2015-2021 Jeep Renegade Front Left Driver S Fenders: The Ultimate B2B Sourcing Guide…

Introduction: Navigating the Global Market for 2015-2021 jeep renegade front left driver s fenders

In the competitive landscape of the automotive parts market, sourcing high-quality replacement components such as the 2015-2021 Jeep Renegade front left driver’s fender can be a daunting challenge for international B2B buyers. With a growing demand across diverse markets, including Africa, South America, the Middle East, and Europe, understanding the nuances of quality, compatibility, and supplier reliability is essential. This comprehensive guide delves into the various types of fenders available, their applications, and critical considerations for vetting suppliers, ensuring that businesses can make informed purchasing decisions.

The guide is designed to empower B2B buyers by providing actionable insights into the procurement process, from identifying reputable manufacturers to evaluating cost factors and shipping logistics. It addresses common challenges such as variations in OEM specifications and the importance of selecting parts that meet rigorous quality standards. Moreover, by highlighting best practices for sourcing and offering tips on navigating potential pitfalls, this resource equips buyers with the knowledge needed to optimize their purchasing strategies.

As the global market continues to evolve, staying informed about trends and supplier capabilities is paramount. This guide serves as a valuable tool for businesses seeking to enhance their supply chains while ensuring customer satisfaction through reliable and durable automotive parts. By leveraging this information, B2B buyers can confidently navigate the complexities of sourcing the right fenders for the Jeep Renegade, ultimately driving their success in the automotive sector.

Understanding 2015-2021 jeep renegade front left driver s fenders Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| OEM Replacement Fender | Made to match original specifications; high durability | Auto repair shops, dealerships | Pros: Perfect fit, quality assurance; Cons: Higher cost compared to aftermarket options. |

| Aftermarket Fender | Available in various styles and materials; often lighter | Independent auto part retailers | Pros: Cost-effective; Cons: Potential fitment issues, variable quality. |

| Used/Recycled Fender | Sourced from salvage yards; may show wear | Budget-conscious repair shops | Pros: Affordable; Cons: Limited availability, potential quality concerns. |

| Primed Fender | Comes prepped for painting; ready for customization | Custom auto shops, restoration firms | Pros: Saves time on painting; Cons: Requires additional paint job for color matching. |

| Fender Flare | Extends coverage beyond the fender; enhances aesthetics | Off-road vehicle modifications | Pros: Improved look and functionality; Cons: May require additional installation effort. |

What Are the Characteristics of OEM Replacement Fenders?

OEM (Original Equipment Manufacturer) replacement fenders are designed to meet the exact specifications of the Jeep Renegade, ensuring a seamless fit and finish. These fenders are crafted from high-quality materials to provide durability and longevity, making them ideal for auto repair shops and dealerships that prioritize quality. B2B buyers should consider the higher cost associated with OEM parts, as they offer a guarantee of compatibility and performance, which can be crucial for maintaining customer satisfaction.

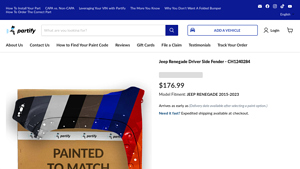

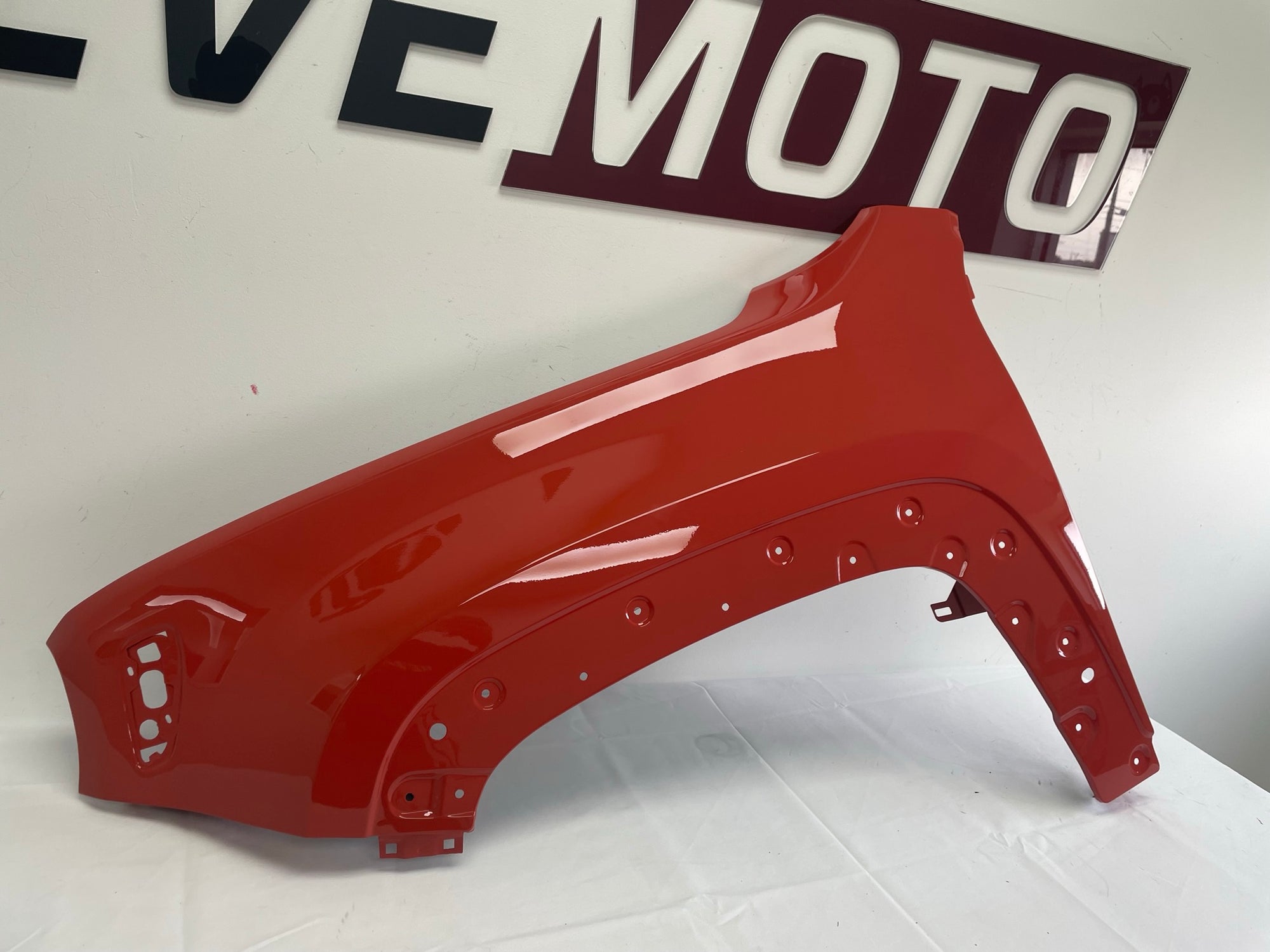

Illustrative image related to 2015-2021 jeep renegade front left driver s fenders

How Do Aftermarket Fenders Differ from OEM Options?

Aftermarket fenders offer a range of styles and materials, often at a lower price point than OEM options. They are typically produced by third-party manufacturers and may not always adhere to the original specifications. This makes them a popular choice for independent auto part retailers looking to provide cost-effective solutions for customers. However, buyers should be cautious of potential fitment issues and varying quality, which could affect installation and vehicle performance.

What Should B2B Buyers Know About Used/Recycled Fenders?

Used or recycled fenders are sourced from salvage yards and can be a budget-friendly option for repair shops looking to minimize costs. These fenders may show signs of wear and tear, but they offer a sustainable choice for environmentally-conscious businesses. B2B buyers should be aware of the limited availability and potential quality concerns, as the condition of used parts can vary significantly. Thorough inspection and assurance of fitment are essential before purchase.

Why Consider Primed Fenders for Customization?

Primed fenders are prepped for painting, making them an excellent choice for custom auto shops and restoration firms. These fenders save time and labor costs associated with painting, as they arrive ready for customization. B2B buyers should evaluate the additional costs of painting to match specific vehicle colors, as this can influence the overall project budget. The ability to customize offers significant value for businesses focused on unique vehicle modifications.

What Advantages Do Fender Flares Offer for Modifications?

Fender flares extend the coverage of the fender, providing both aesthetic enhancements and functional benefits, particularly for off-road vehicles. They are popular among modification enthusiasts and businesses specializing in custom builds. While fender flares improve the vehicle’s appearance and may provide additional tire clearance, buyers should consider the installation complexity and ensure compatibility with existing vehicle components.

Illustrative image related to 2015-2021 jeep renegade front left driver s fenders

Key Industrial Applications of 2015-2021 jeep renegade front left driver s fenders

| Industry/Sector | Specific Application of 2015-2021 Jeep Renegade Front Left Driver’s Fenders | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair Shops | Replacement for damaged vehicle fenders in collision repair services | Enhances customer satisfaction through quality repairs | Ensure compatibility with OEM specifications; consider local sourcing options for quick delivery. |

| Auto Parts Retailers | Inventory for aftermarket parts sales to DIY customers | Increases revenue streams through diverse product offerings | Focus on reliable suppliers with competitive pricing and fast shipping options. |

| Fleet Management Companies | Maintenance of company-owned Jeep Renegades to ensure operational efficiency | Reduces downtime and repair costs for fleet vehicles | Prioritize bulk purchasing agreements to lower costs and ensure consistent supply. |

| Export and Import Dealers | Supply of fenders for international markets where Jeep Renegades are popular | Expands market reach and meets local demand | Navigate import regulations and ensure compliance with local market standards. |

| Automotive Restoration | Use in classic vehicle restorations or custom builds involving Jeep Renegades | Attracts niche customers looking for high-quality parts | Source fenders that match original specifications for authenticity in restorations. |

The automotive repair industry heavily relies on the availability of quality replacement parts, such as the 2015-2021 Jeep Renegade front left driver’s fenders. Collision repair shops often encounter vehicles needing fender replacements due to accidents. These fenders must meet OEM specifications to ensure proper fit and finish, which is crucial for customer satisfaction. Repair shops should consider sourcing fenders from reputable suppliers that guarantee compatibility and offer expedited shipping options to minimize vehicle downtime.

Auto parts retailers can benefit from stocking the 2015-2021 Jeep Renegade front left driver’s fenders as part of their aftermarket inventory. With the growing DIY automotive repair market, having readily available fenders can attract customers looking to perform their own repairs. Retailers should focus on partnerships with reliable manufacturers that provide competitive pricing and quality assurance, as this will enhance customer trust and encourage repeat business.

For fleet management companies, maintaining a fleet of Jeep Renegades requires consistent access to replacement parts like fenders. Ensuring that vehicles are quickly repaired helps minimize downtime and maintain operational efficiency. Fleet managers should consider establishing bulk purchasing agreements with suppliers to secure lower prices and a steady supply of fenders, ultimately reducing overall maintenance costs.

Export and import dealers can tap into the international demand for Jeep Renegade fenders, especially in markets across Africa, South America, and Europe. Understanding the specific needs of these markets, including compliance with local regulations, is essential for successful transactions. Dealers should ensure they have a solid logistics plan in place to handle shipping and customs efficiently, thereby improving their market reach.

Finally, the automotive restoration sector often seeks high-quality fenders for custom builds or restorations of Jeep Renegades. Enthusiasts and restorers look for parts that meet original specifications to maintain authenticity. Sourcing these fenders from manufacturers that specialize in restoration parts can attract niche customers and enhance the business’s reputation within the restoration community.

Illustrative image related to 2015-2021 jeep renegade front left driver s fenders

3 Common User Pain Points for ‘2015-2021 jeep renegade front left driver s fenders’ & Their Solutions

Scenario 1: Sourcing Quality Replacement Fenders in Diverse Markets

The Problem: B2B buyers often struggle to source high-quality replacement fenders for the 2015-2021 Jeep Renegade, particularly when operating in regions with limited access to OEM parts. This challenge is exacerbated by variations in local suppliers, inconsistent product quality, and potential delays in shipping. Buyers may find it frustrating to navigate through numerous options that do not meet the necessary specifications or durability standards, leading to wasted time and resources.

The Solution: To effectively source quality replacement fenders, B2B buyers should establish partnerships with reputable suppliers who specialize in automotive parts. Utilize online platforms that aggregate inventories from multiple suppliers, such as Car-Part.com, which can provide access to a broad range of options, including OEM and aftermarket parts. Ensure that the selected fender (part number CH1240284) is verified for compatibility with the 2015-2021 Jeep Renegade model. It is advisable to request samples or detailed specifications prior to bulk purchasing to assess quality. Additionally, consider investing in expedited shipping options to mitigate delays, especially when fulfilling urgent client needs.

Scenario 2: Navigating Installation Challenges for Front Left Fenders

The Problem: Many B2B buyers face difficulties during the installation process of front left fenders, particularly if their customers lack technical expertise. The complexity of the installation, including the need to remove hidden bolts or specific panels, can lead to improper fitting and potential damage to the vehicle. This not only affects customer satisfaction but can also result in additional costs for repairs or replacements.

Illustrative image related to 2015-2021 jeep renegade front left driver s fenders

The Solution: To alleviate installation challenges, suppliers should provide comprehensive installation guides along with the fenders. These guides can include step-by-step instructions, tools required, and tips for common issues encountered during the process. Additionally, offering training sessions or workshops for automotive technicians can enhance their skills in handling fender installations. Utilizing online video tutorials can also be beneficial, as they provide visual assistance that can simplify complex steps. Encouraging buyers to utilize professional installation services for those less confident in their abilities can further ensure that the fender is correctly fitted and functional.

Scenario 3: Addressing Color Matching and Aesthetic Consistency

The Problem: A frequent pain point for B2B buyers is ensuring that the replacement fender matches the existing vehicle color. Color discrepancies can lead to unsatisfactory results for end customers, affecting the overall aesthetic appeal of the vehicle and potentially harming the buyer’s reputation. This issue is particularly pronounced in regions where local paint matching services may not be readily available or reliable.

The Solution: To tackle the color matching issue effectively, B2B buyers should prioritize sourcing fenders that come pre-painted to OEM specifications. When purchasing, inquire about the color codes to ensure a perfect match with the Jeep Renegade’s original color palette. Providing buyers with a color reference guide can assist them in selecting the appropriate shade. If pre-painted options are not available, recommend partnering with reputable local auto body shops that specialize in color matching and finishing. This collaboration can enhance customer satisfaction and ensure that the fender installation meets aesthetic expectations, thereby reinforcing the buyer’s brand reputation in the market.

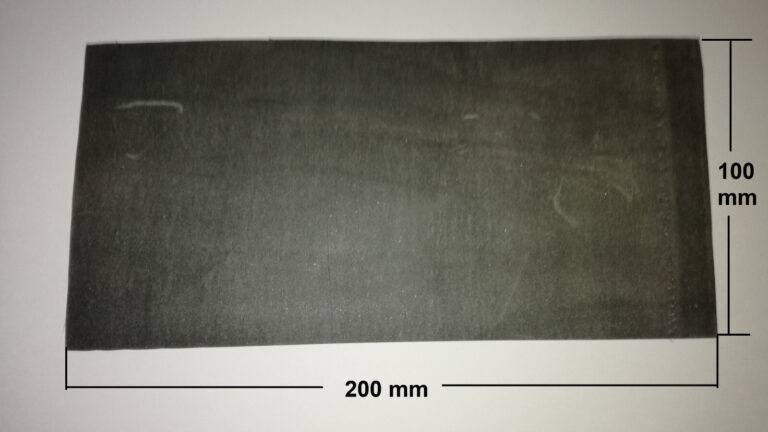

Strategic Material Selection Guide for 2015-2021 jeep renegade front left driver s fenders

When selecting materials for the front left driver side fenders of the 2015-2021 Jeep Renegade, it is essential to consider various factors that influence performance, cost, and suitability for international markets. The primary materials used in fender manufacturing include steel, aluminum, plastic, and composite materials. Each of these materials has distinct properties and implications for B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Steel for Jeep Renegade Fenders?

Steel is a traditional choice for automotive fenders due to its strength and durability. It typically offers high tensile strength, making it resistant to deformation under stress. Steel fenders can withstand extreme temperatures and pressures, making them suitable for various climates. However, they are prone to corrosion if not treated properly, which can be a significant concern in humid or coastal regions.

Pros and Cons of Steel Fenders

The primary advantage of steel is its durability and ability to absorb impacts, which enhances vehicle safety. However, the weight of steel can lead to increased fuel consumption, and the manufacturing process is often more complex due to the need for additional treatments to prevent rust. For international buyers, compliance with standards such as ASTM A1008 for cold-rolled steel is crucial.

How Does Aluminum Compare for Jeep Renegade Fenders?

Aluminum has gained popularity in recent years due to its lightweight nature and resistance to corrosion. It is highly malleable, allowing for complex shapes and designs, which can enhance the aesthetic appeal of the vehicle. Aluminum fenders generally perform well in various temperature ranges and are less likely to rust compared to steel.

Illustrative image related to 2015-2021 jeep renegade front left driver s fenders

Pros and Cons of Aluminum Fenders

The key advantage of aluminum is its lightweight property, which can improve fuel efficiency. However, aluminum can be more expensive than steel, and its lower tensile strength means it may not absorb impacts as effectively. International buyers should consider compliance with standards like DIN 1725 for aluminum alloys.

What Role Does Plastic Play in Fender Manufacturing for Jeep Renegade?

Plastic fenders, often made from high-density polyethylene (HDPE) or polypropylene, are increasingly used due to their cost-effectiveness and versatility. They are resistant to corrosion and can be produced in various colors, reducing the need for additional painting processes.

Pros and Cons of Plastic Fenders

The main advantage of plastic is its lightweight nature, which contributes to overall vehicle efficiency. However, plastic may not provide the same level of impact resistance as metal options, making it less suitable for rugged applications. Buyers in regions with stringent environmental regulations should ensure that the plastics used comply with local standards.

How Do Composite Materials Benefit Jeep Renegade Fenders?

Composite materials, which combine various substances to enhance performance characteristics, are becoming popular in the automotive industry. These materials can offer a balance of strength, weight, and corrosion resistance.

Pros and Cons of Composite Fenders

The primary advantage of composites is their ability to be tailored for specific performance needs, such as enhanced impact resistance or reduced weight. However, the manufacturing process can be complex and costly. International buyers must consider the varying standards for composites in different regions, such as JIS K 6911 in Japan.

Summary Table of Material Options for Jeep Renegade Fenders

| Material | Typical Use Case for 2015-2021 jeep renegade front left driver s fenders | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Standard fender for durability and impact resistance | High strength and durability | Prone to corrosion | Medium |

| Aluminum | Lightweight fender for improved fuel efficiency | Lightweight and corrosion-resistant | Higher cost than steel | High |

| Plastic | Cost-effective fender for aesthetic appeal | Resistant to corrosion | Lower impact resistance | Low |

| Composite | Advanced fender with tailored performance characteristics | Customizable for specific needs | Complex and costly manufacturing | High |

In conclusion, the selection of materials for the front left driver side fenders of the Jeep Renegade involves a careful analysis of performance characteristics, cost implications, and compliance with international standards. Understanding these factors will enable B2B buyers to make informed decisions that align with their operational needs and market demands.

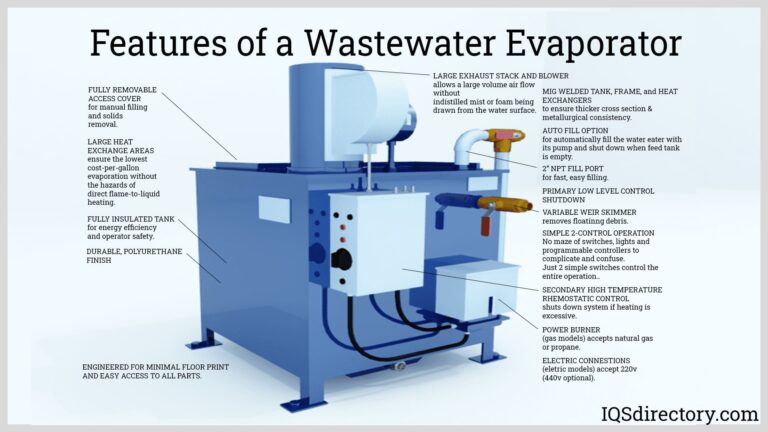

In-depth Look: Manufacturing Processes and Quality Assurance for 2015-2021 jeep renegade front left driver s fenders

What Are the Key Manufacturing Processes for 2015-2021 Jeep Renegade Front Left Driver’s Fenders?

The manufacturing of front left driver’s fenders for the 2015-2021 Jeep Renegade involves several critical stages that ensure the final product meets both performance and aesthetic standards. Understanding these stages is vital for B2B buyers looking to source high-quality automotive components.

Material Preparation: What Materials Are Used?

The primary materials used for manufacturing fenders are high-strength steel and plastic composites. Steel is preferred for its durability and impact resistance, which is essential for automotive applications. The initial stage involves sourcing raw materials that comply with international standards, ensuring they are free from defects. Quality checks are performed on incoming materials to confirm they meet specifications, which is crucial for maintaining the integrity of the final product.

Forming: How Are Fenders Shaped?

Once the materials are prepared, the forming process begins. This typically involves methods such as stamping and hydroforming. Stamping is commonly used for metal fenders, where large sheets of steel are pressed into shape using molds. Hydroforming, on the other hand, uses high-pressure hydraulic fluid to mold materials into complex shapes, allowing for more intricate designs while minimizing weight.

During this stage, precision is key. Advanced machinery equipped with CNC (Computer Numerical Control) technology ensures that each fender is formed to exact specifications. This not only enhances fitment but also reduces waste, making the process more efficient.

Assembly: What Techniques Are Employed?

After forming, the fenders undergo assembly, where additional components such as brackets, clips, and reinforcement elements are attached. Automated assembly lines are often employed to ensure consistency and speed. Robotic arms may be used for tasks that require precision, such as welding or riveting.

Additionally, assembly processes are designed to facilitate easy installation on the Jeep Renegade. For example, fenders are often pre-drilled for mounting, which is a consideration that B2B buyers should factor into their procurement decisions.

Finishing: How Is the Surface Treated?

The finishing stage is crucial for aesthetic appeal and corrosion resistance. Fenders typically undergo processes such as sanding, priming, and painting. Powder coating is a popular choice for its durability and color retention. This stage not only enhances the visual appeal of the fender but also provides protection against environmental factors, which is particularly important for regions with harsh climates.

Illustrative image related to 2015-2021 jeep renegade front left driver s fenders

Quality checks during the finishing stage ensure that the surface finish meets industry standards, providing an added layer of assurance for B2B buyers.

What Quality Assurance Measures Are Implemented?

Quality assurance (QA) is integral to the manufacturing process, especially for components like fenders that must withstand rigorous conditions. Compliance with international standards such as ISO 9001 ensures that manufacturers maintain consistent quality throughout production.

Which International Standards Are Relevant?

ISO 9001 is a widely recognized standard that focuses on quality management systems. Adhering to this standard helps manufacturers streamline processes and reduce defects. Other certifications, such as CE marking, indicate compliance with European safety standards, which can be particularly relevant for buyers in Europe.

Illustrative image related to 2015-2021 jeep renegade front left driver s fenders

In addition to ISO standards, industry-specific certifications may apply, including those from the American Petroleum Institute (API) for manufacturers dealing with automotive parts.

What Are the Key QC Checkpoints?

Quality control involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial checkpoint ensures that raw materials meet specified criteria before they enter production.

- In-Process Quality Control (IPQC): This ongoing monitoring occurs during the manufacturing process. It includes checks at various stages, such as after forming and before assembly, to catch defects early.

- Final Quality Control (FQC): This final inspection ensures that the finished product meets all specifications and is free from defects. It typically involves dimensional checks, visual inspections, and performance testing.

How Can B2B Buyers Verify Supplier Quality?

B2B buyers can take several steps to verify the quality of suppliers:

- Audits: Conducting on-site audits of manufacturing facilities can provide insight into the production processes and quality control measures in place.

- Quality Reports: Requesting regular quality reports can help buyers track performance over time, ensuring that suppliers maintain high standards.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the manufacturer’s quality practices and product compliance.

What Are the QC/CERT Nuances for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must navigate various regulations and standards. Understanding local compliance requirements is essential. For example, the importation of automotive parts into the European Union may require adherence to specific directives that differ from those in other regions.

Additionally, language barriers and differences in regulatory frameworks can complicate the procurement process. B2B buyers should establish clear communication channels with suppliers to ensure that all quality and compliance requirements are understood and met.

Conclusion: Why Is Understanding Manufacturing and Quality Assurance Crucial?

For B2B buyers in the automotive sector, a comprehensive understanding of the manufacturing processes and quality assurance measures for the 2015-2021 Jeep Renegade front left driver’s fenders is crucial. This knowledge not only aids in sourcing high-quality components but also helps establish long-term relationships with reliable suppliers. By prioritizing quality and compliance, buyers can ensure that they are investing in products that will meet their needs and those of their customers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘2015-2021 jeep renegade front left driver s fenders’

Introduction

This sourcing guide aims to assist international B2B buyers in procuring front left driver side fenders for the 2015-2021 Jeep Renegade. By following this step-by-step checklist, buyers can ensure they are making informed decisions, optimizing cost-effectiveness, and securing quality parts that meet OEM specifications.

Step 1: Define Your Technical Specifications

Clearly outline the specifications required for the fender, including the make, model, and year. Accurate specifications help avoid compatibility issues and ensure that the part fits seamlessly. Focus on identifying whether you need an OEM (Original Equipment Manufacturer) part or an aftermarket alternative, as this will impact both price and quality.

Step 2: Research Reputable Suppliers

Conduct thorough research to find suppliers with a proven track record in the automotive parts industry. Look for companies that specialize in Jeep parts and have positive reviews from previous customers. Utilize platforms such as industry-specific forums and trade directories to identify potential suppliers.

- Check Online Marketplaces: Sites like Car-Part.com can aggregate options from various recycling yards, offering both new and used fenders at competitive prices.

- Visit Supplier Websites: Ensure the suppliers provide detailed product descriptions and fitment data.

Step 3: Evaluate Supplier Certifications

Before finalizing a supplier, verify their certifications and compliance with industry standards. This ensures that the parts meet necessary safety and quality benchmarks.

- Request Documentation: Ask for ISO certifications or any other relevant quality assurance documents.

- Review Warranty Policies: A robust warranty can indicate supplier confidence in their product quality.

Step 4: Assess Shipping Options and Costs

Understanding shipping logistics is crucial, especially for international transactions. Determine the shipping methods available and associated costs to avoid unexpected expenses.

- Inquire About Freight Options: Some suppliers may offer free shipping on bulk orders, which can be cost-effective.

- Check Delivery Times: Ensure that the supplier can meet your required timelines, particularly if you are operating under tight schedules.

Step 5: Inspect Return and Exchange Policies

Before making a purchase, review the supplier’s return and exchange policies. This step is vital in case the part does not meet your expectations or is incompatible with your vehicle.

- Clarify Conditions for Returns: Understand what circumstances allow for returns and whether there are restocking fees.

- Examine Exchange Processes: Ensure that the process for exchanging parts is straightforward and clearly outlined.

Step 6: Negotiate Pricing and Terms

Once you have identified a suitable supplier, engage in negotiations regarding pricing, payment terms, and bulk order discounts. Effective negotiation can lead to significant cost savings.

Illustrative image related to 2015-2021 jeep renegade front left driver s fenders

- Discuss Volume Discounts: If you plan to order multiple units, inquire about pricing tiers based on order quantity.

- Explore Payment Flexibility: Check if the supplier offers various payment methods that might be more convenient for your business.

Step 7: Finalize Your Order

After completing due diligence, finalize your order by confirming all details, including specifications, pricing, and delivery expectations. A well-documented order helps minimize errors and ensures clarity for both parties.

- Create a Purchase Order: Draft a formal purchase order that includes all agreed-upon terms to serve as a reference point.

- Follow Up on Confirmation: Maintain communication with the supplier to confirm order processing and shipping timelines.

By following this checklist, B2B buyers can effectively source front left driver side fenders for the Jeep Renegade, ensuring quality, compatibility, and cost-efficiency in their procurement process.

Comprehensive Cost and Pricing Analysis for 2015-2021 jeep renegade front left driver s fenders Sourcing

What Are the Key Cost Components in Sourcing Jeep Renegade Front Left Driver’s Fenders?

The cost structure for sourcing front left driver’s fenders for the 2015-2021 Jeep Renegade includes several critical components. The primary factors are materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The fender is typically made from high-quality steel or composite materials that ensure durability and compatibility with OEM specifications. Prices for raw materials can fluctuate based on market demand and global supply chain conditions.

-

Labor: Labor costs vary significantly by region, influenced by local wage standards and the expertise required for manufacturing. Countries with lower labor costs may offer more competitive pricing, but it’s essential to assess the impact on quality.

-

Manufacturing Overhead: This includes costs related to the facility, utilities, and equipment maintenance. Efficient production processes can reduce overhead, contributing to a more favorable pricing structure.

-

Tooling: Initial tooling costs for producing fenders can be substantial, especially for custom orders. However, these costs can be amortized over larger production runs, making bulk orders more cost-effective.

-

Quality Control (QC): Rigorous QC processes ensure that the fenders meet the required specifications and standards. While this may add to costs, it is essential for maintaining product integrity and minimizing returns.

-

Logistics: Shipping costs are influenced by the weight and size of the fenders, as well as the distance to the destination. Incoterms play a crucial role in determining who bears these costs and responsibilities.

-

Margin: Suppliers typically add a margin to cover operational costs and profit. This margin can vary based on the supplier’s market positioning and competition.

How Do Pricing Influencers Affect the Cost of Jeep Renegade Fenders?

Several factors influence the pricing of Jeep Renegade fenders, impacting international B2B buyers significantly:

-

Volume/MOQ: Suppliers often provide discounts for bulk purchases. Understanding the minimum order quantity (MOQ) can lead to better pricing arrangements.

-

Specifications/Customization: Custom features or specific color matching can increase costs. Buyers should weigh the benefits of customization against budget constraints.

-

Materials and Quality/Certifications: Higher-quality materials and certifications (like ISO standards) can increase the price. However, they also enhance durability and performance, offering long-term value.

-

Supplier Factors: The reputation, reliability, and location of the supplier can affect pricing. Establishing relationships with trusted suppliers can lead to more favorable terms.

-

Incoterms: Understanding the delivery terms (e.g., FOB, CIF) is crucial as they dictate who is responsible for shipping costs, insurance, and risk during transit.

What Tips Should Buyers Consider for Cost-Efficiency in Fender Sourcing?

To optimize cost-efficiency when sourcing fenders, international buyers should consider the following strategies:

Illustrative image related to 2015-2021 jeep renegade front left driver s fenders

-

Negotiation: Engage in discussions with suppliers to negotiate better prices, especially for larger orders. Building a rapport can lead to favorable terms.

-

Total Cost of Ownership: Assess not just the initial purchase price but also the total cost of ownership, which includes shipping, customs duties, and potential future repairs.

-

Market Research: Conduct thorough market research to identify competitive pricing and supplier options across different regions, including Africa, South America, the Middle East, and Europe.

-

Quality Assessment: Prioritize suppliers that provide high-quality products and reliable service, even if they are slightly more expensive. This can save costs associated with defective parts and returns.

-

Local Regulations: Be aware of local import regulations, tariffs, and taxes that can impact overall costs. Understanding these can help in budgeting and financial planning.

By considering these factors and strategies, B2B buyers can navigate the complexities of sourcing Jeep Renegade front left driver’s fenders more effectively, ensuring a balance between cost and quality.

Alternatives Analysis: Comparing 2015-2021 jeep renegade front left driver s fenders With Other Solutions

Introduction to Alternative Solutions for Jeep Renegade Fenders

When considering replacement options for the 2015-2021 Jeep Renegade front left driver side fenders, it is essential for B2B buyers to explore various alternatives. This analysis aims to provide insights into different solutions available in the market, evaluating their performance, cost, ease of implementation, maintenance, and best use cases. By comparing these options, businesses can make informed decisions that align with their operational needs.

Comparison Table

| Comparison Aspect | 2015-2021 Jeep Renegade Front Left Driver S Fenders | Aftermarket Fenders | Used OEM Fenders |

|---|---|---|---|

| Performance | High-quality, OEM fit ensures durability and aesthetics | Varies; may not fit perfectly | Good if in excellent condition, OEM quality |

| Cost | $176.99 | $100-$150 | $50-$100 |

| Ease of Implementation | Requires professional installation for best results | Often straightforward; may need adjustments | Varies; may require additional repairs |

| Maintenance | Minimal; designed for longevity | Depends on quality; may require frequent checks | Variable; depends on age and wear |

| Best Use Case | Ideal for businesses seeking reliable, long-term solutions | Suitable for cost-sensitive projects needing quick fixes | Best for budget-conscious buyers looking for OEM quality |

Detailed Breakdown of Alternatives

Aftermarket Fenders

Aftermarket fenders provide a cost-effective solution for businesses looking to replace damaged fenders without investing in OEM parts. Priced between $100 and $150, these parts are generally easier to source and may offer a quicker delivery. However, the fit and finish can vary significantly, and some aftermarket products may not align perfectly with the vehicle’s body, potentially leading to aesthetic discrepancies. This option is best for companies focused on tight budgets and quick repairs, but it may require additional adjustments during installation.

Used OEM Fenders

Used Original Equipment Manufacturer (OEM) fenders present another alternative, typically priced between $50 and $100, making them an attractive option for budget-conscious buyers. These parts are genuine and maintain the original quality and fit of the vehicle. However, the condition of used parts can vary widely, and there may be hidden damages or wear that could affect their performance. Businesses considering this option should ensure thorough inspections and consider the potential for additional repairs or painting costs. This solution is ideal for those who prioritize OEM quality but need to stay within a limited budget.

Conclusion: Choosing the Right Solution for Your Needs

In selecting the appropriate fender replacement for the 2015-2021 Jeep Renegade, B2B buyers should weigh factors such as cost, performance, and the specific requirements of their operations. For those needing a reliable and durable solution, the OEM fender is the best choice despite its higher cost. In contrast, cost-sensitive projects may benefit from aftermarket or used OEM options, provided that proper evaluations are conducted to ensure quality. Ultimately, understanding the trade-offs between price, quality, and performance will enable businesses to make informed decisions that best suit their operational demands.

Illustrative image related to 2015-2021 jeep renegade front left driver s fenders

Essential Technical Properties and Trade Terminology for 2015-2021 jeep renegade front left driver s fenders

What Are the Key Technical Properties of 2015-2021 Jeep Renegade Front Left Driver’s Fenders?

Understanding the essential technical properties of the front left driver’s fender for the 2015-2021 Jeep Renegade is critical for B2B buyers looking to source quality automotive parts. Below are key specifications that define the fender’s quality and compatibility.

1. Material Composition

The fender is typically made from high-quality steel or aluminum, designed to endure various environmental conditions and physical impacts. Steel offers strength and durability, while aluminum is lighter and resistant to corrosion. For B2B buyers, selecting the right material is crucial for ensuring the longevity and performance of the vehicle.

2. OEM Specifications

OEM (Original Equipment Manufacturer) specifications guarantee that the replacement fender meets the exact design and performance standards of the original part. The fender part number, such as CH1240284, ensures compatibility with specific Jeep Renegade models from 2015 to 2021. Adhering to OEM standards is essential for maintaining vehicle integrity and safety, making it a significant consideration for wholesalers and retailers.

3. Fitment Tolerance

Fitment tolerance refers to the allowable variation in the fender’s dimensions to ensure a precise fit on the vehicle. Tight tolerances minimize gaps and misalignments, which can affect both aesthetics and aerodynamics. For buyers, knowing the fitment tolerance helps in sourcing parts that will seamlessly integrate with existing vehicle structures, reducing installation time and potential return costs.

4. Surface Finish

Fenders may come in various finishes, such as primed or painted. A primed finish allows for easy customization, while a pre-painted option can save time for end-users. For B2B buyers, understanding the available finishes can influence inventory decisions, especially for markets that require quick turnaround times.

5. Weight

The weight of the fender is another critical property that can impact shipping costs and handling. Lighter materials can reduce freight expenses, which is a vital consideration for international shipping. Buyers should assess weight specifications to make informed decisions on logistics and inventory management.

6. Warranty and Durability Ratings

Most reputable manufacturers provide warranty terms that reflect the durability and expected lifespan of the fender. A longer warranty period often indicates higher quality and reliability. For B2B buyers, evaluating warranty options is essential to ensure customer satisfaction and minimize returns.

What Are Common Trade Terms Related to Jeep Renegade Fenders?

Navigating the automotive parts market involves familiarizing oneself with industry jargon. Below are common trade terms relevant to the procurement of 2015-2021 Jeep Renegade front left driver’s fenders.

Illustrative image related to 2015-2021 jeep renegade front left driver s fenders

1. OEM

As mentioned earlier, OEM refers to parts that are made by the vehicle’s original manufacturer. Using OEM parts ensures compatibility and quality, which is vital for maintaining the vehicle’s performance and safety.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers to manage inventory levels and cash flow effectively.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and terms for specific products. This is a vital process in B2B transactions, enabling buyers to compare costs and negotiate better deals.

4. Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms is essential for B2B buyers, especially when dealing with international suppliers.

5. Aftermarket

Aftermarket refers to parts that are made by companies other than the original manufacturer. While often less expensive, aftermarket parts may vary in quality, making it crucial for buyers to conduct thorough research.

6. Freight Class

Freight class is a classification system that helps determine shipping costs based on the type of goods being shipped. Understanding freight class can aid B2B buyers in optimizing shipping expenses and logistics planning.

Illustrative image related to 2015-2021 jeep renegade front left driver s fenders

In conclusion, a solid grasp of the technical properties and trade terminology related to Jeep Renegade front left driver’s fenders equips B2B buyers with the knowledge to make informed purchasing decisions, streamline operations, and enhance customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the 2015-2021 jeep renegade front left driver s fenders Sector

What Are the Current Market Dynamics and Key Trends for 2015-2021 Jeep Renegade Front Left Driver’s Fenders?

The market for replacement parts, particularly for vehicles like the 2015-2021 Jeep Renegade, is evolving rapidly due to several global drivers. Increasing vehicle ownership in emerging markets, particularly in Africa and South America, has led to heightened demand for affordable and durable automotive parts. Additionally, the trend toward vehicle customization and personalization is fueling interest in fender replacements, as buyers seek to enhance the aesthetic appeal of their vehicles.

Emerging B2B technologies are playing a pivotal role in sourcing trends. Digital platforms and online marketplaces are streamlining the procurement process, allowing international buyers to easily compare products, prices, and suppliers. This shift toward e-commerce in the automotive parts sector is particularly pronounced in Europe, where buyers are increasingly favoring online sourcing to reduce lead times and enhance transparency in pricing.

Furthermore, the market is witnessing a growing inclination towards original equipment manufacturer (OEM) parts, driven by the assurance of quality and fitment. Buyers in regions like Germany prioritize OEM specifications to ensure that replacements maintain the integrity of the vehicle. However, there is also a burgeoning market for aftermarket parts, which offer cost-effective alternatives without compromising performance. This duality in sourcing options presents opportunities for B2B buyers to strategically navigate their procurement decisions based on budget and quality preferences.

Illustrative image related to 2015-2021 jeep renegade front left driver s fenders

How Is Sustainability and Ethical Sourcing Reshaping the Automotive Parts Sector?

The environmental impact of automotive parts manufacturing is becoming a focal point for B2B buyers. As awareness of sustainability grows, international buyers are increasingly seeking suppliers who prioritize ethical sourcing and sustainable practices. For fenders, this includes the use of recycled materials and low-impact manufacturing processes that minimize carbon footprints.

The importance of ethical supply chains cannot be overstated, particularly for businesses looking to enhance their corporate social responsibility (CSR) profiles. Buyers are now looking for suppliers that provide transparency in their sourcing practices, ensuring that materials are sourced responsibly and labor conditions are ethical. Certifications such as ISO 14001 for environmental management systems are becoming critical in the procurement process, signaling a commitment to sustainability.

In the context of the 2015-2021 Jeep Renegade front left driver’s fenders, the use of eco-friendly materials and sustainable production methods can serve as a significant differentiator for suppliers. Buyers are encouraged to engage with manufacturers who demonstrate a commitment to sustainability, as this not only aligns with global environmental goals but also resonates with consumers increasingly concerned about the ecological impact of their purchases.

What Is the Historical Context of Sourcing Trends for Jeep Renegade Fenders?

The evolution of sourcing trends for Jeep Renegade fenders from 2015 to 2021 reflects broader shifts in the automotive industry. Initially, the focus was predominantly on OEM parts, as vehicle owners prioritized quality and compatibility. However, as aftermarket parts gained traction, driven by affordability and the rise of e-commerce platforms, buyers began to explore these alternatives more actively.

Illustrative image related to 2015-2021 jeep renegade front left driver s fenders

In recent years, the rise of digital platforms has transformed how businesses source parts. The ease of accessing a global marketplace has enabled international buyers to find competitive pricing and diverse product offerings, significantly impacting traditional sourcing methods. This shift has been particularly beneficial for regions with growing automotive markets, where cost-effective solutions are paramount.

This historical context underlines the importance of adaptability for suppliers in the automotive parts sector. Understanding these trends allows B2B buyers to make informed decisions that align with both current market dynamics and future sourcing needs. As the market continues to evolve, staying abreast of technological advancements and consumer preferences will be crucial for successful procurement strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of 2015-2021 jeep renegade front left driver s fenders

-

How do I ensure the right fit for a 2015-2021 Jeep Renegade front left driver fender?

To guarantee the correct fit for a 2015-2021 Jeep Renegade front left driver fender, it’s crucial to verify compatibility with OEM specifications. Check the part number, such as CH1240284, against your vehicle’s records. Additionally, consult with your supplier to confirm the fender matches your specific model year. Taking measurements or visual comparisons can further ensure that the fender will fit seamlessly during installation. -

What are the benefits of using OEM vs aftermarket fenders for Jeep Renegades?

OEM fenders are designed specifically for your vehicle, ensuring a perfect fit and finish, and often come with warranties. They are typically made from high-quality materials that match factory standards. On the other hand, aftermarket fenders may offer cost savings and a wider variety of styles, but quality can vary significantly. For B2B buyers, choosing OEM can enhance customer satisfaction and reduce returns due to fitment issues. -

What is the typical lead time for shipping Jeep Renegade fenders internationally?

Lead times for international shipping of Jeep Renegade fenders can vary based on the supplier, shipping method, and destination. Generally, standard shipping can take between 2 to 6 weeks, while expedited options may reduce this to as little as 5-10 days. It’s advisable to discuss timelines with your supplier and consider potential customs delays, especially for shipments to regions like Africa or South America. -

What payment terms should I expect when sourcing Jeep Renegade fenders?

Payment terms for sourcing Jeep Renegade fenders can vary widely among suppliers. Common arrangements include upfront payment, 30-day net terms, or payment upon delivery. For international transactions, using secure payment methods such as letters of credit or escrow services can mitigate risks. It’s essential to negotiate terms that align with your cash flow needs and to clarify any additional fees related to currency exchange or international transactions. -

How can I vet suppliers for Jeep Renegade fenders to ensure quality?

To vet suppliers effectively, start by checking their reputation through online reviews and industry forums. Request references from previous clients and assess their experience in handling automotive parts. Additionally, inquire about their quality assurance processes, certifications, and warranty policies. A reputable supplier should be transparent about their manufacturing processes and willing to provide samples for evaluation. -

Are there customization options available for Jeep Renegade fenders?

Many suppliers offer customization options for Jeep Renegade fenders, including color matching and specific finishes. Custom paint jobs or the addition of decals can enhance the fender’s aesthetics and align with branding needs. When discussing options with suppliers, ensure they have the capability to meet your specifications and confirm any additional costs or lead times associated with customization. -

What are the minimum order quantities (MOQs) for Jeep Renegade fenders?

Minimum order quantities for Jeep Renegade fenders can vary by supplier and depend on factors such as production capabilities and inventory levels. Some suppliers may have MOQs as low as 5-10 units, while others may require larger orders to achieve better pricing. Always clarify MOQs during negotiations to ensure they align with your business needs and budget constraints. -

What logistics considerations should I keep in mind when importing fenders?

When importing Jeep Renegade fenders, consider logistics factors such as shipping methods, customs regulations, and potential tariffs. Choosing a reliable freight forwarder can help navigate these complexities. Ensure that you have all necessary documentation, such as commercial invoices and packing lists, to facilitate smooth customs clearance. Additionally, account for delivery timelines and choose a shipping method that balances cost and speed based on your operational needs.

Top 4 2015-2021 Jeep Renegade Front Left Driver S Fenders Manufacturers & Suppliers List

1. Partify USA – Jeep Renegade Driver Side Fender

Domain: partifyusa.com

Registered: 2024 (1 years)

Introduction: {“product_name”: “Jeep Renegade Driver Side Fender”, “part_number”: “CH1240284”, “compatible_models”: “Jeep Renegade 2015-2023”, “price”: “$176.99”, “quality_options”: [{“type”: “Aftermarket”, “price”: “$176.99”, “description”: “Budget-friendly alternative for vehicle repairs, dependable fit and functionality.”}, {“type”: “CAPA”, “price”: “$303.99”, “description”: “Meets or exceeds OEM standards, …

2. Mopar – Fenders for 2021 Jeep Renegade

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Fenders for 2021 Jeep Renegade available for sale on eBay. Categories include various brands such as Action, AP CAR, Cequent, Unbranded, Crown Automotive, EvanFischer, Jeep, Keystone Automotive Operations, Link, LKQ, Martins, Mopar, Perfect Fit, Sherman, Tongyang, TRQ, and X AUTOHAUX. Placement options include Front Left, Rear Right, Upper, and Not Specified. Types available include Fender and Fen…

3. Jeep Renegade – Front Fenders

Domain: jeeprenegadeforum.com

Registered: 2014 (11 years)

Introduction: Front fenders for Jeep Renegade; replacement options include painted or primed fenders; sourcing suggestions include Car-Part.com for used auto parts; removal may involve hidden bolts; some fenders are plastic and can be removed with clips, while others are metal.

4. Zinad – Jeep Renegade Fender Trim Molding

Domain: zinad.sa

Introduction: Jeep Renegade 15-21 Fender Trim Molding Moulding

Strategic Sourcing Conclusion and Outlook for 2015-2021 jeep renegade front left driver s fenders

As we conclude our exploration of sourcing front left driver side fenders for the 2015-2021 Jeep Renegade, it is crucial to emphasize the importance of strategic sourcing in today’s competitive market. The consistent demand for high-quality, durable fenders underscores the necessity for international buyers to establish reliable partnerships with manufacturers and suppliers. Prioritizing OEM specifications and compatibility ensures optimal performance and longevity, which can significantly enhance customer satisfaction and brand loyalty.

In regions such as Africa, South America, the Middle East, and Europe, understanding local market dynamics and logistics is vital for successful procurement. Leveraging online platforms and aggregators can streamline the sourcing process, enabling buyers to find the right parts efficiently and at competitive prices.

Looking ahead, the automotive parts market will likely see continued growth, driven by the increasing need for reliable replacement components. B2B buyers are encouraged to stay informed about market trends and to seek out innovative sourcing strategies that can provide a competitive edge. Embrace the opportunity to enhance your supply chain by investing in quality parts and building strong supplier relationships today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to 2015-2021 jeep renegade front left driver s fenders

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.