Is Your Digital Platform Weighing Scale Sourcing Strategy Flawed? Read This 2025 Report

Introduction: Navigating the Global Market for digital platform weighing scale

In today’s competitive landscape, sourcing the right digital platform weighing scale can pose significant challenges for international B2B buyers. With varying specifications and applications across industries, the need for accurate and reliable weighing solutions is paramount, especially for businesses operating in sectors such as logistics, manufacturing, and agriculture. This guide serves as a comprehensive resource to navigate the complexities of the global market for digital platform weighing scales, providing insights into different types of scales, their applications, and essential features to consider during the purchasing process.

Throughout this guide, we will explore the diverse applications of digital platform weighing scales, ranging from warehouse operations to hazardous material handling. Additionally, we will delve into effective supplier vetting strategies, ensuring that buyers can identify trustworthy manufacturers who meet stringent quality and compliance standards. Cost analysis will also be a critical component, helping you understand the factors that influence pricing and the best practices for budgeting your investment.

By empowering B2B buyers from Africa, South America, the Middle East, and Europe—such as those in Saudi Arabia and Germany—this guide aims to facilitate informed purchasing decisions. With the right information at your fingertips, you can confidently select a digital platform weighing scale that enhances operational efficiency, ensures compliance, and ultimately drives business success.

Understanding digital platform weighing scale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Pallet Scales | Heavy-duty construction, high capacity (up to 10,000 lbs), low-profile design | Warehousing, shipping, logistics | Pros: Efficient for palletized goods; space-saving design. Cons: Limited to palletized items. |

| Industrial Platform Scales | Robust build, high accuracy (up to 1 part in 500,000), water-resistant | Manufacturing, recycling, hazardous materials | Pros: Durable in harsh conditions; versatile applications. Cons: Higher initial investment. |

| Commercial Scales | User-friendly interface, compact size, quick-connect features | Retail, inventory management | Pros: Easy to use; fits in small spaces. Cons: May not handle heavy loads as industrial scales. |

| Hazardous Material Scales | Specialized for safety, chemical resistance, built-in safety features | Chemical processing, waste management | Pros: Ensures safety compliance; accurate for hazardous substances. Cons: More costly due to specialized features. |

| Digital Floor Scales | Advanced connectivity options (USB/Bluetooth), large display, easy calibration | General industrial use, food processing | Pros: Integrates with data systems; user-friendly. Cons: May require regular updates and maintenance. |

What Are the Key Characteristics of Pallet Scales?

Pallet scales are designed specifically for weighing goods on pallets, making them essential in warehousing and shipping environments. They are built to handle heavy loads, often with capacities reaching up to 10,000 pounds. The low-profile design facilitates easy loading and unloading, enhancing operational efficiency. When purchasing a pallet scale, consider the weight capacity and dimensions to ensure compatibility with your existing equipment and workflow.

How Do Industrial Platform Scales Stand Out?

Industrial platform scales are engineered for durability and precision, suitable for harsh environments where chemicals and extreme temperatures may be present. They often feature stainless steel load cells and are designed to provide accurate measurements with high resolution. These scales are ideal for manufacturing and recycling applications. Buyers should focus on the scale’s load capacity, environmental resistance, and accuracy specifications to meet their industrial needs.

What Makes Commercial Scales Ideal for Retail?

Commercial scales are compact and user-friendly, making them ideal for retail and inventory management applications. They often come equipped with quick-connect features and easy-to-read displays, streamlining the weighing process. For businesses with limited space, these scales are advantageous. When selecting a commercial scale, consider the maximum weight limit and ease of integration with existing systems to optimize operations.

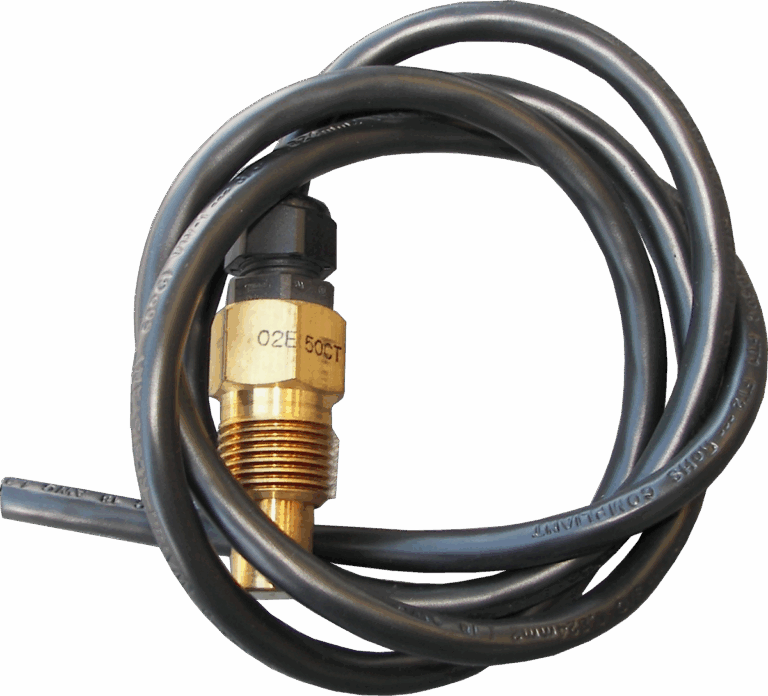

Illustrative image related to digital platform weighing scale

Why Are Hazardous Material Scales Essential?

Hazardous material scales are specifically designed to safely weigh chemicals and other dangerous substances. They incorporate safety features and chemical-resistant materials to prevent accidents. These scales are crucial in industries such as chemical processing and waste management. B2B buyers should prioritize compliance with safety regulations and the scale’s ability to handle specific hazardous materials when making a purchasing decision.

How Do Digital Floor Scales Enhance Operational Efficiency?

Digital floor scales offer advanced features like connectivity options and easy calibration, making them suitable for a wide range of industrial applications. They can integrate with data management systems, allowing for real-time data access and analysis. These scales are particularly useful in food processing and general industrial use. Buyers should assess the scale’s connectivity features and user interface to ensure it aligns with their operational requirements.

Key Industrial Applications of digital platform weighing scale

| Industry/Sector | Specific Application of digital platform weighing scale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Logistics and Shipping | Weighing palletized goods for freight calculations | Accurate weight measurements reduce shipping costs and improve compliance with regulations | Capacity requirements, durability under heavy loads, connectivity options for data transfer |

| Manufacturing | Weighing raw materials and finished products during production | Enhances quality control and ensures correct inventory levels | Precision specifications, environmental resistance, ease of cleaning |

| Food and Beverage | Weighing ingredients for recipe accuracy and portion control | Improves product consistency and minimizes waste | Compliance with food safety standards, calibration needs, and hygiene features |

| Recycling and Waste Management | Weighing recyclable materials for processing | Optimizes recycling operations and enhances reporting accuracy | Material compatibility, robustness in harsh environments, size and weight capacity |

| Chemical and Hazardous Materials | Weighing chemicals for formulation and shipping | Ensures safety and compliance with regulations | Explosion-proof features, resistance to chemicals, and accuracy in extreme conditions |

How are Digital Platform Weighing Scales Used in Logistics and Shipping?

In the logistics and shipping sector, digital platform weighing scales are essential for accurately measuring the weight of palletized goods before transport. This ensures compliance with weight regulations and optimizes freight costs. Accurate measurements help businesses avoid overloading penalties and streamline their shipping processes. International buyers should consider the scale’s weight capacity and durability, as well as connectivity options for seamless data integration with logistics management systems.

What Role Do Digital Platform Weighing Scales Play in Manufacturing?

In manufacturing, digital platform scales are used to weigh raw materials and finished products, facilitating quality control throughout the production process. By ensuring that the correct amounts of materials are used, manufacturers can maintain product consistency and avoid costly errors. For B2B buyers, it’s crucial to look for scales that offer high precision and are resistant to environmental factors such as dust and moisture. Additionally, ease of maintenance and cleaning features are essential for sustaining operational efficiency.

How Do Digital Platform Weighing Scales Enhance Food and Beverage Operations?

In the food and beverage industry, digital platform weighing scales are vital for accurately measuring ingredients to ensure recipe fidelity and portion control. This precision helps minimize waste and enhances product consistency, which is critical for customer satisfaction. Buyers should prioritize scales that meet food safety standards and are easy to clean, as well as those with calibration capabilities to maintain accuracy over time. Compliance with local regulations regarding food handling is also a significant consideration for international buyers.

Illustrative image related to digital platform weighing scale

Why Are Digital Platform Weighing Scales Important in Recycling and Waste Management?

Digital platform weighing scales are pivotal in recycling and waste management for weighing recyclable materials before processing. Accurate measurements optimize operations and improve reporting accuracy, allowing companies to track their recycling efforts effectively. Buyers in this sector should consider the scale’s robustness, especially in harsh environments, and its capacity to handle various materials. Durability, along with features that ensure easy operation and maintenance, are essential for maximizing efficiency in recycling processes.

How Do Digital Platform Weighing Scales Support Chemical Handling?

In the chemical industry, digital platform weighing scales are crucial for accurately weighing raw materials and finished products, particularly hazardous materials. These scales ensure safety and compliance with regulations by providing precise measurements essential for formulation and shipping. International buyers should focus on scales with explosion-proof features, chemical resistance, and the ability to perform accurately under extreme conditions. Ensuring that the scales can handle the specific requirements of chemical handling is vital for maintaining operational safety and efficiency.

3 Common User Pain Points for ‘digital platform weighing scale’ & Their Solutions

Scenario 1: Inaccurate Weighing Leading to Costly Errors

The Problem: A manufacturing company in South America relies on digital platform weighing scales to measure raw materials for production. However, they frequently encounter issues with inaccurate weight readings, resulting in over or underordering supplies. This not only inflates costs due to excess purchases but also leads to production delays when materials are insufficient. The company’s inability to trust the scales has created frustration and inefficiencies in their operations.

The Solution: To mitigate this issue, it is crucial for B2B buyers to prioritize regular calibration and maintenance of their digital platform weighing scales. Establish a routine schedule for calibration as per the manufacturer’s guidelines to ensure accuracy. Additionally, consider investing in high-quality scales that offer advanced features such as automatic zero tracking and error notifications. These features can help users identify discrepancies in real time. When sourcing scales, look for manufacturers that provide robust customer support and training on proper usage and maintenance practices. This proactive approach not only enhances weighing accuracy but also improves overall operational efficiency.

Illustrative image related to digital platform weighing scale

Scenario 2: Challenges in Weighing Heavy Loads Safely

The Problem: In the Middle East, a logistics company faces difficulties when weighing heavy cargo on their digital platform scales. The scales often lack the necessary weight capacity to handle the loads, leading to potential safety hazards and equipment damage. Employees are forced to find workaround solutions, which can be risky and inefficient, ultimately impacting worker safety and operational productivity.

The Solution: It’s essential for B2B buyers to assess the weight capacity of digital platform scales before making a purchase. Look for scales that are specifically designed for high-capacity loads, ideally with a minimum capacity of 10,000 pounds. Additionally, ensure the scales are constructed from durable materials, such as heavy-duty steel, to withstand the demands of frequent heavy use. Consider models that feature low profiles to reduce the risk of injury and equipment damage. For added safety, invest in scales equipped with safety features such as overload indicators and robust base designs that prevent tipping. Partnering with suppliers who offer customization options can also help businesses find the right solution tailored to their unique operational needs.

Scenario 3: Difficulties in Data Management and Integration

The Problem: A European retail company struggles with integrating their digital platform weighing scales into their inventory management system. The lack of connectivity features in their current scales means that data must be manually entered into the system, leading to increased labor costs and a higher risk of human error. This inefficiency hampers the company’s ability to track inventory accurately, complicating both order fulfillment and stock management.

The Solution: To address this challenge, B2B buyers should prioritize digital platform scales that offer advanced connectivity options, such as USB or Bluetooth capabilities. These features enable seamless integration with existing inventory management systems, allowing for real-time data transfer and analysis. When evaluating potential scales, ask suppliers about their software compatibility and whether they provide installation assistance. Additionally, consider investing in scales with built-in data management tools that can enhance operational efficiency. Training employees on how to use these features effectively can also help to streamline processes and reduce manual errors. By focusing on connectivity, businesses can significantly improve their inventory management and overall operational effectiveness.

Illustrative image related to digital platform weighing scale

Strategic Material Selection Guide for digital platform weighing scale

What Are the Key Materials Used in Digital Platform Weighing Scales?

When selecting digital platform weighing scales, the choice of material plays a critical role in determining performance, durability, and suitability for specific applications. Below, we analyze four common materials used in the manufacturing of these scales, focusing on their properties, advantages, disadvantages, and implications for international buyers.

How Does Stainless Steel Perform in Digital Platform Weighing Scales?

Key Properties: Stainless steel is renowned for its excellent corrosion resistance, high strength, and ability to withstand extreme temperatures. It typically has a temperature rating of up to 1,500°F (815°C) and can handle high-pressure environments.

Pros & Cons: The durability of stainless steel makes it ideal for heavy-duty applications, ensuring longevity even in harsh industrial settings. However, its higher manufacturing complexity and cost can be a drawback for budget-conscious buyers.

Impact on Application: Stainless steel scales are particularly well-suited for industries dealing with corrosive materials, such as chemicals and food processing, where hygiene and resistance to rust are paramount.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East must ensure compliance with standards such as ASTM and DIN, particularly for food safety and industrial applications. The higher cost may be justified by the longevity and reliability of the product.

What Are the Advantages of Aluminum in Digital Platform Weighing Scales?

Key Properties: Aluminum is lightweight, resistant to corrosion, and has a good strength-to-weight ratio. It can withstand temperatures up to 1,200°F (649°C) and is generally less dense than steel.

Pros & Cons: The lightweight nature of aluminum makes it easy to transport and install, which is a significant advantage in mobile applications. However, it is less durable than stainless steel and may not be suitable for heavy loads or extreme environments.

Impact on Application: Aluminum scales are often used in industries where portability is essential, such as logistics and shipping. However, their susceptibility to deformation under heavy loads can limit their application in more demanding environments.

Considerations for International Buyers: Buyers in Africa and South America should consider the environmental conditions, as aluminum may not perform well in extreme heat or humidity without proper treatment. Compliance with local standards is also necessary to ensure product reliability.

How Does Carbon Steel Compare for Digital Platform Weighing Scales?

Key Properties: Carbon steel is known for its high tensile strength and ability to withstand heavy loads. It has a lower corrosion resistance compared to stainless steel, making it suitable for dry environments.

Pros & Cons: The cost-effectiveness of carbon steel makes it an attractive option for budget-conscious buyers. However, its susceptibility to rust and corrosion can limit its lifespan, particularly in humid or wet conditions.

Impact on Application: Carbon steel scales are ideal for applications in warehouses and manufacturing where heavy loads are common, but they may not be suitable for environments exposed to moisture or corrosive substances.

Considerations for International Buyers: Buyers must be aware of the need for protective coatings to enhance corrosion resistance, especially in regions with high humidity, such as parts of Africa and South America. Compliance with local standards for safety and performance is also crucial.

Illustrative image related to digital platform weighing scale

What Role Does Plastic Play in Digital Platform Weighing Scales?

Key Properties: Plastic materials, often used in the construction of scale housings, are lightweight, resistant to corrosion, and can withstand moderate temperatures.

Pros & Cons: The low cost and ease of manufacturing make plastic an attractive option for less demanding applications. However, its lower strength and durability compared to metals can limit its use in heavy-duty scenarios.

Impact on Application: Plastic scales are often used in retail and light industrial applications where portability and cost are more critical than extreme durability.

Considerations for International Buyers: Buyers should evaluate the specific requirements of their applications, particularly in regions with high temperatures, where certain plastics may degrade. Ensuring compliance with safety standards is also essential.

Summary Table of Material Selection for Digital Platform Weighing Scales

| Material | Typical Use Case for digital platform weighing scale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food processing, chemical handling | Excellent corrosion resistance | Higher manufacturing cost | High |

| Aluminum | Logistics, shipping | Lightweight and portable | Less durable under heavy loads | Medium |

| Carbon Steel | Warehousing, manufacturing | Cost-effective for heavy loads | Susceptible to rust and corrosion | Low |

| Plastic | Retail, light industrial applications | Low cost and lightweight | Lower strength and durability | Low |

This strategic material selection guide equips international B2B buyers with essential insights to make informed decisions when selecting digital platform weighing scales tailored to their operational needs.

In-depth Look: Manufacturing Processes and Quality Assurance for digital platform weighing scale

The manufacturing of digital platform weighing scales involves several crucial stages, each contributing to the overall performance, reliability, and accuracy of the final product. Understanding these processes can empower B2B buyers to make informed decisions when sourcing these essential instruments for their operations.

What are the Main Stages in the Manufacturing Process of Digital Platform Weighing Scales?

Material Preparation: Ensuring Quality from the Start

The manufacturing process begins with the careful selection and preparation of materials. Heavy-duty steel is often the primary material used for the platform frame due to its strength and durability. The steel is cut to size, and surface treatments such as galvanization or powder coating may be applied to enhance corrosion resistance, which is particularly important in harsh industrial environments.

Other components, such as load cells and electronic displays, are sourced from specialized suppliers. These components are critical for the scale’s accuracy and reliability, necessitating rigorous quality checks upon receipt. Buyers should inquire about the sourcing practices of their suppliers to ensure that only high-quality materials are used.

Forming: Shaping Components with Precision

Once materials are prepared, the next stage involves forming the various components of the scale. This includes processes such as welding, machining, and stamping. The platform is typically welded together to create a robust structure that can withstand heavy weights and potential impacts.

Advanced techniques such as computer numerical control (CNC) machining are often employed to achieve precise dimensions and tolerances. This level of precision is essential for ensuring that the scales function correctly and provide accurate measurements. B2B buyers should consider asking suppliers about their forming processes and the technologies they use, as this can impact the final product’s quality.

Assembly: Bringing Components Together

The assembly stage involves integrating all components into a fully functional weighing scale. This includes the installation of load cells, wiring, and the digital display. During assembly, it is crucial to follow strict guidelines to ensure proper alignment and functionality.

Manufacturers may employ automated assembly lines to enhance efficiency and reduce human error. However, skilled technicians often oversee the assembly process to address any issues that may arise. Buyers should inquire about the assembly processes used by potential suppliers, as well as the qualifications of the technicians involved.

Finishing: Final Touches for Quality Assurance

The finishing stage includes testing, calibration, and quality checks. Each scale is calibrated to ensure accurate readings, often using precision weights for verification. Additional processes such as painting or labeling may also occur at this stage.

Finishing touches not only enhance the aesthetic appeal of the scales but also ensure they meet industry standards for safety and performance. Buyers should ensure that their suppliers have robust finishing processes to guarantee the reliability of the scales.

What Quality Assurance Practices Are Essential for Digital Platform Weighing Scales?

What International Standards Should B2B Buyers Look For?

Quality assurance is critical in the manufacturing of digital platform weighing scales. Compliance with international standards such as ISO 9001 ensures that manufacturers adhere to quality management principles, including customer focus, process approach, and continuous improvement.

Additionally, industry-specific certifications such as CE marking in Europe indicate compliance with health, safety, and environmental protection standards. For buyers in the Middle East, certifications like G-Mark may be relevant, while those in Africa and South America should look for local compliance standards that ensure product safety and efficacy.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves several checkpoints throughout the manufacturing process, including:

-

Incoming Quality Control (IQC): This phase checks raw materials and components upon arrival to ensure they meet specified standards before production begins.

-

In-Process Quality Control (IPQC): Continuous monitoring occurs during manufacturing to identify and rectify any deviations from quality standards promptly.

-

Final Quality Control (FQC): Before products are shipped, final inspections and tests are conducted to verify that each scale meets performance and safety criteria.

B2B buyers should inquire about the QC processes employed by suppliers and request documentation of these procedures to ensure they are robust and reliable.

What Common Testing Methods Are Used to Ensure Accuracy?

Testing methods commonly employed in the quality assurance of digital platform scales include:

-

Load Testing: Scales are subjected to various weights to verify their accuracy and functionality across their specified range.

-

Environmental Testing: Scales are tested under various conditions (temperature, humidity, exposure to chemicals) to ensure durability and reliability in real-world applications.

-

Calibration Checks: Regular calibration using certified weights ensures that scales provide accurate measurements throughout their operational lifespan.

Buyers should seek suppliers that offer comprehensive testing reports to verify that their scales have undergone these essential checks.

How Can B2B Buyers Verify Supplier Quality Control?

What Steps Can Buyers Take to Ensure Supplier Compliance?

To verify a supplier’s quality control practices, B2B buyers can take several proactive steps:

-

Conduct Audits: Regular audits of the manufacturing facility can provide insights into the supplier’s adherence to quality standards and manufacturing practices.

-

Request Documentation: Buyers should ask for detailed reports on quality control processes, including IQC, IPQC, and FQC procedures.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s manufacturing and quality control processes.

What Nuances Should Buyers Consider in International Trade?

When sourcing digital platform weighing scales internationally, particularly from regions such as Africa, South America, the Middle East, and Europe, buyers should consider:

-

Local Compliance Requirements: Different regions may have specific regulatory requirements that products must meet to be sold legally.

-

Cultural and Language Differences: Effective communication is key; buyers should ensure that all specifications and quality expectations are clearly articulated and understood.

-

Logistical Considerations: Shipping and customs regulations can impact delivery timelines and costs, necessitating careful planning to avoid delays.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing digital platform weighing scales, ensuring they invest in reliable, high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘digital platform weighing scale’

In the fast-paced world of industrial operations, selecting the right digital platform weighing scale is critical for ensuring efficiency and accuracy. This guide aims to streamline your sourcing process by providing a practical checklist that covers essential considerations for B2B buyers, particularly those operating in diverse international markets.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline your technical requirements for the digital platform scale. Consider factors such as weight capacity, platform dimensions, and accuracy levels. For instance, if your operations involve heavy pallets, look for scales that can handle capacities of 5,000 to 10,000 pounds, as these are common in warehouse settings.

Step 2: Assess Industry-Specific Needs

Different industries have unique requirements when it comes to weighing solutions. Identify the specific applications for which the scale will be used—be it shipping, manufacturing, or hazardous materials handling. Ensure that the scale you choose is compatible with the conditions it will face, such as exposure to extreme temperatures or chemicals, to avoid operational disruptions.

Step 3: Evaluate Potential Suppliers

Thoroughly vet suppliers before making a commitment. Request company profiles, case studies, and references from businesses in similar industries or regions. Look for suppliers who demonstrate a solid reputation for reliability and customer support, as these factors can significantly impact your operational efficiency.

Step 4: Verify Supplier Certifications

Ensure that potential suppliers possess relevant industry certifications and compliance with international standards. Certifications such as ISO 9001 for quality management systems can indicate a supplier’s commitment to quality and reliability. This step is vital, as it assures you that the scale will meet the necessary regulatory requirements.

Step 5: Examine Technical Support and Maintenance Options

Assess the level of technical support and maintenance services offered by the supplier. A reliable supplier should provide comprehensive support, including installation assistance, calibration services, and ongoing maintenance plans. This ensures that your scale remains accurate and functional over time, minimizing downtime and maximizing productivity.

Step 6: Request Demonstrations or Trials

Whenever possible, request a demonstration or trial of the digital platform scale. This allows you to assess its usability, accuracy, and features firsthand. Pay attention to the scale’s interface and ease of use, as a user-friendly design can significantly impact your team’s efficiency and training time.

Step 7: Compare Total Cost of Ownership

Finally, analyze the total cost of ownership (TCO) associated with each scale option. Beyond the initial purchase price, consider factors such as maintenance costs, warranty terms, and potential downtime. A lower upfront cost may not always translate to savings in the long run, so a thorough cost analysis is crucial for informed decision-making.

By following these steps, B2B buyers can ensure a well-informed procurement process, leading to the selection of a digital platform weighing scale that meets their operational needs and enhances overall productivity.

Comprehensive Cost and Pricing Analysis for digital platform weighing scale Sourcing

What Are the Key Cost Components in Sourcing Digital Platform Weighing Scales?

When sourcing digital platform weighing scales, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materials: The choice of materials, such as heavy-duty steel for the scale structure and stainless steel for load cells, significantly influences costs. High-quality materials enhance durability and performance but may increase the upfront cost.

-

Labor: Labor costs encompass the workforce required for manufacturing, assembly, and quality control. Skilled labor may demand higher wages, impacting overall costs.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and maintenance of machinery. Efficient manufacturing processes can reduce overhead, thus lowering the total cost.

-

Tooling: Specialized tools and equipment for production can be a substantial initial investment. However, they are vital for ensuring precision and quality in the manufacturing process.

-

Quality Control (QC): Implementing rigorous QC processes to ensure the accuracy and reliability of scales adds to the cost but is necessary to meet industry standards and customer expectations.

-

Logistics: Shipping and handling costs can vary widely based on the destination and the scale’s weight and dimensions. This is particularly relevant for international buyers who must consider customs duties and tariffs.

-

Margin: Suppliers typically add a profit margin to cover their operational costs and ensure sustainability. This margin can vary based on market demand and competitive pricing strategies.

How Do Price Influencers Affect Digital Platform Weighing Scale Pricing?

Several factors influence the pricing of digital platform weighing scales, including:

-

Volume/MOQ: Ordering in larger quantities often leads to lower per-unit costs due to economies of scale. Manufacturers may offer tiered pricing based on minimum order quantities (MOQ).

-

Specifications and Customization: Custom features, such as specific weight capacities or connectivity options, can increase costs. Buyers should balance their needs with budget constraints.

-

Materials and Quality Certifications: High-quality materials and certifications (e.g., ISO, OIML) can raise the price. However, they often enhance the scale’s reliability and lifespan, making them a worthwhile investment.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more due to their proven track record and superior customer service.

-

Incoterms: The chosen Incoterm can affect pricing by determining who bears the responsibility for shipping costs and risks. Buyers should understand how these terms influence the total cost of ownership.

What Are the Best Buyer Tips for Cost-Efficiency in Sourcing?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider the following tips to enhance cost-efficiency:

-

Negotiation: Engage in open dialogue with suppliers to negotiate better pricing, especially for bulk orders. Clearly communicating your needs and volume can lead to favorable terms.

-

Total Cost of Ownership: Evaluate not just the purchase price but the total cost of ownership, including maintenance, operational costs, and potential downtime. Scales that are more expensive initially may offer lower long-term costs due to durability and lower maintenance needs.

-

Understanding Pricing Nuances: Be aware of regional pricing differences. Factors like local tariffs, currency fluctuations, and shipping costs can significantly affect the final price.

-

Supplier Relationships: Build strong relationships with suppliers for better pricing and service. Long-term partnerships can lead to preferential pricing and better support.

Disclaimer on Indicative Prices

Prices for digital platform weighing scales can vary widely based on specifications, supplier factors, and market conditions. It is advisable for buyers to conduct thorough research and obtain multiple quotes to ensure competitive pricing tailored to their specific needs.

Alternatives Analysis: Comparing digital platform weighing scale With Other Solutions

When evaluating weighing solutions for industrial applications, it’s essential to consider alternatives to digital platform weighing scales. Each option has unique advantages and drawbacks, making it vital for businesses to understand their specific requirements before making a decision. Below, we compare digital platform weighing scales with two alternative solutions: mechanical scales and load cell-based weighing systems.

| Comparison Aspect | Digital Platform Weighing Scale | Mechanical Scale | Load Cell-Based Weighing System |

|---|---|---|---|

| Performance | High accuracy (up to 1 part in 500,000) and quick readouts. | Moderate accuracy; prone to wear over time. | High accuracy; can be customized for specific needs. |

| Cost | Generally higher initial investment; cost-effective in long run. | Lower upfront cost; limited lifespan can lead to additional costs. | Varies widely based on customization; potentially high investment. |

| Ease of Implementation | Simple setup with digital interfaces for data management. | Manual operation; requires physical effort. | Installation can be complex; requires calibration and configuration. |

| Maintenance | Low maintenance; digital calibration and monitoring features. | High maintenance; mechanical parts wear out and need frequent servicing. | Moderate maintenance; regular calibration necessary for accuracy. |

| Best Use Case | Ideal for industries requiring frequent and precise measurements (e.g., logistics, manufacturing). | Suitable for small-scale applications or basic weight measurements. | Excellent for specialized applications needing tailored solutions (e.g., chemical processing). |

What Are the Advantages and Disadvantages of Mechanical Scales?

Mechanical scales are often favored for their simplicity and lower initial cost. These scales operate on a spring mechanism, allowing for straightforward weight measurement without the need for power or digital interfaces. However, their accuracy can diminish over time due to wear and tear, and they lack the advanced features that digital scales offer. Consequently, while they may be suitable for light or infrequent weighing tasks, they fall short in environments where precision is critical.

How Do Load Cell-Based Weighing Systems Compare?

Load cell-based weighing systems utilize sensors to measure the weight of objects with high precision. They can be customized to meet specific industrial needs, making them versatile across various applications. These systems are particularly useful in environments where extreme accuracy is required, such as in chemical or food processing industries. However, they often come with a higher price tag and may require more complex installation and regular calibration to maintain accuracy.

How Should B2B Buyers Choose the Right Weighing Solution?

Choosing the right weighing solution hinges on understanding the specific requirements of your business operations. Buyers should assess the necessary accuracy, the volume of goods to be weighed, and the environment in which the scales will operate. For industries demanding high precision and efficiency, digital platform weighing scales are typically the best choice. Conversely, for smaller-scale operations or budget-conscious businesses, mechanical scales may suffice. Load cell-based systems present a compelling option for specialized applications but require a careful evaluation of cost versus benefit. Ultimately, aligning the chosen solution with operational needs and budget constraints will lead to optimal results.

Essential Technical Properties and Trade Terminology for digital platform weighing scale

What Are the Essential Technical Properties of Digital Platform Weighing Scales?

Understanding the technical properties of digital platform weighing scales is crucial for B2B buyers aiming to enhance operational efficiency. Below are key specifications that influence performance and reliability:

-

Material Grade

– Definition: The quality of materials used in the construction of the scale, typically heavy-duty steel or stainless steel.

– B2B Importance: High-grade materials ensure durability and resistance to corrosion, which is vital in industrial environments. This reduces the frequency of replacements, leading to long-term cost savings. -

Weighing Capacity

– Definition: The maximum weight that a scale can accurately measure, commonly ranging from 5,000 to 10,000 pounds.

– B2B Importance: A scale’s capacity must align with the typical loads handled by your business. Selecting a scale with an appropriate capacity prevents overloading, ensuring accurate measurements and compliance with safety standards. -

Tolerance

– Definition: The permissible limit of variation in a measurement, often expressed in terms of a percentage of the total weight.

– B2B Importance: Tolerance levels affect the precision of weight readings. For industries where accurate weight is critical (e.g., pharmaceuticals, food), understanding tolerance helps in selecting a scale that meets regulatory requirements and minimizes errors. -

Display Type

– Definition: The technology used for the scale’s display, which can include LED or LCD screens.

– B2B Importance: A clear, high-resolution display enhances usability, especially in fast-paced environments. Features like backlighting improve visibility in low-light conditions, facilitating efficient operations. -

Connectivity Options

– Definition: The capabilities that allow the scale to connect to other devices, such as computers or inventory management systems, often through USB or Bluetooth.

– B2B Importance: Enhanced connectivity allows for real-time data transfer, improving inventory accuracy and operational efficiency. This integration is crucial for businesses looking to optimize workflows and data management. -

Calibration and Maintenance Features

– Definition: Built-in functionalities that facilitate regular calibration and maintenance of the scale.

– B2B Importance: Scales that offer easy calibration options ensure ongoing accuracy and compliance with industry standards. Regular maintenance minimizes downtime, which is essential for productivity.

What Are Common Trade Terms Related to Digital Platform Weighing Scales?

Familiarity with trade terminology can streamline the procurement process and improve communication between suppliers and buyers. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts and equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships helps buyers identify the source of parts, ensuring quality and reliability in the equipment they purchase. -

MOQ (Minimum Order Quantity)

– Definition: The smallest number of units that a supplier is willing to sell.

– Importance: Knowing the MOQ helps businesses plan their purchases effectively. It can influence cash flow and inventory management strategies. -

RFQ (Request for Quotation)

– Definition: A document used to solicit price quotes from suppliers for specific goods or services.

– Importance: Submitting an RFQ enables buyers to compare prices and terms from multiple vendors, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

– Definition: A set of international rules that define the responsibilities of sellers and buyers for the delivery of goods.

– Importance: Familiarity with Incoterms helps businesses understand shipping costs, risks, and responsibilities, which are critical for international transactions. -

Load Cell

– Definition: A transducer that converts a force into an electrical signal, crucial for the operation of digital scales.

– Importance: Understanding load cells helps buyers appreciate the technology behind scale accuracy and reliability, allowing for better decision-making in selecting appropriate weighing solutions. -

Calibration Certificate

– Definition: A document provided by the manufacturer that verifies the accuracy of a scale after calibration.

– Importance: A calibration certificate ensures compliance with industry standards and is essential for businesses that require precise measurements for regulatory purposes.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring that they select the right digital platform weighing scale to meet their operational needs effectively.

Navigating Market Dynamics and Sourcing Trends in the digital platform weighing scale Sector

What Are the Key Market Dynamics and Trends in Digital Platform Weighing Scales?

The digital platform weighing scale market is experiencing significant growth driven by several global factors. Increased demand for accurate and efficient weighing solutions across various industries—such as logistics, manufacturing, and agriculture—has spurred innovation in scale technology. For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial. Enhanced connectivity features, like Bluetooth and USB integration, are becoming standard, allowing for seamless data management and operational efficiency. Additionally, the rise of e-commerce has amplified the need for reliable weighing solutions in shipping and logistics, making digital platform scales essential for inventory management and order fulfillment.

Emerging trends indicate a shift towards automation and integration with broader supply chain systems. Buyers are increasingly looking for scales that can interface with their existing software, enabling real-time data analytics and improved decision-making. In regions like Saudi Arabia and Germany, where industrial automation is rapidly advancing, suppliers that offer customizable solutions are more likely to capture market share. Furthermore, the focus on accuracy and durability in harsh environments is driving manufacturers to innovate, leading to the development of scales that can withstand extreme conditions while maintaining precision.

Illustrative image related to digital platform weighing scale

How Does Sustainability Influence the Sourcing of Digital Platform Weighing Scales?

Sustainability is a growing concern for B2B buyers in the digital platform weighing scale sector. As environmental regulations tighten globally, companies are prioritizing sustainable sourcing practices. The impact of manufacturing processes on the environment, including resource consumption and waste generation, is now a pivotal factor in procurement decisions. For buyers in Africa and South America, where environmental challenges are pronounced, sourcing from suppliers that adhere to sustainable practices is not only ethical but also essential for long-term viability.

Ethical supply chains are becoming a competitive differentiator. Suppliers that can demonstrate their commitment to sustainability through certifications—such as ISO 14001 for environmental management or the use of eco-friendly materials—are more appealing to conscientious buyers. Additionally, the integration of sustainable materials in the production of digital platform weighing scales, such as recycled metals and environmentally friendly coatings, is gaining traction. This shift not only helps mitigate environmental impact but also appeals to a growing consumer base that values corporate responsibility.

What Is the Historical Context of Digital Platform Weighing Scales?

The evolution of digital platform weighing scales can be traced back to the integration of electronic measurement technology in the late 20th century. Initially, weighing solutions were predominantly mechanical, which limited accuracy and efficiency. The introduction of digital technology revolutionized the industry, allowing for precise measurements and enhanced functionality. Over the years, advancements in load cell technology and microprocessor capabilities have significantly improved the reliability and ease of use of these scales.

In recent years, the rise of the Internet of Things (IoT) has further transformed the landscape. Digital platform scales are now equipped with smart technology, enabling remote monitoring and data collection. This historical progression highlights the industry’s responsiveness to technological advancements and market needs, positioning digital platform weighing scales as vital tools for modern businesses seeking to optimize their operations and ensure compliance with international standards.

Frequently Asked Questions (FAQs) for B2B Buyers of digital platform weighing scale

-

How do I ensure accurate weighing with my digital platform scale?

To ensure accurate weighing with your digital platform scale, regular calibration and maintenance are essential. Follow the manufacturer’s guidelines for operation, and always place the scale on a stable, flat surface to prevent inaccuracies. Utilize advanced features such as automatic zero tracking and error notifications, which help maintain precision. Additionally, consider environmental factors such as temperature and humidity, as these can affect accuracy, particularly in harsh industrial conditions. -

What is the best digital platform scale for my industry?

The best digital platform scale for your industry depends on specific requirements such as weight capacity, environment, and application. For heavy-duty industrial use, look for scales with robust construction, high accuracy, and features that withstand harsh conditions, such as exposure to chemicals or extreme temperatures. Scales with customizable options for size and functionality can also be beneficial. Research models that have proven reliability in your sector, whether it’s manufacturing, logistics, or food processing, to ensure you make an informed decision. -

What should I consider when vetting suppliers for digital platform scales?

When vetting suppliers, consider their reputation, industry experience, and customer reviews. Check for certifications that indicate compliance with international standards, which is crucial for quality assurance. Evaluate their product range, ensuring they offer the specific scales suited for your needs. Additionally, assess their customer service and support capabilities, as ongoing assistance and warranty provisions are vital for long-term operational success. Finally, request samples or references from existing clients to gauge product performance. -

What are the typical minimum order quantities (MOQs) for digital platform scales?

Minimum order quantities (MOQs) for digital platform scales can vary significantly between suppliers. Typically, MOQs range from 1 to 10 units for standard models, while customized scales may require higher quantities. It’s essential to discuss your specific needs with the supplier, as many are willing to negotiate MOQs based on your business requirements or potential for future orders. Understanding MOQs can help in budgeting and ensuring you meet your operational demands without overcommitting. -

What payment terms should I expect when purchasing digital platform scales internationally?

Payment terms for international purchases of digital platform scales often include options such as wire transfers, letters of credit, or payment through secure online platforms. Expect to negotiate terms based on order size and supplier policies; common arrangements include a deposit upfront with the balance due upon delivery. Ensure you clarify any additional costs related to shipping, customs, and taxes that may apply, as these can significantly impact your total expenditure. -

How can I customize my digital platform scale to fit my specific needs?

Customization options for digital platform scales typically include modifications to size, weight capacity, and features such as connectivity options (USB, Bluetooth) or specialized load cells. Discuss your specific requirements with the supplier, as many manufacturers offer tailored solutions to meet unique operational needs. Consider factors such as the environment in which the scale will be used and any industry-specific regulations that may influence your customization choices. -

What quality assurance processes should I expect from my supplier?

Reputable suppliers should have robust quality assurance (QA) processes in place, including regular testing and calibration of scales before shipment. Look for suppliers who provide documentation of compliance with international standards and certifications, ensuring that their products meet safety and accuracy requirements. Additionally, inquire about their return policies and warranty options, as these will reflect their commitment to product quality and customer satisfaction. -

What logistics considerations should I keep in mind when importing digital platform scales?

When importing digital platform scales, consider logistics factors such as shipping methods, lead times, and customs regulations. Choose a reliable freight forwarder familiar with international shipping to navigate potential complexities. Ensure that all necessary documentation is prepared, including commercial invoices and packing lists, to facilitate smooth customs clearance. Additionally, factor in costs related to shipping, insurance, and potential duties, as these can impact your overall investment.

Top 7 Digital Platform Weighing Scale Manufacturers & Suppliers List

1. Floorscales Online – High-Capacity Digital Platform Scales

Domain: floorscalesonline.com

Registered: 2007 (18 years)

Introduction: Non-NTEP Digital Platform Scales, High-Capacity Warehouse Pallet Scales, 4′ x 4′ and 5′ x 5′ sizes, weighing capacities of 5,000lbs and 10,000lbs, heavy-duty steel construction, heavy-duty diamond tread plate, two-part epoxy paint finish, four NTEP approved alloy steel load cells, four ball and cup support feet for scale leveling, top access foot adjustment, 1″ LED monitor displaying pounds or kil…

2. Arlyn Scales – Platform Scales

Domain: arlynscales.com

Registered: 1999 (26 years)

Introduction: Platform Scales from Arlyn Scales are designed for various industries including airline travel, commercial laundry, recycling, and hazardous waste management. Key features include:

– Industrial Technology: Available in stainless steel (starting at $1099) and aluminum (starting at $739).

– Robust construction with four stainless steel load cells embedded in a welded frame for durability in harsh co…

3. MT – PBK9 Premium Weighing Platforms

Domain: mt.com

Registered: 1993 (32 years)

Introduction: Platform scales are designed for accurate weighing of items and materials in industrial settings. They are available in analog or smart load cell technology with ergonomic designs. Key product offerings include:

– PBK9 Premium Weighing Platforms: High-accuracy weighing for challenging environments.

– PBD659 / PBA639 Hygienic Scale Platforms: Wet area scales for simplified cleaning and compliance …

4. Fairbanks – Portable Digital Platform Scales

Domain: fairbanks.com

Registered: 1995 (30 years)

Introduction: [{‘name’: ‘Portable Digital Platform Scale – 1200’, ‘type’: ‘Portable Electro-mechanical’, ‘capacity’: ‘1,000 lb’, ‘price’: ‘$2,040.00’}, {‘name’: ‘Portable Digital Platform Scale – 1155’, ‘type’: ‘Advanced digital weighing’, ‘capacity’: ‘1,000 lb’, ‘price’: ‘$2,350.00’}]

5. Scales Plus – Floor Scales

Domain: scalesplus.com

Registered: 2008 (17 years)

Introduction: Floor scales, also known as platform scales, are designed for heavy-capacity weighing in industrial, agricultural, and laboratory settings. They come in various platform sizes and capacities to accommodate a wide range of heavy weighing applications. Common uses include shipping departments, warehouses, food processing facilities, chemical manufacturing, bulk material weighing, and agriculture. Op…

6. Adam Equipment – Heavy Duty Platform Scales

Domain: adamequipment.com

Registered: 1998 (27 years)

Introduction: Adam Equipment offers a range of heavy duty and robust platform scales designed for demanding weighing environments such as factories, shipping and receiving departments, warehouses, and loading docks. These industrial platform scales are ideal for weighing bulky and large items such as boxes, shipping crates, and pallets.

7. Ishida – INS-100 Price Computing Scale

Domain: ishida.com

Registered: 1999 (26 years)

Introduction: Ishida offers a wide range of scales equipment, including high-precision electronic balances, top-dish weighing scales for trade and certification, electronic weighing scales, waterproof designs, and counting scales. Key products include: 1. INS-100: Price computing scales for simple, efficient weighing on the shop floor. 2. IPC: Portable scales for high accuracy and multi-range weighing, ideal fo…

Strategic Sourcing Conclusion and Outlook for digital platform weighing scale

In the evolving landscape of industrial operations, the strategic sourcing of digital platform weighing scales has become essential for businesses aiming to enhance efficiency and accuracy. These scales, designed for robust performance across various industries—from manufacturing to logistics—offer features that streamline weighing processes while ensuring compliance with safety standards. By investing in high-quality digital platform scales, organizations can improve inventory management, reduce labor costs, and mitigate the risks associated with inaccurate measurements.

International B2B buyers from regions such as Africa, South America, the Middle East, and Europe must prioritize sourcing scales that not only meet their specific operational requirements but also provide scalability for future growth. Engaging with suppliers that offer customization and support can further enhance the value of these investments.

As industries continue to embrace digital transformation, the demand for sophisticated weighing solutions will only grow. Now is the time to explore innovative options in digital platform weighing scales that can elevate your business operations. Take the next step toward operational excellence by connecting with leading suppliers to find the right solutions tailored to your needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.