or galvanization, are then applied to enhance the aesthetic appeal and protect against environmental wear. These processes not only improve the durability of the hinge pipe but also ensure compliance with international standards regarding environmental impact.

How Is Quality Assurance Implemented in Hinge Pipe Manufacturing?

Quality assurance is vital in ensuring that hinge pipes meet international standards and customer specifications. Manufacturers typically adhere to several relevant standards, including ISO 9001, which outlines criteria for an effective quality management system. Here’s how quality assurance is integrated throughout the manufacturing process:

What Are the Key International Standards for Hinge Pipe Quality Control?

- ISO 9001: This standard emphasizes a process approach to quality management, ensuring that products are consistently produced to meet customer requirements.

- CE Marking: In Europe, CE marking indicates compliance with health, safety, and environmental protection standards for products sold within the European Economic Area.

- API Standards: For hinge pipes used in the oil and gas industry, API standards ensure that products meet specific performance criteria for safety and durability.

These standards guide manufacturers in developing their quality management systems and provide a framework for continuous improvement.

What Are the Critical Quality Control Checkpoints in Hinge Pipe Manufacturing?

Quality control checkpoints are implemented throughout the manufacturing process to identify defects early and ensure product integrity. Key checkpoints include:

- Incoming Quality Control (IQC): At this stage, raw materials are inspected for compliance with specified requirements.

- In-Process Quality Control (IPQC): This involves monitoring the manufacturing processes to ensure that production standards are being met. Regular checks are performed at various stages, such as during forming and assembly.

- Final Quality Control (FQC): After finishing, the final products undergo comprehensive testing, including dimensional checks, functional testing, and sometimes destructive testing to ensure that they can withstand operational stresses.

What Testing Methods Are Commonly Used for Hinge Pipes?

Testing methods vary based on the intended application of the hinge pipe but generally include:

- Dimensional Inspection: Ensures that the hinge pipe meets specified dimensions using calipers and gauges.

- Functional Testing: Assesses the movement and stability of hinge assemblies to confirm they operate as intended.

- Corrosion Testing: Involves exposing samples to corrosive environments to evaluate the durability of protective coatings.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is essential to ensure product reliability. Here are practical steps buyers can take:

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control systems, and compliance with international standards.

- Quality Assurance Reports: Requesting detailed reports on quality control processes, including any certifications and testing results, can provide insights into the supplier’s commitment to quality.

- Third-Party Inspections: Engaging independent third-party inspectors to evaluate the manufacturing facility can offer an unbiased view of the supplier’s quality management practices.

What Are the QC Considerations for International B2B Buyers?

International buyers must also consider the nuances of quality certification in different regions. For example, while CE marking is critical in Europe, other regions may have different regulatory requirements. Buyers should be aware of local standards and certifications relevant to their markets to ensure compliance and avoid potential legal issues.

Additionally, understanding the supply chain dynamics in regions such as Africa, South America, and the Middle East can help in assessing risks related to quality. Factors such as local manufacturing practices, availability of materials, and logistical challenges should be considered when evaluating potential suppliers.

Illustrative image related to hinge pipe

In conclusion, a thorough understanding of the manufacturing processes and quality assurance practices for hinge pipes is crucial for B2B buyers. By focusing on these aspects, buyers can make informed decisions, ensuring they procure high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hinge pipe’

In the competitive landscape of B2B procurement, sourcing the right hinge pipe is essential for ensuring operational efficiency and product reliability. This guide provides a systematic approach to help international buyers navigate the complexities of sourcing hinge pipes, particularly for applications across diverse industries.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the cornerstone of the sourcing process. This includes determining the material (such as galvanized steel or stainless steel), dimensions, weight capacity, and any specific functional requirements like corrosion resistance or adjustability. Defining these parameters upfront helps to streamline supplier searches and ensures compatibility with your existing systems.

Step 2: Conduct Market Research

Understanding market dynamics is crucial for making informed purchasing decisions. Research the current trends in hinge pipe manufacturing, including popular materials and innovative designs that could enhance your projects. Pay attention to regional suppliers who can offer competitive pricing and understand local regulations, especially if you are sourcing from Africa, South America, the Middle East, or Europe.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers who have a proven track record of delivering quality products and reliable service. Additionally, consider their production capacity and lead times to ensure they can meet your demands.

Step 4: Verify Supplier Certifications

Ensure that potential suppliers hold the necessary certifications and adhere to industry standards. Certifications such as ISO 9001 for quality management or specific industry-related approvals can indicate a commitment to quality and safety. Ask for documentation and verify their compliance with international standards, particularly if the hinge pipes will be used in critical applications.

Step 5: Request Samples for Testing

Before finalizing your order, request samples of the hinge pipe products. Testing samples allows you to assess their quality, durability, and compatibility with your existing structures. This step is vital to prevent costly errors and ensures that the products will perform as expected in real-world applications.

Step 6: Discuss Terms and Conditions Clearly

Engage in transparent discussions about payment terms, delivery schedules, and warranties. Clear communication regarding expectations can prevent misunderstandings and build a solid relationship with your supplier. Be sure to negotiate terms that protect your interests, especially regarding returns and defect policies.

Step 7: Establish a Communication Plan

Once you’ve selected a supplier, develop a communication plan to facilitate ongoing dialogue. Regular updates regarding production, shipping, and any potential issues will help maintain transparency and ensure that both parties are aligned throughout the procurement process. Establishing a clear point of contact can streamline communication and enhance collaboration.

By following this checklist, B2B buyers can effectively navigate the sourcing of hinge pipes, ensuring they select the right products and suppliers for their specific needs.

Comprehensive Cost and Pricing Analysis for hinge pipe Sourcing

What Are the Key Cost Components in Hinge Pipe Sourcing?

When analyzing the cost structure for hinge pipe sourcing, several key components come into play. Materials typically account for a significant portion of the total cost. Common materials used in hinge pipe manufacturing include galvanized steel and other high-strength alloys, which provide durability and resistance to corrosion. Labor costs also factor in, particularly in regions with varying wage standards. The complexity of the manufacturing process can further influence labor expenses, especially if skilled labor is required.

Manufacturing overhead encompasses utilities, facility costs, and indirect labor, which can vary greatly depending on the location of the manufacturing plant. Tooling costs are another important consideration, as specialized equipment may be necessary for producing specific hinge designs. Furthermore, quality control (QC) processes are essential to ensure product reliability, and the costs associated with QC can impact pricing.

Logistics should not be overlooked, as transportation and handling fees can vary based on the distance from the supplier to the buyer’s location. Finally, profit margin adds to the final price, which can differ among suppliers based on their business model and market positioning.

How Do Price Influencers Impact Hinge Pipe Sourcing?

Several factors influence the pricing of hinge pipes. Volume and minimum order quantities (MOQ) play a crucial role; larger orders often result in reduced prices per unit due to economies of scale. Customization options, including specific dimensions or finishes, can also affect pricing. Higher specifications or certifications, such as ISO compliance or environmental standards, typically increase costs due to the additional quality assurance measures required.

Supplier factors, including their reputation and reliability, may also influence pricing. Buyers should consider that established suppliers might charge a premium for their products due to their track record of quality and service. Furthermore, understanding Incoterms is vital as they dictate the responsibilities of buyers and sellers in terms of shipping costs and risks.

Illustrative image related to hinge pipe

What Tips Can Help Buyers Negotiate Better Prices for Hinge Pipes?

B2B buyers can leverage several strategies to negotiate better pricing on hinge pipes. First, understanding the total cost of ownership (TCO) is critical. This includes not only the purchase price but also shipping, installation, and maintenance costs over the product’s lifespan.

Buyers should be prepared to negotiate based on volume; presenting larger orders can provide leverage for better pricing. It’s also beneficial to request quotes from multiple suppliers to create a competitive environment.

Additionally, buyers should investigate the total supply chain, as sourcing from local suppliers may minimize logistics costs and lead times, which is particularly advantageous for buyers in Africa, South America, and the Middle East.

Illustrative image related to hinge pipe

Finally, being aware of pricing nuances, such as currency fluctuations and import duties, is crucial for international buyers, especially those in Europe and emerging markets like Vietnam. Understanding these dynamics will help in formulating a comprehensive purchasing strategy.

Conclusion: What Should Buyers Keep in Mind About Pricing for Hinge Pipes?

While prices for hinge pipes can vary widely, understanding the cost components and the factors influencing pricing can empower buyers to make informed decisions. As a general disclaimer, the prices can fluctuate based on market conditions and specific project requirements. Therefore, maintaining open communication with suppliers and staying updated on market trends is essential for securing the best deals in hinge pipe sourcing.

Alternatives Analysis: Comparing hinge pipe With Other Solutions

Exploring Alternatives to Hinge Pipe: A Comprehensive Comparison

In the world of industrial applications, selecting the right hinge solution is crucial for ensuring functionality, durability, and cost-effectiveness. Hinge pipes are a popular choice for various mechanisms, but several alternatives may also serve similar purposes. This section delves into a comparative analysis of hinge pipe against other viable solutions, helping B2B buyers make informed decisions.

| Comparison Aspect | Hinge Pipe | Tee Hinge Joint Set | Adjustable Clamp-on Gate Hinge |

|---|---|---|---|

| Performance | Durable, supports heavy loads | Excellent for sliding/swiveling | Versatile, easy to adjust |

| Cost | Moderate initial investment | Low-cost, around $2.85 | Higher initial cost, around $16.84 |

| Ease of Implementation | Requires assembly and tools | Simple assembly, minimal tools | Easy installation, no tools needed |

| Maintenance | Low, generally robust | Low, but depends on use | Moderate, may require adjustments |

| Best Use Case | Industrial applications, gates | Movable structures, shelves | Gates, doors, and adjustable setups |

What Are the Benefits and Drawbacks of the Tee Hinge Joint Set?

The Tee Hinge Joint Set is an economical choice for applications requiring sliding or swiveling capabilities. Priced affordably, it allows for easy assembly with minimal tools, making it accessible for smaller businesses or projects with budget constraints. However, while it performs well under lighter loads, it may not support the same heavy-duty applications as hinge pipes. Thus, it is best suited for lighter-duty tasks, such as movable shelves or partition doors.

How Does the Adjustable Clamp-on Gate Hinge Compare?

The Adjustable Clamp-on Gate Hinge offers unique flexibility, particularly in installations where adjustments may be necessary over time. It is suitable for gates and doors, allowing for quick modifications without specialized tools. However, the initial investment is higher than that of hinge pipes and Tee Hinges, which may deter cost-sensitive buyers. Additionally, while its versatility is a strong point, it may require more maintenance as adjustments can be needed based on wear over time.

Conclusion: Which Hinge Solution Should B2B Buyers Choose?

When choosing between hinge pipe and its alternatives, B2B buyers should consider specific operational needs, budget constraints, and the intended application. Hinge pipes are ideal for heavy-duty requirements, while Tee Hinge Joint Sets and Adjustable Clamp-on Gate Hinges offer flexibility and ease of use for lighter applications. By assessing performance, cost, ease of implementation, and maintenance needs, buyers can select the most suitable hinge solution for their projects, ensuring optimal functionality and long-term satisfaction.

Essential Technical Properties and Trade Terminology for hinge pipe

What Are the Key Technical Properties of Hinge Pipe?

When selecting hinge pipes for various applications, understanding their technical properties is essential. Here are some critical specifications to consider:

1. Material Grade

Hinge pipes are typically made from materials like galvanized steel, stainless steel, or aluminum. The grade of the material affects strength, corrosion resistance, and durability. For instance, galvanized steel is often used for outdoor applications due to its resistance to rust, while stainless steel is preferred in environments with high moisture levels. B2B buyers should assess material grades to ensure they meet the specific requirements of their projects.

2. Tolerance

Tolerance refers to the permissible limit of variation in the dimensions of the hinge pipe. It is crucial for ensuring that hinge pipes fit accurately with other components in a system. High tolerance levels can enhance the performance and longevity of the installation. Buyers should prioritize suppliers who provide clear tolerance specifications to avoid compatibility issues during assembly.

3. Load Capacity

The load capacity of a hinge pipe indicates how much weight it can support without compromising structural integrity. This property is vital for applications such as gates, doors, or shelving systems, where excessive weight could lead to failure. Understanding load capacity helps businesses make informed decisions about which hinge pipes are suitable for their specific applications.

4. Temperature Resistance

Hinge pipes may be exposed to varying temperature conditions depending on their application. Temperature resistance is a measure of how well the material can withstand extreme heat or cold without losing functionality. For instance, hinge pipes used in outdoor settings or industrial environments should have a higher temperature resistance. Buyers must evaluate this property to ensure longevity and reliability.

5. Surface Finish

The surface finish of hinge pipes, such as powder coating or anodizing, affects both aesthetics and functionality. A quality finish can enhance corrosion resistance and reduce friction in moving parts. B2B buyers should consider surface finishes that align with their specific operational environments and visual requirements.

6. Dimensions and Configuration

The dimensions and configuration of hinge pipes, including diameter and length, are tailored to specific applications. Custom sizes might be necessary for unique projects, and understanding the available configurations can help buyers optimize their designs. Ensuring that the right dimensions are selected is crucial for seamless installation and functionality.

What Are Common Trade Terms Related to Hinge Pipe?

Navigating the procurement process requires familiarity with industry jargon. Here are some common terms that B2B buyers should understand:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the hinge pipe industry, an OEM might supply components that are used in larger systems. Understanding OEM relationships can help buyers identify reliable suppliers and assess product quality.

2. MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. This term is essential for B2B buyers to understand, as it affects inventory management and purchasing strategies. Buyers should negotiate MOQs to align with their project requirements while managing costs effectively.

3. RFQ (Request for Quotation)

An RFQ is a formal document requesting price quotes from suppliers for specific products or services. When dealing with hinge pipes, submitting an RFQ allows businesses to compare prices, terms, and conditions from various manufacturers. This process is critical for making informed purchasing decisions.

Illustrative image related to hinge pipe

4. Incoterms (International Commercial Terms)

Incoterms are standardized terms that define the responsibilities of buyers and sellers in international trade. They clarify who is responsible for shipping, insurance, and tariffs. Understanding Incoterms is vital for B2B transactions involving hinge pipes, as they can significantly impact total costs and delivery times.

5. Lead Time

Lead time refers to the amount of time it takes for a supplier to fulfill an order from the moment it is placed until it is delivered. In the hinge pipe industry, shorter lead times can enhance project timelines. Buyers should inquire about lead times to ensure their supply chain remains efficient.

By understanding these essential technical properties and trade terminology, B2B buyers can navigate the hinge pipe market more effectively, ensuring that they make informed decisions that meet their operational needs.

Navigating Market Dynamics and Sourcing Trends in the hinge pipe Sector

What Are the Current Market Trends in the Hinge Pipe Sector for International Buyers?

The hinge pipe sector is experiencing significant shifts driven by globalization, technological advancements, and evolving buyer preferences. Key drivers include the increasing demand for modular and customizable solutions across industries such as construction, agriculture, and transportation. As international markets expand, particularly in regions like Africa, South America, the Middle East, and Europe, B2B buyers are increasingly seeking suppliers that offer not only high-quality products but also quick turnaround times and flexible ordering processes.

Emerging technologies like automated manufacturing and digital supply chain management are transforming sourcing strategies. Buyers are leveraging e-commerce platforms and digital marketplaces to streamline procurement, allowing for easier comparison of products and prices. Additionally, the rise of Industry 4.0 is encouraging manufacturers to adopt smart technologies that enhance product design and efficiency, making it easier for buyers to access innovative hinge solutions tailored to their specific needs.

Furthermore, sustainability is becoming a pivotal factor in sourcing decisions. Buyers are increasingly focused on suppliers’ environmental credentials, pushing manufacturers to adopt greener practices in production and distribution. As a result, companies that prioritize eco-friendly materials and processes are likely to gain a competitive edge in the market.

How Does Sustainability Impact Sourcing Decisions in the Hinge Pipe Sector?

Sustainability has emerged as a critical consideration in the hinge pipe sector, reflecting a broader shift in B2B procurement practices. The environmental impact of manufacturing processes—ranging from resource extraction to waste generation—has prompted buyers to prioritize ethical sourcing. Companies are now more inclined to partner with suppliers who demonstrate a commitment to reducing their carbon footprint and implementing sustainable practices.

Buyers are increasingly seeking products that come with certifications indicating environmental responsibility. Materials such as recycled steel and eco-friendly coatings are becoming more popular as businesses aim to meet regulatory requirements and consumer expectations for sustainability. Additionally, suppliers that provide transparency in their supply chains, including sourcing practices and labor conditions, are favored by buyers looking to align with ethical business standards.

As global regulations tighten around environmental impacts, companies in the hinge pipe sector must adapt their practices to remain compliant while also appealing to eco-conscious buyers. This trend not only fosters brand loyalty but also positions companies favorably in a market that is shifting toward sustainability.

What Is the Historical Context of Hinge Pipes in the B2B Landscape?

The hinge pipe has evolved significantly from its early applications in construction and agriculture to a versatile component used across various industries today. Historically, hinge pipes were primarily crafted from basic materials, focusing on functionality over form. However, as industrial processes advanced, manufacturers began to explore diverse materials and designs, enhancing durability and performance.

In the last few decades, the introduction of galvanized and coated hinge pipes has revolutionized their use, offering improved resistance to corrosion and wear. This evolution reflects broader trends in manufacturing, where innovation and customization have become essential to meet the diverse needs of international buyers. As the market continues to evolve, the hinge pipe sector remains poised for growth, driven by technological advancements and a growing focus on sustainability.

Frequently Asked Questions (FAQs) for B2B Buyers of hinge pipe

-

How do I choose the right hinge pipe for my application?

Selecting the appropriate hinge pipe involves understanding your specific application requirements. Consider factors such as load capacity, environmental conditions (e.g., exposure to moisture or chemicals), and the type of movement needed (swiveling, sliding, etc.). Consult with suppliers to review technical specifications, including material composition and strength ratings. It’s also beneficial to request samples or prototypes to assess compatibility with your existing systems before making a bulk purchase. -

What are the most common materials used for hinge pipes?

Hinge pipes are typically made from materials like steel, aluminum, or plastic. Steel is favored for its strength and durability, especially in heavy-duty applications. Aluminum offers a lighter alternative with good corrosion resistance, making it suitable for outdoor use. Plastic hinge pipes can be utilized in less demanding environments where weight and cost savings are priorities. Always verify the material’s compatibility with your operational conditions to ensure longevity. -

What is the minimum order quantity (MOQ) for hinge pipes?

MOQs for hinge pipes can vary significantly based on the manufacturer and the specific product line. Typically, manufacturers may set MOQs ranging from 100 to 500 units, depending on production costs and material availability. It is advisable to negotiate with suppliers, especially if you require a custom size or design. Some suppliers may offer flexibility in MOQs for initial orders or trial runs. -

How do I verify the reliability of a hinge pipe supplier?

To assess a supplier’s reliability, conduct thorough research including checking their business credentials, customer reviews, and industry certifications. Request references from past clients and evaluate their response times and customer service quality. Additionally, visiting the supplier’s facility can provide insights into their manufacturing processes and quality control measures, ensuring they meet your standards and expectations. -

What customization options are available for hinge pipes?

Many manufacturers offer customization options for hinge pipes, including variations in size, shape, material, and finish. Custom designs can accommodate specific operational needs, such as unique load requirements or environmental conditions. When considering customization, discuss your requirements with the supplier early in the process to determine feasibility and any associated costs or lead times. -

What payment terms should I expect when sourcing hinge pipes internationally?

International payment terms can vary widely among suppliers. Common arrangements include advance payments, letters of credit, or payment upon receipt of goods. Discuss terms upfront to avoid misunderstandings, and consider utilizing secure payment methods that provide protection for both parties. It’s also wise to clarify any currency exchange implications, especially if you’re dealing with suppliers in different countries. -

How can I ensure quality assurance (QA) for my hinge pipe orders?

Establishing a robust QA process is crucial when sourcing hinge pipes. Request detailed quality control documentation from your supplier, including certifications and inspection reports. Consider implementing third-party inspections at various stages of production, especially for large orders. Regular communication with your supplier about quality expectations and potential issues can also help mitigate risks. -

What logistics considerations should I keep in mind when importing hinge pipes?

When importing hinge pipes, factor in shipping methods, lead times, and customs regulations. Assess the most cost-effective and timely shipping options, whether by air or sea, and understand the potential tariffs or duties applicable to your order. Collaborate with logistics providers experienced in international trade to ensure compliance with all import regulations, thereby minimizing delays and unexpected costs during transit.

Top 4 Hinge Pipe Manufacturers & Suppliers List

1. Spring Creek Products – Pipe Hinges

Domain: springcreekproducts.com

Registered: 2008 (17 years)

Introduction: This company, Spring Creek Products – Pipe Hinges, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. BulletFence – Adjustable Clamp-on Gate Hinge Pair

Domain: bulletfence.com

Registered: 2015 (10 years)

Introduction: Adjustable Clamp-on gate hinge pair from $16.84 USD

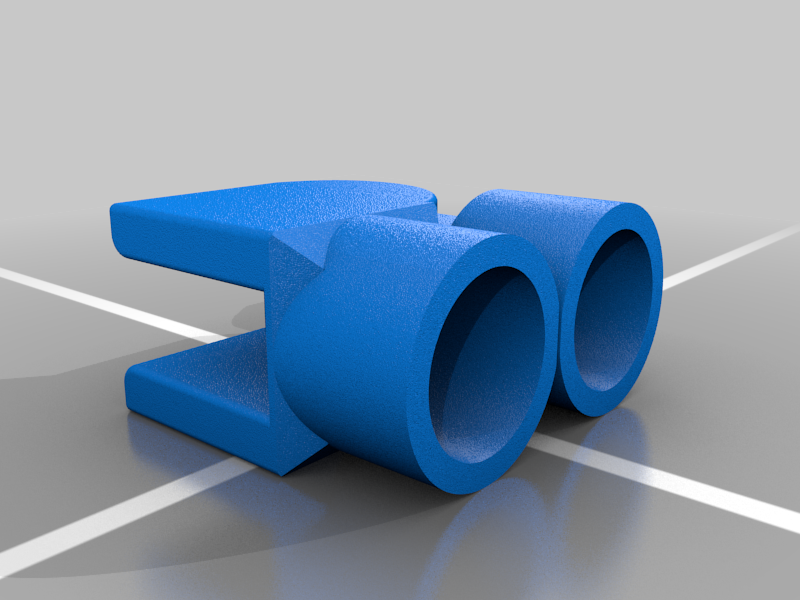

3. Flexpipe – Double Pipe Single Hinge Set Steel

Domain: shop.flexpipeinc.com

Registered: 2011 (14 years)

Introduction: {“SKU”:”HJ-23″,”Product Name”:”Double Pipe Single Hinge Set Steel”,”Material”:”Hot rolled steel (SPHC) with black cathodic electrodeposition (Ecoating)”,”Dimensions”:{“Length”:”3 13/16 in (97 mm)”,”Height”:”1 7/8 in (48 mm)”,”Width”:”1 5/16 in (33 mm)”},”Material Thickness”:”1/8 in (2.5 mm)”,”Weight”:”0.315 lb (0.143 kg)”,”Temperature Resistance”:”-148°F to 572°F (-100°C to 300°C)”,”Electric Condu…

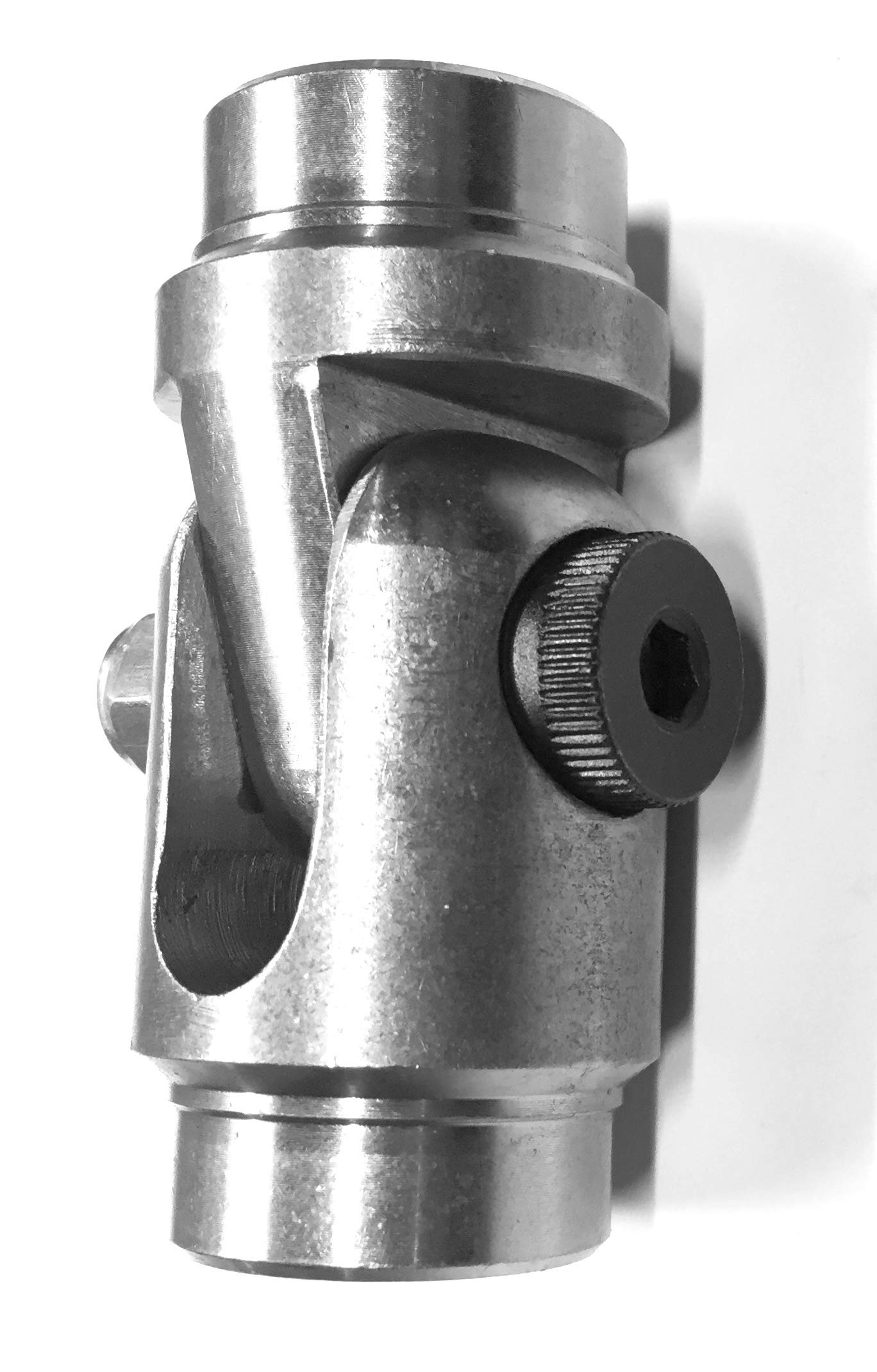

4. Maker Pipe – Barrel Hinge

Domain: makerpipe.com

Registered: 2012 (13 years)

Introduction: {“product_name”:”Barrel Hinge”,”price”:”$8.49″,”availability”:”Out of Stock”,”dimensions”:{“height”:”4 inches”,”outside_diameter”:”0.94 inches”},”compatibility”:”3/4 inch Maker Pipe Connectors”,”description”:”These inline barrel hinges are incredibly useful for creating doors and adding motion to EMT Conduit builds. To use it, simply clamp 3/4″ Maker Pipe Connectors around the top and bottom half …

Strategic Sourcing Conclusion and Outlook for hinge pipe

As international markets continue to evolve, the strategic sourcing of hinge pipes presents a unique opportunity for B2B buyers to enhance operational efficiency and reduce costs. By leveraging high-quality materials such as galvanized steel and advanced manufacturing techniques, companies can ensure product durability and reliability across various applications—from construction to industrial machinery.

Investing in strategic sourcing not only fosters better supplier relationships but also enables buyers to adapt to changing market demands, particularly in regions such as Africa, South America, the Middle East, and Europe. Buyers are encouraged to evaluate suppliers who offer comprehensive product lines, competitive pricing, and robust support services, ensuring that they can meet diverse project requirements effectively.

Looking ahead, the demand for innovative hinge pipe solutions is set to grow, driven by increased infrastructure development and industrialization. B2B buyers are urged to take proactive steps in their sourcing strategies, focusing on collaboration with suppliers who are committed to quality and sustainability. Embrace the future of hinge pipe procurement by engaging with trusted partners today, positioning your business for success in a competitive global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to hinge pipe

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.