Everything You Need to Know About 60 Volt Dc Power Supply Sourcing in 2025

Introduction: Navigating the Global Market for 60 volt dc power supply

In the rapidly evolving landscape of industrial applications, sourcing a reliable 60 volt DC power supply poses significant challenges for B2B buyers, particularly in emerging markets such as Africa, South America, the Middle East, and Europe. As the demand for efficient and robust power solutions grows, understanding the intricacies of these power supplies—from their specifications to their applications—becomes crucial for making informed purchasing decisions. This comprehensive guide is designed to navigate these complexities, providing insights into various types of 60 volt DC power supplies, their specific applications across industries, and essential criteria for supplier vetting.

Throughout this guide, we will explore the diverse range of 60 volt DC power supplies available on the market, including their configurations, performance metrics, and the latest technological advancements. We will also address critical factors such as pricing strategies, warranty considerations, and the importance of compliance with international standards. By equipping B2B buyers with actionable insights and practical knowledge, this resource aims to empower you to make strategic decisions that align with your operational needs and budget constraints.

In a global market where reliable power solutions are essential for maintaining operational efficiency, this guide serves as a vital tool for businesses in countries like Vietnam and Nigeria, ensuring that you can confidently source the right 60 volt DC power supply to meet your unique requirements.

Understanding 60 volt dc power supply Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Linear Power Supplies | High precision, low noise, simple design | Laboratory equipment, medical devices | Pros: Stable output, easy to design; Cons: Less efficient, bulkier. |

| Switching Power Supplies | High efficiency, compact size, adjustable output | Telecommunications, industrial automation | Pros: Lightweight, energy-efficient; Cons: Potential for electrical noise. |

| Unregulated Power Supplies | Simple construction, low cost | Basic electronic devices, testing equipment | Pros: Cost-effective; Cons: Less stable output, sensitive to load variations. |

| Programmable Power Supplies | Adjustable voltage and current settings | Research and development, prototyping | Pros: Versatile, customizable; Cons: Higher initial investment. |

| Rack Mount Power Supplies | Designed for installation in standard racks | Data centers, server farms | Pros: Space-saving, easy integration; Cons: Requires additional infrastructure. |

What Are Linear Power Supplies and When Should They Be Used?

Linear power supplies are known for their precision and low noise output, making them ideal for sensitive applications such as laboratory equipment and medical devices. These supplies maintain a stable voltage regardless of load changes, which is crucial for applications requiring high reliability. However, they tend to be less efficient than other types, generating more heat and taking up more physical space. Buyers should consider their specific power needs and the importance of output stability versus efficiency when choosing this type.

How Do Switching Power Supplies Differ from Other Types?

Switching power supplies are characterized by their high efficiency and compact design, making them suitable for various applications, including telecommunications and industrial automation. They convert power using high-frequency switching techniques, which allows for a smaller form factor. While they are energy-efficient, buyers should be aware of potential electrical noise that could affect sensitive equipment. When selecting a switching power supply, consider the balance between efficiency and electromagnetic interference.

Illustrative image related to 60 volt dc power supply

What Are the Advantages of Unregulated Power Supplies?

Unregulated power supplies feature a simple construction and low cost, making them attractive for basic electronic devices and testing equipment. They provide a straightforward solution for applications where precise voltage regulation is not critical. However, their output can fluctuate significantly with load changes, which may not be suitable for all applications. Buyers should assess the importance of cost versus stability based on their project requirements.

Why Choose Programmable Power Supplies for Your Applications?

Programmable power supplies offer adjustable voltage and current settings, making them highly versatile for research, development, and prototyping. They allow users to customize their power delivery based on specific test requirements, enabling greater flexibility in experimental setups. While they typically come with a higher initial investment, the long-term benefits of adaptability and efficiency can justify the cost for businesses focused on innovation.

What Should You Know About Rack Mount Power Supplies?

Rack mount power supplies are designed for easy integration into standard server racks, making them a popular choice for data centers and server farms. They maximize space efficiency while providing reliable power to critical systems. However, implementing rack mount solutions may require additional infrastructure, such as cooling and mounting systems. Buyers should consider their existing setups and future scalability needs when evaluating this type of power supply.

Key Industrial Applications of 60 volt dc power supply

| Industry/Sector | Specific Application of 60 volt dc power supply | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Telecommunications | Powering telecom equipment and base stations | Ensures reliable communication and service uptime | Durability, efficiency ratings, and compliance with local standards |

| Manufacturing | Operating industrial machinery and robotics | Enhances production efficiency and reduces downtime | Customization options, output stability, and safety features |

| Renewable Energy | Supporting solar and wind energy systems | Facilitates energy storage and conversion processes | Scalability, integration capabilities, and environmental compliance |

| Automotive | Charging electric vehicle (EV) batteries | Supports the transition to sustainable transport | Fast charging capabilities, safety certifications, and compatibility with various EV models |

| Laboratory Equipment | Running scientific instruments and testing devices | Provides precise and stable power for accurate results | Voltage regulation, thermal management, and reliability under variable loads |

How Is a 60 Volt DC Power Supply Used in Telecommunications?

In the telecommunications sector, a 60 volt DC power supply is crucial for powering base stations and communication equipment. This application ensures that systems remain operational, providing uninterrupted service to users. For international buyers, especially in regions like Africa and South America, sourcing power supplies with high efficiency and reliability is vital to meet the demands of growing telecom networks. Additionally, considerations such as compliance with local electrical standards and the ability to withstand harsh environmental conditions are essential.

What Role Does 60 Volt DC Power Supply Play in Manufacturing?

In manufacturing, 60 volt DC power supplies are used to operate various industrial machinery, including robotics and automated systems. This application enhances production efficiency by providing stable and reliable power, thereby minimizing downtime caused by power fluctuations. Buyers from the Middle East and Europe should focus on sourcing power supplies that offer customization options to fit specific machinery requirements, as well as features like overload protection and thermal management to ensure safe operation.

How Is 60 Volt DC Power Supply Beneficial in Renewable Energy?

The renewable energy sector utilizes 60 volt DC power supplies primarily for solar and wind energy systems. These supplies play a critical role in energy storage and conversion, allowing for effective management of energy resources. For businesses in Africa and South America, sourcing power supplies that are scalable and capable of integration with existing systems is crucial. Additionally, compliance with environmental regulations and energy efficiency standards can significantly enhance the sustainability of operations.

How Does 60 Volt DC Power Supply Facilitate the Automotive Industry?

In the automotive sector, particularly in electric vehicles (EVs), 60 volt DC power supplies are essential for charging batteries. They support the shift towards sustainable transport by enabling fast and efficient charging solutions. International buyers, especially in emerging markets, should prioritize sourcing power supplies that offer fast charging capabilities and compatibility with various EV models. Safety certifications are also important to ensure compliance with automotive standards.

What Is the Importance of 60 Volt DC Power Supply in Laboratory Equipment?

Laboratories rely on 60 volt DC power supplies to run sensitive scientific instruments and testing devices. This application requires precise voltage regulation to ensure accurate test results and reliable performance. For B2B buyers in Europe and beyond, sourcing power supplies that offer thermal management and reliability under variable loads is essential. Additionally, understanding the specific power requirements of laboratory equipment can help in selecting the right power supply solution.

3 Common User Pain Points for ’60 volt dc power supply’ & Their Solutions

Scenario 1: Inconsistent Power Delivery Affecting Equipment Performance

The Problem: Many B2B buyers, especially those in manufacturing or industrial sectors, face challenges with inconsistent power delivery from their 60V DC power supplies. Fluctuations in voltage can lead to equipment malfunctions, resulting in production delays and increased operational costs. For instance, if a power supply does not maintain a stable voltage output, sensitive electronic components may become damaged, leading to costly repairs or replacements. Additionally, the variability can create safety hazards, further complicating the operational environment.

The Solution: To combat this issue, buyers should prioritize sourcing power supplies with built-in voltage regulation features. Look for models that offer constant voltage/current operation, ensuring a stable output even when input voltage varies. It’s also advisable to invest in power supplies that include overvoltage protection and monitoring capabilities, which can provide alerts for any irregularities in performance. When specifying a power supply, consider integrating a power management system that can adjust output based on real-time feedback from the equipment, thus maintaining optimal performance and minimizing the risk of damage.

Scenario 2: Limited Availability of Custom Solutions for Unique Applications

The Problem: In many cases, B2B buyers require a 60V DC power supply tailored to specific applications or environments, such as harsh industrial settings or unique equipment requirements. However, they often find that standard models do not meet their needs, leading to frustration and delays in project timelines. This lack of customization can impede innovation, as companies are unable to effectively power new technologies or solutions that could give them a competitive edge.

The Solution: Buyers should actively seek suppliers that offer customizable power supply solutions. Engage with manufacturers who have a robust engineering team capable of designing tailored systems based on precise specifications. For instance, if a company operates in an environment with high temperatures or dust, they might need a power supply with enhanced thermal management or IP-rated enclosures. Requesting a consultation with an engineering team can facilitate the development of a bespoke solution, ensuring that the power supply not only meets voltage requirements but also complies with environmental standards and operational needs.

Scenario 3: Difficulty in Sourcing Reliable Suppliers

The Problem: Sourcing a reliable 60V DC power supply can be a daunting task for B2B buyers, particularly in regions with less access to quality electronics. Buyers often encounter difficulties with supplier reliability, including inconsistent product quality, lack of support, and extended lead times for deliveries. This can disrupt project timelines, complicate supply chain logistics, and ultimately lead to increased costs.

The Solution: To mitigate these risks, buyers should conduct thorough due diligence on potential suppliers before making purchasing decisions. Look for vendors with a proven track record in the industry, as evidenced by customer testimonials, certifications, and quality assurance processes. Additionally, consider establishing relationships with suppliers who offer comprehensive support, including technical assistance and after-sales service. Prioritize those who can provide transparency in their manufacturing processes and have established logistics capabilities to ensure timely delivery. Engaging in long-term partnerships with reputable suppliers can enhance reliability and reduce future procurement challenges, fostering a more seamless operational experience.

Strategic Material Selection Guide for 60 volt dc power supply

What Materials Are Commonly Used in 60 Volt DC Power Supplies?

When selecting materials for 60 volt DC power supplies, it is essential to consider their properties, advantages, and limitations to ensure optimal performance and compliance with international standards. Below, we analyze four common materials used in the construction of these power supplies.

How Does Aluminum Perform as a Material for 60 Volt DC Power Supplies?

Key Properties: Aluminum is lightweight, has excellent thermal conductivity, and is resistant to corrosion. It typically withstands temperatures up to 150°C and can handle moderate pressure.

Pros & Cons: The primary advantage of aluminum is its low weight, which facilitates easier installation and transport. It is also relatively inexpensive compared to other metals. However, aluminum can be less durable than alternatives like steel, especially in harsh environments, and may require additional protective coatings to enhance its corrosion resistance.

Impact on Application: Aluminum is suitable for applications where weight is a critical factor, such as portable power supplies. However, its lower mechanical strength may limit its use in high-stress environments.

Considerations for International Buyers: Buyers from regions such as Africa and South America should consider local corrosion factors (like humidity and salt exposure) and ensure compliance with relevant standards such as ASTM B209 for aluminum alloys.

What Role Does Copper Play in 60 Volt DC Power Supply Construction?

Key Properties: Copper has excellent electrical conductivity, thermal conductivity, and resistance to corrosion. It can operate effectively at temperatures up to 200°C.

Pros & Cons: The primary advantage of copper is its superior conductivity, which makes it ideal for power distribution. However, it is more expensive than aluminum and can be prone to oxidation if not properly insulated.

Impact on Application: Copper is essential in applications requiring efficient energy transfer, such as in transformers and connectors. Its high conductivity ensures minimal energy loss.

Considerations for International Buyers: Buyers should be aware of the fluctuating copper prices and consider sourcing from local suppliers to mitigate costs. Compliance with standards such as ASTM B170 for copper wire may also be necessary.

Illustrative image related to 60 volt dc power supply

Why Is Steel a Preferred Material for Structural Components in Power Supplies?

Key Properties: Steel offers high tensile strength, durability, and resistance to deformation. It can withstand high temperatures and pressures, making it suitable for heavy-duty applications.

Pros & Cons: The main advantage of steel is its strength and durability, which makes it ideal for structural components. However, it is heavier than aluminum and can be susceptible to corrosion if not treated.

Impact on Application: Steel is commonly used in the frames and enclosures of power supplies, providing robust protection for internal components. Its strength is crucial in environments where mechanical stress is a concern.

Considerations for International Buyers: Buyers should ensure that steel components meet relevant standards such as ASTM A36 for structural steel. In humid regions, additional corrosion protection may be necessary.

How Does Plastic Contribute to the Design of 60 Volt DC Power Supplies?

Key Properties: Plastics are lightweight, non-conductive, and resistant to corrosion. They can operate at varying temperatures, depending on the type of plastic used.

Pros & Cons: The primary advantage of plastic is its versatility and low cost. It is easy to mold into complex shapes, which can reduce manufacturing complexity. However, plastics may not withstand high temperatures as well as metals and can be less durable in extreme conditions.

Impact on Application: Plastics are often used for insulating components and housing, providing safety and protection against electrical hazards. They are suitable for applications where weight and cost efficiency are priorities.

Considerations for International Buyers: Buyers should look for plastics that comply with international standards, such as UL 94 for flammability. In regions with high UV exposure, UV-resistant plastics may be necessary.

Illustrative image related to 60 volt dc power supply

Summary Table of Material Selection for 60 Volt DC Power Supplies

| Material | Typical Use Case for 60 volt dc power supply | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight enclosures and heat sinks | Low weight and good thermal conductivity | Less durable in harsh environments | Medium |

| Copper | Conductors and connectors | Superior electrical conductivity | Higher cost and oxidation risk | High |

| Steel | Structural frames and enclosures | High strength and durability | Heavier and prone to corrosion | Medium |

| Plastic | Insulation and housing | Lightweight and cost-effective | Limited high-temperature resistance | Low |

This analysis provides a comprehensive overview of material options for 60 volt DC power supplies, helping international B2B buyers make informed decisions based on performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for 60 volt dc power supply

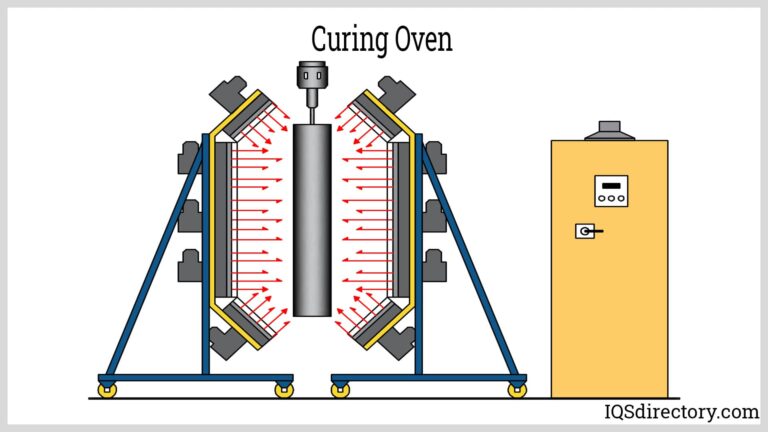

What Are the Key Stages in the Manufacturing Process of a 60 Volt DC Power Supply?

The manufacturing process of a 60 Volt DC power supply involves several critical stages that ensure the final product meets the desired specifications and quality standards. Understanding these stages is essential for B2B buyers who are looking to source reliable power supplies for their operations.

Material Preparation: How Are Raw Materials Selected and Processed?

The first step in manufacturing a 60 Volt DC power supply is material preparation. This involves sourcing high-quality components such as transformers, capacitors, resistors, and semiconductors, all of which must comply with industry standards. Suppliers typically conduct rigorous assessments to ensure that materials meet specifications for electrical performance and durability.

Once sourced, the raw materials undergo processing, which may include cutting, molding, and soldering. Precision in this stage is crucial, as even minor defects can lead to failures in the final product. Manufacturers often employ automated machinery to enhance accuracy and reduce human error.

What Techniques Are Used in the Forming Stage of Production?

Following material preparation, the forming stage begins, where components are shaped and assembled. This stage often employs techniques such as:

- PCB Fabrication: Printed Circuit Boards (PCBs) are fabricated using photolithography, etching, and solder mask application. This is a critical step, as the PCB serves as the backbone for electrical connections in the power supply.

- Component Mounting: After PCB fabrication, components are mounted using surface mount technology (SMT) or through-hole technology. Automation in this stage can significantly increase production efficiency and consistency.

Additionally, manufacturers may utilize thermal management techniques, such as heat sinks and thermal paste, to ensure that the power supply operates within safe temperature ranges.

How Is Assembly Conducted for Optimal Performance?

The assembly stage involves integrating all components into a cohesive unit. This can be done through various methods, including:

- Manual Assembly: Skilled technicians assemble components, ensuring proper alignment and connection. This method is beneficial for low-volume production or custom builds.

- Automated Assembly: For mass production, automated assembly lines are employed, which can rapidly integrate components while maintaining high precision.

Quality checks are integrated throughout the assembly process to catch defects early. This includes visual inspections and initial electrical testing.

What Finishing Processes Are Essential Before Quality Control?

Once assembled, the power supply undergoes finishing processes. These include:

- Enclosure: The unit is housed in a protective enclosure, which is crucial for safety and durability. The choice of materials for the enclosure can affect thermal performance and electromagnetic interference (EMI).

- Labeling and Documentation: Proper labeling is essential for user guidance and compliance with regulatory standards. Documentation, including specifications and user manuals, is prepared for distribution.

How Is Quality Assurance Implemented in Manufacturing 60 Volt DC Power Supplies?

Quality assurance is paramount in the manufacturing of 60 Volt DC power supplies. Adhering to international and industry-specific standards ensures reliability and safety for end-users.

What International Standards Should B2B Buyers Look For?

Manufacturers of power supplies often comply with international standards, such as ISO 9001, which focuses on quality management systems. This certification indicates that a manufacturer has established processes to meet customer and regulatory requirements consistently. Additionally, CE marking is essential for products sold in Europe, signaling compliance with safety, health, and environmental protection standards.

Other relevant certifications may include API (American Petroleum Institute) standards for power supplies used in industrial applications, particularly in the oil and gas sector.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) is typically structured around three main checkpoints:

- Incoming Quality Control (IQC): This involves inspecting raw materials and components upon arrival to ensure they meet specifications before production begins.

- In-Process Quality Control (IPQC): During production, various tests are conducted to monitor the assembly process. This includes checking solder joints, electrical connections, and thermal management systems.

- Final Quality Control (FQC): Once the power supply is assembled, it undergoes comprehensive testing, including load testing, thermal cycling, and safety assessments to confirm performance under specified conditions.

What Testing Methods Are Commonly Used to Ensure Product Reliability?

Testing methods employed for quality assurance of 60 Volt DC power supplies include:

- Electrical Testing: This verifies that the power supply outputs the correct voltage and current under load conditions.

- Environmental Testing: Assessing the unit’s performance under various environmental conditions, such as temperature extremes and humidity, helps ensure reliability in real-world applications.

- Safety Testing: Ensuring compliance with safety standards through high-voltage and insulation resistance tests is crucial for preventing electrical hazards.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are actionable steps:

Illustrative image related to 60 volt dc power supply

- Conduct Audits: Regular audits of suppliers can provide insights into their manufacturing processes and adherence to quality standards.

- Request Quality Reports: Suppliers should provide documentation of their quality control processes and test results, including certifications and compliance with relevant standards.

- Third-Party Inspections: Engaging third-party inspection services can add an additional layer of verification. These organizations can conduct independent assessments of the supplier’s quality assurance practices.

What Are the Quality Control Nuances for International Buyers?

International buyers must be aware of specific nuances when sourcing power supplies. Understanding local regulations and compliance requirements can prevent costly delays and ensure that products are market-ready. Additionally, cultural differences in business practices and communication styles should be taken into account when establishing supplier relationships.

By prioritizing quality assurance and understanding the manufacturing processes behind 60 Volt DC power supplies, B2B buyers can make informed decisions, ensuring they select reliable suppliers that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ’60 volt dc power supply’

This guide provides a comprehensive checklist for international B2B buyers looking to procure a 60 volt DC power supply. With the increasing demand for reliable power solutions in various industries, understanding the sourcing process is essential for ensuring quality and efficiency.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications required for your application. This includes the output voltage, current capacity, power rating, and any specific features such as programmability or redundancy.

– Output Voltage and Current: Ensure the power supply meets the exact voltage (60V) and current requirements for your devices.

– Power Rating: Consider the total wattage needed for your operations to avoid underperformance.

Step 2: Research Market Options

Conduct thorough research to identify potential suppliers who offer 60V DC power supplies. Utilize industry directories, trade shows, and online marketplaces to gather a list of candidates.

– Supplier Reputation: Look for established companies with a proven track record in the power supply market.

– Product Range: Evaluate if they offer a variety of models, including single and multi-output options, to meet diverse needs.

Step 3: Evaluate Potential Suppliers

Before making a commitment, vet suppliers comprehensively. Request company profiles, case studies, and references from buyers in similar industries or regions.

– Quality Certifications: Verify that the suppliers hold relevant certifications (e.g., ISO 9001) to ensure product quality and reliability.

– Customer Reviews: Look for feedback on the supplier’s responsiveness and service quality.

Step 4: Assess Compliance with International Standards

Ensure that the power supplies comply with international safety and performance standards. This is particularly crucial for buyers in regions with stringent regulations.

– Safety Certifications: Check for certifications like CE, UL, or RoHS, which indicate compliance with safety regulations.

– Testing Procedures: Inquire about the testing processes the manufacturer employs to ensure product reliability.

Step 5: Request Samples for Testing

Once you have shortlisted suppliers, request samples of the power supplies for testing in your specific applications. This allows you to evaluate performance and compatibility.

– Testing Conditions: Conduct tests under the same conditions expected during normal operation to gauge performance accurately.

– Documentation: Ensure you receive detailed technical documentation, including datasheets and user manuals, to assist in the testing process.

Step 6: Negotiate Terms and Pricing

Engage in negotiations to establish favorable terms and pricing. This step is crucial for optimizing your procurement budget while ensuring quality.

– Bulk Discounts: Discuss potential discounts for bulk purchases, which can significantly reduce costs.

– Warranty and Support: Clarify warranty terms and the level of technical support available post-purchase.

Step 7: Finalize Purchase and Logistics

After selecting the supplier, finalize the purchase agreement and logistics arrangements. Consider factors such as shipping times, costs, and delivery terms.

– Lead Times: Confirm lead times for production and delivery to ensure alignment with your operational schedule.

– Customs and Import Regulations: Be aware of customs requirements and import regulations in your country to avoid delays upon arrival.

Following this checklist will help you make informed decisions when sourcing a 60V DC power supply, ensuring that you select the right solution for your business needs.

Comprehensive Cost and Pricing Analysis for 60 volt dc power supply Sourcing

When sourcing 60 volt DC power supplies, understanding the comprehensive cost structure is vital for international B2B buyers. The costs associated with these power supplies can be broken down into several key components, each influencing the final pricing.

What Are the Key Cost Components for 60 Volt DC Power Supplies?

-

Materials: The raw materials used in manufacturing 60 volt DC power supplies, such as transformers, capacitors, and printed circuit boards (PCBs), significantly impact the overall cost. Higher-quality components may lead to increased durability and efficiency but come at a premium.

-

Labor: Labor costs vary by region and can influence pricing. In countries with higher labor costs, the overall price of power supplies may be higher. Conversely, sourcing from regions with lower labor costs might reduce expenses but could affect quality assurance.

-

Manufacturing Overhead: This includes costs related to utilities, rent, and equipment depreciation. Manufacturers with advanced facilities and technology may have lower per-unit overhead costs, allowing them to offer competitive pricing.

-

Tooling: The initial investment in specialized tools and molds for production can be substantial. These costs are often amortized over the production volume, meaning that higher volume orders can reduce the per-unit tooling cost.

-

Quality Control (QC): Rigorous QC processes ensure that power supplies meet international standards. This can add to costs but is essential for reliability, especially in critical applications.

-

Logistics: Shipping and handling costs can vary significantly based on the supplier’s location and the destination. Factors like freight rates, customs duties, and insurance should be considered as they can considerably affect the total cost.

-

Margin: Suppliers will mark up their costs to ensure profitability. This margin can vary based on market competition, brand reputation, and perceived value.

What Influences the Pricing of 60 Volt DC Power Supplies?

Several factors can influence the pricing structure of 60 volt DC power supplies:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases typically result in lower prices per unit. Understanding the supplier’s MOQ can help negotiate better deals.

-

Specifications and Customization: Custom-designed power supplies or those with specific features (like programmable outputs) will generally cost more. Buyers must weigh the need for customization against budget constraints.

-

Materials and Quality Certifications: Products that meet stringent quality certifications (such as ISO or CE) may command higher prices but offer assurances of reliability and compliance.

-

Supplier Factors: Supplier reputation, reliability, and production capabilities can affect pricing. Established suppliers with a track record of quality may charge more due to their perceived value.

-

Incoterms: The terms of shipment (Incoterms) chosen can affect overall costs. For instance, choosing Ex-Works (EXW) may lead to lower product costs but higher logistics expenses, while Delivered Duty Paid (DDP) may increase initial costs but simplify the buying process.

How Can Buyers Negotiate for Better Pricing?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider the following tips for effective negotiation:

-

Understand Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also long-term costs like maintenance, energy efficiency, and potential downtime. This holistic view can justify a higher upfront investment for a more reliable product.

-

Leverage Volume Discounts: If planning to order in bulk, communicate this to suppliers to negotiate better pricing and terms.

-

Build Relationships: Developing a long-term relationship with suppliers can lead to better pricing, priority service, and access to new products.

-

Consider Local Suppliers: Sourcing from local manufacturers can reduce shipping costs and lead times, potentially offsetting higher per-unit prices.

-

Stay Informed on Market Trends: Understanding market dynamics and pricing trends can provide leverage in negotiations, allowing buyers to make informed decisions.

Conclusion

Navigating the cost and pricing landscape for 60 volt DC power supplies requires a keen understanding of the various components and influencers involved. By employing strategic negotiation tactics and considering the total cost of ownership, international buyers can make informed decisions that align with their operational needs and budgetary constraints. Always remember that indicative prices can fluctuate based on market conditions and should be verified with suppliers.

Alternatives Analysis: Comparing 60 volt dc power supply With Other Solutions

When considering power solutions for industrial applications, a 60-volt DC power supply often emerges as a preferred choice due to its robust performance and versatility. However, various alternatives may provide comparable benefits tailored to specific operational requirements. This analysis will explore two notable alternatives: AC power supplies and battery systems, comparing them across essential performance aspects.

Illustrative image related to 60 volt dc power supply

| Comparison Aspect | 60 Volt DC Power Supply | AC Power Supply | Battery Systems |

|---|---|---|---|

| Performance | High efficiency, stable output | Variable efficiency depending on design | Limited output, dependent on charge level |

| Cost | Moderate initial investment | Generally lower upfront cost | High initial cost, ongoing maintenance |

| Ease of Implementation | Requires proper installation and configuration | Easier to install in existing systems | Complex setup, requires charging infrastructure |

| Maintenance | Low maintenance needs, durable | Moderate; depends on the quality of components | Regular monitoring and replacement of batteries |

| Best Use Case | Industrial applications needing stable DC output | General applications where AC is sufficient | Portable applications, renewable energy systems |

What Are the Advantages and Disadvantages of AC Power Supplies Compared to 60 Volt DC Power Supplies?

AC power supplies convert mains electricity to usable power for various applications. One of the key advantages of AC power supplies is their lower initial cost and ease of integration into existing electrical systems. They are commonly used in general industrial and commercial applications, making them a familiar choice for many businesses. However, their performance can be variable, particularly in terms of efficiency and stability, which may not meet the precise needs of sensitive equipment requiring consistent DC output.

How Do Battery Systems Compare to 60 Volt DC Power Supplies?

Battery systems offer a portable and flexible power solution, particularly advantageous in environments where grid power is unavailable or unreliable. They can store energy from renewable sources, making them a sustainable option. However, the initial investment can be substantial, and ongoing maintenance is required to ensure battery health and performance. Additionally, the output may vary depending on the charge level, making it less reliable for continuous operations compared to a dedicated 60-volt DC power supply.

In Conclusion, Which Power Solution Should B2B Buyers Choose?

Selecting the right power solution hinges on the specific needs of your operations. A 60-volt DC power supply excels in applications requiring stable, efficient, and reliable power delivery, particularly in industrial settings. However, if budget constraints are a significant concern, or if your business primarily utilizes AC equipment, an AC power supply may be a more practical choice. For businesses focused on sustainability or requiring mobility, battery systems could be the best fit, despite the higher initial costs and maintenance needs. By evaluating these factors, B2B buyers can make informed decisions that align with their operational goals and budgetary constraints.

Essential Technical Properties and Trade Terminology for 60 volt dc power supply

What Are the Key Technical Properties of a 60 Volt DC Power Supply?

Understanding the essential specifications of a 60 Volt DC power supply is crucial for B2B buyers, particularly those involved in manufacturing and industrial applications. Here are some of the critical technical properties:

-

Output Voltage and Current Rating

The output voltage indicates the nominal voltage the power supply delivers, which in this case is 60 volts. The current rating, measured in amps, indicates the maximum output current. For example, a 60V/5A power supply can deliver up to 5 amps of current. This specification is vital for ensuring that the power supply can adequately support the connected load without causing damage or underperformance. -

Power Rating (Wattage)

The power rating, expressed in watts (W), is calculated by multiplying the output voltage by the output current (e.g., 60V x 5A = 300W). This rating is essential for B2B buyers to ensure that the power supply can handle the total power requirements of their applications, preventing overloads that could lead to failure. -

Efficiency

Efficiency is the ratio of the output power to the input power, typically expressed as a percentage. A higher efficiency means less energy waste and lower operating costs. For international buyers, selecting a power supply with high efficiency can lead to significant savings over time, especially in large-scale operations. -

Regulation Type

Power supplies can be linear or switching, with each type having its advantages. Linear power supplies offer low noise and stable output, making them suitable for sensitive electronics. In contrast, switching power supplies are more compact and efficient but may introduce noise. Understanding the regulation type helps buyers select the right power supply for their specific applications. -

Input Voltage Range

This specification indicates the range of input voltages that the power supply can accept. A wide input voltage range allows for flexibility in various geographical locations where voltage levels may fluctuate. For B2B buyers, ensuring compatibility with local power grids is crucial for uninterrupted operations. -

Operating Temperature Range

The operating temperature range specifies the environmental conditions under which the power supply can function effectively. It is essential for applications in extreme climates, as exceeding this range can lead to performance issues or complete failure. This specification is particularly relevant for buyers in regions with harsh weather conditions.

What Common Trade Terminology Should B2B Buyers Know?

Familiarity with industry jargon can facilitate smoother negotiations and purchasing processes. Here are some common terms relevant to 60 Volt DC power supplies:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. For buyers, understanding OEM relationships can help identify reputable suppliers and assess product quality. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is critical for B2B buyers to manage inventory and budget effectively, especially when entering new markets. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing information for specific products or services. This process is essential for buyers to obtain competitive pricing and assess supplier capabilities. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international shipping, including costs, risks, and responsibilities. Familiarity with these terms helps B2B buyers navigate shipping logistics and avoid unexpected costs. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. Understanding lead times is crucial for supply chain management, especially in industries where timely delivery impacts production schedules. -

Warranty Period

The warranty period is the duration during which the manufacturer guarantees the product’s performance. A robust warranty can provide peace of mind to buyers, ensuring support in case of defects or failures.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing 60 Volt DC power supplies, optimizing their operations and minimizing risks.

Navigating Market Dynamics and Sourcing Trends in the 60 volt dc power supply Sector

What Are the Global Drivers and Trends Influencing the 60 Volt DC Power Supply Market?

The global market for 60 volt DC power supplies is experiencing significant growth, driven by several key factors. Increased demand for renewable energy sources, particularly in developing regions such as Africa and South America, is pushing the need for efficient and reliable power supplies. Industries including telecommunications, electric vehicles, and industrial automation are increasingly integrating 60V DC power supplies into their systems due to their versatility and efficiency.

Emerging technologies, such as energy storage systems and smart grids, are also shaping the landscape. These innovations require power supplies that can deliver stable voltage levels while accommodating fluctuating loads. Moreover, the trend toward miniaturization and compact design in electronics is prompting manufacturers to develop smaller, more efficient power supply solutions. For international B2B buyers, particularly in regions like Nigeria and Vietnam, understanding these trends is essential for making informed sourcing decisions that align with their operational needs.

Illustrative image related to 60 volt dc power supply

How Are Sustainability and Ethical Sourcing Affecting the 60 Volt DC Power Supply Market?

Sustainability has become a crucial consideration for B2B buyers in the power supply sector. The environmental impact of manufacturing processes and materials used in 60 volt DC power supplies is under scrutiny, leading to a demand for greener alternatives. Companies are increasingly seeking suppliers that prioritize ethical sourcing and offer products certified for environmental compliance, such as RoHS (Restriction of Hazardous Substances) and Energy Star certifications.

Adopting sustainable practices not only fulfills corporate social responsibility commitments but also enhances brand reputation. For buyers in the Middle East and Europe, aligning with suppliers who embrace eco-friendly practices can lead to long-term partnerships and improved market positioning. Moreover, investing in “green” materials and technologies can yield cost savings in the long run, making sustainability not just an ethical choice but a smart business strategy.

What Is the Evolution of the 60 Volt DC Power Supply Market?

The 60 volt DC power supply market has evolved significantly over the past few decades. Initially, these power supplies were primarily used in niche applications. However, as industries began to recognize the advantages of DC power—such as improved efficiency and lower operational costs—demand surged.

Illustrative image related to 60 volt dc power supply

The advent of renewable energy technologies, particularly solar and wind, has further accelerated this trend. Today, 60 volt DC power supplies are integral to a wide range of applications, from industrial machinery to consumer electronics. As technological advancements continue to drive innovation, the market is expected to expand, offering more sophisticated and efficient solutions for international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of 60 volt dc power supply

-

How do I choose the right 60 volt DC power supply for my application?

Choosing the right 60 volt DC power supply involves assessing your specific application requirements, including the voltage, current ratings, and power capacity needed. Consider whether you need a linear or switching power supply, as this affects efficiency and heat dissipation. Additionally, check for features such as programmable settings or built-in protections like overvoltage and overcurrent. Always ensure compatibility with your equipment and consider future scalability needs. -

What are the common applications for 60 volt DC power supplies?

60 volt DC power supplies are commonly used in telecommunications, industrial automation, and medical devices. They provide stable power for various applications, including testing and measurement equipment, battery charging systems, and electric vehicle charging stations. Understanding your application will help you select the appropriate specifications and features that align with industry standards. -

What customization options are available for 60 volt DC power supplies?

Many suppliers offer customization options for 60 volt DC power supplies, such as specific output voltages, current ratings, and form factors. You can also request features like programmable outputs, enhanced cooling systems, or specific connectors. When seeking customization, ensure you communicate your requirements clearly to the manufacturer, as this may impact lead times and costs. -

What is the typical minimum order quantity (MOQ) for 60 volt DC power supplies?

The MOQ for 60 volt DC power supplies varies by supplier and can range from a single unit to several hundred units. Smaller manufacturers may accommodate lower quantities, while larger firms often have higher MOQs due to production efficiencies. It’s essential to discuss your needs with suppliers to find a suitable arrangement, especially if you are testing products for initial use. -

How should I vet suppliers of 60 volt DC power supplies?

To vet suppliers effectively, start by reviewing their reputation and experience in the industry. Look for certifications such as ISO or UL, which indicate adherence to quality standards. Request references from previous clients and assess their ability to meet delivery timelines and service support. Additionally, consider suppliers that offer warranties and post-purchase support, as this can be crucial for long-term partnerships. -

What payment terms are typically offered for international purchases of power supplies?

Payment terms for international purchases of 60 volt DC power supplies can vary widely. Common arrangements include advance payments, letters of credit, and net 30 or net 60 terms. Always clarify payment expectations upfront and consider using secure payment methods to protect your investment. Be aware of additional costs such as customs duties and taxes, which may affect your overall budget. -

What quality assurance practices should I expect from suppliers?

Reputable suppliers of 60 volt DC power supplies should have robust quality assurance practices in place. This typically includes testing each unit for performance metrics such as voltage stability, load regulation, and thermal performance. Inquire about their testing protocols and certifications to ensure they comply with international standards. Request documentation of quality tests as part of your purchase agreement. -

How do logistics and shipping affect my order of 60 volt DC power supplies?

Logistics and shipping can significantly impact the delivery timeline and cost of your order. Discuss with suppliers their shipping methods, estimated delivery times, and any potential delays due to customs clearance. Opt for suppliers that offer transparent logistics solutions and consider incoterms that define the responsibilities of both parties in the shipping process. Planning for these factors can help ensure timely delivery and avoid unexpected expenses.

Top 5 60 Volt Dc Power Supply Manufacturers & Suppliers List

1. Mouser – 60 VDC Power Supplies

Domain: mouser.com

Registered: 1995 (30 years)

Introduction: This company, Mouser – 60 VDC Power Supplies, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Acopian – Single Output 60V Power Supplies

Domain: acopian.com

Registered: 1996 (29 years)

Introduction: This company, Acopian – Single Output 60V Power Supplies, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. MEAN WELL – 24V 2.5A Industrial DIN Rail Power Supply

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: 60V Adjustable Power Supplies available for sale on eBay. Maximum current outputs range from 2.5 A to 60 A. Notable products include: MEAN WELL 24V 2.5A 60W Industrial DIN Rail Power Supply for $18.99, Tekpower 60V 15A Adjustable Switching Power Supply for $23.34, B&K Precision 9110 60V Multi Range DC Power Supply for $375.00 (new) and $199.00 (used), and WEP 605D-III DC Variable Power Supply for …

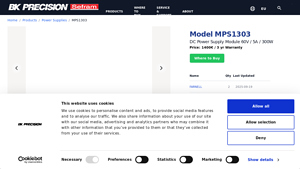

4. BK Precision – MPS1303 DC Power Supply Module

Domain: bkprecision.com

Registered: 1996 (29 years)

Introduction: {“Model”:”MPS1303″,”Type”:”DC Power Supply Module”,”Max Voltage”:”60V”,”Max Current”:”5A”,”Max Power”:”300W”,”Price”:”1400€”,”Warranty”:”3 yr”,”Outputs”:”1″,”Interfaces”:”USB (USBTMC-compliant), GPIB, LAN (LXI-Class C compliant)”,”Features”:[“Modular design”,”Multi-ranging operation”,”Advanced list mode programming”,”Series/parallel operation”,”Module synchronization and output coupling”,”Adjustab…

5. Circuit Specialists – 60 Volt High Output Switching DC Power Supply

Domain: circuitspecialists.com

Registered: 1996 (29 years)

Introduction: {“Product Name”: “60 Volt High Output Switching DC Power Supply”, “Model”: “CSI6010SW”, “Voltage”: “60 Volt”, “Current”: “10.0 Amps”, “Price”: “$209.27”, “Availability”: “9 In Stock”, “Shipping”: “Free Shipping on Orders over $149”, “Warranty”: “1 Year Limited Warranty”, “Shipping Details”: “Ships Same Day for orders placed before 12pm EST Monday through Friday”}

Strategic Sourcing Conclusion and Outlook for 60 volt dc power supply

In navigating the landscape of 60-volt DC power supplies, strategic sourcing emerges as a pivotal strategy for B2B buyers, particularly in dynamic markets across Africa, South America, the Middle East, and Europe. By leveraging a comprehensive approach to sourcing, businesses can ensure they are obtaining high-quality power supplies that meet their specific operational needs while also optimizing costs. It is essential to consider factors such as reliability, regulatory compliance, and supplier reputation when making purchasing decisions.

Moreover, as industries increasingly embrace automation and advanced technologies, the demand for robust power solutions will only grow. Buyers are encouraged to engage with suppliers who offer customizable options and rapid prototyping services to align with unique project requirements.

As you look to the future, consider the potential of forming long-term partnerships with reputable manufacturers. This will not only enhance supply chain resilience but also enable access to innovative technologies that can drive efficiency and sustainability in your operations. Take the next step in your sourcing journey by exploring reliable suppliers and unlocking the benefits of strategic sourcing for your business’s power supply needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.