Is Your Rings Of Rubber Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for rings of rubber

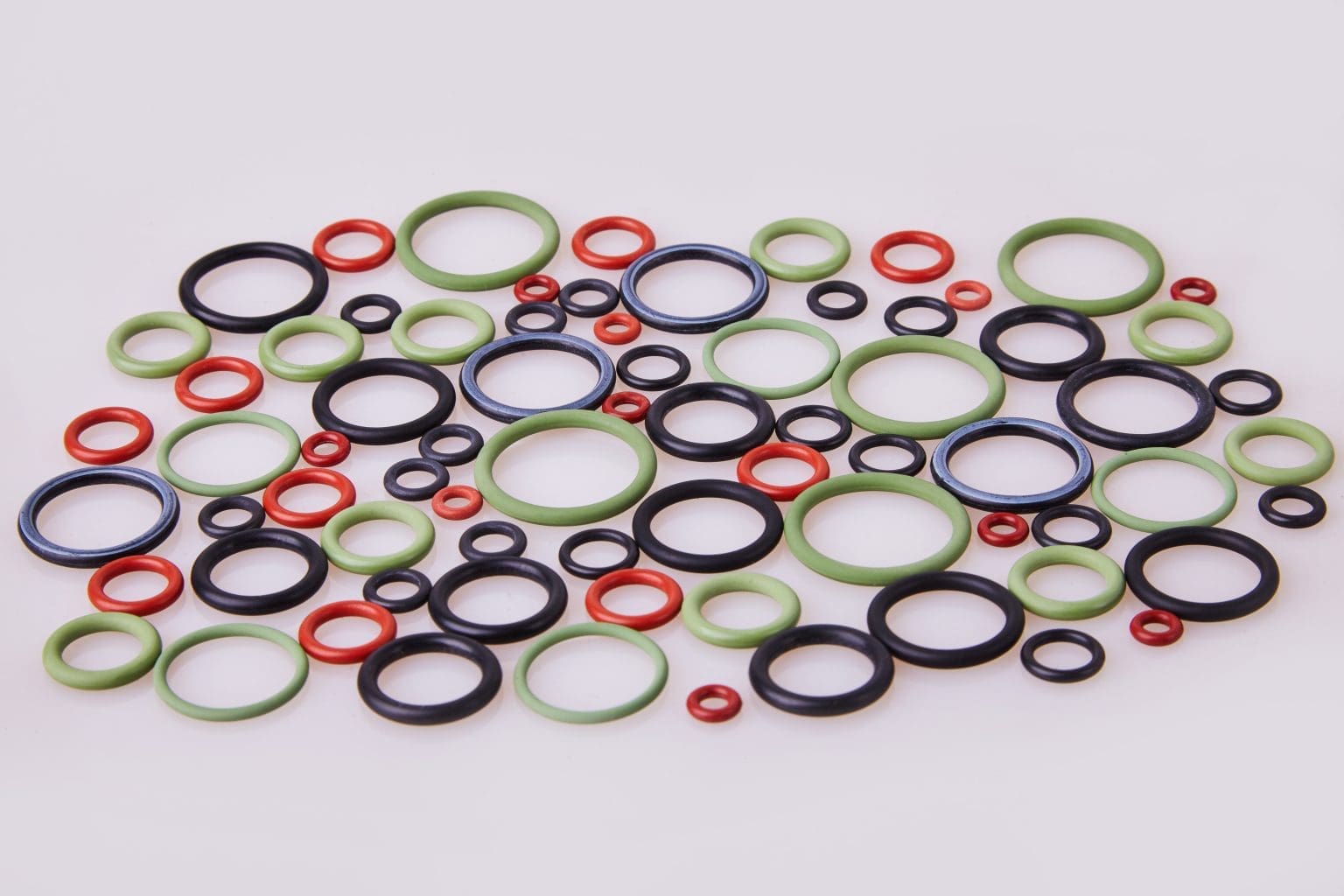

In today’s competitive landscape, sourcing high-quality rings of rubber can pose significant challenges for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. The demand for reliable rubber components—ranging from gaskets to O-rings—has surged across various industries, including automotive, plumbing, and manufacturing. However, navigating the complexities of supplier selection, pricing, and compliance with local regulations can be daunting.

This comprehensive guide aims to equip B2B buyers with the insights necessary to make informed purchasing decisions regarding rubber rings. We will explore the different types of rubber rings available, their specific applications, and the critical factors to consider when vetting suppliers. Additionally, we will discuss pricing structures, potential cost-saving strategies, and tips for ensuring product quality and compliance with international standards.

By leveraging the knowledge presented in this guide, buyers will not only enhance their procurement processes but also foster long-term partnerships with reliable suppliers. This resource is designed to empower businesses to overcome common sourcing hurdles, ensuring that they secure the right rubber rings to meet their operational needs effectively. Whether you are a buyer in Vietnam or Brazil, this guide will serve as your go-to reference for navigating the global market for rings of rubber.

Understanding rings of rubber Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| O-Rings | Circular cross-section, versatile sizes | Sealing in hydraulic applications | Pros: Cost-effective, good sealing properties. Cons: Limited temperature range. |

| Gaskets | Flat, often with cutouts for bolts | Engine seals, plumbing connections | Pros: High durability, customizable shapes. Cons: More expensive than O-rings. |

| Rubber Washers | Flat, thin rings for load distribution | Electrical insulation, plumbing | Pros: Easy to install, reduces wear. Cons: Less effective in high-pressure scenarios. |

| V-Rings | V-shaped cross-section for dynamic sealing | Rotating shafts, heavy machinery | Pros: Excellent for axial sealing. Cons: Requires precise alignment. |

| Quad-Rings | Square cross-section for better sealing | Aerospace, automotive applications | Pros: Improved sealing performance. Cons: Higher cost than standard O-rings. |

What Are O-Rings and Their Key Characteristics for B2B Buyers?

O-rings are circular rubber seals that are essential in various applications, especially in hydraulic and pneumatic systems. Their simple design allows them to fit into grooves, creating a tight seal that prevents leaks. When purchasing O-rings, B2B buyers should consider the material (such as nitrile or silicone), size, and temperature resistance, as these factors greatly influence performance. Their affordability and effectiveness make them a popular choice, though they may not be suitable for extreme temperatures.

How Do Gaskets Differ from Other Rubber Rings?

Gaskets are flat rubber seals that often include cutouts for bolts or other fasteners. They are primarily used in applications where there is a need to seal two surfaces together, such as in engines or plumbing systems. B2B buyers should evaluate the gasket material, thickness, and specific application requirements when sourcing. Gaskets provide high durability and can be customized, but they generally come at a higher price point compared to O-rings.

What Are the Advantages of Rubber Washers in B2B Applications?

Rubber washers are flat, thin rings designed to distribute load and prevent leaks in various applications, including plumbing and electrical insulation. Their ease of installation and ability to reduce wear on surfaces make them a favored choice among B2B buyers. However, they may not perform well under high-pressure conditions. Buyers should focus on the washer’s material and size to ensure compatibility with their specific applications.

Why Choose V-Rings for Dynamic Sealing Needs?

V-rings feature a unique V-shaped cross-section that allows them to provide effective sealing for rotating shafts and heavy machinery. They are particularly useful in applications where axial sealing is required. B2B buyers must ensure precise alignment during installation to maximize their sealing capabilities. While V-rings offer excellent performance, they may require a higher upfront investment compared to other rubber rings.

What Are Quad-Rings and Their Unique Benefits for B2B Buyers?

Quad-rings have a square cross-section that enhances their sealing performance, making them suitable for demanding applications in aerospace and automotive industries. Their design allows for better contact with sealing surfaces, which reduces the likelihood of leaks. B2B buyers should consider the specific application requirements, as quad-rings are typically more expensive than standard O-rings but provide superior sealing capabilities.

Key Industrial Applications of rings of rubber

| Industry/Sector | Specific Application of rings of rubber | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Seals and gaskets in engines | Prevents fluid leakage, enhancing engine efficiency | Material durability, temperature resistance, and compliance with automotive standards |

| Oil & Gas | Sealing applications in pipelines | Reduces leakage, ensuring safety and compliance | Resistance to chemicals and extreme temperatures, certifications for safety standards |

| Manufacturing | Vibration dampening in machinery | Extends equipment lifespan and reduces maintenance costs | Custom sizing, hardness specifications, and sourcing from reliable suppliers |

| Construction | Weatherproofing in building structures | Enhances energy efficiency and structural integrity | UV resistance, compatibility with construction materials, and local sourcing options |

| Food & Beverage | Sealing in processing equipment | Maintains hygiene and prevents contamination | Compliance with food safety regulations, material certifications, and custom sizes |

How Are Rings of Rubber Used in the Automotive Sector?

In the automotive industry, rings of rubber are primarily used as seals and gaskets within engines and other critical components. These rings prevent fluid leakage, which is essential for maintaining engine efficiency and performance. Buyers in this sector must consider the durability of the rubber material and its resistance to high temperatures and pressure. For international buyers, it’s crucial to source products that comply with regional automotive standards to ensure compatibility and reliability.

What Role Do Rings of Rubber Play in Oil & Gas Applications?

In the oil and gas sector, rubber rings are vital for sealing applications in pipelines and storage tanks. Their primary role is to minimize leakage, which is critical for safety and environmental compliance. Buyers need to focus on sourcing rings that are resistant to harsh chemicals and extreme temperatures. Additionally, certifications for safety and environmental standards are essential to mitigate risks associated with leaks and spills, particularly in regions with stringent regulatory frameworks.

How Are Rings of Rubber Beneficial in Manufacturing?

In manufacturing, rubber rings serve as vibration dampeners in machinery, helping to extend equipment lifespan and reduce maintenance costs. These rings absorb shocks and vibrations, promoting smoother operation and minimizing wear and tear. Buyers should look for custom sizing and hardness specifications that meet the unique demands of their machinery. Reliable sourcing is key, as high-quality rubber can significantly impact operational efficiency and productivity.

Why Are Rings of Rubber Important in Construction?

Rubber rings are used in construction primarily for weatherproofing building structures, enhancing energy efficiency, and ensuring structural integrity. They create seals that prevent water ingress and air leaks, thus contributing to better energy performance. When sourcing these rings, buyers must consider UV resistance and compatibility with various construction materials. Local sourcing options can be advantageous for timely delivery and cost management in construction projects.

How Do Rings of Rubber Ensure Safety in Food & Beverage Processing?

In the food and beverage industry, rings of rubber are crucial for sealing processing equipment to maintain hygiene and prevent contamination. They help create airtight seals that are essential for food safety. Buyers should prioritize compliance with food safety regulations and ensure that the materials used are certified for food contact. Custom sizes may also be necessary to fit specific equipment, making reliable sourcing from specialized suppliers a critical consideration.

3 Common User Pain Points for ‘rings of rubber’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Size and Material for Rubber Rings

The Problem: Many B2B buyers face challenges when selecting the appropriate size and material for rubber rings, such as O-rings and gaskets. This issue often arises in industries like manufacturing and plumbing, where the specifications of these components are critical for ensuring equipment functionality and preventing leaks. A wrong choice can lead to costly downtime, production halts, or even damage to machinery, which can be particularly detrimental in regions where operational efficiency is paramount.

The Solution: To mitigate this risk, buyers should begin by thoroughly assessing their application requirements. This involves understanding the operating conditions, such as temperature and pressure, and the type of fluids the rubber rings will encounter. It’s crucial to consult product datasheets provided by manufacturers to identify compatible materials, like Nitrile or Silicone rubber, that can withstand specific environments. Additionally, buyers should utilize tools like calipers or ring gauges to measure existing components accurately, ensuring that new rings fit perfectly. Establishing a relationship with a trusted supplier who offers customization options can also help in sourcing rings tailored to specific needs.

Scenario 2: Short Lifecycle and Wear Issues with Rubber Rings

The Problem: A common pain point for many businesses is the premature wear and tear of rubber rings. This can occur due to harsh operating environments, chemical exposure, or thermal cycling, leading to frequent replacements and increased operational costs. Industries that rely on hydraulic systems or high-temperature applications, like automotive or aerospace, often experience this issue, which can disrupt production schedules and lead to safety hazards.

The Solution: To extend the lifecycle of rubber rings, buyers should focus on selecting high-performance materials that are resistant to the specific conditions they will face. For example, using fluorocarbon-based rubber for chemical resistance or high-temperature silicone can significantly improve durability. Implementing regular maintenance schedules to inspect and replace worn-out rings before they fail is also beneficial. Furthermore, training staff on the importance of proper installation techniques can prevent damage during the installation process, thereby enhancing the lifespan of the rings.

Scenario 3: Sourcing Quality Rubber Rings at Competitive Prices

The Problem: In today’s global market, B2B buyers often struggle to find suppliers that offer high-quality rubber rings at competitive prices. This challenge is exacerbated for companies operating in developing regions, where access to reliable suppliers can be limited. The risk of sourcing low-quality products can lead to increased operational costs and compromised product integrity, affecting overall business reputation.

The Solution: To overcome this sourcing challenge, businesses should consider leveraging online marketplaces and industry-specific platforms that aggregate multiple suppliers, allowing for price comparisons and supplier reviews. Engaging in bulk purchasing agreements can also yield significant discounts and foster long-term relationships with suppliers. Buyers should prioritize suppliers with certifications, such as ISO or ASTM, as these indicate adherence to quality standards. Additionally, conducting periodic audits and requesting samples before committing to large orders can ensure that the rubber rings meet the necessary specifications and quality standards, ultimately safeguarding the business’s operational efficiency.

Strategic Material Selection Guide for rings of rubber

What are the Key Properties of Common Materials Used for Rings of Rubber?

When selecting materials for rubber rings, it is crucial to consider their properties, as these directly impact performance in various applications. Here, we analyze four common materials used in the manufacturing of rubber rings: Nitrile (Buna-N), Silicone, EPDM (Ethylene Propylene Diene Monomer), and Fluoroelastomer (FKM).

Nitrile (Buna-N): A Versatile Choice for General Applications

Nitrile rubber is known for its excellent resistance to oils and fuels, making it a popular choice for applications in the automotive and aerospace industries. It typically operates effectively within a temperature range of -40°F to +250°F (-40°C to +121°C) and can withstand moderate pressure.

Illustrative image related to rings of rubber

Pros: Nitrile rings are durable and cost-effective, making them suitable for mass production. They also provide good mechanical properties, including tensile strength and abrasion resistance.

Cons: However, nitrile is not suitable for exposure to ozone, sunlight, or extreme temperatures, which can lead to degradation over time.

Impact on Application: Nitrile rings are ideal for sealing applications involving petroleum-based fluids but may not perform well in environments with high humidity or extreme temperatures.

Considerations for International Buyers: Compliance with ASTM D2000 standards is essential for ensuring quality. Buyers in regions like Africa and South America should also be aware of local sourcing capabilities to avoid supply chain disruptions.

Silicone: High-Temperature and Chemical Resistance

Silicone rubber is renowned for its exceptional temperature resistance, functioning effectively from -100°F to +500°F (-73°C to +260°C). It is also highly resistant to UV light, ozone, and various chemicals.

Illustrative image related to rings of rubber

Pros: The flexibility and stability of silicone make it ideal for high-temperature applications, such as in the food and pharmaceutical industries.

Cons: Silicone tends to be more expensive than other rubber materials and may not withstand high mechanical stress as well as nitrile.

Impact on Application: Silicone rings are perfect for applications requiring high-temperature stability and chemical resistance, such as gaskets in food processing equipment.

Considerations for International Buyers: Buyers should ensure compliance with FDA regulations if using silicone in food-related applications. Additionally, international standards such as ISO 9001 can help ensure product quality.

EPDM: An Excellent Choice for Weather Resistance

EPDM rubber is particularly known for its excellent weather resistance, making it suitable for outdoor applications. It typically operates effectively between -60°F and +300°F (-51°C to +149°C) and has good resistance to steam and hot water.

Pros: EPDM is durable and maintains its properties over a wide temperature range. It is also resistant to UV radiation and ozone.

Cons: However, EPDM is not compatible with petroleum-based oils and solvents, which limits its use in certain applications.

Impact on Application: EPDM rings are ideal for sealing applications in outdoor environments, such as automotive weather seals and roofing membranes.

Considerations for International Buyers: Compliance with ASTM and DIN standards is critical for EPDM products. Buyers should also consider local climate conditions when selecting materials for outdoor applications.

Fluoroelastomer (FKM): Superior Chemical Resistance

Fluoroelastomers are known for their exceptional chemical resistance and high-temperature performance, functioning effectively from -15°F to +400°F (-26°C to +204°C). They are often used in industries that require exposure to harsh chemicals.

Pros: FKM rings offer excellent durability and can withstand aggressive chemicals, making them suitable for industrial applications.

Illustrative image related to rings of rubber

Cons: The primary drawback is the high cost of fluoroelastomer materials, which may not be justifiable for all applications.

Impact on Application: FKM rings are ideal for applications in the chemical processing and aerospace industries, where exposure to aggressive substances is common.

Considerations for International Buyers: Buyers should ensure compliance with international chemical compatibility standards and be aware of the higher upfront costs associated with FKM materials.

Summary Table of Material Selection for Rubber Rings

| Material | Typical Use Case for rings of rubber | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nitrile (Buna-N) | Automotive seals, fuel systems | Good oil resistance | Poor ozone and UV resistance | Low |

| Silicone | Food processing, high-temperature gaskets | High-temperature stability | Higher cost, lower mechanical strength | High |

| EPDM | Outdoor seals, automotive weather strips | Excellent weather resistance | Not oil-resistant | Medium |

| Fluoroelastomer (FKM) | Chemical processing, aerospace | Superior chemical resistance | High cost | High |

This guide provides actionable insights for international B2B buyers, ensuring informed decisions when selecting materials for rubber rings. Understanding the properties, advantages, and limitations of each material will help in choosing the most suitable option for specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for rings of rubber

What Are the Main Stages in the Manufacturing Process for Rubber Rings?

The manufacturing process for rubber rings, commonly used as gaskets, seals, and various mechanical applications, involves several key stages. Understanding these stages is crucial for B2B buyers looking to evaluate suppliers and ensure product quality.

Illustrative image related to rings of rubber

Material Preparation: How Are Raw Materials Selected and Processed?

The first step in manufacturing rubber rings is the preparation of raw materials. The primary materials used are synthetic or natural rubber compounds, which can include various additives to enhance properties such as durability, flexibility, and resistance to temperature and chemicals. Suppliers often conduct a thorough analysis of the rubber compounds to ensure they meet specific requirements for application.

After selecting the appropriate rubber material, it undergoes mixing, where additives like carbon black, sulfur, and accelerators are combined. This process is critical as it determines the physical properties of the final product. The mixed compound is then subjected to quality checks to confirm consistency and adherence to specifications before moving to the next stage.

How Are Rubber Rings Formed and Shaped?

Once the material is prepared, the next stage is forming. There are several techniques used to shape rubber into rings, including:

-

Compression Molding: In this method, the rubber compound is placed into a heated mold, where it is compressed under high pressure. This technique is suitable for producing large quantities of simple shapes and is often used for standard-sized rubber rings.

-

Transfer Molding: Similar to compression molding, this method involves transferring rubber from a pot into a mold cavity. It allows for more intricate designs and is ideal for complex shapes or multiple cavities.

-

Injection Molding: This modern method injects the rubber compound directly into a mold under high pressure. It offers excellent precision and is suitable for high-volume production with tight tolerances.

Each of these methods requires careful control of temperature and pressure to ensure that the rubber cures properly, achieving the desired mechanical properties.

What Finishing Processes Are Applied to Rubber Rings?

After forming, rubber rings undergo finishing processes that may include trimming excess material, surface treatment, and quality inspections. Trimming ensures that the rings have smooth edges and meet dimensional specifications. Surface treatments, such as coating or polishing, can improve the aesthetic and functional properties of the rings, such as friction resistance.

Additionally, final inspections are conducted to verify that each product meets the required specifications before packaging and shipping. This stage is essential for maintaining quality assurance and customer satisfaction.

What Are the Key Quality Assurance Practices for Rubber Rings?

Quality assurance (QA) in the rubber ring manufacturing process is critical to ensure that products meet international standards and customer expectations. B2B buyers should be aware of the following aspects of QA:

Illustrative image related to rings of rubber

Which International Standards Are Relevant for Rubber Ring Quality Assurance?

Several international standards govern the quality and safety of rubber products, including:

-

ISO 9001: This standard outlines requirements for a quality management system (QMS). Manufacturers seeking ISO 9001 certification demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

-

CE Marking: For products sold in the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

-

API Standards: The American Petroleum Institute (API) sets standards for rubber products used in the oil and gas industry, ensuring safety and performance under extreme conditions.

Understanding these standards is vital for B2B buyers, as compliance can significantly affect product reliability and marketability.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are established throughout the manufacturing process to ensure product integrity. The main checkpoints include:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins.

-

In-Process Quality Control (IPQC): During the manufacturing process, random samples are taken to test for dimensional accuracy, hardness, and other key properties. This ongoing monitoring helps identify issues early in the production cycle.

-

Final Quality Control (FQC): After production, finished products are rigorously tested against specifications. This may include pressure testing, chemical resistance tests, and visual inspections to confirm there are no defects.

These QC checkpoints help manufacturers maintain high-quality standards and address any issues proactively.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, verifying the quality control processes of potential suppliers is crucial to ensure reliability and performance. Here are some practical steps to consider:

What Are Effective Methods for Auditing Suppliers?

Conducting audits is one of the most effective ways to assess a supplier’s quality control processes. Buyers should consider:

-

On-Site Audits: Visiting the manufacturing facility allows buyers to observe processes, equipment, and overall production practices firsthand. It also provides an opportunity to meet the quality assurance team.

-

Supplier Reports: Requesting quality control reports, including data on product testing and compliance with international standards, can provide insights into the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging independent third-party inspection services can offer an unbiased assessment of a supplier’s quality control measures and product quality.

What Are the Nuances in Quality Control for International Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must navigate specific challenges in quality assurance. These challenges may include:

-

Regulatory Compliance: Different regions may have varying regulations regarding rubber products. Buyers should ensure that suppliers comply with local and international standards applicable to their markets.

-

Logistics and Supply Chain Risks: Transportation and handling of rubber products can impact quality. Buyers should inquire about how suppliers manage these risks, including storage conditions and transportation methods.

-

Cultural and Language Barriers: Effective communication is vital for quality assurance. Buyers should consider suppliers that provide clear documentation and support in the buyer’s preferred language.

By being proactive in understanding manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing rubber rings, ensuring they receive high-quality products that meet their specifications and regulatory requirements.

Illustrative image related to rings of rubber

Practical Sourcing Guide: A Step-by-Step Checklist for ‘rings of rubber’

To effectively source rings of rubber, a structured approach is essential. This guide offers a step-by-step checklist to help international B2B buyers navigate the procurement process efficiently. By following these steps, you can ensure that you select high-quality products while mitigating risks associated with sourcing.

Step 1: Define Your Technical Specifications

Understanding your specific requirements is crucial. Determine the dimensions, hardness, material type (such as EPDM or silicone), and intended application (e.g., gaskets, seals). This clarity will help streamline the sourcing process and ensure that you receive products that meet your operational needs.

- Consider industry standards: Familiarize yourself with relevant specifications and standards (e.g., ASTM, ISO) that apply to your application to ensure compliance.

- Identify environmental factors: Consider exposure to chemicals, temperature ranges, and other environmental conditions that may affect the performance of the rubber rings.

Step 2: Conduct Market Research

Before reaching out to suppliers, it’s essential to understand the market landscape. Research potential suppliers in your target regions, focusing on their reputation, product range, and pricing.

- Use online platforms: Explore B2B marketplaces and directories such as Alibaba or Global Sources to identify suppliers.

- Gather insights: Look for reviews, ratings, and testimonials from other buyers to assess supplier reliability.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website.

- Check for certifications: Ensure that suppliers possess relevant certifications (e.g., ISO 9001) that demonstrate their commitment to quality management.

- Assess production capabilities: Inquire about their manufacturing processes, capacity, and lead times to ensure they can meet your demands.

Step 4: Request Samples

Never finalize a purchase without first evaluating product samples. This step allows you to assess the quality, durability, and suitability of the rubber rings for your specific application.

Illustrative image related to rings of rubber

- Specify your requirements: When requesting samples, provide clear instructions regarding the specifications you need them to meet.

- Conduct performance tests: Evaluate the samples under actual operating conditions to confirm their functionality and reliability.

Step 5: Negotiate Terms and Pricing

Once you’ve identified a suitable supplier, initiate negotiations regarding pricing, payment terms, and delivery schedules. This step is critical to ensuring favorable conditions for your purchase.

- Consider bulk discounts: If you plan on ordering large quantities, inquire about volume discounts to reduce costs.

- Clarify payment terms: Establish clear payment terms to avoid misunderstandings; consider using secure payment methods that offer buyer protection.

Step 6: Finalize the Order and Monitor Production

After negotiating terms, finalize your order. Maintain clear communication with the supplier throughout the production process to ensure timelines are met.

- Set milestones: Agree on key milestones for production updates and quality checks.

- Prepare for logistics: Plan the logistics for shipping, including customs clearance and import duties, especially when sourcing from international suppliers.

Step 7: Review and Evaluate Post-Purchase

After receiving your order, conduct a thorough review of the products. Evaluate their performance in your application to determine if they meet your expectations.

- Provide feedback: Share your experience with the supplier, which can lead to improved future transactions.

- Maintain supplier relationships: Cultivating good relationships with suppliers can lead to better service, pricing, and product offerings in future transactions.

By following this checklist, B2B buyers can effectively source rings of rubber that meet their specific needs while ensuring quality and reliability in their supply chain.

Comprehensive Cost and Pricing Analysis for rings of rubber Sourcing

What Are the Key Cost Components for Sourcing Rings of Rubber?

Understanding the cost structure for sourcing rings of rubber is crucial for international B2B buyers. The primary cost components include:

-

Materials: The type of rubber used significantly impacts cost. Natural rubber may be more expensive than synthetic alternatives, but it can offer superior performance in specific applications. Buyers should also consider the cost of additives, such as fillers and stabilizers, which enhance durability and resistance.

-

Labor: Labor costs vary by region and influence overall pricing. In countries with higher labor costs, such as those in Europe, the production costs for rubber rings will be higher compared to regions with lower labor costs, like parts of Asia or South America.

-

Manufacturing Overhead: This includes costs related to utilities, factory maintenance, and equipment depreciation. Understanding the production environment can provide insights into potential hidden costs.

-

Tooling: Custom tooling for specialized ring designs can significantly increase upfront costs. Buyers should evaluate the necessity of such investments based on their order volume and the expected lifespan of the tooling.

-

Quality Control (QC): Ensuring that products meet required standards is essential, especially for applications in critical industries. The QC process can add to manufacturing costs, but it is vital for maintaining product integrity.

-

Logistics: Shipping and handling costs can vary based on the Incoterms agreed upon. Costs may increase for remote locations or due to tariffs and import duties, particularly for buyers in regions like Africa and South America.

-

Margin: Supplier profit margins can vary widely. Factors influencing margins include market demand, supplier reputation, and competition. Buyers should be aware that lower prices might indicate compromised quality or service.

What Influences Pricing for Rubber Rings?

Several factors affect the pricing of rubber rings, which buyers should consider:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to lower per-unit costs. Negotiating favorable MOQs can yield significant savings.

-

Specifications and Customization: Custom designs or unique specifications can increase production complexity, thus raising costs. Buyers should clarify their requirements early in the negotiation process to avoid unexpected expenses.

-

Materials and Quality Certifications: The choice of materials and any necessary quality certifications (such as ISO or ASTM) can impact pricing. Higher-quality materials typically command higher prices, but they may offer long-term savings through increased durability.

-

Supplier Factors: The supplier’s location, reputation, and reliability can influence pricing. Established suppliers may charge more for their assurance of quality and reliability.

-

Incoterms: The agreed-upon Incoterms will determine who bears the shipping costs and risk during transit. Understanding these terms is vital for calculating the total landed cost.

How Can Buyers Optimize Costs When Sourcing Rubber Rings?

For international buyers, especially in Africa, South America, the Middle East, and Europe, optimizing costs involves several strategic approaches:

-

Negotiation: Engage in thorough negotiations with suppliers. Understanding the cost components can empower buyers to negotiate better terms based on their needs and market conditions.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes not only the purchase price but also shipping, handling, and potential costs related to quality issues. This holistic view helps identify the most cost-effective options.

-

Pricing Nuances: Be aware that international pricing may include fluctuations due to exchange rates and tariffs. Regularly reviewing supplier contracts and market conditions can help mitigate these risks.

-

Supplier Relationships: Establishing long-term relationships with suppliers can yield benefits such as better pricing, priority in production schedules, and improved service.

Conclusion

When sourcing rings of rubber, international B2B buyers must navigate a complex landscape of costs and pricing influences. By understanding the key components of the cost structure and leveraging negotiation strategies, buyers can make informed decisions that enhance their procurement efficiency while maintaining product quality. Always remember to consider the total cost implications and the specifics of international trade to secure the best deals.

Alternatives Analysis: Comparing rings of rubber With Other Solutions

Understanding Alternatives for Rings of Rubber in Industrial Applications

In the pursuit of efficient sealing and cushioning solutions, businesses often explore alternatives to rings of rubber. While rubber rings are widely used for applications like gaskets and seals, it’s essential to evaluate other viable options. This analysis will compare rings of rubber with two alternatives: silicone seals and metal gaskets. Each option has unique characteristics that may align better with specific industrial needs.

Illustrative image related to rings of rubber

| Comparison Aspect | Rings of Rubber | Silicone Seals | Metal Gaskets |

|---|---|---|---|

| Performance | Good elasticity, effective in sealing | Excellent temperature resistance, durable | High strength, excellent sealing under pressure |

| Cost | Generally low cost | Moderate cost | Higher cost due to materials |

| Ease of Implementation | Easy to install | Requires precision in fitting | Installation may require specialized tools |

| Maintenance | Minimal upkeep required | Durable but may need replacement over time | Long lifespan, but can corrode if not maintained |

| Best Use Case | General sealing applications | High-temperature environments | High-pressure applications |

What Are the Benefits and Drawbacks of Silicone Seals?

Silicone seals are a popular alternative due to their ability to withstand extreme temperatures and harsh chemicals. They are suitable for applications in automotive and aerospace industries where high performance is critical. However, silicone seals can be more expensive than rubber rings, which might deter cost-sensitive projects. Their installation requires precision to ensure a proper fit, and while they are durable, they may eventually need replacement if subjected to extreme conditions over prolonged periods.

How Do Metal Gaskets Compare to Rings of Rubber?

Metal gaskets offer a robust sealing solution, particularly in high-pressure and high-temperature scenarios. They are favored in industries such as oil and gas or power generation. One of the significant advantages of metal gaskets is their strength and longevity, which can lead to lower maintenance costs in the long run. However, their initial costs are higher compared to rubber and silicone options, and installation might necessitate specialized tools and expertise. Additionally, if not properly maintained, metal gaskets can corrode, leading to potential failures.

Conclusion: How to Choose the Right Sealing Solution?

When selecting a sealing solution, B2B buyers must consider specific application requirements such as temperature, pressure, and cost. Rings of rubber offer a cost-effective and easy-to-implement option for standard sealing needs. In contrast, silicone seals provide enhanced performance in extreme conditions, while metal gaskets excel in high-pressure environments. Evaluating these factors will enable businesses to make informed decisions that align with their operational requirements and budget constraints.

Essential Technical Properties and Trade Terminology for rings of rubber

What Are the Key Technical Properties of Rubber Rings?

When sourcing rubber rings for industrial applications, understanding their technical properties is crucial for ensuring compatibility and performance in your specific use case. Here are several essential specifications to consider:

Material Grade

The material grade of rubber rings indicates the quality and type of rubber used, such as Nitrile (Buna-N), EPDM, or Silicone. Each material has distinct properties like temperature resistance, chemical compatibility, and durability. For example, Nitrile is preferred for oil resistance, while EPDM excels in outdoor applications due to its UV stability. Choosing the right material grade is essential for ensuring that the rubber rings meet the operational demands of your application.

Tolerance

Tolerance refers to the allowable variation in dimensions of the rubber rings, including diameter and thickness. Tighter tolerances are often required for applications that involve precise fittings, such as hydraulic systems. In contrast, more lenient tolerances may suffice for general sealing purposes. Proper tolerance levels ensure that the rubber rings provide adequate sealing without causing undue stress on equipment, thereby extending service life.

Hardness

Measured in Shore A durometer, hardness indicates the firmness of the rubber. A lower Shore A value corresponds to a softer rubber, which can provide better sealing but may wear out faster. Conversely, higher values indicate harder rubber, which offers better wear resistance but may not seal as effectively. Selecting the appropriate hardness is vital for achieving optimal performance in applications like gaskets and seals.

Compression Set

This property measures the ability of rubber to return to its original shape after being compressed. A lower compression set indicates better resilience and long-term sealing capability. This is particularly important in dynamic applications where rubber rings are subjected to repeated compression and decompression. Understanding compression set can help you assess the longevity and reliability of rubber rings in your application.

Illustrative image related to rings of rubber

What Trade Terminology Should B2B Buyers Know for Rubber Rings?

Familiarity with trade terminology is essential for effective communication and negotiation in the rubber rings market. Here are some key terms to understand:

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that are sold under another company’s brand. When sourcing rubber rings, knowing whether a supplier is an OEM can assure you of the quality and reliability of the products, as they are often designed to meet specific industry standards.

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is crucial for budget planning and inventory management. If your needs are below the MOQ, you may need to negotiate or seek alternative suppliers to avoid excess inventory costs.

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specific products or services. Crafting a detailed RFQ for rubber rings helps ensure you receive accurate pricing and technical specifications, enabling better decision-making.

Illustrative image related to rings of rubber

Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in the shipping process. Familiarity with terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can help you understand shipping costs and responsibilities, which is vital for budgeting and logistics planning.

Understanding these technical properties and trade terms will empower B2B buyers to make informed decisions when sourcing rubber rings, ultimately leading to enhanced operational efficiency and cost-effectiveness.

Navigating Market Dynamics and Sourcing Trends in the rings of rubber Sector

What Are the Key Trends Shaping the Global Rings of Rubber Market?

The global market for rings of rubber, particularly gaskets and O-rings, is witnessing significant growth driven by various factors. Increased industrialization across emerging economies in Africa, South America, and Asia is a primary driver. As manufacturing and construction sectors expand, the demand for durable sealing solutions rises. Furthermore, technological advancements are reshaping sourcing methods, with businesses increasingly relying on digital platforms for procurement. E-commerce solutions are making it easier for international buyers to connect with suppliers, enhancing transparency and efficiency in the supply chain.

Emerging trends include the rise of custom solutions, as businesses seek specific specifications to meet unique operational requirements. The shift towards automation and smart manufacturing is also influencing the design and production of rubber rings, leading to innovations in material properties and manufacturing processes. For buyers in regions like Brazil and Vietnam, understanding these market dynamics is crucial for optimizing sourcing strategies and maintaining competitive edges.

How Is Sustainability Influencing Sourcing in the Rings of Rubber Sector?

Sustainability has become a pivotal consideration in the sourcing of rings of rubber. The environmental impact of rubber production, particularly in terms of deforestation and carbon emissions, is under scrutiny. B2B buyers are increasingly prioritizing suppliers who adhere to ethical sourcing practices and demonstrate commitment to sustainability. This includes the use of natural rubber sourced from certified plantations and the adoption of recycled materials in production.

In addition, the demand for ‘green’ certifications, such as the Forest Stewardship Council (FSC) and ISO 14001, is rising among international buyers. These certifications not only ensure compliance with environmental standards but also enhance brand reputation in a market that values corporate responsibility. By selecting suppliers who prioritize sustainable practices, companies can reduce their environmental footprint and appeal to a growing segment of environmentally conscious consumers.

What Is the Historical Context of the Rings of Rubber Market?

The rings of rubber sector has a rich history that dates back to the industrial revolution when rubber began to be used as a versatile material for various applications. Initially, the production of rubber rings was limited to basic shapes and sizes, primarily for sealing and cushioning purposes in mechanical systems. Over time, advancements in polymer chemistry and manufacturing techniques led to the development of specialized rubber compounds, allowing for increased durability and resistance to extreme conditions.

In the late 20th century, the introduction of synthetic rubber significantly expanded the market, making rubber rings more accessible and cost-effective for various industries. Today, the sector is characterized by a blend of traditional manufacturing techniques and innovative technologies, providing a wide array of solutions tailored to specific industry needs. Understanding this evolution is essential for B2B buyers as it highlights the importance of innovation and adaptability in sourcing strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of rings of rubber

-

How do I select the right rubber rings for my application?

Choosing the right rubber rings involves understanding the specific requirements of your application. Consider factors such as temperature tolerance, chemical compatibility, and pressure ratings. For example, if the rings will be used in a plumbing application, look for materials that resist water and certain chemicals. Consulting with suppliers about your specific needs can provide tailored recommendations, ensuring you select the most suitable rubber rings. -

What are the common applications for rubber rings in industrial settings?

Rubber rings are widely used in various industries, including automotive, plumbing, and manufacturing. They function as gaskets, seals, and cushioning components to prevent leaks, reduce vibration, and ensure airtight connections. Understanding the specific application can help you choose the right type of rubber and design, whether for sealing joints in machinery or providing a tight fit in hydraulic systems. -

What are the minimum order quantities (MOQs) for rubber rings?

Minimum order quantities for rubber rings can vary significantly by supplier and product type. Typically, MOQs range from a few dozen to thousands of units, depending on the manufacturing process and material costs. When sourcing internationally, it’s essential to discuss MOQs with suppliers to ensure they align with your production needs and budget constraints. -

How can I ensure the quality of rubber rings from suppliers?

To ensure the quality of rubber rings, conduct thorough supplier vetting. Request samples to evaluate material properties and performance. Additionally, check for certifications such as ISO 9001, which indicates adherence to quality management standards. Regularly communicate with suppliers about quality expectations and consider implementing quality assurance protocols to monitor production batches. -

What payment terms are common in B2B transactions for rubber rings?

Payment terms in B2B transactions can vary widely, but common practices include net 30, net 60, or upfront payments for larger orders. Many suppliers may offer discounts for early payments or larger quantities. It’s advisable to negotiate terms that are favorable for both parties while ensuring that the payment structure aligns with your cash flow needs. -

What logistics considerations should I keep in mind when importing rubber rings?

When importing rubber rings, consider shipping methods, customs regulations, and potential tariffs. Choose a reliable freight forwarder familiar with international logistics to streamline the process. Additionally, factor in lead times for production and shipping to avoid delays in your supply chain. Understanding the import regulations of your country can also prevent costly compliance issues. -

Can I customize rubber rings to meet specific requirements?

Yes, many suppliers offer customization options for rubber rings, including size, shape, and material composition. Customization allows you to tailor products to specific applications, such as increasing durability or chemical resistance. Discuss your requirements with suppliers to explore available options and lead times for custom orders, ensuring that the final product meets your exact specifications. -

What are the advantages of sourcing rubber rings from international suppliers?

Sourcing rubber rings internationally can provide access to a broader range of products, often at competitive prices. Many international suppliers specialize in specific types of rubber and manufacturing processes, which can enhance product quality. Additionally, international sourcing can lead to innovation through exposure to different technologies and materials. However, it’s crucial to weigh the benefits against potential challenges, such as language barriers and longer lead times.

Top 5 Rings Of Rubber Manufacturers & Suppliers List

1. Online Crosswords – Gaskets

Domain: onlinecrosswords.net

Registered: 2006 (19 years)

Introduction: Rings of rubber, crossword clue answer: GASKETS. Related clues include engine seals, eyelets, leakage stoppers, mechanical parts, plumber’s rubber rings, and soft washers.

2. Wordplays – Crossword Solver

Domain: wordplays.com

Registered: 1999 (26 years)

Introduction: This company, Wordplays – Crossword Solver, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Danword – Crossword Clue Solutions

Domain: danword.com

Registered: 2012 (13 years)

Introduction: Rubber rings are referenced in crossword puzzles, specifically in a clue from The USA Today quick crossword. Possible answers for the clue ‘Rubber rings’ include ‘TIRES’ and ‘GASKETS’. The website encourages users to submit additional solutions if they find them.

4. Daily Themed Crossword – Gaskets

Domain: dailythemedcrossword.info

Introduction: Rings of rubber are referred to as GASKETS in the context of the Daily Themed Crossword.

5. Spiderchain – Silicone Rubber Rings

Domain: spiderchain.com

Registered: 1999 (26 years)

Introduction: Rubber Rings from Spiderchain Jewelry Boutique are silicone-based, non-latex, closed rubber jump rings developed and tested by Blue Buddha Boutique. They are designed to help finish traditional chainmaille weaves faster, resulting in flexible and stretchy pieces. The rings can be manipulated to create unique patterns not achievable with metal. They maintain vibrant colors over time and can be clea…

Strategic Sourcing Conclusion and Outlook for rings of rubber

In the competitive landscape of rubber ring sourcing, strategic procurement emerges as a pivotal factor for success. Understanding the diverse applications of rubber rings, including gaskets and seals, enables buyers to select high-quality products that meet specific operational needs. By leveraging local suppliers and exploring international markets, businesses can optimize costs while ensuring compliance with regional standards and regulations.

For international buyers, particularly from Africa, South America, the Middle East, and Europe, the focus should be on establishing strong relationships with manufacturers who can provide consistent quality and reliable supply chains. Engaging in strategic sourcing not only enhances product availability but also fosters innovation through collaboration with suppliers, ensuring that businesses stay ahead of market trends.

Looking ahead, the demand for rubber rings is expected to grow, driven by advancements in manufacturing processes and the increasing need for durable sealing solutions. B2B buyers are encouraged to stay informed about emerging technologies and market dynamics to make proactive sourcing decisions. Embrace this opportunity to enhance your supply chain resilience and drive value through strategic sourcing of rubber rings.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.