A B2B Buyer’s Guide to Dust Collection System Parts: Price, Quality, and Suppliers

Introduction: Navigating the Global Market for dust collection system parts

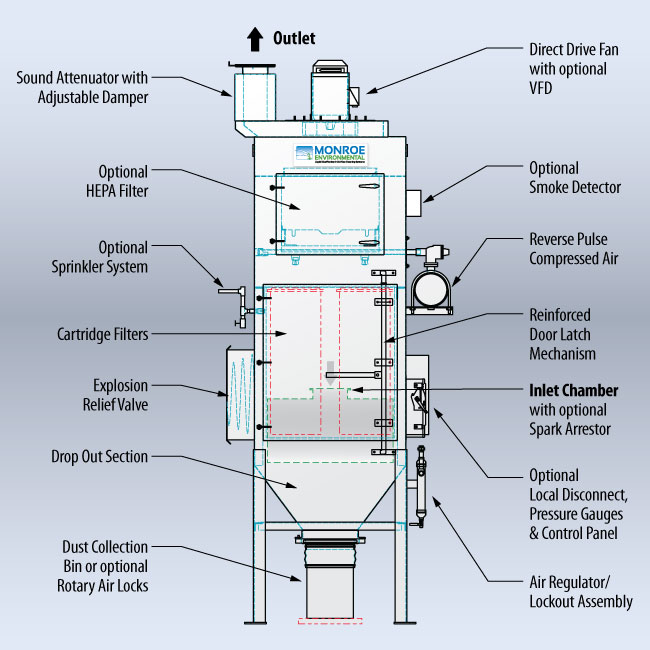

In an increasingly competitive global market, sourcing high-quality dust collection system parts can be a daunting challenge for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. The effectiveness of a dust collection system is crucial not only for compliance with environmental regulations but also for ensuring a safe and productive workplace. This guide addresses the complexities involved in acquiring essential components, including filters, fittings, and control systems, that optimize dust collection performance and efficiency.

Covering a wide array of topics, this comprehensive resource delves into various types of dust collection system parts, their specific applications across industries, and the importance of supplier vetting to ensure reliability and quality. Buyers will gain insights into cost considerations, enabling them to make informed financial decisions that align with their operational budgets. Furthermore, the guide highlights key factors to consider when selecting parts that suit specific needs, thus empowering organizations to enhance their dust management strategies.

By equipping B2B buyers with actionable insights and best practices, this guide serves as a vital tool in navigating the complex landscape of dust collection system parts. With a focus on optimizing sourcing processes, international buyers can confidently invest in solutions that not only meet their immediate requirements but also contribute to long-term operational success.

Understanding dust collection system parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Dust Collector Filters | Vary in material (e.g., polyester, nanofiber), designed for airflow efficiency. | Woodworking, metal fabrication, industrial processes. | Pros: High efficiency, various sizes; Cons: Regular replacement needed, can be costly. |

| Dust Collection Fittings | Components like elbows, couplings, and blast gates for ductwork. | Custom duct layouts in workshops and factories. | Pros: Customizable, improves airflow; Cons: Requires careful planning and installation. |

| Pulse Valves | Control airflow and dust release with timed pulses. | Industrial dust control systems, sandblasting. | Pros: Enhances filter life, reduces maintenance; Cons: Can be complex to install and operate. |

| Differential Pressure Gauges | Measure pressure drop across filters to indicate blockage. | Monitoring filter performance in various industries. | Pros: Easy diagnostics, prevents system failure; Cons: Requires regular calibration for accuracy. |

| Mobile Dust Collectors | Portable units for on-site dust collection, often diesel-powered. | Construction sites, renovations, and remote locations. | Pros: Flexibility, easy to transport; Cons: Fuel dependency, may require maintenance. |

What Are Dust Collector Filters and How Do They Benefit B2B Buyers?

Dust collector filters are essential components that trap airborne particles, ensuring clean air in industrial settings. They come in various materials such as polyester and nanofiber, each suited for different applications. B2B buyers should consider the filter’s efficiency, size, and replacement frequency. While high-efficiency filters may incur higher upfront costs, they often lead to long-term savings by reducing maintenance and ensuring compliance with environmental regulations.

How Do Dust Collection Fittings Optimize Airflow in Industrial Settings?

Dust collection fittings, including elbows, couplings, and blast gates, play a critical role in connecting various parts of a dust collection system. They are designed to facilitate optimal airflow and can be customized to fit specific workshop layouts. B2B buyers must assess their workshop design to select the right fittings that enhance system efficiency. While these components are vital for performance, they require careful planning and installation to maximize their benefits.

Why Are Pulse Valves Important for Effective Dust Collection?

Pulse valves are vital for controlling airflow and managing dust release in dust collection systems. They operate by releasing timed bursts of air, which help clean filters and extend their lifespan. For B2B buyers, investing in high-quality pulse valves can lead to reduced maintenance costs and improved operational efficiency. However, these systems can be complex to install and may require technical expertise to operate effectively.

What Role Do Differential Pressure Gauges Play in Dust Collection Systems?

Differential pressure gauges are crucial for monitoring the performance of dust collection systems. They measure the pressure drop across filters, indicating when maintenance is needed. For B2B buyers, these gauges offer an easy diagnostic tool that can prevent system failure and maintain optimal performance. However, regular calibration is necessary to ensure accurate readings, which can be a consideration for operational budgets.

How Do Mobile Dust Collectors Support On-Site Operations?

Mobile dust collectors provide a flexible solution for dust management on construction sites and other remote locations. These portable units, often powered by diesel, can be easily transported and set up as needed. B2B buyers benefit from their versatility and ease of use, but should also consider the ongoing fuel and maintenance requirements. Investing in mobile dust collectors can enhance safety and compliance in varied operational environments.

Key Industrial Applications of dust collection system parts

| Industry/Sector | Specific Application of dust collection system parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Woodworking | Use of dust collection fittings in sawmills | Improved air quality and worker safety | Compatibility with existing systems, material quality |

| Metal Fabrication | Cartridge filters in welding operations | Enhanced equipment longevity and compliance | Filter efficiency ratings, size compatibility |

| Pharmaceuticals | Dust collection systems for powder processing | Compliance with health regulations and safety standards | FDA compliance, ease of cleaning and maintenance |

| Construction | Mobile dust collectors for site work | Flexibility and portability for various job sites | Durability, ease of transport, power source options |

| Mining | Dust control systems in mineral processing | Minimization of environmental impact and health risks | Local regulations, effectiveness in harsh environments |

How are Dust Collection System Parts Utilized in Various Industries?

In the woodworking industry, dust collection fittings are essential for creating efficient systems in sawmills and workshops. These components, such as elbows and reducers, ensure optimal airflow, capturing harmful dust particles at the source. This not only enhances air quality but also significantly improves worker safety, reducing the risk of respiratory issues. International buyers should focus on the compatibility of these fittings with existing ductwork and the quality of materials used, especially in regions where humidity and temperature fluctuations are common.

In metal fabrication, cartridge filters play a crucial role in welding operations. They trap harmful metal dust and fumes, extending the life of welding equipment and ensuring compliance with safety regulations. This is particularly important for businesses in regions with stringent environmental laws. Buyers should consider the efficiency ratings of these filters and ensure they are sized appropriately for their systems, as inadequate filtration can lead to increased operational costs and potential regulatory fines.

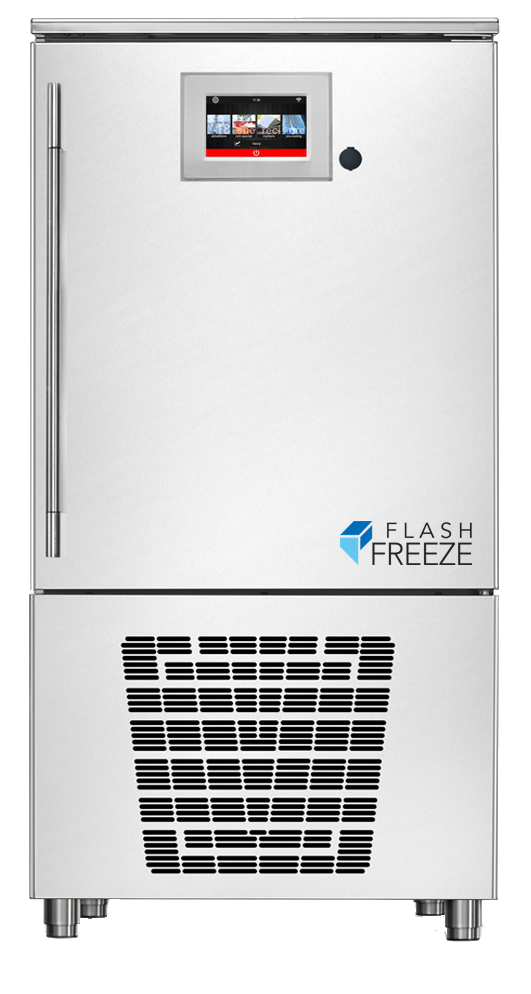

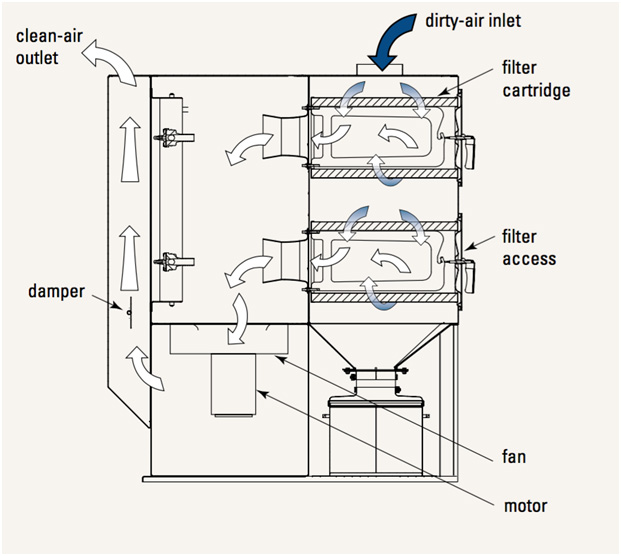

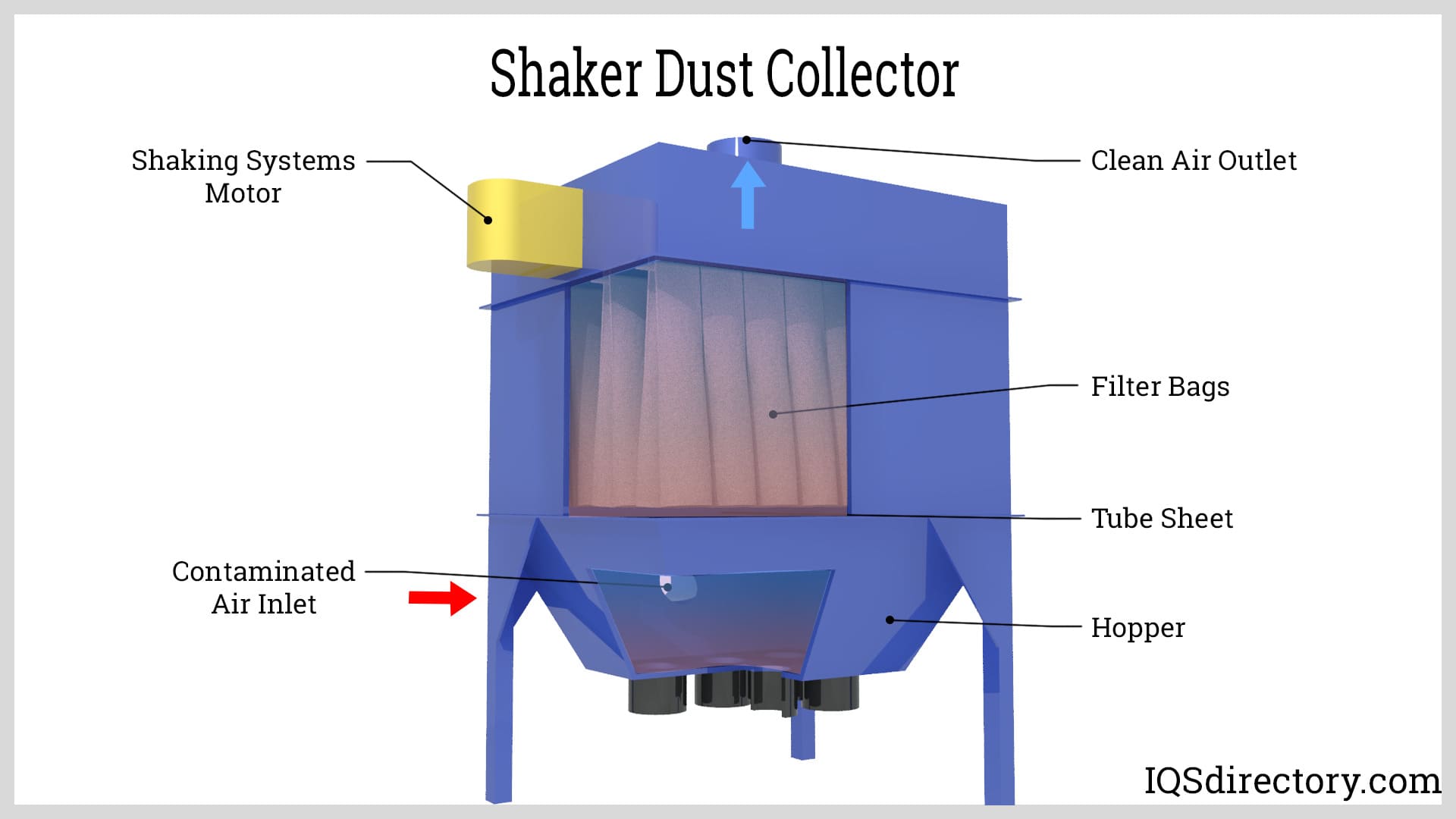

Illustrative image related to dust collection system parts

The pharmaceutical sector requires stringent dust control measures during powder processing to comply with health regulations. Dust collection systems equipped with specialized filters help maintain a clean environment, preventing contamination of products. Buyers in this industry must ensure that all components are FDA-compliant and easy to clean, as maintaining hygiene is paramount. Additionally, understanding the specific requirements for filter media can lead to better operational efficiencies.

In construction, mobile dust collectors are vital for maintaining air quality on job sites. These portable systems can be easily transported and set up in various locations, providing flexibility for contractors. The value lies in their ability to minimize dust exposure, thereby enhancing worker safety and compliance with local regulations. Buyers should look for durable models that can withstand rough site conditions and evaluate power source options to ensure operational efficiency.

Finally, in the mining industry, effective dust control systems are essential for mineral processing operations. These systems help reduce environmental impact and safeguard worker health by minimizing dust emissions. Buyers should be aware of local regulations regarding dust control and ensure that the systems they source are effective in harsh conditions, as the mining environment can be particularly challenging. Understanding the specific needs of their operations will help in selecting the most suitable dust collection solutions.

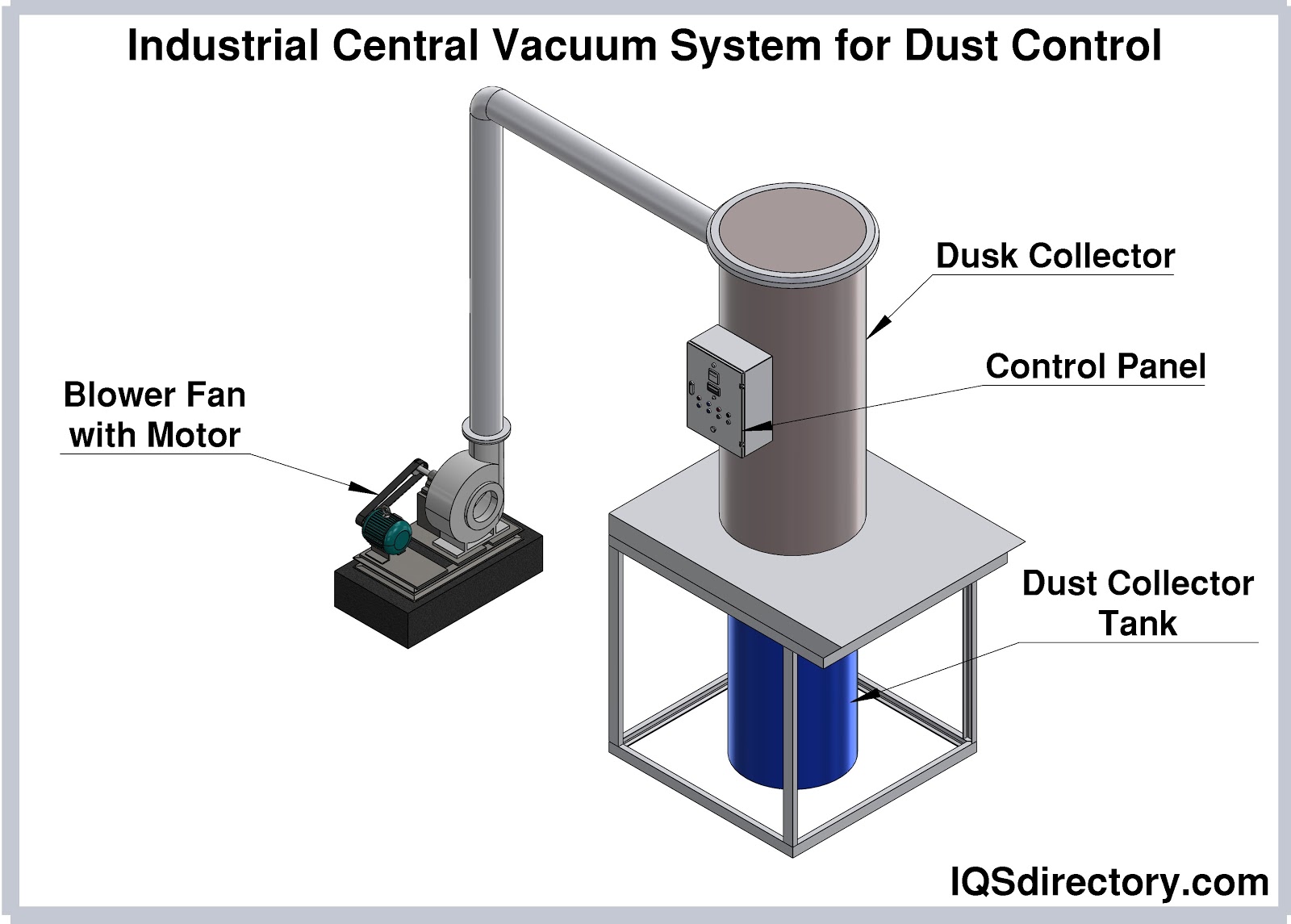

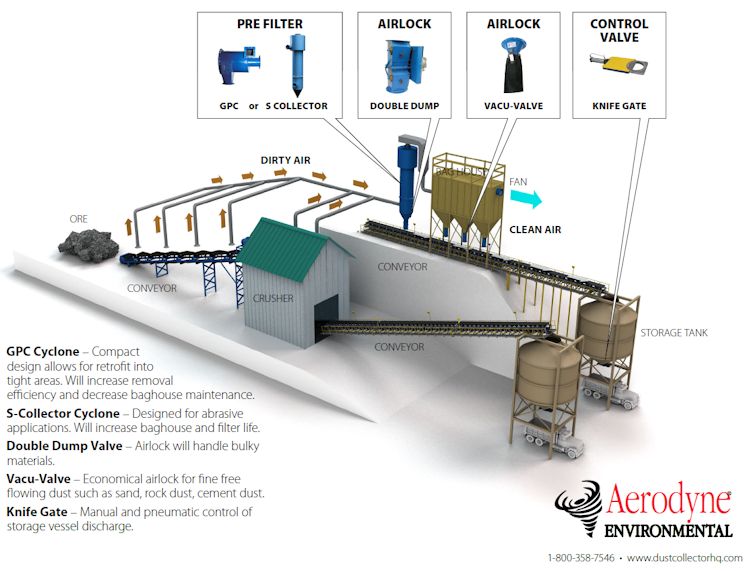

Illustrative image related to dust collection system parts

3 Common User Pain Points for ‘dust collection system parts’ & Their Solutions

Scenario 1: Difficulty in Ensuring Proper Airflow in Dust Collection Systems

The Problem: B2B buyers often face challenges in maintaining optimal airflow within their dust collection systems. This can be due to poorly designed duct layouts or the use of incompatible fittings, which can lead to inefficient dust extraction. For instance, if a woodworking shop uses standard elbows instead of specialized dust collection elbows, the airflow may be significantly restricted, causing dust to accumulate and not be properly collected. This can create a hazardous working environment, reduce productivity, and increase maintenance costs.

The Solution: To address airflow issues, buyers should invest in specialized dust collection fittings, such as smooth-bore elbows and tapered reducers. These fittings are designed to minimize airflow resistance and optimize the system’s efficiency. When designing a dust collection system, it’s essential to map out the layout and calculate the necessary duct sizes and fittings. Using software tools or consulting with experts can help ensure that the system is tailored to the specific requirements of the workspace. Additionally, regular maintenance checks should be scheduled to ensure that all connections are secure and that there are no blockages, which can further impede airflow.

Scenario 2: Frequent Filter Clogging and Reduced System Performance

The Problem: Another common issue faced by B2B buyers is the frequent clogging of filters in dust collection systems. This not only leads to reduced efficiency but can also cause costly downtimes. Industries such as woodworking and metal fabrication generate varying types of dust that can adhere to filters, making them less effective. Buyers often find themselves having to replace filters more frequently than anticipated, impacting their operational budget.

The Solution: To mitigate filter clogging, buyers should consider investing in high-efficiency filters specifically designed for their applications, such as nanofiber or pulse-jet filters. These filters are engineered to capture fine particles while allowing for better airflow, reducing the frequency of clogging. Implementing a differential pressure gauge can also provide real-time data on filter performance, alerting users when filters need cleaning or replacement. Regularly scheduled maintenance, including cleaning or replacing filters based on pressure readings, will help maintain system performance and extend the life of the filters.

Scenario 3: Inconsistent Quality and Availability of Replacement Parts

The Problem: B2B buyers often encounter difficulties in sourcing high-quality replacement parts for their dust collection systems. This can be particularly challenging for companies operating in regions with limited access to reliable suppliers. Inconsistent quality of parts can lead to system failures, increased downtime, and potentially hazardous work environments due to inadequate dust control.

The Solution: To ensure the availability of high-quality replacement parts, buyers should establish relationships with reputable suppliers who specialize in dust collection systems. It is advisable to conduct thorough research and seek suppliers that offer a comprehensive range of compatible parts, including filters, valves, and fittings. Additionally, implementing a parts inventory management system can help track stock levels and automatically reorder essential components before they run out. Buyers should also consider investing in standardized systems that use common components, making it easier to source replacements from multiple suppliers, thus minimizing the risk of operational disruptions.

Strategic Material Selection Guide for dust collection system parts

What Are the Key Materials Used in Dust Collection System Parts?

Selecting the right materials for dust collection system parts is crucial for ensuring optimal performance, longevity, and compliance with international standards. Here, we analyze four commonly used materials: steel, plastic, fiberglass, and aluminum, focusing on their properties, advantages, disadvantages, and implications for international buyers.

How Does Steel Perform in Dust Collection Systems?

Steel is a prevalent choice for dust collection system components due to its strength and durability. It typically exhibits high resistance to impact and wear, making it suitable for heavy-duty applications. Steel can withstand high temperatures and pressures, which is essential in industrial environments where dust collection systems operate under challenging conditions.

Pros: Steel’s robustness ensures a long service life, reducing the frequency of replacements. It is also widely available and can be manufactured into various shapes and sizes, making it versatile for different applications.

Cons: The primary drawback of steel is its susceptibility to corrosion, particularly in humid or chemically aggressive environments. This can lead to increased maintenance costs and reduced lifespan if not properly treated or coated.

Impact on Application: Steel is compatible with a wide range of media, including wood dust, metal shavings, and other industrial particulates. However, buyers must ensure that the specific grade of steel used meets local compliance standards.

Illustrative image related to dust collection system parts

Considerations for International Buyers: Buyers from regions like Africa or South America should verify if the steel parts meet relevant standards such as ASTM or ISO to ensure quality and performance. Corrosion-resistant coatings may be necessary in humid climates.

What Advantages Does Plastic Offer for Dust Collection Components?

Plastic materials, particularly high-density polyethylene (HDPE) and polypropylene, are increasingly used in dust collection systems. These materials are lightweight and resistant to corrosion, making them ideal for environments where moisture or chemicals are present.

Pros: Plastics are generally lower in cost compared to metals and can be easily molded into complex shapes, allowing for innovative designs. They also exhibit excellent chemical resistance, which is beneficial in diverse industrial applications.

Cons: While durable, plastics may not withstand high temperatures as effectively as metals, limiting their use in high-heat applications. They can also be less structurally robust, leading to potential issues in high-impact scenarios.

Impact on Application: Plastic components are particularly suitable for systems that handle non-abrasive materials. Buyers should consider the specific dust types and operating conditions to ensure compatibility.

Considerations for International Buyers: Buyers should check for compliance with local standards, such as DIN or JIS, especially in regions with stringent regulations. The availability of recycled plastic options may also appeal to environmentally conscious buyers.

How Does Fiberglass Compare in Dust Collection Systems?

Fiberglass is another material that offers unique advantages for dust collection applications. It is lightweight yet strong and has excellent resistance to corrosion and temperature variations.

Pros: Fiberglass is non-conductive, making it safe for use in environments with electrical hazards. Its durability and resistance to chemicals make it suitable for various industrial applications.

Cons: The manufacturing process for fiberglass can be complex and costly, which may increase the overall price of the final product. Additionally, fiberglass can be more brittle than other materials, which may lead to cracking under certain conditions.

Impact on Application: Fiberglass is ideal for systems that deal with aggressive chemicals or high humidity, as it does not corrode. However, it may not be suitable for heavy-duty applications involving abrasive materials.

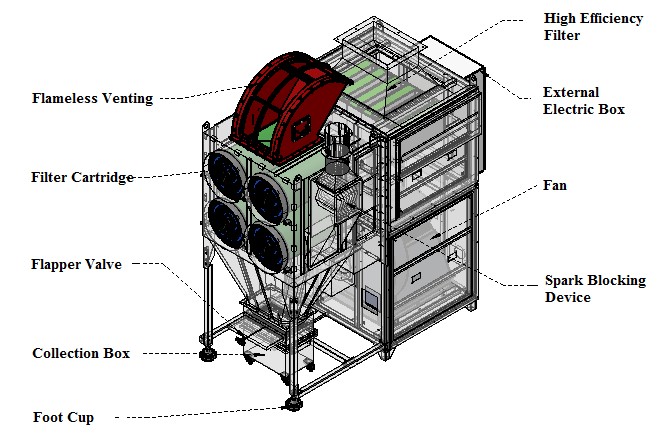

Illustrative image related to dust collection system parts

Considerations for International Buyers: Buyers should ensure that fiberglass components comply with local safety standards and regulations, particularly in regions like the Middle East where environmental conditions can be extreme.

What Role Does Aluminum Play in Dust Collection Systems?

Aluminum is a lightweight metal that offers a good balance between strength and weight. It is often used in dust collection systems for components such as ductwork and fittings.

Pros: Aluminum is resistant to corrosion and has a high strength-to-weight ratio, making it easy to install and maintain. Its thermal conductivity also allows for effective heat dissipation.

Cons: While aluminum is durable, it may not be as strong as steel, making it less suitable for heavy-duty applications. Additionally, it can be more expensive than other materials, impacting overall project costs.

Impact on Application: Aluminum is well-suited for systems that require lightweight components without sacrificing performance. It is compatible with various dust types but may require careful handling to prevent deformation.

Illustrative image related to dust collection system parts

Considerations for International Buyers: Buyers should consider the cost implications of aluminum, especially in regions where import tariffs may apply. Ensuring compliance with international standards will also be crucial for successful procurement.

Summary Table of Material Selection for Dust Collection System Parts

| Material | Typical Use Case for dust collection system parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty components like ductwork and frames | High strength and durability | Susceptible to corrosion | Medium |

| Plastic | Fittings and lightweight components | Corrosion-resistant and cost-effective | Limited temperature resistance | Low |

| Fiberglass | Chemical-resistant applications | Excellent corrosion resistance | Higher manufacturing complexity | High |

| Aluminum | Ductwork and lightweight fittings | Lightweight with good corrosion resistance | Less strong than steel | Medium |

This strategic material selection guide provides valuable insights for B2B buyers in diverse regions, helping them make informed decisions when sourcing dust collection system parts.

In-depth Look: Manufacturing Processes and Quality Assurance for dust collection system parts

What Are the Key Stages in the Manufacturing Process of Dust Collection System Parts?

The manufacturing process for dust collection system parts involves several critical stages, each designed to ensure the integrity, performance, and reliability of the final product. These stages include material preparation, forming, assembly, and finishing.

Material Preparation

The first step involves selecting high-quality raw materials suitable for dust collection systems, such as metal alloys, plastics, and filter media. Depending on the specific part being manufactured, these materials may undergo processes such as cutting, shredding, and treating to enhance their properties. For instance, filter media may be treated for fire resistance or enhanced filtration efficiency. Ensuring that materials meet industry specifications is crucial to prevent premature failure in demanding environments.

Forming Techniques

Once materials are prepared, they are shaped into the desired forms using various techniques. Common methods include stamping, welding, and injection molding. For metal components, techniques such as laser cutting and CNC machining are often employed to achieve precise dimensions and tolerances. In the case of filter bags and cartridges, processes like sewing and pleating are used to create effective filtration surfaces. The choice of forming technique can significantly influence the performance characteristics of the dust collection parts.

Assembly Processes

After forming, components are assembled into final products. This stage may involve manual assembly or automated processes, depending on the complexity and volume of the parts. For example, in the case of dust collector units, various fittings and valves are integrated, ensuring proper connectivity and functionality. High-quality assembly practices are essential to avoid leaks and ensure that components work together seamlessly.

Finishing Techniques

The finishing stage includes surface treatments, painting, and coating to enhance durability and resistance to environmental factors. Techniques like powder coating or galvanization may be used to protect against corrosion, especially for parts exposed to harsh conditions. Proper finishing not only improves aesthetics but also extends the lifespan of the dust collection components.

How Is Quality Assurance Implemented in Dust Collection System Parts Manufacturing?

Quality assurance (QA) is a critical aspect of manufacturing dust collection system parts, ensuring that products meet regulatory standards and customer expectations. Implementing a robust QA system involves adherence to international standards, regular quality checkpoints, and various testing methods.

What International Standards Should B2B Buyers Look For?

Manufacturers of dust collection system parts should comply with relevant international standards, such as ISO 9001, which focuses on quality management systems. Compliance with industry-specific standards like CE marking in Europe or API standards for specific applications can also be vital. These certifications signify that products meet safety, health, and environmental protection requirements.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are essential throughout the manufacturing process. These typically include:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins.

-

In-Process Quality Control (IPQC): During manufacturing, various parameters are monitored to detect deviations from quality standards. This may include dimensional checks and process control metrics.

-

Final Quality Control (FQC): Before shipping, finished products undergo rigorous testing to verify their performance and compliance with specifications. This may include functional testing, pressure testing, and filtration efficiency assessments.

What Common Testing Methods Are Used?

Testing methods vary based on the component being manufactured but often include:

-

Flow Testing: To measure the airflow and ensure the efficiency of dust collection.

-

Durability Testing: Simulating operational conditions to assess the lifespan of components under stress.

-

Filtration Efficiency Testing: Evaluating how well filters capture particles of various sizes.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s QC processes is essential for ensuring product reliability.

What Steps Can Buyers Take?

1. Conduct Supplier Audits: Regular audits of potential suppliers can provide insight into their manufacturing practices and quality systems. This includes reviewing their compliance with international standards and the effectiveness of their QC processes.

-

Request Quality Reports: Buyers should ask for detailed quality reports, including inspection results and compliance certificates. These documents should outline the testing methods used and the results obtained.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of a supplier’s manufacturing and quality assurance processes. This is particularly important for buyers unfamiliar with local manufacturing practices.

-

Evaluate Quality Certifications: Ensure that suppliers possess the necessary certifications relevant to your industry. This not only reflects their commitment to quality but also provides assurance regarding their operational standards.

What Are the Unique QC Considerations for International B2B Buyers?

Navigating the complexities of international procurement requires an understanding of specific QC nuances that can impact product quality and compliance.

What Should Buyers Be Aware Of?

– Cultural Differences in Quality Standards: Different regions may have varying interpretations of quality standards. Buyers should educate themselves about local practices and ensure that suppliers align with their quality expectations.

Illustrative image related to dust collection system parts

-

Regulatory Compliance: Understanding the regulatory landscape in your market is essential. For instance, components exported to Europe must meet CE marking requirements, while products sold in the U.S. may need to comply with OSHA regulations.

-

Logistical Considerations: Shipping and handling can affect the quality of dust collection parts. Buyers should ensure that suppliers implement proper packaging and handling procedures to prevent damage during transport.

In conclusion, understanding the manufacturing processes and quality assurance measures for dust collection system parts is crucial for B2B buyers. By focusing on these aspects, buyers can make informed decisions, ensuring they procure reliable and high-quality components that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘dust collection system parts’

Introduction

This sourcing guide aims to equip B2B buyers with a practical checklist for procuring dust collection system parts. Understanding the intricacies of these components is crucial for ensuring optimal performance, safety, and compliance in various industrial applications. By following these steps, buyers can make informed decisions that meet their operational needs.

1. Define Your Technical Specifications

Begin by outlining the specific requirements for your dust collection system. This includes determining the type of materials being processed, expected airflow rates, and the size of the workspace. Clear specifications help in identifying suitable parts, ensuring compatibility and efficiency.

- Airflow Requirements: Calculate the necessary cubic feet per minute (CFM) based on your machinery and workspace dimensions.

- Material Compatibility: Ensure that selected components can handle the specific types of dust or particulates generated in your operations.

2. Research Available Parts and Components

Conduct thorough research on the various dust collection system parts available in the market. This includes filters, fittings, valves, and ducting materials. Understanding the options allows you to tailor your system effectively.

- Types of Filters: Consider options like cartridge filters, bag filters, or cyclone separators based on your dust type.

- Fittings and Ductwork: Ensure you have the necessary elbows, couplings, and blast gates to create an efficient airflow system.

3. Evaluate Potential Suppliers

Before making any purchases, vet potential suppliers comprehensively. This step is critical to ensuring that you partner with reputable companies that provide quality products and support.

Illustrative image related to dust collection system parts

- Supplier Background: Request company profiles and check their history in the industry.

- References and Reviews: Seek testimonials or case studies from other businesses in similar sectors to gauge satisfaction and reliability.

4. Verify Certifications and Compliance

Check that suppliers provide products that meet relevant industry standards and regulations. Compliance with safety and environmental guidelines is essential to avoid legal issues and ensure worker safety.

- Quality Certifications: Look for ISO certifications or other relevant quality assurance marks.

- Regulatory Compliance: Ensure parts comply with local environmental regulations, particularly in regions with strict guidelines.

5. Assess Pricing and Total Cost of Ownership

While initial pricing is important, consider the total cost of ownership, including maintenance, replacement parts, and energy consumption. This holistic view can prevent unexpected expenses in the long run.

- Long-Term Costs: Factor in the lifespan of parts and frequency of replacements.

- Operational Efficiency: Evaluate how the choice of components impacts overall energy use and productivity.

6. Request Samples or Prototypes

Whenever possible, request samples or prototypes before finalizing large orders. Testing parts in your operational environment can reveal compatibility and performance issues that may not be apparent from specifications alone.

- Performance Testing: Evaluate how well the parts function in real-world conditions.

- Fit and Compatibility: Ensure that all components fit seamlessly within your existing system layout.

7. Finalize Your Order and Establish Communication

Once you have selected a supplier and confirmed all details, proceed with placing your order. Establish clear communication channels for ongoing support and future orders, ensuring that you can address any issues that arise promptly.

- Order Confirmation: Ensure all specifications are clearly outlined in the purchase agreement.

- Support and Follow-Up: Confirm the availability of technical support and replacement parts for future needs.

By following these steps, B2B buyers can effectively navigate the procurement process for dust collection system parts, ensuring a reliable and efficient dust management solution tailored to their specific needs.

Illustrative image related to dust collection system parts

Comprehensive Cost and Pricing Analysis for dust collection system parts Sourcing

What Are the Key Cost Components of Dust Collection System Parts?

Understanding the cost structure for dust collection system parts is essential for international B2B buyers to make informed purchasing decisions. The primary cost components include:

- Materials: The choice of materials significantly impacts cost. High-quality materials such as stainless steel or specialized plastics may increase initial costs but can enhance durability and performance.

- Labor: Labor costs are influenced by the complexity of manufacturing and the skill level required. Regions with lower labor costs may offer competitive pricing, but this can vary widely based on local economic conditions.

- Manufacturing Overhead: This includes costs associated with factory operations, equipment maintenance, and utilities. Efficient manufacturing processes can help minimize overhead, thus lowering the overall price.

- Tooling: Custom tooling for specialized parts can add to costs. However, investing in the right tooling can lead to better precision and reduced waste in the long run.

- Quality Control (QC): Implementing stringent QC processes ensures product reliability but adds to the overall cost. Certifications (like ISO) can also influence pricing, as they reflect a commitment to quality.

- Logistics: Shipping costs can vary based on the mode of transport, distance, and any tariffs applicable to international trade. Effective logistics planning can mitigate these costs.

- Margin: Supplier profit margins can vary significantly based on market demand, competition, and perceived value of the product.

How Do Price Influencers Affect Dust Collection Parts Sourcing?

Several factors can influence the pricing of dust collection system parts, particularly for international buyers:

- Volume/MOQ (Minimum Order Quantity): Bulk purchases typically offer price breaks, making it advantageous to consolidate orders where possible.

- Specifications and Customization: Custom parts often come at a premium due to additional engineering and production processes. Understanding your exact needs can help avoid unnecessary costs.

- Materials and Quality: Higher-quality materials generally command higher prices. Buyers should assess the trade-offs between cost and durability, especially for critical components.

- Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more but often provide better support and assurance of quality.

- Incoterms: Understanding Incoterms (International Commercial Terms) is vital for determining who bears shipping costs and risks. This can significantly impact the total cost of ownership.

What Buyer Tips Can Enhance Cost-Efficiency in Dust Collection Parts Procurement?

To maximize cost efficiency and value when sourcing dust collection parts, consider the following strategies:

- Negotiation: Engage suppliers in discussions about pricing, especially for larger orders. Establishing a long-term relationship can lead to better pricing and terms.

- Total Cost of Ownership (TCO): Evaluate not just the upfront costs but also the long-term costs associated with maintenance, energy consumption, and potential downtime due to equipment failure.

- Pricing Nuances for International Buyers: Be aware of currency fluctuations, import duties, and local regulations that may affect overall costs. Researching local suppliers can sometimes yield better pricing compared to international shipping.

- Quality vs. Cost: While it might be tempting to opt for the lowest price, consider the long-term implications of quality. Investing in reliable parts can save costs associated with repairs or replacements down the line.

Conclusion

In the competitive landscape of dust collection system parts, understanding the intricate cost components and pricing influencers is crucial for international B2B buyers. By applying strategic sourcing tips and focusing on total cost of ownership, companies can achieve a balance between cost and quality, ensuring a more efficient and effective procurement process. Prices can vary widely based on numerous factors, so it is advisable to consult with multiple suppliers and consider all aspects of the purchasing process to make informed decisions.

Alternatives Analysis: Comparing dust collection system parts With Other Solutions

Exploring Alternatives to Dust Collection System Parts

In industries where dust generation is a significant concern, choosing the right dust collection system is crucial for maintaining a safe and efficient workspace. While dust collection system parts offer a robust solution for managing airborne particles, alternative technologies and methods exist that can also achieve effective dust control. This analysis will compare dust collection system parts with two viable alternatives: Cyclone Dust Collectors and Industrial Air Scrubbers.

Comparison Table

| Comparison Aspect | Dust Collection System Parts | Cyclone Dust Collectors | Industrial Air Scrubbers |

|---|---|---|---|

| Performance | Highly effective at removing fine dust particles when properly configured | Excellent for separating larger particles; may miss finer dust | Effective for both particulate and gaseous contaminants |

| Cost | Varies significantly based on components; typically moderate initial investment | Generally lower upfront cost but can incur high maintenance expenses | Higher initial investment; long-term savings on energy and efficiency |

| Ease of Implementation | Requires careful planning and installation; may need customization | Relatively simple installation; requires space for the cyclone unit | Requires professional installation; may need additional ducting |

| Maintenance | Regular maintenance of filters and parts needed; straightforward | Requires regular cleaning of collection bins and occasional maintenance | Regular filter changes and servicing needed; more complex |

| Best Use Case | Ideal for woodworking and manufacturing environments with various tool setups | Best suited for industries generating larger dust particles like woodworking and metalworking | Effective in environments with both dust and chemical emissions, such as foundries and chemical plants |

Detailed Breakdown of Alternatives

Cyclone Dust Collectors

Cyclone dust collectors use centrifugal force to separate dust and debris from the air stream, making them particularly effective for larger particles. Their simple design allows for easy installation, often resulting in lower initial costs compared to traditional dust collection systems. However, they may struggle with fine dust, which can lead to inefficiencies in certain applications. Maintenance involves regular cleaning of the collection bins, which can become labor-intensive if not monitored properly.

Industrial Air Scrubbers

Industrial air scrubbers are advanced systems designed to remove both particulate and gaseous contaminants from the air. These units are particularly effective in environments where chemical fumes are present, making them a versatile choice. While they typically require a higher initial investment, they can lead to long-term savings by improving air quality and reducing health risks. However, their complexity means that professional installation is necessary, and ongoing maintenance can be more demanding than simpler dust collection systems.

Illustrative image related to dust collection system parts

Conclusion: How to Choose the Right Dust Collection Solution

Selecting the appropriate dust collection solution hinges on the specific needs of your business. Factors such as the type of dust generated, the scale of operations, and budget constraints should guide your decision. Dust collection system parts offer tailored solutions for various setups, while cyclone dust collectors and industrial air scrubbers provide alternative approaches that may suit different operational requirements. By assessing the performance, cost, ease of implementation, maintenance, and best use cases of each option, B2B buyers can make informed decisions that enhance workplace safety and productivity.

Essential Technical Properties and Trade Terminology for dust collection system parts

What Are the Key Technical Properties of Dust Collection System Parts?

When selecting dust collection system parts, understanding their technical specifications is crucial for ensuring optimal performance and compliance with industry standards. Here are some essential properties to consider:

1. Material Grade

The material grade of components, such as filters and ductwork, directly impacts durability and performance. Common materials include galvanized steel, stainless steel, and high-density polyethylene (HDPE). Stainless steel, for example, offers superior corrosion resistance, making it ideal for harsh environments. Choosing the right material can enhance the longevity of the system, reduce maintenance costs, and improve overall efficiency.

2. Tolerance Levels

Tolerance refers to the permissible limits of variation in a physical dimension. In dust collection systems, precise tolerances ensure that fittings and components fit together correctly, preventing leaks and maintaining airflow efficiency. For instance, a tolerance of ±0.01 inches on duct diameter can significantly affect airflow and suction power. Understanding tolerances is crucial for B2B buyers, as it directly influences installation success and system reliability.

3. Filter Efficiency Ratings (MERV)

The Minimum Efficiency Reporting Value (MERV) rating indicates a filter’s ability to capture particles of varying sizes. A higher MERV rating means better filtration, which is essential for maintaining air quality in industrial settings. For buyers, selecting filters with appropriate MERV ratings ensures compliance with health regulations and enhances worker safety.

4. Airflow Capacity

Airflow capacity, measured in cubic feet per minute (CFM), is a critical specification that determines how effectively a dust collection system can remove airborne particles. Different applications require different airflow capacities; for example, woodworking shops may need higher CFM ratings to manage fine dust. Understanding airflow requirements helps buyers select the right system to match their operational needs.

5. Static Pressure

Static pressure is the resistance to airflow within the system, influenced by duct size, length, and the number of bends. Buyers need to consider static pressure ratings when designing a dust collection system to ensure it operates efficiently. High static pressure can lead to reduced airflow and increased energy consumption, impacting operational costs.

6. Noise Level

Noise levels, measured in decibels (dB), are another technical property that can affect workplace comfort and compliance with local regulations. Selecting quieter dust collection systems can improve the working environment, making it essential for buyers to consider noise ratings, especially in settings where employee well-being is a priority.

What Are Common Trade Terms Related to Dust Collection Systems?

Understanding industry jargon is essential for effective communication and negotiation in the procurement process. Here are some common trade terms relevant to dust collection systems:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts that may be sold under another company’s brand name. In the context of dust collection systems, buyers often seek OEM parts to ensure compatibility and reliability. Understanding OEM standards helps buyers make informed decisions about sourcing replacement parts.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ is crucial when planning inventory and budget, especially for components that may have a longer lead time or are less frequently needed.

Illustrative image related to dust collection system parts

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price quotation for specific products or services. This process is vital for buyers looking to compare costs and negotiate terms effectively. A well-prepared RFQ can lead to better pricing and terms.

4. Incoterms (International Commercial Terms)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risks, and responsibilities associated with transporting dust collection system parts across borders.

5. Lead Time

Lead time refers to the time taken from placing an order to its delivery. For businesses relying on dust collection systems, understanding lead times is critical for planning operations and maintaining productivity. Long lead times may necessitate advance ordering to avoid disruptions.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when purchasing dust collection system parts, ensuring they meet their operational needs while staying compliant with industry standards.

Navigating Market Dynamics and Sourcing Trends in the dust collection system parts Sector

What Are the Key Trends Shaping the Global Dust Collection System Parts Market?

The dust collection system parts market is experiencing significant transformation driven by several global trends. Increasing regulatory pressures aimed at reducing airborne pollutants and enhancing workplace safety are prompting businesses to invest in advanced dust collection solutions. These regulations are particularly stringent in developed markets across Europe and North America, yet emerging economies in Africa and South America are also recognizing the importance of compliance as they industrialize. As a result, international B2B buyers are seeking reliable suppliers who can provide high-quality parts that adhere to these regulations.

Technological advancements are also reshaping the landscape. The integration of IoT (Internet of Things) in dust collection systems allows for real-time monitoring and data analytics, which enhances operational efficiency. B2B buyers are increasingly interested in sourcing parts that can integrate with these smart technologies, offering predictive maintenance and improved performance insights. Furthermore, there is a notable trend toward modular systems that allow for easy upgrades and customization, catering to the specific needs of various industries, including woodworking, metalworking, and construction.

Additionally, the rising demand for sustainable solutions is influencing purchasing decisions. Companies are not only looking for effective dust collection but also for parts that contribute to energy efficiency and waste reduction. This trend is particularly evident among buyers in regions like Europe, where sustainability is a core aspect of business operations.

How Is Sustainability Influencing B2B Sourcing for Dust Collection Parts?

Sustainability is becoming a crucial factor in the sourcing of dust collection system parts. The environmental impact of manufacturing processes and the materials used in these components cannot be overlooked. B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to eco-friendly practices, such as using recyclable materials and minimizing waste during production.

Ethical sourcing is equally important, as businesses seek to ensure that their supply chains are free from exploitative practices and that they contribute positively to local communities. Certifications such as ISO 14001 for environmental management and other green certifications are becoming essential criteria for selecting suppliers. Buyers are encouraged to inquire about the sourcing of materials, the manufacturing processes, and the overall lifecycle impact of the products they purchase.

Furthermore, the demand for ‘green’ materials, such as biodegradable filters and energy-efficient components, is on the rise. Companies that can offer innovative, sustainable solutions will have a competitive edge in attracting international buyers who are increasingly conscious of their environmental footprint.

How Has the Dust Collection System Parts Market Evolved Over Time?

The dust collection system parts market has evolved significantly over the decades, transitioning from basic filtration systems to sophisticated, technology-driven solutions. In the early days, dust collection primarily relied on simple mechanical filters and fabric bags to capture airborne particles. However, as industries have advanced, the need for more efficient and effective dust control has led to the development of high-performance materials and advanced filtration technologies.

The introduction of pulse jet cleaning systems and cartridge filters marked a significant leap forward, offering enhanced efficiency and longer service life. As industries faced stricter environmental regulations, the market began to see an influx of innovative designs aimed at improving both performance and compliance. Today, the focus is on integrating smart technologies and sustainable practices into dust collection systems, reflecting the broader trends in industrial manufacturing and environmental stewardship.

In summary, understanding the market dynamics and sourcing trends within the dust collection system parts sector is crucial for international B2B buyers. By staying informed about technological advancements, sustainability efforts, and regulatory changes, businesses can make strategic decisions that enhance their operational efficiency and align with global standards.

Frequently Asked Questions (FAQs) for B2B Buyers of dust collection system parts

-

1. How do I solve issues with insufficient dust collection performance?

To enhance dust collection efficiency, first assess the system’s design and layout. Ensure that the ductwork is properly sized and configured with minimal bends and obstructions. Regularly inspect and maintain filters, as clogged or damaged filters can severely impact performance. Additionally, utilize dust collection fittings strategically to optimize airflow and capture dust at the source. If problems persist, consider consulting with a dust collection expert to analyze your system and recommend specific improvements tailored to your operational needs. -

2. What is the best type of filter for a dust collection system?

The best filter for a dust collection system largely depends on the type of dust generated and the specific application. For fine particulate matter, HEPA filters are recommended due to their high efficiency in capturing small particles. In contrast, for heavier dust loads, cartridge filters made from polyester or nanofiber materials are ideal, as they provide robust performance and longer service life. Always consider the environmental regulations in your region to ensure compliance while selecting the appropriate filter type. -

3. How can I ensure quality when sourcing dust collection parts internationally?

To ensure quality, start by vetting suppliers thoroughly. Look for manufacturers with a proven track record and certifications such as ISO 9001. Request samples of parts for testing before placing large orders to evaluate their performance and durability. Additionally, consider visiting manufacturing facilities if feasible, or use third-party inspection services to verify product quality before shipment. Establish clear quality assurance protocols and communication channels with your suppliers to address any potential issues promptly. -

4. What are the typical minimum order quantities (MOQs) for dust collection parts?

Minimum order quantities can vary significantly depending on the supplier and the specific components being ordered. Generally, MOQs for dust collection parts range from 50 to 200 units. However, some manufacturers may accommodate smaller orders, especially for replacement parts or custom solutions. It is advisable to discuss MOQs upfront with potential suppliers to understand their policies and negotiate terms that align with your procurement strategy. -

5. What payment terms should I expect when purchasing dust collection system parts?

Payment terms can vary widely among suppliers, but common practices include a deposit (usually 30-50%) upon order confirmation, with the balance due before shipment or upon delivery. For international transactions, it’s crucial to discuss payment methods such as letters of credit, wire transfers, or escrow services to minimize risk. Ensure that all payment terms are clearly outlined in the purchase agreement to avoid misunderstandings and protect your interests. -

6. How can I customize dust collection parts to fit my specific needs?

Customization options typically include variations in size, material, and design features to align with your operational requirements. Most suppliers offer customization services, but it is essential to communicate your specific needs clearly. Provide detailed specifications and any unique challenges your operation faces. Collaborating with the supplier’s engineering team can lead to tailored solutions that enhance performance and efficiency in your dust collection system. -

7. What logistics considerations should I keep in mind when importing dust collection parts?

When importing dust collection parts, consider factors such as shipping methods, transit times, and customs regulations in your country. Select a reliable logistics provider experienced in handling industrial equipment to ensure timely delivery. Familiarize yourself with import duties and taxes to avoid unexpected costs. Additionally, having a clear understanding of the incoterms used in your contract can help clarify responsibilities regarding shipping, insurance, and risk during transit. -

8. How do I handle warranty claims for dust collection parts purchased internationally?

To effectively manage warranty claims, first familiarize yourself with the warranty terms provided by the supplier. Document any issues with the parts, including photographs and detailed descriptions, to support your claim. Contact the supplier promptly to initiate the claims process and follow their guidelines for returns or replacements. Building a good relationship with your supplier can facilitate smoother claims handling, so maintain open communication and address any concerns proactively.

Top 8 Dust Collection System Parts Manufacturers & Suppliers List

1. Powertec – Dust Collection Solutions

Domain: powertecproducts.com

Registered: 2014 (11 years)

Introduction: Dust Collector parts including: Dust Collection Kits, Air Filtration System, Filters, Filter/Collector Bags, Hoses/Pipes, Blast Gates, Hangers, Dust Hood & Dust Port, Y-Fittings, Reducers, Hose Clamps (Key, Worm Drive, Double Wire).

2. Woodcraft – Ductwork Fittings

Domain: woodcraft.com

Registered: 1995 (30 years)

Introduction: This company, Woodcraft – Ductwork Fittings, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

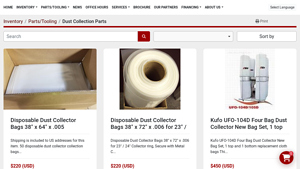

3. John G. Weber – Disposable Dust Collector Bags

Domain: johngweber.com

Registered: 1998 (27 years)

Introduction: 1. Disposable Dust Collector Bags 38″ x 64″ x .005 – 50 bags for $220 (USD)\n2. Disposable Dust Collector Bags 38″ x 72″ x .006 for 23″ / 24″ Collector ring – $220 (USD)\n3. Kufo UFO-104D Four Bag Dust Collector New Bag Set – 1 top and 1 bottom replacement cloth bags for $450 (USD)\n4. Kufo UFO-104D Four Bag Dust Collector New Bag Set – 4 top and 4 bottom replacement cloth bags for $1,400 (USD)\n5…

4. Oneida Air – Dust Collection Systems and Accessories

Domain: oneida-air.com

Registered: 1998 (27 years)

Introduction: Dust Collection System Components and Accessories include: 1. Dust Deputy Cyclone Separators – High-efficiency cyclones that remove over 99% of dust and debris. 2. Dust Collector Kits – Various models including Super Dust Deputy 4/5, Super Dust Deputy XL, and accessories. 3. Steel and Stainless Steel Cyclones – For hot, heavy, abrasive, and clean corrosive applications. 4. Ductwork – Heavy-gauge s…

5. Universal Air Systems – Valve Replacements for Dust Collectors

Domain: universalairsys.com

Registered: 2018 (7 years)

Introduction: Replacements and Parts for Valves for Dust Collectors include: Mecair® DB16 3/4″ – Price: $29.00; GOYEN® K2000 3/4″ – Price: $29.70; GOYEN® K2003 3/4″ – Price: Not specified. Note: Some items may require additional freight charges due to unexpected costs. Freight is not final until the product ships. Universal Air Systems offers a variety of dust collection systems and parts including mist collect…

6. Camfil APC – Dust Collector Parts & Accessories

Domain: camfilapc.com

Registered: 2013 (12 years)

Introduction: Dust Collector Parts & Accessories include: 1. Controllers: Gold Series Timer, Touch Screen Controller, GSX Controller, DCT1000 Dust Collector Controller, Integrated Control Panel, Smart Solenoid Controller. 2. GoldLink+ Filter Monitoring: Provides anytime access to dust collection diagnostics. 3. Safety Monitoring Filters: Glide/Pack Housing, Magna/Pack Housing, Riga-flo® Final Filters, XH Absolu…

7. Lee Valley – Dust Collection Control System Transmitter

Domain: leevalley.com

Registered: 1996 (29 years)

Introduction: [{‘name’: ‘Transmitter for iVAC Pro Dust Collection Control System’, ‘price’: ‘$92.50’, ‘availability’: ‘Online: Available’}, {‘name’: ‘Festool Dust Extraction Adapter AV-BHC/KHC’, ‘price’: ‘From: $42.40’, ‘availability’: ‘Online: Limited Stock’}, {‘name’: ‘5″ to 4″ Reducer’, ‘price’: ‘$23.50’, ‘availability’: ‘Online: Available’}, {‘name’: ‘Waste Bags for Oneida Mini Gorilla (Pkg. of 5)’, ‘price’…

8. TP Tools – Dust Collector Parts & Accessories

Domain: tptools.com

Registered: 1999 (26 years)

Introduction: Dust Collector Parts & Accessories for Abrasive Blasting Cabinets. Includes various components such as cabinet blasting gloves, nozzles, air jets, gaskets, lenses/window components, trigger & foot-pedal siphon guns & parts, high-volume siphon guns & parts, siphon hose & pickup tubes, foot pedal & parts, gaskets, trim & miscellaneous parts, lighting, and useful blast cabinet accessories.

Strategic Sourcing Conclusion and Outlook for dust collection system parts

In navigating the complexities of sourcing dust collection system parts, international B2B buyers can derive significant value from strategic sourcing practices. Key takeaways include understanding the essential components that optimize dust collection efficiency, such as fittings, filters, and control systems. By prioritizing quality and compatibility, buyers can enhance operational safety, extend equipment lifespan, and ensure compliance with environmental regulations.

Establishing strong relationships with reputable suppliers not only facilitates access to high-quality parts but also enables better negotiation terms and improved supply chain resilience. As market dynamics shift and the demand for effective dust management solutions grows, particularly in emerging markets across Africa, South America, the Middle East, and Europe, buyers are encouraged to leverage data-driven insights and market intelligence to inform their purchasing decisions.

Looking ahead, the emphasis on sustainable practices and technological advancements in dust collection systems will continue to reshape the industry landscape. Now is the time for international B2B buyers to invest in robust sourcing strategies that align with their operational goals and regulatory requirements, ensuring they remain competitive in a rapidly evolving marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.