The Definitive Guide to Basket Cable: Cost, Materials & Top Vendors

Introduction: Navigating the Global Market for basket cable

In today’s fast-paced global marketplace, sourcing the right basket cable solutions can be a daunting challenge for B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe, including key markets like Saudi Arabia and Germany. As businesses increasingly rely on efficient cable management systems to support their operations, understanding the nuances of basket cable—from types and materials to applications and compliance standards—becomes critical.

This comprehensive guide delves into the multifaceted world of basket cable, offering insights into various types, their specific applications across industries, and essential factors to consider when vetting suppliers. Additionally, it addresses cost considerations, ensuring that you can make informed purchasing decisions that align with your budgetary constraints and project requirements.

By equipping international B2B buyers with actionable insights and expert advice, this guide empowers you to navigate the complexities of the basket cable market confidently. Whether you’re looking to optimize installation efficiency, enhance safety standards, or ensure compliance with local regulations, the information contained herein will help you streamline your sourcing process and achieve your business objectives effectively.

Understanding basket cable Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Steel Wire Mesh Trays | Made from durable steel, available in various sizes | Data centers, industrial settings | Pros: High strength, corrosion resistance. Cons: Heavier, may require more installation time. |

| Aluminum Trays | Lightweight and corrosion-resistant | Commercial buildings, airports | Pros: Easy to handle, good thermal conductivity. Cons: Higher cost compared to steel. |

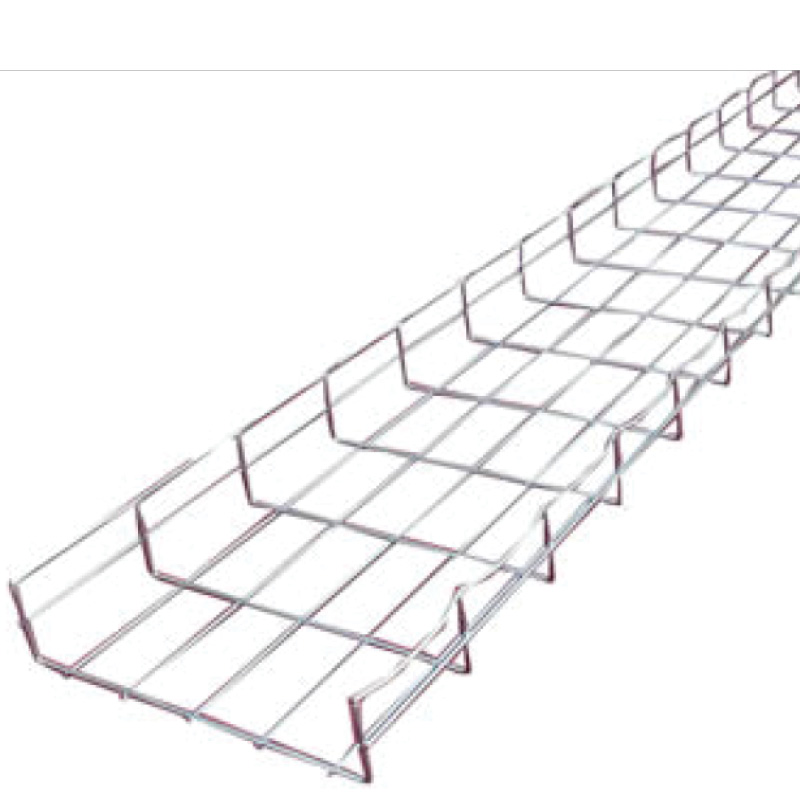

| Ladder Cable Trays | Ladder-like design for maximum airflow and cable support | Telecommunications, IT networks | Pros: Excellent cable ventilation, easy access. Cons: Limited cable protection from external elements. |

| Solid Bottom Trays | Solid base for maximum protection | Manufacturing, harsh environments | Pros: Protects cables from dust and debris. Cons: Can trap heat, potentially leading to overheating. |

| Cable Raceways | Enclosed channels for cable management | Office spaces, retail environments | Pros: Aesthetically pleasing, protects cables from damage. Cons: May be less accessible for maintenance. |

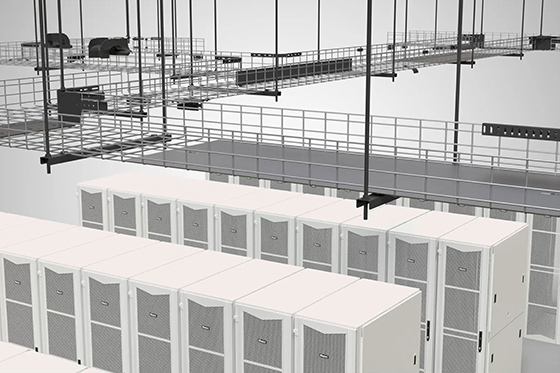

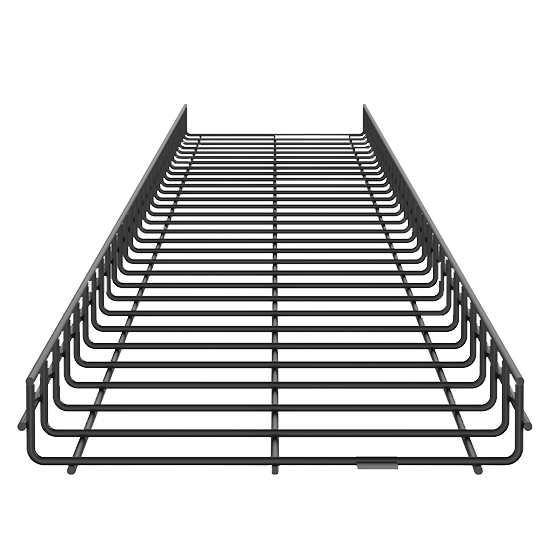

What Are the Key Characteristics of Steel Wire Mesh Trays?

Steel wire mesh trays are known for their robustness and durability, making them ideal for heavy-duty applications. They are typically used in environments such as data centers and industrial settings where high strength is essential. Buyers should consider factors such as load capacity and corrosion resistance when selecting steel trays. They require more effort for installation due to their weight but provide long-term reliability.

How Do Aluminum Trays Compare in Terms of Suitability?

Aluminum trays offer a lighter alternative to steel, making them easier to handle and install. They are particularly suitable for commercial buildings and airports where weight considerations are paramount. Their corrosion resistance makes them ideal for humid or coastal environments. However, buyers should be aware that the initial cost can be higher compared to steel options, which may impact budget considerations.

What Advantages Do Ladder Cable Trays Offer?

Ladder cable trays are designed with a ladder-like structure that promotes excellent airflow around the cables, reducing the risk of overheating. This design is particularly advantageous in telecommunications and IT networks where cooling is crucial. While they provide easy access for maintenance, buyers should consider their limited protection against environmental factors, which may necessitate additional protective measures.

When Should Solid Bottom Trays Be Used?

Solid bottom trays are ideal for applications in manufacturing and harsh environments where dust and debris could damage cables. Their solid base provides maximum protection, but buyers must consider the potential for heat retention, which could lead to overheating of cables. These trays are best suited for environments where cable integrity is a priority, and airflow is less of a concern.

Why Choose Cable Raceways for Office Spaces?

Cable raceways are enclosed channels that provide a clean and organized look for cable management in office spaces and retail environments. They protect cables from damage while enhancing the aesthetics of the installation. However, their design may limit accessibility for maintenance and upgrades, which is an important consideration for buyers looking for long-term solutions.

Key Industrial Applications of basket cable

| Industry/Sector | Specific Application of Basket Cable | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Telecommunications | Data Center Cable Management | Enhanced organization and efficiency in data handling | Compliance with international standards and certifications |

| Manufacturing | Power Distribution and Control Systems | Improved safety and reliability in electrical setups | Material durability and load-bearing capacity |

| Construction | Electrical Wiring in Building Infrastructure | Streamlined installation and maintenance processes | Customization options for different project specifications |

| Oil & Gas | Cable Support in Harsh Environments | Resistance to corrosion and environmental factors | Sourcing from suppliers with proven industry experience |

| Renewable Energy | Solar Farm Cable Management | Efficient energy transmission and reduced downtime | Availability of compatible accessories and components |

How is Basket Cable Used in Telecommunications?

In the telecommunications sector, basket cable is primarily utilized for data center cable management. This application involves organizing and supporting various data cables within server rooms, ensuring optimal airflow and reducing the risk of overheating. By implementing basket cable systems, businesses can enhance the organization of their infrastructure, leading to improved efficiency in data handling and easier maintenance. International buyers should consider sourcing products that comply with rigorous standards to ensure reliability and safety in their operations.

What Role Does Basket Cable Play in Manufacturing?

In manufacturing, basket cable serves a crucial role in power distribution and control systems. It supports electrical wiring, ensuring that cables are securely held in place while minimizing the risk of damage. This application not only enhances safety but also improves the reliability of electrical setups, which is vital for uninterrupted production processes. Buyers in this sector must prioritize the durability of materials and the load-bearing capacity of basket cables to meet the demanding requirements of industrial environments.

Why is Basket Cable Essential in Construction?

In the construction industry, basket cable is integral to the electrical wiring of building infrastructure. It streamlines the installation process by providing a flexible and adaptable solution for routing cables through various building layouts. This flexibility allows for easier modifications and maintenance in the future. Buyers should consider customization options to fit specific project specifications, ensuring that the basket cable meets local building codes and standards.

How is Basket Cable Used in Oil & Gas?

The oil and gas sector frequently employs basket cable for cable support in harsh environments. Given the corrosive and extreme conditions often encountered in this industry, basket cables must be resistant to environmental factors while maintaining structural integrity. This application enhances safety by preventing cable damage and potential hazards. Buyers should source from suppliers with proven experience in the oil and gas sector to ensure that the products meet the industry’s stringent safety and durability requirements.

What is the Importance of Basket Cable in Renewable Energy?

In renewable energy, particularly solar farms, basket cable is crucial for effective cable management. It facilitates the organization of cables that connect solar panels to inverters and the grid, ensuring efficient energy transmission and minimizing the risk of downtime. For international buyers, it is essential to consider the availability of compatible accessories and components that can enhance the overall system’s performance, thus optimizing energy production and efficiency.

3 Common User Pain Points for ‘basket cable’ & Their Solutions

Scenario 1: Navigating Complex Installation Environments

The Problem: Many B2B buyers face the challenge of installing basket cable in complex environments, such as industrial plants or data centers. These settings often have varying heights, tight spaces, and existing infrastructure that complicate installation. Misalignment and insufficient support can lead to cable strain, potential damage, and costly downtimes. Buyers frequently express frustration over how to adapt standard installation practices to fit their unique layouts without compromising safety and performance.

The Solution: To address this challenge, it’s essential to conduct a thorough site assessment before installation. Utilize detailed CAD drawings or 3D modeling to visualize the cable tray layout, factoring in existing structures and equipment. When specifying basket cables, choose adjustable systems that allow for height and angle flexibility. For example, look for products that offer various mounting options and accessories like adjustable hangers and support brackets. Additionally, investing in modular basket cable solutions can significantly ease installation, as they can be tailored on-site to fit specific requirements. Partnering with experienced suppliers who provide installation support can also streamline the process, ensuring that your team can effectively manage the complexities of the installation.

Scenario 2: Managing Cable Organization and Maintenance

The Problem: As businesses grow and expand their networks, the challenge of maintaining organized and accessible cable management becomes increasingly pressing. Cluttered cables can lead to inefficient troubleshooting, hindered maintenance efforts, and even safety hazards. B2B buyers often struggle with how to keep their basket cable systems orderly over time, especially when adding new cables or rerouting existing ones.

The Solution: Implementing a proactive cable management strategy is key to maintaining organization. Start by utilizing identification tags and color-coding systems for different cable types or functions, which can simplify future maintenance and troubleshooting. Incorporate dividers within the basket cable trays to separate distinct cable categories, preventing tangling and confusion. Regular audits of your cable management system can help identify unused or outdated cables that can be removed or repurposed, streamlining your setup. Additionally, consider investing in cable management accessories such as cable ties and clips to keep everything neatly bundled. By establishing a routine maintenance schedule, you can ensure that the cable management system remains functional and efficient, ultimately reducing downtime and enhancing productivity.

Scenario 3: Ensuring Compliance and Safety Standards

The Problem: Compliance with local and international safety and quality standards is a critical concern for B2B buyers. Failure to adhere to these regulations can result in costly penalties and unsafe working conditions. Many buyers are uncertain about the specific standards their basket cable systems must meet, leading to hesitation in sourcing and implementation decisions.

The Solution: To ensure compliance, it’s vital to familiarize yourself with the relevant standards applicable to your region and industry. Begin by consulting the regulatory guidelines provided by local authorities or industry organizations, such as IEC or NEC standards, which outline safety requirements for cable installations. When sourcing basket cable, choose manufacturers that provide detailed certification information, ensuring that their products meet these standards. Additionally, consider working with a compliance consultant or a knowledgeable supplier who can guide you through the certification process and help you understand any local variations in regulations. Regularly review and update your installation practices in line with changing standards to maintain compliance. By prioritizing safety and regulatory adherence from the outset, you can protect your business from potential liabilities and foster a safer working environment.

Strategic Material Selection Guide for basket cable

What Are the Key Properties of Common Materials Used in Basket Cable?

When selecting materials for basket cable, understanding the properties of common materials is crucial for ensuring optimal performance and compliance with industry standards. Here, we analyze four prevalent materials: steel, aluminum, fiberglass, and plastic.

Steel: The Robust Choice for Heavy-Duty Applications

Steel is widely recognized for its strength and durability, making it an ideal choice for basket cables in heavy-duty applications. Key properties include a high temperature and pressure rating, along with excellent corrosion resistance when treated with galvanization or coatings.

Pros: Steel’s durability allows it to withstand harsh environments, making it suitable for industrial settings. Its strength enables it to support heavy loads, which is essential in applications where large volumes of cables are managed.

Cons: However, steel can be heavier and more expensive than alternative materials. Manufacturing complexity can also increase due to the need for coatings to enhance corrosion resistance, especially in humid or coastal environments.

Impact on Application: Steel is highly compatible with various media, including electrical and communication cables. It is essential for projects requiring high load-bearing capacity.

Considerations for International Buyers: Compliance with standards such as ASTM and DIN is critical. Buyers from regions like Europe and the Middle East should ensure that the steel used meets local regulations regarding corrosion resistance and structural integrity.

Aluminum: Lightweight and Corrosion-Resistant

Aluminum offers a lightweight alternative to steel while maintaining good strength and corrosion resistance. Its key properties include a lower temperature rating compared to steel but a high resistance to oxidation.

Pros: The lightweight nature of aluminum facilitates easier installation and reduces overall transportation costs. It is also less expensive than steel, making it a cost-effective choice for many applications.

Cons: While aluminum is corrosion-resistant, it may not withstand extreme temperatures as effectively as steel. Additionally, it can be less durable under heavy loads.

Impact on Application: Aluminum is suitable for a variety of media, particularly in environments where weight is a concern, such as in overhead installations.

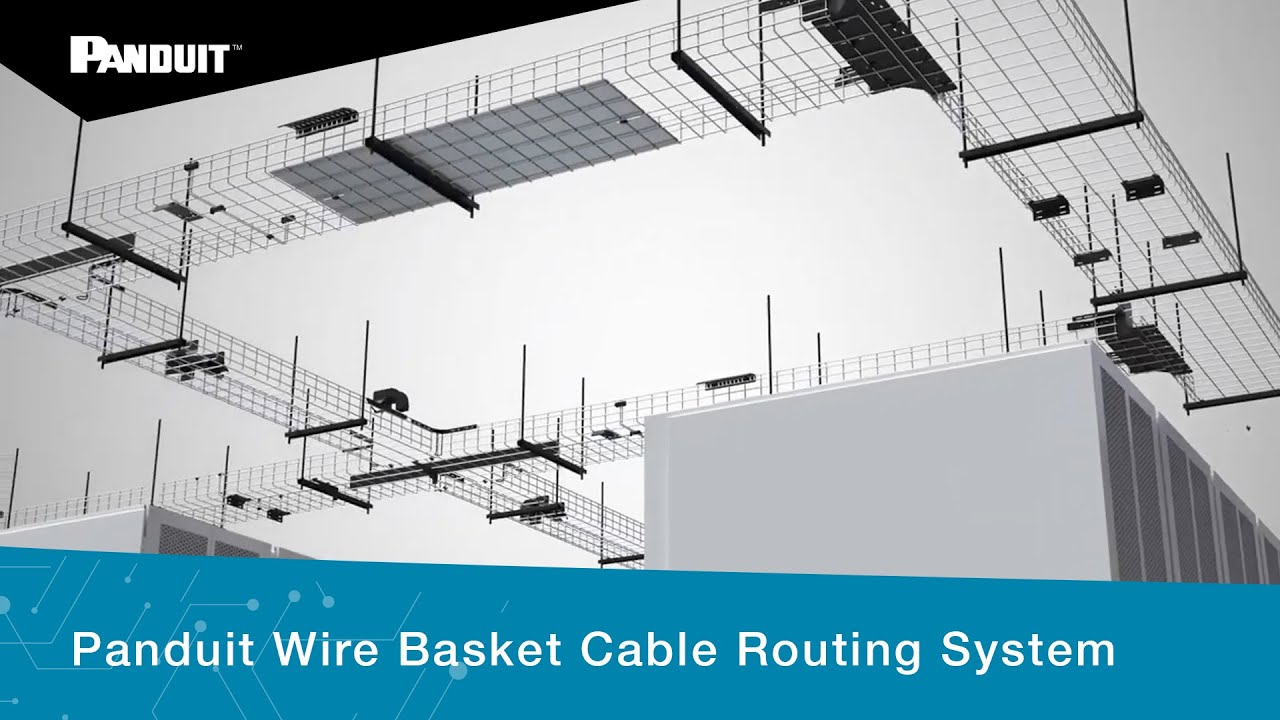

Illustrative image related to basket cable

Considerations for International Buyers: Buyers should verify compliance with JIS standards, especially in Japan and other Asian markets. The choice of aluminum may also be influenced by local availability and cost fluctuations.

Fiberglass: The Non-Metallic Solution

Fiberglass is increasingly popular for basket cables due to its non-metallic nature and excellent corrosion resistance. Key properties include a high temperature rating and low thermal conductivity.

Pros: Fiberglass is lightweight and resistant to a wide range of chemicals, making it suitable for diverse applications, including those in corrosive environments. Its non-conductive properties enhance safety in electrical installations.

Cons: The initial cost of fiberglass can be higher than that of metals, and it may not support as heavy a load as steel or aluminum.

Impact on Application: Fiberglass is particularly effective in environments where chemical exposure is a concern, such as in petrochemical facilities.

Considerations for International Buyers: Compliance with international standards for safety and performance is essential. Buyers in Africa and South America should consider local regulations regarding the use of non-metallic materials.

Plastic: The Economical and Versatile Option

Plastic materials, such as PVC and polyethylene, are often used for basket cables in less demanding applications. Their key properties include low weight and good chemical resistance.

Pros: Plastic is generally the most economical option, making it attractive for budget-sensitive projects. It is also easy to manufacture and install.

Illustrative image related to basket cable

Cons: However, plastic may not offer the same level of durability or load-bearing capacity as metals. It can also degrade under UV exposure unless treated.

Impact on Application: Plastic is suitable for indoor applications or environments with minimal exposure to harsh conditions.

Considerations for International Buyers: Buyers should ensure that the plastic materials comply with local environmental regulations, particularly in Europe where restrictions on certain chemicals are stringent.

Summary Table of Material Selection for Basket Cable

| Material | Typical Use Case for basket cable | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty industrial applications | High strength and load capacity | Heavier and more expensive | High |

| Aluminum | Overhead installations | Lightweight and cost-effective | Lower load capacity than steel | Medium |

| Fiberglass | Corrosive environments | Excellent chemical resistance | Higher initial cost | Medium |

| Plastic | Indoor applications | Economical and easy to install | Limited durability and UV exposure | Low |

This strategic guide provides B2B buyers with insights into material selection, ensuring that they can make informed decisions tailored to their specific operational needs and compliance requirements.

Illustrative image related to basket cable

In-depth Look: Manufacturing Processes and Quality Assurance for basket cable

What Are the Key Stages in the Manufacturing Process of Basket Cable?

The manufacturing process of basket cable involves several critical stages, each designed to ensure the durability, functionality, and compliance of the final product. Understanding these stages can aid B2B buyers in making informed purchasing decisions.

Material Preparation: What Materials Are Used?

The manufacturing of basket cables typically begins with material preparation. High-quality metals, such as steel or aluminum, are commonly used for their strength and conductivity. These materials undergo a thorough inspection to ensure they meet specific standards before being processed. Suppliers often rely on international standards such as ISO 9001 to guide their material selection and preparation processes, ensuring that only the best materials are used.

How Is Basket Cable Formed?

Once the materials are prepared, the next step is forming. This process involves cutting and shaping the metal into the desired dimensions. Techniques such as stamping, bending, and welding are commonly employed to create the framework of the basket cable. Advanced machinery and CNC (Computer Numerical Control) technology are often utilized to achieve precise dimensions and reduce human error. The use of high-quality dies and molds is crucial at this stage to ensure that the components fit together perfectly in later assembly stages.

What Does the Assembly Process Involve?

After forming, the individual components are assembled. This stage is critical as it directly impacts the structural integrity and overall performance of the basket cable. The assembly process often involves welding or bolting various parts together, depending on the design specifications. Quality assurance teams monitor this stage closely to ensure that all components fit seamlessly and that the assembly meets predefined standards.

How Is Finishing Done to Ensure Quality in Basket Cable?

Finishing is the final stage of manufacturing, where the assembled basket cable is treated to enhance its durability and aesthetics. This can include galvanization, powder coating, or other surface treatments that protect against corrosion and wear. These finishing processes are vital for applications in harsh environments, such as those found in industrial settings. B2B buyers should inquire about the specific finishing techniques used, as these can significantly affect the lifespan and performance of the basket cable.

What Are the Key Quality Assurance Procedures in Basket Cable Manufacturing?

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that each product meets stringent quality standards. Different checkpoints are established throughout the manufacturing process to maintain quality.

What International Standards Should B2B Buyers Be Aware Of?

Manufacturers of basket cables often adhere to international standards such as ISO 9001, which outlines requirements for a quality management system. In addition, industry-specific certifications like CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) for those used in the oil and gas sector may also be relevant. Understanding these certifications helps B2B buyers assess the quality and safety of the products.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are established at various stages of the manufacturing process:

- Incoming Quality Control (IQC): This initial stage involves inspecting raw materials for defects or non-compliance with specifications.

- In-Process Quality Control (IPQC): During manufacturing, continuous monitoring is performed to ensure that processes remain within defined limits. This may include measuring dimensions, checking welds, and verifying material properties.

- Final Quality Control (FQC): Before the final product is shipped, comprehensive tests are conducted to ensure that the basket cables meet all performance and safety standards.

What Testing Methods Are Commonly Used for Basket Cables?

Common testing methods for basket cables include tensile strength tests, corrosion resistance tests, and electrical conductivity tests. These tests help verify that the cables can withstand the conditions they will encounter during use. Moreover, B2B buyers should request documentation of these tests to ensure compliance with relevant standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

When sourcing basket cables, B2B buyers must ensure that their suppliers maintain robust quality control practices. Here are some actionable insights:

Illustrative image related to basket cable

- Conduct Supplier Audits: Regular audits can help assess a supplier’s adherence to quality standards and manufacturing processes. This can include on-site inspections to evaluate machinery, processes, and overall factory conditions.

- Request Quality Assurance Reports: Suppliers should provide detailed reports on their quality control measures, including any certifications or test results. These documents offer transparency and build trust in the supplier’s capabilities.

- Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased evaluation of the manufacturing process and final products. This is particularly important for international buyers who may not be able to visit suppliers directly.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, must be aware of specific nuances in quality control. For instance, different countries may have varying standards and certifications. Buyers should ensure that the supplier’s products are compliant with local regulations in their respective markets.

Furthermore, cultural and logistical differences can impact communication and expectations regarding quality. Establishing clear communication channels and understanding each other’s standards can facilitate smoother transactions and better product quality.

In conclusion, the manufacturing processes and quality assurance practices for basket cables are intricate and vital for ensuring product reliability and performance. By understanding these processes, B2B buyers can make more informed decisions and foster successful partnerships with their suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘basket cable’

Introduction

Navigating the procurement process for basket cable can be complex, especially for international B2B buyers. This guide provides a step-by-step checklist designed to streamline your sourcing process, ensuring that you select the right products for your specific needs. By following these actionable steps, you can minimize risks and make informed decisions that align with your project requirements.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, establish clear technical specifications for the basket cable you need. This includes determining the material (e.g., steel, aluminum), dimensions (width, height, length), and load capacity. Understanding these parameters helps ensure that the selected cable trays meet the demands of your application, whether for industrial, commercial, or residential use.

Step 2: Research Industry Standards and Certifications

Verify that the basket cable products you are considering comply with relevant industry standards and certifications. Look for certifications such as UL, CE, or ISO, as these indicate that the products have undergone rigorous testing and adhere to safety and quality benchmarks. This step is crucial to ensure that your installation meets local regulations and international best practices.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to assess their reliability and product quality. Request company profiles, case studies, and references from buyers in similar industries or regions. It’s beneficial to engage with suppliers who have a proven track record in your geographical area, as they will be more familiar with local regulations and market conditions.

Step 4: Request Samples for Testing

Once you have shortlisted suppliers, request samples of the basket cable for testing. Evaluating samples allows you to assess the quality, durability, and suitability of the product for your specific application. This hands-on approach can help you avoid costly mistakes and ensure that the products perform as expected in your environment.

Step 5: Compare Pricing and Terms

Gather detailed quotations from multiple suppliers, ensuring that you understand the pricing structure, including any hidden costs like shipping and taxes. Compare the total cost of ownership, not just the initial price. Consider factors such as warranty, after-sales support, and lead times, which can significantly impact your overall project budget and timeline.

Illustrative image related to basket cable

Step 6: Negotiate Terms and Conditions

Once you have selected a preferred supplier, engage in negotiations to finalize terms and conditions. Be clear about your expectations regarding delivery schedules, payment terms, and any additional services such as installation support. A well-negotiated contract can protect your interests and foster a positive long-term relationship with the supplier.

Step 7: Plan for Future Maintenance and Upgrades

Consider the long-term implications of your basket cable procurement. Inquire about maintenance requirements and the availability of replacement parts. Planning for future upgrades or expansions ensures that your cable management system remains effective and adaptable to changing technological needs.

By following this checklist, you can enhance your procurement process for basket cable, ensuring that you make informed decisions that align with your operational goals and standards.

Comprehensive Cost and Pricing Analysis for basket cable Sourcing

What Are the Key Cost Components in Basket Cable Sourcing?

When sourcing basket cables, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

-

Materials: The cost of raw materials such as steel, aluminum, or other metals used in the production of basket cables significantly influences the final price. The choice of material affects durability, weight capacity, and corrosion resistance.

-

Labor: Labor costs encompass wages for workers involved in manufacturing, assembly, and quality control. These costs can vary depending on the region, with countries in Africa and South America typically experiencing lower labor costs compared to Europe.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, maintenance, and equipment depreciation. Efficient manufacturing processes can help reduce overhead costs, thereby lowering the price for buyers.

-

Tooling: Initial tooling costs for machinery and molds can be substantial, especially for custom specifications. These costs are often amortized over the production run, making larger orders more cost-effective.

-

Quality Control (QC): Ensuring product quality through rigorous testing and certification processes incurs costs. Products that meet international standards may command higher prices but provide better reliability and safety.

-

Logistics: Transportation and handling fees can add to the total cost, especially for international shipments. Factors such as shipping methods, distance, and customs duties must be considered.

-

Margin: Suppliers typically add a profit margin to cover their operational costs and ensure profitability. This margin can vary widely based on market conditions, competition, and perceived value.

How Do Pricing Influencers Affect Basket Cable Costs?

Several factors can influence pricing and should be considered when negotiating:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide discounts for larger orders. Understanding the MOQ can help buyers negotiate better pricing and optimize their inventory management.

-

Specifications and Customization: Customized cables or those with specific certifications may incur additional costs. Buyers should weigh the benefits of customization against potential price increases.

-

Materials and Quality Certifications: Higher-quality materials or certifications that meet specific industry standards can lead to increased costs. However, investing in quality may reduce long-term operational risks.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more but offer better service and product assurance.

-

Incoterms: The terms of shipping and delivery can significantly impact costs. Understanding Incoterms can help buyers clarify their responsibilities regarding transportation, insurance, and customs clearance.

What Are Effective Buyer Tips for Cost-Efficiency in Basket Cable Sourcing?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, can maximize value by applying these strategies:

-

Negotiate Effectively: Always seek to negotiate prices, especially for larger orders. Leverage competitive quotes from multiple suppliers to strengthen your bargaining position.

-

Consider Total Cost of Ownership (TCO): TCO includes not only the purchase price but also maintenance, operational efficiency, and longevity. Investing in higher-quality cables may lead to lower overall costs over time.

-

Understand Pricing Nuances for International Transactions: Exchange rates, tariffs, and local taxes can affect pricing. Familiarize yourself with these elements to better calculate total expenses.

-

Engage with Local Suppliers: Local suppliers may offer more competitive pricing due to reduced shipping costs and faster delivery times. Building relationships with local vendors can also lead to better service and support.

Disclaimer on Indicative Prices

Prices for basket cables can vary significantly based on the aforementioned factors. It is essential to request quotes from multiple suppliers to obtain accurate pricing tailored to your specific requirements. Always consider market fluctuations and regional economic conditions when budgeting for your sourcing needs.

Alternatives Analysis: Comparing basket cable With Other Solutions

Understanding Alternatives to Basket Cable in Cable Management

In the rapidly evolving landscape of cable management solutions, it is essential for B2B buyers to evaluate various options to ensure optimal performance and cost-effectiveness. Basket cable trays are widely recognized for their flexibility and ease of installation; however, alternatives exist that may better suit specific applications or environments. This section explores two viable alternatives: Wire Mesh Trays and Cable Ducts.

Comparison Table

| Comparison Aspect | Basket Cable | Wire Mesh Trays | Cable Ducts |

|---|---|---|---|

| Performance | High load capacity, ventilation | Excellent airflow, customizable | Good protection, less airflow |

| Cost | Moderate cost | Similar to basket cable | Often lower initial cost |

| Ease of Implementation | Quick installation with minimal tools | Relatively easy, requires some assembly | Requires precise cutting and fitting |

| Maintenance | Low maintenance | Low maintenance | Moderate maintenance required |

| Best Use Case | Open spaces, data centers | Industrial applications, high airflow environments | Enclosed spaces, harsh conditions |

In-Depth Analysis of Alternatives

What are Wire Mesh Trays and Their Advantages?

Wire mesh trays are an excellent alternative to basket cables, particularly in environments requiring high airflow and easy access for maintenance. Made from durable materials, these trays can support significant weight while allowing for optimal ventilation of cables. They are highly customizable, enabling users to adapt to specific routing needs. However, the installation process can be slightly more involved than that of basket cables due to the need for assembly and secure fastening.

How Do Cable Ducts Compare to Basket Cables?

Cable ducts provide an alternative that excels in protecting cables from physical damage and environmental factors. They are particularly suited for enclosed spaces where aesthetics and safety are paramount. While they may not offer the same level of ventilation as basket cables, they shield cables from dust, moisture, and impact. The primary downside is that installation can be more complex, requiring precise cutting and fitting, which may increase labor costs. Additionally, maintenance can be more challenging due to limited access.

Making the Right Choice: How Should B2B Buyers Decide?

When choosing between basket cables and alternatives like wire mesh trays or cable ducts, B2B buyers must consider several factors. Assessing the specific environment in which the cable management system will be used is crucial. For instance, if airflow and flexibility are priorities, basket cables or wire mesh trays may be the best fit. Conversely, in situations where protection from environmental hazards is essential, cable ducts may be the superior choice.

Illustrative image related to basket cable

Ultimately, evaluating performance, cost, ease of implementation, and maintenance will empower buyers to select the most appropriate solution for their needs. By carefully considering these aspects, businesses can enhance their cable management efficiency and overall operational effectiveness.

Essential Technical Properties and Trade Terminology for basket cable

What Are the Essential Technical Properties of Basket Cable?

When considering the purchase of basket cable, understanding its technical properties is crucial for ensuring that the product meets specific project requirements. Here are key specifications that buyers should consider:

1. Material Grade

Basket cables are typically constructed from materials like aluminum or steel. The material grade impacts durability, weight capacity, and corrosion resistance. For instance, galvanized steel offers excellent corrosion protection, making it suitable for outdoor or humid environments. Selecting the appropriate material grade is vital for ensuring the longevity and performance of the cable management system in various applications.

2. Load Capacity

The load capacity, or working load limit, indicates the maximum weight that the basket cable can support without compromising its structural integrity. This specification is particularly important for projects with substantial cabling needs, such as data centers or industrial applications. Understanding the load capacity ensures that the selected basket cable can handle the expected weight of the cables while maintaining safety and compliance standards.

3. Tray Dimensions

Tray dimensions include width, height, and length, which are critical for ensuring compatibility with existing infrastructure. Buyers need to select the right dimensions to accommodate the volume and type of cables being managed. Inadequate dimensions can lead to overcrowding, reduced airflow, and potential overheating of cables, which may affect overall system performance.

4. Finish Type

The finish type, such as powder coating or galvanization, affects both aesthetics and durability. A powder-coated finish provides additional protection against scratches and corrosion, making it ideal for environments where appearance matters. On the other hand, a galvanized finish is more suited for outdoor applications where exposure to moisture is a concern. Understanding the finish type helps buyers align their choice with the operational environment of the installation.

5. Certification Standards

Certifications such as UL (Underwriters Laboratories) or IEC (International Electrotechnical Commission) signify that the basket cable meets specific safety and performance standards. For international buyers, ensuring that products adhere to recognized certification standards is essential for compliance and assurance of quality. This can help prevent costly delays due to non-compliance with local regulations.

What Common Trade Terminology Should Buyers Know?

Navigating the procurement process for basket cable involves familiarizing oneself with industry jargon. Here are some common terms that buyers should understand:

Illustrative image related to basket cable

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of basket cables, understanding the OEM can help buyers identify quality and compatibility with existing systems.

2. MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units that a supplier is willing to sell. Knowing the MOQ is essential for budget planning and inventory management, particularly for international buyers looking to optimize shipping costs.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. For buyers, issuing an RFQ helps gather competitive quotes, allowing for informed decision-making based on cost and service offerings.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that outline the responsibilities of buyers and sellers. Familiarity with these terms is crucial for understanding shipping costs, risk transfer, and delivery obligations, especially when dealing with international suppliers.

5. Lead Time

Lead time refers to the time taken from placing an order to the delivery of goods. Understanding lead times is vital for project planning, ensuring that materials arrive on schedule to avoid project delays.

By grasping these essential technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing basket cables, leading to more successful project outcomes.

Navigating Market Dynamics and Sourcing Trends in the basket cable Sector

What Are the Current Market Dynamics and Key Trends in the Basket Cable Sector?

The basket cable market is experiencing a transformative phase driven by several global factors. As industries increasingly rely on robust and flexible cable management systems, basket cables have gained prominence due to their versatility in various applications—from commercial buildings to industrial facilities. Key trends include the adoption of advanced materials that enhance durability and reduce installation time. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for sourcing decisions.

One notable trend is the rise of smart technologies that integrate with basket cable systems. These technologies enable real-time monitoring of electrical systems, enhancing safety and efficiency. Additionally, the shift towards modular and customizable solutions is becoming more prevalent, allowing businesses to tailor cable management systems to their specific needs. Buyers are also showing a growing preference for suppliers who offer comprehensive product ranges that include accessories and installation support, thus simplifying the procurement process.

Illustrative image related to basket cable

Furthermore, the market is responding to economic fluctuations and geopolitical factors, necessitating agile supply chain strategies. Companies are increasingly focusing on regional suppliers to mitigate risks associated with long-distance logistics, especially in volatile markets. This shift not only reduces lead times but also fosters local partnerships that can enhance service delivery and support.

How Is Sustainability Influencing Sourcing Trends in the Basket Cable Market?

Sustainability has become a critical consideration for B2B buyers in the basket cable sector. The environmental impact of cable production, including energy consumption and waste generation, is prompting companies to seek sustainable sourcing options. Buyers are increasingly interested in manufacturers that prioritize ethical supply chains and demonstrate a commitment to reducing their carbon footprint.

The importance of certifications cannot be overstated. Green certifications, such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals), are becoming essential criteria for procurement decisions. These certifications assure buyers that products meet stringent environmental standards and are free from harmful substances. Moreover, the use of recyclable materials in the production of basket cables is gaining traction, appealing to companies aiming to enhance their sustainability credentials.

B2B buyers are encouraged to engage with suppliers who provide transparency in their sourcing practices. This includes understanding the lifecycle of products and the environmental impacts associated with their use. By prioritizing suppliers with sustainable practices, buyers not only contribute to environmental preservation but also align their businesses with the growing consumer demand for eco-friendly solutions.

Illustrative image related to basket cable

How Has the Basket Cable Sector Evolved Over Time?

The evolution of the basket cable sector reflects broader technological advancements and changing industry needs. Initially developed for simple cable management, basket cables have transformed into sophisticated systems that accommodate the growing complexity of electrical installations. The introduction of wire mesh trays and other innovative designs has significantly improved cable organization, safety, and accessibility.

As digitalization and automation have taken center stage in various sectors, the demand for effective cable management solutions has surged. Today, basket cables are integral to data centers, commercial buildings, and industrial environments, underscoring their importance in a connected world. This evolution not only highlights the adaptability of basket cable systems but also emphasizes the need for ongoing innovation to meet the demands of modern infrastructure.

In summary, the basket cable sector’s journey from basic cable management solutions to advanced, sustainable systems showcases the industry’s responsiveness to market dynamics and buyer expectations, making it a vital component of B2B procurement strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of basket cable

-

How do I solve issues with cable management in my facility?

Effective cable management can be achieved by using basket cables and wire mesh trays. Start by assessing your current layout and identifying areas where cables are tangled or improperly secured. Choose the right size and type of basket cable that accommodates your specific needs, such as load capacity and environmental conditions. Implementing a structured system with proper support brackets and accessories can enhance organization and safety. Regular maintenance checks will also help in addressing any emerging issues promptly. -

What is the best type of basket cable for industrial applications?

For industrial applications, it is crucial to select basket cables made from durable materials, such as galvanized steel or aluminum, which can withstand harsh environments. Look for designs that offer flexibility and adaptability to your specific installation needs, including load-bearing capabilities and resistance to corrosion. Additionally, ensure that the basket cable complies with local and international safety standards, as this will enhance reliability and performance in demanding settings. -

How can I customize basket cable solutions for my project?

Customization options for basket cables often include various sizes, materials, and configurations tailored to your project’s specific requirements. Work closely with your supplier to determine the exact specifications needed, such as tray width, height, and load capacity. Many manufacturers offer bespoke solutions that can accommodate unique layouts and cable types. This collaborative approach ensures that the final product effectively meets your operational needs while adhering to compliance and safety standards. -

What should I consider when vetting suppliers for basket cables?

When vetting suppliers, consider their industry reputation, certifications, and experience in the market. Check for compliance with international standards and their ability to provide quality assurance documentation. Evaluate their production capabilities, lead times, and flexibility in fulfilling your order quantities. Customer service and support are also critical; a responsive supplier can provide valuable insights and assistance throughout the purchasing process. -

What are the typical minimum order quantities (MOQs) for basket cables?

Minimum order quantities for basket cables can vary significantly among suppliers, often ranging from a few dozen to several hundred units. It’s essential to discuss MOQs upfront with potential suppliers to ensure they align with your project needs and budget. Some manufacturers may offer lower MOQs for customized products, while others may have higher thresholds for standard items. Consider negotiating terms that can accommodate your purchasing strategy while ensuring a cost-effective solution. -

What payment terms should I expect when sourcing basket cables internationally?

Payment terms for international transactions can vary widely, typically ranging from advance payments to net 30 or net 60 days after delivery. Discuss payment options early in negotiations to find a mutually agreeable arrangement. Common methods include wire transfers, letters of credit, and online payment platforms. Ensure that the terms are clearly defined in your contract to avoid misunderstandings and protect both parties during the transaction. -

How do I ensure quality assurance when purchasing basket cables?

To ensure quality assurance, request product certifications and compliance documentation from your supplier. Many manufacturers adhere to international standards such as ISO or IEC, which signifies their commitment to quality and safety. Consider conducting factory visits or audits if feasible, and ask for samples before finalizing large orders. Establishing a clear quality control process, including inspection upon delivery, will help maintain high standards and prevent potential issues in your supply chain. -

What logistics considerations should I keep in mind when importing basket cables?

When importing basket cables, factor in shipping methods, customs regulations, and potential tariffs that may affect overall costs. Choose a reliable logistics partner experienced in handling industrial materials to ensure timely delivery. Understand the documentation required for customs clearance, including invoices and certificates of origin. Additionally, plan for potential delays by allowing extra time in your project schedule, especially if sourcing from international suppliers in regions with complex logistics challenges.

Top 7 Basket Cable Manufacturers & Suppliers List

1. Legrand – Wire and Cable Management Solutions

Domain: legrand.us

Registered: 2004 (21 years)

Introduction: This company, Legrand – Wire and Cable Management Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Electrix International – Stainless Steel Wire Basket Cable Tray

Domain: electrixinternational.com

Registered: 2005 (20 years)

Introduction: This company, Electrix International – Stainless Steel Wire Basket Cable Tray, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Fiber Savvy – Wire Cable Trays and Management Solutions

Domain: fibersavvy.com

Registered: 2010 (15 years)

Introduction: Wire Cable Trays and Cable Management products from Fiber Savvy include a variety of options designed to safeguard networks and provide organized cable management. Key details include:

– Brands: Arlington, GRI, Wiremaid

– Lengths available: 59 inches to 8 feet

– Widths available: 1/2 inch to 36 inches

– Additional components: corners, couplers, cross junctions, supports

– Example products:

– 10’…

4. Kable Kontrol – Basket Cable Tray

Domain: kablekontrol.com

Registered: 2022 (3 years)

Introduction: Basket Cable Tray:

– Design: Mesh-like structure made of intersecting steel wires.

– Applications: Ideal for managing smaller, lighter cables in data centers, telecommunications, and light industrial settings.

– Key Benefits:

– Versatile cable management for fiber optics and low-voltage cables.

– Excellent airflow for heat dissipation, preventing overheating.

– Lightweight and easy to …

5. SitOnIt Seating – Cable Caddy

Domain: sitonit.net

Registered: 1998 (27 years)

Introduction: Cable Caddy | SitOnIt Seating

Features:

– Clear the cable clutter with options to conceal, control, or clip cables.

Product Variants:

1. Cable Caddy + Power:

– Dimensions: 4.93 inches (W) x 36.00 inches (L) x 6.00 inches (H)

– Channel Dimensions: 3.85 inches (W) x 36.00 inches (L) x 2.00 inches (H)

– Desk Attachment: 1.00 inches (W)

– Power Strip: 15 amp/125 volt with 8-foot cord

…

6. Hubbell – Wiring Basket Tray

Domain: hubbell.com

Registered: 1995 (30 years)

Introduction: Wiring basket tray for cable management in commercial, industrial, and data center applications. Features include: detailed models for design compatibility, step-by-step installation videos, brochures, technical data sheets, and installation manuals. Products include field-adaptable wire basket trays for overhead, wall, or underfloor installation, brackets for secure mounting, durable covers for c…

7. Basor Electric – Cable Management Solutions

Domain: basor.com

Registered: 1998 (27 years)

Introduction: Basor Electric offers a variety of cable management solutions including: 1. Basorfil Wire Basket Cable Trays 2. Basorplast Insulating PVC Cable Trays 3. Basortray Metal Cable Trays 4. Basortrav Ladder Trays (available in Aluminum, Fiberglass, and Steel) 5. Accessories such as Cable Ladder Runway, J-Hooks, and Bridal Rings. The products are suitable for applications in sectors like petrochemical, d…

Strategic Sourcing Conclusion and Outlook for basket cable

Why is Strategic Sourcing Essential for Basket Cable Procurement?

In the competitive landscape of basket cable procurement, strategic sourcing emerges as a vital component for international buyers. It not only streamlines the purchasing process but also enhances the overall value derived from your investments. By focusing on quality, compliance, and the specific requirements of your projects, businesses can minimize risks and ensure that they select the best suppliers, whether in Africa, South America, the Middle East, or Europe.

Illustrative image related to basket cable

What are the Key Takeaways for B2B Buyers?

Understanding the intricacies of basket cable materials, certifications, and applications can empower buyers to make informed decisions. Opting for products that offer durability and flexibility will lead to long-term cost savings and improved operational efficiency. Furthermore, leveraging local suppliers can enhance supply chain resilience, especially in regions facing logistical challenges.

How Can You Prepare for Future Trends in Basket Cable?

As technology continues to evolve, so too will the demands for more sophisticated cable management solutions. Buyers should remain vigilant about emerging trends, such as sustainable materials and innovative designs that cater to specific industrial needs. Engaging with suppliers who are committed to innovation and quality will position your business advantageously.

In conclusion, the journey of sourcing basket cable is not merely transactional; it is strategic. Embrace the opportunity to refine your sourcing strategies, and connect with trusted suppliers who align with your operational goals. The future of efficient cable management is bright, and your proactive approach today can pave the way for success tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.