Is Your Day Pak Inc Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for day pak inc

In today’s competitive landscape, sourcing high-quality packaging machinery from Day-Pak Inc. can be a daunting task for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. The challenge lies not only in identifying reliable suppliers but also in ensuring that the machinery meets the specific needs of various industries—from food and beverage to pharmaceuticals and cosmetics. This comprehensive guide is designed to equip you with the essential insights needed to navigate the complexities of the global packaging market, focusing on Day-Pak Inc. as a leading provider of customizable packaging solutions.

Throughout this guide, we will explore the diverse range of machinery offered by Day-Pak Inc., including filling, labeling, capping, and cartoning machines. We will also delve into the applications of these machines, supplier vetting processes, and cost considerations that are crucial for making informed purchasing decisions. By addressing key factors such as technology, customization options, and after-sales support, this guide empowers B2B buyers to make strategic choices that enhance operational efficiency and reduce long-term costs. Whether you are based in Nigeria, Saudi Arabia, or a country in Europe, this resource will serve as your roadmap to successfully procure innovative packaging solutions that drive your business forward.

Understanding day pak inc Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Filling Machines | Designed for accurate liquid or powder filling; customizable. | Food, beverage, pharmaceuticals. | Pros: High accuracy; customizable sizes. Cons: Initial cost can be high. |

| Labeling Machines | Automated application of labels; supports various label types. | Food, cosmetics, pharmaceuticals. | Pros: Increases efficiency; reduces labor costs. Cons: Maintenance can be complex. |

| Capping Machines | Ensures secure sealing of containers; compatible with various caps. | Beverage, pharmaceuticals, personal care. | Pros: Enhances product integrity; versatile. Cons: Requires calibration for different cap types. |

| Cartoning Machines | Automates the packaging of products into cartons; fast operation. | Food, electronics, consumer goods. | Pros: Speeds up packaging process; reduces labor. Cons: Requires space and investment. |

| Wrapping Machines | Provides protective wrapping; suitable for various materials. | Food, electronics, industrial products. | Pros: Protects products during transport; customizable. Cons: Setup time can be lengthy. |

What Are the Key Characteristics of Filling Machines from Day-Pak Inc.?

Filling machines from Day-Pak Inc. are engineered for precision, ensuring that liquids and powders are dispensed accurately into containers. These machines can be tailored to accommodate different product types and container sizes, making them versatile for industries like food, beverages, and pharmaceuticals. When considering a filling machine, B2B buyers should evaluate the machine’s capacity, speed, and compatibility with their specific products to ensure optimal performance.

How Do Labeling Machines Enhance Packaging Efficiency?

Labeling machines are crucial for automating the labeling process across various industries, including food, cosmetics, and pharmaceuticals. These machines can apply labels quickly and accurately, which helps maintain product integrity and brand consistency. Buyers should consider factors such as the types of labels supported, the machine’s speed, and ease of maintenance when selecting a labeling machine, as these elements directly impact operational efficiency.

What Are the Benefits of Capping Machines for Secure Packaging?

Capping machines from Day-Pak Inc. are designed to ensure that containers are sealed securely, preventing product leakage and contamination. They are compatible with a wide range of cap types, making them suitable for multiple industries, including beverages and pharmaceuticals. B2B buyers should assess the machine’s adaptability to different cap sizes and its calibration requirements, as these factors influence the overall effectiveness and longevity of the capping solution.

Why Are Cartoning Machines Important for High-Speed Packaging?

Cartoning machines automate the process of packaging products into cartons, significantly improving packaging speed and efficiency for sectors like food and electronics. These machines can handle various carton sizes and styles, providing flexibility for manufacturers. When purchasing a cartoning machine, buyers should consider the machine’s throughput capacity and the space required for installation, as these will affect production workflow and facility layout.

How Do Wrapping Machines Provide Protection During Transport?

Wrapping machines are essential for providing protective wrapping around products, ensuring they remain intact during transportation. They can handle different materials and are customizable to meet specific packaging needs across industries like food and electronics. B2B buyers should evaluate the machine’s setup time and the materials it can accommodate, as these aspects will determine how well the wrapping solution integrates into their existing packaging processes.

Key Industrial Applications of day pak inc

| Industry/Sector | Specific Application of day pak inc | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Automated filling and labeling machines | Increases production efficiency and accuracy in packaging | Compliance with food safety standards and regulations |

| Pharmaceuticals | Custom packaging solutions for medicines | Ensures product integrity and extends shelf life | Requirements for child-proof and tamper-evident packaging |

| Cosmetics | High-speed cartoning and wrapping machines | Enhances product presentation and brand visibility | Need for customization to match brand aesthetics |

| Household Products | Capping and sealing solutions for cleaning agents | Reduces leakage and improves user safety | Compatibility with various container types and sizes |

| Military Packaging | Durable and secure packaging for military supplies | Protects sensitive materials during transport | Must meet stringent military specifications and durability tests |

How Does Day-Pak Inc. Cater to the Food and Beverage Industry?

Day-Pak Inc. provides automated filling and labeling machines specifically designed for the food and beverage sector. These machines streamline the packaging process, ensuring that products are filled accurately and labeled correctly, which is crucial for compliance with food safety standards. For international buyers, especially in regions like Africa and South America, it’s essential to consider local regulations regarding food packaging, as well as the need for machines that can handle a variety of product viscosities and container shapes.

What Solutions Does Day-Pak Inc. Offer for Pharmaceuticals?

In the pharmaceutical industry, Day-Pak Inc. specializes in custom packaging solutions that cater to the unique needs of medications. This includes child-proof and tamper-evident packaging that ensures product safety and integrity. Buyers from the Middle East and Europe should prioritize sourcing equipment that complies with stringent health regulations and can accommodate various packaging formats, such as blister packs and bottles, to meet diverse market demands.

How Can Day-Pak Inc. Enhance the Cosmetics Sector?

For the cosmetics industry, Day-Pak Inc. offers high-speed cartoning and wrapping machines that improve product presentation and brand visibility. These machines can be tailored to meet specific branding requirements, ensuring that packaging aligns with marketing strategies. International buyers, particularly in Europe, should consider the aesthetic customization options available, as well as the machinery’s ability to handle fragile containers without damaging the product.

What Are the Benefits of Day-Pak Inc.’s Household Product Solutions?

Day-Pak Inc. provides capping and sealing solutions for household cleaning agents, which are essential for preventing leaks and ensuring user safety. These solutions can be customized to fit various container types, which is important for buyers in diverse markets like Nigeria and Saudi Arabia. When sourcing these solutions, businesses should evaluate the compatibility of the machinery with their existing production lines to ensure seamless integration.

How Does Day-Pak Inc. Support Military Packaging Needs?

Day-Pak Inc. excels in providing durable and secure packaging for military supplies, essential for protecting sensitive materials during transport. The company’s solutions meet stringent military specifications, ensuring reliability under challenging conditions. International buyers must consider the durability and compliance of packaging materials with military standards, as well as the logistical aspects of sourcing such specialized equipment.

3 Common User Pain Points for ‘day pak inc’ & Their Solutions

Scenario 1: Difficulty in Customizing Packaging Solutions for Unique Products

The Problem: Many B2B buyers, particularly those in specialized industries like pharmaceuticals or food and beverage, often encounter the challenge of needing highly customized packaging solutions. Standard machinery may not adequately address the specific requirements of their products, leading to inefficiencies and potential product damage. These buyers may feel overwhelmed by the complexity of customizing machinery to fit their unique needs, fearing that they might invest in a solution that ultimately does not meet their expectations.

The Solution: To overcome this challenge, B2B buyers should engage directly with Day-Pak Inc. to leverage their expertise in customizable packaging machinery. Start by conducting a thorough assessment of your packaging requirements, including product dimensions, materials, and desired production speed. Once you have this information, reach out to Day-Pak’s team of engineers who specialize in designing tailored machinery. By collaborating closely, you can ensure that the machinery developed is specifically suited to your product line, thus maximizing efficiency and minimizing waste. Additionally, take advantage of Day-Pak’s training and support services, which will equip your staff to operate and maintain the new machinery effectively, ensuring seamless integration into your existing processes.

Scenario 2: Managing Downtime and Maintenance of Packaging Equipment

The Problem: Downtime due to equipment failure can be a significant pain point for B2B buyers. In industries where timely packaging is crucial, such as e-commerce and food production, any halt in operations can lead to financial losses and customer dissatisfaction. Buyers may struggle with inadequate support for maintenance, leading to prolonged downtimes and an increased burden on their operational teams.

The Solution: Buyers should proactively utilize Day-Pak Inc.’s comprehensive maintenance and support services to mitigate downtime risks. Establish a maintenance schedule in collaboration with Day-Pak’s technicians, who can provide routine checks and preventive maintenance tailored to your specific equipment. This proactive approach not only extends the lifespan of your machinery but also keeps production running smoothly. Furthermore, consider investing in training sessions for your staff, facilitated by Day-Pak, to ensure they are equipped to handle minor issues independently. This will empower your team and further reduce the likelihood of operational disruptions.

Scenario 3: Navigating Compliance and Quality Standards in Packaging

The Problem: In the global marketplace, B2B buyers often face the challenge of adhering to various compliance and quality standards, especially in industries such as pharmaceuticals and food packaging. Failing to meet these regulations can result in costly fines, product recalls, and damage to brand reputation. Buyers may feel uncertain about whether their packaging solutions are up to par with industry standards, which can lead to hesitance in decision-making.

The Solution: To effectively navigate compliance challenges, B2B buyers should leverage Day-Pak Inc.’s ISO 9001 certification and their commitment to quality assurance. Start by discussing your specific regulatory requirements with Day-Pak’s team, who can provide insights into how their machinery meets or exceeds industry standards. Additionally, request documentation and certifications that validate the compliance of the packaging solutions you are considering. This will not only provide peace of mind but also assist in streamlining your own compliance processes. Furthermore, engage in discussions about the traceability features of the packaging machinery, which can help in maintaining records that are essential for audits and inspections. By aligning your packaging strategy with Day-Pak’s proven capabilities, you can ensure compliance while also enhancing product integrity and consumer trust.

Strategic Material Selection Guide for day pak inc

What Are the Key Materials Used in Day-Pak Inc. Packaging Solutions?

Day-Pak Inc. utilizes a variety of materials in its packaging machinery and solutions, each chosen for specific properties and applications. Here, we analyze four common materials: plastic, metal, paper, and foam, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Plastic Perform in Packaging Applications?

Plastic is one of the most versatile materials used in packaging machinery. Key properties include excellent moisture resistance, lightweight characteristics, and the ability to be molded into complex shapes. Plastics like polyethylene (PE) and polypropylene (PP) are commonly used due to their high tensile strength and flexibility.

Pros: Plastics are generally durable, cost-effective, and can be produced in high volumes with relatively low manufacturing complexity. They are suitable for a wide range of products, from food to pharmaceuticals.

Cons: However, plastics can be less environmentally friendly, raising concerns about sustainability. Additionally, certain types may have limitations in terms of temperature resistance and may not be suitable for high-pressure applications.

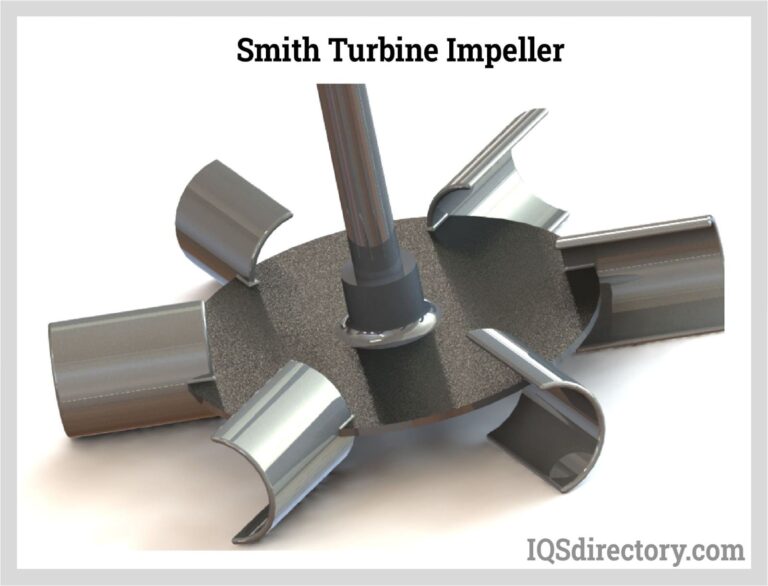

Illustrative image related to day pak inc

Impact on Application: Plastics are compatible with a variety of media, making them ideal for food and beverage packaging. However, buyers should consider local regulations regarding plastic use, particularly in regions with stringent environmental policies.

What Role Does Metal Play in Packaging Machinery?

Metal, particularly stainless steel and aluminum, is widely used in the construction of packaging machinery due to its strength and durability. Key properties include high corrosion resistance and the ability to withstand extreme temperatures and pressures.

Pros: Metals are highly durable and can provide a longer lifespan for machinery, which is crucial in high-volume production environments. They also offer better structural integrity compared to plastics.

Cons: The main drawbacks are the higher cost and increased manufacturing complexity. Metal components can be heavier, which may affect shipping and installation costs.

Impact on Application: Metal is ideal for applications that require high hygiene standards, such as food processing and pharmaceuticals. International buyers must ensure compliance with standards such as ASTM and ISO, which govern the use of metals in packaging.

How Does Paper Contribute to Sustainable Packaging Solutions?

Paper is increasingly being recognized for its sustainability and recyclability. Key properties include biodegradability and the ability to be produced from renewable resources.

Pros: Paper is lightweight, cost-effective, and can be printed on easily, making it ideal for branding and marketing purposes. It is also highly customizable in terms of thickness and finish.

Cons: On the downside, paper may not provide the same level of moisture and barrier protection as plastic or metal, which can limit its use in certain applications. It is also less durable when exposed to water or heavy handling.

Impact on Application: Paper is suitable for products that do not require extensive protection from environmental factors, such as cosmetics and household goods. Buyers in regions like Europe, where sustainability is prioritized, may prefer paper-based solutions.

What Advantages Does Foam Offer in Packaging Solutions?

Foam materials, including polyethylene foam and polyurethane foam, are commonly used for protective packaging. Key properties include excellent shock absorption and lightweight characteristics.

Illustrative image related to day pak inc

Pros: Foam provides superior protection against impacts and is highly customizable in terms of density and thickness. It is often used in combination with other materials for added protection.

Cons: The main limitation of foam is that it may not be as environmentally friendly as paper or certain plastics, raising concerns among eco-conscious buyers. Additionally, it can be more expensive than traditional packaging materials.

Impact on Application: Foam is particularly effective for fragile items, making it suitable for electronics and glass products. International buyers should consider local regulations regarding foam materials, especially in regions with strict environmental standards.

Summary Table of Material Selection for Day-Pak Inc.

| Material | Typical Use Case for day pak inc | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Food and beverage packaging | Durable and cost-effective | Environmental concerns | Medium |

| Metal | Machinery construction | High durability and structural integrity | Higher cost and manufacturing complexity | High |

| Paper | Branding and marketing | Sustainable and customizable | Limited moisture protection | Low |

| Foam | Protective packaging | Excellent shock absorption | Environmental concerns and higher cost | Medium |

This strategic material selection guide provides valuable insights for international B2B buyers, helping them make informed decisions based on their specific needs and regional compliance requirements.

Illustrative image related to day pak inc

In-depth Look: Manufacturing Processes and Quality Assurance for day pak inc

What Are the Main Stages of Manufacturing at Day-Pak Inc.?

Day-Pak Inc. employs a systematic approach to manufacturing packaging machinery, which encompasses several critical stages: material preparation, forming, assembly, and finishing. Each stage is designed to ensure efficiency, precision, and customization to meet the specific needs of diverse industries including food and beverage, pharmaceuticals, and cosmetics.

How Does Day-Pak Inc. Prepare Materials for Production?

The material preparation stage involves sourcing high-quality materials that meet stringent industry standards. Day-Pak Inc. collaborates with trusted suppliers to procure materials such as metals, plastics, and composites that are integral to their packaging machines. The company prioritizes sustainability and often opts for materials that are recyclable or have reduced environmental impact.

Once the materials are sourced, they undergo rigorous inspection (Incoming Quality Control – IQC) to verify their quality and suitability for production. This step is crucial in minimizing defects and ensuring that only the best materials are used in the manufacturing process.

Illustrative image related to day pak inc

What Techniques Are Used in the Forming Stage?

In the forming stage, Day-Pak Inc. utilizes advanced manufacturing techniques tailored to the types of machinery being produced. These techniques include CNC machining, injection molding, and sheet metal fabrication. CNC machining is particularly valuable for creating precise components that fit together seamlessly, while injection molding allows for the efficient production of complex plastic parts.

The forming stage is characterized by high levels of automation, which not only speeds up production but also enhances accuracy. Operators closely monitor the process, ensuring that all components meet the specified dimensions and tolerances.

How Is Assembly Conducted at Day-Pak Inc.?

The assembly stage is where the various components come together to create the final product. Day-Pak Inc. employs a combination of manual and automated assembly techniques. Skilled technicians work alongside robotic systems to ensure that each machine is assembled correctly and functions as intended.

This stage also incorporates quality checkpoints (In-Process Quality Control – IPQC) where technicians test the functionality of the machinery at various assembly points. This proactive approach helps identify any issues early in the process, reducing the likelihood of costly rework later on.

What Finishing Processes Are Implemented?

Once assembly is complete, the finishing stage involves testing, painting, and branding the packaging machinery. Day-Pak Inc. conducts Final Quality Control (FQC) inspections to ensure that each machine meets its operational specifications before it is shipped to clients.

Finishing also includes applying protective coatings and branding elements, such as logos and labels, which not only enhance the machine’s appearance but also provide essential product information.

How Does Day-Pak Inc. Ensure Quality Assurance?

Quality assurance is a cornerstone of Day-Pak Inc.’s manufacturing philosophy. The company is ISO 9001 certified, which signifies its commitment to maintaining high-quality standards across all processes. This certification is recognized internationally, providing assurance to B2B buyers that they are partnering with a reputable supplier.

What Are the Relevant International Standards for Quality Control?

In addition to ISO 9001, Day-Pak Inc. adheres to various industry-specific standards such as CE marking for products sold in Europe and API standards for products used in the oil and gas sector. These certifications not only facilitate compliance with regulatory requirements but also enhance the marketability of their machinery in different regions.

What Quality Control Checkpoints Are in Place?

Day-Pak Inc. implements multiple quality control checkpoints throughout the manufacturing process.

-

Incoming Quality Control (IQC): This involves inspecting raw materials and components upon arrival to ensure they meet predefined specifications.

-

In-Process Quality Control (IPQC): Continuous monitoring during manufacturing allows for immediate corrections if any deviations are detected, thus maintaining production integrity.

-

Final Quality Control (FQC): Before products are dispatched, a thorough inspection ensures that all machinery functions optimally and meets client specifications.

Which Testing Methods Are Commonly Used?

Day-Pak Inc. employs a variety of testing methods to validate the quality and performance of its machinery. These include functional tests, endurance tests, and safety tests, each designed to simulate real-world operating conditions.

Functional tests verify that each machine operates as intended, while endurance tests check for durability under prolonged use. Safety tests ensure that all machinery complies with local and international safety regulations, providing peace of mind for B2B buyers.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to verify the quality control processes of Day-Pak Inc. One effective method is to request audits and reports that detail the company’s compliance with ISO standards and other certifications.

Additionally, buyers may consider third-party inspections to gain an unbiased perspective on the manufacturing processes and quality assurance measures in place. Engaging with existing clients or reviewing case studies can also provide insights into the reliability of Day-Pak Inc.’s products and services.

Illustrative image related to day pak inc

What Are the Quality Control Nuances for International Buyers?

For international buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, understanding local regulations and standards is crucial. Day-Pak Inc. is well-versed in navigating these complexities and can offer guidance on compliance with regional laws, including import regulations and safety standards.

Moreover, international buyers should inquire about the company’s experience in exporting machinery to their specific regions. This knowledge can significantly influence the reliability and performance of the equipment once it reaches its destination.

Conclusion

Day-Pak Inc. exemplifies excellence in manufacturing processes and quality assurance. By focusing on each stage of production—from material preparation to finishing—and adhering to rigorous quality control standards, the company ensures that it delivers high-quality, customized packaging solutions that meet the diverse needs of its international clientele. B2B buyers can confidently engage with Day-Pak Inc., knowing that their packaging machinery will adhere to the highest industry standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘day pak inc’

This guide aims to provide B2B buyers with a clear, actionable checklist for sourcing packaging machinery and solutions from Day-Pak Inc. By following these steps, you can ensure a successful procurement process that meets your specific needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline the technical requirements for your packaging machinery. Consider factors such as the type of products you will be packaging, desired automation level, and production capacity. Providing detailed specifications will help suppliers like Day-Pak Inc. tailor their offerings to your unique needs.

Step 2: Research Day-Pak Inc.’s Product Range

Explore the variety of packaging machinery that Day-Pak Inc. offers, including filling, labeling, capping, cartoning, and wrapping machines. Understanding the full scope of their products will allow you to identify which machines align with your production goals. Additionally, assess whether their machinery can be customized to fit specific applications within your industry.

Step 3: Evaluate Supplier Certifications and Standards

Verify that Day-Pak Inc. holds necessary certifications, such as ISO 9001, which ensures compliance with international quality management standards. Certifications not only affirm the quality of their products but also indicate a commitment to continuous improvement. This step is crucial for mitigating risks associated with equipment reliability and performance.

Step 4: Request Proposals and Quotes

Reach out to Day-Pak Inc. to request detailed proposals and quotes based on your specifications. A well-structured proposal should include pricing, lead times, warranty details, and terms of service. This information is essential for comparing costs and understanding the value proposition of their machinery and services.

Illustrative image related to day pak inc

Step 5: Assess After-Sales Support and Services

Inquire about the after-sales support provided by Day-Pak Inc., including installation, maintenance, and training services. Effective support ensures that your machinery operates efficiently and minimizes downtime. Look for a supplier that offers comprehensive training for your staff to maximize the potential of the equipment.

Step 6: Check Customer References and Case Studies

Request references or case studies from Day-Pak Inc. that showcase their work with similar industries or applications. Hearing from existing customers can provide insights into the supplier’s reliability, customer service, and overall satisfaction. This step is vital for building confidence in your supplier choice.

Step 7: Negotiate Terms and Finalize Your Order

Once you have evaluated all aspects of your potential partnership with Day-Pak Inc., negotiate the terms of your purchase. This includes discussing payment terms, delivery timelines, and any customization requirements. Finalizing these details ensures clarity and helps establish a strong working relationship moving forward.

By following this checklist, international B2B buyers can effectively navigate the procurement process with Day-Pak Inc., ensuring they secure the right packaging solutions for their needs.

Comprehensive Cost and Pricing Analysis for day pak inc Sourcing

What Are the Key Cost Components in Day-Pak Inc.’s Pricing Structure?

Understanding the cost structure of Day-Pak Inc. is essential for international B2B buyers seeking to source packaging machinery effectively. The primary cost components include:

Illustrative image related to day pak inc

-

Materials: The cost of raw materials significantly impacts pricing. Day-Pak utilizes high-quality materials for its machinery, ensuring durability and performance. Buyers should inquire about the types of materials used, as this can vary based on the specific machinery and customization.

-

Labor: Labor costs encompass both direct and indirect expenses related to the workforce involved in manufacturing, assembly, and quality assurance. Day-Pak emphasizes skilled labor to maintain high standards, which can influence the overall pricing.

-

Manufacturing Overhead: This includes costs associated with utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can help mitigate these costs, ultimately benefiting the buyer.

-

Tooling: Custom tooling is often required for specialized machinery. The cost of designing and producing these tools can be substantial, particularly for tailored solutions. Understanding tooling costs upfront can aid in budgeting.

-

Quality Control (QC): Rigorous QC processes ensure that machinery meets industry standards and customer expectations. This investment in quality can elevate pricing but is crucial for maintaining reliability.

-

Logistics: Shipping and handling costs are critical, especially for international buyers. Factors such as distance, shipping method, and customs duties should be considered in the overall cost.

-

Margin: Day-Pak Inc. typically includes a profit margin that reflects the company’s operational costs and market positioning. Buyers should understand that the margin can vary based on order size and customer relationship.

What Influences Pricing for Day-Pak Inc.’s Machinery?

Several factors can influence the pricing of Day-Pak’s machinery, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to better pricing per unit due to economies of scale. Buyers should consider negotiating for favorable terms based on expected order volumes.

-

Specifications and Customization: Custom solutions tailored to specific needs may incur additional costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Material Quality and Certifications: Higher-quality materials and certifications (e.g., ISO 9001) can justify higher prices. Buyers should assess the value these certifications bring in terms of reliability and compliance.

-

Supplier Factors: The experience and reputation of Day-Pak Inc. as a trusted manufacturer can influence pricing. Established suppliers may command premium prices but often provide better service and reliability.

-

Incoterms: Understanding the chosen Incoterms is vital for international transactions. They dictate responsibilities regarding shipping, insurance, and tariffs, which can affect total costs significantly.

What Tips Can Help Buyers Negotiate Better Pricing with Day-Pak Inc.?

To achieve cost efficiency when sourcing from Day-Pak Inc., consider the following strategies:

-

Negotiate Terms: Engage in discussions about pricing, payment terms, and delivery schedules. Leverage potential long-term partnerships to secure better deals.

-

Assess Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also long-term costs such as maintenance, downtime, and operational efficiency. A higher upfront cost may be justified by lower operational costs.

-

Understand Pricing Nuances for International Markets: Different regions may have varying expectations and pricing models. Buyers from Africa, South America, the Middle East, and Europe should conduct market research to align their expectations with local practices.

-

Request Detailed Quotes: Seek comprehensive quotes that break down all cost components. This transparency can facilitate better comparisons and informed negotiations.

-

Consider Local Regulations and Standards: Understanding local compliance requirements can help mitigate unforeseen costs associated with meeting regulatory standards in different markets.

Conclusion

While pricing from Day-Pak Inc. can vary based on multiple factors, international B2B buyers can navigate the complexities by understanding the cost structure and employing strategic negotiation techniques. By focusing on total cost considerations and leveraging their purchasing power, buyers can achieve favorable outcomes in their sourcing endeavors.

Alternatives Analysis: Comparing day pak inc With Other Solutions

When evaluating packaging solutions, it’s crucial for B2B buyers to consider various alternatives to ensure they select the best fit for their specific operational needs. This analysis will compare Day Pak Inc. with two viable alternatives, providing insights into each option’s performance, cost, ease of implementation, maintenance requirements, and ideal use cases.

Comparison Table

| Comparison Aspect | Day Pak Inc | Alternative 1: IPS Packaging & Automation | Alternative 2: U.S. Packaging & Wrapping LLC |

|---|---|---|---|

| Performance | High customization; robust support | Comprehensive automation solutions; strong engineering support | Good range of packaging solutions; flexible options |

| Cost | Moderate to high, depending on customization | Competitive pricing; offers bundled solutions | Generally lower cost; good value for standard solutions |

| Ease of Implementation | Requires training; tailored setup | Streamlined processes; engineering support aids implementation | Quick setup for standard machinery; less custom work |

| Maintenance | Ongoing support; dedicated technicians | In-house engineers for maintenance and support | Basic support; may rely on third-party services |

| Best Use Case | Custom packaging needs across various industries | Large-scale operations needing automation | Smaller operations or businesses looking for cost-effective solutions |

Pros and Cons of Alternatives

IPS Packaging & Automation

IPS Packaging offers a robust suite of packaging and automation solutions that cater to large-scale operations. Their strength lies in their engineering expertise, which can help businesses optimize processes and reduce costs. However, the initial investment might be higher for companies seeking extensive automation. Additionally, their offerings are less customizable compared to Day Pak Inc., which may limit options for unique packaging needs.

U.S. Packaging & Wrapping LLC

This alternative is known for its affordability and a wide range of standard packaging solutions. It is particularly suitable for smaller operations or businesses looking to minimize capital expenditure. The ease of implementation is a significant advantage, as their machinery often requires less training. However, the lack of customization options may not meet the needs of companies with specific packaging requirements, making it less ideal for industries with unique products.

Conclusion

Choosing the right packaging solution involves a careful assessment of operational needs, budget constraints, and the level of customization required. Day Pak Inc. stands out for its tailored solutions and ongoing support, making it an excellent choice for businesses with unique packaging demands. In contrast, IPS Packaging & Automation is ideal for large-scale operations focused on efficiency and process optimization, while U.S. Packaging & Wrapping LLC offers a more budget-friendly option for companies with standard packaging needs. B2B buyers should evaluate these aspects against their specific requirements to make an informed decision that aligns with their business goals.

Illustrative image related to day pak inc

Essential Technical Properties and Trade Terminology for day pak inc

What Are the Key Technical Properties Relevant to Day-Pak Inc.’s Packaging Machinery?

When evaluating packaging machinery, understanding the technical properties is crucial for B2B buyers. Here are some essential specifications that should be considered:

-

Material Grade

– Definition: The classification of materials used in machinery components, often indicated by standards such as ASTM or ISO.

– Importance: Higher material grades ensure durability and resistance to wear and tear, which is critical for maintaining the integrity of packaging operations. This is especially important in industries like food and pharmaceuticals, where contamination risks must be minimized. -

Tolerance

– Definition: The permissible limit or limits of variation in a physical dimension or measured value, typically expressed in millimeters or micrometers.

– Importance: Tight tolerances are essential for the precision of packaging machinery, affecting the accuracy of filling, capping, and sealing processes. For B2B buyers, understanding tolerance levels can help ensure that machinery meets specific operational requirements. -

Production Speed

– Definition: The rate at which a packaging machine can operate, usually measured in units per minute (UPM).

– Importance: Knowing the production speed is vital for businesses looking to optimize their packaging processes. A higher production speed can lead to increased efficiency and reduced labor costs, making it a key factor in ROI calculations. -

Customization Capability

– Definition: The ability of machinery to be tailored to specific packaging needs, including size, format, and automation level.

– Importance: The flexibility to customize equipment allows businesses to adapt to changing market demands without significant capital investments. This is particularly valuable for companies in dynamic sectors, such as cosmetics or food and beverage. -

Energy Efficiency

– Definition: A measure of how effectively a machine uses energy to perform its functions, often rated by energy consumption per unit produced.

– Importance: Energy-efficient machinery reduces operational costs and supports sustainability initiatives, which are increasingly important to global buyers. Understanding energy usage can help companies make environmentally responsible purchasing decisions. -

Maintenance Requirements

– Definition: The frequency and complexity of maintenance activities required to keep machinery operational.

– Importance: Machines with lower maintenance requirements can minimize downtime and labor costs. Buyers should consider the total cost of ownership, including maintenance, when assessing machinery.

What Are Common Trade Terms Used in the Packaging Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are several important terms:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts and equipment that may be marketed by another manufacturer.

– Relevance: Understanding OEM relationships can help buyers identify reliable suppliers and ensure compatibility with existing machinery. -

MOQ (Minimum Order Quantity)

– Definition: The smallest number of units that a supplier is willing to sell in a single order.

– Relevance: Knowing the MOQ is crucial for budgeting and inventory management, allowing buyers to align their purchasing strategies with production schedules. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers requesting pricing and terms for specific goods or services.

– Relevance: An RFQ helps buyers gather competitive pricing and evaluate suppliers based on cost and service offerings, leading to informed purchasing decisions. -

Incoterms (International Commercial Terms)

– Definition: A set of international rules that define the responsibilities of sellers and buyers in shipping goods.

– Relevance: Understanding Incoterms is essential for managing shipping costs and logistics, particularly for international transactions. It helps clarify who is responsible for costs and risks at various points in the shipping process. -

Lead Time

– Definition: The time taken from placing an order to receiving the goods.

– Relevance: Knowing the lead time is critical for inventory planning and ensuring that production schedules are met, especially in industries with tight timelines. -

Warranty

– Definition: A guarantee provided by the manufacturer concerning the condition of its product.

– Relevance: A robust warranty can provide peace of mind for buyers, ensuring that they are protected against defects and performance issues. Understanding warranty terms can influence purchasing decisions significantly.

By grasping these technical properties and trade terms, international B2B buyers can make more informed decisions when sourcing packaging machinery from Day-Pak Inc.

Navigating Market Dynamics and Sourcing Trends in the day pak inc Sector

What Are the Key Market Dynamics and Trends Influencing the Day Pak Inc Sector?

The global packaging machinery market is experiencing robust growth, driven by increasing demand across various sectors, including food and beverage, pharmaceuticals, and personal care. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for informed sourcing decisions. Key trends include the rise of automation and smart technology, which enhance operational efficiency and minimize labor costs. The adoption of Industry 4.0 technologies, such as IoT and AI, is facilitating real-time monitoring and predictive maintenance, thus reducing downtime and improving productivity.

Additionally, the shift towards sustainability is reshaping sourcing strategies. Buyers are increasingly prioritizing suppliers who offer eco-friendly packaging solutions, prompting manufacturers like Day-Pak Inc. to develop innovative, sustainable materials and machinery. The integration of customization capabilities allows businesses to tailor their packaging solutions to meet specific market needs, making it easier for companies to differentiate their products in competitive landscapes.

Illustrative image related to day pak inc

Furthermore, geopolitical factors and supply chain disruptions have heightened the importance of local sourcing and establishing resilient supply chains. This is particularly relevant for buyers in regions like Nigeria and Saudi Arabia, where local economic conditions and regulations can significantly impact procurement strategies. Understanding these market dynamics will enable B2B buyers to navigate challenges effectively and seize opportunities for growth.

How Can Sustainability and Ethical Sourcing Impact Your B2B Partnerships in the Day Pak Inc Sector?

Sustainability and ethical sourcing are becoming non-negotiable components for B2B partnerships in the packaging industry. The environmental impact of packaging materials is under increasing scrutiny, leading businesses to seek suppliers that prioritize eco-friendly practices. Day-Pak Inc. is well-positioned in this regard, as the company focuses on developing sustainable packaging solutions that reduce waste and carbon footprints.

The importance of ethical supply chains extends beyond environmental concerns; it also encompasses social responsibility. Buyers are increasingly aware of the implications of their sourcing decisions on local communities and labor practices. Partnering with suppliers that adhere to ethical standards not only enhances brand reputation but also fosters customer loyalty, particularly in regions where consumers are becoming more socially conscious.

To align with these trends, Day-Pak Inc. offers a variety of sustainable materials and holds certifications that demonstrate its commitment to environmentally responsible practices. For B2B buyers, selecting partners with recognized ‘green’ certifications can enhance credibility and appeal to eco-aware consumers, ultimately driving sales and market share.

What Is the Historical Context of Day Pak Inc That Buyers Should Consider?

Founded in 1981, Day-Pak Inc. has established itself as a veteran player in the packaging machinery sector, catering to a wide range of industries. Over the decades, the company has evolved from a traditional packaging supplier to a comprehensive solutions provider, focusing on customization and automation. The recent acquisition by IPS Packaging & Automation has further strengthened its capabilities, allowing for expanded resources and a broader range of innovative solutions.

As Day-Pak Inc. continues to adapt to changing market demands, its rich history and commitment to quality position it as a reliable partner for international B2B buyers. Understanding this evolution offers valuable insights into the company’s strategic direction and its potential to meet the diverse needs of global clients.

Frequently Asked Questions (FAQs) for B2B Buyers of day pak inc

1. How do I customize packaging machinery to fit my specific needs?

Day-Pak Inc. specializes in creating tailored packaging solutions. To customize your machinery, start by identifying your specific requirements, such as production volume, product type, and packaging materials. Day-Pak’s team works closely with clients, conducting assessments and consultations to design equipment that aligns with your operational goals. Whether you need semi-automatic or fully automated systems, their engineers will ensure that the final product meets your unique specifications.

2. What is the minimum order quantity (MOQ) for packaging machinery from Day-Pak Inc.?

The minimum order quantity for packaging machinery can vary based on the type of equipment and customization required. Typically, Day-Pak Inc. is flexible with MOQs, especially for international buyers. It’s advisable to discuss your specific needs directly with their sales team to get detailed information on MOQs, lead times, and any potential discounts for bulk orders, which can be particularly beneficial for large-scale operations.

Illustrative image related to day pak inc

3. What payment terms does Day-Pak Inc. offer for international buyers?

Day-Pak Inc. provides various payment options tailored for international buyers, including wire transfers, letters of credit, and other secure payment methods. Payment terms are generally negotiated based on the order size and the buyer’s creditworthiness. It’s recommended to clarify these terms during the initial discussions to ensure a smooth transaction process and avoid any misunderstandings later on.

4. How does Day-Pak Inc. ensure quality assurance for their packaging machinery?

Day-Pak Inc. is ISO 9001 certified, reflecting their commitment to maintaining high-quality standards throughout the manufacturing process. Quality assurance is integrated at every stage, from design and production to installation and after-sales support. Each machine undergoes rigorous testing to ensure it meets both the company’s and industry standards before shipment. Buyers can request specific quality assurance documentation to verify compliance with their requirements.

5. What logistics options are available for international shipping of Day-Pak Inc. products?

Day-Pak Inc. collaborates with experienced logistics partners to facilitate international shipping. Options include air freight for expedited delivery and sea freight for cost-effective bulk shipments. They provide comprehensive support in navigating customs regulations and documentation, ensuring a smooth import process. It’s advisable to discuss your shipping needs early in the order process to select the most suitable logistics solution for your business.

6. How can I evaluate the reliability of Day-Pak Inc. as a supplier?

To assess Day-Pak Inc.’s reliability, consider their years of experience in the industry, customer testimonials, and their ISO 9001 certification. Additionally, reviewing their track record for timely deliveries and after-sales support can provide insights into their operational effectiveness. Engaging in direct communication with their team can also help gauge their responsiveness and willingness to meet your specific needs.

Illustrative image related to day pak inc

7. What industries does Day-Pak Inc. serve with their packaging solutions?

Day-Pak Inc. caters to a wide array of industries, including food and beverage, pharmaceuticals, cosmetics, and household products. Their diverse product line includes filling, labeling, capping, cartoning, and wrapping machines, making them versatile for various packaging applications. Understanding which industry you belong to can help you identify the most suitable machinery and solutions for your operations.

8. What kind of support and training does Day-Pak Inc. provide after purchasing machinery?

Day-Pak Inc. offers comprehensive support services post-purchase, including installation, maintenance, and repair. Their experienced technicians provide training sessions for your staff to ensure they are proficient in operating and maintaining the equipment. This ongoing support is crucial for minimizing downtime and optimizing the performance of your packaging machinery, ensuring you get the most out of your investment.

Top 5 Day Pak Inc Manufacturers & Suppliers List

1. Day-Pak Inc. – Packaging Machinery Solutions

Domain: packagingmachinerycompanies.com

Registered: 2019 (6 years)

Introduction: Day-Pak Inc. is a manufacturer and supplier of packaging machinery and solutions, established in 1981. Their product line includes filling machines, labeling machines, capping machines, cartoning machines, and wrapping machines, designed for various industries such as food and beverage, pharmaceuticals, cosmetics, and household products. The machinery is highly customizable to meet specific custom…

2. Day-Pak – Custom Packaging Solutions

Domain: ipack.com

Registered: 1996 (29 years)

Introduction: Day-Pak offers converting capabilities for a variety of materials including sheet foam, bubble, poly bags, and pouches. IPS Packaging & Automation provides comprehensive packaging solutions, including packaging products, automation, equipment, and service, with a team of degree-certified engineers specializing in design work, process improvements, and automated equipment.

3. Day-Pak – Packaging Materials & Equipment

Domain: pitchbook.com

Registered: 2004 (21 years)

Introduction: Day-Pak is a distributor of packaging materials and equipment, providing a full range of packaging services. The company offers stock cartons, corrugated mailers, book folds, pads, and storage bins, along with logistic and maintenance services.

4. Day-Pak Inc. – Packaging Machinery Solutions

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Day-Pak Inc. offers a range of packaging machinery including bagging machines, shrink packaging machinery, converting equipment, case sealing equipment, and strapping products for industrial and military applications.

5. RocketReach – Custom Packaging Solutions

Domain: rocketreach.co

Registered: 2015 (10 years)

Introduction: Packaging, Custom Boxes, Containers, Shipping Boxes, Packaging Design, Corrugated Boxes, Custom Packaging, Shipping Supplies, Packaging Supplies, Wholesale Packaging, Storage Containers, Packaging Solutions, Box Packaging, Cardboard Boxes, Paperboard Packaging, Packaging Materials, Protective Packaging, Bulk Packaging, Sustainable Packaging, Eco-Friendly Packaging

Strategic Sourcing Conclusion and Outlook for day pak inc

In summary, Day-Pak Inc. stands out as a premier provider of customized packaging machinery solutions, offering a diverse range of products tailored to meet the unique needs of various industries, including food and beverage, pharmaceuticals, and cosmetics. The company’s commitment to quality, backed by ISO 9001 certification, ensures that international B2B buyers can trust in the reliability and efficiency of their machinery. Furthermore, the integration of Day-Pak into IPS Packaging & Automation enhances its capabilities, providing extensive resources and expertise that address the evolving demands of global markets.

For businesses in Africa, South America, the Middle East, and Europe, strategic sourcing from Day-Pak Inc. can lead to significant cost savings and improved operational efficiency. By leveraging their customizable solutions, buyers can mitigate challenges related to labor, material costs, and logistics, while ensuring compliance with international standards.

Illustrative image related to day pak inc

As you consider your packaging needs, we encourage you to explore the innovative offerings from Day-Pak Inc. and engage with their knowledgeable team to find solutions that not only meet your requirements but also enhance your competitive edge in the marketplace. The future of your packaging strategy begins with a partnership that prioritizes quality and customization—take the next step today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.