Hidden Cabinet Hinges No Bore: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for hidden cabinet hinges no bore

In the competitive landscape of cabinetry, sourcing hidden cabinet hinges no bore presents a unique challenge for international B2B buyers. As the demand for seamless and aesthetically pleasing designs grows, manufacturers and suppliers must understand the intricacies of these innovative hinges that eliminate the need for traditional drilling. This guide is designed to equip buyers with vital knowledge about various types of no-bore hinges, their applications across different cabinet styles, and the best practices for supplier vetting.

From understanding the technical specifications that dictate hinge performance to evaluating cost-effectiveness and quality assurance, our comprehensive exploration empowers businesses in Africa, South America, the Middle East, and Europe—including countries like Germany and Vietnam—to make informed purchasing decisions. We delve into critical factors such as the durability of materials, installation requirements, and the latest trends in hinge technology, ensuring that you have a complete understanding of the market landscape.

By addressing these pivotal aspects, this guide serves as an essential resource for professionals seeking to enhance their product offerings with reliable, high-quality hidden cabinet hinges no bore, ultimately leading to improved customer satisfaction and business success.

Understanding hidden cabinet hinges no bore Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 175 Degree Concealed No-Bore Hinge | Allows smooth opening to 175 degrees; suitable for various door types | Kitchen cabinets, commercial furniture | Pros: Versatile, easy installation; Cons: Limited weight capacity per hinge. |

| 170 Degree Easy-On No Bore Hinge | Adjustable opening between 150 and 170 degrees; surface-mounted | Office cabinetry, retail displays | Pros: No drilling required, heavy-duty; Cons: Requires skilled installation. |

| Soft Close Hidden Hinge | Integrated soft-close mechanism for quiet operation | Residential and commercial cabinetry | Pros: Enhanced user experience, reduces wear; Cons: Higher cost compared to standard hinges. |

| Heavy Duty European Concealed Hinge | Designed for larger overlay doors; robust construction | High-traffic areas, heavy-duty applications | Pros: Durable, supports significant weight; Cons: May require specialized mounting. |

| Invisible Spring Hinge | Provides a clean aesthetic with spring-loaded functionality | High-end residential, custom cabinetry | Pros: Seamless design, enhances aesthetics; Cons: Potentially complex installation. |

What Are the Characteristics of the 175 Degree Concealed No-Bore Hinge?

The 175 Degree Concealed No-Bore Hinge is notable for its ability to open doors up to 175 degrees, making it ideal for full overlay, half-overlay, and inset doors. Its installation requires minimal drilling, only needing small screw holes, which simplifies the process significantly. This hinge is commonly used in kitchen cabinets and commercial furniture, where versatility and ease of use are paramount. Buyers should consider the weight capacity per hinge, as this can affect the overall sturdiness of the installation.

Why Choose the 170 Degree Easy-On No Bore Hinge?

This hinge features an adjustable opening angle between 150 and 170 degrees, making it suitable for various applications, including office cabinetry and retail displays. Its surface-mounted design eliminates the need for concealed hinge cup boring, which can save time and labor costs. However, it requires a certain level of expertise for installation. B2B buyers should weigh the benefits of easy installation against the need for skilled labor when considering this option.

How Does the Soft Close Hidden Hinge Enhance User Experience?

The Soft Close Hidden Hinge integrates a soft-close mechanism that ensures doors close quietly and smoothly. This feature is particularly beneficial in residential and commercial cabinetry, where noise reduction is a priority. While the initial cost may be higher compared to standard hinges, the long-term benefits of reduced wear and improved user experience can justify the investment. Buyers must evaluate their budget against the potential for increased customer satisfaction.

What Makes the Heavy Duty European Concealed Hinge Ideal for High-Traffic Areas?

Designed for larger overlay doors, the Heavy Duty European Concealed Hinge is built to handle significant weight, making it suitable for high-traffic applications. Its robust construction ensures durability, which is essential in environments where doors are frequently used. While it may require specialized mounting techniques, the long-term performance and reliability can make it a worthwhile investment for B2B buyers in commercial settings.

Why Consider the Invisible Spring Hinge for Custom Cabinetry?

The Invisible Spring Hinge offers a seamless design that enhances the aesthetic appeal of high-end residential and custom cabinetry. Its spring-loaded functionality allows for smooth operation while maintaining a clean look. However, installation can be more complex than traditional hinges, which may necessitate hiring skilled professionals. B2B buyers should assess the balance between aesthetic benefits and installation complexity when selecting this hinge type.

Key Industrial Applications of hidden cabinet hinges no bore

| Industry/Sector | Specific Application of hidden cabinet hinges no bore | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Used in modular and custom furniture designs | Enhances aesthetic appeal and functionality of furniture | Durability, weight capacity, and compatibility with various designs |

| Kitchen and Bath Cabinetry | Installation in frameless kitchen cabinets | Provides seamless integration and space efficiency | Corrosion resistance, ease of installation, and adjustment features |

| Retail Display Fixtures | Utilized in display cabinets for merchandise | Increases visibility of products while maintaining design | Load rating, mounting options, and ease of access for maintenance |

| Office Furniture | Applied in office cabinetry and storage solutions | Maximizes storage space while maintaining a clean look | Reliability, installation ease, and compliance with ergonomic standards |

| Residential Renovation | Used in cabinetry during home improvement projects | Offers modern design while ensuring durability | Customization options, finish compatibility, and local availability |

How Are Hidden Cabinet Hinges No Bore Used in Furniture Manufacturing?

In the furniture manufacturing sector, hidden cabinet hinges no bore are integral to creating modular and custom furniture pieces that require a clean and modern aesthetic. These hinges allow for a smooth operation of doors while eliminating visible hardware, which is essential for contemporary designs. For international buyers, particularly from Europe and South America, sourcing hinges that can support various door thicknesses and styles is crucial to meet diverse market demands. Additionally, the durability of these hinges ensures long-lasting performance in high-use environments.

What Role Do Hidden Cabinet Hinges No Bore Play in Kitchen and Bath Cabinetry?

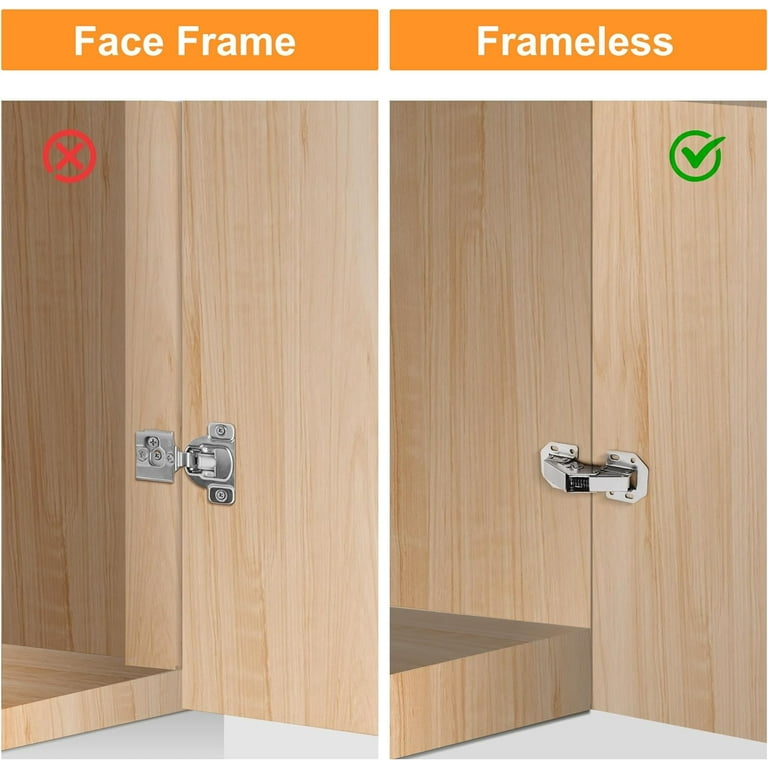

In kitchen and bath cabinetry, hidden cabinet hinges no bore facilitate the installation of frameless cabinets, allowing for a sleek look that maximizes space. These hinges enable full overlay or inset door configurations, which are popular in modern kitchen designs. For buyers in regions like Africa and the Middle East, sourcing hinges that are resistant to moisture and humidity is vital to ensure longevity in demanding environments. The ease of installation and adjustment features also provide significant labor cost savings during assembly.

How Are Hidden Cabinet Hinges No Bore Utilized in Retail Display Fixtures?

Retail display fixtures benefit from hidden cabinet hinges no bore by enhancing product visibility while maintaining an elegant design. These hinges allow doors to open smoothly without obstructing the view of displayed items. For B2B buyers in Europe and South America, it’s essential to consider the load rating and mounting options of these hinges to ensure they can support the weight of merchandise without compromising aesthetics. Additionally, the ability to easily access products for restocking or maintenance is a critical factor in retail environments.

In What Ways Are Hidden Cabinet Hinges No Bore Applied in Office Furniture?

In office furniture, hidden cabinet hinges no bore are utilized in cabinetry and storage solutions, promoting a clean and professional appearance. These hinges help maximize storage space while ensuring doors operate smoothly and quietly, which is essential in work environments. For international buyers, particularly from regions like Germany and Vietnam, compliance with ergonomic standards and reliability are key sourcing considerations. The hinges’ ability to accommodate various cabinet designs enhances their appeal in diverse office settings.

How Do Hidden Cabinet Hinges No Bore Benefit Residential Renovation Projects?

During residential renovation projects, hidden cabinet hinges no bore are favored for their modern design and functional benefits. They provide a seamless look in cabinetry, appealing to homeowners seeking contemporary aesthetics. For B2B buyers in emerging markets, customization options and compatibility with various finishes are crucial for meeting local design preferences. Additionally, sourcing hinges that are easy to install can significantly reduce labor costs, making them an attractive option for contractors and renovators.

3 Common User Pain Points for ‘hidden cabinet hinges no bore’ & Their Solutions

Scenario 1: Installation Complexity of No-Bore Hinges

The Problem:

B2B buyers often encounter significant challenges when it comes to the installation of hidden cabinet hinges that require no boring. The complexity lies not only in the technical specifications of the hinges but also in the need for precise installation to ensure optimal functionality. Many buyers may lack the technical know-how or experience with European-style hinges, leading to improper installation, which can result in doors that don’t close properly or operate smoothly. This can lead to costly delays and increased labor costs.

The Solution:

To address these installation challenges, it is crucial to provide comprehensive training resources and installation guides tailored specifically for the hinges being sourced. Buyers should seek suppliers that offer detailed installation manuals and instructional videos, showcasing step-by-step processes. Additionally, consider collaborating with a local technician or contractor who specializes in cabinetry to assist with initial installations, ensuring that the hinges are correctly mounted and adjusted. By investing in training and expert assistance, businesses can minimize installation errors and enhance operational efficiency.

Scenario 2: Matching Hinges with Cabinet Designs

The Problem:

Another prevalent issue for B2B buyers is ensuring that the chosen no-bore hinges are compatible with various cabinet designs and door overlays. Different cabinet styles—such as full overlay, half overlay, or inset—require specific hinge types, and failing to match these can result in aesthetic and functional problems. Buyers may struggle with selecting the correct hinge that not only fits the door style but also accommodates the weight and movement of the door.

The Solution:

To overcome this compatibility issue, it is essential to conduct thorough research on hinge specifications and their appropriate applications. Buyers should work closely with manufacturers who provide extensive product catalogs, including detailed diagrams and compatibility charts for various cabinet styles. Utilizing these resources will enable buyers to specify the right hinge for their specific project needs. Additionally, consider employing a hinge selection tool or consulting with a hinge specialist who can assist in selecting the appropriate hinges based on the project’s requirements. This proactive approach will ensure that all components work harmoniously together.

Scenario 3: Quality Assurance and Durability Concerns

The Problem:

Quality assurance is a critical concern for B2B buyers when sourcing hidden cabinet hinges. Given the wide range of products available in the market, distinguishing between high-quality hinges and subpar alternatives can be challenging. Poor-quality hinges may lead to premature wear, malfunction, and ultimately, increased replacement costs. Buyers often fear investing in products that will not perform adequately over time, especially in environments that demand durability.

The Solution:

To mitigate quality concerns, buyers should prioritize sourcing hinges from reputable manufacturers known for their rigorous quality control processes and robust product warranties. Requesting samples for testing before making bulk purchases can also be a practical strategy. Additionally, seeking third-party certifications or endorsements from industry standards can provide further assurance of the hinge’s reliability. Engaging in direct communication with manufacturers to discuss material specifications, weight ratings, and load capacities can also inform better purchasing decisions. By focusing on quality assurance, businesses can ensure long-term satisfaction and reduce the likelihood of costly replacements.

Strategic Material Selection Guide for hidden cabinet hinges no bore

What Materials Are Commonly Used for Hidden Cabinet Hinges No Bore?

When selecting materials for hidden cabinet hinges no bore, it’s crucial to consider properties that affect performance, durability, and compatibility with various applications. Here, we analyze four common materials used in the manufacturing of these hinges: steel, stainless steel, zinc alloy, and plastic.

How Does Steel Perform in Hidden Cabinet Hinges?

Steel is a popular choice for hidden cabinet hinges due to its strength and rigidity. It typically has a high temperature and pressure rating, making it suitable for heavy-duty applications. Steel hinges can withstand significant wear and tear, ensuring longevity.

Pros:

– Durability: Steel offers excellent strength and load-bearing capabilities, making it ideal for heavy cabinet doors.

– Cost-Effectiveness: Generally, steel is less expensive than other metals, making it an attractive option for budget-conscious buyers.

Illustrative image related to hidden cabinet hinges no bore

Cons:

– Corrosion Susceptibility: Steel is prone to rusting if not properly coated or maintained, which can limit its use in humid environments.

– Weight: Steel hinges can be heavier than alternatives, which may affect the overall weight of the cabinet design.

For international buyers, compliance with standards like ASTM A36 for structural steel is essential, particularly in regions with strict building codes.

What Are the Benefits of Stainless Steel in Hidden Cabinet Hinges?

Stainless steel is another common material for hidden cabinet hinges, known for its corrosion resistance and aesthetic appeal. The alloy typically contains chromium, which protects against rust and staining.

Pros:

– Corrosion Resistance: Ideal for humid or coastal environments, stainless steel retains its appearance and functionality over time.

– Aesthetic Quality: Its sleek finish makes it a preferred choice for high-end cabinetry.

Cons:

– Cost: Stainless steel is generally more expensive than regular steel, which can impact budget considerations for large orders.

– Manufacturing Complexity: The fabrication process for stainless steel can be more complex, potentially leading to longer lead times.

For buyers in Europe and other regions, adherence to standards like EN 10088 for stainless steel is crucial to ensure quality and compliance.

How Do Zinc Alloys Compare for Hidden Cabinet Hinges?

Zinc alloys are often used in the production of hidden cabinet hinges due to their lightweight nature and good corrosion resistance. They are typically coated or plated to enhance their durability.

Pros:

– Lightweight: Zinc alloys are lighter than steel, making them suitable for applications where weight is a concern.

– Corrosion Resistance: The natural properties of zinc provide good protection against rust, making them suitable for various environments.

Cons:

– Strength Limitations: Zinc alloys may not bear as much weight as steel or stainless steel, which could limit their use in heavy applications.

– Cost Variability: Depending on the alloy composition, costs can vary significantly, which may complicate budgeting.

International buyers should consider compliance with standards such as ASTM B69 for zinc alloys to ensure quality.

What Role Does Plastic Play in Hidden Cabinet Hinges?

Plastic hinges are increasingly popular for lightweight applications, especially in environments where moisture is a concern. They are often made from high-density polyethylene or polycarbonate.

Pros:

– Moisture Resistance: Plastic does not corrode or rust, making it ideal for humid environments.

– Cost-Effective: Generally, plastic hinges are less expensive than metal alternatives, making them suitable for budget-sensitive projects.

Illustrative image related to hidden cabinet hinges no bore

Cons:

– Strength Limitations: Plastic hinges may not support heavy doors, limiting their application scope.

– Durability Concerns: Over time, plastic can become brittle, especially under UV exposure, which may affect longevity.

For international buyers, ensuring compliance with standards like ISO 9001 for quality management systems can help maintain product integrity.

Summary Table of Material Selection for Hidden Cabinet Hinges No Bore

| Material | Typical Use Case for hidden cabinet hinges no bore | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty applications, commercial cabinetry | High strength and durability | Prone to corrosion without coating | Low |

| Stainless Steel | High-end cabinetry, humid environments | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Zinc Alloy | Lightweight applications, moisture-prone areas | Good corrosion resistance | Limited strength compared to steel | Medium |

| Plastic | Lightweight, moisture-sensitive applications | Moisture resistant and cost-effective | Limited load-bearing capacity | Low |

This guide provides a comprehensive overview of material options for hidden cabinet hinges no bore, helping international B2B buyers make informed decisions based on their specific needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for hidden cabinet hinges no bore

What Are the Key Stages in the Manufacturing Process of Hidden Cabinet Hinges No Bore?

The manufacturing process for hidden cabinet hinges no bore involves several critical stages that ensure high-quality production. These stages include material preparation, forming, assembly, and finishing.

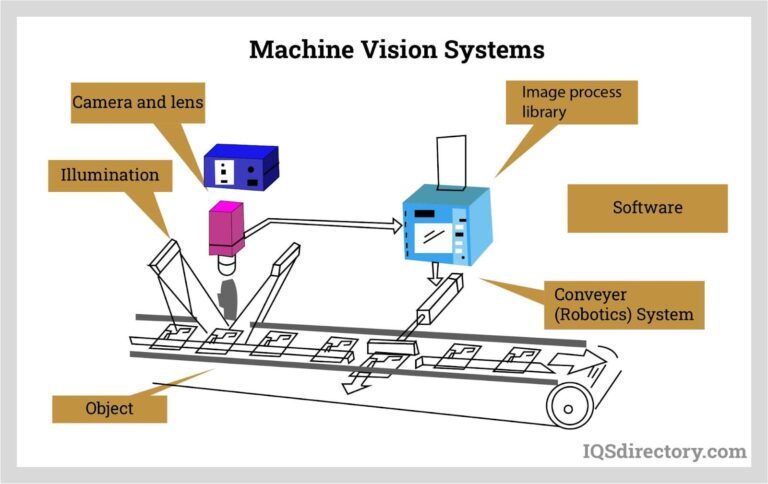

Illustrative image related to hidden cabinet hinges no bore

-

Material Preparation: The process begins with sourcing high-quality materials, typically hardened steel, which is known for its durability and strength. Suppliers often conduct metallurgical tests to verify the properties of the steel, ensuring it meets the necessary specifications for strength and resistance to corrosion.

-

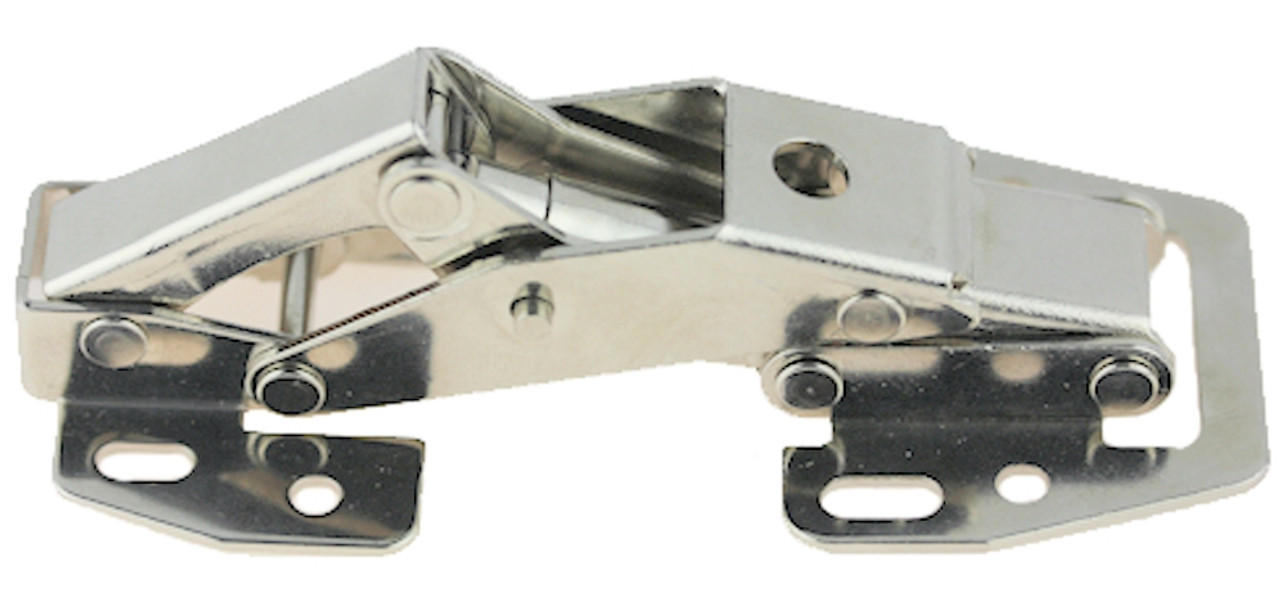

Forming: After material preparation, the steel sheets are cut into predetermined sizes using precision cutting techniques such as laser cutting or stamping. This stage also involves forming the hinge components using techniques like bending or pressing. Advanced machinery, including CNC (Computer Numerical Control) machines, is often employed to ensure accuracy and repeatability in the dimensions of the hinges.

-

Assembly: The next stage is assembly, where individual components such as hinge plates and springs are brought together. This may involve automated assembly lines or manual labor, depending on the complexity of the hinge design. Quality control checks are performed at this stage to ensure that each component fits correctly and operates smoothly.

-

Finishing: Finally, the hinges undergo finishing processes, which may include polishing, coating, or plating. Finishing not only enhances the aesthetic appeal of the hinges but also provides additional protection against rust and wear. Common finishes include nickel plating, which is popular for its durability and modern appearance.

How Is Quality Assurance Implemented in Manufacturing Hidden Cabinet Hinges No Bore?

Quality assurance (QA) is integral to the manufacturing process, ensuring that the final product meets international standards and customer expectations. Key QA practices include adherence to relevant standards such as ISO 9001, CE marking, and industry-specific certifications like API.

-

International Standards Compliance: ISO 9001 outlines a framework for quality management systems, emphasizing continuous improvement and customer satisfaction. Manufacturers often obtain this certification to demonstrate their commitment to maintaining high-quality production processes. CE marking is crucial for products sold in the European market, indicating compliance with health, safety, and environmental protection standards.

-

Quality Control Checkpoints: Quality control checkpoints are established at various stages of production:

– Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon receipt. Manufacturers verify material specifications and perform tests to ensure they meet required standards.

– In-Process Quality Control (IPQC): During the manufacturing process, ongoing inspections are conducted to monitor production quality. This includes measuring dimensions, checking for defects, and ensuring that assembly processes are correctly followed.

– Final Quality Control (FQC): At the end of the production line, a thorough inspection is performed on the finished hinges. This may involve functional testing, such as opening and closing cycles, to assess performance and durability.

What Testing Methods Are Commonly Used for Hidden Cabinet Hinges No Bore?

Several testing methods are employed to ensure the performance and reliability of hidden cabinet hinges no bore. These tests are vital for verifying that the hinges can withstand typical usage conditions.

-

Durability Testing: This involves subjecting hinges to repeated opening and closing cycles to simulate long-term use. The hinges are tested for smooth operation and structural integrity after a predetermined number of cycles.

-

Load Testing: Manufacturers conduct load tests to ensure that the hinges can support specified weights without deformation or failure. This is particularly important for B2B buyers who require hinges that can accommodate heavy cabinet doors.

-

Corrosion Resistance Testing: For hinges intended for various environments, corrosion resistance tests are crucial. This may include salt spray testing, where hinges are exposed to saline conditions to evaluate their resistance to rust and degradation.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to verify the quality control processes of potential suppliers. This is essential for ensuring that products meet the required standards and specifications.

Illustrative image related to hidden cabinet hinges no bore

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control systems in place. During an audit, buyers can review documentation, observe production practices, and evaluate the implementation of quality assurance measures.

-

Requesting Quality Reports: Buyers should request detailed quality control reports from suppliers, which should include results from IQC, IPQC, and FQC checks. These documents provide insights into the consistency and reliability of the production process.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of the supplier’s quality control practices. These agencies can perform random inspections and testing to verify that products meet specified standards before shipment.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, may face unique challenges in quality control. Understanding these nuances is crucial for successful procurement.

-

Regulatory Compliance: Different countries have varying regulations regarding product standards. Buyers must ensure that suppliers comply with local regulations, which may include specific certifications or labeling requirements.

-

Language and Communication Barriers: Clear communication is essential for understanding quality expectations. Buyers should consider using translation services or appointing representatives familiar with the local language and industry standards.

-

Cultural Differences in Quality Expectations: Quality perceptions can vary across regions. Buyers must clearly define their quality requirements and ensure that suppliers understand these expectations to avoid misunderstandings.

In conclusion, understanding the manufacturing processes and quality assurance practices for hidden cabinet hinges no bore is essential for B2B buyers. By focusing on these aspects, buyers can make informed decisions, ensuring they procure high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hidden cabinet hinges no bore’

In the competitive landscape of furniture hardware, sourcing hidden cabinet hinges without bore is a critical process for B2B buyers. This guide provides a step-by-step checklist to ensure that you procure high-quality, reliable products that meet your specific needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential before initiating the sourcing process. Consider factors such as the hinge opening angle, door thickness, and overlay requirements. This clarity will help in narrowing down potential products that fit your design and functional needs.

Step 2: Research Market Trends and Needs

Understanding current market trends can inform your purchasing decisions. Analyze the demand for hidden cabinet hinges in your target regions, such as Africa, South America, and Europe. This knowledge can guide you in selecting products that are not only in demand but also align with consumer preferences.

Illustrative image related to hidden cabinet hinges no bore

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations. Request company profiles, product catalogs, and references from other buyers in similar industries or regions. Pay attention to supplier reliability, delivery capabilities, and customer service quality, as these factors significantly impact your procurement experience.

- Sub-bullet: Check for certifications and compliance with international standards, which can assure product quality and safety.

Step 4: Request Samples for Testing

Once you have shortlisted potential suppliers, request samples of the hinges. Testing these samples for durability, ease of installation, and overall functionality will provide insight into how well they meet your specifications. This step is crucial to prevent potential issues during the installation phase.

Step 5: Compare Pricing and Terms

Pricing is a key consideration in any procurement process. Compare the costs of hinges from different suppliers, but also evaluate the terms of sale, including minimum order quantities, shipping costs, and payment terms. Sometimes, a higher upfront cost can be justified by better quality or service.

Step 6: Assess After-Sales Support and Warranty

Reliable after-sales support is critical for long-term satisfaction with your purchase. Inquire about warranty terms and support services offered by the supplier. A strong warranty can provide peace of mind and protect your investment against defects or performance issues.

Step 7: Finalize Your Order and Monitor Delivery

After selecting a supplier, finalize your order, ensuring all specifications and terms are clearly stated in the purchase agreement. Monitor the delivery process closely to ensure timely arrival. Effective communication with the supplier during this phase can help mitigate any logistical issues.

Illustrative image related to hidden cabinet hinges no bore

By following this structured checklist, B2B buyers can effectively navigate the procurement of hidden cabinet hinges without bore, ensuring they select the right products for their business needs while minimizing risk and maximizing value.

Comprehensive Cost and Pricing Analysis for hidden cabinet hinges no bore Sourcing

What Are the Key Cost Components for Hidden Cabinet Hinges No Bore?

When analyzing the cost structure of hidden cabinet hinges no bore, several components are critical. The primary materials typically include hardened steel or brass, which can influence the hinge’s durability and performance. Labor costs factor into the assembly and quality control processes, with skilled labor often required for precision manufacturing. Manufacturing overhead encompasses utilities, equipment maintenance, and facility costs, which can vary significantly by region.

Tooling costs are essential for producing specialized hinge designs, particularly for custom or high-volume orders. Quality control (QC) is another vital aspect, ensuring that hinges meet industry standards and specifications, which may include certifications for load capacity and safety. Logistics costs, including shipping and handling, can vary depending on the geographical location of the supplier and the buyer, impacting the overall pricing structure. Finally, suppliers typically incorporate a margin that reflects their operational costs and profit objectives, which can vary widely.

How Do Price Influencers Impact Hidden Cabinet Hinges No Bore Pricing?

Several factors influence the pricing of hidden cabinet hinges no bore. Volume and minimum order quantities (MOQ) play a significant role; larger orders often lead to discounted pricing due to economies of scale. Specifications and customization can also affect costs, as bespoke solutions generally require additional tooling and labor.

The choice of materials directly impacts the price; for instance, high-grade steel or unique finishes can elevate costs. The quality and certifications of the hinges are crucial, especially for B2B buyers who may need to comply with specific industry standards. Supplier factors, including their reputation and reliability, can also influence pricing; established suppliers may command higher prices due to their perceived quality and service.

Incoterms are vital for international transactions, as they define the responsibilities of buyers and sellers regarding shipping and logistics. Understanding these terms can help buyers anticipate additional costs related to freight, insurance, and customs duties, which can significantly affect the total purchase price.

What Negotiation Strategies Can B2B Buyers Employ for Cost-Efficiency?

B2B buyers should consider several negotiation strategies to enhance cost-efficiency when sourcing hidden cabinet hinges no bore. One effective approach is to leverage volume purchasing; committing to larger orders can lead to lower unit prices. Additionally, establishing long-term relationships with suppliers may provide opportunities for better pricing, especially if the buyer consistently orders from the same vendor.

Illustrative image related to hidden cabinet hinges no bore

Buyers should also conduct thorough market research to understand competitive pricing structures. This knowledge empowers them to negotiate more effectively and seek alternative suppliers if necessary. It’s beneficial to request quotes from multiple suppliers, as this can reveal pricing variances and highlight potential areas for negotiation.

Moreover, buyers should assess the Total Cost of Ownership (TCO), which includes not only the purchase price but also maintenance, installation, and potential downtime costs. This holistic view can assist in making informed decisions that align with their budget and operational needs.

What Pricing Nuances Should International Buyers Be Aware Of?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be mindful of several pricing nuances. Currency fluctuations can impact pricing significantly; thus, securing a fixed exchange rate at the time of order could mitigate risks. Additionally, understanding local regulations and import duties is crucial, as these can add unforeseen costs to the final price.

Shipping logistics, including lead times and freight options, should also be carefully considered. Buyers should inquire about the supplier’s shipping capabilities and any associated costs. Ensuring that the chosen Incoterms align with their logistics strategy can help avoid unexpected expenses.

Lastly, buyers should evaluate the supplier’s capacity to provide ongoing support, such as after-sales service and warranty options. These factors can contribute to the overall value proposition and assist buyers in making a cost-effective choice in their sourcing strategy.

Disclaimer

The prices mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific order requirements. It is advisable for buyers to request updated quotes directly from suppliers to obtain accurate pricing information.

Alternatives Analysis: Comparing hidden cabinet hinges no bore With Other Solutions

When evaluating solutions for cabinet construction, particularly in the context of hidden cabinet hinges, it’s essential to consider viable alternatives that meet similar requirements. This analysis explores how ‘hidden cabinet hinges no bore’ stack up against traditional concealed hinges and surface-mounted hinges, providing B2B buyers with actionable insights to make informed decisions.

| Comparison Aspect | Hidden Cabinet Hinges No Bore | Traditional Concealed Hinges | Surface-Mounted Hinges |

|---|---|---|---|

| Performance | Offers a 170-175 degree opening with minimal installation hassle | Provides a smooth operation but requires precise drilling | Functional but may disrupt aesthetics due to visibility |

| Cost | Typically ranges from $8 to $15 each | Usually costs between $5 to $30 per pair | Generally low-cost, around $2 to $10 each |

| Ease of Implementation | Very easy; requires minimal drilling | Moderate; requires accurate drilling and alignment | Simple; surface mounting requires no advanced skills |

| Maintenance | Low maintenance; durable and designed for longevity | Moderate; may require adjustments over time | Low; straightforward but may need replacement due to wear |

| Best Use Case | Ideal for frameless cabinets with modern designs | Suitable for various cabinet types needing concealed functionality | Best for budget-conscious projects or temporary installations |

What Are the Advantages and Disadvantages of Traditional Concealed Hinges?

Traditional concealed hinges offer a well-established solution for cabinet doors, providing smooth operation and a clean aesthetic. However, they require precise drilling, which can complicate installation, especially in frameless cabinetry. While they are often durable, they may need periodic adjustments to maintain optimal performance. Additionally, their cost can be higher, especially when considering the need for specialized installation tools and skills.

How Do Surface-Mounted Hinges Compare?

Surface-mounted hinges are a budget-friendly alternative that is easy to install without the need for advanced skills. They are particularly appealing for projects with tight budgets or temporary installations. However, their visibility can detract from the overall aesthetic of modern cabinetry designs. Performance-wise, they may not provide the same level of smooth operation or durability as concealed options, potentially leading to a need for more frequent replacements.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When selecting the right hinge solution, B2B buyers should consider their specific project requirements, including budget constraints, aesthetic goals, and installation capabilities. Hidden cabinet hinges no bore are ideal for modern, frameless cabinets where aesthetics and ease of installation are priorities. In contrast, traditional concealed hinges may suit projects requiring a more classic look, while surface-mounted hinges could be appropriate for more cost-sensitive or temporary applications. By carefully evaluating these factors, buyers can make informed decisions that align with their operational needs and client expectations.

Essential Technical Properties and Trade Terminology for hidden cabinet hinges no bore

What are the Essential Technical Properties of Hidden Cabinet Hinges No Bore?

1. Material Grade

The material of hidden cabinet hinges is crucial for durability and performance. Most hinges are made from hardened steel, which provides strength and resistance to wear. Steel hinges often feature a gauge specification, such as .082, indicating thickness. High-quality materials ensure that the hinges can withstand daily use without deforming or failing, a critical consideration for B2B buyers focused on long-term reliability in commercial applications.

2. Opening Angle

The opening angle of a hinge dictates how far a door can swing open. For instance, hidden cabinet hinges typically offer angles ranging from 170 to 175 degrees. This feature is essential for maximizing access to cabinet interiors, particularly in tight spaces. Buyers should consider the required opening angle based on their specific cabinet designs to ensure functionality aligns with their needs.

3. Weight Rating

The weight capacity of hinges varies based on the number used. For example, a hinge may support 13 lbs with two units, up to 53 lbs with five. Understanding weight ratings is vital for B2B buyers to ensure that their chosen hinges can adequately support the cabinet doors they intend to install. This prevents premature wear and potential failure due to inadequate support.

4. Installation Requirements

Hidden cabinet hinges no bore are designed for surface mounting, minimizing the need for additional drilling. This installation method simplifies the process and reduces labor costs, making it attractive for manufacturers and contractors. Buyers should confirm that their cabinets meet the required depth specifications, typically around 4-1/8 inches, to ensure compatibility.

5. Overlay Types

These hinges can accommodate various overlay types, including full overlay, half overlay, and inset doors. The overlay type affects the aesthetics and functionality of cabinet installations. Understanding the distinctions between these overlays is essential for buyers to select hinges that align with their cabinet designs and customer preferences.

6. Adjustability Features

Many no bore hinges come with adjustability options that allow for fine-tuning after installation. Features such as set screws enable adjustments to the opening angle, which can be critical for achieving the desired door alignment. This adaptability is beneficial for installers and manufacturers, as it allows for correction of minor misalignments without needing to replace the hinge.

What Common Trade Terminology Should B2B Buyers Know When Purchasing Hidden Cabinet Hinges?

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the hinge industry, buyers often seek OEM components to ensure compatibility with existing products. Understanding OEM relationships can help buyers source high-quality hinges tailored to their specific design needs.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers, as it impacts inventory management and cost structures. Knowing the MOQ helps businesses plan their purchases effectively, ensuring they meet production demands without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a standard business process used to invite suppliers to bid on specific products or services. In the context of hidden cabinet hinges, submitting an RFQ can help buyers obtain competitive pricing and terms. This process is vital for procurement teams looking to optimize costs while ensuring quality.

Illustrative image related to hidden cabinet hinges no bore

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in shipping transactions. They cover aspects like shipping costs, insurance, and risk management. Understanding Incoterms is essential for international buyers to navigate logistics and ensure smooth transactions when sourcing hinges from overseas suppliers.

5. Surface Mounting

Surface mounting refers to the installation method where hinges are attached directly to the surface of the cabinet without requiring additional boring. This terminology is important for buyers to understand the ease of installation and the potential cost savings associated with no bore hinges.

6. Full Overlay and Half Overlay

These terms describe how cabinet doors are positioned relative to the cabinet frame. Full overlay doors cover the entire frame, while half overlay doors only partially cover it. Understanding these terms helps buyers choose the right hinge type that aligns with their cabinet design preferences and functional needs.

Illustrative image related to hidden cabinet hinges no bore

Navigating Market Dynamics and Sourcing Trends in the hidden cabinet hinges no bore Sector

What Are the Key Trends Influencing the Hidden Cabinet Hinges No Bore Market?

The market for hidden cabinet hinges, particularly no bore options, is experiencing notable growth driven by several global factors. With the ongoing rise of minimalist and modern interior design, there is a significant demand for hardware that offers both functionality and aesthetic appeal. International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, are increasingly looking for hinges that provide a seamless look without compromising on performance. The trend towards frameless cabinetry, particularly in European markets like Germany, has further fueled this demand, as no bore hinges are essential for achieving the desired sleek appearance.

Emerging technologies in manufacturing, such as advanced materials and precision engineering, are making these hinges more durable and easier to install. The introduction of adjustable hinges that allow for precise alignment and operation at various angles—such as the 170-degree and 175-degree options—has also gained traction. Furthermore, the increasing shift towards online sourcing and e-commerce platforms allows international buyers to access a broader range of products and suppliers, enhancing competition and driving innovation in the sector.

How Is Sustainability and Ethical Sourcing Impacting the No Bore Hinge Industry?

The importance of sustainability and ethical sourcing in the B2B landscape cannot be overstated, especially in the hardware sector. As consumers and businesses become more environmentally conscious, the demand for hinges made from sustainable materials is on the rise. Manufacturers of hidden cabinet hinges no bore are increasingly adopting eco-friendly practices, such as using recycled metals and reducing waste during production.

Additionally, certifications for sustainable practices, such as Forest Stewardship Council (FSC) certification or ISO 14001 for environmental management, are becoming critical for suppliers aiming to differentiate themselves in a competitive market. International buyers are advised to inquire about the sourcing practices of their suppliers to ensure that they align with their corporate social responsibility goals. This not only enhances brand reputation but also opens opportunities in markets that prioritize sustainability.

What Is the Historical Context of Hidden Cabinet Hinges No Bore?

The evolution of hidden cabinet hinges can be traced back to the need for improved aesthetics and functionality in cabinetry. Initially, hinges were exposed, often detracting from the sleek designs of furniture. The introduction of concealed hinges in the mid-20th century marked a significant shift, allowing for a cleaner appearance and better usability. The no bore variant emerged as a solution to installation challenges, eliminating the need for complex drilling and providing a straightforward installation process that caters to both DIY enthusiasts and professional installers alike.

As the market has matured, innovations such as soft-close mechanisms and adjustable opening angles have become standard, reflecting the industry’s responsiveness to consumer demands for convenience and quality. This historical context highlights the ongoing need for suppliers and manufacturers to stay ahead of trends and continuously improve their offerings to meet the dynamic needs of international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of hidden cabinet hinges no bore

-

How do I solve installation issues with hidden cabinet hinges no bore?

To address installation challenges, ensure you have a comprehensive understanding of the specific hinge type you’re using, as different models may have unique requirements. Familiarize yourself with the manufacturer’s installation guidelines, which often include visual aids. It’s also advisable to use a level and proper measuring tools to ensure accurate placement. If you encounter difficulties, consider consulting with a professional or reaching out to the supplier for expert advice on installation techniques. -

What is the best type of hidden cabinet hinge no bore for frameless cabinets?

The best choice for frameless cabinets typically includes heavy-duty no bore hinges that offer a wide opening angle, such as 170 or 175 degrees. These hinges provide smooth operation and accommodate various door overlays, ensuring a clean aesthetic. Look for options constructed from hardened steel for durability and stability. Additionally, consider whether you need features like soft-close mechanisms or self-closing functions based on your clients’ preferences. -

What are the standard lead times for ordering hidden cabinet hinges no bore internationally?

Lead times for international orders can vary significantly based on the supplier, shipping method, and destination. Typically, expect a range of 2 to 6 weeks for delivery, including processing and customs clearance. It’s essential to confirm lead times with your supplier prior to placing an order and to factor in potential delays due to customs or logistics challenges specific to your region, especially when sourcing from countries in Africa, South America, or the Middle East. -

What should I consider when vetting suppliers for hidden cabinet hinges no bore?

When vetting suppliers, assess their manufacturing capabilities, certifications, and quality assurance processes. Look for suppliers with a proven track record in producing hardware for your target market. Request samples to evaluate product quality and consistency. It’s also beneficial to check reviews and testimonials from other buyers, and ensure they can meet your specific needs regarding customization, minimum order quantities (MOQ), and delivery timelines. -

Can I customize hidden cabinet hinges no bore for my projects?

Yes, many manufacturers offer customization options for hidden cabinet hinges, including finishes, sizes, and functionalities. When discussing customization with potential suppliers, provide detailed specifications and requirements for your project. This may include the desired weight capacity, opening angle, and additional features like soft-close or self-closing mechanisms. Keep in mind that custom orders may have longer lead times and higher MOQs. -

What are the typical payment terms for international B2B transactions involving hidden cabinet hinges?

Payment terms can vary widely among suppliers, but common practices include options like a 30% deposit upon order confirmation and the remaining balance before shipping. Some suppliers may offer net 30 or net 60 terms, allowing you to pay after receiving the goods. Be sure to clarify payment methods accepted, such as wire transfer or letters of credit, and confirm any potential fees associated with international transactions. -

What quality assurance measures should I expect when sourcing hidden cabinet hinges no bore?

Reputable suppliers should have established quality assurance (QA) processes in place, including material inspections, performance testing, and adherence to international standards. Inquire about their QA protocols, such as ISO certifications or third-party testing. Request documentation or reports that outline their testing procedures and the results, ensuring that the hinges you receive meet your specifications for durability and performance. -

What logistics considerations should I keep in mind when importing hidden cabinet hinges no bore?

When importing hinges, consider logistics factors such as shipping methods, customs duties, and potential tariffs. Choose a reliable freight forwarder who understands the nuances of your destination market, particularly in regions like Africa or South America. Ensure your supplier provides all necessary documentation for customs clearance, including invoices, packing lists, and certificates of origin. Planning for potential delays and having a clear understanding of local import regulations can help streamline the process.

Top 3 Hidden Cabinet Hinges No Bore Manufacturers & Suppliers List

1. Blum – Soft Close Hidden Hinge for Frameless Cabinet

Domain: cabinetdoorsdepot.com

Registered: 2002 (23 years)

Introduction: {“product_name”: “Blum Soft Close Hidden Hinge For Frameless Cabinet”, “part_number”: “B073B3550/B175H6000”, “features”: {“adjustability”: “6-Way Adjustable”, “overlay”: “Adjustable 5/8 – 3/4 Overlay”, “included_items”: [“2 – Hinges”, “2 – Mounting Plates”, “4 – 6 x 5/8 Screws (mounting hinges to door)”, “2 – 10 x 5/8 Screws (mounting hinges to cabinet)”], “note”: “ORDER ONE SET PER DOOR”}, “price…

2. Reddit – No-Bore Concealed Hinges

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: No-bore concealed hinges for kitchen cabinets, designed to replace outer hinges. Installation went smoothly with a pilot test. Requires a bit of force to open and close compared to previous hinges. Potential issue with screws loosening over time due to frequent use.

3. Hardware Hut – Free Delivery on Orders Over $600

Domain: hardwarehut.com

Registered: 1998 (27 years)

Introduction: This company, Hardware Hut – Free Delivery on Orders Over $600, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for hidden cabinet hinges no bore

In conclusion, the strategic sourcing of hidden cabinet hinges, particularly no-bore options, presents a unique opportunity for B2B buyers seeking to enhance their product offerings with modern, efficient solutions. The advantages of these hinges—such as reduced installation time, versatility for various cabinet types, and aesthetic appeal—make them an attractive choice for manufacturers and suppliers alike. By prioritizing high-quality materials, such as hardened steel, and understanding the specific requirements of different markets, businesses can ensure they meet customer expectations and maintain competitive pricing.

As international buyers from regions like Africa, South America, the Middle East, and Europe explore sourcing options, it’s essential to consider not only cost but also the long-term value that reliable and innovative products bring to their operations. Establishing partnerships with reputable suppliers who understand local market dynamics can lead to significant advantages.

Illustrative image related to hidden cabinet hinges no bore

Looking ahead, the demand for concealed hinges is expected to grow as the trend toward minimalist design continues. Engaging with suppliers who offer a range of products and customization options will position your business to capitalize on emerging opportunities. Start your sourcing journey today and unlock the potential of hidden cabinet hinges in your product line.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.