Everything You Need to Know About Metal Conveyor Belts Stainless Steel Sourcing in 2025

Introduction: Navigating the Global Market for metal conveyor belts stainless steel

Navigating the global market for metal conveyor belts stainless steel can be daunting for international B2B buyers, especially when considering the diverse applications and performance standards required across various industries. One of the key challenges faced by procurement professionals is sourcing reliable and high-quality conveyor solutions that align with their specific operational needs, from food processing to automotive manufacturing. This guide aims to equip buyers with essential insights into the types of stainless steel conveyor belts available, their respective applications, and the factors influencing cost.

In the following sections, we will delve into the different styles of metal conveyor belts, including Flat-Flex®, Eye-Flex®, and Compact-Grid™, highlighting their unique features and suitability for various environments. Additionally, we will explore best practices for vetting suppliers to ensure quality and reliability, offering tips on how to assess their manufacturing capabilities and customer service responsiveness.

With a focus on empowering buyers from regions such as Africa, South America, the Middle East, and Europe—including emerging markets like Vietnam and Brazil—this comprehensive guide is designed to facilitate informed purchasing decisions. By understanding the nuances of metal conveyor belts and the global supply chain, businesses can optimize their operations, enhance productivity, and ultimately, drive growth in a competitive marketplace.

Understanding metal conveyor belts stainless steel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Eye-Flex® | Flexible design with open mesh for airflow | Food processing, baking, and packaging | Pros: Excellent hygiene, easy to clean. Cons: May require specific frame design. |

| Flat-Flex® | Flat surface with high open area for drainage | Freezing, cooling, and drying applications | Pros: Versatile, reliable, and long-lasting. Cons: Limited load capacity compared to heavy-duty belts. |

| Compact-Grid™ | Compact design with minimal surface area | Pharmaceutical, cosmetic, and electronics | Pros: Efficient use of space, easy handling. Cons: Higher upfront cost. |

| Versa-Link® | Modular link design for easy maintenance | Automotive and heavy manufacturing | Pros: Quick repairs, customizable lengths. Cons: Complexity in installation. |

| Ladder-Track™ | Ladder-like structure for high-temperature use | Oven and furnace applications | Pros: High thermal resistance, durable. Cons: Limited to specific applications. |

What are the characteristics and suitability of Eye-Flex® conveyor belts?

Eye-Flex® conveyor belts are designed with a unique flexible mesh structure that allows for optimal airflow and drainage, making them ideal for applications in the food processing industry. Their open design enhances hygiene standards by facilitating easy cleaning and minimizing product buildup. B2B buyers should consider the specific frame requirements needed for installation, as the flexibility of these belts may necessitate custom configurations to ensure proper functioning.

How does Flat-Flex® cater to various industrial needs?

Flat-Flex® conveyor belts feature a flat surface that maximizes open area, providing efficient drainage and airflow in processes like freezing, cooling, and drying. Their versatility makes them suitable for a wide range of applications across different industries. Buyers should weigh the benefits of reliability and longevity against the potential limitation in load capacity, especially when transporting heavier materials.

What advantages does Compact-Grid™ offer for specialized applications?

The Compact-Grid™ belt is characterized by its compact design, which allows for efficient use of space while maintaining high strength. This type is particularly favored in the pharmaceutical and cosmetics industries, where product integrity and handling are crucial. B2B buyers should assess the higher upfront costs against the long-term benefits of durability and reduced maintenance needs.

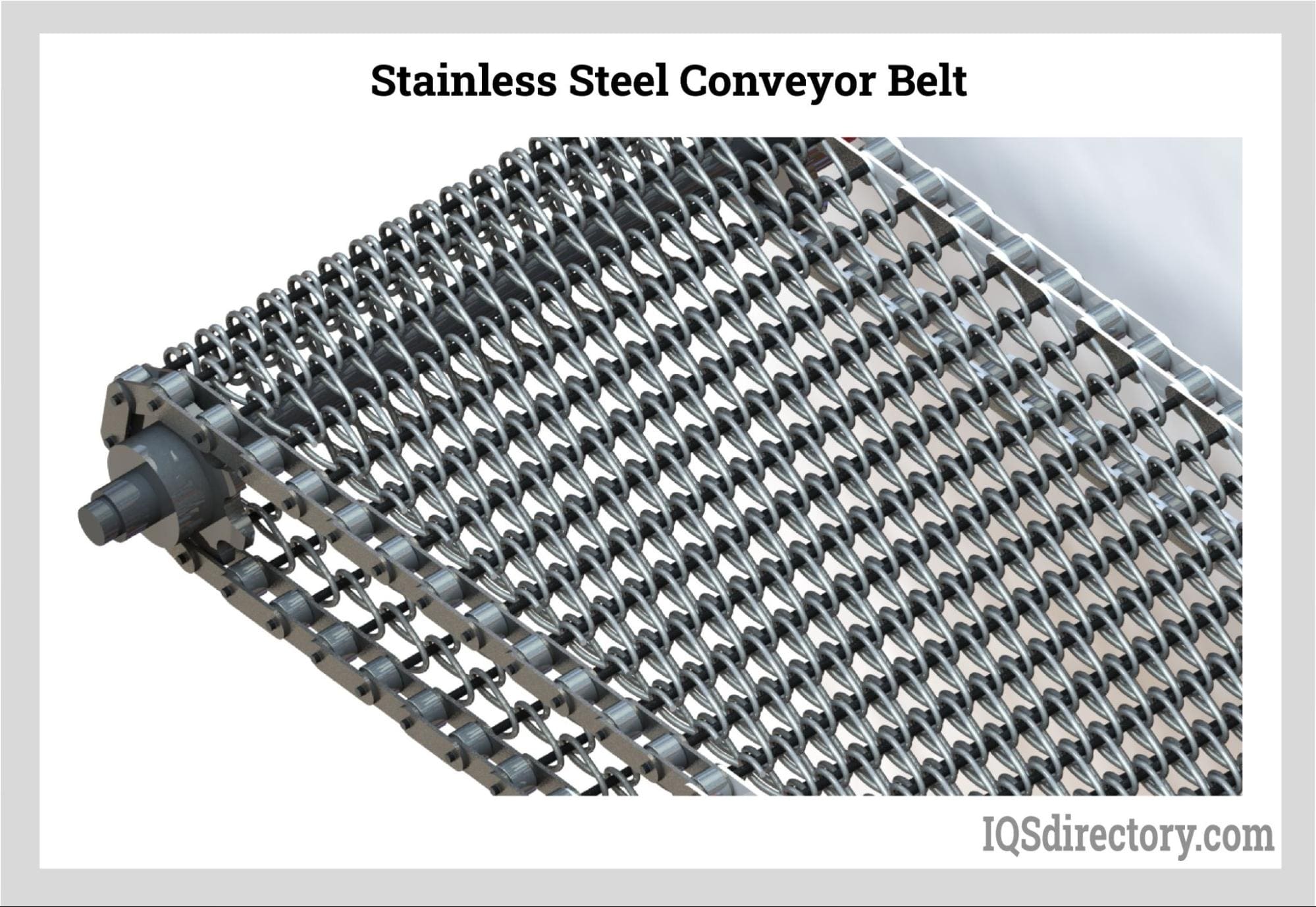

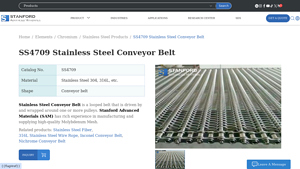

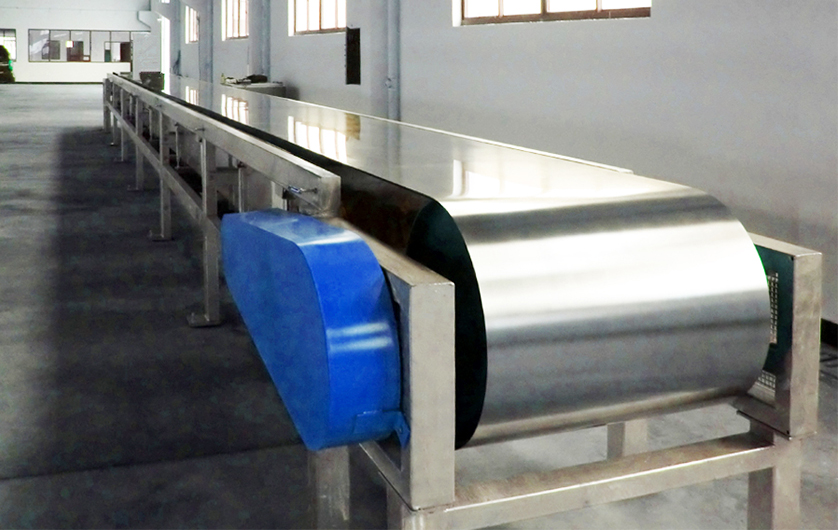

Illustrative image related to metal conveyor belts stainless steel

Why is Versa-Link® a popular choice for automotive manufacturing?

Versa-Link® conveyor belts utilize a modular link design that allows for easy maintenance and quick repairs, making them a favored choice in automotive and heavy manufacturing sectors. Their customizable lengths cater to various production line requirements, enhancing operational efficiency. Buyers should consider the complexity of installation as a potential drawback, requiring skilled labor for optimal setup.

In what scenarios is Ladder-Track™ the best option?

Ladder-Track™ conveyor belts are specifically designed for high-temperature applications, such as in ovens and furnaces. Their ladder-like structure provides excellent durability and thermal resistance, making them ideal for transporting products through extreme conditions. B2B buyers should note that while these belts excel in specific applications, their use may be limited outside high-temperature environments, necessitating careful consideration of operational needs.

Key Industrial Applications of metal conveyor belts stainless steel

| Industry/Sector | Specific Application of metal conveyor belts stainless steel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Transporting food products through cooking and cooling processes | Ensures hygiene and compliance with food safety regulations | Look for belts with high open area for drainage and easy cleaning |

| Pharmaceutical | Moving pharmaceutical products in sterile environments | Reduces contamination risk while maintaining product integrity | Ensure compliance with FDA regulations and choose corrosion-resistant materials |

| Automotive | Assembly line for vehicle components | Enhances efficiency and reduces downtime in production | Consider belts with high tensile strength and resistance to oil and chemicals |

| Electronics | Transporting electronic components during assembly | Minimizes static build-up and ensures precision handling | Opt for belts that can handle sensitive components without damage |

| Environmental Services | Conveying recyclables and waste materials | Improves sorting efficiency and reduces operational costs | Assess durability and resistance to harsh materials and conditions |

How Are Metal Conveyor Belts Used in the Food and Beverage Industry?

In the food and beverage sector, stainless steel metal conveyor belts are essential for transporting products through various stages of processing, including cooking, cooling, and packaging. These belts are designed to meet stringent hygiene standards, preventing contamination while allowing for easy cleaning. International buyers should prioritize sourcing belts with high open areas to facilitate drainage and drying, which is crucial for maintaining food safety in hot and humid climates typical in regions like Africa and South America.

Illustrative image related to metal conveyor belts stainless steel

What Role Do Metal Conveyor Belts Play in the Pharmaceutical Sector?

Metal conveyor belts are vital in the pharmaceutical industry, where they transport products in sterile environments. These belts help minimize contamination risks, ensuring that pharmaceuticals maintain their integrity throughout production. Buyers in this sector must ensure that the belts comply with FDA regulations and are made of corrosion-resistant materials. This is particularly important in markets such as the Middle East and Europe, where regulatory compliance is strictly enforced.

How Are Metal Conveyor Belts Utilized in the Automotive Industry?

In automotive manufacturing, stainless steel conveyor belts are used to transport vehicle components along assembly lines. Their robust design enhances operational efficiency by reducing downtime caused by equipment failure. When sourcing these belts, businesses should consider tensile strength and resistance to oils and chemicals, which are common in automotive environments. Buyers from regions like Brazil and Vietnam should also evaluate local suppliers’ capabilities to ensure timely delivery and support.

What Are the Benefits of Metal Conveyor Belts in Electronics Manufacturing?

Metal conveyor belts are crucial in the electronics industry for transporting sensitive components during assembly. These belts are engineered to minimize static build-up and ensure precise handling of delicate parts. International buyers should look for options that provide excellent durability without compromising the safety of the products being transported. Sourcing from manufacturers that understand the specific needs of electronics assembly can lead to significant operational efficiencies.

How Do Metal Conveyor Belts Support Environmental Services?

In environmental services, stainless steel metal conveyor belts facilitate the efficient movement of recyclables and waste materials. These belts improve sorting processes, thereby reducing operational costs and enhancing recycling rates. When sourcing for this application, businesses should assess the belts’ durability and resistance to harsh materials, especially in regions with varied waste management practices like Africa and South America. Ensuring that the belts can withstand challenging conditions is vital for maintaining operational effectiveness.

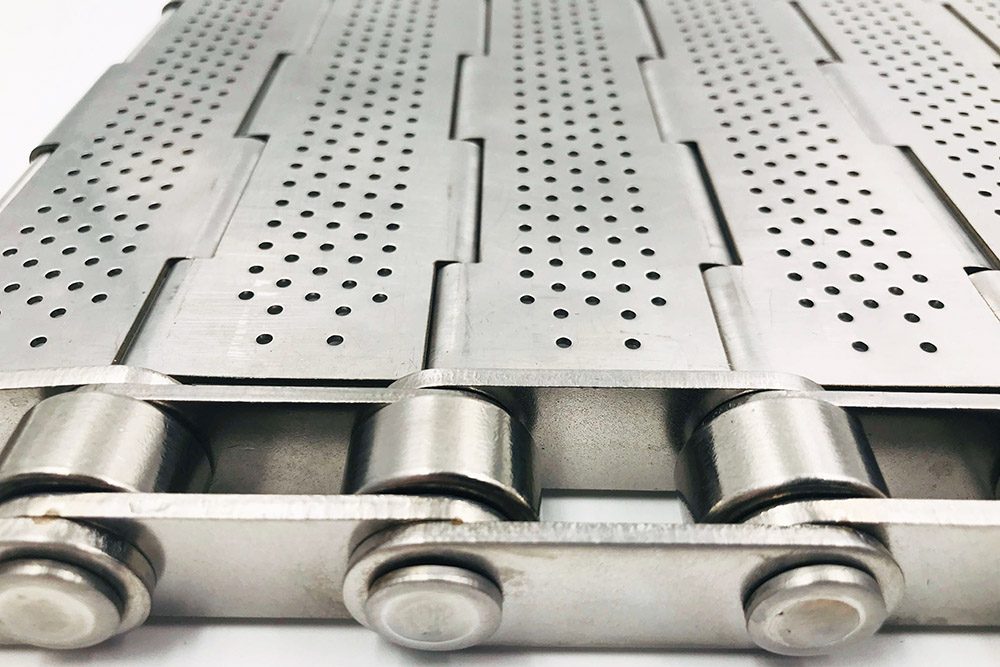

Illustrative image related to metal conveyor belts stainless steel

3 Common User Pain Points for ‘metal conveyor belts stainless steel’ & Their Solutions

Scenario 1: High Maintenance Costs Due to Wear and Tear

The Problem: B2B buyers often face escalating maintenance costs associated with metal conveyor belts, particularly in demanding environments such as food processing or heavy manufacturing. Over time, these belts can wear down, leading to frequent repairs or replacements. This not only disrupts production schedules but also strains budgets, especially for companies operating in regions with limited access to replacement parts or specialized maintenance services.

The Solution: To mitigate wear and tear, it’s crucial to select the right type of stainless steel conveyor belt tailored to the specific application. For instance, opting for high-grade materials, such as T316 stainless steel, can enhance corrosion resistance and extend the lifespan of the belt in harsh environments. Additionally, implementing a proactive maintenance program that includes regular inspections, cleaning, and lubrication can significantly reduce downtime and repair costs. It’s advisable to work closely with manufacturers to understand the specific tolerances and operational limits of the belts, ensuring they are used within those parameters to maximize durability.

Scenario 2: Hygiene Compliance Challenges in Food Processing

The Problem: B2B buyers in the food and beverage sector often struggle with maintaining hygiene standards when using metal conveyor belts. Contaminated surfaces can lead to product recalls and brand damage, especially in markets with stringent health regulations. The challenge is further compounded when belts are difficult to clean or harbor bacteria in their design.

The Solution: Selecting a stainless steel conveyor belt designed for hygienic applications is essential. Look for belts with open mesh designs that minimize surface area and allow for better cleaning and drainage. Additionally, consider models with smooth edges and minimal crevices, which facilitate easier sanitation. Regular training for staff on proper cleaning techniques and adherence to hygiene protocols can also bolster compliance. Partnering with manufacturers that provide detailed cleaning and maintenance guidelines can help ensure that these belts meet the required standards and improve overall product safety.

Illustrative image related to metal conveyor belts stainless steel

Scenario 3: Limited Customization Options Affecting Production Efficiency

The Problem: Many buyers encounter limitations in the customization of metal conveyor belts, which can hinder the efficiency of their operations. Standard belt designs may not accommodate specific product sizes or shapes, leading to bottlenecks in production lines or inefficient handling of materials. This challenge is particularly relevant in industries like automotive or electronics, where precision and adaptability are paramount.

The Solution: To address customization issues, it’s important to collaborate with manufacturers that offer a wide range of customizable options. When sourcing stainless steel conveyor belts, buyers should inquire about the ability to tailor specifications such as width, pitch, and surface treatments. Advanced manufacturers often utilize modular designs that allow for easy modifications or upgrades as production needs evolve. Engaging in discussions about future scalability during the procurement process can help ensure that the chosen belts will remain efficient as production demands change, thus enhancing overall operational productivity.

Strategic Material Selection Guide for metal conveyor belts stainless steel

When selecting materials for metal conveyor belts, particularly stainless steel options, it’s crucial to understand the specific properties, advantages, and limitations of each material. This knowledge empowers B2B buyers to make informed decisions that align with their operational needs and compliance requirements.

What Are the Key Properties of Stainless Steel in Conveyor Belts?

1. Stainless Steel Type 304

Type 304 stainless steel is one of the most commonly used materials for metal conveyor belts. It offers excellent corrosion resistance and is suitable for a wide range of temperatures, typically up to 870°C (1600°F) in intermittent service. This material is non-magnetic and has good weldability, making it versatile for various applications.

Pros:

– High corrosion resistance, ideal for food and beverage applications.

– Cost-effective and widely available.

– Easy to fabricate and weld.

Cons:

– Less resistant to chloride environments compared to Type 316.

– Moderate strength at high temperatures.

Impact on Application:

Type 304 is suitable for environments where exposure to moisture and cleaning agents is common, such as food processing plants.

Considerations for International Buyers:

Compliance with food safety standards (e.g., FDA, EU regulations) is essential. Buyers should ensure that Type 304 meets local standards such as ASTM or DIN.

2. Stainless Steel Type 316

Type 316 stainless steel is often chosen for its superior resistance to corrosion, particularly in chloride environments. It can withstand temperatures up to 870°C (1600°F) and is known for its durability and strength.

Illustrative image related to metal conveyor belts stainless steel

Pros:

– Excellent corrosion resistance, particularly against saltwater and acidic environments.

– Longer lifespan due to enhanced durability.

Cons:

– Higher cost compared to Type 304.

– More challenging to machine and weld.

Impact on Application:

Ideal for marine environments or chemical processing where exposure to harsh substances is prevalent.

Considerations for International Buyers:

Ensure compliance with international standards for chemical processing and marine applications. Buyers should verify certifications that align with local regulations.

3. Stainless Steel Type 430

Type 430 is a ferritic stainless steel that offers moderate corrosion resistance and is often used in less demanding applications. It is magnetic and generally has lower strength than austenitic grades like 304 and 316.

Pros:

– Cost-effective for applications with lower corrosion risk.

– Good formability and surface finish.

Cons:

– Limited corrosion resistance compared to austenitic grades.

– Not suitable for high-temperature applications.

Impact on Application:

Best suited for indoor applications where exposure to moisture is minimal, such as packaging or light-duty handling.

Considerations for International Buyers:

Buyers should assess the application environment to ensure Type 430 meets their durability and compliance needs, particularly in regions with varying humidity levels.

Summary Table of Material Selection for Metal Conveyor Belts

| Material | Typical Use Case for Metal Conveyor Belts Stainless Steel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Type 304 | Food processing, general manufacturing | High corrosion resistance | Less effective in chloride environments | Medium |

| Type 316 | Marine, chemical processing | Superior corrosion resistance | Higher cost and more difficult to machine | High |

| Type 430 | Indoor packaging, light-duty applications | Cost-effective and good formability | Limited corrosion resistance | Low |

By understanding the properties, advantages, and limitations of these stainless steel types, B2B buyers can strategically select the most suitable material for their conveyor belt applications, ensuring compliance with international standards and optimizing operational efficiency.

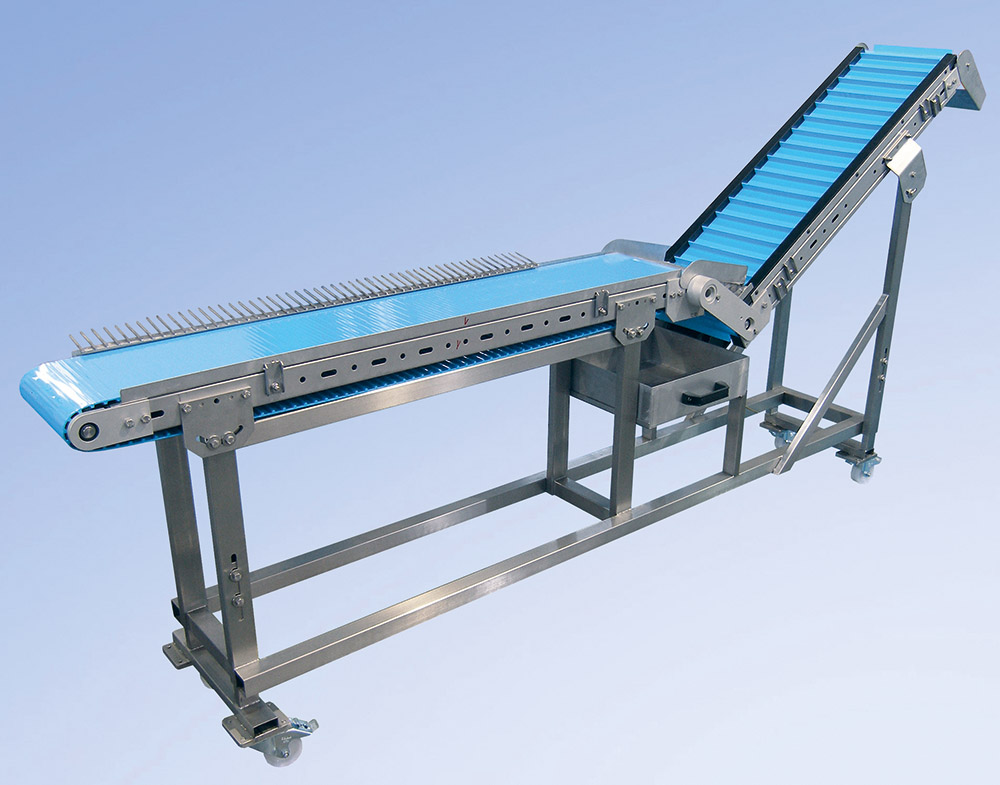

Illustrative image related to metal conveyor belts stainless steel

In-depth Look: Manufacturing Processes and Quality Assurance for metal conveyor belts stainless steel

What Are the Key Stages in the Manufacturing Process of Stainless Steel Metal Conveyor Belts?

The manufacturing process of stainless steel metal conveyor belts involves several critical stages, each essential for ensuring the final product meets the required specifications and performance standards. These stages include material preparation, forming, assembly, and finishing.

Material Preparation

The first step in manufacturing stainless steel conveyor belts is the preparation of raw materials. High-quality stainless steel, known for its corrosion resistance and strength, is sourced according to specific grades, such as T303 and T316. The raw materials undergo rigorous inspection to ensure they meet industry standards, which is crucial for applications in sectors like food processing and pharmaceuticals. Suppliers often provide Material Test Reports (MTRs) to verify the quality of the steel.

Forming Techniques

After preparation, the steel is processed using various forming techniques. Common methods include welding, bending, and stamping. For instance, flat wire conveyor belts are typically manufactured by forming flat wire into a specific pattern. Advanced machinery and computer-controlled systems are employed to ensure precision in dimensions and tolerances. Techniques like laser cutting may also be used to enhance accuracy and efficiency.

Illustrative image related to metal conveyor belts stainless steel

Assembly of Components

The assembly phase involves combining the formed components into a complete conveyor belt system. This may include integrating various attachments such as side guards, cleats, or pin-up attachments, which help in transporting products efficiently and safely. The assembly process is critical, as it affects the belt’s overall functionality and durability. Automated assembly lines can increase productivity while maintaining high standards of quality.

Finishing Processes

Finishing processes are vital for enhancing the durability and aesthetic appeal of the conveyor belts. These may include surface treatments such as passivation, which removes free iron and enhances corrosion resistance. Polishing is often employed to achieve a smooth surface, which is especially important in hygienic applications. The finishing stage also includes final inspections to ensure that the belts meet the specified standards before they are packaged for delivery.

What Quality Assurance Measures Are Essential for Metal Conveyor Belts?

Quality assurance (QA) is a critical aspect of the manufacturing process for stainless steel conveyor belts. It involves adhering to international standards and implementing rigorous testing protocols at various stages of production.

International Standards and Certifications

To ensure high quality, many manufacturers comply with international standards such as ISO 9001, which focuses on quality management systems. Specific industry certifications, such as CE marking for European markets, also indicate compliance with health, safety, and environmental protection standards. For B2B buyers, understanding these certifications is crucial as they reflect a manufacturer’s commitment to quality.

Quality Control Checkpoints

Quality control (QC) should be integrated throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Ongoing inspections during production help identify and rectify issues early. This may involve monitoring tolerances, dimensions, and weld quality.

- Final Quality Control (FQC): The finished products undergo comprehensive testing before shipping. This may include load testing, visual inspections, and performance evaluations.

Common Testing Methods

Manufacturers employ various testing methods to ensure product reliability. Common tests include tensile strength testing, fatigue testing, and corrosion resistance testing. For B2B buyers, understanding these methods can provide insights into the durability and performance of the conveyor belts.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential for ensuring product reliability.

Conducting Audits and Inspections

One effective way to verify QC practices is by conducting supplier audits. These audits can assess the supplier’s adherence to quality standards and their manufacturing capabilities. Buyers may also engage third-party inspection services to conduct independent assessments of the supplier’s facilities and processes.

Illustrative image related to metal conveyor belts stainless steel

Requesting Quality Reports

Buyers should request detailed quality reports that outline the QC measures implemented by the manufacturer. These reports can include inspection results, testing data, and compliance certifications. Regular updates on quality metrics can also help buyers gauge the supplier’s commitment to maintaining high standards.

Understanding Quality Control Nuances for International Trade

It’s important for B2B buyers to be aware of the nuances in quality control that may vary by region. For example, different countries may have specific regulatory requirements for materials used in food processing or pharmaceutical applications. Understanding these differences can help buyers select suppliers that not only meet local standards but also provide products suitable for their specific market needs.

Conclusion: The Importance of Manufacturing Processes and Quality Assurance in B2B Metal Conveyor Belt Procurement

In conclusion, the manufacturing processes and quality assurance measures for stainless steel metal conveyor belts are crucial elements that B2B buyers must consider. A clear understanding of the stages involved in manufacturing, coupled with robust quality control practices, can significantly impact the performance and reliability of the conveyor systems. By prioritizing suppliers with established QA protocols and relevant certifications, businesses can enhance their operational efficiency and ensure compliance with international standards. This approach is vital for companies looking to invest in durable, high-quality conveyor solutions that meet their specific industry requirements.

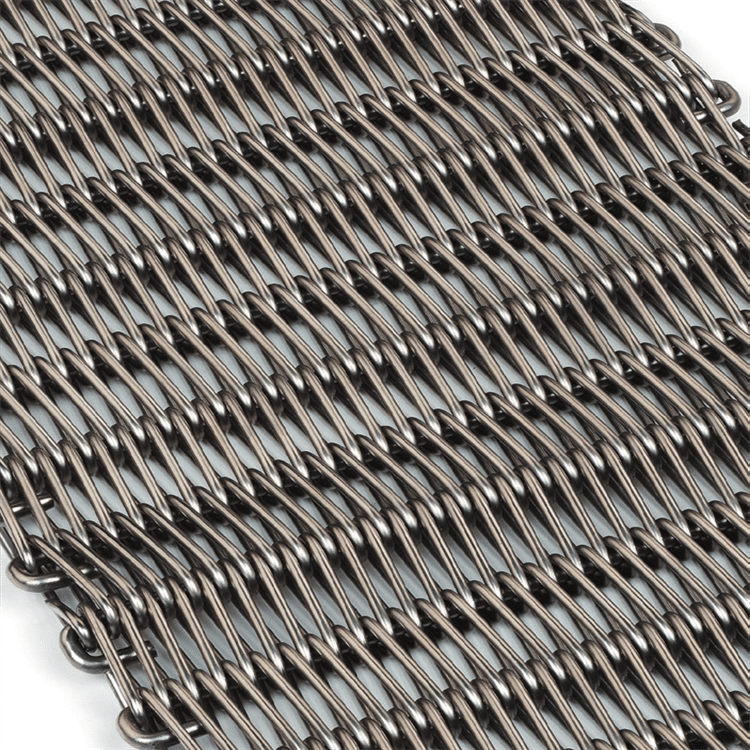

Illustrative image related to metal conveyor belts stainless steel

Practical Sourcing Guide: A Step-by-Step Checklist for ‘metal conveyor belts stainless steel’

To assist B2B buyers in sourcing stainless steel metal conveyor belts effectively, this guide outlines a practical step-by-step checklist. By following these steps, buyers can ensure they make informed decisions that align with their operational needs and quality standards.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is vital for ensuring the conveyor belt meets your operational requirements. Consider factors such as belt width, load capacity, temperature resistance, and environmental conditions. Specific applications, like food processing or pharmaceuticals, may require belts that comply with hygiene standards or have specific certifications.

Step 2: Research Market Trends and Innovations

Staying informed about current market trends and innovations can help you select a conveyor belt that offers the best performance and efficiency. Review industry reports, attend trade shows, and consult with industry experts to understand the latest advancements in conveyor technology. This knowledge can influence your purchasing decisions and ensure you are investing in cutting-edge solutions.

Illustrative image related to metal conveyor belts stainless steel

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s essential to thoroughly vet potential suppliers. Request detailed company profiles, product catalogs, and case studies that showcase their expertise and success in your specific industry. Additionally, check for references from buyers in similar regions or sectors to gauge their reliability and service quality.

- Key Considerations:

- Look for suppliers with a strong track record in your industry.

- Assess their ability to meet your technical specifications consistently.

Step 4: Request Samples and Prototypes

Obtaining samples or prototypes is a crucial step to ensure the product meets your expectations. Evaluate the quality, durability, and functionality of the conveyor belts in real-world scenarios. Testing samples can also help you assess compatibility with your existing equipment and operational processes.

Step 5: Verify Supplier Certifications and Compliance

Ensure that your selected suppliers hold necessary certifications and comply with industry standards. This is particularly important in regulated industries, such as food and beverage or pharmaceuticals, where safety and hygiene are paramount. Certifications may include ISO standards, FDA approvals, or specific industry certifications relevant to your operations.

Illustrative image related to metal conveyor belts stainless steel

Step 6: Negotiate Terms and Conditions

Once you’ve identified a suitable supplier, engage in negotiations regarding pricing, delivery schedules, and payment terms. Clearly outline warranty and support conditions to avoid misunderstandings later. A well-negotiated contract can safeguard your investment and ensure a smooth procurement process.

Step 7: Plan for Maintenance and Support

Consider the long-term maintenance needs of your conveyor belts. Inquire about the supplier’s support services, including installation guidance and ongoing maintenance assistance. A proactive approach to maintenance can extend the lifespan of your equipment and improve overall operational efficiency.

By following this checklist, B2B buyers can navigate the sourcing process for stainless steel metal conveyor belts with confidence, ensuring they select the right products that meet their business needs.

Comprehensive Cost and Pricing Analysis for metal conveyor belts stainless steel Sourcing

What Are the Key Cost Components in Sourcing Metal Conveyor Belts Made of Stainless Steel?

When sourcing stainless steel metal conveyor belts, understanding the underlying cost structure is crucial for effective budgeting and decision-making. The primary cost components include:

-

Materials: The type and quality of stainless steel significantly impact the cost. Higher grades (like T316) offer better corrosion resistance but come at a premium. Additionally, other materials used for components, such as bearings or drive systems, contribute to the overall material costs.

-

Labor: Labor costs vary by region and depend on the complexity of manufacturing processes. Skilled labor for precision engineering and assembly can increase costs, particularly in countries with higher wage standards.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, rent, and equipment maintenance. Efficient production processes can help mitigate these costs.

-

Tooling: Initial tooling costs can be significant, particularly for custom designs. Buyers should consider whether the supplier’s tooling is amortized over high production volumes or if they will incur these costs upfront.

-

Quality Control (QC): Rigorous quality assurance processes ensure that the belts meet industry standards, particularly for sectors like food and pharmaceuticals. Investing in QC can reduce long-term costs by minimizing defects and product returns.

-

Logistics: Shipping costs can vary widely based on distance, weight, and mode of transportation. For international buyers, understanding Incoterms is essential to clarify responsibilities for shipping, insurance, and tariffs.

-

Margin: Suppliers will add a profit margin to their costs, which can fluctuate based on competition, market demand, and the supplier’s positioning.

How Do Price Influencers Affect the Cost of Stainless Steel Conveyor Belts?

Several factors can influence the pricing of stainless steel conveyor belts:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often qualify for volume discounts. Buyers should evaluate their needs carefully, as ordering in bulk can reduce the per-unit cost.

-

Specifications and Customization: Customization can lead to higher costs due to additional engineering, tooling, and material requirements. Standard products are generally more cost-effective.

-

Material Quality and Certifications: Certifications (like FDA or ISO) can increase costs but are essential for industries with strict compliance requirements. The quality of materials impacts durability and longevity, influencing the total cost of ownership.

-

Supplier Factors: The reputation, reliability, and geographical location of suppliers can affect pricing. Established suppliers with a good track record may charge a premium but offer better service and quality assurance.

-

Incoterms: Understanding Incoterms is vital for international transactions. They dictate the responsibilities of buyers and sellers regarding shipping costs, insurance, and customs clearance, which can significantly impact total costs.

What Tips Can Help Buyers Negotiate Better Prices for Metal Conveyor Belts?

To maximize value and minimize costs when sourcing stainless steel conveyor belts, consider the following strategies:

-

Negotiate Terms: Always negotiate pricing and payment terms. Suppliers may be open to offering discounts for early payment or larger orders.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider factors like maintenance, longevity, and efficiency. A higher upfront cost may lead to savings in the long run.

-

Research Market Trends: Stay informed about market conditions and material prices. Understanding trends can provide leverage in negotiations and help identify the right time to purchase.

-

Supplier Diversification: Engaging multiple suppliers can foster competition and lead to better pricing. It also mitigates risks associated with reliance on a single source.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better service and pricing. Trust and communication can facilitate smoother negotiations and more favorable terms.

Conclusion

While sourcing stainless steel metal conveyor belts involves various cost components and price influencers, a strategic approach can lead to significant savings. By understanding the intricacies of pricing and implementing smart negotiation tactics, buyers can optimize their purchasing decisions and enhance their operational efficiency. Always remember that prices can vary widely based on specifications and market conditions; therefore, it’s prudent to seek multiple quotations and conduct thorough due diligence before finalizing contracts.

Alternatives Analysis: Comparing metal conveyor belts stainless steel With Other Solutions

Exploring Alternatives to Metal Conveyor Belts Made of Stainless Steel

In the competitive landscape of industrial manufacturing and logistics, selecting the right conveyor solution is crucial for operational efficiency. Metal conveyor belts, particularly those made of stainless steel, are widely recognized for their durability and performance. However, other alternatives exist that may better suit specific operational needs, depending on factors such as cost, maintenance, and application requirements. Below is a comparative analysis of stainless steel metal conveyor belts against other viable solutions.

| Comparison Aspect | Metal Conveyor Belts Stainless Steel | Plastic Modular Belts | Fabric Conveyor Belts |

|---|---|---|---|

| Performance | High strength, temperature resistant | Good flexibility, lower friction | Moderate strength, limited temperature resistance |

| Cost | Higher upfront cost | Mid-range cost | Lower upfront cost |

| Ease of Implementation | Requires specialized installation | Generally easy to install | Simple installation |

| Maintenance | Requires regular cleaning, robust | Low maintenance, easy to clean | Moderate maintenance, less durable |

| Best Use Case | Heavy-duty applications, high hygiene | Food processing, packaging | Light to medium-duty applications |

What Are the Benefits and Drawbacks of Plastic Modular Belts?

Plastic modular belts are constructed from interlocking plastic modules, providing flexibility and ease of maintenance. These belts are particularly effective in food processing and packaging applications where hygiene is paramount. Their lower friction surface reduces wear on products, allowing smoother transportation. However, while they offer a lower initial investment, their long-term durability may not match that of stainless steel belts, especially under heavy loads or extreme temperatures.

How Do Fabric Conveyor Belts Compare?

Fabric conveyor belts are made of woven textile materials and offer a cost-effective solution for light to medium-duty applications. These belts are lightweight and easy to install, making them suitable for applications where heavy loads are not a concern. While fabric belts are generally less expensive and easier to maintain, they may not withstand high temperatures or abrasive materials as effectively as stainless steel options. Their lifespan can also be shorter, making them a less attractive option for industries requiring high durability.

Conclusion: How Can Buyers Choose the Right Conveyor Solution?

When selecting a conveyor solution, B2B buyers should assess their specific operational needs, including load requirements, environmental conditions, and budget constraints. Metal conveyor belts made of stainless steel excel in durability and performance, making them ideal for heavy-duty and high-hygiene applications. Conversely, plastic modular and fabric conveyor belts offer cost-effective alternatives for lighter applications or those requiring flexibility and ease of maintenance. A thorough evaluation of these factors will enable buyers to make an informed decision that aligns with their operational objectives and enhances overall efficiency.

Essential Technical Properties and Trade Terminology for metal conveyor belts stainless steel

What Are the Key Technical Properties of Stainless Steel Metal Conveyor Belts?

Understanding the technical specifications of stainless steel metal conveyor belts is essential for B2B buyers to make informed purchasing decisions. Here are critical specifications to consider:

-

Material Grade

Stainless steel conveyor belts are typically made from grades such as T303 and T316. T316 offers superior corrosion resistance, making it ideal for food processing and chemical handling applications. Choosing the right grade ensures longevity and reliability, reducing maintenance costs. -

Belt Width and Thickness

These specifications determine the load capacity and compatibility with existing systems. A belt’s width can range from a few inches to several feet, while thickness impacts durability. For high-load applications, selecting the appropriate width and thickness is crucial to prevent premature wear and tear. -

Open Area Percentage

This refers to the proportion of the belt that is open space, which is critical for applications requiring airflow or drainage. A higher open area percentage enhances efficiency in cooling or drying processes and reduces material buildup. Buyers should assess this feature based on specific operational needs. -

Rod Diameter and Picket Dimensions

The rod diameter affects the strength and flexibility of the belt. Picket dimensions define the belt’s mesh structure, impacting the type of products that can be conveyed. For instance, smaller picket dimensions might be suitable for delicate items, while larger dimensions are better for heavy-duty applications. -

Tolerance Levels

Tolerance indicates the allowable variation in dimensions during manufacturing. High tolerance levels ensure better fit and function within conveyor systems, minimizing the risk of operational disruptions. In industries where precision is vital, such as pharmaceuticals, adhering to strict tolerances can significantly enhance production efficiency. -

Maximum Allowable Tension

This specification defines how much tension the belt can withstand before failure. It is critical for maintaining the belt’s integrity during operation. Understanding the maximum allowable tension is essential for preventing slippage and extending the life of the conveyor system.

What Are Common Trade Terminology and Their Importance in the Conveyor Belt Industry?

Familiarity with industry jargon can streamline communication and decision-making in B2B transactions. Here are some commonly used terms:

Illustrative image related to metal conveyor belts stainless steel

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reliable sources for conveyor belts that are compatible with their existing machinery. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is vital for budgeting and inventory planning. Buyers should negotiate MOQs based on their specific operational needs to avoid overstocking or stockouts. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers. This document is essential for comparing options and ensuring that the procurement process is transparent and competitive. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risks, and obligations, which is crucial when importing conveyor belts from manufacturers in different countries. -

Lead Time

This refers to the time taken from placing an order to the delivery of the product. Understanding lead times is essential for production scheduling and ensuring that operational timelines are met. -

Hygienic Design

This term refers to the design features that facilitate easy cleaning and sanitation of conveyor belts, especially in food processing. Buyers in sectors that prioritize hygiene should consider this aspect to comply with regulatory standards and maintain product safety.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions, ensuring they select the right stainless steel metal conveyor belts for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the metal conveyor belts stainless steel Sector

What Are the Key Trends and Dynamics Influencing the Metal Conveyor Belts Stainless Steel Market?

The global market for stainless steel metal conveyor belts is experiencing robust growth, driven by the increasing demand for automation and efficiency across various industries. Key sectors such as food and beverage, pharmaceuticals, and automotive are leading the charge, necessitating reliable and durable conveyor systems. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe seek to enhance operational efficiencies, they are increasingly turning to advanced conveyor solutions. Notably, the rise of Industry 4.0 technologies, including IoT and AI, is shaping sourcing strategies, allowing businesses to optimize their supply chains and enhance productivity through data-driven insights.

Emerging trends also highlight the importance of customization and flexibility in conveyor systems. Buyers are looking for manufacturers that offer a range of specifications tailored to their unique operational needs. Moreover, there is a growing preference for hygiene-focused designs, particularly in food processing applications, where compliance with safety standards is paramount. The trend towards modular conveyor systems is gaining traction as companies aim for more adaptable and scalable solutions.

How Is Sustainability Shaping Sourcing Decisions in the Metal Conveyor Belts Sector?

Sustainability and ethical sourcing are becoming critical considerations for B2B buyers in the metal conveyor belts sector. The environmental impact of manufacturing processes and materials used in conveyor belts is under increasing scrutiny. Buyers are more inclined to partner with suppliers who demonstrate a commitment to sustainable practices, such as using recycled materials and minimizing waste during production.

Certifications like ISO 14001 for environmental management systems and compliance with green standards are becoming essential benchmarks for evaluating suppliers. Additionally, there is a growing market for conveyor belts made from eco-friendly materials that do not compromise on quality or durability. Buyers are encouraged to inquire about the sourcing of raw materials, ensuring that they originate from responsible suppliers who adhere to ethical labor practices. This focus on sustainability not only aligns with corporate social responsibility goals but can also enhance brand reputation and customer loyalty in an increasingly eco-conscious market.

Illustrative image related to metal conveyor belts stainless steel

What Has Been the Evolution of Metal Conveyor Belts and Their Relevance Today?

The history of metal conveyor belts dates back to the early 20th century, with significant advancements occurring throughout the decades. Initially designed for basic material handling, these systems have evolved into sophisticated solutions capable of addressing complex operational challenges. The introduction of stainless steel as a primary material has revolutionized the sector, offering enhanced durability, corrosion resistance, and hygiene standards, particularly in food processing and pharmaceuticals.

Today, the relevance of metal conveyor belts lies in their ability to support automation and streamline production processes. Continuous innovation, including the development of specialized belt designs like Flat-Flex and Eye-Flex, allows for greater versatility and efficiency in various applications. As industries continue to evolve, the demand for high-quality stainless steel conveyor belts will remain strong, making them a vital component in the supply chains of international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of metal conveyor belts stainless steel

-

How do I select the right stainless steel conveyor belt for my industry?

Selecting the right stainless steel conveyor belt depends on your specific industry requirements. Consider factors such as the type of materials being conveyed, the operating environment (e.g., temperature, humidity), and hygiene standards, especially in food and pharmaceutical sectors. It’s also essential to evaluate the belt’s load capacity, flexibility, and resistance to corrosion. Engaging with suppliers who offer a range of belt styles and can provide recommendations based on your operational needs is crucial for making an informed decision. -

What are the key benefits of using stainless steel conveyor belts?

Stainless steel conveyor belts offer numerous advantages, including durability, resistance to corrosion, and ease of cleaning, making them ideal for industries like food processing and pharmaceuticals. Their robust construction ensures long-term performance even under challenging conditions, such as high temperatures or exposure to chemicals. Additionally, stainless steel belts can be customized for specific applications, enhancing efficiency and productivity in your operations. -

What should I consider when vetting a supplier for stainless steel conveyor belts?

When vetting suppliers, assess their industry experience, product range, and manufacturing capabilities. Look for suppliers with a proven track record and positive customer testimonials. Ensure they comply with international quality standards and certifications relevant to your industry. Additionally, inquire about their customer service, lead times, and support for customization to ensure they can meet your specific needs effectively. -

What is the typical minimum order quantity (MOQ) for stainless steel conveyor belts?

Minimum order quantities for stainless steel conveyor belts can vary widely among suppliers. Generally, MOQs can range from a few meters for standard sizes to larger quantities for custom orders. It’s advisable to discuss your requirements with potential suppliers to understand their policies. Some manufacturers may offer flexibility in MOQs, especially for new customers or bulk orders, allowing you to scale your purchases according to your business needs. -

What payment terms are common for international B2B transactions involving conveyor belts?

Common payment terms for international transactions can include options such as advance payment, letters of credit, or payment upon delivery. Suppliers may also offer net payment terms (e.g., net 30 or net 60) after the invoice date, allowing you to manage cash flow better. It’s essential to negotiate terms that work for both parties, considering factors like order size, delivery timelines, and your financial capabilities. -

How do I ensure quality assurance for stainless steel conveyor belts?

To ensure quality assurance, request samples or conduct trials before finalizing your order. Verify that the supplier adheres to established quality standards, such as ISO certifications. Additionally, inquire about their quality control processes, including inspections during production and pre-shipment. Consider establishing a clear agreement on specifications and performance standards to hold the supplier accountable for delivering high-quality products. -

What logistics considerations should I keep in mind when sourcing conveyor belts internationally?

When sourcing conveyor belts internationally, consider shipping methods, transit times, and customs regulations in both the exporting and importing countries. Evaluate the cost-effectiveness of different shipping options, including air freight for urgent needs versus sea freight for bulk orders. Collaborating with a logistics partner experienced in international trade can help navigate potential challenges, ensuring timely delivery and compliance with local regulations. -

Can stainless steel conveyor belts be customized for specific applications?

Yes, stainless steel conveyor belts can be extensively customized to meet specific application requirements. Options include variations in belt width, thickness, mesh size, and edge treatments. Some suppliers also offer tailored features, such as attachments or special coatings, to enhance performance in unique environments. Discussing your specific needs with the supplier will help them provide the most suitable solutions for your operations.

Top 5 Metal Conveyor Belts Stainless Steel Manufacturers & Suppliers List

1. Ashworth – Flat Wire Conveyor Belts

Domain: ashworth.com

Registered: 1996 (29 years)

Introduction: Flat Wire Conveyor Belts manufactured by Ashworth since 1951. Features include:

– Engineered to strict tolerances for longer belt life.

– Maximum open area minimizes spray deflection.

– Available in standard weight and heavy-duty variants.

– Precision manufactured for increased reliability and smooth operation.

– Proven reliability with over 75 years of customer satisfaction.

Applications include…

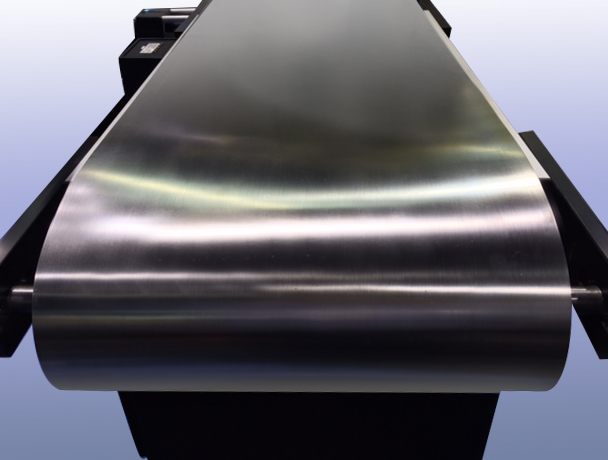

2. Belt Technologies – Stainless Steel Conveyor Belts

Domain: belttechnologies.com

Registered: 1996 (29 years)

Introduction: Stainless Steel Conveyor Belts for Food Processing, designed for cooking, freezing, and handling edible products. Features include: PureSteel® stainless steel metal belts, sanitary design, customizable for specific food processing applications, integration with existing food-handling systems, and assistance with retrofitting solutions. Benefits include meeting food safety requirements, durability,…

3. IPCO – Engineered Industrial Processing Solutions

Domain: ipco.com

Registered: 1995 (30 years)

Introduction: IPCO offers engineered industrial processing solutions with a focus on steel belts and conveyor belts. Their products cater to various industries including automotive, building materials, chemicals, and energy. Key solutions include steel belts, conveyor components, Rotoform systems, scattering systems, and double belt presses.

4. SAMaterials – Stainless Steel Conveyor Belt

Domain: samaterials.com

Registered: 2013 (12 years)

Introduction: {“Product Name”: “Stainless Steel Conveyor Belt”, “Catalog No.”: “SS4709”, “Material”: “Stainless Steel 304, 316L, etc.”, “Shape”: “Conveyor belt”, “Belt Width (mm)”: “500-1400mm”, “Specifications”: [{“Material”: “1Cr13”, “C”: “0.15”, “Si”: “0.6”, “Mn”: “0.6”, “Ni”: “-“, “Cr”: “12-14”, “Mo”: “-“, “Max Working Temp (℃)”: “650”}, {“Material”: “1Cr17”, “C”: “0.15”, “Si”: “0.6”, “Mn”: “0.6”, “Ni”: “-“…

5. Maertens – Metal Conveyor Belts

Domain: maertens-conveyorbelts.com

Registered: 2012 (13 years)

Introduction: Metal conveyor belts include various types such as wide spiral link belts, tight spiral link belts, loop-joined wire belts, wire mesh belts, and flat-rolled baking oven belts. These belts are designed for durability and efficient load transportation across different applications, from frying to freezing. Key features include:

– Wide spiral link belts: Permeable construction, suitable for straight …

Strategic Sourcing Conclusion and Outlook for metal conveyor belts stainless steel

How Can Strategic Sourcing Enhance Your Metal Conveyor Belt Procurement?

In conclusion, strategic sourcing of stainless steel metal conveyor belts offers international B2B buyers a competitive edge across various industries, including food and beverage, pharmaceuticals, and automotive sectors. By focusing on high-quality materials and innovative designs, businesses can improve operational efficiency and product safety while reducing long-term costs. The emphasis on hygiene and durability in these conveyor systems aligns with global standards, making them suitable for diverse applications across regions.

Moreover, establishing strong relationships with trusted manufacturers ensures timely delivery and support, crucial for maintaining productivity. As markets in Africa, South America, the Middle East, and Europe evolve, it’s essential for businesses to stay ahead by leveraging the latest advancements in conveyor technology.

Looking forward, now is the time to assess your sourcing strategies and connect with reliable suppliers who can meet your specific requirements. Investing in high-quality stainless steel conveyor belts will not only enhance your operational capabilities but also contribute to sustainable practices within your supply chain. Take the next step towards optimizing your production processes by engaging with leading manufacturers today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to metal conveyor belts stainless steel

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.