Top 4 A Switch That Completes A Circuit When Pressure Is Applied Suppliers (And How to…

Introduction: Navigating the Global Market for a switch that completes a circuit when pressure is applied

In today’s competitive industrial landscape, sourcing a reliable switch that completes a circuit when pressure is applied poses a significant challenge for B2B buyers. With the increasing demand for precision in automation and control systems, understanding the nuances of pressure switches is crucial for optimizing operational efficiency. This guide provides a comprehensive overview of various types of pressure switches, their applications across multiple sectors—including industrial machinery, automotive systems, and household appliances—and key considerations for supplier vetting and cost analysis.

International buyers, particularly those from Africa, South America, the Middle East, and Europe (notably Germany and Saudi Arabia), will find actionable insights tailored to their specific market needs. The guide empowers decision-makers by detailing the essential features to consider, such as durability, responsiveness, and safety compliance, ensuring that they can make informed purchasing decisions that align with their operational goals. Additionally, it addresses potential challenges in sourcing, including supply chain logistics and regional regulatory requirements, enabling buyers to navigate the complexities of the global market effectively.

By equipping B2B buyers with the knowledge and tools necessary to evaluate and select pressure switches, this guide fosters a deeper understanding of how to leverage these critical components to enhance productivity and reliability in their operations.

Understanding a switch that completes a circuit when pressure is applied Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Pressure Switch | Activates circuit upon reaching a specific pressure | Industrial machinery, HVAC systems | Pros: Reliable, versatile; Cons: Calibration required, can fail under extreme conditions |

| Momentary Contact Switch | Completes circuit only while pressure is applied | Automotive, consumer electronics | Pros: Simple operation, cost-effective; Cons: Limited to temporary actions, may wear out quickly |

| Toggle Switch | Maintains circuit state until manually changed | Lighting systems, machinery controls | Pros: Durable, easy to use; Cons: Requires manual intervention, not suitable for automated systems |

| Mercury Switch | Uses liquid mercury to complete circuit | Industrial applications, safety devices | Pros: Sensitive, reliable; Cons: Environmental hazards, limited to specific orientations |

| Pneumatic Pressure Switch | Operates using air pressure | Pneumatic systems, manufacturing | Pros: Fast response, suitable for high-speed applications; Cons: Requires air supply, can be bulky |

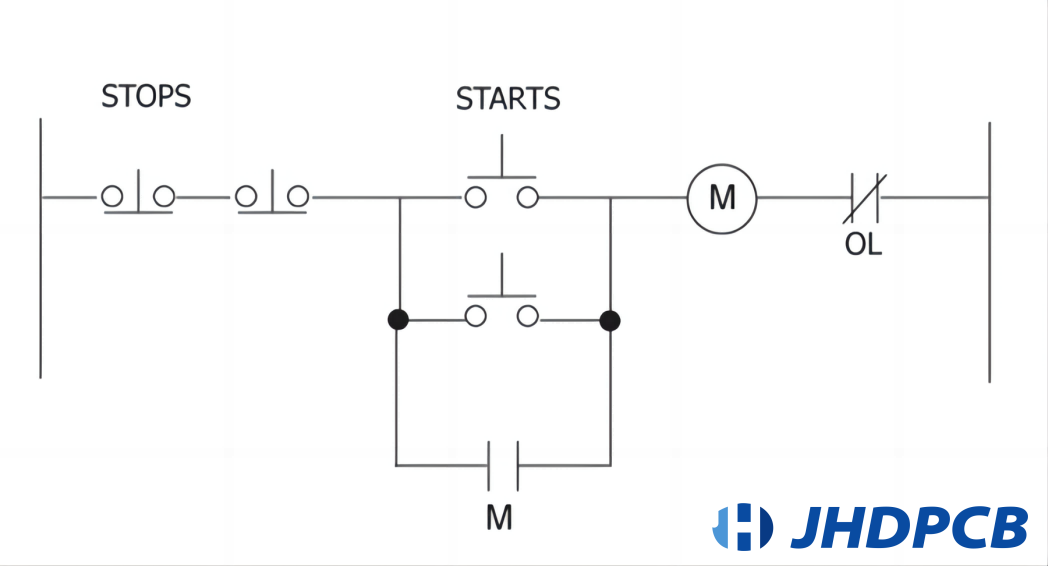

What Are the Key Characteristics of a Pressure Switch?

Pressure switches are essential components that complete a circuit when a predetermined pressure level is achieved. They are widely used in industrial machinery and HVAC systems for monitoring and controlling processes. B2B buyers should consider the switch’s pressure range, response time, and environmental durability. These switches are particularly suitable for applications requiring safety mechanisms, such as preventing over-pressurization in hydraulic systems.

How Does a Momentary Contact Switch Function in B2B Settings?

Momentary contact switches are designed to complete a circuit only while pressure is applied. They are commonly found in automotive systems and consumer electronics, where temporary actions are necessary, such as starting a device or activating a feature. When purchasing, businesses should evaluate the switch’s lifespan and ease of installation. While these switches are cost-effective, they may require more frequent replacements due to wear from repetitive use.

What Makes a Toggle Switch a Good Option for Buyers?

Toggle switches are robust devices that maintain their circuit state until manually switched off. They are commonly used in lighting systems and machinery controls, providing a straightforward user experience. B2B buyers should assess the switch’s durability and ease of installation, especially in environments where frequent operation occurs. Although toggle switches are reliable, they may not be ideal for automated systems where continuous operation is required.

Illustrative image related to a switch that completes a circuit when pressure is applied

Why Choose a Mercury Switch for Specific Applications?

Mercury switches utilize liquid mercury to complete a circuit, making them sensitive and reliable for various applications, including industrial settings and safety devices. Buyers should be aware of their environmental impact and limitations in orientation. While mercury switches are effective, their use is increasingly scrutinized due to health and environmental concerns. Businesses should weigh these factors against the switch’s performance benefits in specific applications.

What Are the Advantages of Pneumatic Pressure Switches?

Pneumatic pressure switches operate using air pressure and are ideal for high-speed applications in pneumatic systems and manufacturing. They offer fast response times and are suitable for environments requiring quick action. When considering a pneumatic switch, buyers should evaluate the necessary air supply and the switch’s size, as these factors can affect overall system design. While they excel in speed, the requirement for an air supply may limit their use in certain scenarios.

Key Industrial Applications of a switch that completes a circuit when pressure is applied

| Industry/Sector | Specific Application of a switch that completes a circuit when pressure is applied | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Pressure switches in hydraulic systems for machinery operation | Enhances operational efficiency and safety | Reliability, compatibility with existing systems, certifications |

| Automotive | Tire pressure monitoring systems (TPMS) | Improves safety by preventing under-inflation | Sensitivity, durability, and response time |

| HVAC | Pressure switches in air conditioning units | Ensures optimal performance and energy efficiency | Temperature range, pressure rating, and environmental resistance |

| Food Processing | Monitoring pressure in packaging machines | Maintains product quality and safety | Compliance with health regulations, robustness, and accuracy |

| Oil & Gas | Pressure switches for monitoring pipeline systems | Prevents leaks and ensures operational integrity | High-pressure rating, material compatibility, and reliability |

How is a switch that completes a circuit when pressure is applied used in manufacturing?

In the manufacturing sector, pressure switches are integral to hydraulic systems, which are pivotal for the operation of heavy machinery. These switches ensure that the machinery operates within safe pressure limits, preventing equipment failures and accidents. For international buyers, particularly in regions like Africa and South America, sourcing durable and reliable pressure switches that can withstand varying environmental conditions is crucial. Additionally, compatibility with existing hydraulic systems is a significant consideration to minimize installation costs and downtime.

What role do pressure switches play in automotive applications?

In the automotive industry, pressure switches are vital components of tire pressure monitoring systems (TPMS). They detect the air pressure in tires and alert drivers when levels drop below safe thresholds, significantly enhancing vehicle safety. For B2B buyers in Europe and the Middle East, sourcing high-sensitivity switches that provide quick response times is essential. Moreover, understanding the regulatory standards for automotive safety in their respective markets will guide buyers in selecting appropriate products.

Illustrative image related to a switch that completes a circuit when pressure is applied

How do pressure switches enhance HVAC systems?

Within HVAC systems, pressure switches help regulate the operation of air conditioning units by monitoring refrigerant pressure. This functionality is critical for maintaining optimal performance and energy efficiency, reducing operational costs for businesses. Buyers from regions like Germany and Saudi Arabia should prioritize sourcing switches that can operate effectively within their specific temperature and pressure ranges, ensuring reliability in diverse climatic conditions.

What is the significance of pressure switches in food processing?

In the food processing industry, pressure switches are used to monitor and control the pressure in packaging machines. This ensures that products are sealed correctly, maintaining quality and safety standards. For international buyers, compliance with health regulations is a key consideration when sourcing these switches. Additionally, robustness and accuracy are essential to minimize product loss and ensure consistent packaging quality.

How do pressure switches contribute to safety in the oil and gas sector?

In the oil and gas industry, pressure switches are crucial for monitoring pipeline systems to prevent leaks and ensure operational integrity. These switches help maintain safe pressure levels, which is vital for avoiding catastrophic failures. Buyers in this sector should focus on sourcing high-pressure rated switches made from materials that can withstand harsh environmental conditions. Reliability and adherence to industry standards are paramount when selecting pressure switches for such critical applications.

3 Common User Pain Points for ‘a switch that completes a circuit when pressure is applied’ & Their Solutions

Scenario 1: Difficulty in Ensuring Consistent Operational Efficiency

The Problem: B2B buyers often face challenges in maintaining operational efficiency due to the unreliability of pressure switches. In industries such as manufacturing and automotive, a failure in these switches can lead to significant downtime, halting production processes. This can stem from poor quality switches that do not provide the required pressure sensitivity, leading to inconsistent circuit completion when needed. The result is not only a loss of productivity but also increased costs associated with repairs and delays.

The Solution: To combat this issue, buyers should prioritize sourcing high-quality pressure switches from reputable manufacturers known for their reliability and durability. Conducting thorough research and requesting samples can help assess the performance of different models. Additionally, implementing a robust maintenance schedule that includes regular testing and calibration of the switches can ensure they operate within specified pressure ranges. Utilizing switches with built-in diagnostic features can also alert operators to potential failures before they result in costly downtime, thus ensuring smoother operations.

Scenario 2: Challenges with Environmental Conditions

The Problem: Pressure switches can be susceptible to environmental factors such as temperature fluctuations, humidity, and dust, particularly in outdoor or harsh industrial environments. B2B buyers often report that standard switches fail prematurely when exposed to these conditions, leading to frequent replacements and increased operational costs. This not only affects the reliability of equipment but also raises safety concerns in critical applications.

The Solution: To address these challenges, it is essential to select pressure switches designed for extreme environmental conditions. Buyers should look for switches with IP (Ingress Protection) ratings that indicate their resistance to moisture and dust. Additionally, considering temperature-rated switches can prevent failures caused by thermal expansion or contraction. Implementing protective enclosures or weatherproofing strategies can further enhance the longevity of pressure switches in adverse environments. Collaborating with suppliers who offer customizable options to suit specific environmental needs can also lead to more tailored solutions, ensuring better performance.

Scenario 3: Complexity in Integration with Existing Systems

The Problem: Integrating new pressure switches into existing systems can often pose significant challenges for B2B buyers. Many buyers find themselves grappling with compatibility issues, where new switches do not seamlessly connect or communicate with legacy systems. This can lead to additional costs for system modifications or the need for extensive training for personnel to adapt to new technologies.

The Solution: To simplify the integration process, buyers should engage with suppliers who provide comprehensive technical support and detailed product specifications. Before purchasing, it’s crucial to conduct a compatibility assessment between the new pressure switches and existing systems. Opting for modular pressure switches that can easily interface with various control systems can mitigate integration complexities. Additionally, utilizing standardized communication protocols such as Modbus or CAN bus can facilitate smoother integration. Investing in training programs for staff on new technologies can also enhance their understanding and ensure effective utilization of the new systems.

Strategic Material Selection Guide for a switch that completes a circuit when pressure is applied

What Are the Key Properties of Common Materials Used for Pressure Switches?

When selecting materials for switches that complete a circuit upon pressure application, it is crucial to consider their properties in relation to performance, durability, and compatibility with various media. Below, we analyze four common materials used in the manufacturing of these switches: stainless steel, plastic, brass, and silicone.

Stainless Steel: A Durable Choice for Pressure Switches

Key Properties: Stainless steel is known for its high strength, excellent corrosion resistance, and ability to withstand extreme temperatures and pressures. It typically has a temperature rating of up to 800°F (427°C) and can handle pressures exceeding 10,000 psi.

Pros & Cons: The durability of stainless steel makes it suitable for harsh environments, including industrial applications. However, it is more expensive than other materials, which can increase manufacturing costs. Additionally, the complexity of machining stainless steel may lead to longer lead times.

Impact on Application: Stainless steel pressure switches are ideal for applications involving corrosive substances, such as chemicals or saline environments. They are commonly used in oil and gas, food processing, and water treatment industries.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with relevant standards such as ASTM A276 or DIN 1.4401. The preference for stainless steel in these markets is often driven by stringent regulations regarding material safety and durability.

Illustrative image related to a switch that completes a circuit when pressure is applied

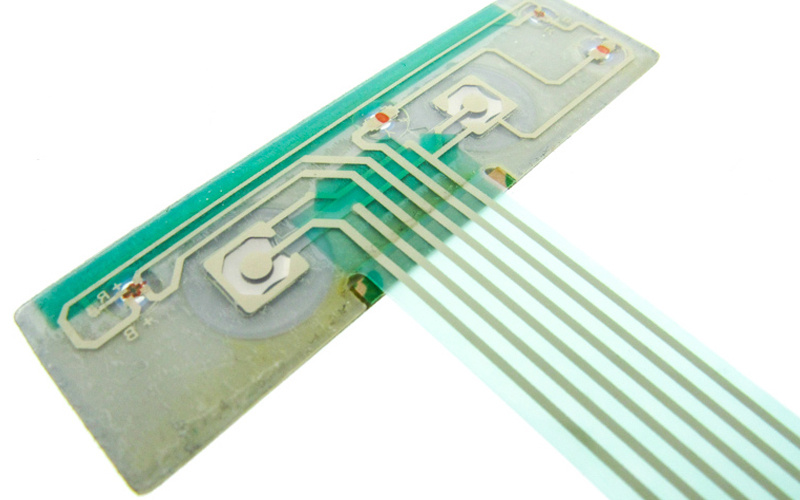

Plastic: A Cost-Effective Alternative

Key Properties: Plastics, particularly polycarbonate and nylon, offer good chemical resistance and can operate effectively at temperatures up to 250°F (121°C). They are lightweight and can be molded into complex shapes.

Pros & Cons: The primary advantage of plastic is its low cost and ease of manufacturing, allowing for high-volume production. However, plastics may not withstand high pressures as effectively as metals and can degrade over time when exposed to UV light or extreme temperatures.

Impact on Application: Plastic pressure switches are suitable for applications in non-corrosive environments, such as residential appliances or light industrial use. They are often used in washing machines and HVAC systems.

Illustrative image related to a switch that completes a circuit when pressure is applied

Considerations for International Buyers: Buyers in South America and Africa should be aware of local regulations regarding plastic materials and their environmental impact. Compliance with standards like ISO 9001 can enhance product acceptance in these markets.

Brass: A Balanced Material for Versatile Applications

Key Properties: Brass offers good corrosion resistance and electrical conductivity, with a typical temperature rating of around 400°F (204°C). It is also relatively easy to machine and can be plated for additional protection.

Pros & Cons: The advantages of brass include its durability and aesthetic appeal, making it suitable for both functional and decorative applications. However, brass is more susceptible to corrosion in certain environments, particularly in the presence of saltwater.

Impact on Application: Brass pressure switches are commonly used in plumbing and automotive applications, where moderate pressures are encountered. They are effective in environments where aesthetic considerations are important.

Considerations for International Buyers: Buyers from Germany and Saudi Arabia may prefer brass due to its historical use in traditional applications. Ensuring compliance with standards such as DIN 17660 can facilitate market entry.

Silicone: A Flexible Solution for Specialized Applications

Key Properties: Silicone is known for its flexibility, high-temperature resistance (up to 500°F or 260°C), and excellent electrical insulating properties. It is also resistant to many chemicals and UV light.

Pros & Cons: The flexibility of silicone allows for the creation of pressure switches that can accommodate movement and vibration. However, silicone can be more expensive than other materials and may not be suitable for high-pressure applications.

Impact on Application: Silicone pressure switches are often used in applications requiring high flexibility, such as medical devices and automotive sensors. They are effective in environments where traditional materials may fail due to movement.

Illustrative image related to a switch that completes a circuit when pressure is applied

Considerations for International Buyers: Buyers in the Middle East and Europe should consider the specific performance requirements of their applications when selecting silicone. Compliance with medical device regulations (ISO 13485) may be necessary for certain applications.

Summary Table of Material Selection for Pressure Switches

| Material | Typical Use Case for a switch that completes a circuit when pressure is applied | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Industrial machinery, oil and gas applications | High durability and corrosion resistance | Higher cost and manufacturing complexity | High |

| Plastic | Residential appliances, HVAC systems | Low cost and ease of manufacturing | Lower pressure tolerance and UV degradation | Low |

| Brass | Plumbing, automotive applications | Good conductivity and aesthetic appeal | Susceptible to corrosion in saline environments | Medium |

| Silicone | Medical devices, automotive sensors | Flexibility and high-temperature resistance | Higher cost and limited pressure capability | Medium |

This strategic material selection guide provides B2B buyers with essential insights to make informed decisions regarding the most suitable materials for pressure switches, considering both performance and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for a switch that completes a circuit when pressure is applied

What Are the Key Manufacturing Processes for Pressure Switches?

The manufacturing of pressure switches, which are vital components in various industrial and consumer applications, involves several critical stages. Understanding these processes can help B2B buyers evaluate potential suppliers effectively.

What Are the Main Stages of Manufacturing Pressure Switches?

-

Material Preparation: The first step involves sourcing high-quality materials such as metals (e.g., stainless steel, brass), plastics, and rubber. The selection of materials is crucial for ensuring durability and reliability. Suppliers often perform material testing to verify compliance with specifications.

-

Forming: In this stage, raw materials are shaped into components of the pressure switch. Techniques such as stamping, machining, and injection molding are commonly used. For instance, metal components may be stamped or machined to precise dimensions, while plastic parts are typically produced through injection molding.

-

Assembly: Once individual components are manufactured, they are assembled into the final product. This stage may involve manual or automated processes, including soldering, fastening, and wiring. Precision is vital here to ensure that the internal mechanisms of the switch function correctly under varying pressure conditions.

-

Finishing: The final stage includes surface treatments such as coating, painting, or plating to enhance corrosion resistance and aesthetics. This step is essential for ensuring the longevity of the pressure switch, especially in harsh environments.

Which Key Techniques Are Used in Manufacturing Pressure Switches?

Several advanced techniques are employed throughout the manufacturing process to enhance quality and efficiency:

Illustrative image related to a switch that completes a circuit when pressure is applied

-

CNC Machining: Computer Numerical Control (CNC) machining provides high precision in creating complex components, ensuring that switches meet stringent specifications.

-

Robotic Assembly: Automation through robotics can increase assembly speed and reduce human error, leading to consistent quality and lower production costs.

-

Quality Control Integration: Incorporating quality control measures at each stage of manufacturing helps identify defects early in the process, minimizing waste and rework.

What Are the Quality Assurance Standards for Pressure Switches?

Quality assurance is a critical aspect of manufacturing pressure switches. International and industry-specific standards guide manufacturers to ensure product reliability and safety.

Which International Standards Are Relevant for Pressure Switches?

-

ISO 9001: This standard outlines requirements for a quality management system (QMS), emphasizing continuous improvement and customer satisfaction. Manufacturers certified to ISO 9001 demonstrate their commitment to quality.

-

CE Marking: In Europe, CE marking indicates compliance with health, safety, and environmental protection standards. Products bearing this mark can be sold within the European Economic Area.

-

API Standards: The American Petroleum Institute (API) provides standards for equipment used in the oil and gas industry, including pressure switches. Compliance with API standards ensures reliability in critical applications.

What Are the Key QC Checkpoints During Manufacturing?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to ensure product integrity.

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials and components upon arrival at the manufacturing facility. Ensuring the quality of incoming materials is essential to prevent defects in the final product.

-

In-Process Quality Control (IPQC): Continuous monitoring during manufacturing helps detect any deviations from quality standards. This may involve regular inspections and testing of components at various stages.

-

Final Quality Control (FQC): Before shipment, the final product undergoes comprehensive testing to verify functionality and safety. Common tests include pressure testing, electrical testing, and performance evaluations.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to ensure their suppliers maintain high-quality standards. Here are some strategies:

-

Supplier Audits: Conducting audits of potential suppliers can provide insights into their manufacturing processes, quality control measures, and compliance with relevant standards.

-

Quality Reports: Requesting detailed quality assurance reports from suppliers can help buyers understand their QC processes and any certifications held.

-

Third-Party Inspections: Engaging third-party inspection services can add an extra layer of verification. These independent inspectors can assess product quality against industry standards before shipment.

What Are the QC and Certification Nuances for International Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control and certification:

-

Understanding Local Regulations: Buyers must familiarize themselves with local regulations and standards applicable to their region. This includes recognizing variations in certification requirements across different countries.

-

Shipping and Compliance: Ensure that products meet the importing country’s regulations to avoid delays or penalties. This may involve additional certifications, testing, or documentation.

-

Cultural Considerations: Different regions may have varying expectations regarding quality and service. Understanding cultural nuances can enhance communication and foster stronger supplier relationships.

Conclusion

Manufacturing pressure switches involves a meticulous process that prioritizes quality and reliability. By understanding the key manufacturing stages, quality assurance standards, and verification methods, B2B buyers can make informed decisions when selecting suppliers. This approach not only ensures product integrity but also fosters long-term partnerships across international markets.

Illustrative image related to a switch that completes a circuit when pressure is applied

Practical Sourcing Guide: A Step-by-Step Checklist for ‘a switch that completes a circuit when pressure is applied’

This guide serves as a practical checklist for B2B buyers who are looking to procure a pressure switch, a device that completes a circuit when pressure is applied. Understanding the critical factors involved in sourcing these switches will ensure you select a product that meets your operational needs, enhances safety, and optimizes efficiency.

Step 1: Define Your Technical Specifications

Before starting your procurement process, clearly outline the technical specifications required for the pressure switch. This includes parameters such as pressure range, voltage ratings, and operational environment (e.g., temperature, humidity). Defining these specifications upfront helps in filtering out unsuitable options and ensures that the switches you consider will function effectively within your application.

Step 2: Research Industry Standards and Compliance Requirements

It’s essential to understand the industry standards and compliance requirements relevant to pressure switches in your sector. Check for certifications such as ISO, UL, or CE, which indicate that the switches meet specific safety and performance criteria. This step not only helps in ensuring safety but also can affect regulatory compliance in your operations.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations to assess their credibility and reliability. Request company profiles, product catalogs, and references from buyers in similar industries or regions. Look for suppliers who have a proven track record in delivering quality products, as this can significantly reduce the risk of operational failures.

Step 4: Request Samples for Testing

Once you have shortlisted potential suppliers, request samples of the pressure switches for testing. This allows you to evaluate the product’s performance under actual working conditions, ensuring it meets your specifications. During testing, pay attention to response times, durability, and compatibility with your existing systems.

Step 5: Compare Pricing and Total Cost of Ownership

While price is a critical factor, it’s important to consider the total cost of ownership, which includes maintenance, operational efficiency, and potential downtime. Gather quotes from multiple suppliers and evaluate what is included in the price (e.g., warranty, support services). A slightly higher initial cost may lead to greater savings over time due to improved reliability and reduced maintenance needs.

Step 6: Negotiate Terms and Conditions

Before finalizing your purchase, negotiate the terms and conditions of the agreement, including payment terms, delivery schedules, and return policies. Clear communication at this stage can prevent misunderstandings later on and ensure that your expectations align with those of the supplier.

Step 7: Plan for Integration and Training

Once the pressure switches are procured, plan for their integration into your existing systems. This may involve training your team on the new equipment, ensuring they understand its operation and maintenance. Proper training can enhance the longevity of the switches and ensure they are used effectively, maximizing your investment.

By following these steps, you will be well-equipped to source a pressure switch that meets your operational needs while ensuring safety and efficiency in your applications.

Comprehensive Cost and Pricing Analysis for a switch that completes a circuit when pressure is applied Sourcing

What Are the Key Cost Components for Sourcing Pressure Switches?

When sourcing pressure switches, several cost components come into play that significantly influence the final price. The primary elements include:

-

Materials: The choice of materials directly impacts cost. High-quality, durable materials such as stainless steel or specialized plastics can increase the price but ensure longevity and performance.

-

Labor: Labor costs vary by region and complexity of the manufacturing process. Countries with higher labor costs, such as Germany, may offer superior craftsmanship, while regions in Africa or South America might provide lower labor costs but may vary in expertise.

-

Manufacturing Overhead: This encompasses all indirect costs related to production, including utilities, equipment depreciation, and facility maintenance. Efficient operations can reduce overhead costs, which can be a selling point for buyers.

-

Tooling: The initial investment in tooling can be substantial, especially for customized switches. Buyers should consider whether the tooling costs are amortized over large production runs, which can reduce per-unit pricing.

-

Quality Control (QC): Implementing stringent QC measures ensures that the switches meet safety and operational standards. While this adds to the cost, it is crucial for maintaining reliability and compliance, particularly in regulated industries.

-

Logistics: Shipping costs, including freight and customs duties, can vary significantly based on the destination. Incoterms will determine who bears these costs, impacting overall pricing.

-

Margin: Suppliers will factor in their profit margins, which can vary based on market conditions, competitive landscape, and the perceived value of the product.

How Do Price Influencers Affect Pressure Switch Costs?

Several factors can influence the pricing of pressure switches, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchasing often results in lower per-unit prices. Buyers should negotiate MOQ terms that align with their needs to maximize cost efficiency.

-

Specifications and Customization: Customized switches tailored to specific applications can lead to higher costs. Buyers should clearly define their requirements to avoid unnecessary expenses and ensure they receive the best value.

-

Materials and Certifications: Higher-grade materials and certifications (e.g., ISO, CE) can elevate costs but may be necessary for specific applications or markets. Buyers should weigh the importance of certifications against budget constraints.

-

Supplier Factors: The reputation and reliability of suppliers play a critical role in pricing. Established suppliers may charge a premium for their proven quality and service, while emerging suppliers may offer lower prices to gain market share.

-

Incoterms: Understanding the Incoterms agreed upon in the contract can significantly affect total costs. Buyers should be aware of who is responsible for shipping, insurance, and customs duties to accurately assess the final price.

What Are the Best Buyer Tips for Cost-Efficiency?

To navigate the complexities of sourcing pressure switches, international B2B buyers should consider the following tips:

-

Negotiate Terms: Engage in open discussions regarding pricing, MOQ, and payment terms. Establishing a good rapport with suppliers can lead to better deals.

-

Evaluate Total Cost of Ownership (TCO): Look beyond initial purchase prices. Consider long-term costs, including maintenance, energy consumption, and potential downtime. A slightly more expensive switch might offer better reliability and lower TCO.

-

Understand Pricing Nuances in Different Markets: Be aware of regional pricing strategies. For example, buyers in Europe may encounter stricter regulations impacting pricing, while those in Africa and South America might benefit from lower labor costs.

-

Leverage Local Knowledge: Utilize local agents or distributors who understand the market dynamics and can facilitate negotiations, ensuring that you are getting the best possible price without compromising on quality.

Disclaimer

The prices discussed herein are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct due diligence and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing a switch that completes a circuit when pressure is applied With Other Solutions

Introduction: Understanding Alternative Solutions in Circuit Completion

In the realm of industrial and household applications, the choice of switches can significantly impact efficiency and functionality. A switch that completes a circuit when pressure is applied, commonly known as a pressure switch, is widely utilized for its reliability and ease of integration. However, various alternatives exist that can also serve similar functions, each with its unique advantages and drawbacks. Understanding these alternatives can empower B2B buyers to make informed decisions that align with their operational needs.

Comparison Table

| Comparison Aspect | A Switch That Completes A Circuit When Pressure Is Applied | Proximity Sensor | Momentary Contact Switch |

|---|---|---|---|

| Performance | Reliable under varying pressure conditions | High precision, no physical contact | Simple operation, low response time |

| Cost | Moderate initial investment | Higher upfront costs | Low cost, easily available |

| Ease of Implementation | Requires specific installation based on pressure settings | May require calibration | Straightforward installation |

| Maintenance | Low maintenance, but calibration may be needed | Minimal maintenance | Moderate maintenance due to wear |

| Best Use Case | Industrial machinery, HVAC systems | Robotics, automation systems | Consumer electronics, basic machinery |

Detailed Breakdown of Alternatives

What are Proximity Sensors and Their Benefits?

Proximity sensors detect the presence of objects without physical contact, using electromagnetic fields or beams of radiation. They offer high precision and are ideal for applications where physical wear and tear are concerns, such as in robotics and automation systems. The downside is that they typically come with a higher initial investment compared to pressure switches. Additionally, they may require calibration to ensure accurate detection, which can increase setup time.

How Do Momentary Contact Switches Compare?

Momentary contact switches operate by completing a circuit only while the button is pressed. They are commonly used in consumer electronics and basic machinery. Their primary advantage lies in their simplicity and low cost, making them accessible for various applications. However, they may not be suitable for environments where continuous operation is required, as they require constant human interaction to maintain circuit completion. This can limit their applicability in automated systems.

Conclusion: Making the Right Choice for Your Needs

Selecting the appropriate switch type hinges on understanding the specific requirements of your application. For scenarios requiring reliable circuit completion under varying pressure conditions, a pressure switch stands out as a robust solution. However, if precision and contactless operation are paramount, investing in a proximity sensor may yield better long-term benefits despite higher initial costs. Conversely, for straightforward applications with limited interaction, a momentary contact switch can offer an economical choice. By carefully evaluating these alternatives, B2B buyers can ensure they select the most suitable technology to enhance their operational efficiency and meet their specific needs.

Essential Technical Properties and Trade Terminology for a switch that completes a circuit when pressure is applied

What are the Critical Technical Properties of Pressure Switches?

When selecting a pressure switch for industrial applications, understanding its technical properties is essential for ensuring optimal performance and reliability. Here are some key specifications to consider:

Illustrative image related to a switch that completes a circuit when pressure is applied

-

Material Grade

The material used in the construction of the switch, typically metals like stainless steel or brass, affects durability and resistance to environmental factors such as moisture and corrosion. A higher-grade material ensures a longer lifespan and reliable operation, particularly in harsh environments like manufacturing plants or outdoors. -

Pressure Range

This specification indicates the operational limits of the pressure switch, typically measured in psi (pounds per square inch) or bar. Understanding the pressure range is crucial for compatibility with the specific applications, as using a switch outside its rated range can lead to failure or inaccurate readings. -

Electrical Ratings

The electrical rating, usually expressed in volts and amperes, defines the maximum electrical load the switch can handle. This specification is critical for ensuring the switch can safely control the intended devices without overheating or causing electrical failures. -

Tolerance

Tolerance indicates the acceptable deviation from the nominal pressure value at which the switch actuates. A tight tolerance is important in applications where precise pressure control is necessary, such as in hydraulic systems or automotive applications. -

Response Time

The response time is the duration it takes for the switch to react to a pressure change. A shorter response time is essential for applications that require immediate feedback, such as safety systems in industrial machinery. -

Mounting Style

The mounting style (e.g., panel mount, pipe mount) determines how the switch integrates into existing systems. Understanding the mounting options is crucial for installation efficiency and ensuring the switch fits within the available space.

What are Common Trade Terms in the Pressure Switch Industry?

Familiarity with industry jargon can facilitate better communication and negotiation between buyers and suppliers. Here are some essential trade terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of pressure switches, understanding OEM relationships can be vital for sourcing high-quality components that meet specific application needs. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers plan their purchasing strategies and manage inventory effectively, particularly for customized pressure switches that may have higher MOQs. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers. This process is essential for comparing costs, understanding lead times, and evaluating supplier capabilities before making purchasing decisions. -

Incoterms (International Commercial Terms)

These terms define the responsibilities of buyers and sellers in international transactions, including shipping and delivery obligations. Understanding Incoterms helps companies navigate logistics and avoid potential disputes during the import/export process. -

Lead Time

Lead time refers to the amount of time from placing an order to its delivery. This term is crucial for planning production schedules and ensuring that projects remain on track, particularly in industries with tight deadlines. -

Certification Standards

Certification standards (e.g., ISO, CE) indicate that a product meets specific safety and quality requirements. Familiarity with these standards can help buyers ensure that the pressure switches they procure comply with industry regulations, enhancing safety and reliability.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and ensure the successful integration of pressure switches into their systems.

Navigating Market Dynamics and Sourcing Trends in the a switch that completes a circuit when pressure is applied Sector

Market Overview & Key Trends in Pressure Switches

The global market for pressure switches, which complete a circuit when pressure is applied, is experiencing robust growth driven by advancements in automation and the increasing demand for safety and efficiency in industrial applications. Key sectors such as automotive, manufacturing, and HVAC are increasingly relying on pressure switches for their operational integrity. In regions like Africa and South America, the push for industrialization and infrastructure development is creating new opportunities for suppliers of pressure switches, while countries in the Middle East are investing heavily in oil and gas applications where these switches are critical for monitoring systems.

Emerging trends include the integration of smart technology into pressure switches, allowing for real-time monitoring and data analytics. This shift towards IoT-enabled devices provides companies with enhanced operational insights, fostering predictive maintenance practices that can minimize downtime and operational costs. Additionally, as industries prioritize energy efficiency, the demand for pressure switches that can operate under varying conditions while maintaining low energy consumption is on the rise.

International buyers should be aware of the regional compliance standards and certifications required for pressure switches, particularly in Europe and the Middle East, where regulations around safety and environmental impact are stringent. Understanding these dynamics will empower buyers to make informed sourcing decisions that align with both operational needs and regulatory requirements.

How is Sustainability Shaping the Sourcing of Pressure Switches?

Sustainability is becoming a pivotal factor in the sourcing of pressure switches. As industries worldwide face mounting pressure to reduce their environmental footprints, the adoption of eco-friendly manufacturing practices is gaining traction. This includes the use of recyclable materials and the implementation of energy-efficient production processes. For B2B buyers, sourcing pressure switches from manufacturers that prioritize sustainability can enhance their own corporate responsibility initiatives and appeal to environmentally conscious consumers.

The importance of ethical supply chains cannot be overstated. Buyers are increasingly seeking suppliers who demonstrate transparency in their sourcing practices and adhere to fair labor standards. Certifications such as ISO 14001 for environmental management and other ‘green’ credentials are becoming essential criteria in supplier evaluation. Furthermore, as regulatory bodies enforce stricter environmental standards, companies that proactively engage in sustainable practices will not only mitigate risks but also position themselves as leaders in their respective industries.

Integrating sustainability into the procurement strategy for pressure switches not only aligns with global trends but also provides a competitive advantage in the marketplace, as companies increasingly favor suppliers who contribute positively to environmental and social governance.

Brief Evolution of Pressure Switch Technology

The evolution of pressure switch technology has been marked by significant advancements that have improved functionality and reliability. Initially, mechanical pressure switches dominated the market, relying on physical movement to complete circuits. However, the introduction of electronic pressure switches in the late 20th century revolutionized the industry, offering increased precision and the ability to integrate with digital systems.

Today, the trend is leaning towards smart pressure switches equipped with sensors and IoT capabilities. These modern devices can communicate data to centralized monitoring systems, allowing for more proactive management of industrial processes. The shift from purely mechanical systems to sophisticated electronic devices reflects broader trends in automation and smart manufacturing, enabling industries to optimize operations and enhance safety protocols effectively.

This historical perspective not only showcases the rapid technological advancements in the sector but also highlights the importance of adapting to evolving market demands as businesses look for solutions that enhance efficiency and reliability.

Frequently Asked Questions (FAQs) for B2B Buyers of a switch that completes a circuit when pressure is applied

-

What are the primary applications of a pressure switch in industrial settings?

Pressure switches are utilized in various industrial applications, including monitoring hydraulic and pneumatic systems, controlling pumps, and ensuring safety protocols in machinery. For instance, in manufacturing processes, they prevent over-pressurization, which can lead to equipment failure or safety hazards. Additionally, these switches are integral in HVAC systems for maintaining optimal pressure levels, thus enhancing energy efficiency and operational reliability. -

How do I select the right pressure switch for my specific needs?

When selecting a pressure switch, consider factors such as the required pressure range, the type of media (liquid or gas), and the environmental conditions (temperature, humidity, etc.). Additionally, evaluate the switch’s electrical specifications, including voltage and current ratings. It is also crucial to assess the switch’s response time and mounting options to ensure compatibility with your equipment and operational requirements. -

What customization options are available for pressure switches?

Many manufacturers offer customization options for pressure switches, including tailored pressure ranges, electrical ratings, and physical configurations. You can also request specific materials for harsh environments, such as corrosion-resistant casings. Discussing your unique requirements with suppliers can lead to a solution that perfectly fits your application, enhancing performance and longevity. -

What are the minimum order quantities (MOQ) for pressure switches?

Minimum order quantities for pressure switches can vary significantly by supplier and region. Generally, MOQs range from 50 to 500 units, depending on the manufacturer’s production capabilities and your specific requirements. It’s advisable to confirm MOQs during initial discussions with suppliers, as they may offer flexibility for first-time buyers or ongoing partnerships. -

What payment terms should I expect when sourcing pressure switches internationally?

Payment terms for international orders typically include options such as upfront payments, letters of credit, or payment upon delivery. Many suppliers may require a deposit (e.g., 30% upfront) with the balance due before shipment. It’s essential to clarify payment terms upfront to avoid misunderstandings and ensure smooth transactions, especially when dealing with international shipping complexities. -

How can I ensure the quality of pressure switches before purchasing?

To ensure quality, request samples from potential suppliers before placing a bulk order. Additionally, inquire about their quality assurance processes, certifications (like ISO 9001), and warranty policies. Conducting a factory audit or checking customer reviews can also provide insights into the supplier’s reliability and product standards. -

What logistics considerations should I be aware of when importing pressure switches?

When importing pressure switches, consider shipping methods, customs regulations, and potential tariffs or taxes in your country. Working with a logistics provider familiar with international shipping can help streamline the process. Ensure that all documentation is complete to avoid delays at customs, and consider insurance options to protect your investment during transit. -

What are the key factors to consider when vetting suppliers of pressure switches?

Key factors to consider include the supplier’s experience in the industry, customer references, and their compliance with international quality standards. Evaluate their production capabilities, lead times, and responsiveness to inquiries. It’s also beneficial to assess their financial stability and willingness to engage in long-term partnerships, which can enhance your supply chain reliability.

Top 4 A Switch That Completes A Circuit When Pressure Is Applied Manufacturers & Suppliers List

1. Brainly – Pressure Switch

Domain: brainly.com

Registered: 2004 (21 years)

Introduction: A pressure switch is a device that completes a circuit when a certain level of pressure is applied. It is used in various applications, including industrial machinery and household appliances like washing machines. When pressure is applied, it activates a mechanism inside the switch that closes the contacts, allowing electricity to flow. Pressure switches can be hydraulic (using liquid pressure) o…

2. Ashcroft – Pressure Switches

Domain: blog.ashcroft.com

Registered: 1995 (30 years)

Introduction: A pressure switch is a control device that senses changes in pressure and mechanically opens and closes an electrical circuit at a pre-determined point. It is used in various applications including hydraulic, oil and gas industries, agriculture, chemical/petrochemical, and water/wastewater operations. Key elements include a switching element (microswitch), normally open (NO) and normally closed (N…

3. Tameson – Pressure Switches

Domain: tameson.com

Registered: 2015 (10 years)

Introduction: A pressure switch controls an electrical circuit based on fluid pressure, activating or deactivating the circuit at preset pressure levels. It is used in various applications such as HVAC systems, well pumps, and furnaces, ensuring system safety and efficiency by preventing overpressure. There are two main types: mechanical and electronic pressure switches. Mechanical pressure switches operate usi…

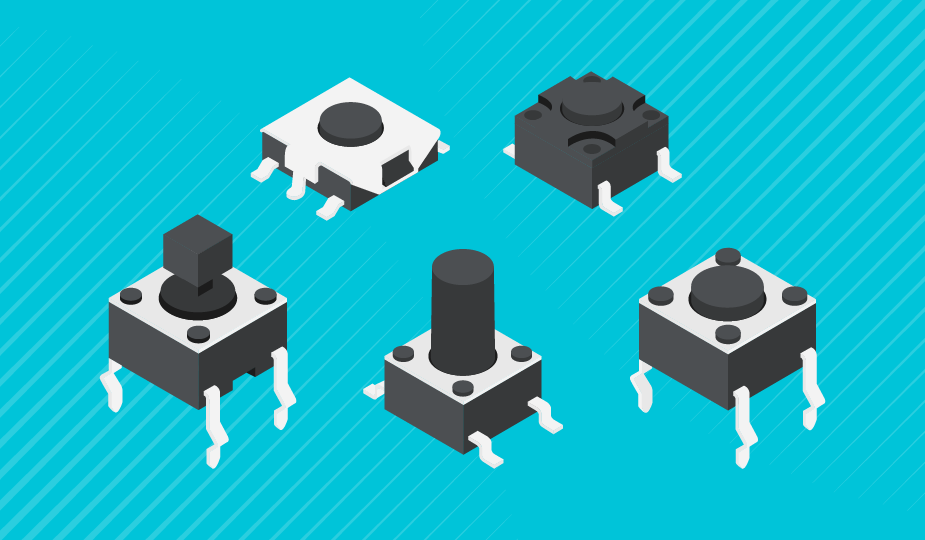

4. Digi-Key – Tactile Switches

Domain: digikey.com

Registered: 1995 (30 years)

Introduction: This company, Digi-Key – Tactile Switches, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for a switch that completes a circuit when pressure is applied

In conclusion, the strategic sourcing of pressure switches is pivotal for businesses looking to enhance operational efficiency and ensure safety in their applications. These switches play a crucial role in various sectors, including industrial machinery, automotive systems, and household appliances. By understanding the specific requirements and applications of pressure switches, B2B buyers can make informed decisions that align with their operational needs and regulatory standards.

The value of strategic sourcing cannot be overstated, particularly in dynamic markets across Africa, South America, the Middle East, and Europe. A well-planned sourcing strategy not only secures high-quality components but also fosters long-term partnerships with suppliers who understand the intricacies of local markets and regulations. This approach can lead to cost savings, improved product reliability, and enhanced innovation.

Looking ahead, businesses are encouraged to explore the latest advancements in pressure switch technology and consider how these innovations can be integrated into their operations. As the demand for automation and smart solutions grows, investing in reliable pressure switches will be essential for maintaining competitive advantage. Engage with your suppliers today to ensure you’re equipped for the future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.