Level Switch High High: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for level switch high high

In an increasingly interconnected world, sourcing the right level switch high high can pose significant challenges for international B2B buyers. Whether managing liquid levels in complex industrial processes or ensuring safety in storage facilities, the need for reliable, high-performance level switches is paramount. This guide provides a comprehensive overview of the types of level switches available, their applications across diverse industries, and essential factors to consider when vetting suppliers. By addressing the intricacies of technology options—from float and capacitive to ultrasonic sensors—this resource equips you with the knowledge to make informed purchasing decisions.

Understanding the nuances of level switch technology is crucial, especially for businesses operating in regions like Africa, South America, the Middle East, and Europe, including key markets such as Saudi Arabia and Germany. This guide not only delves into the technical specifications and certifications necessary for compliance in various markets but also offers insights into cost considerations and warranty evaluations. By leveraging this information, B2B buyers can confidently navigate the global market, ensuring that they select the best solutions for their unique operational needs. Ultimately, this guide empowers your organization to optimize safety, efficiency, and reliability in your processes, fostering long-term success in your industry.

Understanding level switch high high Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Float Level Switch | Mechanical device with a buoyant float that rises and falls with liquid level. | Water treatment, chemical processing, and food & beverage industries. | Pros: Economical, simple installation. Cons: Limited to specific liquid types; potential for mechanical wear. |

| Capacitive Level Switch | Operates on changes in capacitance based on the dielectric properties of the medium. | Oil and gas, petrochemical, and wastewater management. | Pros: Accurate in various conditions. Cons: Not suitable for low-dielectric materials; sensitive to buildup. |

| Conductive Level Switch | Utilizes electrodes to measure conductivity; effective in conductive liquids. | Wastewater treatment, food processing, and chemical industries. | Pros: Reliable and straightforward design. Cons: Limited to conductive media; buildup can affect performance. |

| Ultrasonic Level Switch | Non-contact technology using sound waves to determine liquid levels. | Bulk storage, water reservoirs, and solid-liquid interfaces. | Pros: Versatile; no moving parts; suitable for various media. Cons: Performance can be affected by temperature and pressure changes. |

| Optical Level Switch | Uses infrared light to detect liquid presence by refracting light. | Chemical processing and pharmaceutical industries. | Pros: High accuracy and reliability. Cons: Limited to clear liquids; sensitive to dirt and buildup. |

What Are the Characteristics of Float Level Switches?

Float level switches are mechanical devices that utilize a buoyant float to track liquid levels. As the liquid rises or falls, the float moves accordingly, triggering a switch to indicate the level. They are particularly suitable for industries like water treatment, food and beverage, and chemical processing due to their straightforward design and cost-effectiveness. When purchasing float level switches, buyers should consider the type of liquid being measured, as these switches may not perform well in viscous or turbulent conditions, and they may require more frequent maintenance due to mechanical wear.

How Do Capacitive Level Switches Operate?

Capacitive level switches rely on the electrical characteristics of a capacitor to detect changes in liquid levels. As the dielectric medium varies, the capacitance changes, allowing the sensor to provide accurate level readings. This technology is particularly effective in applications involving oils, chemicals, and wastewater. Buyers should note that while capacitive switches offer high accuracy, they are not ideal for low-dielectric materials or scenarios where material buildup on the sensor could interfere with operation.

What Are the Benefits of Conductive Level Switches?

Conductive level switches operate by measuring the electrical resistance between two electrodes submerged in a liquid. This technology is best suited for conductive liquids such as water and wastewater. The simplicity and reliability of conductive level switches make them a popular choice in industries like food processing and chemical manufacturing. However, buyers must ensure that the media is conductive, as these sensors will not function properly in non-conductive liquids, and buildup can lead to failure.

Why Choose Ultrasonic Level Switches?

Ultrasonic level switches utilize sound waves to measure liquid levels without physical contact. This non-invasive approach is ideal for applications in bulk storage and water reservoirs. The absence of moving parts enhances their durability and reduces maintenance needs. However, buyers should be aware that ultrasonic sensors can be affected by temperature fluctuations and pressure changes, which may impact their accuracy. Proper installation and calibration are crucial for optimal performance.

What Are the Key Features of Optical Level Switches?

Optical level switches employ infrared light to detect the presence of liquids. The sensor changes its output based on the refractive index of the liquid, making it highly accurate. These switches are commonly used in chemical processing and pharmaceutical applications where precision is critical. Buyers should consider the potential limitations in applications involving turbid or opaque liquids, as these can obstruct the infrared signal and affect performance.

Key Industrial Applications of level switch high high

| Industry/Sector | Specific Application of Level Switch High High | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Monitoring high liquid levels in storage tanks | Prevents overflow, ensuring safety and compliance | High-pressure ratings, certifications (ATEX, SIL) |

| Water & Wastewater Treatment | Detecting high levels in treatment basins | Enhances operational efficiency and prevents spills | Corrosion resistance, compatibility with various media |

| Food & Beverage Manufacturing | Controlling high levels in ingredient silos | Ensures product quality and prevents contamination | Hygiene standards, material certifications |

| Chemical Processing | Managing high levels in reaction vessels | Reduces risk of overflows and enhances safety | Chemical compatibility, high-temperature tolerance |

| Power Generation | Monitoring high levels in cooling water systems | Prevents equipment damage and ensures reliability | Robust design, compliance with international standards |

How is Level Switch High High Used in the Oil & Gas Industry?

In the oil and gas sector, level switch high high devices are critical for monitoring high liquid levels in storage tanks. These switches help prevent overflow situations that can lead to environmental hazards and costly spills. Buyers in this sector must prioritize high-pressure ratings and relevant certifications, such as ATEX and SIL, to ensure compliance with safety regulations and reliability under extreme conditions.

What Role Does Level Switch High High Play in Water & Wastewater Treatment?

Level switch high high instruments are essential in wastewater treatment facilities for detecting high levels in treatment basins. By providing accurate level measurements, these switches enhance operational efficiency and prevent potential overflows that could disrupt the treatment process. When sourcing, businesses should consider corrosion resistance and compatibility with various media, as these factors significantly impact longevity and performance.

How is Level Switch High High Beneficial in Food & Beverage Manufacturing?

In food and beverage manufacturing, level switch high high devices are utilized to control high levels in ingredient silos. Accurate monitoring ensures product quality by preventing contamination and maintaining the integrity of ingredients. Buyers should focus on hygiene standards and material certifications to comply with food safety regulations and ensure that the equipment does not adversely affect product quality.

What is the Importance of Level Switch High High in Chemical Processing?

Level switch high high devices are crucial in chemical processing for managing high levels in reaction vessels. These switches reduce the risk of overflows, which can lead to dangerous chemical spills and operational shutdowns. Buyers should prioritize sourcing switches that are compatible with various chemicals and capable of withstanding high temperatures to ensure safety and reliability in their processes.

How Does Level Switch High High Ensure Safety in Power Generation?

In power generation, level switch high high instruments monitor high levels in cooling water systems. These devices play a vital role in preventing equipment damage by ensuring that cooling systems operate within safe levels. When sourcing, businesses should look for robust designs that comply with international standards to guarantee reliability and performance in demanding environments.

3 Common User Pain Points for ‘level switch high high’ & Their Solutions

Scenario 1: Inconsistent Level Monitoring Leading to Overflows

The Problem: B2B buyers, particularly in industries like petrochemicals and manufacturing, often grapple with the challenge of inconsistent level monitoring. This inconsistency can lead to overflows, which not only disrupt operations but also pose safety hazards and environmental risks. A common scenario involves a high-high level switch failing to trigger due to sensor misalignment or calibration issues, resulting in the tank overflowing and costly spills. This situation can escalate quickly, leading to expensive cleanup operations, regulatory fines, and potential damage to equipment and reputation.

The Solution: To prevent such occurrences, it’s crucial to ensure that level switches are properly installed and calibrated. Buyers should opt for high-quality switches that offer robust features like adjustable sensitivity and multiple output options. Regular maintenance checks and recalibrations should be scheduled to ensure consistent operation. Additionally, integrating a dual point level switch can provide redundancy; if one switch fails, the other can maintain operational safety. Investing in training for staff on the importance of proper installation and maintenance of these devices will further mitigate the risk of overflow incidents.

Scenario 2: Difficulties in Handling Harsh Environments

The Problem: Many industries, particularly those in the Middle East and Africa, operate in harsh environments where extreme temperatures and corrosive substances are prevalent. Buyers often face the dilemma of selecting level switches that can withstand these conditions without compromising on accuracy. For instance, a level switch might fail due to corrosion or material degradation, leading to inaccurate readings and potential operational failures. Such failures not only affect production but can also lead to significant financial losses.

The Solution: To address this issue, buyers should prioritize sourcing level switches made from durable materials such as stainless steel or specialized alloys that offer excellent corrosion resistance. Additionally, selecting switches with high-temperature ratings and robust certifications (like ATEX or SIL) ensures they can operate effectively in extreme conditions. It’s advisable to consult with manufacturers about custom solutions tailored to specific environmental challenges. Regular performance assessments and environmental monitoring should also be implemented to ensure the selected switches continue to operate reliably.

Scenario 3: Complicated Integration with Existing Systems

The Problem: B2B buyers often encounter challenges when integrating new level switch technologies with existing monitoring and control systems. This integration complexity can result in delayed project timelines and increased costs. For example, a company may invest in a high-high level switch that does not communicate effectively with their existing PLCs (Programmable Logic Controllers), causing discrepancies in data and leading to decision-making delays.

The Solution: To streamline integration, buyers should conduct a thorough compatibility assessment of the new level switch with existing systems before purchase. Engaging with suppliers who provide comprehensive support during the integration phase can significantly ease this process. Buyers should also consider level switches that offer standard communication protocols (such as Modbus or Profibus) to facilitate seamless data exchange. Additionally, investing in training for technical staff on the integration process can enhance operational efficiency and ensure that the switch operates as intended within the broader control framework. Regular updates and maintenance of software systems will also aid in maintaining compatibility and performance across platforms.

Strategic Material Selection Guide for level switch high high

What Are the Key Properties of Common Materials Used in Level Switch High High?

When selecting materials for level switches, particularly in high-high applications, it is crucial to consider the specific properties that influence performance. Common materials include stainless steel, carbon steel, plastic, and exotic alloys. Each material presents unique characteristics that can significantly impact the operational efficiency and longevity of the level switch.

How Does Stainless Steel Perform in Level Switch Applications?

Stainless steel is a popular choice due to its excellent corrosion resistance and durability. It typically withstands high temperatures (up to 1000°F) and pressures (up to 5000 psi), making it suitable for a variety of harsh environments. The key advantage of stainless steel is its ability to resist oxidation and pitting, which is critical in applications involving corrosive fluids.

However, stainless steel can be costlier than other materials, and its manufacturing process may involve complex machining, which can increase lead times. For international buyers, especially in regions like Europe and the Middle East, compliance with standards such as ASTM and EN is essential, as these regions often require stringent quality certifications.

What Are the Benefits of Using Carbon Steel for Level Switches?

Carbon steel is another material frequently used in level switches, particularly in less corrosive environments. It offers good strength and can be manufactured at a lower cost compared to stainless steel. Carbon steel is suitable for applications with moderate temperature and pressure requirements.

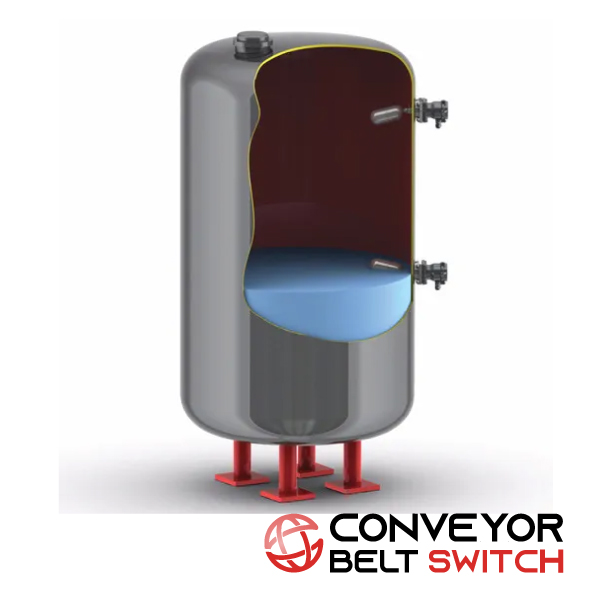

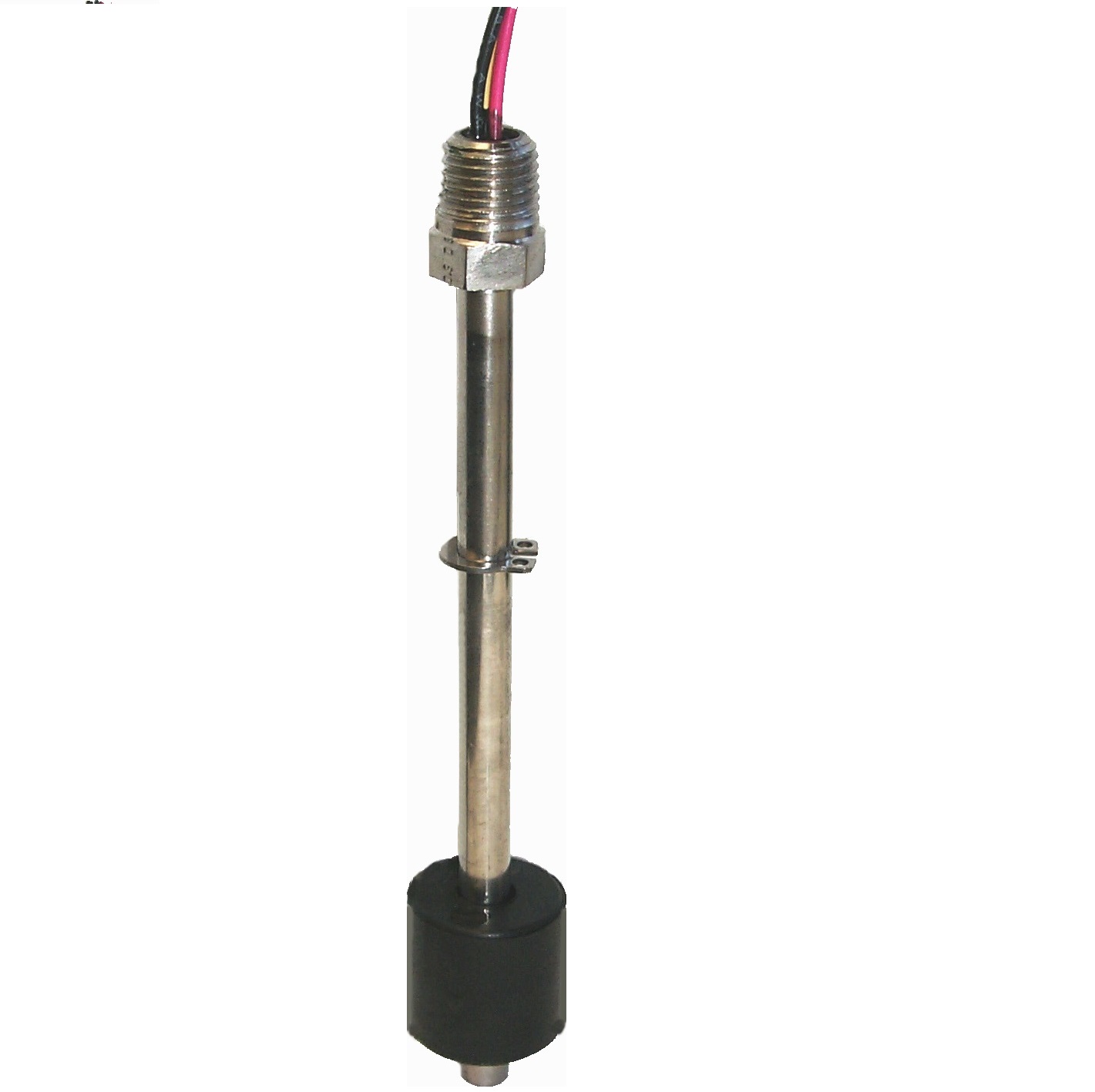

Illustrative image related to level switch high high

The downside is its susceptibility to corrosion, which can limit its use in aggressive chemical environments. Buyers in Africa and South America should consider the local climate and the types of media being measured, as carbon steel may require additional protective coatings to enhance its lifespan.

Why Choose Plastic for Level Switch Applications?

Plastic materials, such as PVC or polypropylene, are often utilized in level switches for non-corrosive applications. They are lightweight and resistant to a variety of chemicals, making them ideal for water and wastewater applications. The manufacturing process for plastic components is generally simpler and less expensive, which can be a significant advantage for budget-conscious buyers.

However, plastics typically have lower temperature and pressure ratings compared to metals, which may limit their use in high-demand applications. Buyers must also ensure that the selected plastic is compatible with the specific media being measured, particularly in regions with varying environmental conditions.

What Role Do Exotic Alloys Play in Level Switch High High Applications?

Exotic alloys, such as Hastelloy or Inconel, are engineered for extreme conditions, including high temperatures and aggressive chemical environments. These materials offer superior corrosion resistance and can handle pressures exceeding those of standard materials. Their unique properties make them suitable for critical applications in industries like petrochemical and power generation.

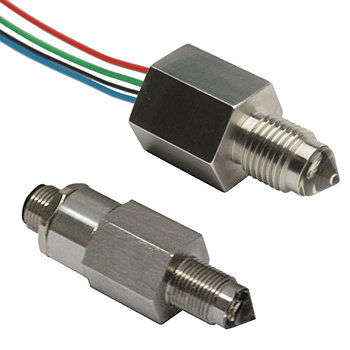

Illustrative image related to level switch high high

The primary drawback is the high cost and complexity of manufacturing. For international buyers, especially in Europe and the Middle East, understanding compliance with specific industry standards is crucial, as these materials often require specialized certifications.

Summary Table of Material Properties for Level Switch High High

| Material | Typical Use Case for level switch high high | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Corrosive environments, high temperatures | Excellent corrosion resistance | Higher cost, complex manufacturing | High |

| Carbon Steel | Moderate environments, non-corrosive fluids | Lower cost, good strength | Susceptible to corrosion | Medium |

| Plastic | Water and wastewater applications | Lightweight, chemical resistance | Lower temperature/pressure ratings | Low |

| Exotic Alloys | Extreme conditions, aggressive chemicals | Superior performance in harsh environments | Very high cost, complex certification | High |

This material selection guide provides a comprehensive overview for B2B buyers, helping them make informed decisions based on performance requirements and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for level switch high high

What Are the Key Stages in the Manufacturing Process of Level Switch High High?

The manufacturing of level switch high high devices involves several critical stages that ensure the final product meets stringent quality and performance standards. Understanding these stages can help B2B buyers evaluate suppliers and ensure they receive reliable and durable products.

Material Preparation: What Materials Are Used in Level Switch Manufacturing?

The first stage in manufacturing level switches involves selecting high-quality materials that can withstand the operational demands of various industries. Common materials include:

- Stainless Steel: Known for its corrosion resistance and durability, stainless steel is often used in the construction of level switches to ensure longevity, especially in harsh environments.

- Exotic Alloys: For specialized applications, exotic materials may be employed to enhance performance under extreme conditions.

- Sealing Materials: High-quality gaskets and seals are essential to ensure the devices are leak-proof and can operate under high pressure and temperature.

Material preparation also includes rigorous testing of raw materials to ensure they meet specific industry standards. This initial quality control step is critical in preventing defects that could lead to failures in the final product.

How Are Level Switches Formed and Assembled?

Once the materials are prepared, the next phase involves forming and assembling the components. This stage typically includes:

- Machining: Precision machining processes are employed to create the various components of the level switch, ensuring tight tolerances and proper fit.

- Welding and Joining: For metal components, welding techniques are used to assemble parts while maintaining structural integrity. Techniques such as TIG or MIG welding may be employed, depending on the material.

- Electronics Integration: For electronic level switches, integrating sensors and circuit boards is a critical step. This process must be handled with care to prevent damage to sensitive components.

The assembly stage is crucial for ensuring that the level switch functions correctly. Components are often tested for compatibility and performance during this phase.

What Finishing Techniques Are Used to Enhance Level Switch Durability?

Finishing processes are vital for enhancing the durability and aesthetic appeal of level switches. Common finishing techniques include:

- Surface Treatments: Processes such as passivation and anodizing may be applied to improve corrosion resistance and reduce wear.

- Coatings: Protective coatings can be applied to prevent corrosion and enhance the lifespan of the switch.

- Calibration: After assembly, level switches undergo calibration to ensure they provide accurate readings and respond correctly to level changes.

Finishing not only improves the product’s performance but also helps meet specific industry certifications.

How is Quality Control Implemented in Level Switch Manufacturing?

Quality control (QC) is a cornerstone of manufacturing processes, especially for critical devices like level switches. It involves multiple checkpoints throughout the production cycle to ensure compliance with international standards and specifications.

What International Standards Guide Quality Control in Level Switch Production?

International standards play a pivotal role in ensuring the quality and reliability of level switches. Key standards include:

Illustrative image related to level switch high high

- ISO 9001: This standard focuses on quality management systems and is essential for manufacturers aiming to demonstrate their commitment to quality and continuous improvement.

- CE Marking: For products sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: In industries like oil and gas, adherence to API standards ensures that level switches can withstand the rigors of demanding environments.

These certifications not only assure buyers of product quality but also facilitate easier market access across different regions.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are strategically placed throughout the manufacturing process to catch defects early. These typically include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before being used in production.

- In-Process Quality Control (IPQC): During manufacturing, periodic checks are performed to monitor processes and identify any deviations from standards, allowing for immediate corrective actions.

- Final Quality Control (FQC): Once the level switches are fully assembled, a final inspection is conducted to verify that they meet all specifications, including performance testing and calibration.

What Common Testing Methods Are Used to Ensure Level Switch Reliability?

Testing methods are crucial in validating the performance and reliability of level switches. Common techniques include:

- Functional Testing: This verifies that the switch operates correctly under specified conditions.

- Pressure Testing: Ensures that the switch can handle the maximum pressure expected in its application without failure.

- Temperature Testing: Confirms that the device can operate within the specified temperature ranges.

These tests are essential for ensuring that the level switch can perform reliably in real-world conditions.

How Can B2B Buyers Verify Supplier Quality Control Practices?

When sourcing level switches, especially from international suppliers, buyers must ensure that quality control practices are robust. Here are actionable steps buyers can take:

What Steps Can Buyers Take to Ensure Supplier Quality?

- Conduct Audits: Regular audits of suppliers can help buyers assess compliance with quality standards and practices.

- Request Documentation: Suppliers should provide quality control reports, certification documents, and testing results to verify adherence to industry standards.

- Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the manufacturing and quality control processes.

What Nuances Should International Buyers Consider Regarding QC?

International buyers should be aware of potential discrepancies in quality standards between regions. For example, while a supplier may comply with ISO 9001, they may not meet specific local certifications required in regions like Europe or the Middle East. Understanding these nuances can help buyers make informed decisions and mitigate risks associated with product quality.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance protocols for level switch high high devices is essential for B2B buyers. By focusing on material quality, manufacturing precision, and rigorous testing, buyers can ensure they select reliable suppliers capable of meeting their industry-specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘level switch high high’

Introduction

This practical sourcing guide aims to assist B2B buyers in procuring high-high level switches, essential instruments for monitoring liquid levels in various industrial applications. By following this step-by-step checklist, you can ensure that your procurement process is efficient, effective, and tailored to your specific operational needs.

Step 1: Define Your Technical Specifications

Understanding your technical requirements is paramount before initiating the procurement process. Clearly outline the application environment, such as pressure and temperature ranges, as well as the type of fluid being monitored.

– Consider factors like compatibility with corrosive materials, required certifications (e.g., ATEX, CSA), and whether you need features such as remote monitoring or automated alerts.

Step 2: Research Available Technologies

Familiarize yourself with the different types of level switch technologies available. This includes float, capacitive, conductive, optical, and ultrasonic level switches.

– Each technology has its strengths and weaknesses; for example, ultrasonic switches are excellent for non-contact measurement but may be affected by foam or vapors. Understanding these nuances will help you select the most suitable option for your application.

Step 3: Evaluate Potential Suppliers

Before committing, thoroughly vet potential suppliers. Request company profiles, case studies, and references from buyers in similar industries or regions.

– Look for suppliers with a proven track record of reliability and quality. Verify their certifications and compliance with international standards, which can be crucial in ensuring product safety and performance.

Step 4: Check Warranty and Support Services

Assess the warranty terms offered by suppliers, as well as their customer support services. A robust warranty (ideally 5 years) can be an indicator of product reliability.

– Ensure that the supplier provides adequate technical support and maintenance services, especially if your operations rely heavily on these level switches for safety and efficiency.

Step 5: Request and Compare Quotes

Once you have narrowed down your suppliers, request detailed quotes that outline pricing, delivery times, and payment terms.

– Compare not just the costs, but also the value offered, including any additional features or services. Make sure to clarify any potential hidden costs associated with installation or maintenance.

Illustrative image related to level switch high high

Step 6: Conduct a Pilot Test

If possible, conduct a pilot test with the selected level switch to evaluate its performance in your specific application.

– This step will help you identify any potential issues early and ensure that the switch meets your operational needs before making a larger investment.

Step 7: Finalize the Procurement Process

After confirming the supplier and the product’s effectiveness, finalize your procurement. Ensure that all contractual terms are clear and mutually agreed upon.

– Pay attention to delivery timelines, installation support, and after-sales service commitments to avoid any disruptions in your operations.

By following these steps, B2B buyers can confidently navigate the procurement of high-high level switches, ensuring they select the right technology and supplier for their specific industrial needs.

Comprehensive Cost and Pricing Analysis for level switch high high Sourcing

When sourcing level switches, particularly high-high level switches, understanding the comprehensive cost structure and pricing dynamics is crucial for B2B buyers. This analysis will provide actionable insights into the various components that contribute to the overall cost and pricing strategies you may encounter.

What Are the Key Cost Components in Level Switch Sourcing?

-

Materials: The choice of materials significantly influences the cost of level switches. High-quality stainless steel or exotic materials for harsh environments lead to higher prices but ensure durability and reliability. Additionally, the complexity of the sensor technology (e.g., ultrasonic vs. float) can also affect material costs.

-

Labor: Labor costs are a critical factor, especially for custom-built switches. Skilled labor is required for assembly and quality control, impacting the final price. Countries with lower labor costs may offer competitive pricing, but this can sometimes compromise quality.

-

Manufacturing Overhead: This includes costs related to facility operations, utilities, and equipment maintenance. Manufacturers with advanced facilities may charge more due to higher operational efficiencies and better quality assurance processes.

-

Tooling: Initial tooling costs for specialized designs or customizations can be substantial. If a buyer requires a unique configuration, this cost will be reflected in the pricing. However, once the tooling is established, unit costs may decrease with higher production volumes.

-

Quality Control (QC): Rigorous testing and certification processes are essential for level switches, especially those used in critical applications. The cost of compliance with international standards (e.g., ATEX, CSA) and additional testing can add to the overall expense.

-

Logistics: Shipping costs vary significantly based on the location of the supplier, the destination, and the chosen Incoterms. International shipments may incur additional charges such as customs duties and tariffs, affecting the total cost.

-

Margin: Suppliers typically apply a margin based on their operational costs and market positioning. Premium suppliers may command higher margins due to brand reputation, advanced technology, and superior service offerings.

What Influences Pricing for Level Switches?

-

Volume and Minimum Order Quantity (MOQ): Pricing often decreases with larger orders due to economies of scale. Suppliers may offer tiered pricing, encouraging buyers to increase their purchase volume for cost savings.

-

Specifications and Customization: Custom features and specifications can lead to increased costs. Buyers should clearly communicate their requirements to avoid unexpected charges.

-

Quality and Certifications: Higher quality standards and certifications can justify a premium price. Buyers should assess the importance of these factors against their application needs.

-

Supplier Factors: Established suppliers with strong reputations may charge more. Buyers should consider the reliability of the supplier and their after-sales support when evaluating costs.

-

Incoterms: The chosen Incoterms can significantly affect the total landed cost. For instance, DDP (Delivered Duty Paid) may include all shipping and customs fees, while EXW (Ex Works) may leave most costs to the buyer, impacting pricing strategies.

How Can Buyers Negotiate Effectively for Level Switches?

-

Leverage Volume: Buyers should negotiate based on order size, as larger quantities can lead to better pricing. Consider forming purchasing groups to increase order volumes.

-

Total Cost of Ownership (TCO): Assess the long-term costs associated with the level switches, including maintenance, operational efficiency, and potential downtime. A slightly higher upfront cost may lead to lower TCO.

-

Understand Pricing Nuances: International buyers, particularly from regions like Africa and South America, should be aware of exchange rate fluctuations and local market conditions that can impact pricing.

-

Request Multiple Quotes: Engaging several suppliers allows for comparison and negotiation. This can reveal competitive pricing and terms that may not be initially apparent.

-

Build Relationships: Establishing long-term relationships with suppliers can lead to better pricing, priority service, and improved terms over time.

Conclusion

In summary, the cost and pricing dynamics of sourcing high-high level switches are multifaceted, influenced by various components and market factors. By understanding these elements, B2B buyers can make informed decisions that optimize their sourcing strategies and achieve better overall value. As always, it’s advisable to approach negotiations with a clear understanding of your specific needs and market conditions.

Alternatives Analysis: Comparing level switch high high With Other Solutions

Exploring Alternatives to Level Switch High High Solutions

In the realm of industrial applications, selecting the right level measurement technology is crucial for ensuring operational efficiency and safety. The ‘level switch high high’ is a specific type of level switch that activates when the liquid level reaches a predetermined high point. However, various alternatives exist that can fulfill similar roles, each with unique advantages and considerations. This analysis compares the level switch high high with two viable alternatives: capacitive level sensors and ultrasonic level sensors.

| Comparison Aspect | Level Switch High High | Capacitive Level Sensor | Ultrasonic Level Sensor |

|---|---|---|---|

| Performance | Reliable under extreme conditions; can handle high pressure and temperature ranges. | Effective for many liquids, but performance can degrade with low capacitance materials. | Non-contact measurement; suitable for various materials but may be affected by foam or vapors. |

| Cost | Moderate initial investment; long-term savings due to durability. | Generally lower cost, but may require more frequent replacements. | Typically higher upfront cost, but offers versatility and less maintenance. |

| Ease of Implementation | Requires installation in a specific orientation; can be complex in retrofitting. | Simple installation; can be integrated into existing systems easily. | Installation requires line-of-sight; may need additional calibration for specific applications. |

| Maintenance | Low maintenance with a long lifespan; routine checks recommended. | Moderate maintenance; buildup can affect performance. | Low maintenance; however, calibration may be needed for accuracy. |

| Best Use Case | Best for high-pressure environments like petrochemical applications. | Ideal for water and wastewater applications where conductivity is high. | Best suited for bulk solids and liquids in open channels or tanks. |

In-Depth Look at Alternatives

1. Capacitive Level Sensors

Capacitive level sensors work by measuring changes in capacitance caused by the presence of a liquid. These sensors are cost-effective and easy to install, making them appealing for applications involving water and other conductive liquids. However, they struggle with low-capacitance materials and can be sensitive to build-up on the sensor, which may lead to inaccurate readings. Their performance can be limited in harsh environments, making them less suitable for high-pressure or extreme temperature applications compared to level switch high high devices.

2. Ultrasonic Level Sensors

Ultrasonic level sensors utilize sound waves to measure liquid levels, providing a non-contact solution that is versatile across various applications, including solids and slurries. Their primary advantages include minimal maintenance and the ability to measure through barriers. However, ultrasonic sensors can be affected by environmental conditions such as foam or vapor, which may lead to unreliable readings. While they typically come at a higher initial cost, their long-term operational benefits can make them a worthwhile investment for many industries.

How Should B2B Buyers Choose the Right Solution?

When selecting the appropriate level measurement technology, B2B buyers should assess their specific operational needs, including the type of materials being measured, environmental conditions, and budget constraints. Factors such as installation complexity, maintenance requirements, and the expected lifespan of the equipment should also be considered. By evaluating these elements against the characteristics of the level switch high high and its alternatives, buyers can make informed decisions that align with their operational goals and ensure optimal performance in their applications.

Essential Technical Properties and Trade Terminology for level switch high high

What Are the Key Technical Properties of Level Switch High High?

1. Pressure Range

The pressure range of a level switch high high indicates the maximum and minimum pressures it can withstand during operation. Common ranges include vacuum to 5000 psi or 0 to 345 bar. This specification is crucial for B2B buyers as it determines the switch’s suitability for various applications, particularly in industries like oil and gas, where high-pressure environments are common.

2. Temperature Tolerance

Temperature tolerance specifies the range of temperatures the level switch can operate within, often from -40°F to 400°F (-40°C to 204°C). Understanding this property is essential for buyers in sectors such as chemical manufacturing or food processing, where extreme temperatures can be a factor. A high tolerance ensures reliability and longevity of the device.

3. Material Composition

Level switches are often constructed from materials such as stainless steel, which offers excellent corrosion resistance and durability. Material choice is vital for B2B buyers to ensure that the switch can withstand the specific conditions of their operational environment, including chemical exposure and mechanical stress.

4. Certification Standards

Certifications such as ATEX, CSA, and IECEx confirm that the level switch meets international safety and performance standards. These certifications are particularly important for B2B buyers to ensure compliance with local regulations and to guarantee the reliability and safety of the equipment in hazardous environments.

5. Warranty Period

A warranty period, typically ranging from 3 to 5 years, indicates the manufacturer’s confidence in the product’s durability. A longer warranty can provide peace of mind for B2B buyers, suggesting lower long-term costs and less risk associated with maintenance and replacement.

6. Switching Mechanism

The type of switching mechanism, whether it be float, capacitive, or ultrasonic, affects how the level switch operates and its suitability for specific applications. Understanding the mechanism helps buyers choose the right switch for their unique needs, ensuring optimal performance.

What Are Common Trade Terms Related to Level Switches?

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of level switches, understanding OEM relationships can help buyers gauge the quality and reliability of the components used in their products.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B buyers as it affects inventory management and overall purchasing costs. Knowing the MOQ helps companies plan their procurement strategies effectively.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request a price quote for specific products or services. For buyers of level switches, issuing an RFQ can help in comparing prices and terms from different suppliers, ensuring they get the best deal possible.

4. Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that are used in international transactions. Familiarity with Incoterms is crucial for B2B buyers to understand their responsibilities regarding shipping, insurance, and tariffs when importing level switches from global suppliers.

Illustrative image related to level switch high high

5. SIL (Safety Integrity Level)

SIL is a measure of the reliability of safety systems, particularly in industrial environments. A higher SIL rating indicates a greater level of safety assurance, which is essential for B2B buyers in sectors where equipment failure could lead to hazardous conditions.

6. Lead Time

Lead time refers to the amount of time it takes from placing an order until the product is delivered. For B2B buyers, understanding lead times is vital for project planning and inventory management, especially in industries where timely delivery is critical to operational success.

Understanding these technical properties and trade terms equips B2B buyers with the knowledge needed to make informed decisions when sourcing level switches high high, ultimately leading to better operational outcomes and cost efficiencies.

Navigating Market Dynamics and Sourcing Trends in the level switch high high Sector

What Are the Key Market Dynamics and Trends Influencing the Level Switch High High Sector?

The global market for level switches, particularly in the high-high sector, is experiencing significant growth driven by various factors. An increasing demand for automation in industries such as oil and gas, chemicals, and water treatment is propelling the adoption of advanced level switch technologies. B2B buyers from regions like Africa, South America, the Middle East, and Europe are particularly focused on sourcing reliable and efficient level switch solutions to optimize their operations and ensure safety.

Emerging technologies such as IoT-enabled level switches are gaining traction, providing real-time monitoring and data analytics capabilities. This trend allows businesses to make informed decisions and enhance operational efficiency. Furthermore, regulatory requirements regarding safety and environmental standards are prompting companies to invest in high-quality, certified level switches that comply with international standards such as ATEX, CSA, and IECEx.

Additionally, the growing emphasis on predictive maintenance is shaping purchasing decisions. Companies are increasingly seeking level switches that not only provide accurate readings but also offer features like self-testing and diagnostics, which help in reducing downtime and maintenance costs. As a result, international buyers are looking for suppliers that can offer customization options, enabling them to tailor solutions to their specific needs.

How Are Sustainability and Ethical Sourcing Shaping the Level Switch High High Market?

Sustainability has become a pivotal factor in the procurement processes of B2B buyers in the level switch sector. The environmental impact of manufacturing processes is under scrutiny, and companies are increasingly prioritizing suppliers that adhere to sustainable practices. This includes sourcing materials with low environmental footprints and implementing energy-efficient manufacturing processes.

Ethical sourcing is equally critical. Buyers are looking for suppliers that can demonstrate transparency in their supply chains, ensuring that materials are sourced responsibly and that labor practices comply with ethical standards. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety are becoming essential for suppliers aiming to establish credibility in the market.

Furthermore, the demand for ‘green’ materials is rising. B2B buyers are interested in level switches that utilize recyclable components or have minimal adverse effects on the environment. This trend not only aligns with global sustainability goals but also enhances a company’s brand reputation, appealing to environmentally conscious consumers and stakeholders.

How Has the Level Switch Technology Evolved Over Time?

The evolution of level switch technology has significantly transformed the landscape for B2B buyers. Initially, mechanical float switches were the standard, providing basic functionality for level detection. As industries grew more complex, the need for advanced technologies led to the development of capacitive, conductive, and ultrasonic level switches, each offering unique advantages in various applications.

The introduction of smart level switches, equipped with IoT capabilities, represents the latest phase of this evolution. These devices allow for remote monitoring and integration with other smart systems, enabling predictive maintenance and enhancing operational efficiency. This technological advancement is critical for industries seeking to reduce operational costs and improve safety measures.

In summary, the level switch high-high sector is rapidly evolving, driven by technological advancements, sustainability demands, and the need for ethical sourcing. B2B buyers must navigate these dynamics carefully to make informed purchasing decisions that align with their operational goals and corporate values.

Frequently Asked Questions (FAQs) for B2B Buyers of level switch high high

1. How do I ensure the reliability of a level switch high high in my application?

To ensure the reliability of a level switch high high, it is essential to consider the operational environment and the specific characteristics of the liquid or solid being measured. Selecting a switch with appropriate certifications for your industry, such as ATEX for hazardous locations, is critical. Additionally, choose a device with a proven track record in similar applications, and consider those with a robust warranty and support options. Regular maintenance and calibration are also vital to maintain accuracy and reliability over time.

2. What type of level switch high high is best for corrosive environments?

For corrosive environments, selecting a level switch high high made from materials that offer excellent corrosion resistance is key. Stainless steel options are often recommended due to their durability and resistance to various chemicals. Furthermore, consider switches with protective coatings or exotic materials specifically designed to withstand harsh conditions. It’s also beneficial to review the switch’s certifications and industry ratings to ensure they meet the necessary standards for your specific application.

3. What are the common certifications I should look for in level switches?

When sourcing level switches, key certifications to look for include ATEX and IECEx for explosive environments, CSA for safety in North America, and SIL ratings indicating functional safety. Additionally, certifications like UKCA and INMETRO may be important depending on your geographic location and industry regulations. These certifications ensure that the level switches meet stringent safety and performance standards, which can significantly impact operational reliability and compliance.

4. How can I customize a level switch high high to fit my specific needs?

Customization options for level switches can vary by manufacturer, but many offer the ability to tailor aspects such as material, size, and sensing technology based on your application requirements. Discuss your specific needs with potential suppliers, including environmental conditions and the type of media being measured. Ensure that the supplier has a proven process for customizing products and can provide documentation to support the modifications, including any testing and quality assurance procedures.

5. What is the minimum order quantity (MOQ) for level switches high high?

Minimum order quantities (MOQs) for level switches high high can vary widely among manufacturers. Some suppliers may have no MOQ, while others could require orders of several units to ensure cost-effectiveness in production. It’s advisable to inquire directly with suppliers about their MOQs and explore any flexibility in orders, especially if you are testing a new product line or have specific project requirements.

6. What payment terms are typically offered by suppliers of level switches?

Payment terms for level switches can range from upfront payments to net 30, 60, or even 90-day terms, depending on the supplier’s policies and your business relationship. It’s essential to negotiate favorable terms that align with your cash flow needs while ensuring that the supplier feels secure in the transaction. Additionally, consider discussing options for letters of credit or escrow services for large orders to mitigate risks.

Illustrative image related to level switch high high

7. How can I vet suppliers for level switches high high?

To vet suppliers effectively, start by researching their reputation in the industry, including customer reviews and case studies. Request references from previous clients to gauge their experience with the supplier. Evaluate their certifications, product quality, and after-sales support. Additionally, consider visiting their manufacturing facility if possible, or request a virtual tour, to better understand their production capabilities and quality assurance processes.

8. What logistics considerations should I keep in mind when sourcing level switches internationally?

When sourcing level switches internationally, consider factors such as shipping times, customs duties, and import regulations in your country. It’s essential to work with suppliers who have experience with international shipping and can provide clear timelines for delivery. Additionally, evaluate their logistics capabilities, including options for expedited shipping in case of urgent needs. Understanding the total landed cost, including shipping and taxes, will help you make informed budgeting decisions.

Top 7 Level Switch High High Manufacturers & Suppliers List

1. SOR Controls Group – Level Switches

Domain: sorinc.com

Registered: 1997 (28 years)

Introduction: Level Switches from SOR Controls Group are designed for high quality and rugged construction, suitable for demanding applications in industries such as power generation, refining, and petrochemical. Key models include: 1510 Side Mounted Level Switch (ranges: vac to 5000 psi, -40° to 400°F, certifications: ATEX, CSA, SIL), 1530 Pneumatic Level Switch (ranges: vac to 5000 psi, -40° to 400°F), 1540 S…

2. E+H – Liquiphant FTL51B Level Switch

Domain: instrumart.com

Registered: 2004 (21 years)

Introduction: E+H Liquiphant FTL51B Level Switch: Specialized for process industry, IEC 61508 compliant, SIL2 and SIL3 applications, Bluetooth enabled, starting at $1,650.13. E+H Liquipoint T FTW31 Level Switch: Rod probe for multipoint detection (up to 5 switch points), starting at $185.00. Rosemount 2120 Liquid Level Switch: Vibrating short fork liquid point level switch with four switching functions, startin…

3. Liquid Level – High/Low Level Switches

Domain: liquidlevel.com

Registered: 1996 (29 years)

Introduction: {“name”:”High/Low Level Switches”,”price”:”$121.00″,”sku”:”92637″,”category”:”Custom Multi Level”,”description”:”This stainless steel float switch has high and low-level switch points, a 1/4\” NPT standard threaded hex fitting, 1\” diameter buna floats, and common lead wires 24\” long. This float switch is good for smaller tanks and is ideal for fuel and oil applications. The two float positions c…

4. Emerson – Level Switch Technology

Domain: emerson.com

Registered: 1995 (30 years)

Introduction: This company, Emerson – Level Switch Technology, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Flowline – Switch-Tek™ LV3X & LH35 High-Temp Float Level Switch

Domain: flowline.com

Registered: 1996 (29 years)

Introduction: {“product_name”: “Switch-Tek™ LV3X & LH35 High-Temp Float Level Switch”, “application”: “Reliable liquid level detection of relatively clean water, diluted chemicals, and light weight oils. Examples include hot deionized water and cooking oil.”, “features”: [“316 SS level sensor for high temp and pressure applications”, “Dry contact reed selectable NO or NC via float orientation”, “Offered in both…

6. IQS Directory – Level Switches

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Level switches are devices that monitor the levels of liquids, powders, or bulk materials, activating alerts when contents reach predetermined heights or depths. They are essential in production processes, especially in extreme environments. Types of level switches include: 1. Capacitive Level Switch: Measures corrosive liquids and high temperatures, operates on capacitance principle. 2. Conductiv…

7. Alfa Laval – Level Switch

Domain: alfalaval.us

Registered: 2002 (23 years)

Introduction: Level Switch from Alfa Laval provides accurate and reliable remote liquid level indication for hygienic processes in brewery, food and beverage, and biopharm industries. Key features include a compact and hygienic design suitable for low and high-viscosity liquids, made from AISI 316L stainless steel and PEEK, withstanding temperatures from -20 to +140°C. These 3-A certified level switches are ide…

Strategic Sourcing Conclusion and Outlook for level switch high high

In summary, strategic sourcing of high-level switches is essential for businesses aiming to enhance operational efficiency and safety across various industries. By understanding the diverse types of level switches—such as float, capacitive, and ultrasonic—buyers can select the most suitable technology for their specific applications. This selection process is further facilitated by considering factors like pressure and temperature ranges, material compatibility, and certification standards, ensuring compliance with local regulations across regions like Africa, South America, the Middle East, and Europe.

The value of strategic sourcing extends beyond just cost savings; it encompasses quality assurance, reliability, and service responsiveness from suppliers. Establishing strong partnerships with manufacturers known for their rugged construction and certifications can lead to long-term benefits, including reduced downtime and maintenance costs.

As the demand for efficient liquid level management continues to grow, international B2B buyers are encouraged to proactively engage with reputable suppliers and leverage the latest technological advancements in level switch solutions. By doing so, businesses can position themselves for future success, ensuring their operations are both efficient and compliant in an ever-evolving market landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to level switch high high