The Definitive Guide to 6754-11-5220 Muffler: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for 6754-11-5220 muffler

Navigating the global market for the 6754-11-5220 muffler presents a unique challenge for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. The task of sourcing high-quality mufflers that meet stringent operational standards while balancing cost-efficiency can often feel daunting. This comprehensive guide serves as a vital resource, equipping buyers with the knowledge to make informed purchasing decisions.

Within these pages, you will explore various types of 6754-11-5220 mufflers, their applications across different machinery, and the critical factors to consider when vetting suppliers. We delve into the intricacies of cost analysis, highlighting how to identify competitive pricing without compromising on quality. Additionally, the guide provides insights into sourcing used versus new parts, ensuring that you can choose the best option for your specific needs.

By empowering you with actionable insights and expert recommendations, this guide aims to streamline your procurement process and enhance your supply chain efficiency. Whether you are operating in a bustling market like Saudi Arabia or the emerging economies of South America, understanding the nuances of the muffler market will enable you to navigate challenges and seize opportunities for growth.

Understanding 6754-11-5220 muffler Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| OEM Muffler | Original equipment manufacturer; guarantees fit and performance | Heavy machinery, construction equipment | Pros: High reliability; Cons: Higher cost |

| Used Muffler | Pre-owned parts; cost-effective alternative | Budget-conscious buyers | Pros: Lower price; Cons: Potential wear issues |

| Rebuilt Muffler | Refurbished to meet OEM specifications | Companies seeking cost-effective solutions | Pros: Good performance; Cons: Warranty limitations |

| Aftermarket Muffler | Third-party manufacturers; various designs available | Diverse machinery types | Pros: Competitive pricing; Cons: Variable quality |

| Custom Muffler | Tailored to specific machinery requirements | Specialized applications | Pros: Perfect fit; Cons: Longer lead times |

What Are the Key Characteristics of OEM Mufflers?

OEM (Original Equipment Manufacturer) mufflers, such as the 6754-11-5220, are designed to meet the exact specifications of the machinery they serve. These mufflers are typically made from high-quality materials and undergo rigorous testing to ensure durability and performance. B2B buyers in sectors like heavy construction and mining often prefer OEM parts due to their reliability and compatibility, which minimizes downtime. However, the premium price can be a barrier for some companies.

How Do Used Mufflers Offer Value to Budget-Conscious Buyers?

Used mufflers represent a cost-effective option for businesses looking to maintain their equipment without incurring the high costs associated with new parts. These mufflers are often sourced from decommissioned machines and can still provide reliable performance if they are in good condition. They are particularly appealing to budget-conscious buyers in developing markets where cost savings are crucial. However, buyers should be cautious about potential wear and ensure they are purchasing from reputable suppliers.

What Are the Advantages of Rebuilt Mufflers for Cost-Effective Solutions?

Rebuilt mufflers are refurbished to meet OEM specifications, offering a middle ground between new and used options. These mufflers are stripped down, repaired, and reassembled, ensuring they function like new. B2B buyers looking for a balance between price and performance often opt for rebuilt mufflers, especially in industries with tight budgets. While they generally come with warranties, the extent of coverage may vary, which is an important consideration for buyers.

How Do Aftermarket Mufflers Provide Competitive Options?

Aftermarket mufflers are produced by third-party manufacturers and can offer various designs and materials that may not be available through OEM suppliers. This flexibility allows businesses to find solutions tailored to their specific machinery needs. While they often come at a lower price point, the quality can vary significantly, making it essential for buyers to conduct thorough research and possibly seek reviews or recommendations before purchasing.

Why Are Custom Mufflers Important for Specialized Applications?

Custom mufflers are designed to meet unique specifications required by specific machinery or operational needs. They are crucial for companies that operate specialized equipment or have specific noise reduction requirements. While custom solutions can ensure a perfect fit and optimal performance, they often come with longer lead times and higher costs. B2B buyers should weigh the benefits of customization against their project timelines and budgets when considering this option.

Key Industrial Applications of 6754-11-5220 muffler

| Industry/Sector | Specific Application of 6754-11-5220 Muffler | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction Equipment | Replacement for Komatsu WA320-6 and WA250-6 machinery | Cost-effective alternative to OEM parts, ensuring operational efficiency in heavy machinery. | Verify compatibility with specific Komatsu models; assess the condition (new vs. used) for reliability. |

| Mining and Quarrying | Used in excavators and wheel loaders for noise reduction | Enhances worker safety by reducing noise pollution, complying with regulations. | Consider local noise regulations; ensure availability of parts for quick replacements. |

| Agriculture | Integration in tractors and agricultural machinery | Improves engine performance and longevity, reducing downtime during critical farming seasons. | Evaluate the durability of the muffler in harsh environments; confirm supply chain reliability. |

| Material Handling | Utilized in forklifts and loaders for effective exhaust management | Increases equipment lifespan and efficiency, lowering operational costs. | Assess sourcing options for timely delivery to minimize equipment downtime. |

| Automotive Repair Services | Servicing heavy-duty vehicles and machinery | Provides a reliable solution for repairs, contributing to customer satisfaction. | Ensure access to quality used parts and warranty options for customers. |

How is the 6754-11-5220 Muffler Used in Key Industries?

In the construction equipment sector, the 6754-11-5220 muffler serves as a vital component for machines like the Komatsu WA320-6 and WA250-6. These mufflers reduce engine noise, providing a more pleasant working environment on job sites. For B2B buyers, sourcing high-quality used mufflers can present a cost-effective alternative to OEM parts, balancing quality with budget constraints.

The mining and quarrying industry benefits significantly from the 6754-11-5220 muffler due to its role in excavators and wheel loaders. By mitigating noise pollution, it not only enhances worker safety but also helps companies comply with environmental regulations. Buyers from regions with strict noise control policies, such as Europe and parts of South America, should ensure that the mufflers meet local compliance standards.

In agriculture, the muffler is essential for tractors and other machinery, improving engine performance and extending equipment lifespan. During peak farming seasons, any downtime can lead to significant losses, making it crucial for international buyers to consider the durability and reliability of the muffler, especially in challenging environments.

The material handling sector utilizes the 6754-11-5220 muffler in forklifts and loaders, where effective exhaust management is critical. This application not only enhances equipment efficiency but also reduces operational costs. B2B buyers should prioritize suppliers that can guarantee timely delivery of these parts to avoid disruptions in operations.

Lastly, automotive repair services find the 6754-11-5220 muffler beneficial for servicing heavy-duty vehicles and machinery. Offering a reliable solution for repairs boosts customer satisfaction, making it essential for repair shops to ensure they have access to quality used parts and favorable warranty options. This aspect is particularly important for international buyers who may face longer lead times for shipping and sourcing.

3 Common User Pain Points for ‘6754-11-5220 muffler’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality Used Mufflers

The Problem: One common pain point for B2B buyers in the construction and machinery sectors is the challenge of sourcing high-quality used parts, particularly for critical components like the 6754-11-5220 muffler. Buyers often face uncertainty regarding the reliability and condition of used parts, which can lead to operational downtime and increased repair costs. This concern is especially pronounced for companies operating in regions with less established supply chains, such as parts of Africa and South America, where quality assurance can be an afterthought.

The Solution: To mitigate this issue, buyers should partner with reputable suppliers who specialize in used machinery parts and have a solid track record. It’s crucial to request detailed inspections and certification of the muffler’s condition before purchase. Buyers can also leverage online marketplaces and forums where verified sellers provide user reviews and ratings. Establishing relationships with local dealers who can vouch for the quality of their inventory can also enhance confidence. Additionally, consider purchasing from suppliers that offer warranties on used parts, as this provides a safety net should the part fail prematurely.

Scenario 2: Understanding Compatibility with Machinery Models

The Problem: Another significant challenge for international B2B buyers is ensuring the compatibility of the 6754-11-5220 muffler with their specific machinery models, such as the Komatsu WA320-6 or WA250-6. Miscommunication regarding part specifications can result in costly returns, extended downtimes, and frustrations that can affect project timelines and budgets. This issue is exacerbated in regions where technical support and documentation may not be readily available.

The Solution: To address compatibility concerns, buyers should conduct thorough research on their machinery specifications and the corresponding parts required. Utilizing detailed parts catalogs and consulting with manufacturers can provide clarity. It’s also advisable to maintain an updated inventory list of existing machinery and their compatible parts. When purchasing, buyers should explicitly confirm the model numbers and compatibility with the seller to avoid misunderstandings. Engaging with suppliers who provide comprehensive technical support or online resources can further streamline this process.

Scenario 3: High Costs of New OEM Mufflers

The Problem: The high costs associated with purchasing new Original Equipment Manufacturer (OEM) parts, such as the 6754-11-5220 muffler, can be a substantial burden for B2B buyers, particularly for small to mid-sized enterprises operating in emerging markets. These elevated costs can limit a company’s ability to maintain their equipment, leading to deferred maintenance and increased long-term operational risks.

The Solution: To combat high costs, buyers should explore the option of purchasing certified refurbished or high-quality used mufflers, which can offer significant savings without compromising on quality. It is essential to verify that these used parts meet industry standards and have been refurbished by credible suppliers. Additionally, buyers can benefit from bulk purchasing agreements or long-term contracts with suppliers, which often provide discounts on large orders. Finally, considering alternative brands that offer competitive pricing for equivalent parts can also be a viable strategy, as long as compatibility and quality are assured.

Strategic Material Selection Guide for 6754-11-5220 muffler

What Are the Common Materials Used in the 6754-11-5220 Muffler?

The selection of materials for the 6754-11-5220 muffler is critical to ensure optimal performance, durability, and compliance with international standards. Below, we analyze four common materials used in muffler manufacturing, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

How Does Stainless Steel Perform in Muffler Applications?

Key Properties: Stainless steel is known for its excellent corrosion resistance, high-temperature tolerance, and strength. It can withstand extreme temperatures and pressures, making it suitable for mufflers that experience significant thermal and acoustic loads.

Pros & Cons: One of the primary advantages of stainless steel is its durability and resistance to rust and corrosion, which prolongs the lifespan of the muffler. However, it is relatively expensive compared to other materials, which may be a concern for budget-conscious buyers. Additionally, manufacturing processes for stainless steel can be complex, requiring specialized equipment.

Impact on Application: Stainless steel mufflers are compatible with a variety of exhaust gases and can maintain structural integrity under varying conditions. This material is particularly beneficial in regions with high humidity or saline environments, such as coastal areas in Africa and South America.

Considerations for International Buyers: Buyers should ensure compliance with ASTM or DIN standards when sourcing stainless steel mufflers. The preference for stainless steel is growing in Europe due to its environmental benefits and recyclability.

Why Choose Aluminized Steel for Mufflers?

Key Properties: Aluminized steel features a layer of aluminum that provides corrosion resistance and can withstand moderate temperatures, making it a popular choice for mufflers.

Pros & Cons: The primary advantage of aluminized steel is its cost-effectiveness; it is less expensive than stainless steel while still offering decent durability. However, it is less resistant to high temperatures and can corrode faster than stainless steel in harsh environments.

Impact on Application: Aluminized steel mufflers are suitable for standard exhaust applications but may not perform well in extreme conditions. They are often used in regions with moderate climates, making them a viable option for buyers in places like Vietnam and parts of the Middle East.

Illustrative image related to 6754-11-5220 muffler

Considerations for International Buyers: Buyers should be aware of the specific environmental conditions in their regions, as aluminized steel may not be suitable for areas with high salt exposure. Compliance with local standards is essential to ensure product longevity.

What Are the Benefits of Mild Steel in Muffler Manufacturing?

Key Properties: Mild steel is characterized by its malleability and weldability, making it easy to manufacture into various shapes and sizes.

Pros & Cons: The main advantage of mild steel is its low cost, making it an attractive option for budget-sensitive projects. However, mild steel lacks the corrosion resistance of stainless and aluminized steel, which can lead to a shorter lifespan in adverse conditions.

Impact on Application: Mild steel mufflers are typically used in less demanding applications where cost is a primary concern. They are suitable for regions with dry climates but may not be ideal for areas with high moisture levels.

Considerations for International Buyers: Buyers should consider protective coatings to enhance the durability of mild steel mufflers. Compliance with local regulations regarding emissions and noise levels is crucial, particularly in Europe and North America.

How Does Titanium Compare as a Muffler Material?

Key Properties: Titanium is known for its exceptional strength-to-weight ratio and excellent corrosion resistance, making it suitable for high-performance applications.

Pros & Cons: The key advantage of titanium is its lightweight nature, which can improve overall vehicle efficiency. However, it is significantly more expensive than other materials, which may limit its use to specialized applications.

Impact on Application: Titanium mufflers perform exceptionally well in high-temperature environments, making them suitable for performance vehicles and heavy machinery. This material is particularly advantageous in regions with high operational demands.

Considerations for International Buyers: Buyers should ensure that titanium mufflers meet specific international standards. The high cost may be justified in applications where performance and weight savings are critical.

Illustrative image related to 6754-11-5220 muffler

Summary Table of Material Properties for 6754-11-5220 Muffler

| Material | Typical Use Case for 6754-11-5220 muffler | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Heavy machinery and high-performance vehicles | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Aluminized Steel | Standard industrial applications | Cost-effective and decent durability | Less resistant to extreme conditions | Medium |

| Mild Steel | Budget-sensitive projects | Low cost and easy to manufacture | Poor corrosion resistance | Low |

| Titanium | High-performance and racing applications | Lightweight and strong | Very high cost | High |

This comprehensive analysis provides B2B buyers with actionable insights into material selection for the 6754-11-5220 muffler, ensuring informed purchasing decisions aligned with their specific operational needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for 6754-11-5220 muffler

What Are the Key Stages in the Manufacturing Process of the 6754-11-5220 Muffler?

The manufacturing process of the 6754-11-5220 muffler involves several critical stages, ensuring that the final product meets the stringent performance and durability requirements expected by B2B buyers.

-

Material Preparation: The process begins with the selection of high-quality raw materials, typically steel or stainless steel, which are chosen for their strength, durability, and resistance to corrosion. These materials undergo rigorous testing for chemical composition and mechanical properties to ensure they meet industry standards.

-

Forming: In this stage, the raw materials are shaped into the desired muffler configuration using various techniques such as stamping, bending, and welding. Advanced machinery, like CNC (Computer Numerical Control) machines, is often employed to achieve precise dimensions and consistent quality. The forming process is crucial as it directly impacts the muffler’s performance, including sound attenuation and exhaust flow efficiency.

-

Assembly: Once the individual components are formed, they are assembled into the final muffler unit. This may involve welding or fastening parts together, depending on the design specifications. Attention to detail is vital during assembly to ensure that there are no gaps or leaks, which could compromise the muffler’s effectiveness.

-

Finishing: The final step in the manufacturing process is finishing, which includes surface treatments such as painting, powder coating, or galvanizing. These treatments enhance the muffler’s resistance to rust and environmental damage, thereby extending its lifespan. Quality checks during this phase are essential to ensure that the surface finish meets aesthetic and functional standards.

How Is Quality Assurance Implemented in Muffler Manufacturing?

Quality assurance (QA) in the production of the 6754-11-5220 muffler is crucial for maintaining product reliability and customer satisfaction. International standards and industry-specific certifications guide the QA processes.

-

International Standards: Manufacturers often adhere to ISO 9001 standards, which outline a framework for quality management systems. Compliance with ISO 9001 demonstrates a commitment to continuous improvement and customer satisfaction, which is vital for B2B transactions. Additionally, certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may apply, depending on the intended use of the muffler.

-

Quality Control Checkpoints: Quality control (QC) is typically integrated at multiple stages of the manufacturing process:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Throughout the manufacturing process, inspections are conducted to monitor key parameters such as dimensions, weld quality, and surface finish.

– Final Quality Control (FQC): Before shipping, the finished muffler undergoes a comprehensive inspection that includes performance testing, dimensional checks, and visual inspections. -

Common Testing Methods: Various testing methods are employed to validate the quality of the muffler. These can include:

– Pressure Testing: Ensures the muffler can withstand the exhaust pressure without leakage.

– Acoustic Testing: Assesses the muffler’s sound attenuation properties.

– Corrosion Resistance Testing: Evaluates the effectiveness of the protective coatings.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially those from regions such as Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is critical to ensuring product reliability.

-

Supplier Audits: Conducting on-site audits of potential suppliers can provide invaluable insights into their manufacturing processes and quality assurance systems. During an audit, buyers can assess the facilities, equipment, and practices firsthand.

-

Review of Quality Reports: Requesting quality control documentation, such as inspection reports and test certificates, can help buyers evaluate the supplier’s adherence to quality standards. These documents should detail the results of various tests conducted during the manufacturing process.

-

Third-Party Inspections: Engaging independent third-party inspection agencies can offer an additional layer of assurance. These agencies can perform random inspections and provide unbiased reports on the quality of the products.

-

Understanding Regional Regulations: Buyers should familiarize themselves with the quality standards and regulations specific to their regions. For instance, certain countries may have additional certifications or testing requirements that suppliers must meet.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

Navigating the quality control landscape as an international B2B buyer involves understanding various nuances that can affect procurement decisions.

Illustrative image related to 6754-11-5220 muffler

-

Cultural Differences in Quality Standards: Different regions may have varying expectations regarding quality. Understanding these cultural differences can help buyers better communicate their requirements and avoid potential misunderstandings.

-

Documentation Requirements: Depending on the destination country, specific documentation may be required for importation. This can include certificates of conformity, material certifications, and compliance declarations. Buyers should ensure that suppliers can provide all necessary documentation to facilitate smooth customs clearance.

-

Warranty and After-Sales Support: Quality assurance does not end with the sale. Buyers should inquire about the warranty policies and after-sales support provided by the supplier. A robust warranty can be an indicator of the supplier’s confidence in their product quality.

-

Building Long-Term Relationships: Establishing long-term relationships with suppliers can lead to better communication regarding quality expectations. Buyers who invest time in nurturing these relationships often find that suppliers are more willing to accommodate specific quality requirements.

In conclusion, understanding the manufacturing processes and quality assurance practices surrounding the 6754-11-5220 muffler is essential for B2B buyers. By focusing on these elements, businesses can make informed purchasing decisions that align with their operational needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘6754-11-5220 muffler’

To facilitate a successful procurement process for the 6754-11-5220 muffler, this guide provides a structured approach to sourcing. By following these steps, international B2B buyers can ensure they make informed decisions, minimize risks, and maximize value in their purchases.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to clearly outline your technical requirements for the 6754-11-5220 muffler. This includes understanding compatibility with equipment models, such as the Komatsu WA320-6 or WA250-6, and the specific performance standards required. Having precise specifications helps in comparing products effectively and ensuring that the muffler meets your operational needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in Komatsu parts. Look for companies with a strong reputation in the industry, and consider their years of operation and customer reviews. This step is crucial as it builds a foundational list of suppliers who are more likely to provide quality products and reliable service.

Step 3: Evaluate Supplier Certifications

Verifying supplier certifications is critical in ensuring that you are dealing with legitimate and compliant businesses. Check for certifications such as ISO 9001, which indicates a commitment to quality management systems. Additionally, inquire about any industry-specific certifications that could affirm their expertise in manufacturing or distributing heavy machinery parts.

Step 4: Request Product Samples or Detailed Specifications

Before making a bulk purchase, request samples or detailed product specifications of the 6754-11-5220 muffler. This allows you to assess the quality and compatibility of the product with your machinery. Pay attention to the material composition and any warranties offered, as these can be indicators of product longevity and reliability.

Step 5: Compare Pricing and Payment Terms

Once you have gathered information from multiple suppliers, compare their pricing structures and payment terms. While lower prices may be tempting, consider the overall value, including shipping costs, warranties, and after-sales support. Ensure that the payment methods offered are secure and align with your company’s procurement policies.

Step 6: Assess Shipping and Delivery Options

Understanding the shipping and delivery terms is vital, especially for international transactions. Confirm the shipping methods available and estimated delivery times, as delays can impact your operations. Additionally, ensure that the supplier has experience with international shipping regulations, particularly if you’re sourcing from regions like Asia or Europe.

Step 7: Establish Communication and Follow-Up Procedures

Effective communication with your chosen supplier can streamline the procurement process. Establish clear points of contact and set expectations for response times. Regular follow-ups can help address any issues promptly and ensure that your order progresses smoothly from placement to delivery.

By adhering to this checklist, B2B buyers can navigate the sourcing process for the 6754-11-5220 muffler with confidence, ensuring a successful procurement experience that meets their operational needs.

Illustrative image related to 6754-11-5220 muffler

Comprehensive Cost and Pricing Analysis for 6754-11-5220 muffler Sourcing

What Are the Key Cost Components in Sourcing the 6754-11-5220 Muffler?

When evaluating the total cost of sourcing the 6754-11-5220 muffler, it’s crucial to break down the cost structure into its fundamental components. The primary cost drivers include:

-

Materials: The quality of materials used significantly impacts cost. High-grade steel or specialized alloys may increase costs but enhance durability and performance.

-

Labor: Labor costs can vary based on geographical location. Regions with higher wage standards will naturally see increased costs, while countries with lower labor costs might offer more competitive pricing.

-

Manufacturing Overhead: This encompasses indirect costs related to production, such as utilities, rent, and equipment depreciation. Efficient manufacturing processes can help minimize these overheads.

-

Tooling: Initial investments in tooling for specific muffler designs can be significant. Buyers should consider whether they need customized tooling, which can increase initial costs but may lead to better product alignment with operational needs.

-

Quality Control (QC): Implementing rigorous QC processes ensures that the mufflers meet industry standards, particularly for international markets. This may add to the cost but is vital for long-term reliability.

-

Logistics: Transportation and shipping costs can fluctuate based on distance, mode of transport, and customs regulations. International buyers must factor in potential tariffs and import duties.

-

Margin: Supplier margins can vary widely based on their operational efficiencies and market positioning. Understanding the supplier’s pricing strategy can aid in negotiation.

What Influences the Pricing of the 6754-11-5220 Muffler?

Several factors can influence the pricing of the 6754-11-5220 muffler:

-

Volume/MOQ: Ordering in bulk can lead to significant cost savings. Suppliers often offer discounts for larger orders, which can lower the per-unit cost.

-

Specifications and Customization: Unique requirements or modifications to the standard design may incur additional costs. Buyers should clarify specifications early to avoid surprises.

-

Materials and Quality Certifications: Higher-quality materials and certifications (e.g., ISO, CE) generally command higher prices. Buyers should assess their quality needs against their budget.

-

Supplier Factors: The supplier’s reputation, location, and production capabilities can affect pricing. Established suppliers with proven track records may charge a premium.

-

Incoterms: Understanding the agreed Incoterms (e.g., FOB, CIF) can help buyers anticipate additional costs. These terms dictate who bears the shipping costs and risks, impacting the overall price.

What Tips Can Help Buyers Negotiate Better Prices for the 6754-11-5220 Muffler?

B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, should consider the following strategies for effective negotiation:

-

Total Cost of Ownership (TCO): Instead of focusing solely on the purchase price, evaluate the TCO, which includes maintenance, durability, and operational efficiency. A higher initial investment may lead to lower long-term costs.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and service. Long-term partnerships often yield favorable terms and priority during supply shortages.

-

Market Research: Conduct thorough market research to understand prevailing prices and competitor offerings. This knowledge empowers buyers to negotiate more effectively.

-

Flexibility in Specifications: Being open to alternative specifications or materials can provide cost-saving opportunities. Suppliers may offer lower-priced options that still meet operational needs.

-

Payment Terms: Negotiate favorable payment terms that align with cash flow requirements. Options such as extended payment schedules can improve financial flexibility.

Conclusion

Sourcing the 6754-11-5220 muffler involves a comprehensive understanding of its cost structure and the various factors influencing pricing. By focusing on these elements and employing strategic negotiation tactics, international B2B buyers can optimize their procurement processes, ensuring they secure quality components at competitive prices. It is essential to note that the indicative prices may vary based on current market conditions, supplier negotiations, and regional factors, emphasizing the need for diligent research and informed decision-making.

Alternatives Analysis: Comparing 6754-11-5220 muffler With Other Solutions

Understanding Alternative Solutions for Mufflers in Heavy Machinery

In the competitive landscape of heavy machinery parts, particularly mufflers, it is crucial for B2B buyers to evaluate multiple options to ensure they are making informed purchasing decisions. The 6754-11-5220 muffler, specifically designed for Komatsu WA320-6 and WA250-6 models, serves as an effective component for exhaust noise reduction. However, exploring alternative solutions can help buyers identify options that best align with their operational needs and budget constraints.

Comparison Table

| Comparison Aspect | 6754-11-5220 Muffler | Aftermarket Muffler | Custom Fabricated Muffler |

|---|---|---|---|

| Performance | OEM quality, reliable noise reduction | Varies by manufacturer, generally acceptable | Tailored to specific requirements, potentially superior performance |

| Cost | Approx. $650 (used) | Typically lower (approx. $400-$600) | Higher initial investment ($800+) |

| Ease of Implementation | Direct fit for specified models | May require slight modifications | Installation can be complex, requires skilled labor |

| Maintenance | Standard maintenance schedule | Similar to OEM, but warranty varies | Dependent on fabrication quality and materials used |

| Best Use Case | Ideal for maintaining OEM standards | Cost-effective for budget-sensitive projects | Best for unique applications needing specific performance |

What Are the Advantages and Disadvantages of Aftermarket Mufflers?

Aftermarket mufflers are often seen as a cost-effective alternative to OEM options like the 6754-11-5220. These components generally come at a lower price point, making them attractive for budget-conscious buyers. However, the performance can be inconsistent, depending on the manufacturer, which may lead to varied results in noise reduction and longevity. Buyers should ensure they source from reputable suppliers to mitigate quality concerns.

How Do Custom Fabricated Mufflers Stack Up Against the 6754-11-5220?

Custom fabricated mufflers offer the advantage of being specifically designed to meet the unique requirements of a particular machine or application. This can lead to enhanced performance and potentially better noise reduction compared to standard options. However, the initial cost is often higher, and the complexity of installation can pose challenges. Companies need to weigh these factors against their operational needs and technical capabilities.

Conclusion: How to Choose the Right Muffler Solution for Your Business

Choosing the right muffler solution involves a careful assessment of performance needs, budget constraints, and installation capabilities. The 6754-11-5220 muffler offers OEM reliability, making it suitable for businesses focused on maintaining original specifications. In contrast, aftermarket and custom solutions can provide cost savings or specialized performance, respectively. B2B buyers should consider their specific operational requirements and the potential trade-offs associated with each option to ensure they select the most effective solution for their machinery needs.

Essential Technical Properties and Trade Terminology for 6754-11-5220 muffler

What Are the Key Technical Properties of the 6754-11-5220 Muffler?

Understanding the essential technical properties of the 6754-11-5220 muffler is critical for B2B buyers, especially when it comes to ensuring compatibility, performance, and longevity of heavy machinery. Here are some key specifications to consider:

-

Material Composition

The 6754-11-5220 muffler is typically constructed from high-grade steel or stainless steel, designed to withstand high temperatures and corrosive environments. This material selection is vital for durability and performance, especially in heavy machinery applications where exhaust systems are subjected to extreme conditions. Buyers should prioritize mufflers made from materials that offer resistance to rust and thermal fatigue. -

Weight

Weighing approximately 61 lbs, the muffler’s weight is an important factor for compatibility with various Komatsu models, such as the WA320-6 and WA250-6. Understanding the weight helps in assessing handling, installation requirements, and the overall balance of the machinery. Lightweight alternatives may reduce operational load, while heavier models might offer more durability. -

Dimensional Tolerances

The 6754-11-5220 muffler must adhere to precise dimensional tolerances to ensure a proper fit within the exhaust system. Tolerances affect how well the muffler integrates with the existing components, influencing installation ease and exhaust flow efficiency. Buyers should verify that the specifications align with their machinery to avoid issues during installation. -

Sound Reduction Capability

This muffler is engineered to minimize noise output, crucial for compliance with environmental regulations and workplace safety standards. The sound reduction capability is typically measured in decibels (dB). B2B buyers must consider how the muffler’s performance will affect operational noise levels, particularly in urban or sensitive environments. -

Warranty Period

A warranty period of 6 to 12 months is common for mufflers, covering manufacturing defects and ensuring reliability. Understanding warranty terms is essential for risk management in procurement decisions. A robust warranty can indicate manufacturer confidence in their product, providing peace of mind for buyers.

What Are Common Trade Terms Related to the 6754-11-5220 Muffler?

In the world of B2B transactions, familiarity with industry jargon is crucial for effective communication and negotiation. Here are some common terms that buyers should know:

-

OEM (Original Equipment Manufacturer)

OEM parts are manufactured by the original producer of the equipment, ensuring compatibility and quality. Buyers often seek OEM components like the 6754-11-5220 muffler for assurance of performance and adherence to specifications. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units a supplier is willing to sell. Understanding MOQ is important for inventory management and budgeting. Buyers should assess their needs against MOQs to avoid excess inventory or supply shortages. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. Crafting a well-defined RFQ can streamline the procurement process, allowing buyers to compare offers effectively and make informed decisions. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, detailing who is responsible for shipping, insurance, and tariffs. Familiarity with Incoterms is essential for international buyers to avoid unexpected costs and clarify terms of delivery. -

CFR (Cost and Freight)

CFR is an Incoterm that indicates the seller is responsible for the cost of transporting the goods to a port, but the buyer assumes risk once the goods are loaded. Understanding CFR can help buyers negotiate better shipping terms and manage risk effectively. -

FOB (Free on Board)

FOB indicates that the seller’s responsibility ends once the goods are loaded onto the transport vessel. This term is crucial for buyers to understand, as it delineates liability and cost responsibilities during shipping.

By grasping these technical properties and trade terms, international B2B buyers can make more informed decisions regarding the procurement of the 6754-11-5220 muffler, ensuring that they acquire the right components for their machinery needs.

Navigating Market Dynamics and Sourcing Trends in the 6754-11-5220 muffler Sector

Market Overview & Key Trends

The global market for the 6754-11-5220 muffler, primarily used in heavy machinery like Komatsu wheel loaders, is driven by several key factors. As infrastructure projects expand in regions such as Africa, South America, and the Middle East, demand for reliable heavy machinery parts is on the rise. The growth of urbanization and industrialization in these areas is leading to increased investments in construction, mining, and agricultural sectors, further driving the need for durable and efficient components.

Emerging B2B technologies are reshaping sourcing strategies within this sector. Online marketplaces and e-commerce platforms have made it easier for international buyers to access a wide range of muffler options, including new, used, and refurbished parts. Additionally, the integration of AI and machine learning tools in inventory management allows suppliers to optimize their stock levels based on real-time demand, improving response times and reducing costs for buyers.

Market dynamics are also influenced by the competitive landscape, with both OEM (Original Equipment Manufacturer) parts and aftermarket alternatives vying for market share. International buyers are increasingly seeking cost-effective solutions without compromising quality. This trend is particularly relevant in regions where budget constraints are common, prompting a growing acceptance of used parts, such as the 6754-11-5220 muffler, as viable alternatives to new components.

Sustainability & Ethical Sourcing in B2B

The importance of sustainability and ethical sourcing in the muffler sector cannot be overstated. As global awareness of environmental issues increases, B2B buyers are prioritizing suppliers who demonstrate a commitment to sustainable practices. This includes the use of recycled materials in the production of mufflers, reducing waste, and minimizing the carbon footprint associated with manufacturing processes.

Buyers should look for suppliers that hold ‘green’ certifications, which indicate adherence to environmental standards. These certifications not only enhance a supplier’s credibility but also align with the values of socially responsible businesses. The demand for sustainable products is particularly strong in Europe, where regulations on emissions and waste management are stringent.

Illustrative image related to 6754-11-5220 muffler

Furthermore, ethical supply chains are becoming a focal point for international buyers. Ensuring that suppliers uphold fair labor practices and responsible sourcing of materials is essential. This not only mitigates risks associated with reputational damage but also fosters long-term relationships built on trust and mutual respect. By prioritizing sustainability and ethical sourcing, businesses can position themselves as leaders in the market while contributing positively to the environment and society.

Brief Evolution/History

The evolution of mufflers, including the 6754-11-5220 model, reflects the broader advancements in heavy machinery technology. Initially designed for simple noise reduction, modern mufflers now incorporate complex engineering to improve efficiency and reduce emissions. The introduction of stricter environmental regulations worldwide has spurred innovation in muffler design, leading to the development of more efficient systems that not only comply with regulations but also enhance machine performance.

As the heavy machinery market continues to grow, the demand for high-quality, efficient mufflers is expected to increase. This evolution highlights the importance of staying abreast of technological advancements and market trends for international B2B buyers, ensuring they make informed purchasing decisions that align with both operational needs and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of 6754-11-5220 muffler

-

How do I ensure the quality of the 6754-11-5220 muffler before purchasing?

To ensure quality, request detailed specifications and certifications from your supplier. Look for parts that come with a warranty or guarantee, indicating the manufacturer’s confidence in their product. It’s beneficial to request samples or detailed images of the muffler to assess its condition, especially if buying used. Additionally, consider suppliers with a strong reputation and positive reviews from other B2B buyers, particularly those in your region. -

What are the best practices for sourcing the 6754-11-5220 muffler internationally?

Start by identifying reputable suppliers through industry networks, trade shows, and online marketplaces. Verify their credentials and ask for references from previous clients. Utilize platforms that facilitate international trade, ensuring they offer secure payment methods and can handle customs documentation. Establish clear communication regarding your specifications, delivery timelines, and post-purchase support to avoid misunderstandings. -

What customization options are available for the 6754-11-5220 muffler?

Customization options may vary by supplier. Common requests include modifications to fit specific machinery or adjustments to enhance performance. When reaching out to suppliers, specify your requirements and inquire about available options. Ensure that any modifications do not compromise the part’s integrity or warranty. Discussing customization at the initial stage can help avoid delays in production and shipping. -

What is the minimum order quantity (MOQ) for the 6754-11-5220 muffler?

MOQ can differ among suppliers based on their production capabilities and inventory levels. Typically, for specialized parts like the 6754-11-5220 muffler, the MOQ may range from one to several units. Always confirm the MOQ before placing an order, as larger quantities might offer better pricing but could increase upfront costs. If you have concerns about MOQ, consider negotiating with the supplier based on your purchasing capabilities. -

What payment terms should I expect when purchasing the 6754-11-5220 muffler?

Payment terms can vary widely depending on the supplier’s policies and your relationship with them. Common terms include advance payment, payment on delivery, or net terms (e.g., 30 days after invoice). For international transactions, options like letters of credit or escrow services can provide added security. Always clarify payment methods accepted, such as wire transfers, credit cards, or digital payment platforms, to avoid delays. -

How can I vet a supplier for the 6754-11-5220 muffler?

To vet a supplier, start with thorough research. Check their business credentials, customer reviews, and industry certifications. Request information about their manufacturing processes, quality control measures, and after-sales support. Engaging in direct communication can also provide insight into their responsiveness and willingness to address your concerns. If possible, visit their facilities or request references from other international clients. -

What logistics considerations should I keep in mind for shipping the 6754-11-5220 muffler?

When arranging logistics, consider the shipping method (air, sea, or land) based on your urgency and budget. Discuss with your supplier about their shipping options and whether they can handle customs clearance. Ensure that you understand the associated costs, including duties and taxes, to avoid unexpected expenses. Additionally, track the shipment to ensure timely delivery and have a contingency plan in case of delays. -

What quality assurance measures should be in place for the 6754-11-5220 muffler?

Quality assurance should include inspections at various production stages, from sourcing materials to final assembly. Request documentation of quality checks conducted by the supplier, including compliance with international standards. If possible, ask for third-party inspection services to verify the muffler’s condition before shipment. Establish a clear return policy to address potential issues post-purchase, ensuring that your investment is protected.

Top 6 6754-11-5220 Muffler Manufacturers & Suppliers List

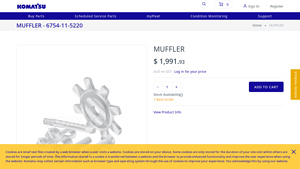

1. Komatsu – WA320-6 Muffler

Domain: hrparts.com

Registered: 1996 (29 years)

Introduction: {“product_name”: “Komatsu WA320-6 Muffler”, “part_number”: “6754-11-5220”, “condition”: “Used”, “description”: “Our used Muffler is an excellent alternative to OEM parts for your machine. When high-quality is a requirement and lower costs are necessary, our used Muffler is the solution for you.”, “fits_model”: “Komatsu WA320-6”, “call_for_price”: true, “contact_phone”: “1-800-333-0650”, “warning”:…

2. KOMATSU – Used Muffler for WA250-6 Wheel Loader

Domain: shop.dukesequipmentandparts.com

Registered: 2018 (7 years)

Introduction: {‘product_id’: ‘6754-11-5220’, ‘manufacturer’: ‘KOMATSU’, ‘condition’: ‘Used’, ‘description’: ‘Good used Komatsu Muffler off of a Komatsu WA250-6 Wheel Loader.’, ‘weight’: ’61 lb’, ‘location’: ‘Union Gap, Washington 98903’, ‘price’: ‘USD $650.00’, ‘shipping_information’: ‘Shipping Available’, ‘contact_number’: ‘+1 509-317-7683’}

3. KOMATSU – Used Muffler for WA250-6 Wheel Loader

Domain: machinerytrader.com

Registered: 1996 (29 years)

Introduction: {“part_number”:”6754-11-5220″,”manufacturer”:”KOMATSU”,”description”:”Good used Komatsu Muffler off of a Komatsu WA250-6 Wheel Loader.”,”condition”:”Used”,”price”:”$650.00″,”location”:”Union Gap, Washington”,”seller_name”:”Dukes Equipment & Parts”,”contact_phone”:”(509) 317-7683″,”shipping”:”Available”}

4. MoverParts – Muffler Silencer 6754-11-5320

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “Muffler Silencer 6754-11-5320″,”Compatible Models”: [“Komatsu PC220”, “PC270”, “PC290”, “PC308″],”Engine Model”: “6D107E”,”Condition”: “New”,”Price”: “US $378.00 or Best Offer”,”Shipping Cost”: “US $99.00″,”Quantity Available”: 4,”Warranty”: “Yes”,”Seller”: {“Name”: “MoverParts”,”Feedback Rating”: “98.5% positive”,”Items Sold”: “83K”,”Joined”: “Dec 2017″},”Returns”: “60 days retu…

5. STZ – Engine SAA6D107E Muffler

Domain: stszcmparts.com

Registered: 2019 (6 years)

Introduction: {“Product Name”: “Engine SAA6D107E Muffler 6754-11-5220”, “Price”: “$99”, “Minimum Order”: “1 Piece/Pieces”, “Payment Types”: [“L/C”, “T/T”, “D/P”, “D/A”, “Paypal”], “Incoterms”: [“FOB”, “CFR”, “CIF”, “EXW”], “Warranty Period”: “6 Months”, “Applicable Industries”: [“Building Material Shops”, “Manufacturing Plant”, “Retail”, “Energy & Mining”, “Advertising Company”], “Place of Origin”: “China”, “Pa…

6. Komatsu – MUFFLER

Domain: my.komatsu.com.au

Introduction: {“product_name”: “MUFFLER”, “part_number”: “6754-11-5220”, “price”: “1,991.93 AUD ex GST”, “stock_availability”: “1 Back Order”, “category”: “Air Intake and Exhaust System”, “brand”: “Komatsu Limited”, “description”: “Komatsu Genuine Mufflers are designed for ease of fitment because they meet the Komatsu Engineering Standard.”}

Strategic Sourcing Conclusion and Outlook for 6754-11-5220 muffler

What Are the Key Benefits of Strategic Sourcing for the 6754-11-5220 Muffler?

In conclusion, strategic sourcing for the 6754-11-5220 muffler offers international B2B buyers a pathway to enhance operational efficiency while managing costs effectively. By opting for high-quality used or rebuilt mufflers, businesses can reduce expenditure without compromising on performance, particularly in regions where budget constraints are prevalent. The availability of multiple suppliers across different continents, including Africa, South America, the Middle East, and Europe, facilitates competitive pricing and diverse sourcing options.

The shift towards strategic sourcing not only ensures access to reliable parts but also strengthens supply chain resilience. As global demand for heavy machinery parts continues to rise, establishing partnerships with trustworthy suppliers can provide a competitive edge in the marketplace.

Looking ahead, international buyers are encouraged to leverage these insights to optimize their procurement strategies for the 6754-11-5220 muffler. Engaging with reputable suppliers and exploring alternative sourcing options will be crucial in navigating the evolving landscape of industrial machinery parts. By taking proactive steps today, businesses can position themselves for success in a dynamic global market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.